Gear forming grinding machine tool

A technology for forming, grinding and processing machine tools, which is applied to the parts of grinding machine tools, gear cutting machines, metal processing equipment, etc. It can solve the problems that gears cannot be milled, affect the processing efficiency of machine tools, and difficult to locate, and achieve simple and convenient disassembly operations. Effective sliding and reliable guarantee, improving the effect of guiding sliding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

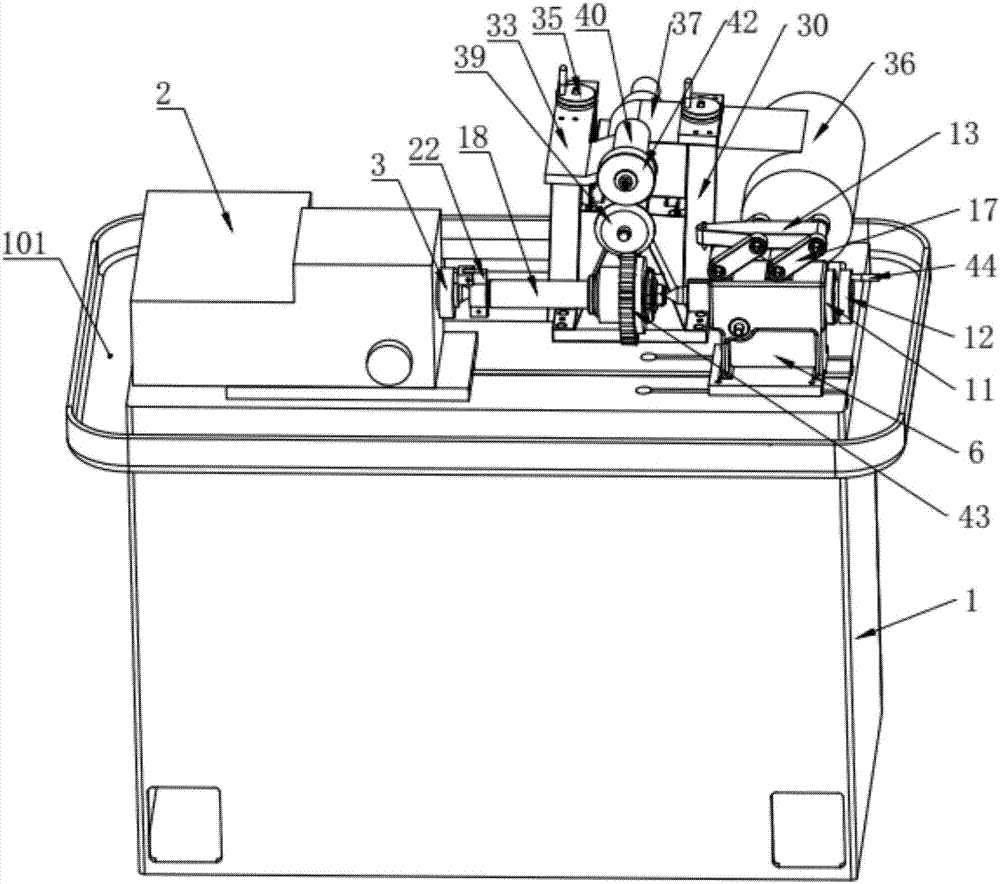

[0064] Such as figure 1 and figure 2 As shown, the present invention provides a gear forming grinding machine tool, including a bed 1, a numerically controlled dividing head 2, a gear centering device, a gear clamping device, a swing device, and a grinding and finishing device; the bed 1 is A box structure, such as Figure 9 As shown, there is an installation base 101 on the bed 1, and the numerical control indexing head 2 is installed on the installation base 101, and the numerical control indexing head 2 is provided with a tooth groove conversion mechanism, and the tooth shape centering device includes a base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com