Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

213 results about "Herringbone gear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

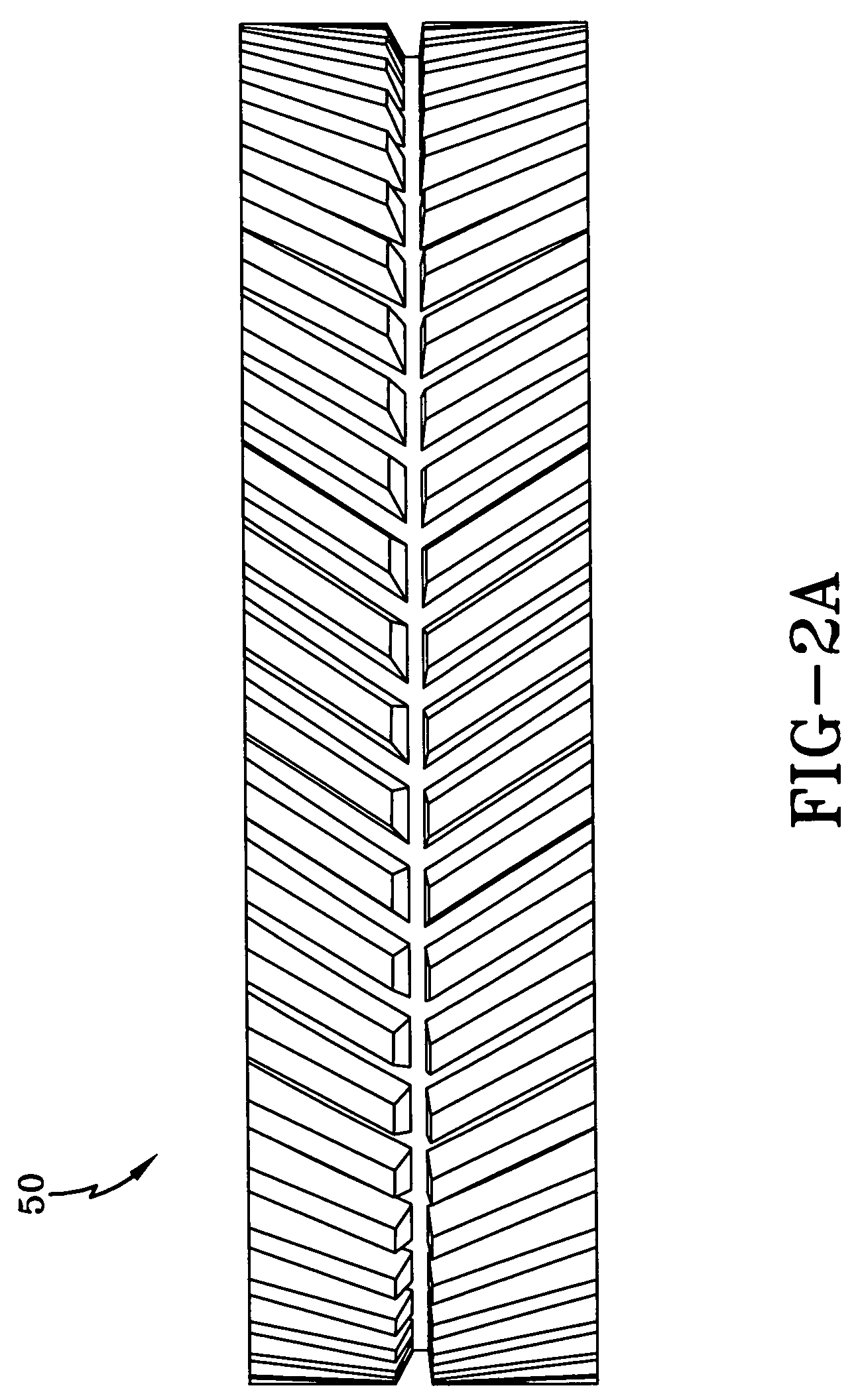

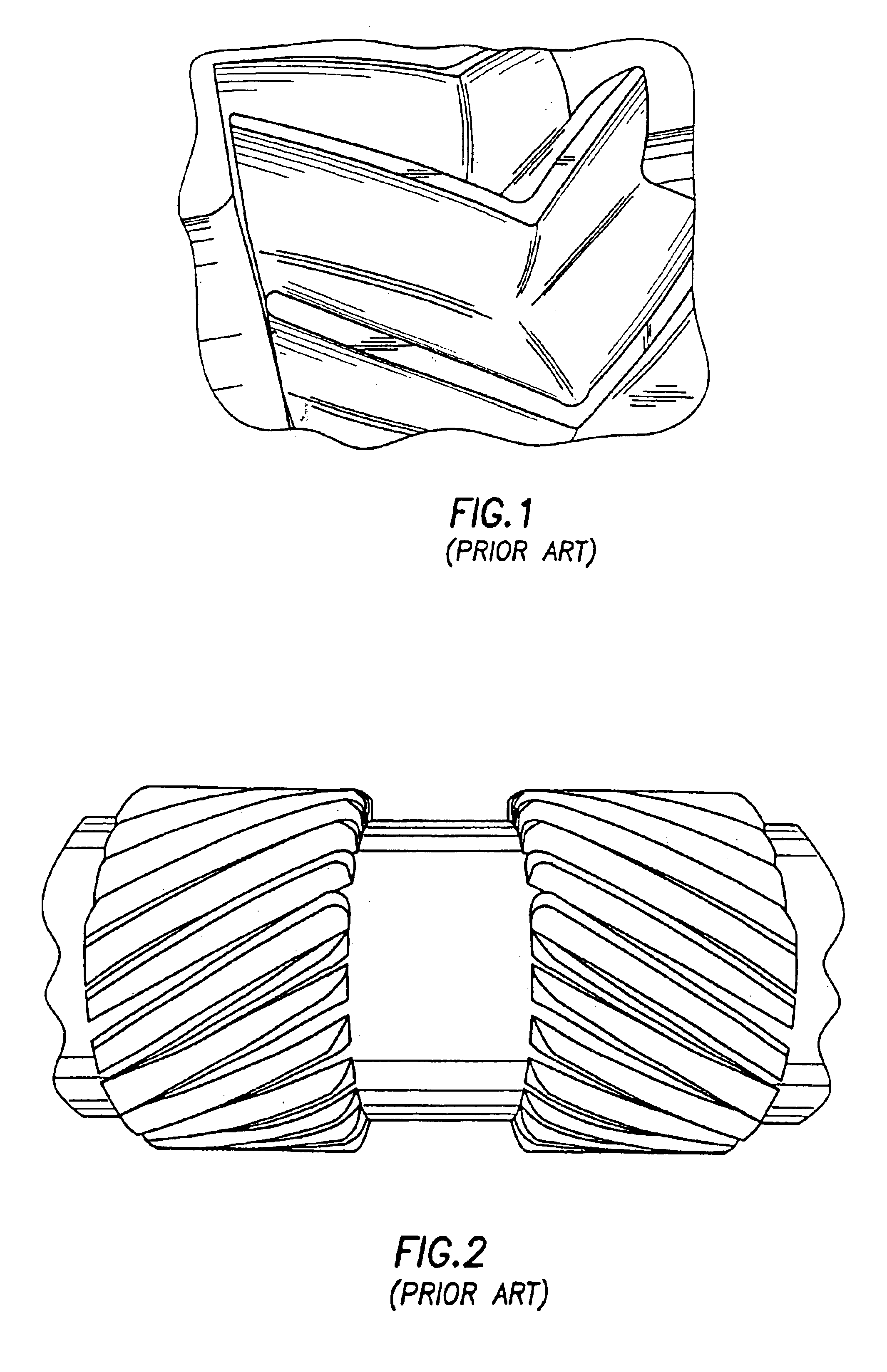

Inventor

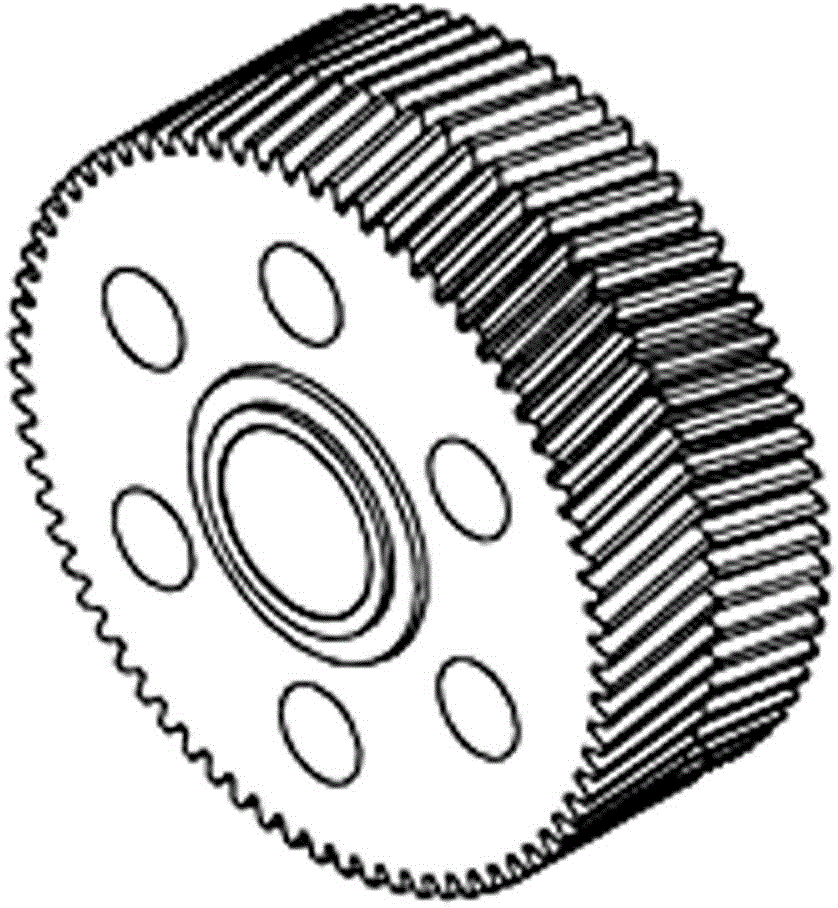

A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring). Unlike helical gears, herringbone gears do not produce an additional axial load.

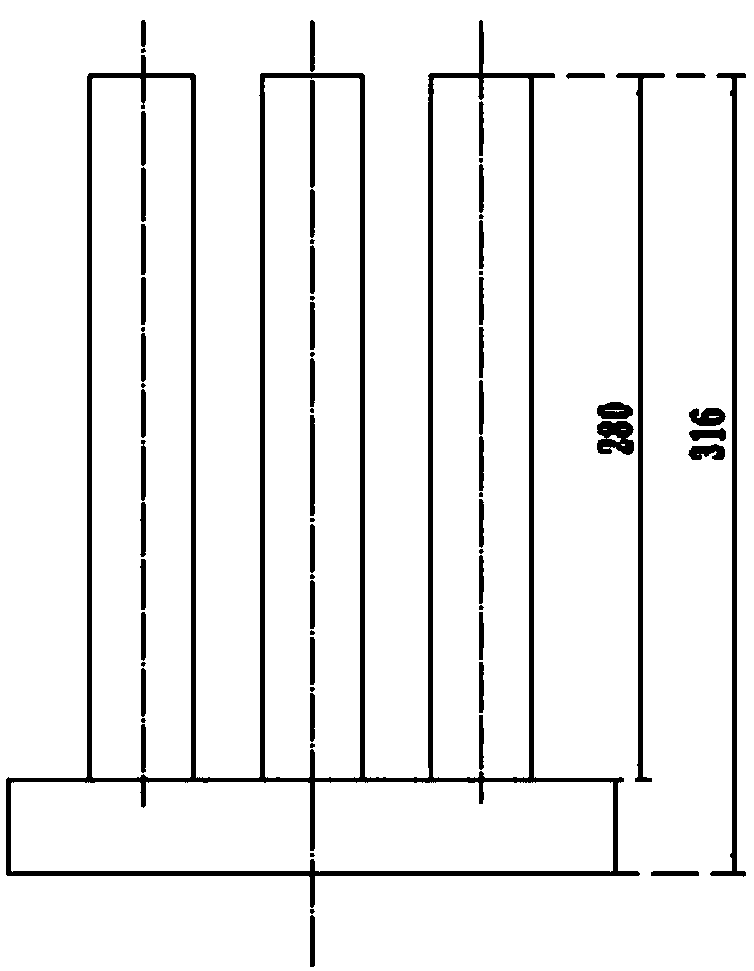

Manufacturing method of integral herringbone gear shaft

ActiveCN101804548AImprove bending strengthSmall diameterMaterials preparationManufacturing cost reduction

The invention discloses a manufacturing method of an integral herringbone gear shaft, which comprises the following steps that: material preparation: a center hole is drilled on one end of a work piece; primary machining; primary detection; heat treatment; secondary machining; secondary detection; rough milling; chamfering at the gear end; coating anti-carburizing layers on both ends of the herringbone gear shaft so that the depth of a carburized layer is 3.55 to 3.95mm, and quenching so as to enable the hardness of a gear part to reach HRC58 to 62, and to enable the hardness of the heart to reach HRC28 to 33; carrying out shoot peening on a gear surface; tertiary machining; gear shaping; external grinding; fine milling; and inspection. The manufacturing method of the integral herringbone gear shaft has the advantages of improving the bending strength of the gear root, reducing the manufacturing cost and improving the manufacturing precision.

Owner:SHANGHAI ZHENHUA HEAVY IND GRP NANTONG TRANSMISSION MACHINERY

Herringbone gear teeth and method for manufacturing same

A method of manufacturing herringbone gears starting with non-hardened cylindrical stock material, establishing a relief notch for each tooth in the cylindrical stock where the two helices meet, roughing the double helical teeth, and case-hardening the gear teeth. The teeth are then finished using high accuracy Cubic Borzon Nitride (CBN)-faced cutters with the relief notch allowing run-out of the cutters.

