Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58 results about "Tooth length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The average tooth length was 21 mm with minimum and maximum tooth length 17.52 mm and 24.69 mm respectively. The mean tooth length in male and female were 21.09± 2.09 mm and 20.99 ± 1.65 mm and mean root length were 13.08 ± 2.00 mm and 12.63 ± 1.50 mm respectively.

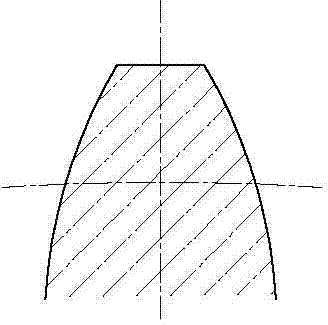

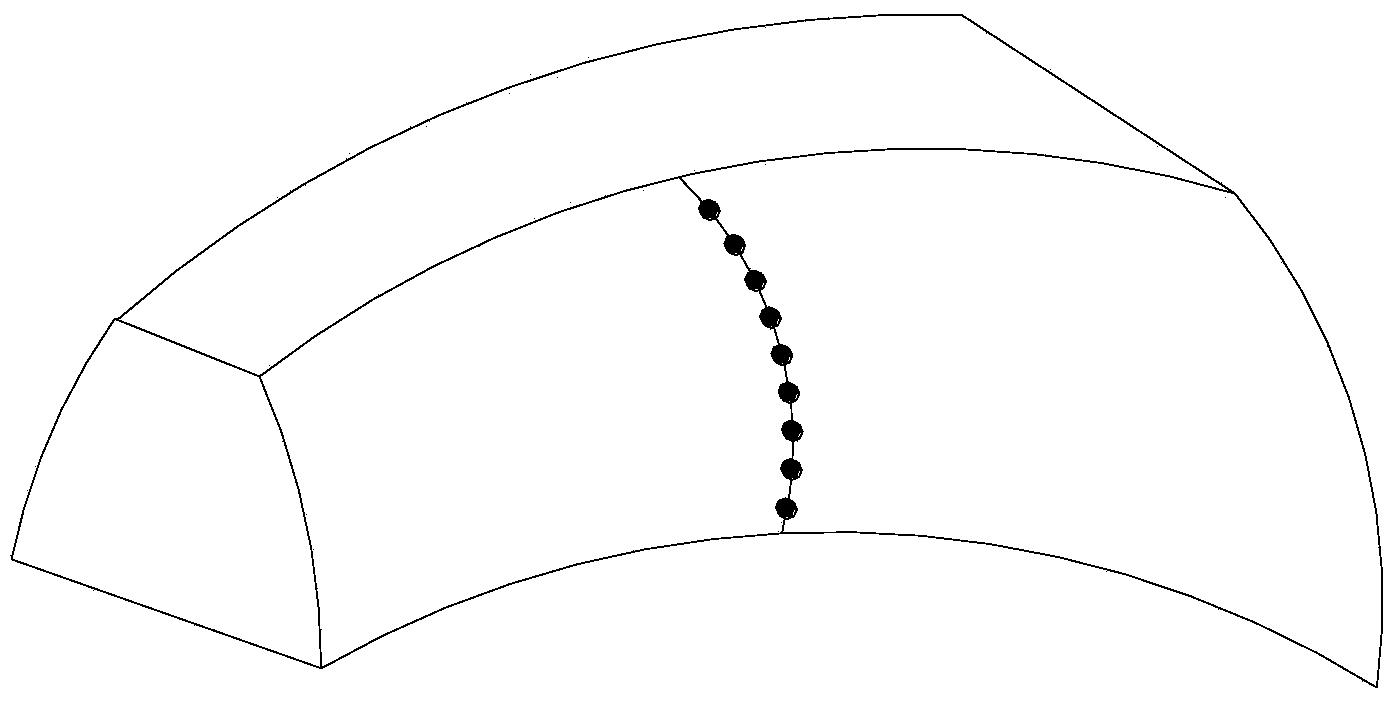

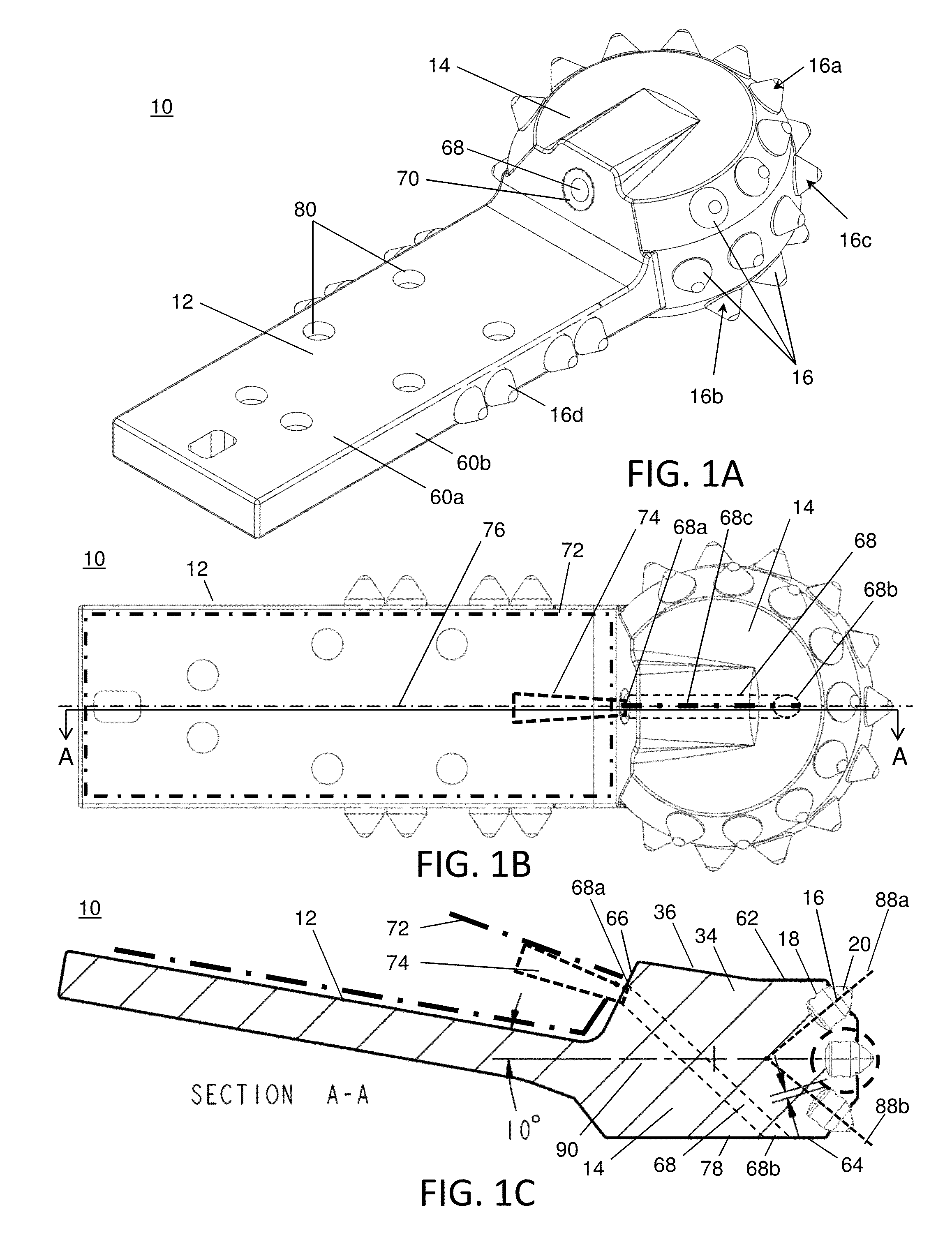

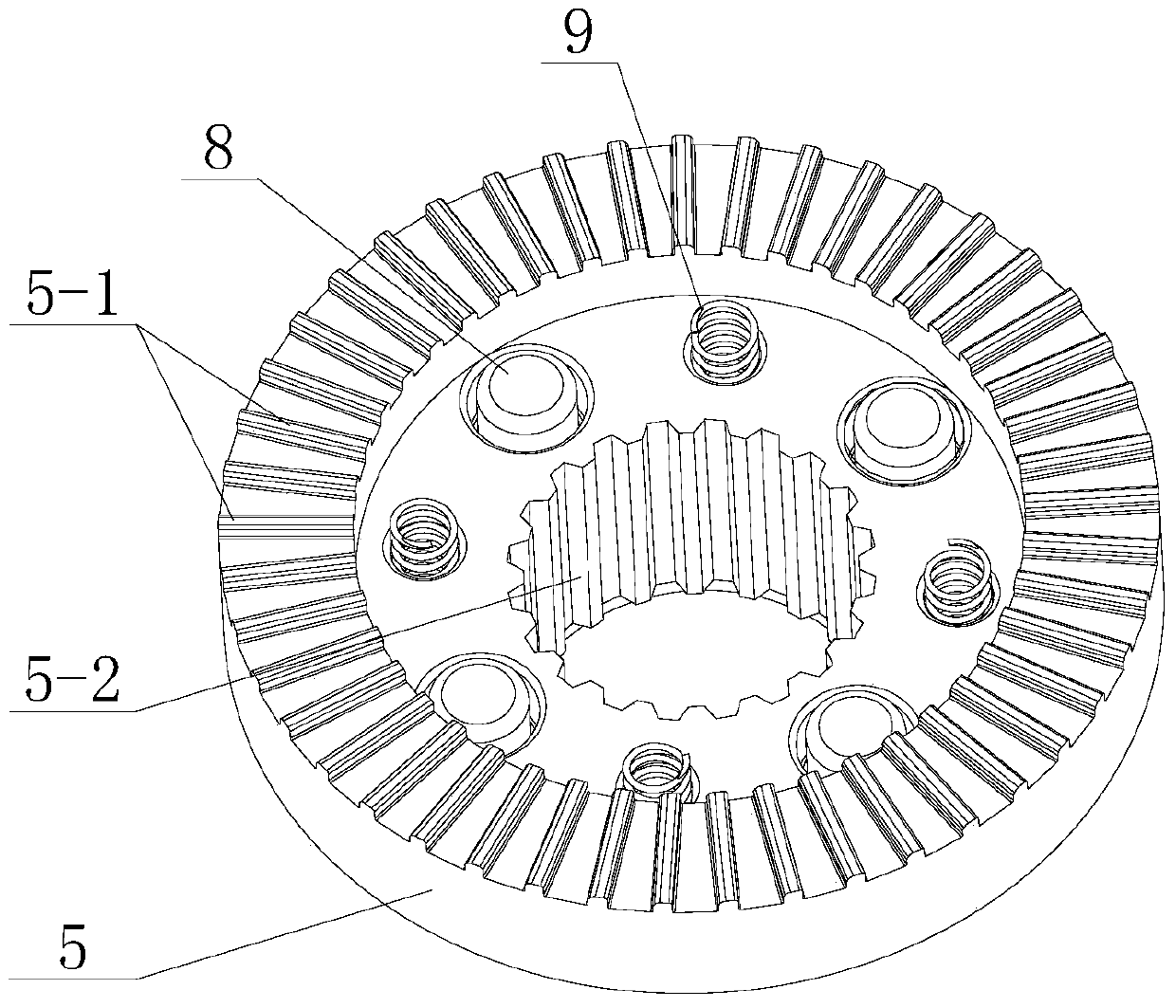

Crowned tooth gear, processing method and processing milling cutter

InactiveCN102506149ASimple structureEasy to processPortable liftingGear teeth manufacturing toolsMilling cutterCoupling

The invention discloses a crowned tooth gear. The teeth of the gear are in the form of a gradual tooth profile angle. The gear is characterized in that: the teeth (14) of the crowned tooth gear are in the form of a gradual tooth profile angle; the tooth length direction of the teeth (14) is crowned; the tooth forms of the radial section of the teeth (14) are consistent; and the tooth roots are fully arcs. A processing method of the crowned tooth gear comprises a step of processing the tooth forms by a forming process. The teeth are processed one by one on a numerically controlled milling machine. A used milling cutter comprises a cutter body (8) and a cutter head (9). The shape of a cutting blade of the cutter head (9) is the same as that of tooth slots (13) on the biggest part of the crowned tooth gear in size. The cutting blade comprises an involute section (10) and an arc section (12). The top end of the cutting blade is in full arc smooth connection. The crowned tooth gear is simple in structure, is convenient to process, is applied to a gear coupler, can ensure good linear contact between the crowned tooth gear and a gear ring and no point contact between the crowned tooth gear, ensures the bending strength of the gear roots at the same time, improves the using performance of the gear coupler and prolongs the service life of the gear coupler.

Owner:YIYANG KANGYI MACHINERY DEV

Curvilinear-tooth point-line meshing gear and processing method thereof

The invention discloses a curvilinear-tooth point-line meshing gear, which is a curvilinear-tooth cylindrical gear. Tooth lines of gear teeth are curvilinear-tooth lines; the cross section of each gear tooth in a middle point of a tooth length direction is a middle cross section; each gear tooth adopts the middle cross section as a center, forms a left spin line from the middle cross section to the left end along the tooth length direction of each gear tooth, and forms a right spin line from the middle cross section to the right end along the tooth length direction of each gear tooth; the left spin line and the right spin line are symmetrical relative to the middle cross section; each tooth top is gradually narrowed and each tooth root is gradually thickened when each gear tooth extends to two ends along the middle cross section of each gear tooth; the radius of a concave curve of each curvilinear-tooth line on each gear tooth along the tooth length direction is larger than and equal to the radius of a convex curve of each curvilinear-tooth line on each gear tooth along the tooth length direction; the meshing manner is point-line meshing. The curvilinear-tooth point-line meshing gear provided by the invention has the advantages of high strength, long service life, low noise, no axial force in gear drive, and material saving, and in addition, a dynamic pressure membrane can be easily built between each two tooth faces, so that the bearing capacity can be improved, the tooth face abrasion is reduced, and the transmission efficiency is improved.

Owner:三门峡骐达科技有限公司

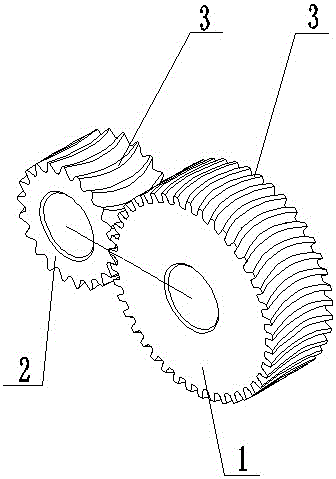

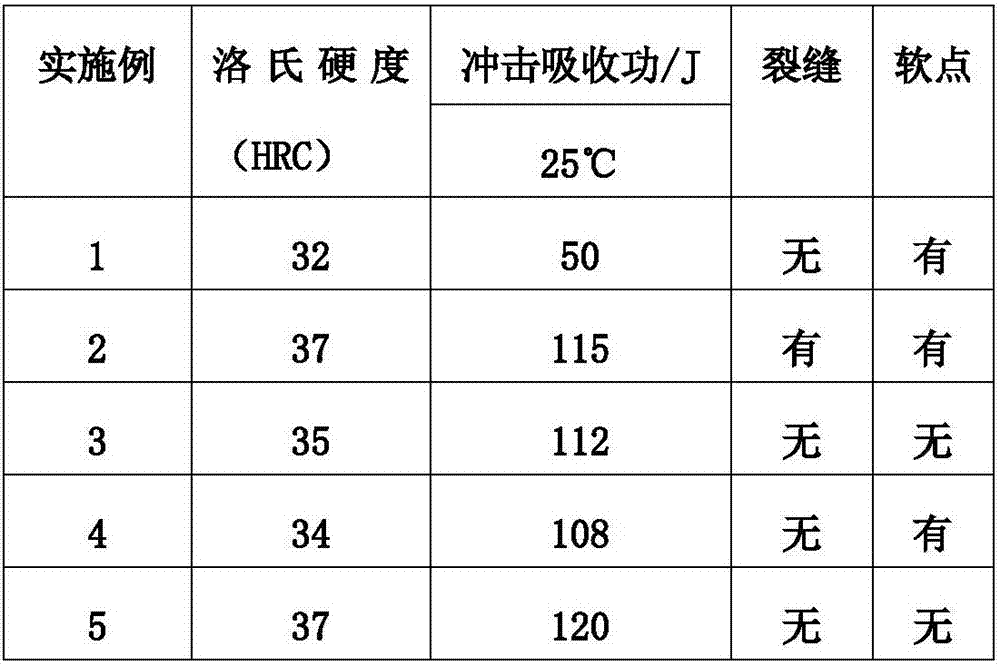

Double-end toothed stud and manufacturing method thereof

PendingCN107023554AImprove hardenabilityImprove toughnessScrewsTooth lengthArchitectural engineering

The invention discloses a double-end toothed stud. The double-end toothed stud comprises a stud body and threaded sections, the threaded sections comprise the first threaded section and the second threaded section, and the stud body is located between the first threaded section and the second threaded section; an included angle formed between a tooth arranged at the initial end of the first threaded section and the vertical line of the stud body is 20 degrees, an included angle formed between a tooth arranged at the tail end of the first threaded section and the vertical line of the stud body is 20 degrees, an included angle formed between a tooth arranged at the initial end of the second threaded section and the vertical line of the stud body is 20 degrees, and an included angle formed between a tooth arranged at the tail end of the second threaded section and the vertical line of the stud body is 20 degrees; the tooth length of the first threaded section is 180 mm, the tooth pitch between the two ends of the first threaded section is 10 mm, the tooth length of the second threaded section is 140 mm, and the tooth pitch between the two ends of the second threaded section is 10 mm; the stud body is in a cylindrical shape; the total length of the stud body and the threaded sections is 470+ / -0.8 mm. The double-end toothed stud has the advantages of being good in smooth finish, free of burrs and high in constant-temperature impact absorbing energy. The invention further discloses a method for manufacturing the double-end toothed stud.

Owner:湖北玖天机车部件有限公司

Forming method of bevel-gear forging tooth-die

InactiveCN101337318AReduce precision lossImprove efficiencyMilling equipment detailsNumerical controlRounding

The invention relates to a processing method for forming a bevel gear forging tooth die. In a three-dimensional design dynamic simulation, contact areas are positioned at the middle parts of the tooth length and the tooth height, and account for 60% in the tooth length direction. In designing, the drum-shape size is increased on the teeth shape; the high speed milled tooth die enable all corners to be round; the rounding off of gear corners and the rounding off of tooth root part are conducted; through the three dimension design, numerical control programming and digital treatment of an entity, an unchanged knife road is generated; repeated processing is conducted at unlimited times; each corner is a filleted corner through the rounding off process; an electrode is milled through a high speed numerical control mill; a semi-finished tooth die after heat treatment is processed through electric sparks; a tooth die cavity is manufactured; and finally a finished tooth die cavity is finely processed through the high speed numerical control mill, wherein, the speed of the main shaft of the fine processing of the high speed numerical control mill is 22000-30000r / min.