Owner:LUFKIN GEARS LLC

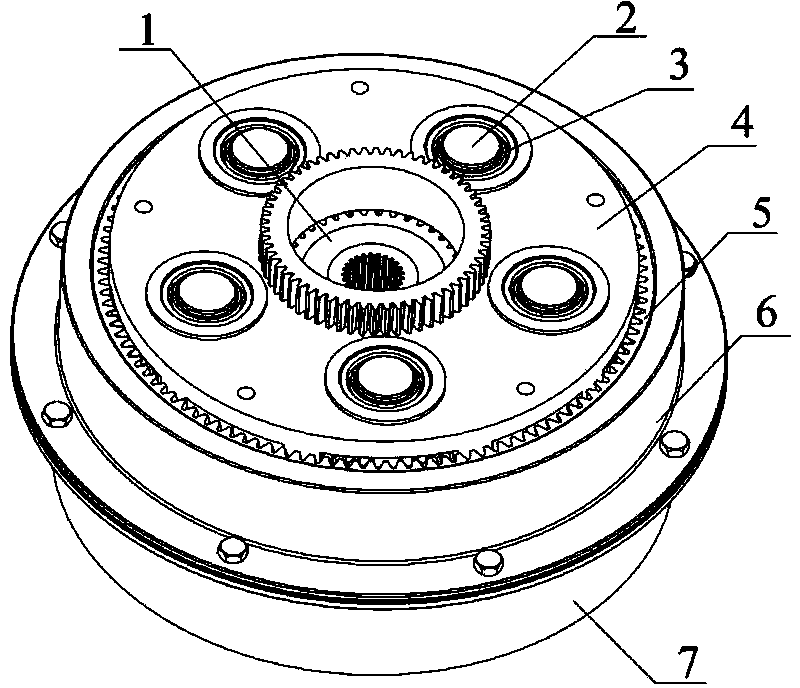

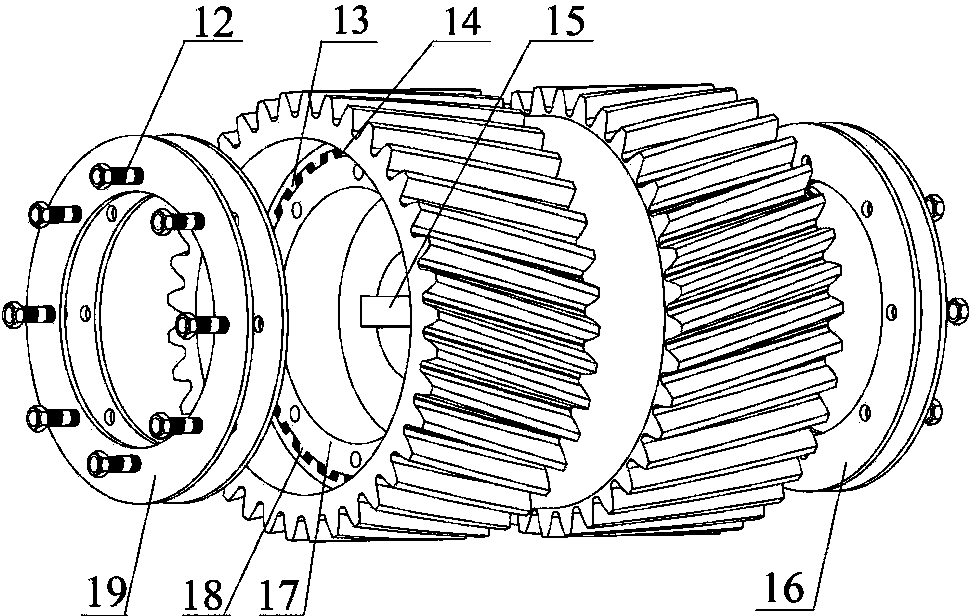

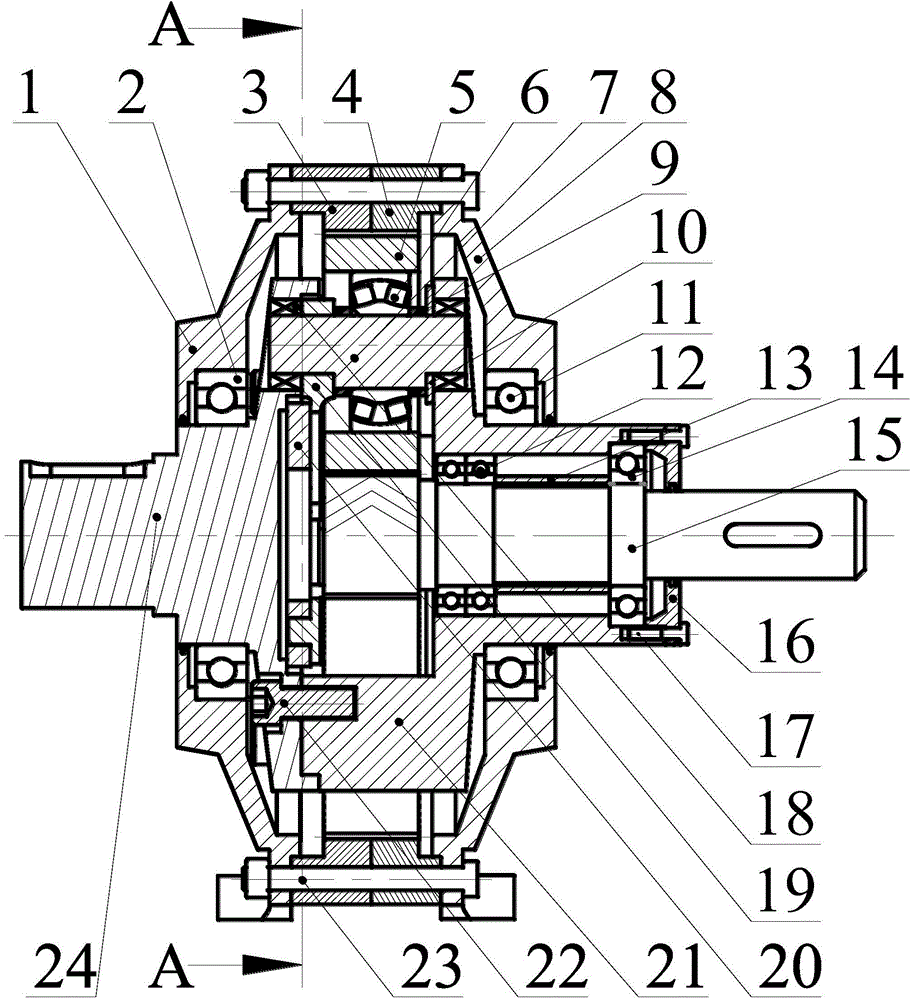

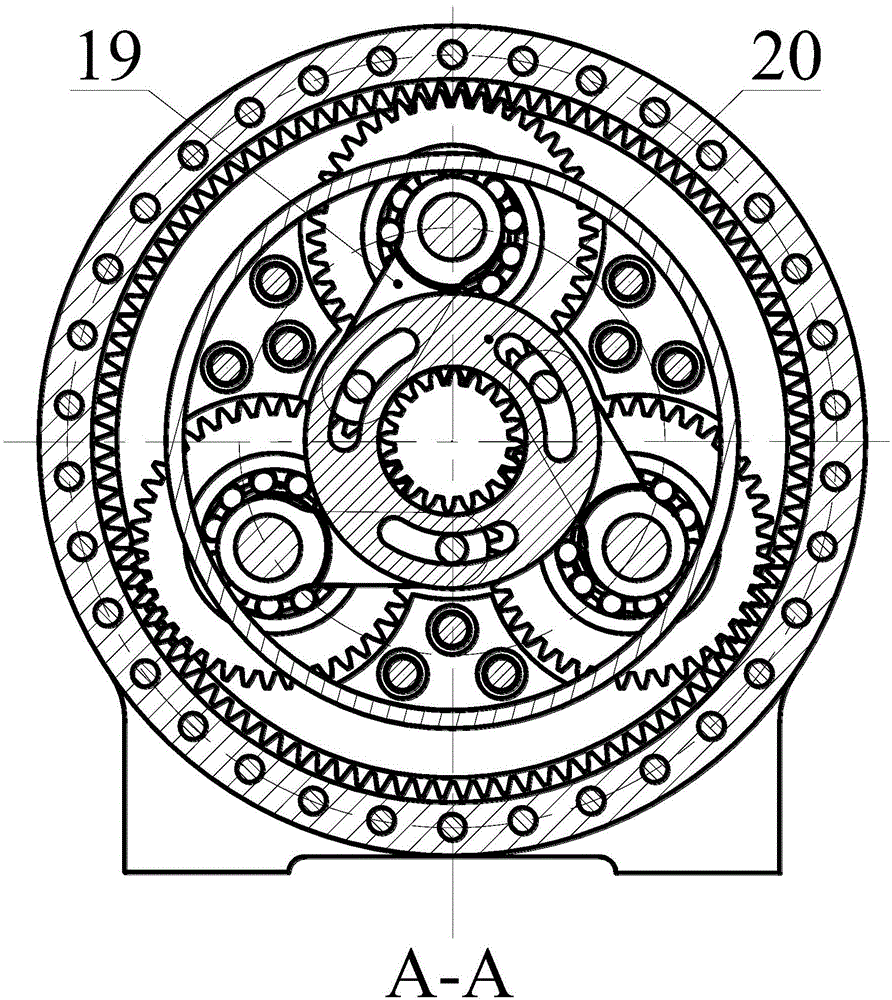

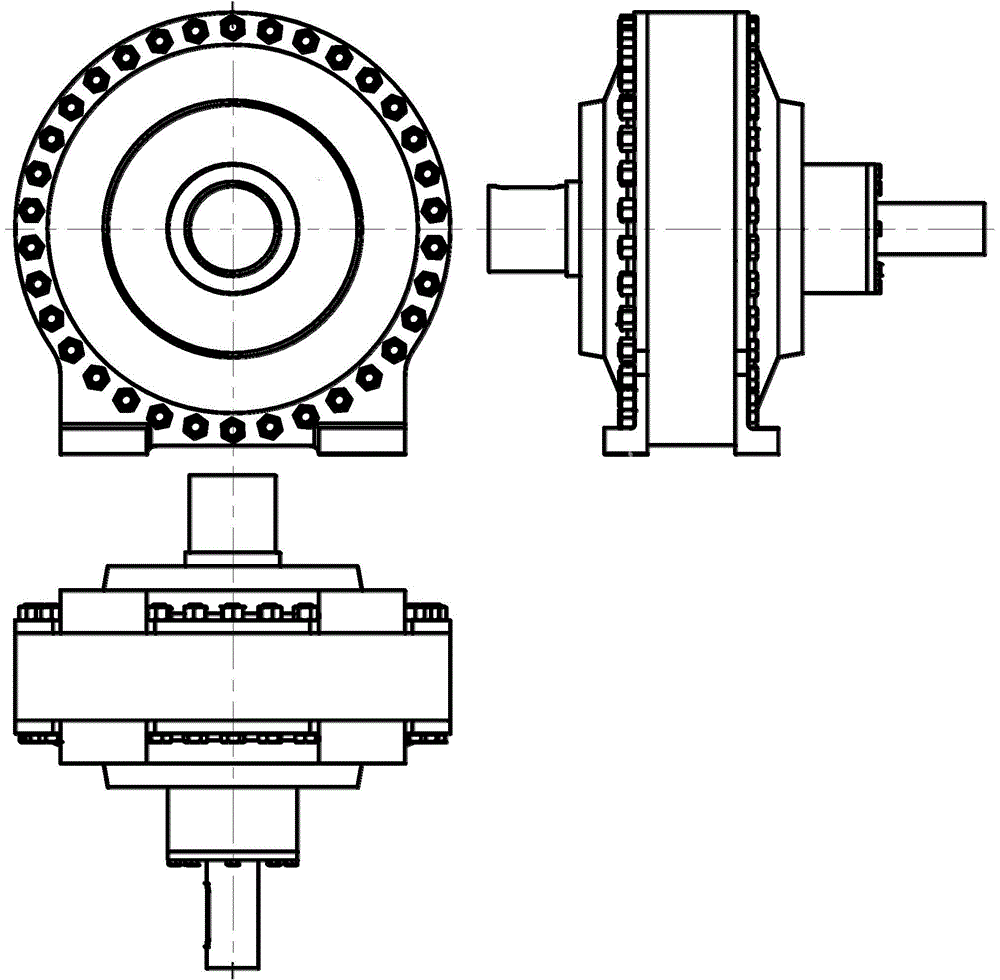

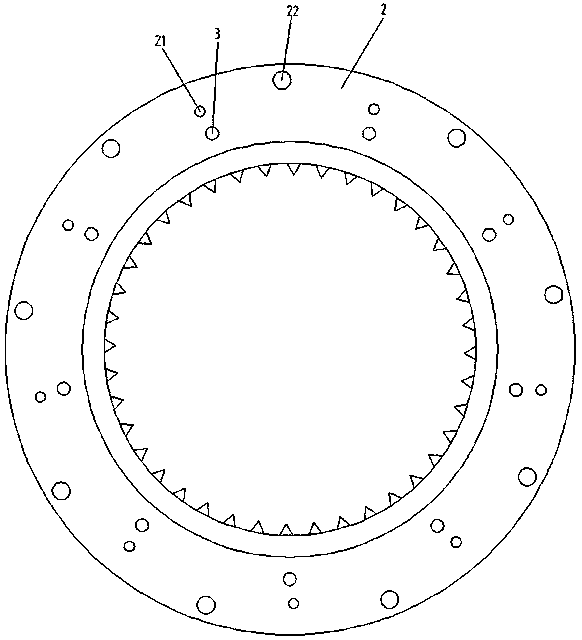

Star type herringbone gear reducer

InactiveCN104141745ARealize the torque output functionIncrease output torqueToothed gearingsGearing detailsReduction driveGear system

The invention discloses a star type herringbone gear reducer. The star type herringbone gear reducer comprises a planet carrier, a fixing ring, a sun gear, and a star gear pair formed by a planet gear and an inner gear ring, wherein the teeth of the sun gear, the teeth of the planet gear and the teeth of the inner gear ring in the star gear pair are all herringbone teeth, the sun gear is integrated, an involute spline is arranged in the sun gear, the sun gear is connected with an input shaft through the spline, the inner gear ring is formed by an upper gear ring and a lower gear ring in a combined installation mode, and the fixing gear and the inner gear ring are assembled so that torque output can be achieved. Due to the fact that the herringbone teeth are adopted, the transmission contact ratio is high, and transmission stability, the uniform load performance and the capacity for outputting torque are high; the planet gear is combined, elastic supporting of the planet gear is achieved, transmission stability of a star gear system is improved, and noise is lowered; because combined installation is adopted for the inner gear ring of the reducer and the inner gear ring is provided with the fixing ring in a matched mode, the inner gear ring torque output function is achieved. The star type herringbone gear reducer has the advantages of being simple in structure and convenient and fast to install. The star type herringbone gear reducer is suitable for engine reducers, and especially suitable for high-power engine reducers.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

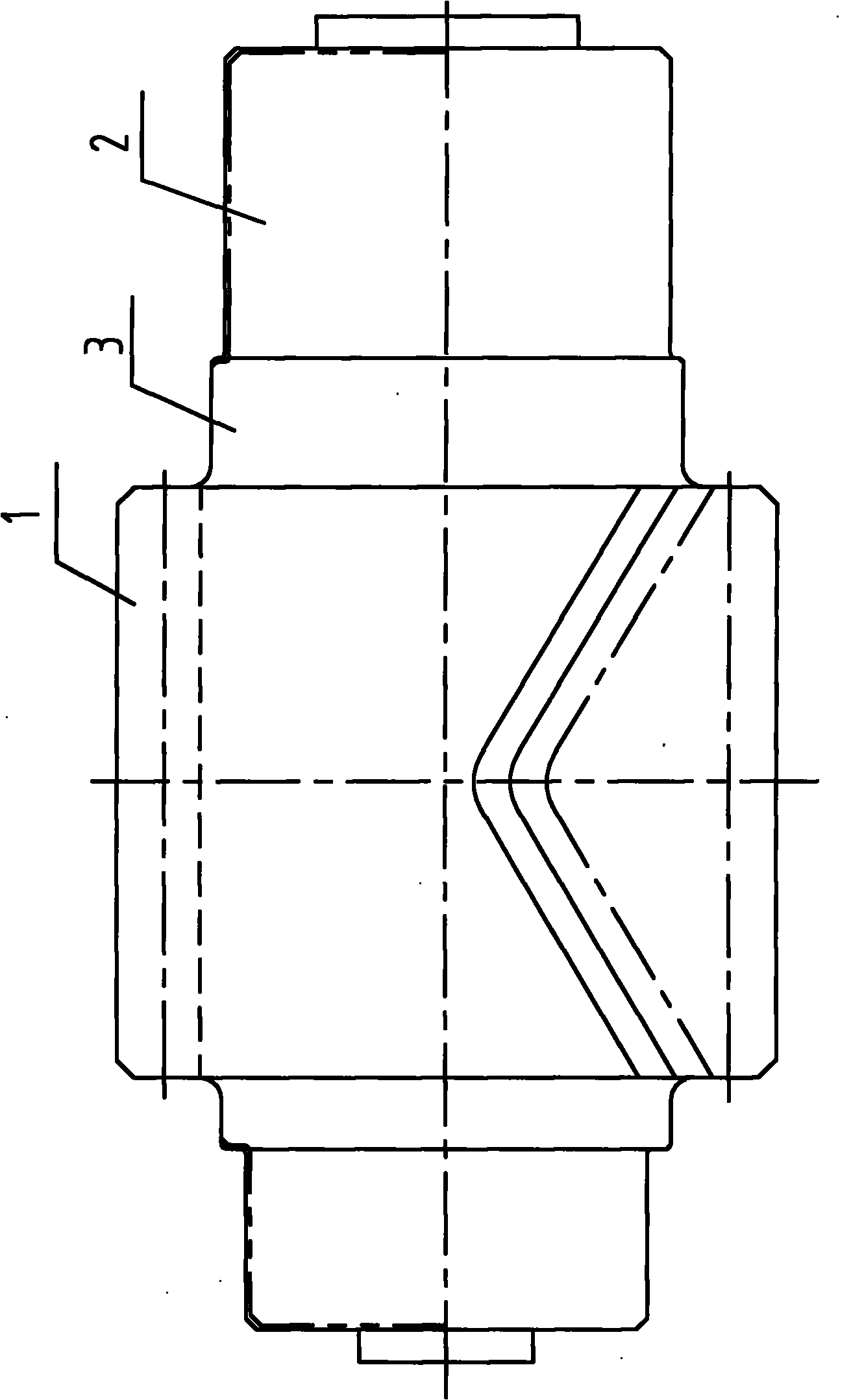

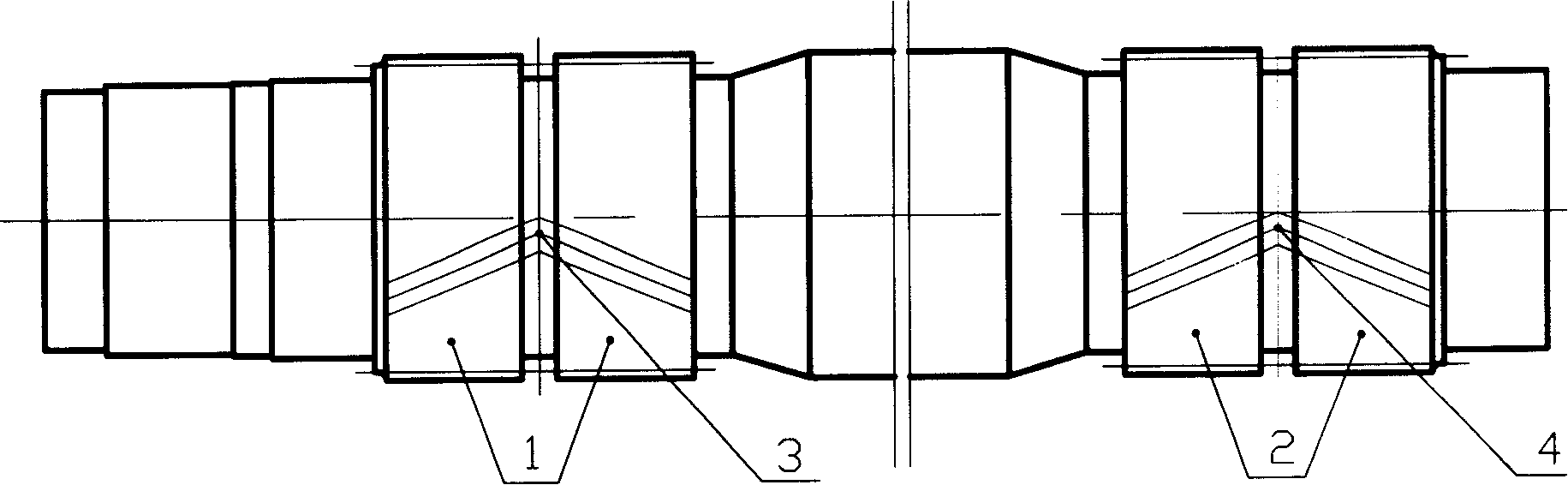

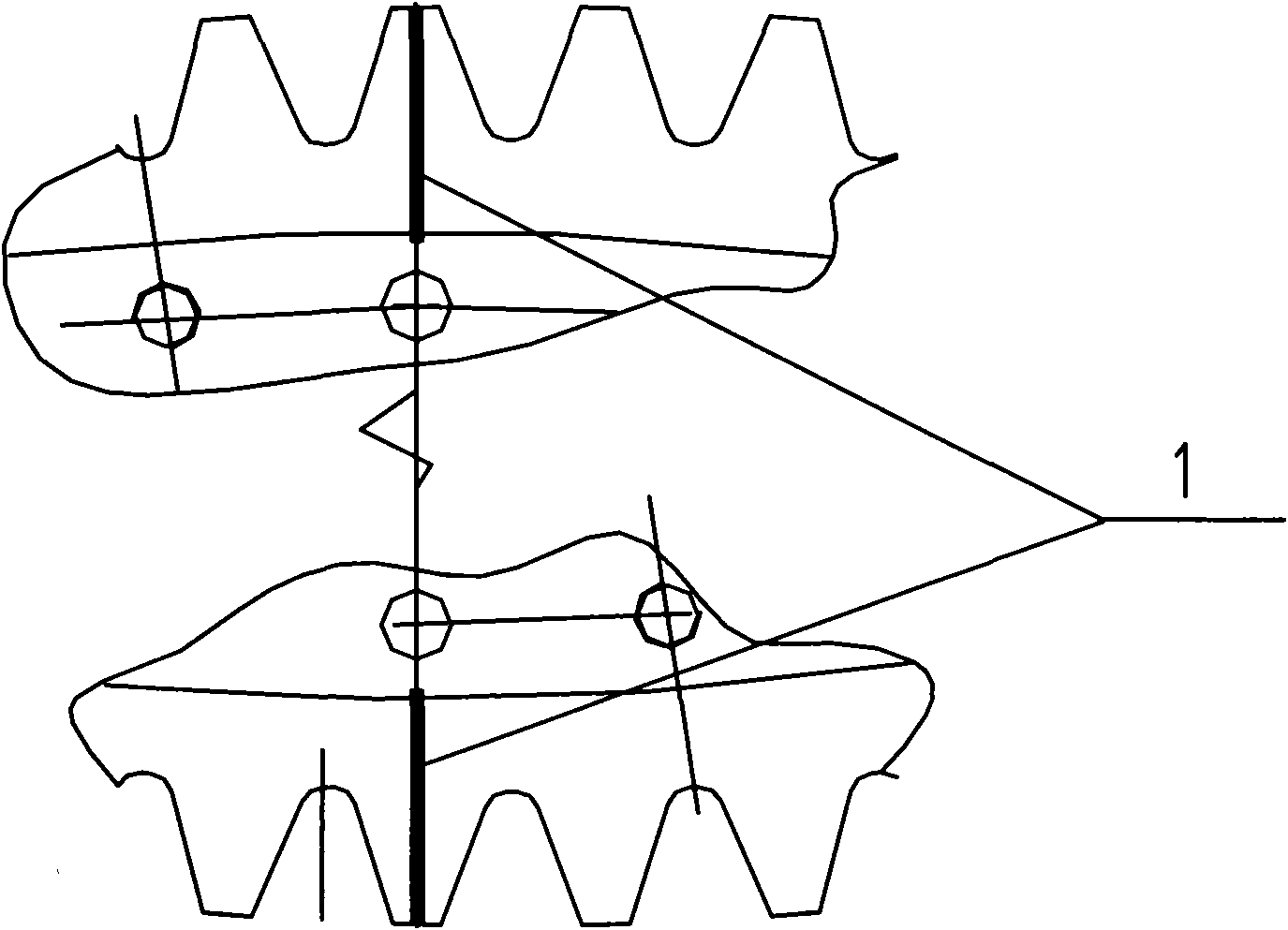

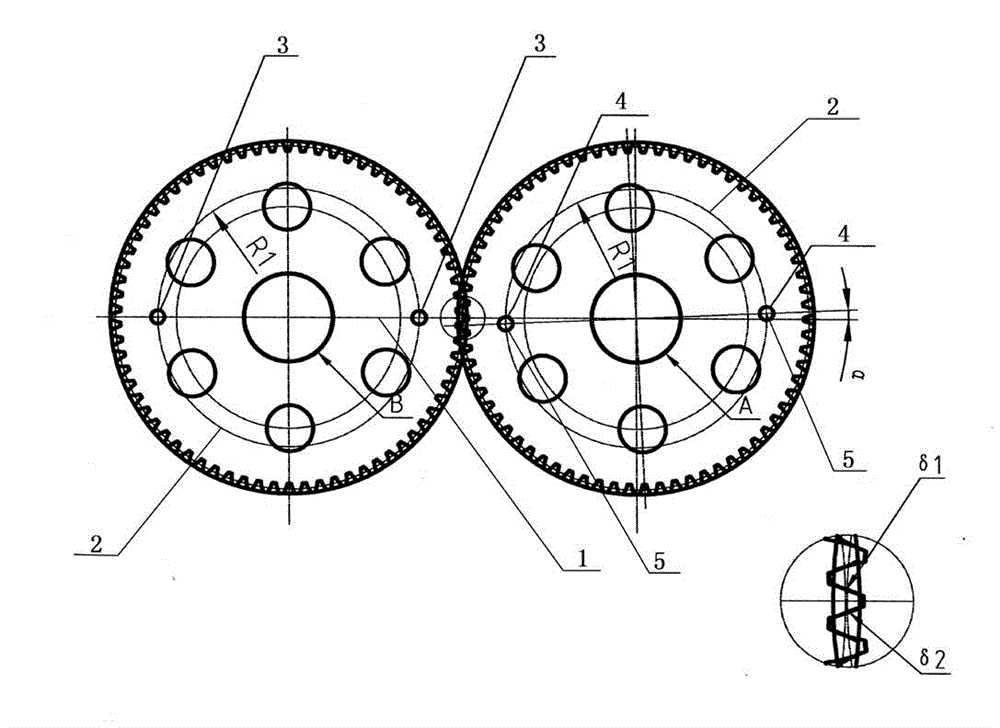

Double herringbone gear in-phase processing method

ActiveCN1876300AHigh precision in phaseEasy to operateGear teethGraduated cylinderAgricultural engineering

The invention discloses a method for preparing double cross gear, belonging to mechanical process technology. Said double cross gear is formed with left-and-right involutes helicoids, the cross gear center is the cross point of left gear central line and the right one; if the two cross gear is the same phase, the cross gear center 3 on graduated cylinder gear 1 and cross center 4 on gear 2 are at the same bus wire; and if projected on gear graduated circumference, the two cross gear center 3 and 4 are at the same circumferential position; and if the cross gear center 3 and 4 are at different phase, the cross gear 1 and 2 are at the same phase, then s1 equals to s2, and the center distance of left gear and right gear of two cross gears are equal, 11=12; clamping double cross gear blank on digital control milling machine for preparation.