Owner:洛阳市冠华精锻齿轮总厂

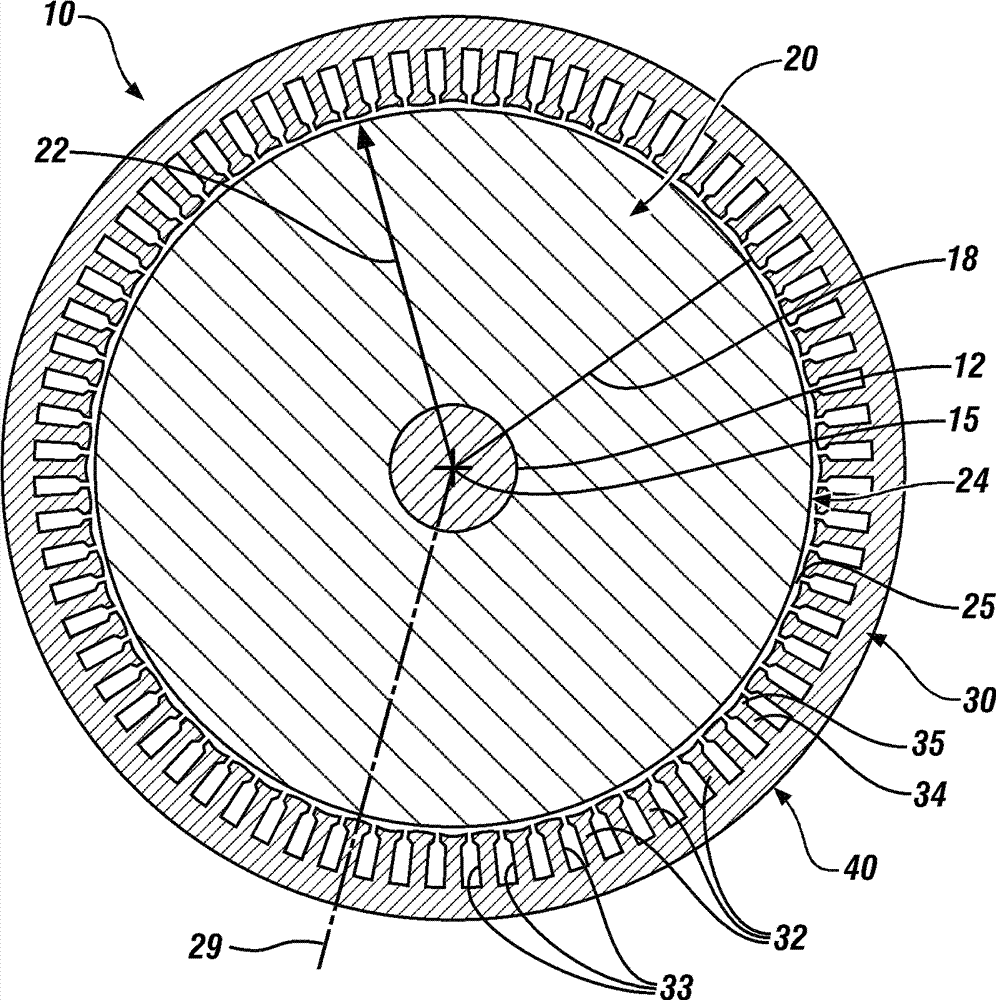

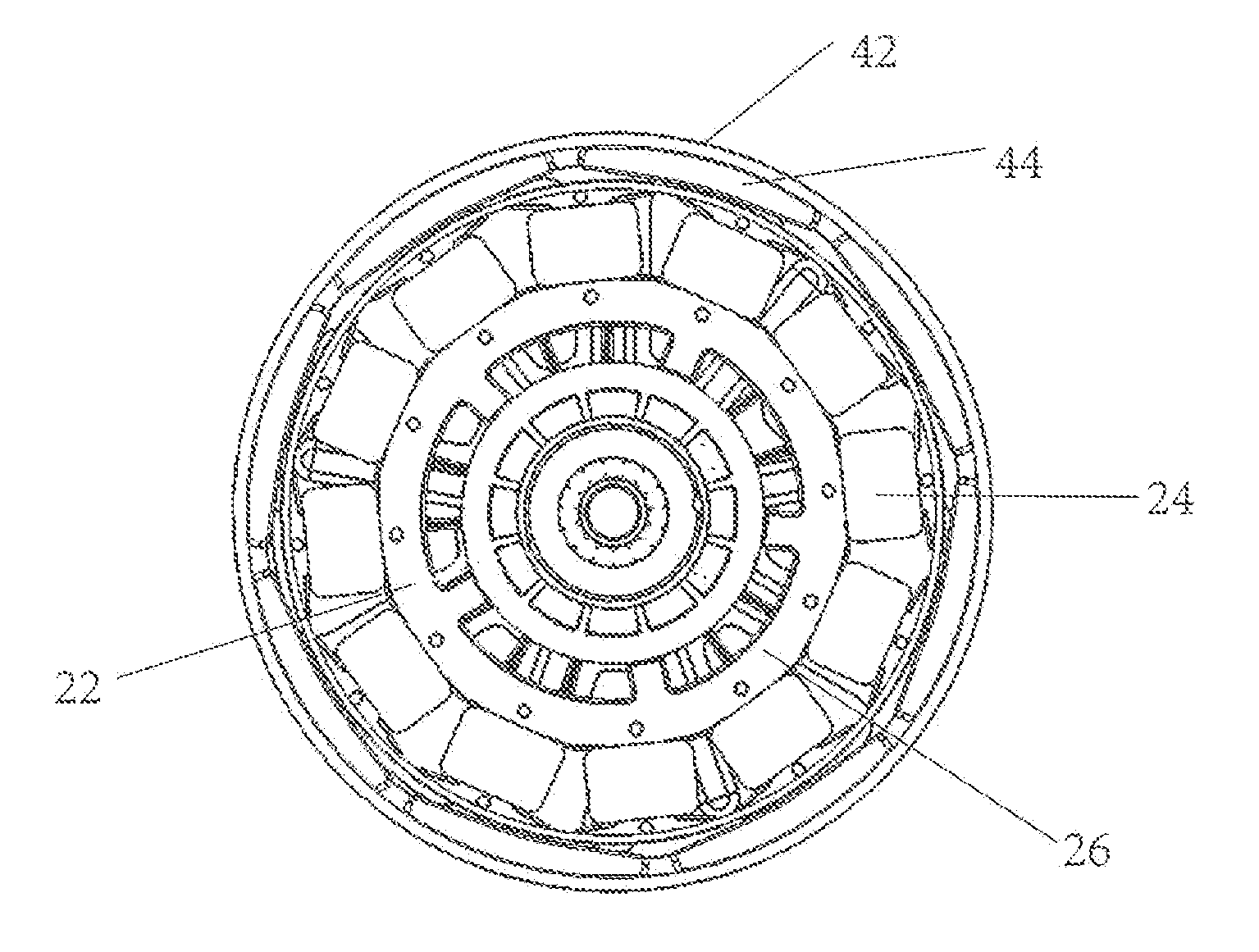

Asymmetric stator teeth in an electric motor

ActiveCN102780286AMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorTooth length

The present invention relates to asymmetric stator teeth in an electronic motor. A permanent magnet motor includes a permanent magnet rotor, a stator surrounding the rotor having a plurality of teeth radially inwardly oriented toward a longitudinal axis of the stator, wherein each tooth has a tooth length and a tooth tip surface geometry. An asymmetric air gap is defined by variations in the tooth lengths and tooth tip surface geometries.

Owner:GM GLOBAL TECH OPERATIONS LLC

Electric Motor

InactiveUS20150349593A1Improve motor efficiencyHeight of tooth is shortenedWindings insulation shape/form/constructionMagnetic circuit rotating partsTooth lengthEngineering

An electric motor has a wound stator and an outer rotor. A core of the stator has outer and inner annular portions. Tooth portions extend radially outwardly from the outer annular portion. Connecting arms interconnect the outer and inner annular portions. The width of the connecting arms is less than the width of the tooth portions. The ratio of tooth height L1 to distance between the roots of adjacent teeth L3 is in the range of 1.0 and 1.3. The ratio of tooth width T3 to L3 is in the range of 0.8 and 1.0. The ratio of tooth length T1 to L3 is in the range of 0.5 and 0.6. The ratio of T3 to outer diameter of the stator core D is in the range of 0.07 and 0.1.

Owner:JOHNSON ELECTRIC SA

Multifunctional comb

The invention relates to a multifunctional comb, which comprises a comb handle, a comb back which is connected to the comb handle and comb teeth which are arranged in the comb back; the multifunctional comb is characterized in that the multifunctional comb is provided with a comb tooth density adjusting mechanism for adjusting a comb tooth density, a comb tooth length adjusting mechanism for adjusting a comb tooth length and a vibrating massaging mechanism for massaging scalps. With the application of a vibrating massaging control method based on the multifunctional comb, a vibrating intensity can be adjusted only in accordance with combing strength, so that the best massaging purpose is achieved. The multifunctional comb provided by the invention integrates functions of adjusting the comb tooth density, adjusting the comb tooth length and massaging the scalps, so as to adapt to the demands of different users; and the multifunctional comb, which is matched with the vibrating control method provided by the invention, can offer more user-friendly choices and experiences to users.

Owner:练达晖

Continuous hobbing method for straight bevel gear

ActiveCN104985260AIncrease productivityHigh production efficiency Machining precisionGear teethHobbingTooth length

The invention discloses a continuous hobbing method for a straight bevel gear. The continuous hobbing method is based on a special hypocycloid approximating a straight line. A cutterhead rotates at the speed being omega t, a gear rotates at the speed being omega g, and at the moment, relative movement of the gear and a cutter is equivalent to pure rolling engagement movement of cutter rolling and gear rolling. When the rolling radius and the reference radius of the cutter are the same or equal to one half of the gear rolling radius, the track formed by cutter noses of cutter teeth on the gear is an approximate straight line, and therefore the cutter and the gear can be used for continuous hobbing of the straight bevel gear. The continuous hobbing method has the advantages that the continuous hobbing technology is adopted, and therefore production efficiency and precision are high; both wet hobbing and dry hobbing can be achieved, the dry hobbing efficiency is higher, the tooth surface finish degree is better, the requirement for the cutter and a machine tool is higher, and wet hobbing just gets the opposite results; the machined straight bevel gear is in a slight drum shape instead of a strict straight line shape in the tooth length direction. The drum-shaped size can be controlled by adjusting machine tool parameters, so that the contact area of the gear is changed to enable the gear to have the better transmission performance, and gears with constant-depth teeth and shrinkage teeth can be machined.

Owner:WUHAN UNIV OF TECH

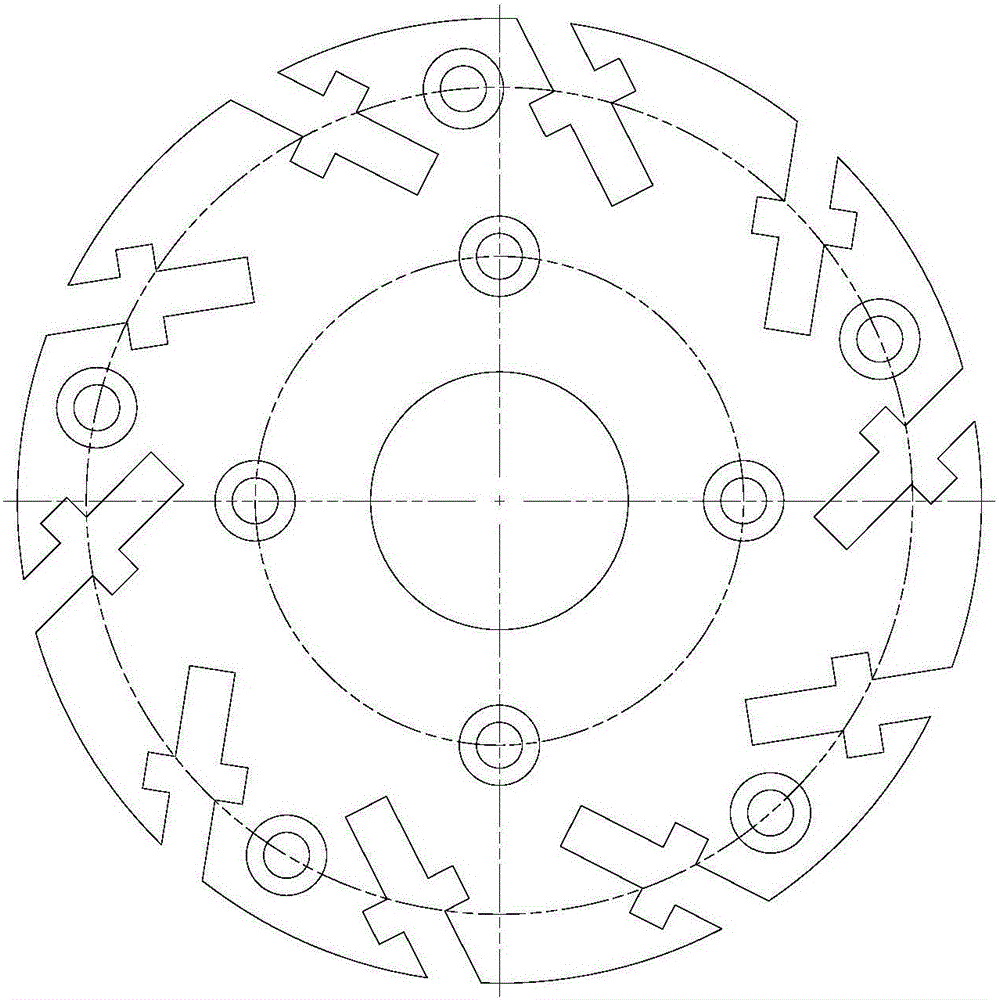

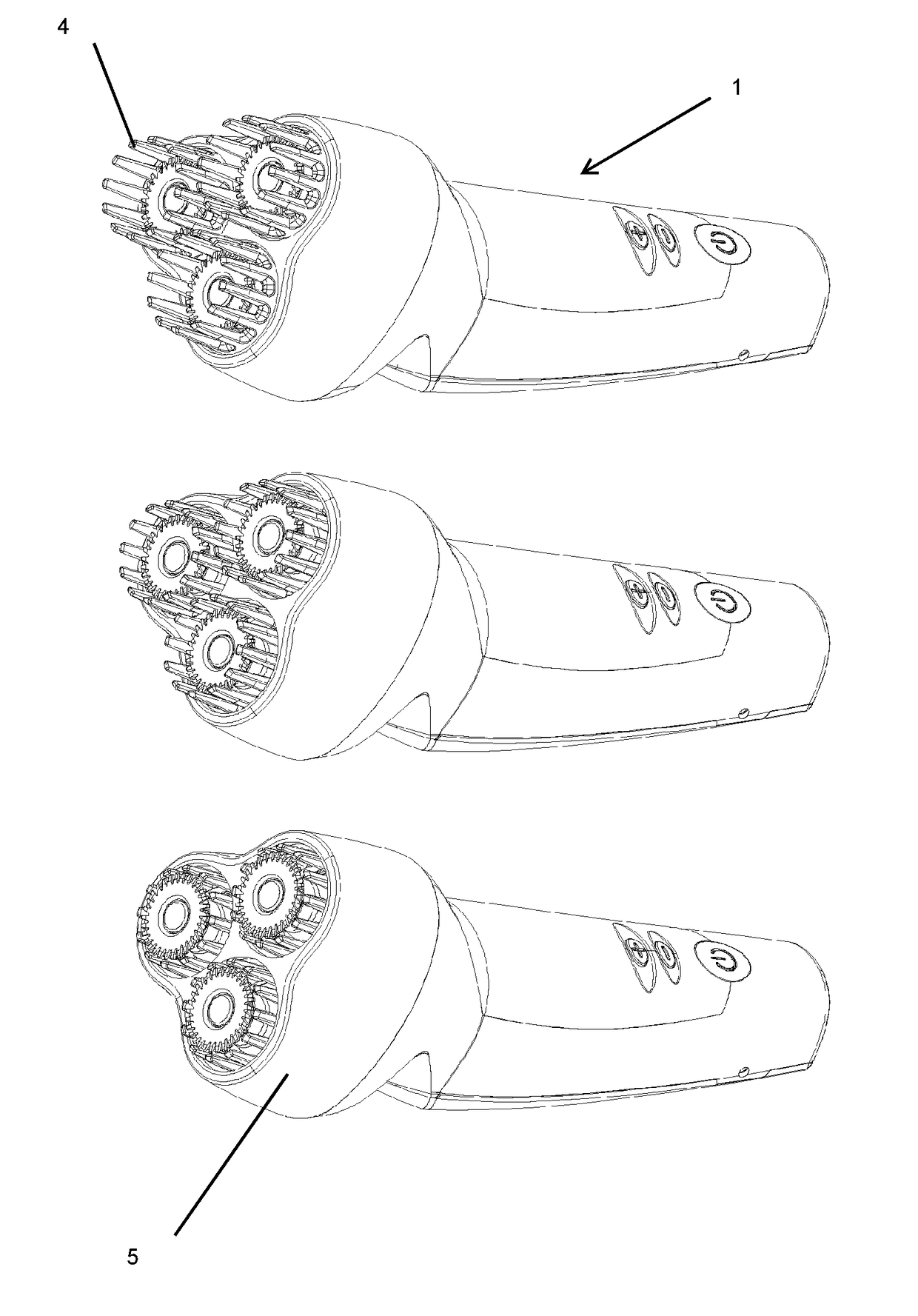

Beard trimmer with one or more rotary heads having a fixed blade with a particular shape

The present invention relates to a beard trimmer having one or more rotary heads (1), said rotary cutting heads having a moving blade (2) and a fixed blade (3), each head being surrounded by a crown-shaped comb (4), said comb being adjustable in height in order to adjust, in use, the distance between said blades and the skin, and thereby to adapt the cutting of the beard to the desired length, characterized in that the trimmer comprises a fixed bade having a shape characterized by: —a tooth length L3 of 1 to 3 mm, preferably 1.5 to 2 mm; —an opening angle between the teeth of 20 to 30°, preferably 22 to 28°, and more preferably 24 and 27°; —a tooth width L2, at the end of the teeth, of 0.3 to 1 mm, preferably 0.4 to 0.9 mm.

Owner:BABYLISS FACO

Sawtooth porous type plate-fin heat exchanger

InactiveCN104390506ACompact structureImprove heat transfer effectLaminated elementsTooth lengthHeat transfer efficiency

The invention provides a sawtooth porous type plate-fin heat exchanger. The existing plate-fin heat exchanger is formed by heat exchange fins, a baffle, a seal strip, a flow deflector, an end plate, an end socket, a liquid inlet and outlet connection pipe and the like. Under the condition that the existing structure is not changed, the characteristics of porous fins and sawtooth fins are combined, many short fragments are cut in the teeth length direction of the porous fin, and sawtooth shapes are staggered at intervals in the teeth length direction of the porous fin to obtain the sawtooth porous type fins. When heat exchange fluid flows in a runner, the sawtooth facilitates fluid disturbance, the heat exchange function is strengthened, and the heat exchange efficiency of the heat exchange fin is improved. By adopting the technical scheme, the plate-fin heat exchanger is formed by porous sawtooth fins; the heat exchange effect is strengthened; the heat exchange efficiency of the heat exchange fin is improved, and the structure of the plate-fin heat exchanger is more compact.

Owner:中国船舶重工集团公司第七〇三研究所

Arc spiral cylindrical gear and arc rack

InactiveCN101818802BThe meshing track is tight and preciseIncrease contact areaPortable liftingGearing elementsTooth lengthConvex side

The invention discloses an arc spiral cylindrical gear. Contour lines (13 and 14) of a mean section of tooth length of a gear tooth on a convex tooth surface (1) and a concave tooth surface (2) are involute profiles of a spur gear, the section apart from the center point is changed into an involute profile of a helical gear, the involute profiles of the spur gear respectively screw to contour involutes (5, 6, 7 and 8) of two end faces of the helical gear from the center point to two ends along a convex tooth top camber line (9) and a convex tooth bottom camber line (10) on the convex tooth surface (1) and a concave tooth bottom camber line (11) and a concave tooth top camber line (12) on the concave tooth surface (2) so as to form a two-way arc screw gear tooth comprising a two-way screw tooth portion with one end provided with a right screw arc helical gear and the other end provided with a left screw arc helical gear. Arc screw meshing tracks of pitch circles and the like of the gear and the rack are accurate, and a concave tooth top arc is equal to a convex tooth bottom arc and is larger than a convex tooth top arc and a concave tooth bottom arc, thereby forming a 100 percent of contact surface and creating a new meshing principle.

Owner:完颜学明

Full-tooth-width line-contact helical bevel gear tooth structure

InactiveCN103671821AGood transmission effectGood oil performancePortable liftingGear lubrication/coolingGear wheelTooth length

The invention discloses a full-tooth-width line-contact helical bevel gear tooth structure which is characterized in that the surface of a helical bevel gear tooth is a full arc in the tooth length direction. According to the full-tooth-width line-contact helical bevel gear tooth structure, an originally-considered point-contact helical bevel gear is changed. Full-tooth-width line contact is achieved in transmission, the contact area is higher than 90%, the coincidence degree is high, transmission is stable, noise is low, the bearing capacity is high, the tooth-surface oil-containing performance is good, a lubricating oil film can be easily formed, friction and abrasions on the tooth surface are reduced, and the transmission performance of a helical gear is improved comprehensively.