Owner:CHINA FIRST HEAVY IND

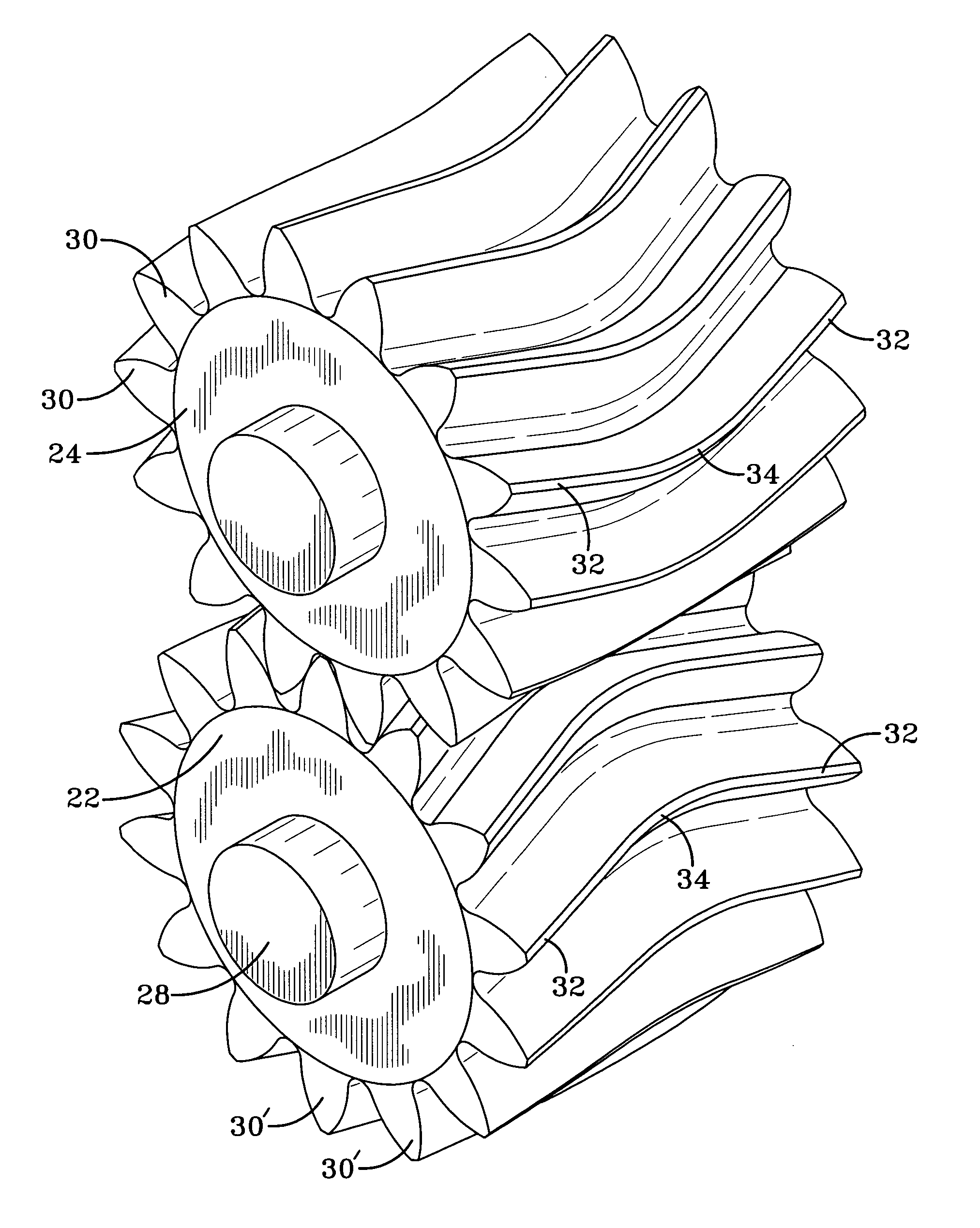

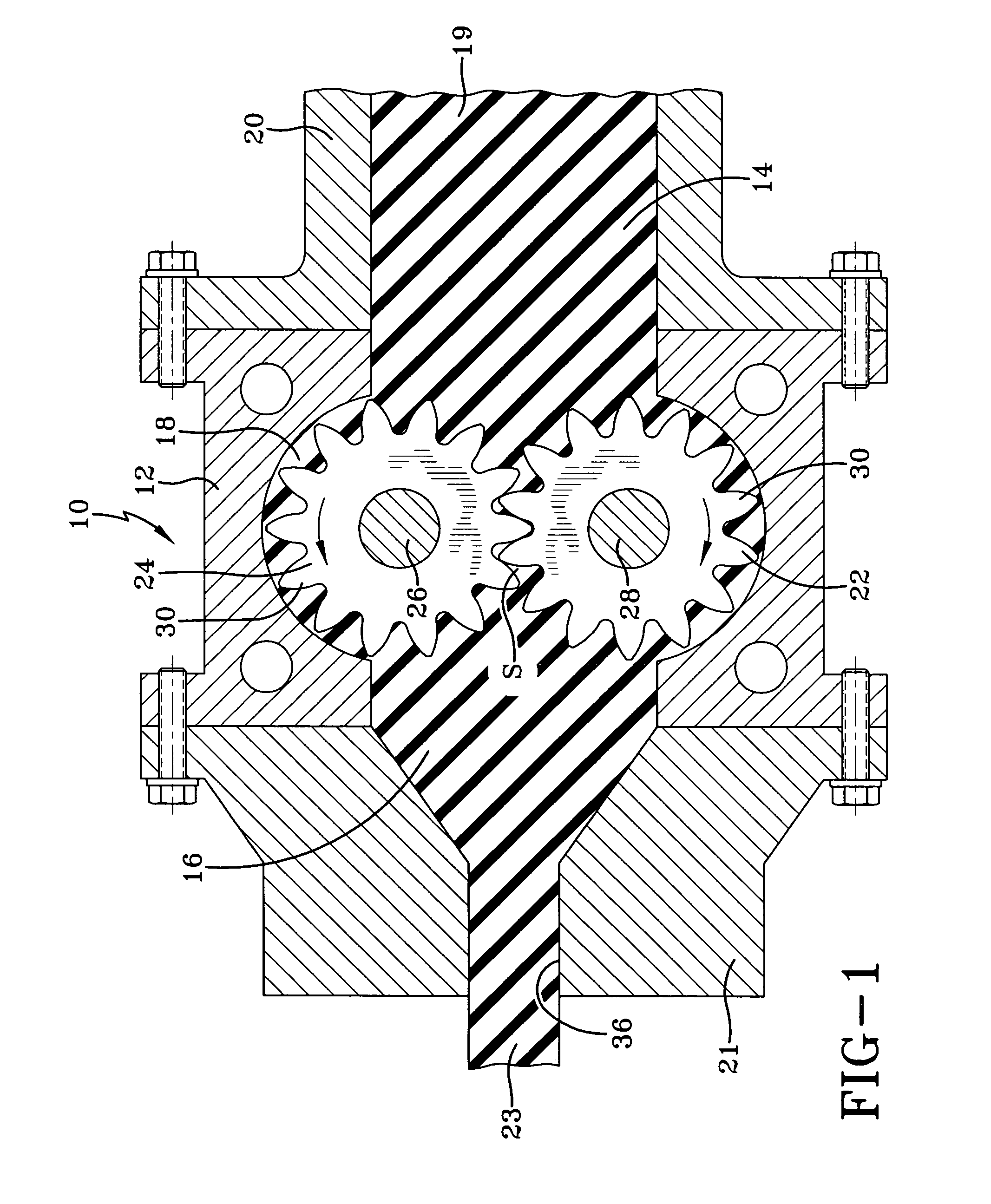

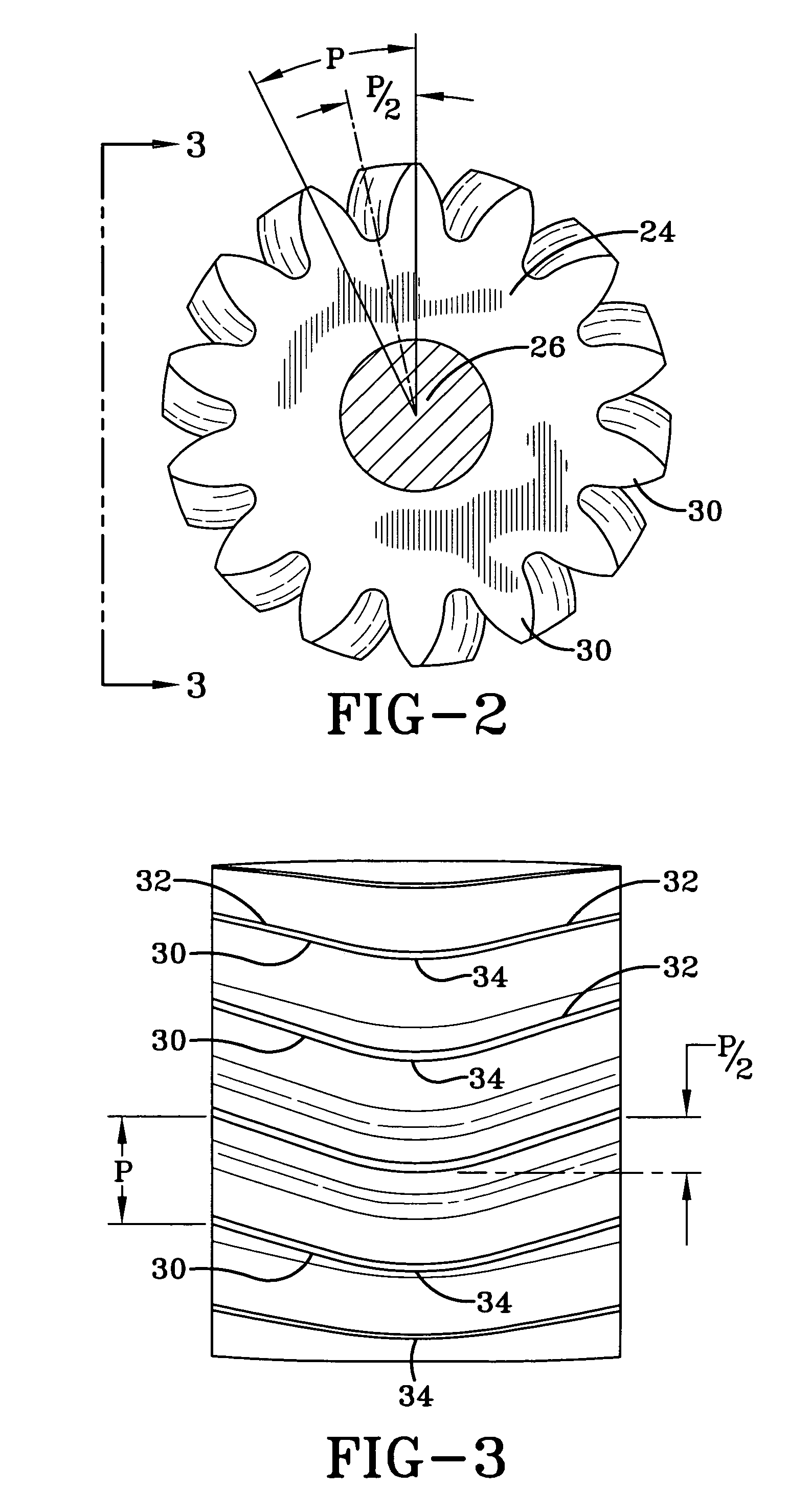

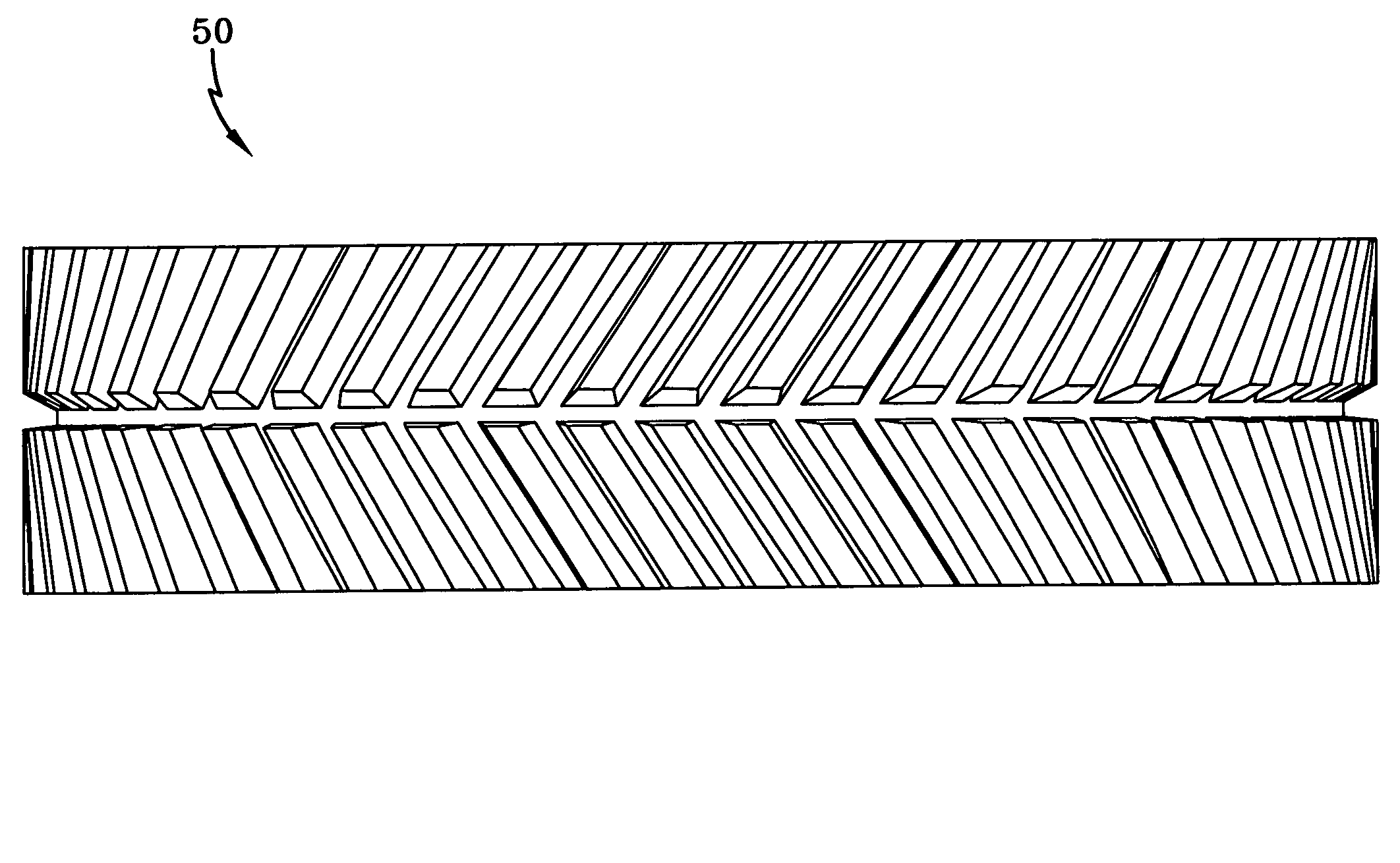

Gear pump with gears having curved teeth and method of feeding elastomeric material

InactiveUS7040870B2Minimizes flow of materialSqueeze evenlyOscillating piston enginesFlexible member pumpsGear pumpHerringbone gear

A gear pump and method for pumping elastomeric material having two gears with meshing herringbone gear teeth. Each of the gear teeth has helical side portions and a curved central portion which extends circumferentially of the gear a distance equal to at least one half the pitch of the gear teeth to provide a continuous squeezing contact between the teeth of the two gears for pumping a uniform strip of elastomeric material from the gear pump.

Owner:THE GOODYEAR TIRE & RUBBER CO

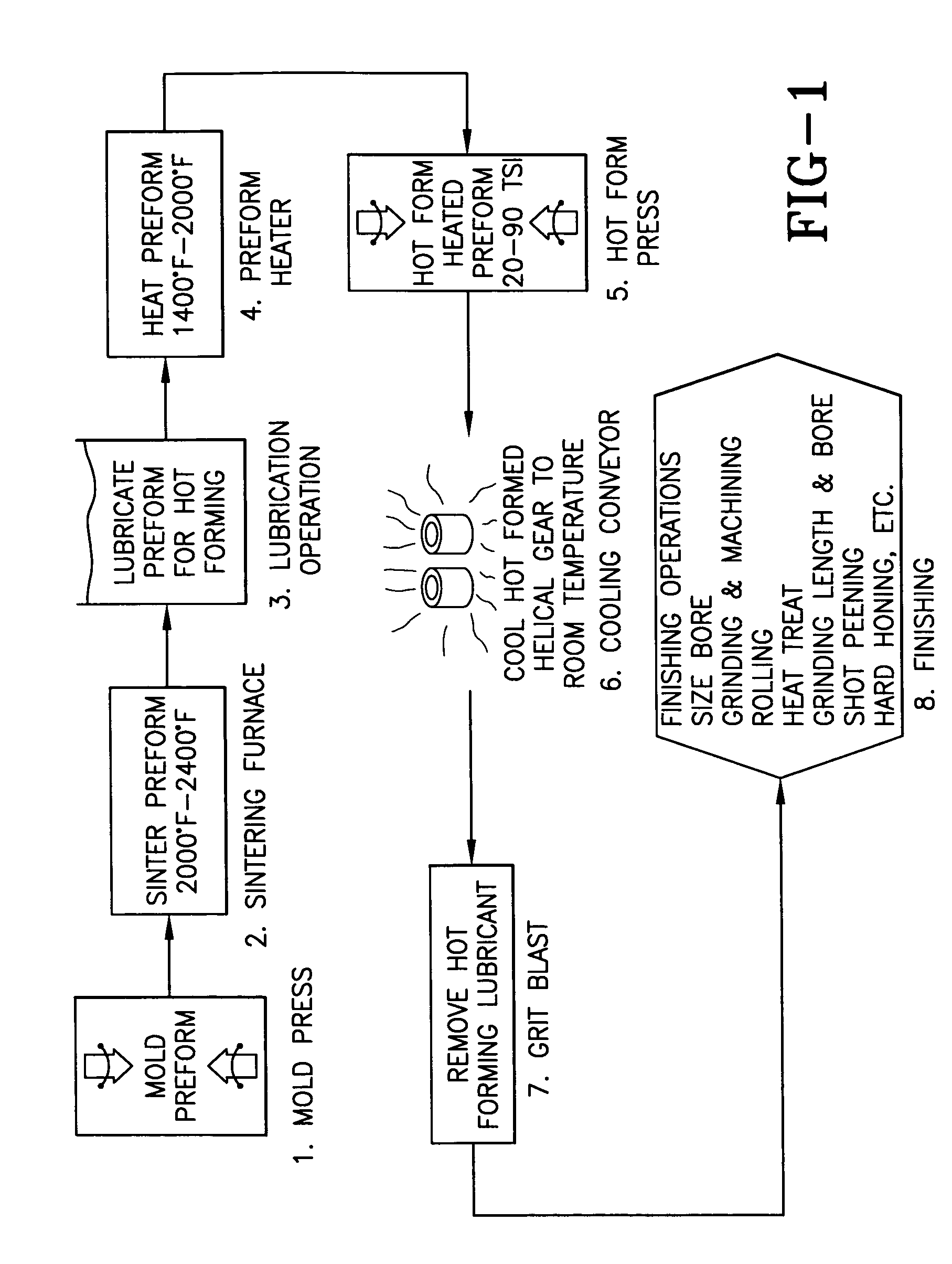

High density dual helical gear

The present invention relates to a low cost technique for manufacturing dual helical gears, such as herringbone gears, from powder metals. The dual helical gears made by this technique are of high density (greater than 92% of theoretical density) and offer superior strength. The present invention more specifically discloses a forged metal herringbone gear which is comprised of a body and a plurality of teeth wherein the metal has a density of greater than 92% of theoretical and wherein the grain in the teeth is one range higher on the ASTM E 112 grain size chart than the grain in the body of the gear.

Owner:KEYSTONE INVESTMENT CORP

Herringbone gear teeth and method for manufacturing same

A method of manufacturing herringbone gears starting with non-hardened cylindrical stock material, establishing a relief notch for each tooth in the cylindrical stock where the two helices meet, roughing the double helical teeth, and case-hardening the gear teeth. The teeth are then finished using high accuracy Cubic Borzon Nitride (CBN)-faced cutters with the relief notch allowing run-out of the cutters.