Owner:林菁

A method for assembly and adjustment of spiral bevel gears

InactiveCN106342200BTransmission ratio without distortionReduce noiseMachine gearing/transmission testingTooth lengthAgricultural engineering

The invention belongs to the technical field of mechanical processing, and relates to a method for assembling and adjusting spiral bevel gears. The adjustment quality of the spiral bevel gear assembly mainly takes the adjustment quality of the contact area as an important index. The position and shape of the contact area of the tooth surface have an important impact on the working stability, life and noise of the spiral bevel gear. According to the structural characteristics and working principle of the spiral bevel gear itself, the present invention analyzes the trend of the gear backlash along the tooth length with the change of the installation distance, which leads to the trend of influence on the position of the gear contact area, and the change of the gear backlash. The position of the contact area of the tooth surface of the gear changes accordingly, and with reference to the actual operation results, the assembly adjustment method is summarized.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for improving tooth trace precision of internal spline after heat treatment

InactiveCN108247304AImprove tooth alignment accuracySolve the problem of not being able to use gear grinding equipment to modify the tooth directionTooth lengthReciprocating motion

The invention relates to a technical method for improving the tooth trace precision of an internal spline after carburization. A core rod of which the shrinking percentage is smaller than that of a part material is applied to tightly support the small diameter of the part internal spline, and accordingly, the stability of the slope deformation tendency of the tooth trace of the part internal spline is controlled; and through data comparison, the tooth trace change error of the internal spline subjected to carburization heat treatment is analyzed and summarized, a grinding rod is applied to make contact with the unilateral tooth face of the part internal spline, and the grinding rod does linear reciprocating motion to finish the tooth face error of the internal spline. According to the technical method, the problem that after the small-modulus internal spline is subjected to carburization heat treatment, the tooth trace cannot be trimmed through tooth grinding equipment is solved. Through the technical scheme, the effects that the tooth length is 40 mm, the tooth trace error of the internal spline is smaller than or equal to 0.01 mm, and the tooth trace precision of the internal spline reaches fifth grade.

Owner:HARBIN DONGAN ENGINE GRP

Anti-clamping cross-seam comb-tooth type bridge expansion device

PendingCN113931063ASolve the card stoneSolve the stuck wheel problemBridge structural detailsShaped beamTooth length

The invention discloses an anti-clamping cross-seam comb-tooth type bridge expansion device, and solves a problem that wheels and stones are clamped by deep and long potholes of a traditional large comb-tooth type bridge expansion device. The fixed tooth pit slot filling and lifting method comprises steps that the tooth length is increased in the post-cast strip direction of the telescopic device, pit slots with certain lengths of adjacent teeth are covered, inter-tooth cavities with certain lengths corresponding to the models are formed, inter-tooth bearing beams with the corresponding lengths are vertically and movably connected to the corresponding tooth ends, the bearing beams have enough strength, during use, the size of the top surface of the full-pit slot long inner bearing beam is only about 15mm lower than that of the tooth top. According to comb tooth beam seam bolt side pit slot filling and lifting, two steel plates are welded to the movable tooth side through the I-shaped cross section of a fixed tooth side tooth beam, and a 20-25 mm gap needed by stretching and retracting of a fixed tooth I-shaped beam web is reserved. After treatment, a top surface of a pit slot on the movable tooth side is about 20mm lower than the road surface, so the conditions of wheel clamping and stone clamping are avoided.

Owner:湖北恋桥交通工程有限公司

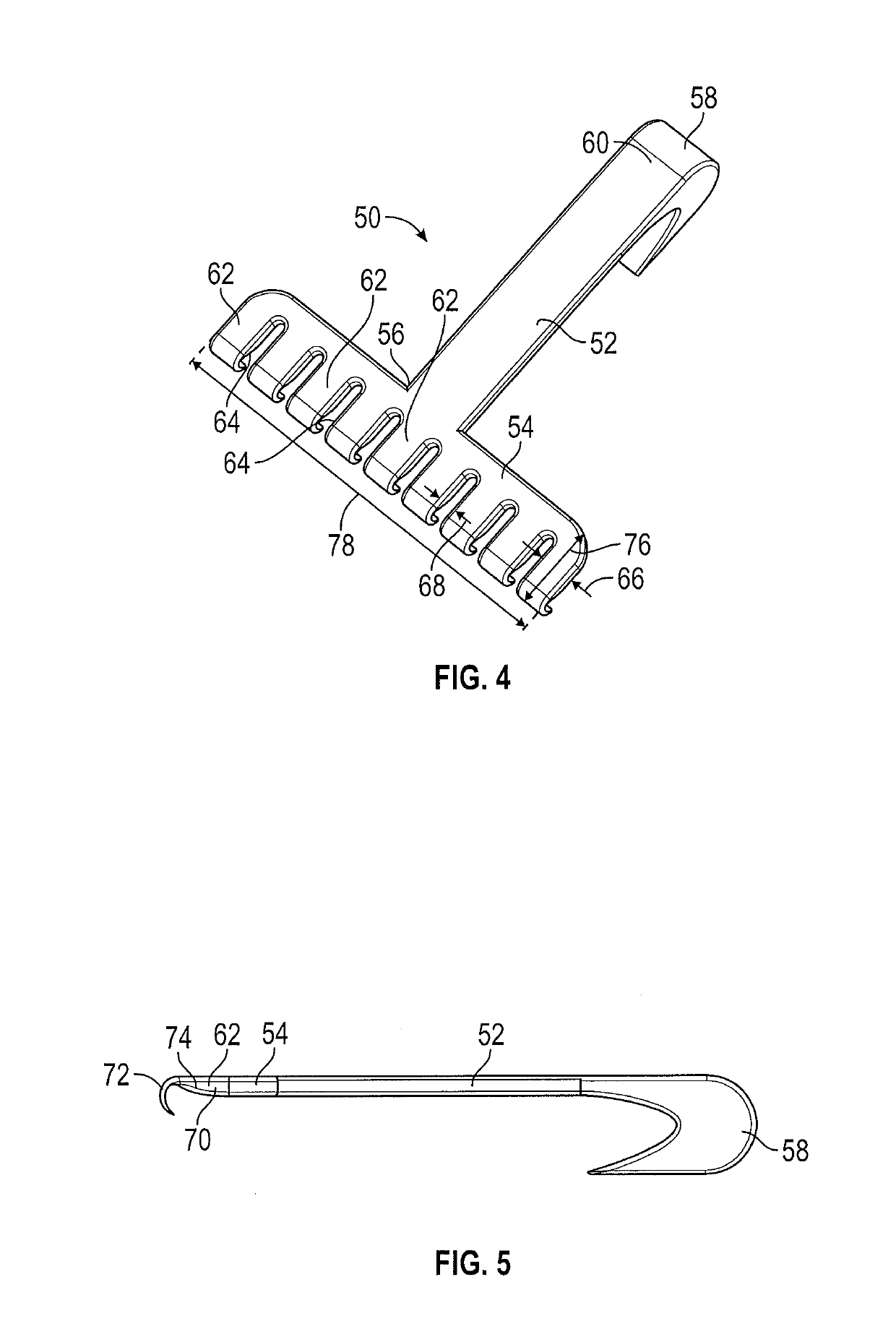

Breast subcutaneous tissue surgical instruments

A dilator configured for separating subcutaneous fat from glandular tissue includes a center section, a first end section extending from a first end of the center section, the first end section extending nonparallel to the center section, the first end section having a first diameter, and a second end section extending from a second end of the center section opposite the first end, the second end section extending nonparallel to the center section, the second end section having a second diameter different than the first diameter. A retractor includes a handle, a shaft extending from the handle, and a head located at a shaft end opposite the handle. The head includes a plurality of teeth, each tooth having a tooth end curving downwardly from a head outer surface, adjacent teeth spaced from one another by a tooth gap therebetween, the plurality of teeth having unequal tooth lengths.

Owner:WESTERN NEW ENGLAND UNIVERSITY

Beard trimmer with one or more rotary heads having a fixed blade with a particular shape

The present invention relates to a beard trimmer having one or more rotary cutting heads (1), said rotary cutting heads having a moving blade (2) and a fixed blade (3), each head being surrounded by acrown-shaped comb (4), said comb being adjustable in height in order to adjust, in use, the distance between said blades and the skin, and thereby to adapt the cutting of the beard to the desired length, characterized in that the trimmer comprises a fixed blade having a shape characterised by: a tooth length L3 of 1 to 3 mm, preferably 1.5 to 2 mm; - an opening angle between the teeth of 20 to 30DEG, preferably 22 to 28DEG, and more preferably 24 and 27DEG;-a tooth width L2, at the end of the teeth, of 0.3 to 1 mm, preferably 0.4 to 0.9 mm.