Owner:LUFKIN GEARS LLC

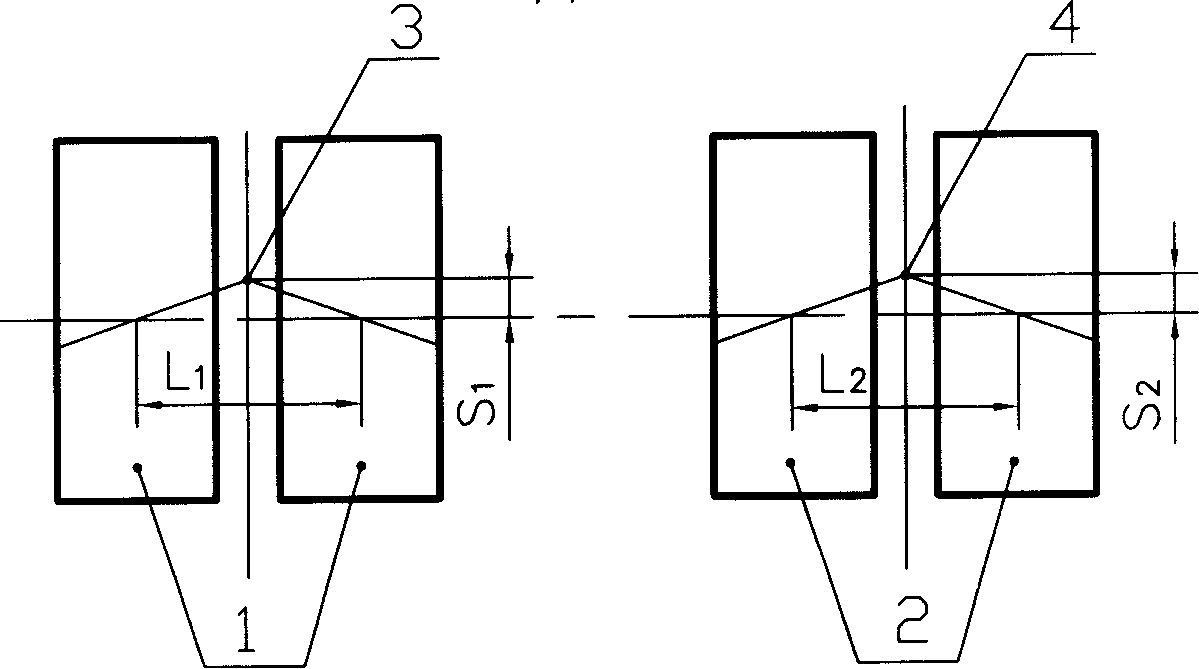

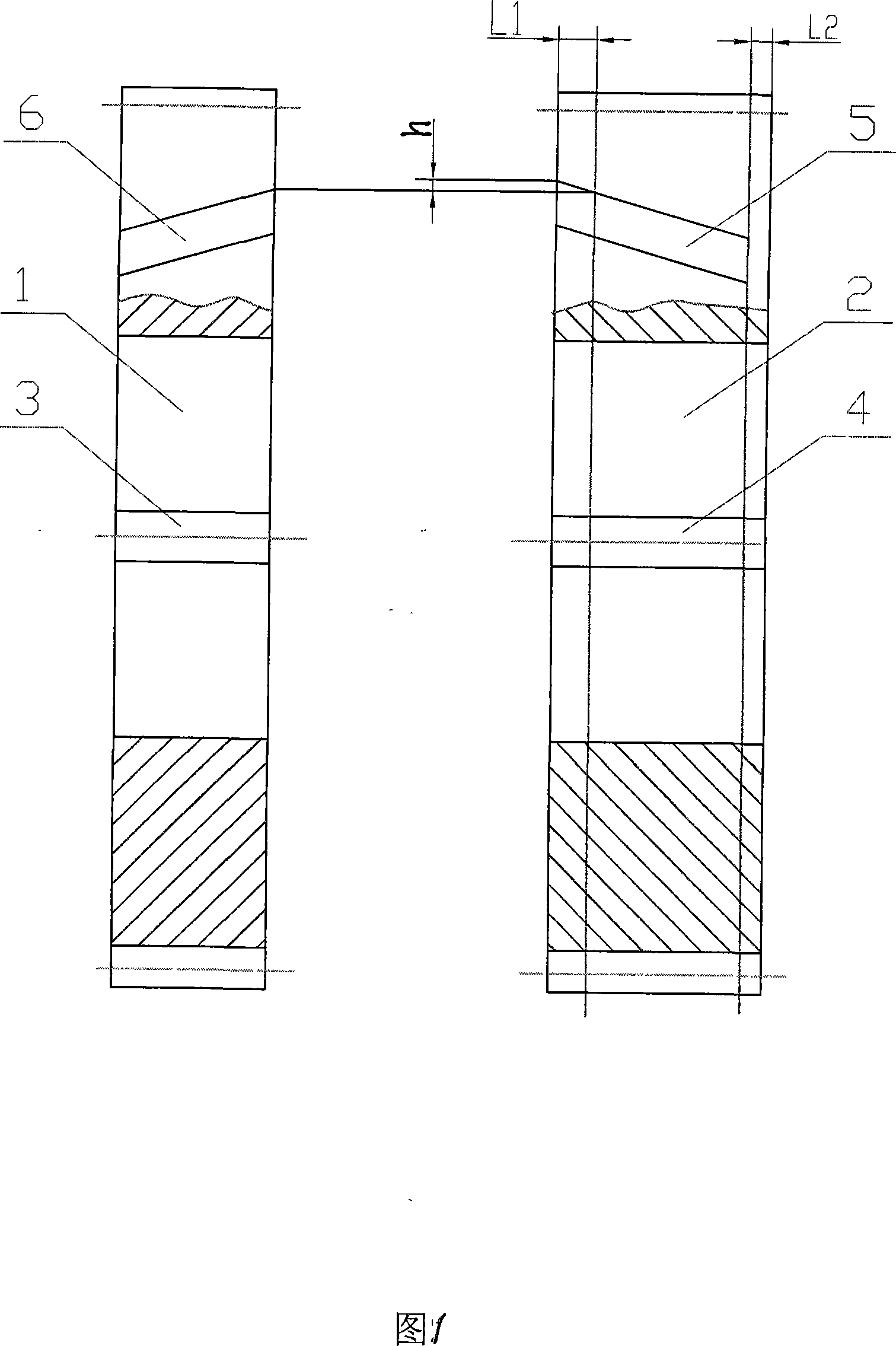

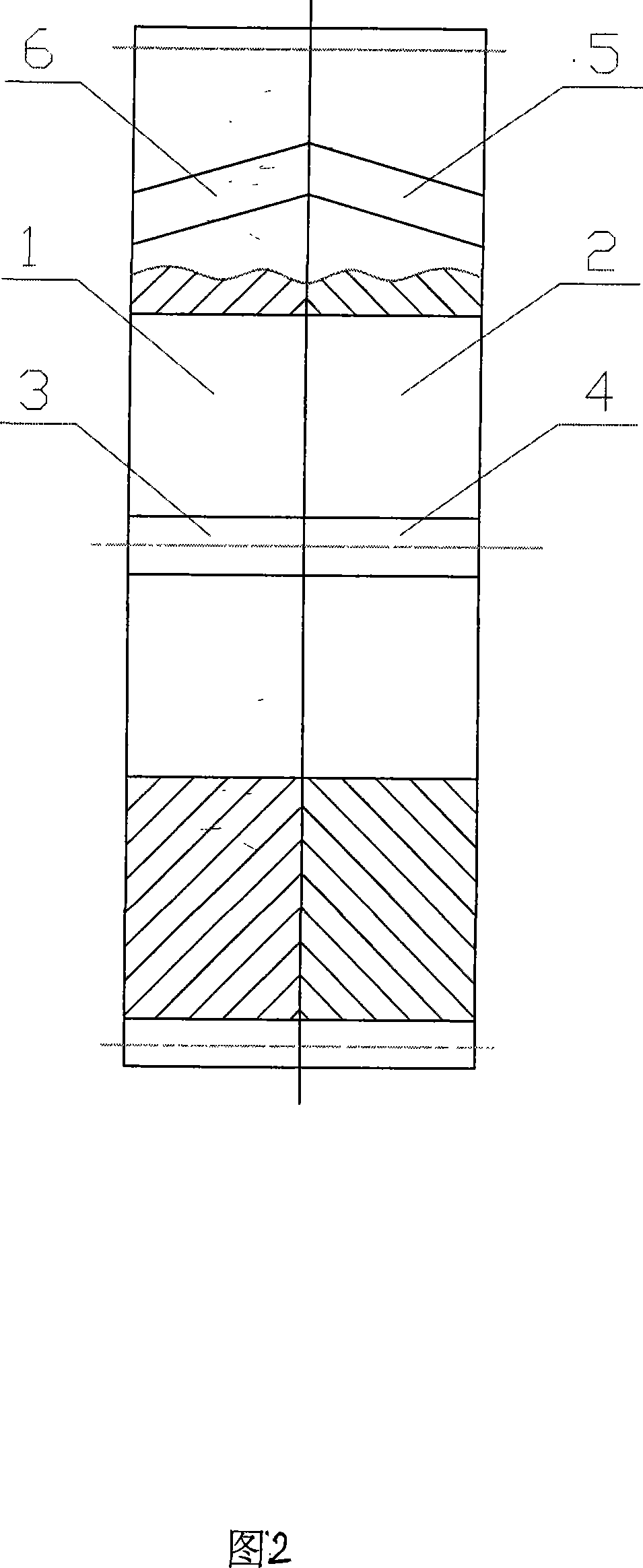

Processing method of high-accuracy herringbone gear without withdrawing groove hard tooth surface

A process method of high accuracy zig-zag gear with solid gear surface and no tool escape is provided, which produces finished left rotating single inclining gear product by the traditional technics, then finish the following procedures: firstly, process right rotating single inclining gear by the traditional technics, the two end surfaces are provided with abrasion margin L1 and L2; secondly, insert into the key groove of the left rotating single inclining gear and the right rotating single inclining gear by key to combine the two parts, and ensures the alignment of the key groove of the two gears; thirdly, measure out the existing error which make the gear blade of the two gears centered; sixthly, abrase the middle end surface of the right rotating single inclining gear off error value L1, to achieve the gear blade of the two gears centered; fifthly, abrase the other end surface of the right rotating single inkling gear suitable value L2, to reach the requirement of design size. The invention can realize the process of zig-zag gear without tool escape, the processed gear has small volume; the invention can not only overcome the error of two gears being centered during process, but also have simple process.

Owner:CHONGQING GEARBOX

Arc spiral line mixed herringbone gear without tool withdrawal groove and processing method thereof

InactiveCN104819266AHigh coincidenceMesh transmission smoothPortable liftingGear teethHybrid typeAgricultural engineering

The invention discloses an arc spiral line mixed herringbone gear without tool withdrawal groove. The gear comprises a herringbone gear body, a plurality of herringbone gear wheel teeth are formed on the herringbone gear body, herringbone tooth groove is formed among herringbone gear wheel teeth, and the herringbone gear wheel teeth is orderly composed of a herringbone gear right rotating wheel tooth, a herringbone gear arc wheel tooth and a herringbone gear left rotating wheel tooth section; two sides of the herringbone gear wheel tooth are the herringbone gear wheel tooth concave tooth surface and the herringbone gear wheel tooth convex tooth surface; a processing method for arc spiral line mixed herringbone gear without tool withdrawal groove is also disclosed, the herringbone gear is characterized of being big in contact ratio, stable in meshing transmission, low in noise, big in bearing capability and compact in structure; the arc spiral line mixed herringbone gear without tool withdrawal groove is suitable for occasions such as ship power, airline mechanical transmission, overloaded vehicle engineering high overloading with close restraint on structure size of gear case.

Owner:XIAN TECHNOLOGICAL UNIV

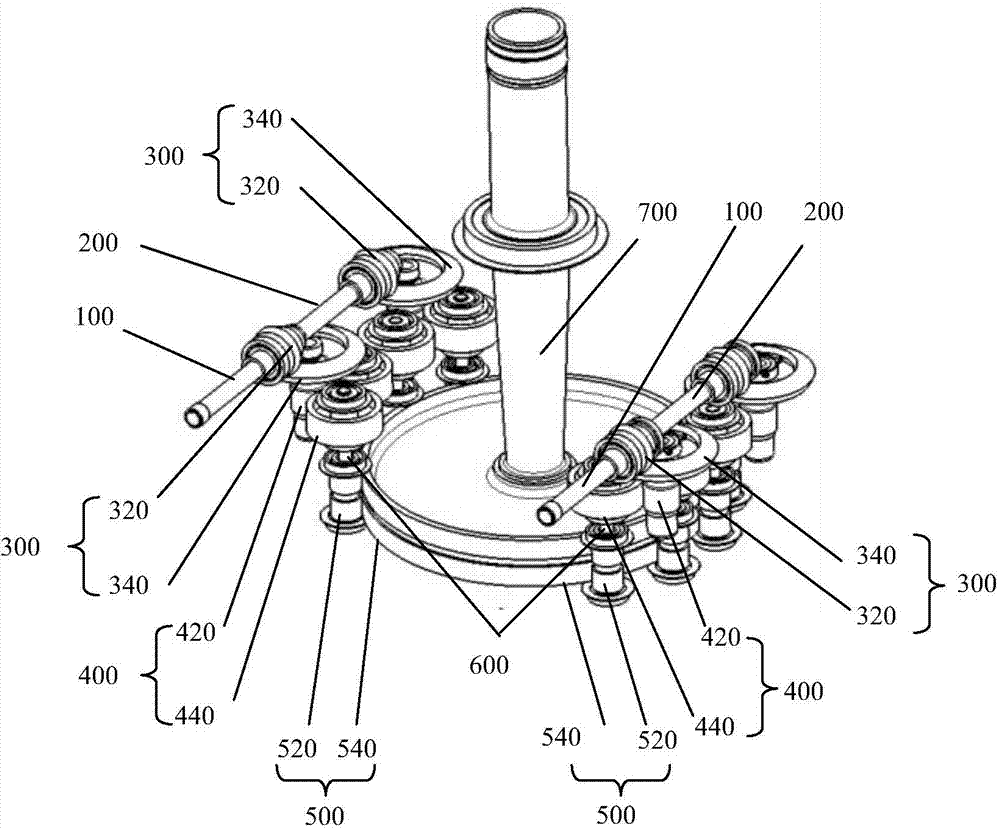

Torsion-transmission helicopter reducer

InactiveCN104500655ALow powerSimple structureToothed gearingsTransmission elementsGear wheelReduction drive

The invention discloses a torsion-transmission helicopter reducer. The torsion-transmission helicopter reducer comprises a reversing gear pair, wherein the reversing gear pair comprises two driving gears and two driven gears which are respectively engaged with different driving gears, the two driving gears are connected with each other through a power elastic shaft, and one driving gear is connected with a power input shaft. A cylindrical gear pair comprises a plurality of cylindrical driving small gears and a plurality of cylindrical drive large gears, and the cylindrical driving small gears are respectively and coaxially connected with the corresponding driven gears. A herringbone gear pair comprises a plurality of driving small herringbone gears and a parallel herringbone gear, the plurality of driving small herringbone gears are simultaneously engaged with the parallel herringbone gear, the transmission ratio is greater than 1, and the driving small herringbone gears are respectively and coaxially arranged with the corresponding cylindrical driven large gears. A rotary wing shaft assembly is coaxially arranged with the parallel herringbone gear. The torsion-transmission helicopter reducer adopts the multichannel power transmission and is simple in structure, less in component quantity, high in reliability, relatively small in size, low in gear linear speed and light in weight.

Owner:CHINA AVIATION POWER MACHINE INST

Method for processing large combination type herringbone gear

ActiveCN101862945ASave materialShorten the timeTransportation and packagingTrepanning drillsGear grindingHobbing

The invention discloses a method for processing a large combination type herringbone gear, which comprises the following steps of: forging; carrying out rough processing of the end surface, an incircle and an excircle on a processed workpiece by utilizing a lathe; drilling a hoisting hole; carrying out rough gear hobbing on the workpiece by utilizing a gear hobbing machine; carrying out tempering processing on a gear; semifinishing an inner hole, the end surface and an addendum circle by utilizing the lathe; drawing any pair of end surface gear central lines based on the end surface of one side of a reference groove, making a reference groove mark on an addendum and drawing a position line of each hole; drawing and drilling each hole by using a drilling machine; finishing and lathing the inner hole and both end surfaces of the lathe to a preset size; positioning based on a reference surface, carrying out correcting gear grinding on the addendum circle ; chambering, drilling and articulating each hole on a gear ring; and screwing a bolt and hinging the bolt and combining two gears into a pair. The invention has the advantages of material saving, cost reduction and mechanical performance improvement of products.

Owner:SHANGHAI ZHENHUA HEAVY IND GRP NANTONG TRANSMISSION MACHINERY

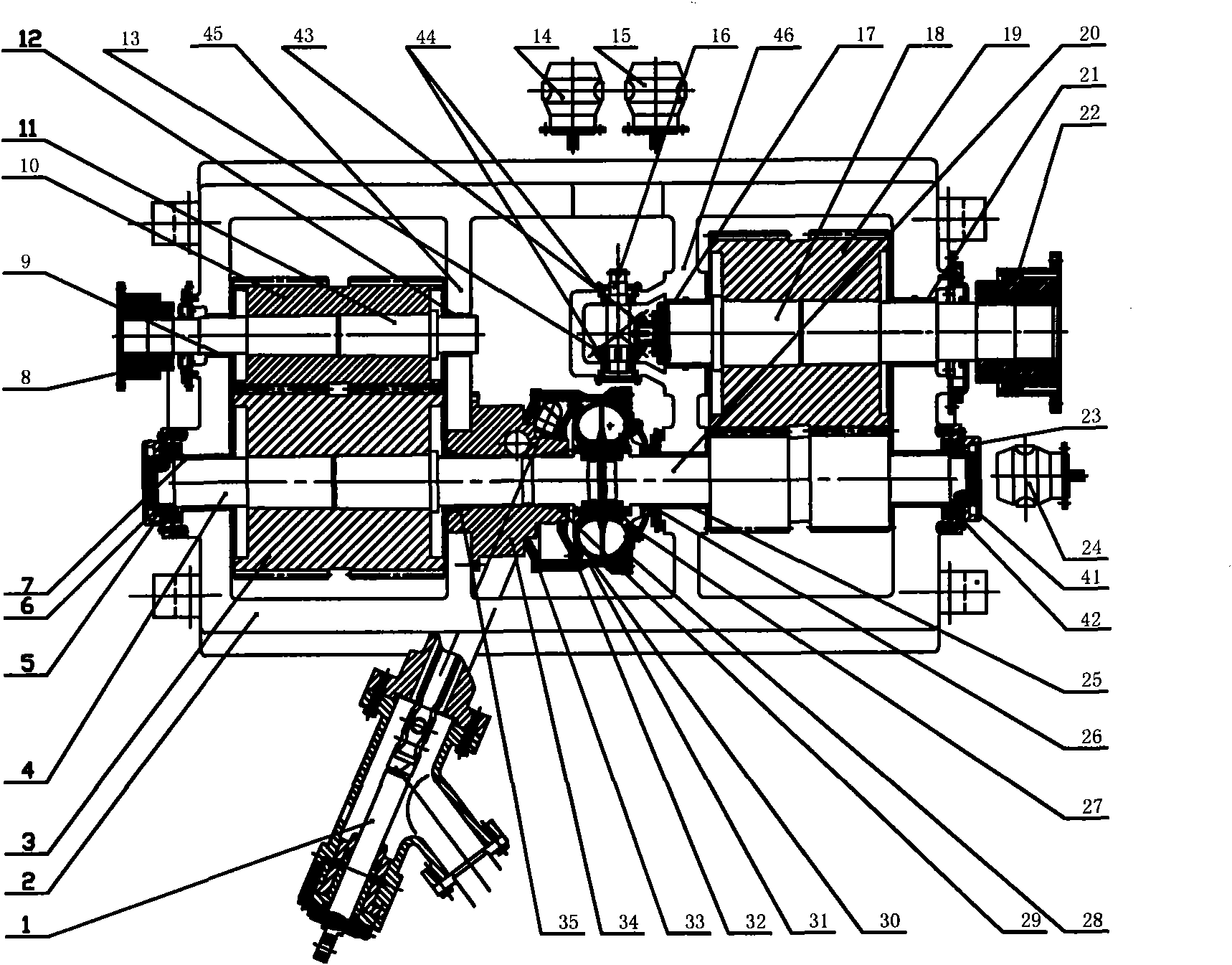

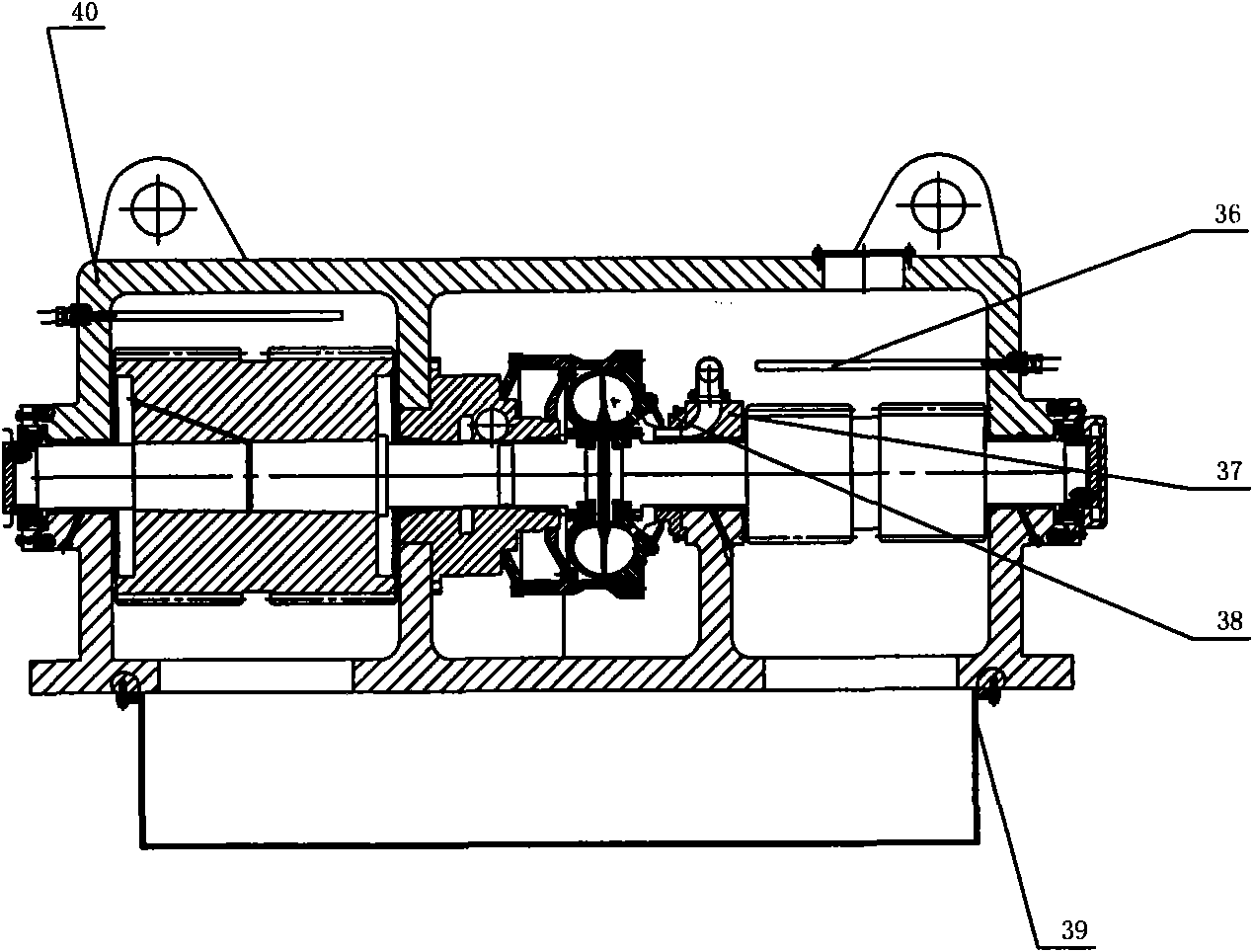

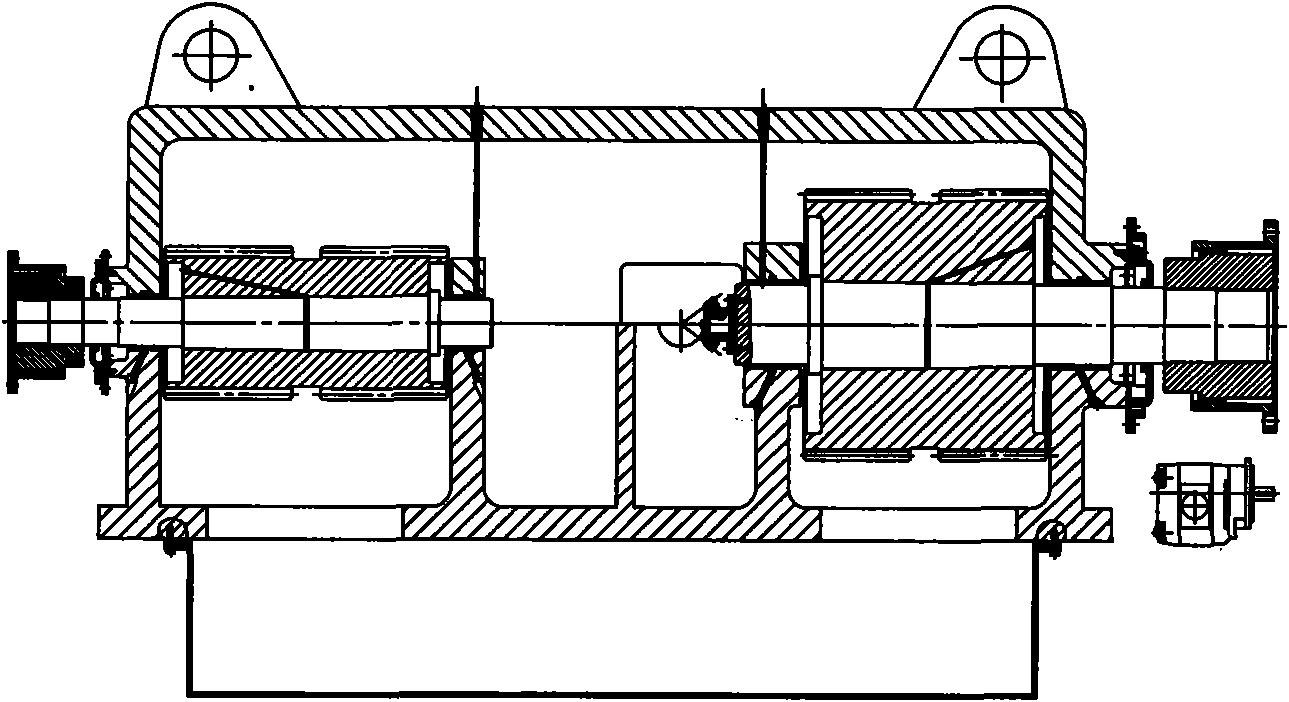

Speed-regulating hydraulic coupler transmission device of large-power composite gear capable of speeding up front and rear

InactiveCN101660596AOptimize the matching relationshipImprove operational efficiencyFeed water supplyFluid gearingsTransmitted powerElectric machine

The utility model relates to a speed-regulating hydraulic coupler transmission device of a large-power compound gear capable of speeding up front and rear. The device consists of a hydraulic coupler,a front speed-up herringbone gear, a rear speed-up herringbone gear and an oil line system; the hydraulic coupler adopts a speed regulation mode of adjusting a telescopic conduit at an outlet; the front part and the rear part of the hydraulic coupler are provided with a primary herringbone gear speed-up transmission mechanism respectively; the input rotating speed and capability for transmitting power of the hydraulic coupler are improved by the front speed-up gear transmission, thus reducing the specification of the coupler; the oil line system comprises a working oil pump, a main lubricatingoil pump and an auxiliary lubricating oil pump that are gear oil pumps. The device leads a motor and a working machine to match well, improves the transmission quality, improves the running efficiency of the working machine, leads a water supply pump of a boiler to work at a high-efficiency area all the time, greatly improves the working efficiency of the water supply pump of the boiler by the hydraulic speed regulation, saves a large amount of electric energy, and greatly reduces the consumption of energy resource.

Owner:JILIN UNIV

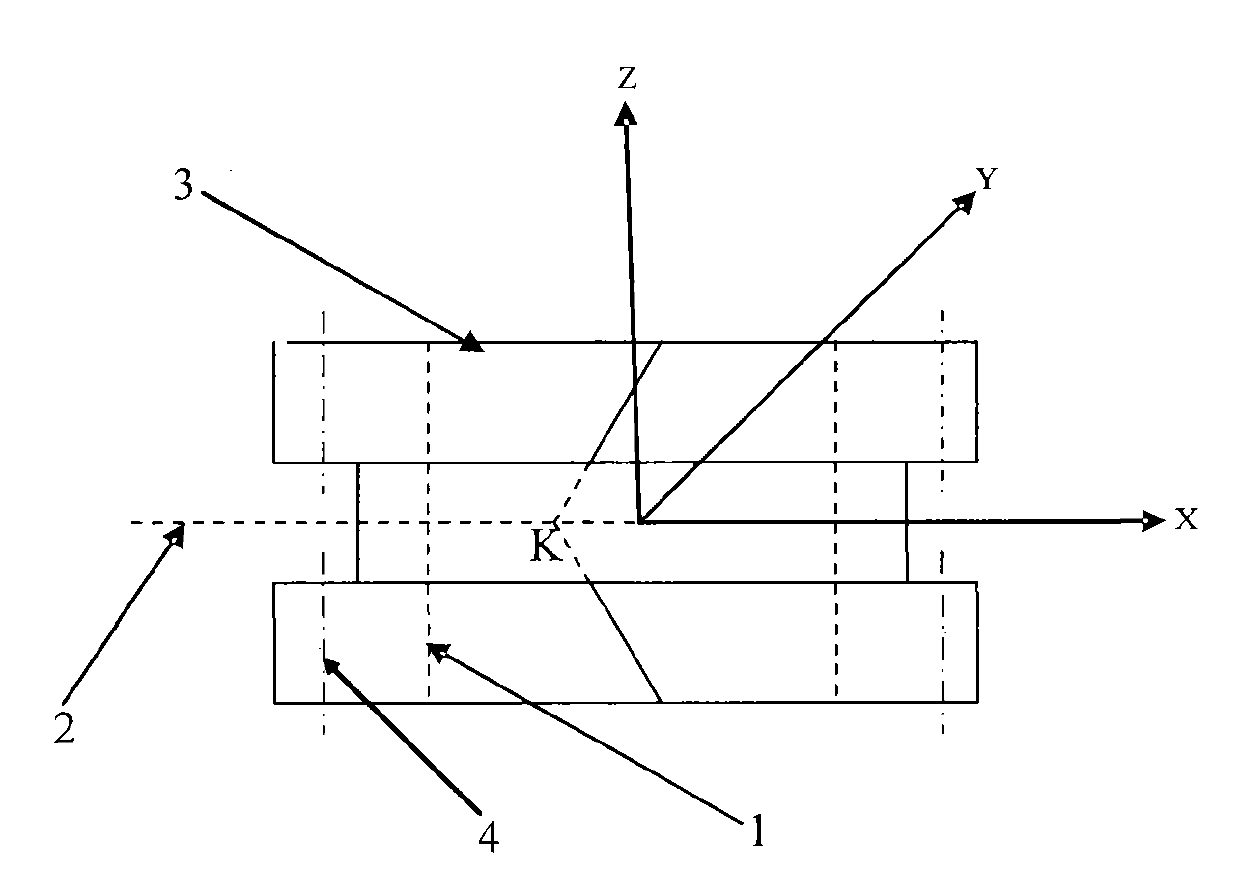

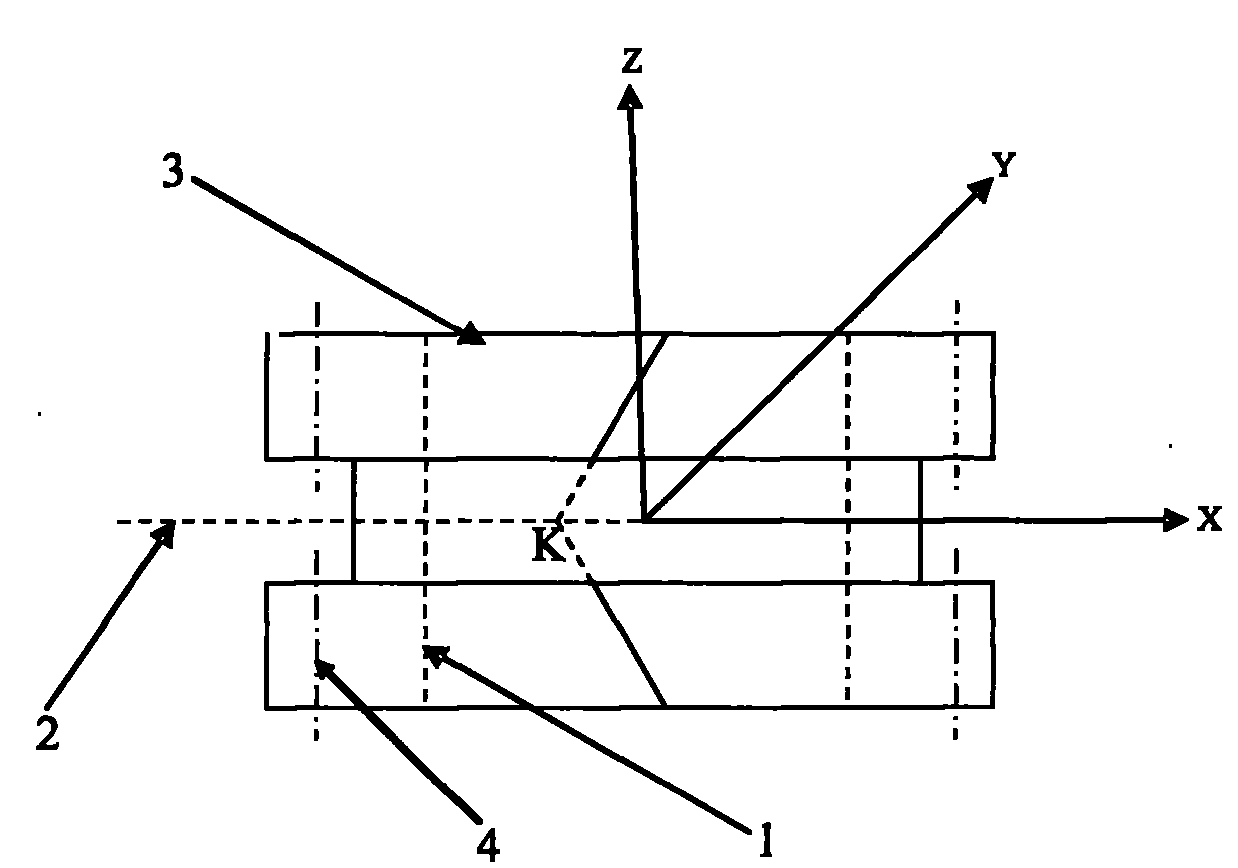

Method for detecting alignment error of herringbone gear

The invention discloses a method for detecting an alignment error of a herringbone gear. The method comprises the following steps: determining a mid-plane of the herringbone gear to be detected; establishing a coordinate system, wherein the original point of the coordinate system is a crossing point of a reference axis and the mid plane, Z axis is in line with the reference axis, Y axis and X axis are in the mid plane, and every two of the X axis, the Y axis and the Z axis are vertical; measuring two points on left and right handed corresponding flanks of the herringbone gear to ensure that values of Y coordinates of the two points are equal, Z coordinates of the two points have the same value but opposite directions, the difference delta X of the coordinate values of the two points in X direction is resolved, the alignment error delta Z of the herringbone gear in the axial direction can be resolved through the formula that delta Z equals to delta X / 2tg beta, wherein beta is an axial spiral angle. By measuring the alignment error delta X of the herringbone gear in the tangential direction, the alignment error delta Z can be indirectly acquired through the formula, and the alignment error delta Z which is difficult to measure can be avoided, and effective measurement to the alignment error can be realized.

Owner:CHONGQING GEARBOX

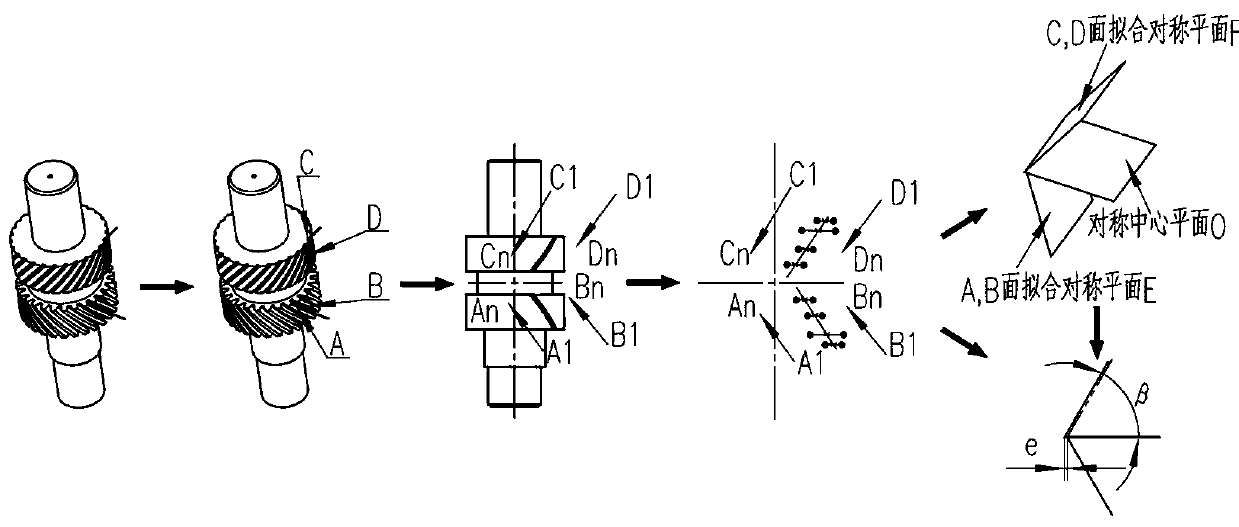

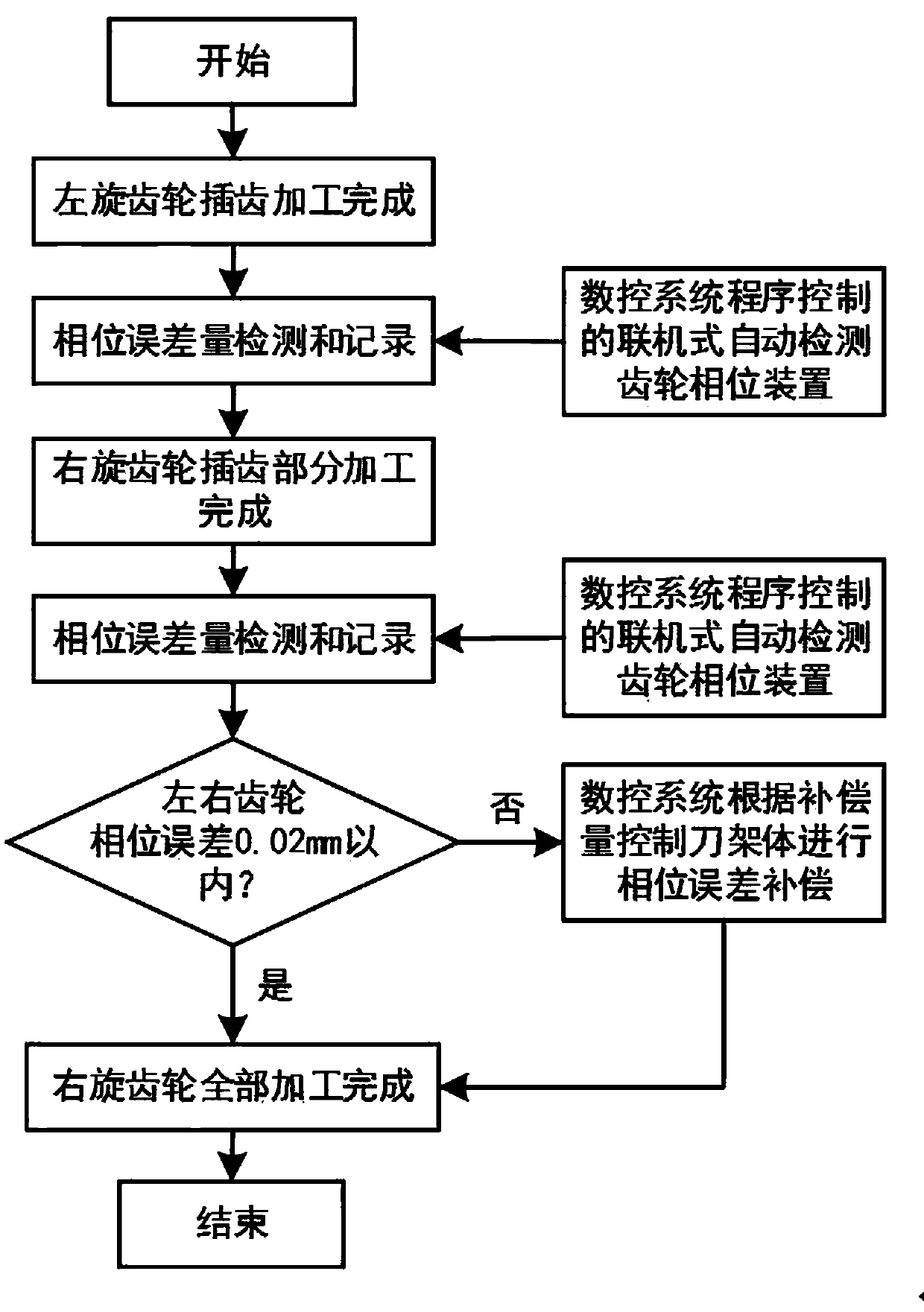

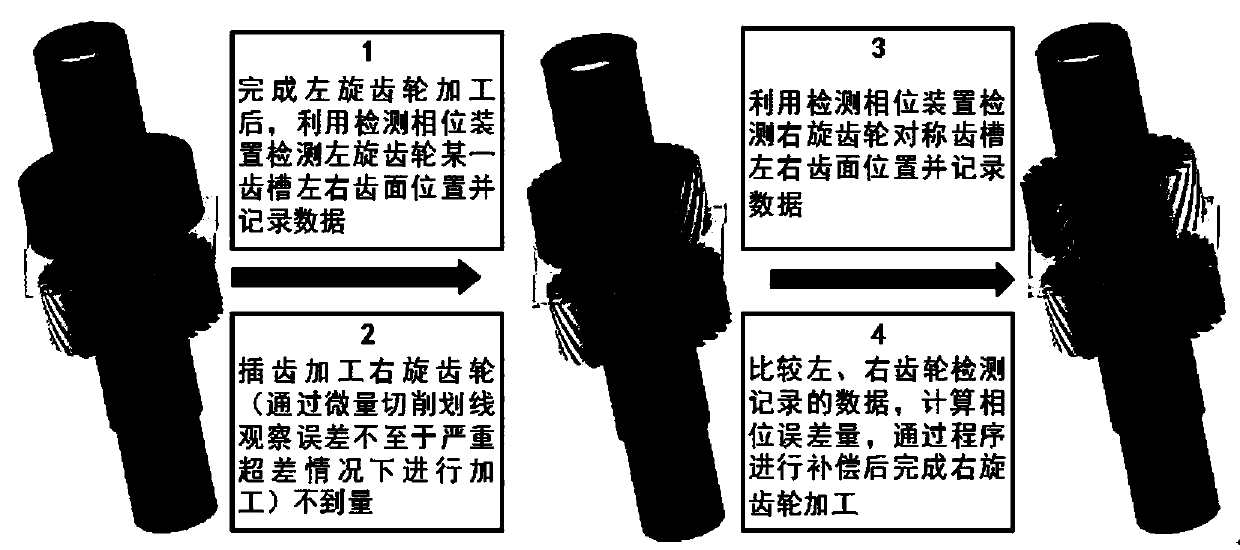

Herringbone gear slotting processing method based on on-line detection and compensation of symmetry error

ActiveCN108672835AAvoid duplicationAvoid stabilityGear-cutting machinesGear teethBatch processingControl system

The invention discloses a herringbone gear slotting processing method based on on-line detection and compensation of symmetry error. The method comprises that a mathematical model of the symmetry error of detection and compensation of a herringbone gear is established based on the spatial planar fitting method, least square method and the symmetric error equivalent processing method, the symmetryerror of herringbone gear is calculated and expressed through the mathematical model calculation, and the on-line detection and compensation processing of the symmetry error is accomplished by using amotion shaft and a numerical control system of a numerical control gear plugging machine. By developing the on-line detection numerical control program of the symmetry error of the herringbone gear and using the fixed angle processing function and the optimized measuring method, high-efficiency, high-precision and batch processing of the on-line detection and compensation of the symmetry error ofthe herringbone gear is achieved.