Owner:BABYLISS FACO

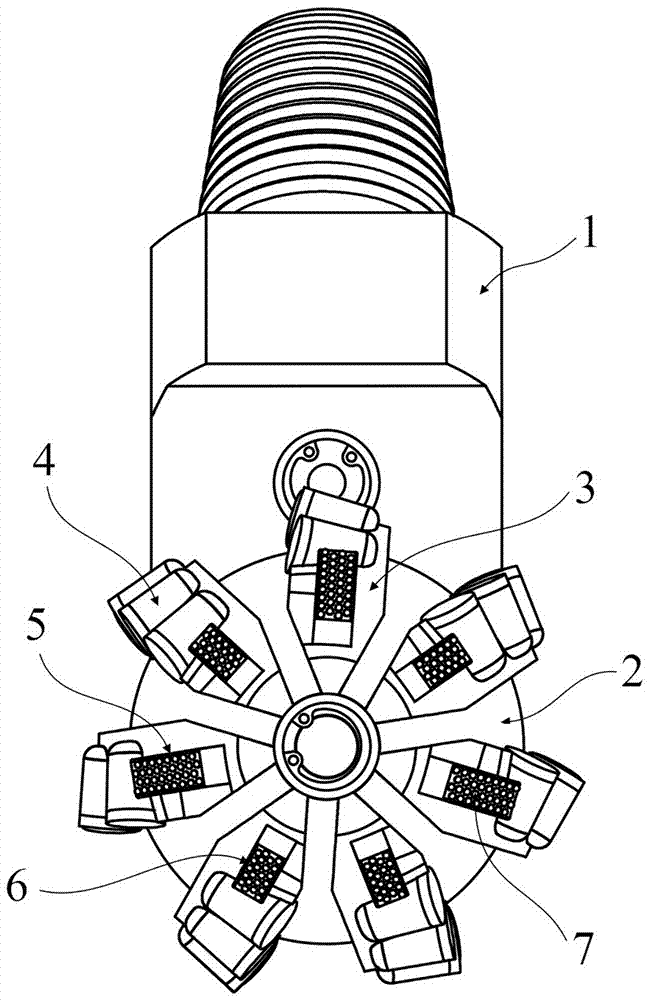

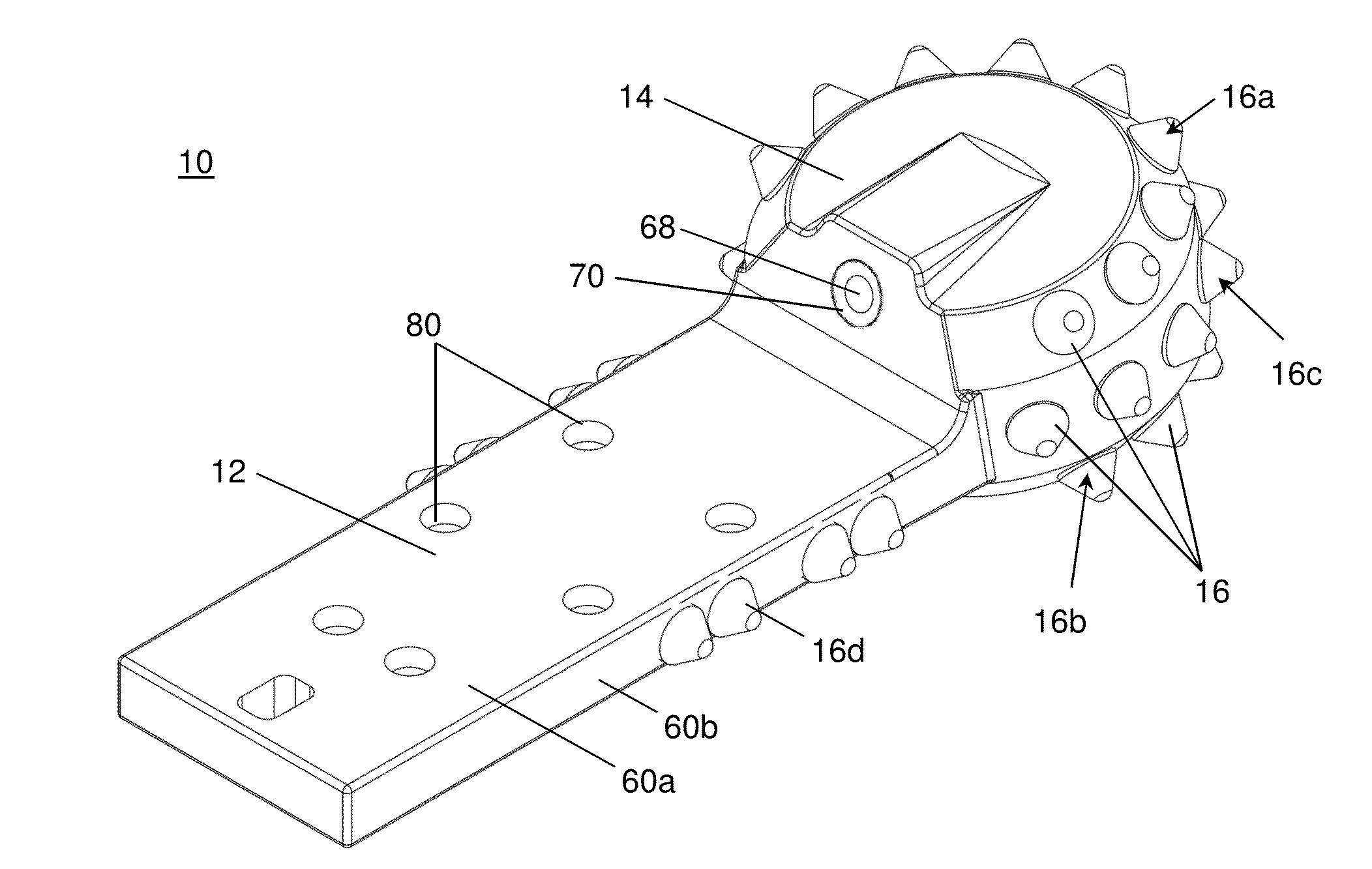

Arc-shaped tooth one-cone drill bit with natural diamond particles embedded on surface

InactiveCN107255017AImprove wear resistanceImprove rock breaking efficiencyDrill bitsTooth lengthAlloy

The invention discloses a curved-tooth single-cone drill bit with natural diamond particles on the surface, which comprises tooth claws (1) and spherical cones (2), and toothed belts ( 3), long arc teeth (5) and short arc teeth (6) are alternately inlaid on the cloth tooth belt (3) on the top of the spherical cone (2), and the long arc teeth (5) and short The surface of the curved tooth (6) is inlaid with natural diamond particles (7), the end faces of the long curved tooth (5) and the short curved tooth (6) are rectangular, and the long curved tooth (5) and the short curved tooth The base body of the teeth (6) is made of hard alloy material; PDC teeth (4) are staggered and welded on the remaining toothed belt (3). The beneficial effect of the present invention is that the wear resistance of the teeth of the head of the single-cone bit is effectively improved, the rock-breaking efficiency of the bit and the life of the cutting teeth are improved, and it is more suitable for hard formations.

Owner:SOUTHWEST PETROLEUM UNIV

Magnetic ratchet hinge structure

The invention provides a magnetic ratchet hinge structure. The structure comprises a first hinge and a second hinge. The first hinge and the second hinge are connected by a rotating shaft. The first hinge is a relative fixed part aimed at the rotating shaft. The second hinge rotates with the rotating shaft. The first hinge is provided with a pawl. The pawl is hinged with the first hinge. The rotating shaft is provided with a ratchet wheel. Distribution range of ratchet on the ratchet wheel is 1 / 6 to 1 / 3 of ratchet wheel circumference. The ratchet wheel is provided with a pushing plate. Lengthof the pushing plate is larger than tooth length of the ratchet. The first hinge is provided with a permanent magnet. The tail part of the pawl is provided with a concentrating flux plate. When the ratchet wheel rotates to one direction and makes the pawl separate from the ratchet, one of the pushing plates pushes the pawl, to make the concentrating flux plate on the pawl get close to the permanent magnet and attract the permanent magnet. A slow recovery piece is arranged between the pawl and the ratchet wheel. The structure is mute, and can fix open-close positions of a door or a window undera certain angle, and the structure can smoothly fold the hinges in an opposite direction after the door or the window is opened to an extreme state.

Owner:俞云祥

Processing method of herringbone gear for heavy machinery

The invention discloses a processing method of a herringbone gear for heavy machinery. The processing method comprises the steps of (1) marking a gear blank; (2) clamping, installing and calibrating the position of a disc milling cutter; (3) performing coarse hobbing by utilizing the disc milling cutter; (4) installing and calibrating the gear blank and a hob; (5) performing finish machining on the gear blank by utilizing the hob; and (6) inspecting after the herringbone gear is formed. According to the processing method of the herringbone gear for heavy machinery, the machining precision andefficiency of the herringbone gear for heavy machinery are greatly increased, and the working area of the integrated forming tooth surface reaches 90% and meets the specification that the contact tooth length is greater than 60% at the initial stage of open gear transmission in the national standard; additionally, the tooth surface finish reaches Ra3.2; and the design size in the design of gear shafts, gears, box bodies and the like in the field of speed reducers and the like can be reduced by adopting the processing method in the condition that the same working bearing performance of the gearis guaranteed, so that raw materials are saved by at least 8% to 10%.

Owner:中实洛阳重型机械有限公司

Boring bit and method of manufacture

InactiveUS20140262535A1Loosens the temporary connectionPigmenting treatmentDrill bitsTooth lengthEngineering

A boring bit has a shank, a head and teeth distributed around the head. The teeth have a root embedded within the head's core body, a tip extending out of the head, and a narrowing region between the root and the tip. More than approximately two-thirds of the tooth length is embedded in the core body, including a portion of the narrowing region. Stabilizing rods are welded to the tips of the teeth to form a temporary connection, and the core body is formed from a molten metal poured into a cavity of a cast mold. The rods are inserted into indentations in the cast to hold the teeth in place, and the molten metal heats the teeth and weld to substantially loosen the temporary connection. As the molten metal cools, it solidifies around the teeth and secures the root and narrowing region of the teeth within the core body.

Owner:ROCKHOUND BORING PROD LLC DBA US DRILLING PROD

Zipper production defect intelligent detection method and system based on optical means

ActiveCN114693681AImplement defect detectionAccurate Defect DetectionImage enhancementImage analysisAlgorithmTooth length

The invention relates to the technical field of artificial intelligence, in particular to an intelligent zipper production defect detection method and system based on optical means, and the system is an artificial intelligence system in the field of zipper production and can realize information system integration service of the artificial intelligence system. The method comprises the following steps: acquiring the unevenness difference of each pixel point; according to the abnormal degree, the tooth width and the standard tooth width of each uneven chain tooth, the weight of each uneven chain tooth is obtained; performing spatial sine curve fitting on the uneven area, solving curve parameters by using fitting errors of starting points and ending points of a plurality of chain teeth in the uneven area and weights of corresponding pixel points to obtain a fitting curve, and calculating actual tooth pitches between adjacent chain teeth according to the fitting curve; and performing defect detection on the zipper according to the tooth length, the tooth width and the actual tooth pitch. According to the embodiment of the invention, the defect of the zipper is tested or analyzed by using an optical means, particularly a visible light image, so that the defect detection accuracy is improved.