Owner:CHINA THREE GORGES UNIV

Anti-carbonation quenching distortion control method of large-size dual-herringbone gear

InactiveCN107937922AQuality improvementHigh strengthSolid state diffusion coatingFurnace typesHerringbone gearUltimate tensile strength

The invention provides an anti-carbonation quenching distortion control method of a large-size dual-herringbone gear. The anti-carbonation quenching distortion control method comprises the steps thatan existing carburizing and quenching tool is changed into a three-point supporting tool, before quenching charging after carburization, the upper face and the lower face of the gear are exchanged, and metallographic structure examination and the carburizing and quenching process parameter improvement after heat treatment are prepared. The anti-carbonation quenching distortion control method is used for the large-size dual-herringbone carburizing and quenching gear of a turbocompressor. According to the carburizing and quenching gear controlled through the anti-carbonation quenching distortioncontrol method, the deformation amount of the whole carburizing and quenching process is reduced by above 50%, the gear deformation amount is greatly reduced, the gear quality is greatly improved, the contact fatigue strength and bending fatigue are greatly improved, the grinding amount is reduced, and the cost is greatly reduced.

Owner:SHENYANG TURBO MASCH CORP

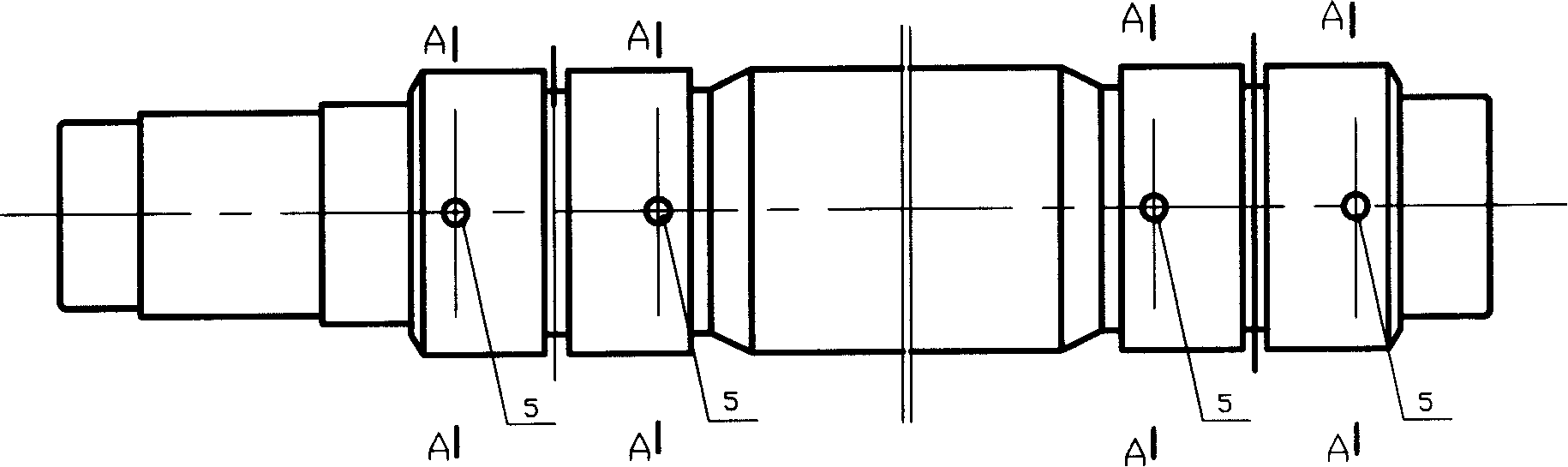

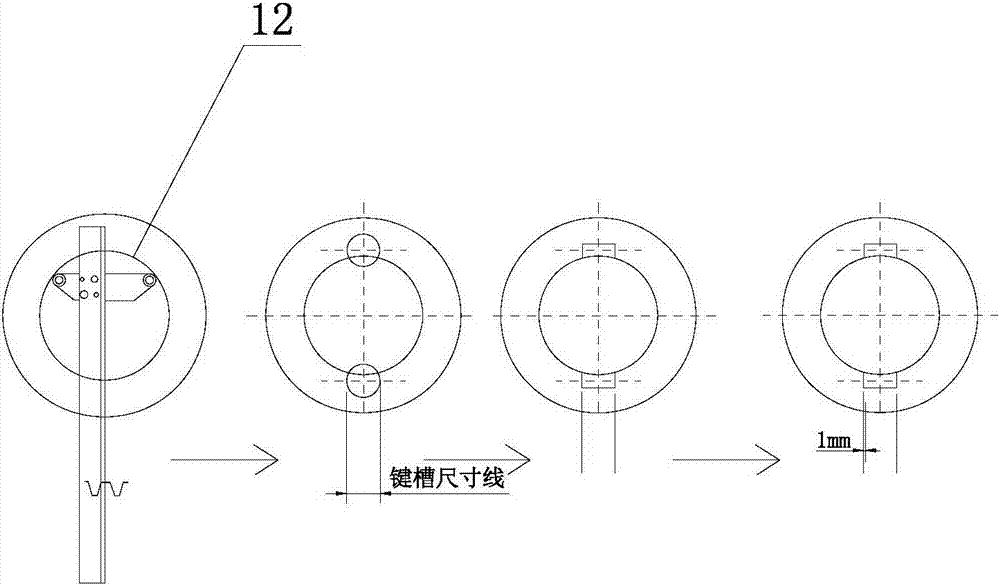

Tooth splicing machining method for machining herringbone gears

The invention relates to a tooth splicing machining method for machining herringbone gears. The tooth splicing machining method comprises the following steps: firstly machining two paired helical gears according to an ordinary helical gear machining method; during the gear grinding process of the two paired helical gears after heat treatment, grinding so that the sizes of the common normal lines of the two helical gears are the same, and then engaging the two helical gears according to an engagement principle, so that the axis centers of the two helical gears are connected to form a long straight line, and two circles are formed by taking the respective axis centers of the two helical gears as centers; manufacturing a plug pin hole from two intersection points on one of the helical gears, calculating the other helical gear according to the formula that a is equal to 360 / number of teeth / 2 to obtain the calibration angles of two technological coordinate holes and the left and the right intersection points; manufacturing the left and the right technological coordinate holes in the helical gears; after the two helical gears are spliced, splicing the two gears by inserting positioning pins in the left and the right plug pin holes which are overlapped and the two technological coordinate holes; then linearly cutting internal keyways of the central axle holes of the two helical gears to manufacture the two paired helical gears.