Owner:南通市通州区锦都拉链有限公司

Face gear pair

InactiveCN107035819AImprove stabilityReduce vibrationToothed gearingsPortable liftingTooth lengthGear tooth

The invention provides a face gear pair which comprises a face gear and a small gear engaged to and matched with the face gear. The face gear pair is characterized in that a gear tooth of the small gear is cut by a plane parallel to the axis of the small gear to form an arc-shaped cross section; the thickness of the arc-shaped cross section is gradually reduced from the middle to the two sides; and an intersecting line between the arc-shaped cross section and the tooth face of the gear tooth is a curved line. Through axial direction correction on the small gear engaged to the face gear, the middle of the small gear is thick and the two sides of the small gear are thin in the tooth length direction of the small gear, so that an allowance of the small gear in an axial mounting process is raised, and the probability of generating an edge foundation due to a mounting error is lowered.

Owner:CHONGQING GEARBOX

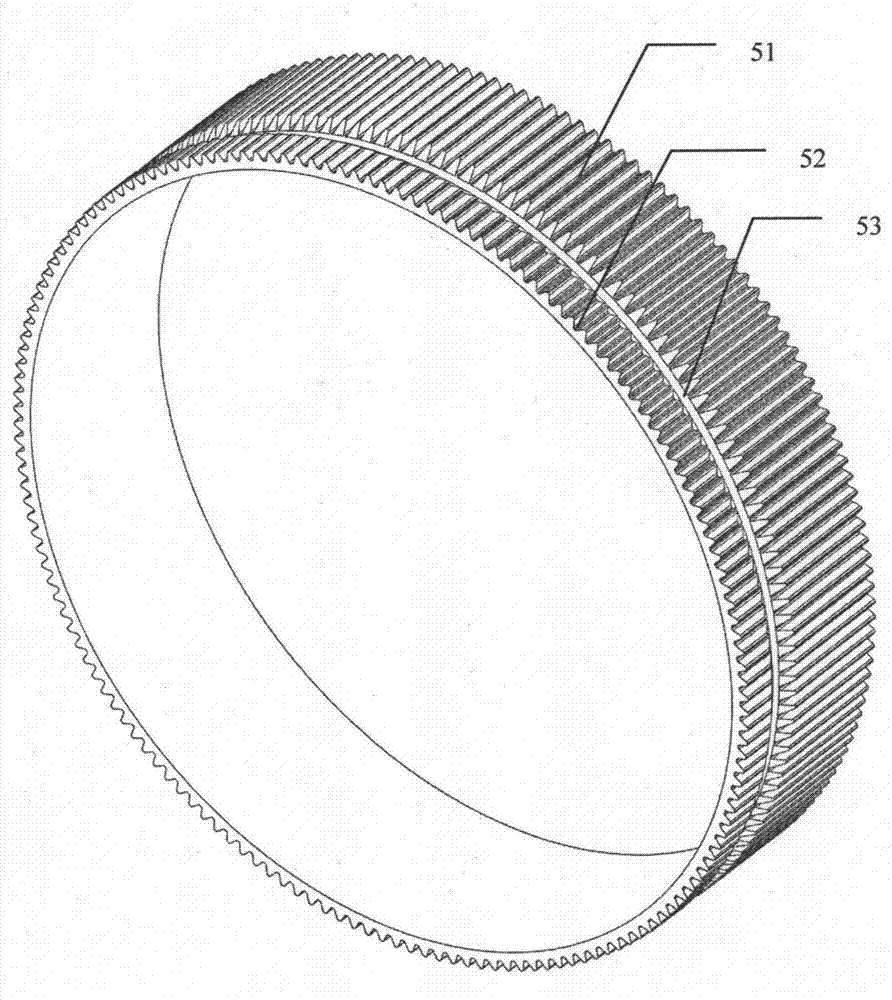

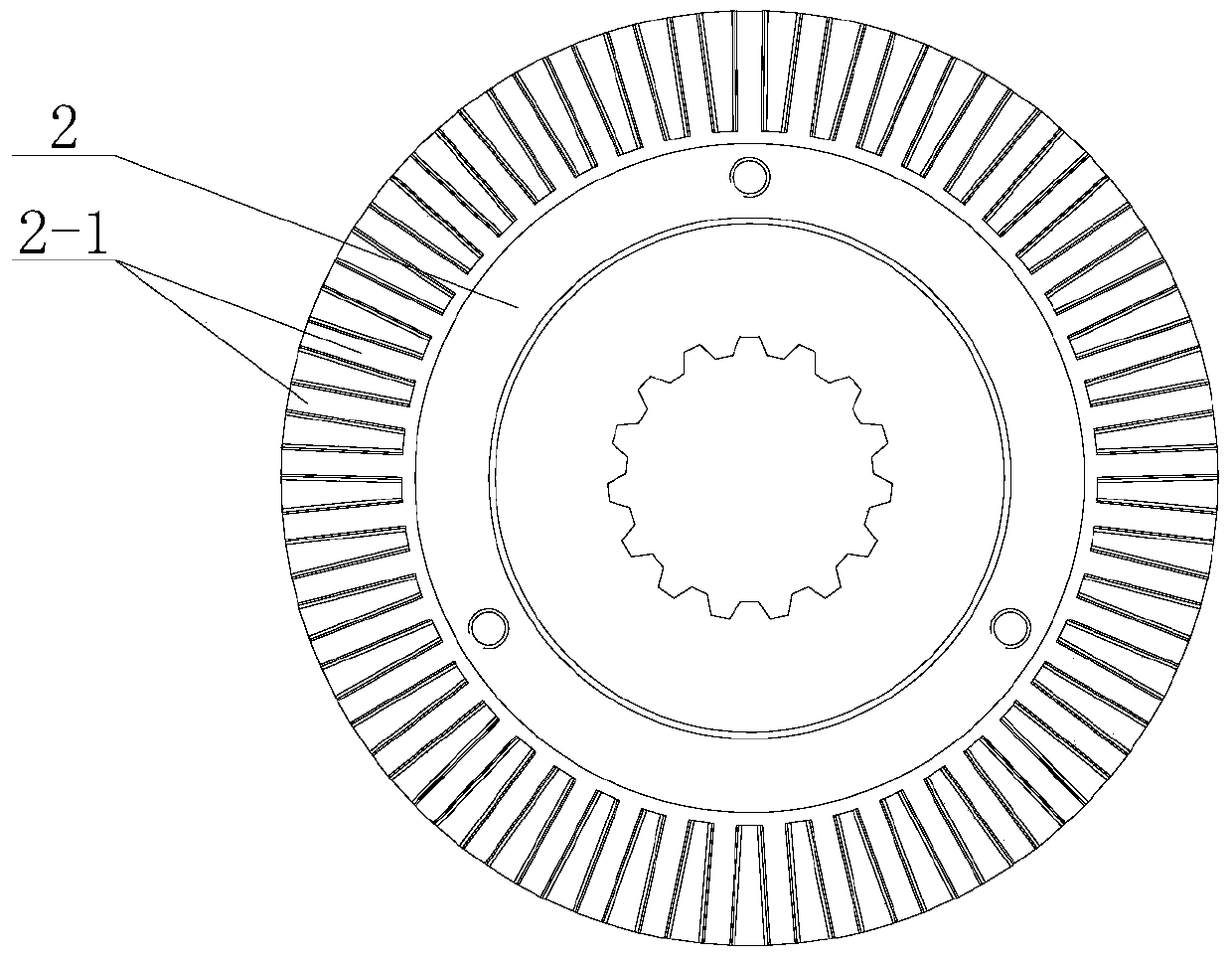

Short-flexspline type harmonic precision transmission device

The invention provides a short-flexspline type harmonic precision transmission device. The device comprises duplex flexible wheels which comprise speed reduction tooth sections and output tooth sections in tooth length direction, wherein inner rings of flexible bearings are arranged on shock wave generators; the speed reduction tooth sections of the duplex flexsplines are arranged on outer rings of the flexible bearings; the output tooth sections of the duplex flexsplines are in engaging transmission with inner tooth rings on output plates through inner engaging zero-tooth-difference transmission; the output plates are connected with inner rings of cross bearings, and outer rings of the cross bearings are fixed to rigid gears; inner tooth rings of the rigid gears are in engaging transmission with the speed reduction tooth sections of the duplex flexsplines. Compared with a traditional device, the short-flexspline type harmonic precision transmission device has the advantages that the zero-tooth-difference harmonic transmission is performed; the structure is compact, and the axial size is greatly reduced; meanwhile, the zero-tooth-difference harmonic transmission has the characteristic of harmonic gear transmission, so that the transmission accuracy and the bearing capacity of the device are high; and the requirement of joints of an aerospace robot on a harmonic gear transmission device is met.

Owner:DONGHUA UNIV

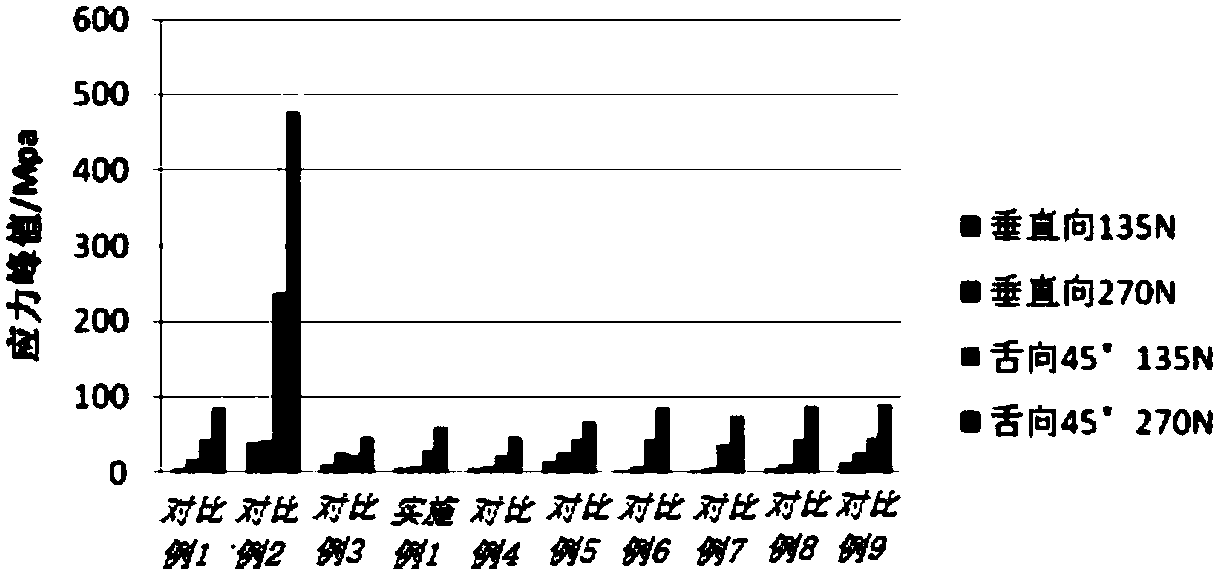

Maxillary premolar severe wedge-shaped defect fiber post restoration and production method thereof

The invention discloses a mandibular premolar severe wedge-shaped defect fiber post restoration. The mandibular premolar severe wedge-shaped defect fiber post restoration comprises a single fiber postand a wedge-shaped composite resin filling, and the single fiber post is a cylinder with the tail end diameter being 0.7-0.8 mm and the occlusion square diameter being 1.3-1.6 mm; and the height of the single fiber post is 6.0-7.5 mm less than that of a tooth length. The depth from the tip end to the bottom end of the wedge-shaped composite resin filling is 1 / 2 to 2 / 3 of the buccolingual diameterof a dental cervical part, the width of the wedge-shaped composite resin filling is from the mesial proximal surface to the distal mandibular premolar of the mandibular premolar tooth, the thicknessis 3.0-5.0 mm, and the wedge-shaped composite resin filling encircles occlusal 1 / 3 to middle 1 / 3 junction of the singe fiber post. The single fiber post of the restoration is positioned in a buccal root canal, and the fiber post is compounded with the composite resin by using the connection and auxiliary retention effects of the fiber post in order to directly complete the restoration without fullcrown.

Owner:西安交通大学口腔医院

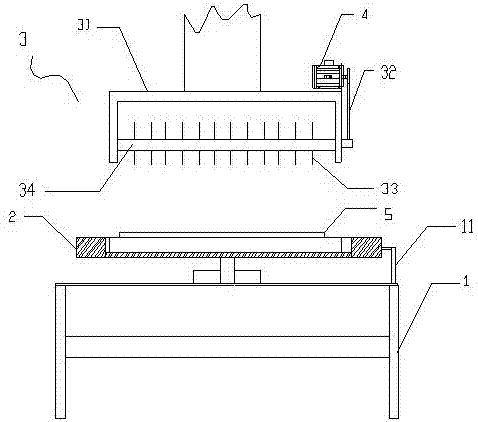

Marble composite board finger joint machining system and working method thereof

ActiveCN106863618AGuaranteed cutting qualityMake up for lack of torqueWorking accessoriesStone-like material working toolsTooth lengthTapering fingers

The invention relates to a marble composite board finger joint machining system and a working method thereof. The marble composite board finger joint machining system is characterized by comprising a base, a machining platform, a cutting device and a driving motor; marble composite board taper finger joint opening cutting is achieved through board installing, angle adjusting, cutting starting, first-time cutting, angle modification and second-time cutting; and a marble composite board machined in the cutting manner is high in cutting accuracy, when marble composite boards are matched, compared with a vertical line combination face, a taper finger joint opening combination face has the beneficial effects that according to the different saw tooth lengths, at least 55% of combination face area and combination strength are increased, and the problems that the marble composite board joining quality is poor and arching breaking is likely to happen due to the fact that marble can only be cut in the longitudinal direction or transverse direction are solved.

Owner:致尊建材有限公司

Planar double enveloping worm drive capable of maintaining precision after wear of worm gear teeth

The invention provides a planar double enveloping worm drive capable of maintaining precision after wear of worm gear teeth. A tooth portion of a worm gear is composed of gear teeth which are formed by feed machining of a cutter along an axis direction of the worm gear or along a rectilinear direction forming a certain angle with an axis of the worm gear, and are consistent in tooth profile along a tooth length direction of the gear teeth. A tooth crest of the worm gear is a cylindrical surface, tooth surfaces on two sides of each gear tooth of the worm gear are planes, and inclination angles of the tooth surfaces, relative to the axis of the worm gear, on two sides of each gear tooth of the worm gear are equal. A worm is meshed with the worm gear and can move along the axis of the worm gear; when the worm moves along the axis of the worm gear to different positions, tooth surfaces on two sides of the worm are enveloping surfaces which are respectively formed by generating movement according to the meshing relationship of the worm gear and the worm by taking the tooth surfaces on the corresponding sides of the gear teeth of the worm gear as generatrices. According to characteristics of distribution of contact lines, after the gear teeth of the worm gear are worn, the worm is moved into an area in which the gear teeth of the worm gear are not in contact with the worm to be worn, and service life is prolonged under the condition that contact performance is unaffected.

Owner:纳密智能科技(东莞)有限公司

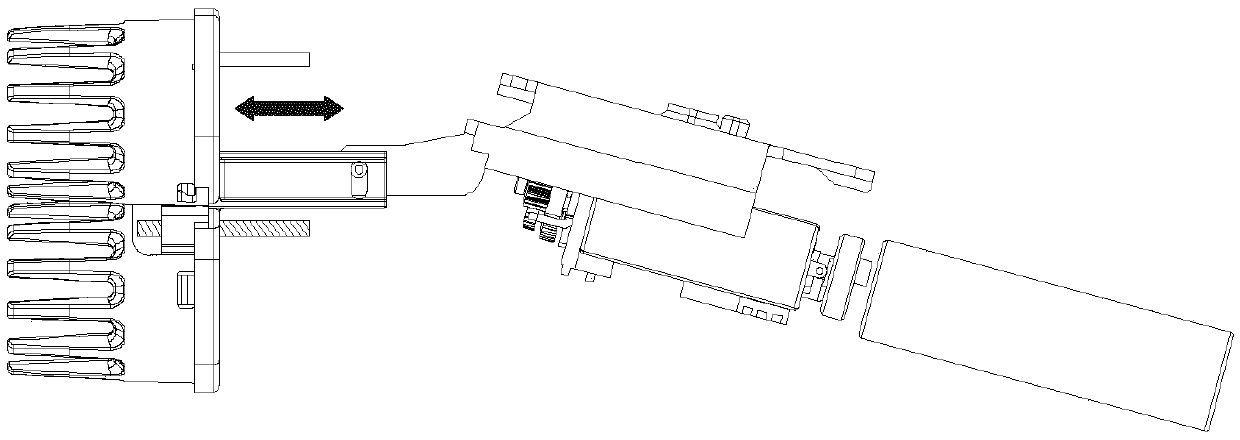

Connector for steel catenary risers

ActiveUS10260290B2Increase pressureMinimizing contact pressurePipe laying and repairDrilling rodsTooth lengthEngineering

Methods that may be employed to help to equalize the length of the teeth on a pin-and-box SCR connector during make-up include locating the make-up groove on the box at the far box end away from the pipe end. This causes the make-up force to tension and stretch the box to make it longer. Additionally or alternatively placing grease or other fluid in the nib groove creates a resistance force to nib entry. The grease or fluid exits through a nib vent port in the box while creating a resistance that compresses the pin and stretches the box causing the tooth spacing of the pin and the box to be similar. Providing a ring groove at both ends of the box allows a tensioning device to be used to tension the box causing box elongation, which equalizes the tooth length of pin and box members during connector make up.

Owner:SINGLE BUOY MOORINGS INC

An electromagnetic tooth clutch

ActiveCN105864315BEasy meshEasy surface contactMagnetically actuated clutchesInterengaging clutchesTransmitted powerTooth length

The present invention discloses an electromagnetic dog clutch, comprising a movable gear sleeve and a fixed toothed sleeve that are engaged to transmit power The movable gear sleeve is provided with contrate transmission teeth or tooth spaces, and the fixed toothed sleeve is correspondingly provided with contrate tooth spaces or transmission teeth. The transmission teeth have a uniform thickness in a direction of tooth length, tooth spaces that engage with the transmission teeth have a sector-shape in a direction of tooth space length, and the width of two sides of the tooth spaces gradually increases outwardly along the radial direction of the fixed toothed sleeve and gradually decreases inwardly along the radial direction of the fixed toothed sleeve. By employing the engagement of transmission teeth of uniform thickness and sector-shaped tooth spaces, the transmission teeth can more easily engage with the tooth spaces, and more easily realize surface contact, which facilities moment transmission and facilities the stability of the transmission structure.

Owner:JING JIN ELECTRIC TECH HEZE CO LTD

Stirring and mixing device for preparing starch-based rubber skin

InactiveCN104888643AIncrease the number ofOvercome severe flocculationRotary stirring mixersMixer accessoriesFlocculationAdditive ingredient

The invention discloses a stirring and mixing device for preparing a starch-based rubber skin and belongs to the field of capsule production equipment. The stirring and mixing device comprises a box body (9), a cover plate, a stirring shaft (11) and a driving motor (12), wherein the stirring shaft is provided with stirring teeth with the quantity being not less than four pairs; the stirring teeth are arranged on the stirring shaft from top to bottom at equal distances; the teeth lengths among the adjacent stirring teeth are increased by an equal value being 5-20cm, and the two adjacent pairs of stirring teeth are arranged on the stirring shaft in a cross shape; the bottom of the box body is provided with a main discharging pipe (8) which is provided with a main valve (8.1); the main discharging pipe between the main valve and the box body is also provided with an auxiliary discharging pipe (7) which is provided with an auxiliary valve (7.1), and the hole diameter of the auxiliary discharging pipe is 5-10cm. The stirring and mixing device disclosed by the invention has the advantages that selected materials are fully stirred, so that the flocculation caused by local viscosity is avoided; by full stirring, the mixing of starch and ingredients is uniform, so that the stable performance of the prepared rubber skin is ensured and the use requirement is met.

Owner:ZHEJIANG YILI CAPSULE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com