Owner:HANGZHOU ADVANCE GEARBOX GRP

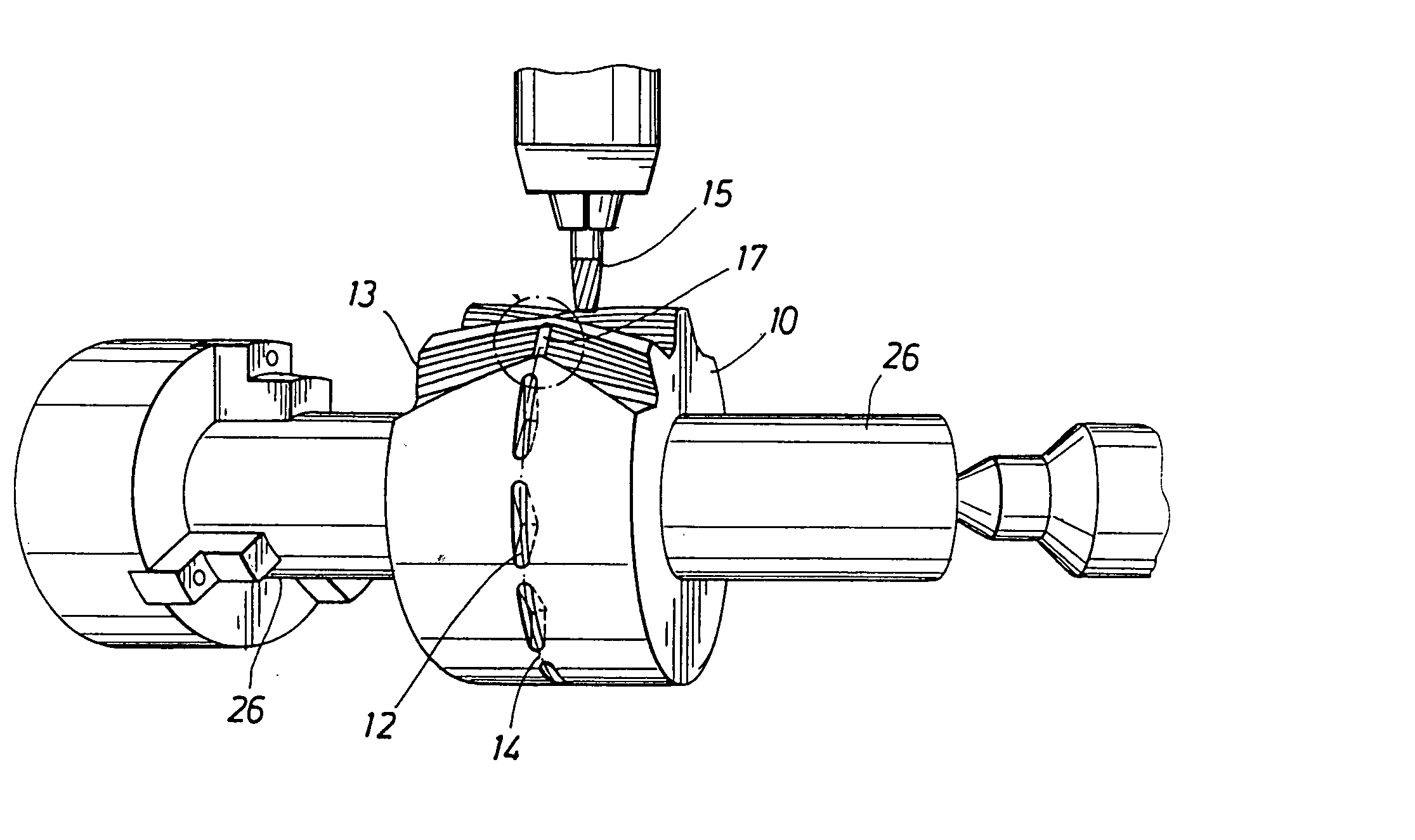

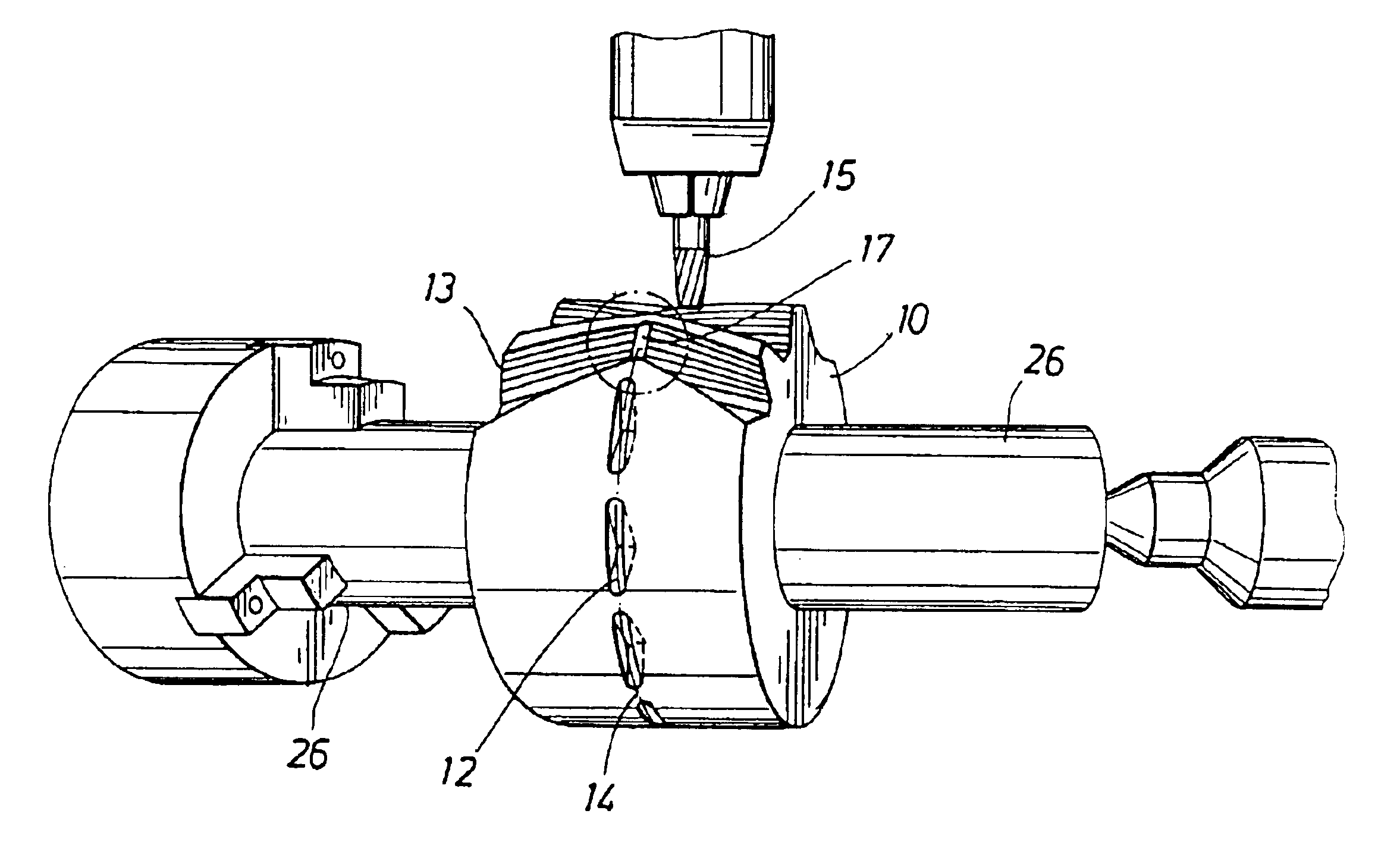

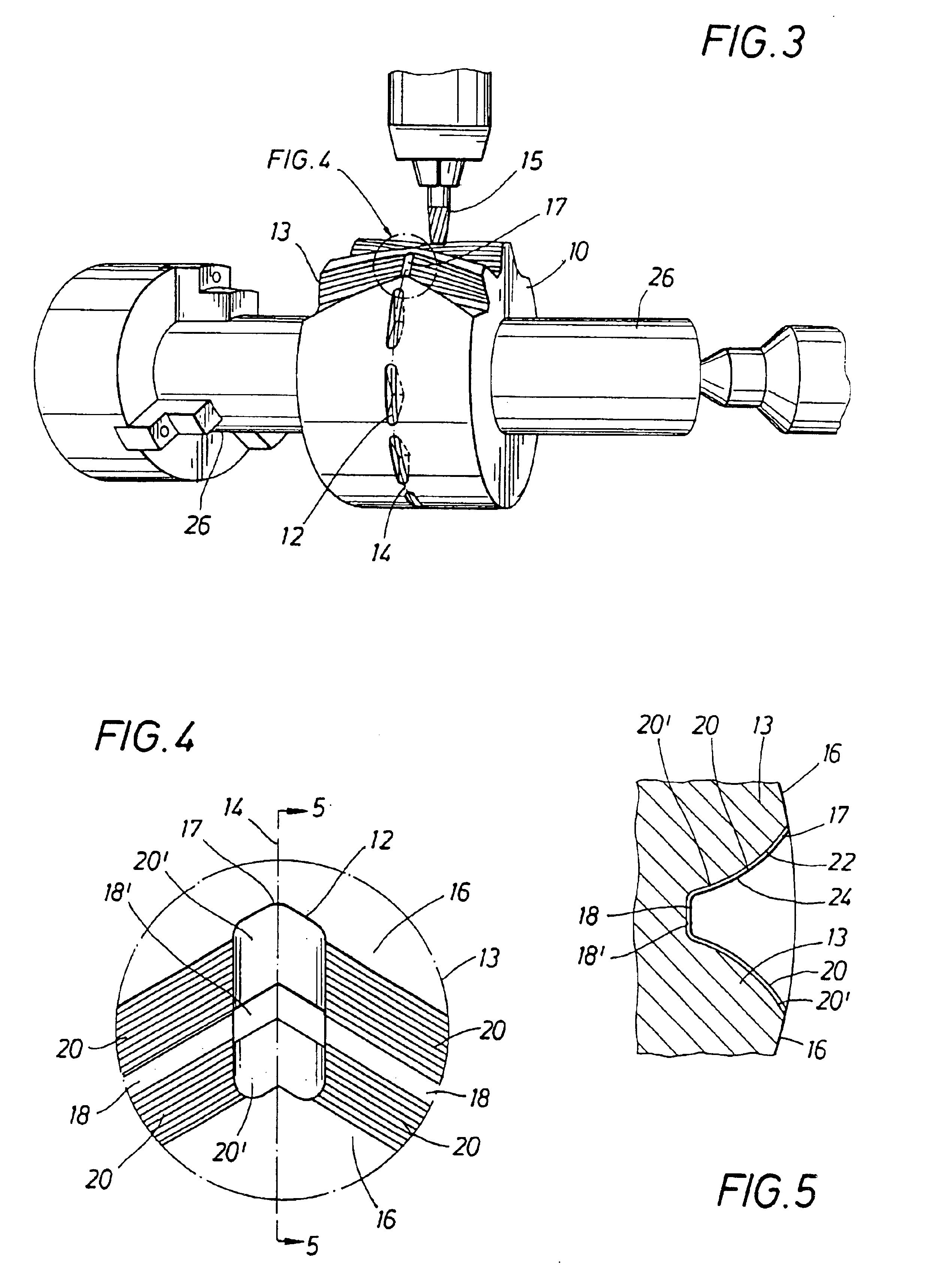

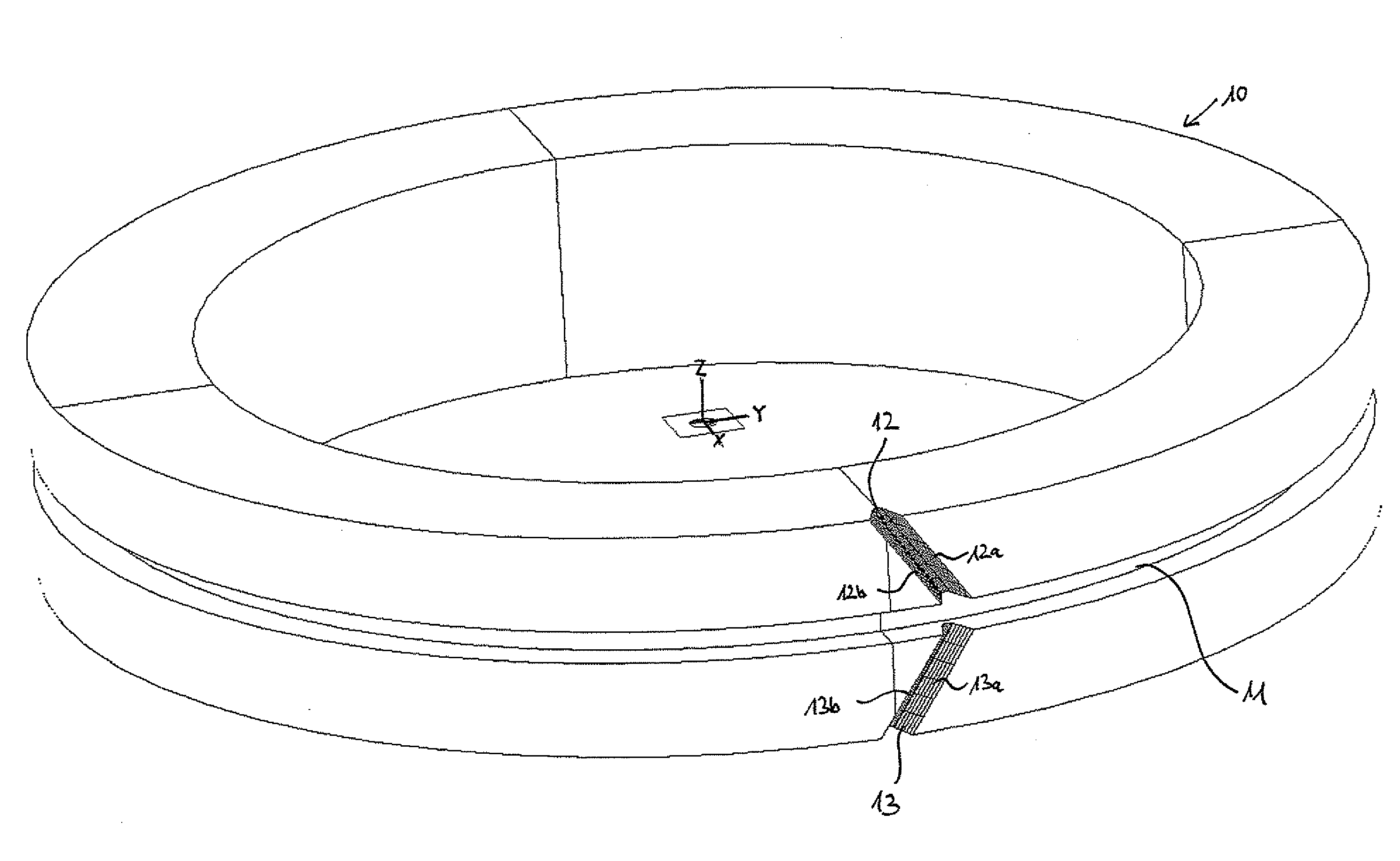

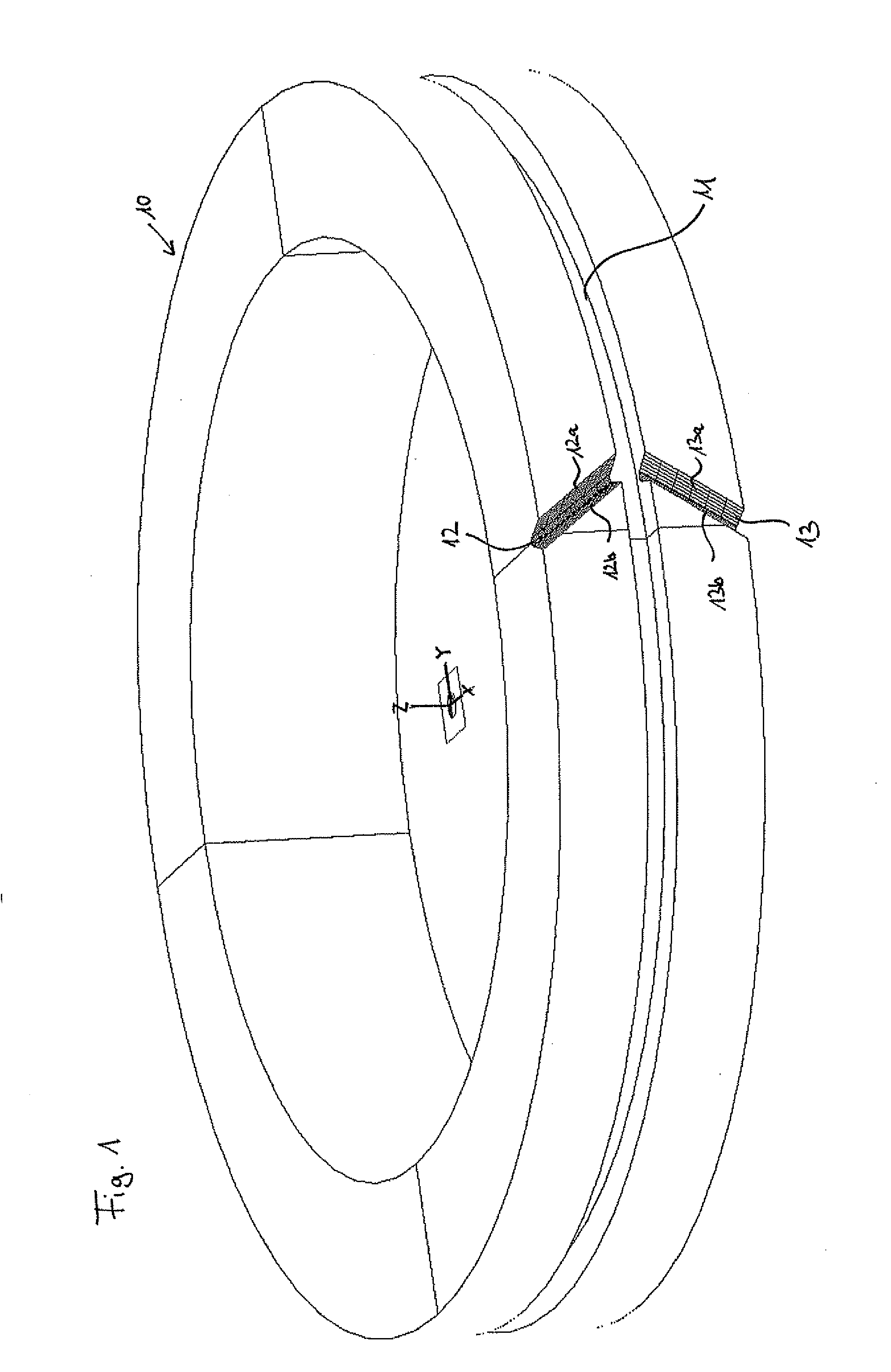

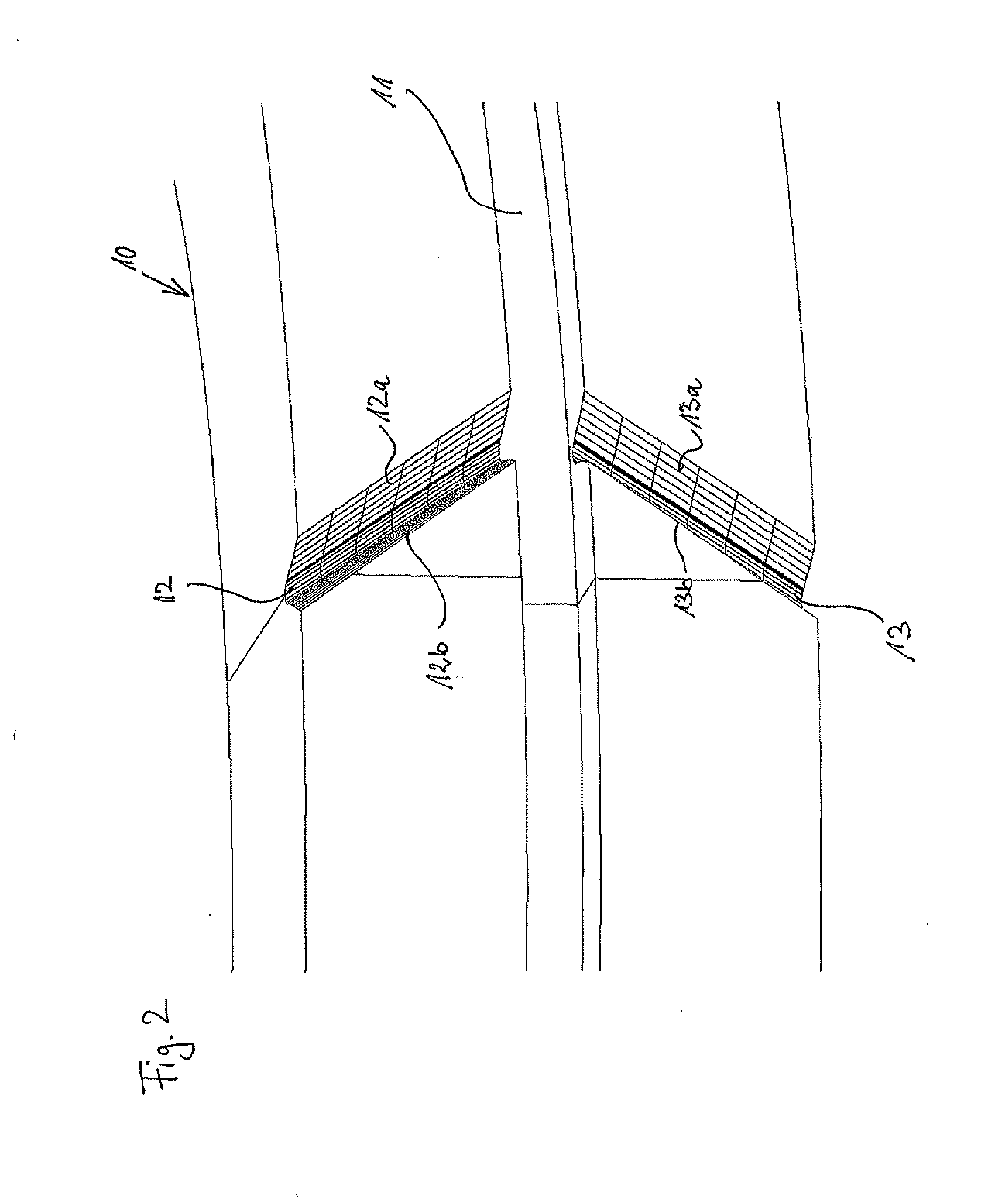

Process for producing a toothed wheel having a herringbone gearing and a process and an apparatus for generating control data to form a herringbone gearing on a workpiece.

ActiveUS20120114441A1Efficient executionReduce processing timeProgramme controlTotal factory controlControl dataEngineering

A process and an apparatus for generating control data, wherein a first tooth flank geometry is determined which corresponds to a geometry of a first tooth flank of the herringbone gearing, a second tooth flank geometry is determined which corresponds to a geometry of a second tooth flank of the herringbone gearing, a transition section geometry is determined which corresponds to a geometry of a transition section between the first tooth flank and the second tooth flank, an overall tooth flank geometry is determined which comprises the first tooth flank geometry, the transition section geometry and the second tooth flank geometry, and the control data is generated based on the overall tooth flank geometry and machining paths are indicated, each extending transversely to the profile direction of the tooth flanks and along the first tooth flank geometry, the transition section geometry and the second tooth flank geometry.

Owner:DECKEL MAHO PFRONTEN GMBH

Antifriction multi- arrangement roller bearing gear

InactiveCN101265967AReduce frictionExtended service lifePortable liftingGearing elementsEngineeringHerringbone gear

In the invention, a gear provided with a center plate gear and two sides of a center plate on the circumference of a gear center plate are inlaid with gear rings; a hard wearing roller bearing gear with multi-arrangement is embedded between two gear ring gears as a rolling gear of the gear; a helical gear, a herring-gear, a rack and the two sides of the center plates of a straight spur gear are inlaid with gear rings; the gear of a roller cylindrical bearing gear with multi-arrangement and the gear of a solid roller cylindrical bearing gear are embedded between two gear rings; and the center plates of a cone gear, a circular gear and a worm and worm wheel are inlaid with a plurality of rows of hard wearing roller cone bearing gears and another plurality of rows of solid cone bearing gears, wherein the center plate gear of the gear engages with the hard wearing multi-arrangement roller bearing gear, and the rack of the worm wheel engages with the plurality of hard wearing multi-arrangement roller cone bearing gear on the center plate of the worm wheel, thereby forming rolling friction between gears instead of sliding friction between gears, thereby reducing mortality factors, and prolonging the service life of the gears. The hard wearing multi-arrangement roller bearing gear can be applied to various gears.

Owner:蔡洪涛

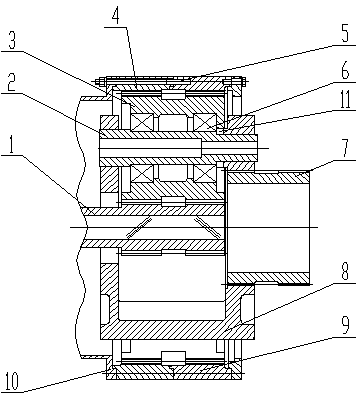

Herringbone-tooth planet gearbox

InactiveCN103629305AImprove carrying capacitySimple structureToothed gearingsGearing detailsGear wheelEngineering

The invention relates to a herringbone-tooth planet gearbox of a planet gear transmission device. The herringbone-tooth planet gearbox is characterized in that two inner gear rings are fixed on a box body of the planet gearbox; three adjusting pads are respectively arranged on three planet gear shafts; the planet gear shafts are arranged on a planet carrier; three planet gears are respectively arranged on the planet gear shafts through bearings; a center gear is arranged in the middle of the planet gearbox, wherein one end of the center gear is an input end; a gear sleeve is connected with the planet carrier, one end, which extends out of the planet gearbox, of the gear sleeve is an output end; the planet carrier is meshed with the gear sleeve 7 through crowned teeth; the three planet gears, the center gear and the two inner gear rings are herringbone gears; the three planet wheels are meshed with the center gear and the two inner gear rings. The herringbone-tooth planet gearbox has the advantages that under the same volume, the bearing capacity of the gearbox is improved, uniform load is realized, the curved safety coefficient of the gears can be increased by 30 percent, and the contact safety coefficient is increased by 20 percent.

Owner:SJ PETROLEUM MACHINERY CO LTD SINOPEC +1

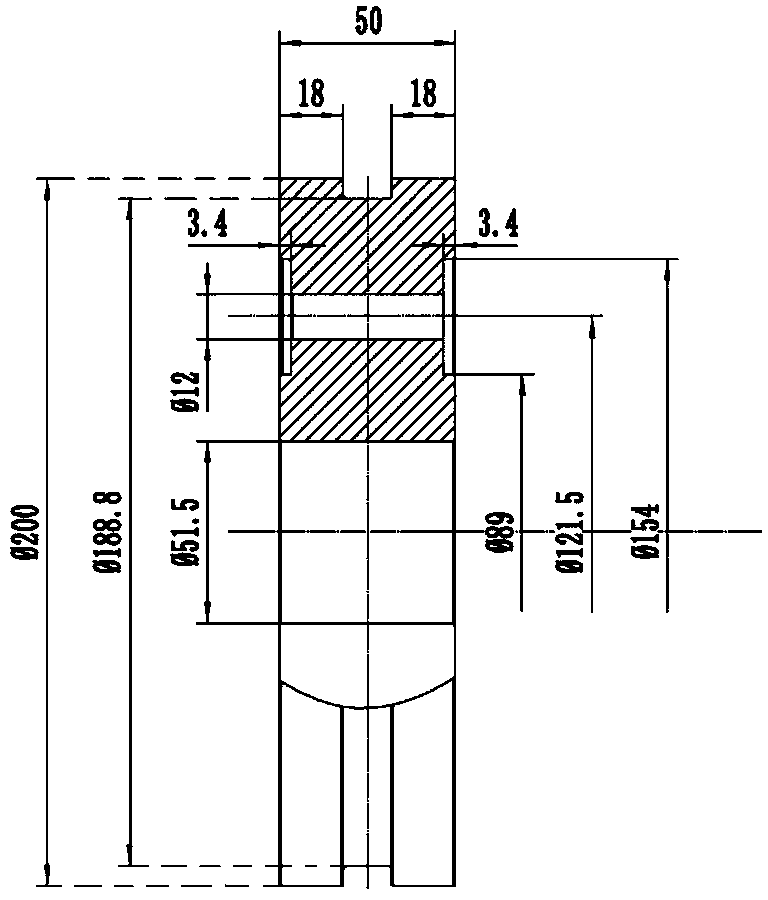

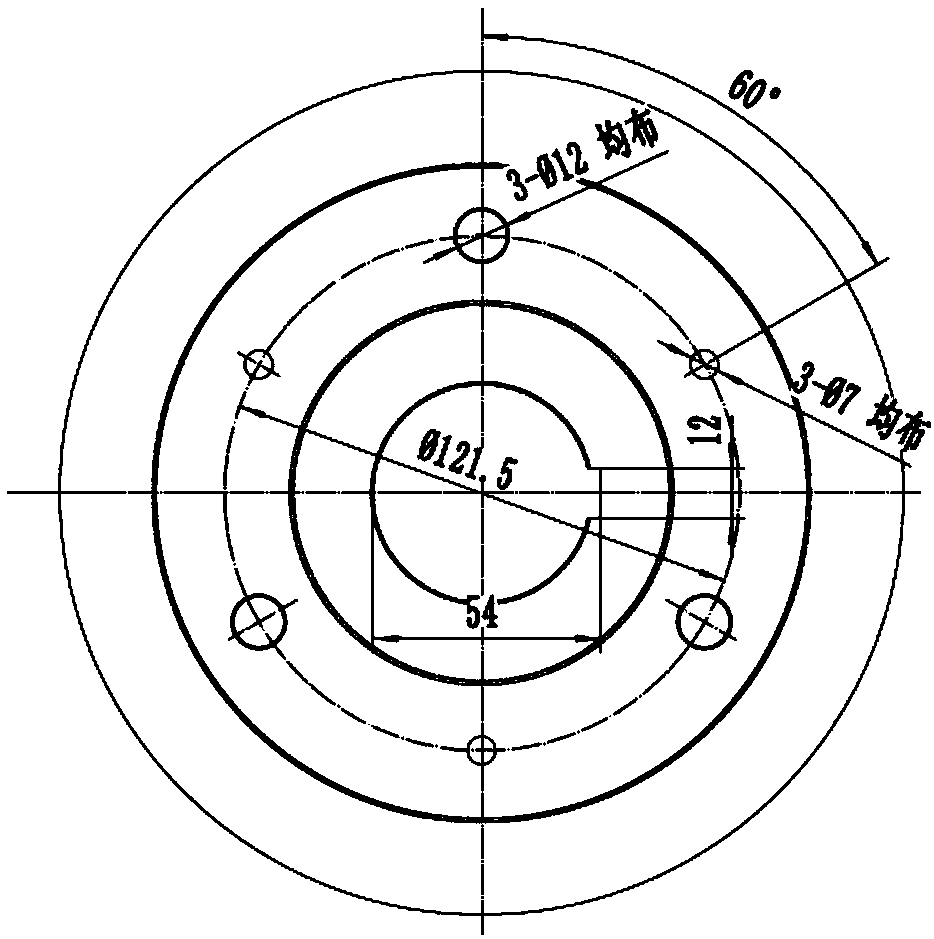

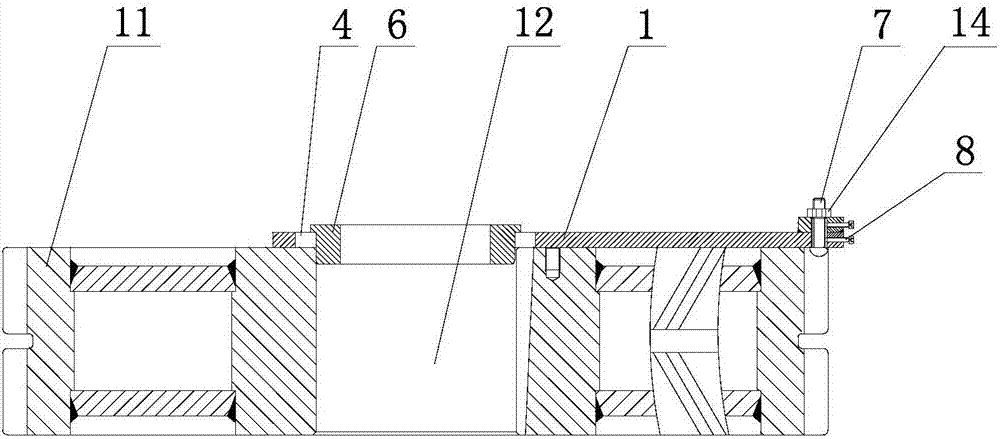

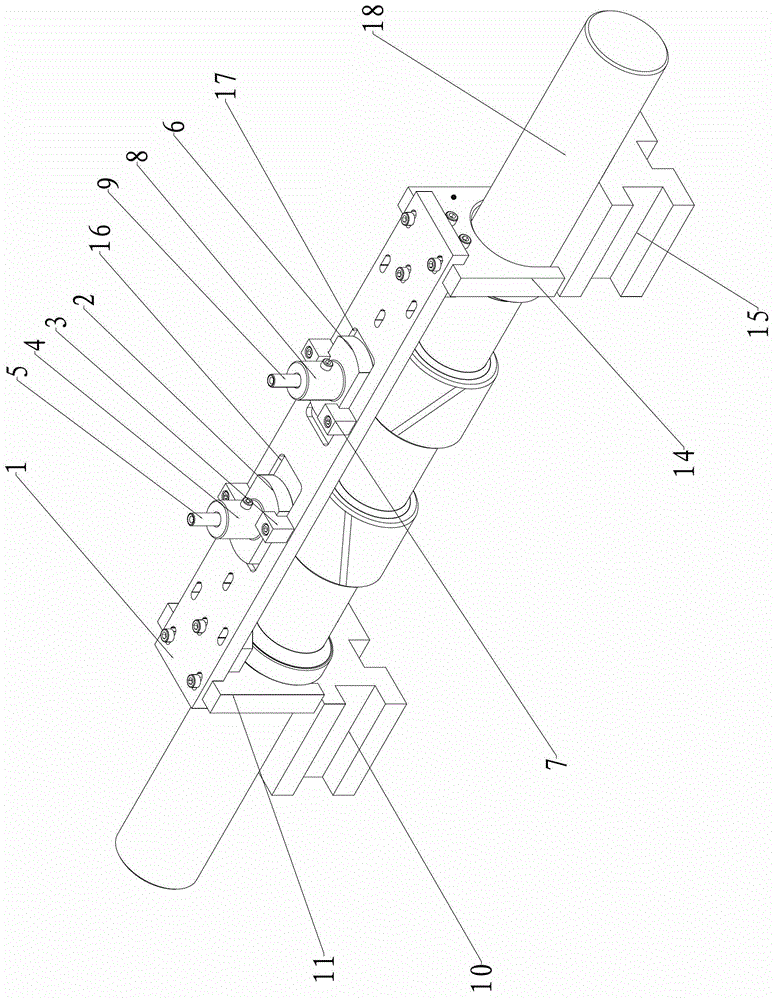

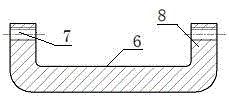

Symmetrical processing tool and processing method of herringbone gear hole keyway

InactiveCN107234288AImprove Symmetry AccuracyEnsure requirements on the same linePlaning/slotting machinesHerringbone gearMechanical engineering

The invention relates to a symmetrical processing tool and a processing method of a herringbone gear hole keyway. The symmetrical processing tool of the herringbone gear hole keyway comprises a tool body, wherein a positioning hole and a keyway positioning hole are respectively formed in both ends of the tool body along the direction of a center line, base keyways are respectively formed in the tool body on the left and right sides of the positioning hole along the direction of the center line, a plurality of threaded holes are formed from top to bottom in the side wall of one end, in which the keyway positioning hole is formed, of the tool body, the centers of the threaded holes are located in the center line of the side wall, a positioning sleeve is arranged in the positioning hole, a keyway positioning shaft is arranged in the keyway positioning hole, and adjusting screws are arranged in the threaded holes. The symmetrical processing tool has the advantage of reasonable structural design, and the processing quality of a workpiece is increased by positioning the tooth profile, tooth surface and hole of the end surface of the reference circle of a herringbone gear according to the technical requirement that the center of the herringbone gear end keyway, the center of the hole keyway and the center line of the hole are on the same straight line by controlling the side symmetry of the keyway in the tool.

Owner:SHANDONG JINCHEN MACHINERY CORP LTD LTD

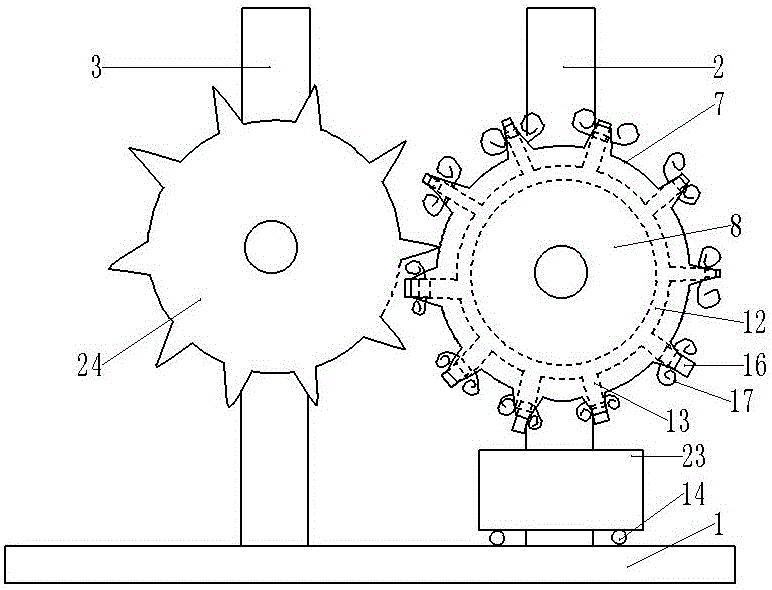

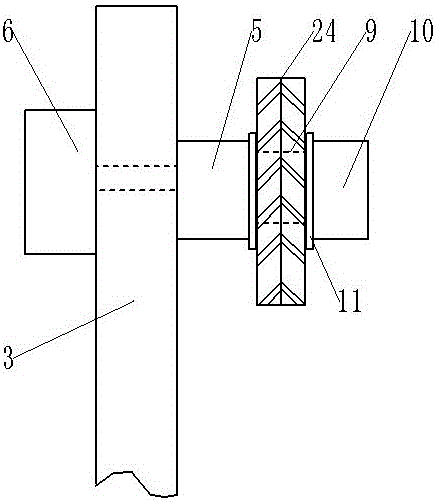

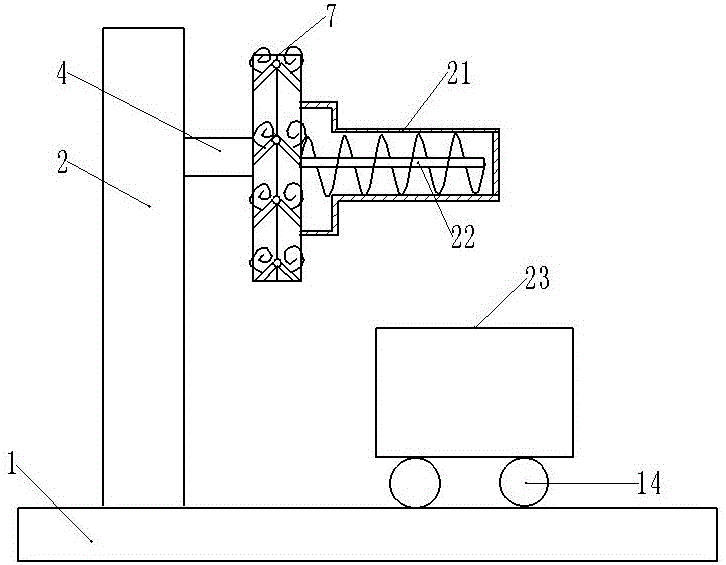

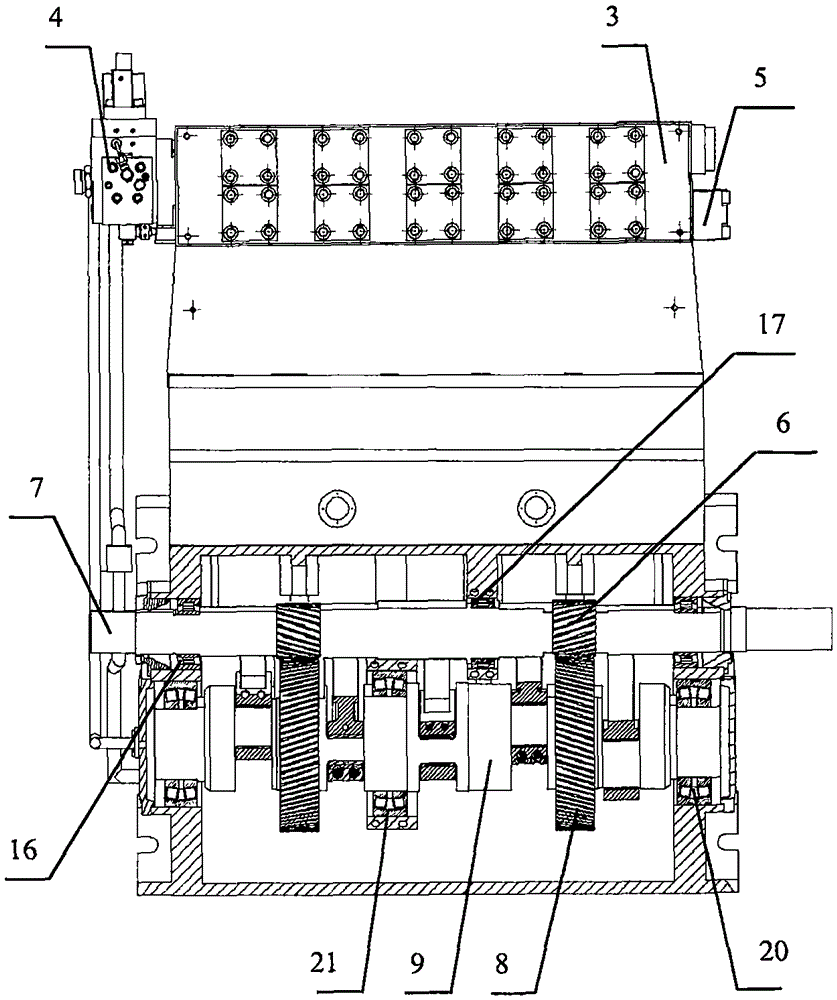

Machining device for herringbone gear

ActiveCN106825774AImprove processing qualityAchieve cleanupMaintainance and safety accessoriesGear teethMaterial removalHerringbone gear

The invention relates to the field of machining equipment for gears and discloses a machining device for a herringbone gear. The machining device comprises a rack. A first stand column and a second stand column are arranged on the rack. A first rotary shaft is rotationally connected to the first stand column. A second rotary shaft is rotationally connected to the second stand column. A motor is connected to the second rotary shaft. A machining position and a fixing block are arranged on the second rotary shaft. A material removal gear is rotationally connected to the first rotary shaft. A storage cavity is formed in the material removal gear. A first air pipe with leakage holes is arranged in the storage cavity and communicates with second air pipes. Through holes are formed in all teeth of the material removal gear. The second air pipes are in one-to-one connection with the through holes. A piston is arranged in each through hole. A reset spring is connected between each piston and the corresponding through hole. Scraping blades are arranged on the two sides of each piston. An air blowing pipe is arranged on each scraping blade and communicates with the corresponding second air pipe. A curl-shaped steel wire is arranged on each air blowing pipe. Air blowing holes are formed in each air blowing pipe. By means of the machining device, burrs on tooth grooves in the herringbone gear can be comprehensively cleaned.

Owner:重庆市顾芳机械有限公司

Five-plunger emulsion pump

ActiveCN105276122AImprove stabilityImprove AssemblabilityGearingPositive-displacement liquid enginesEmulsionTransmission technology

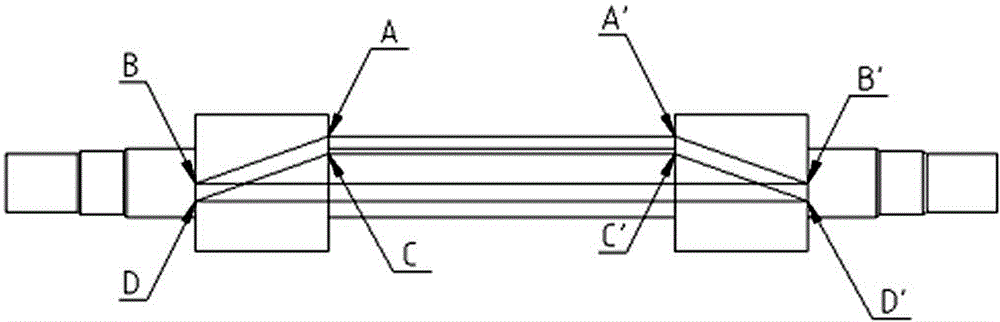

A five-plunger emulsion pump comprises an input shaft and a crankshaft. An even number of input bevel gears are arranged on the input shaft. The input bevel gears include the left input bevel gears and the right bevel gears. The number of the left input bevel gears is the same as that of the right input bevel gear. Three input bearings are arranged on the input shaft and arranged at the two ends and the middle of the input shaft respectively. Crankshaft bevel gears correspondingly meshed with the input bevel gears are arranged on the crankshaft. Three crankshaft bearings are arranged on the crankshaft and arranged at the two ends and the middle of the crankshaft respectively. The herringbone gear pair transmission technology is adopted, and damage caused by axial component force of a traditional one-sided bevel gear pair to supporting bearings is eliminated; the supporting mode that the middle supporting point of the crankshaft and the middle supporting point of the input shaft are distributed in an intersected manner is creatively adopted; and split bearing covers are adopted for middle bearings, and therefore under the condition that the overall strength is not lowered, the bearings can be more conveniently replaced, and maintenance and repair are facilitated.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

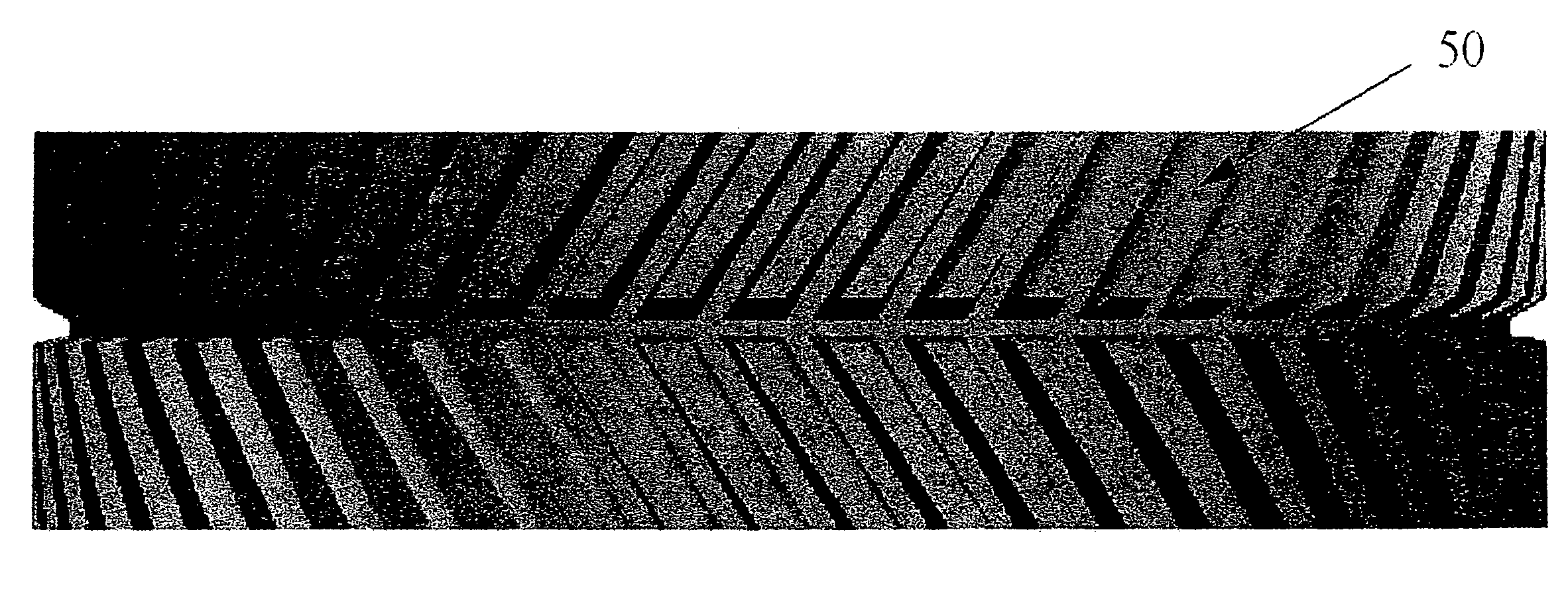

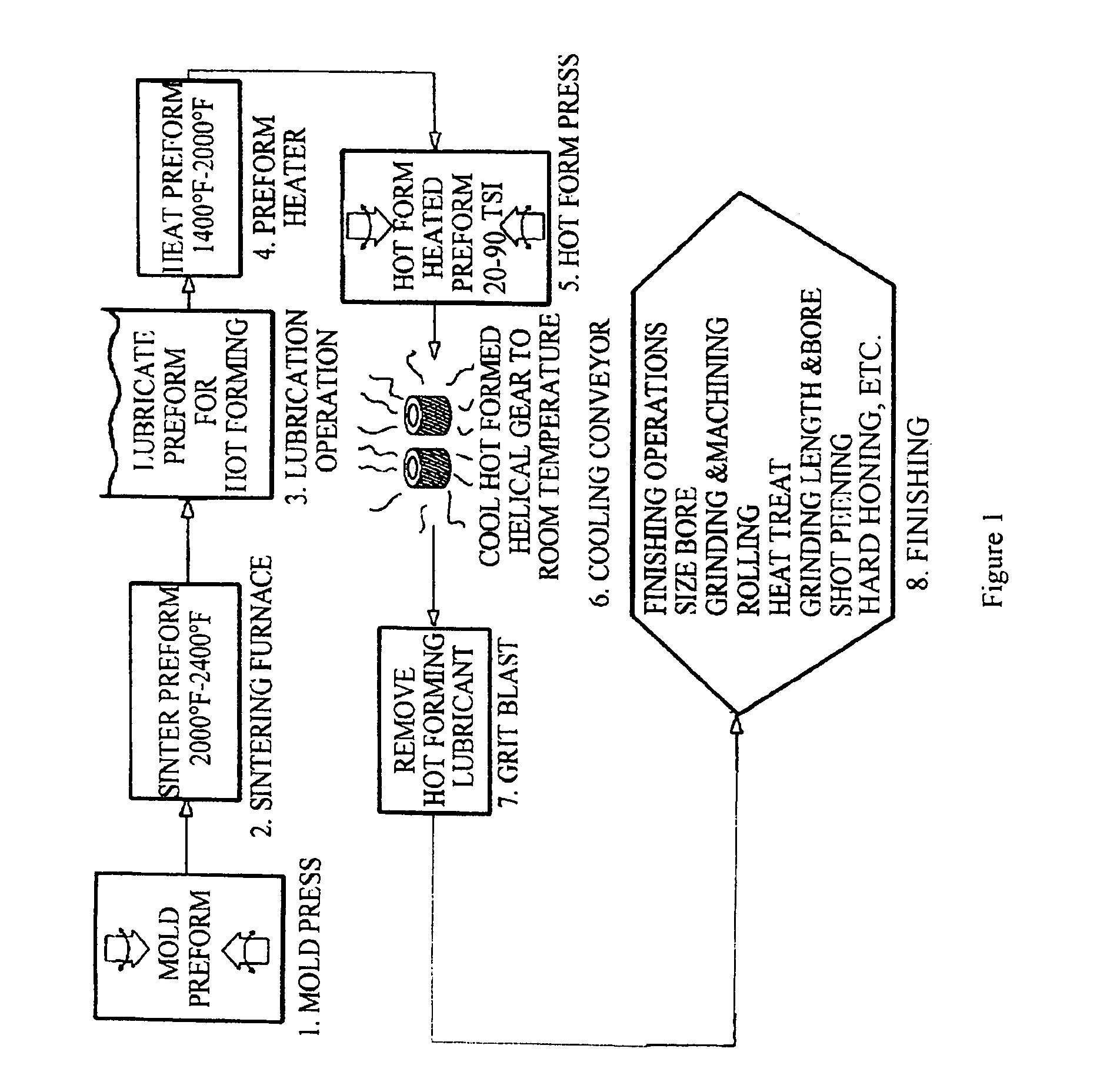

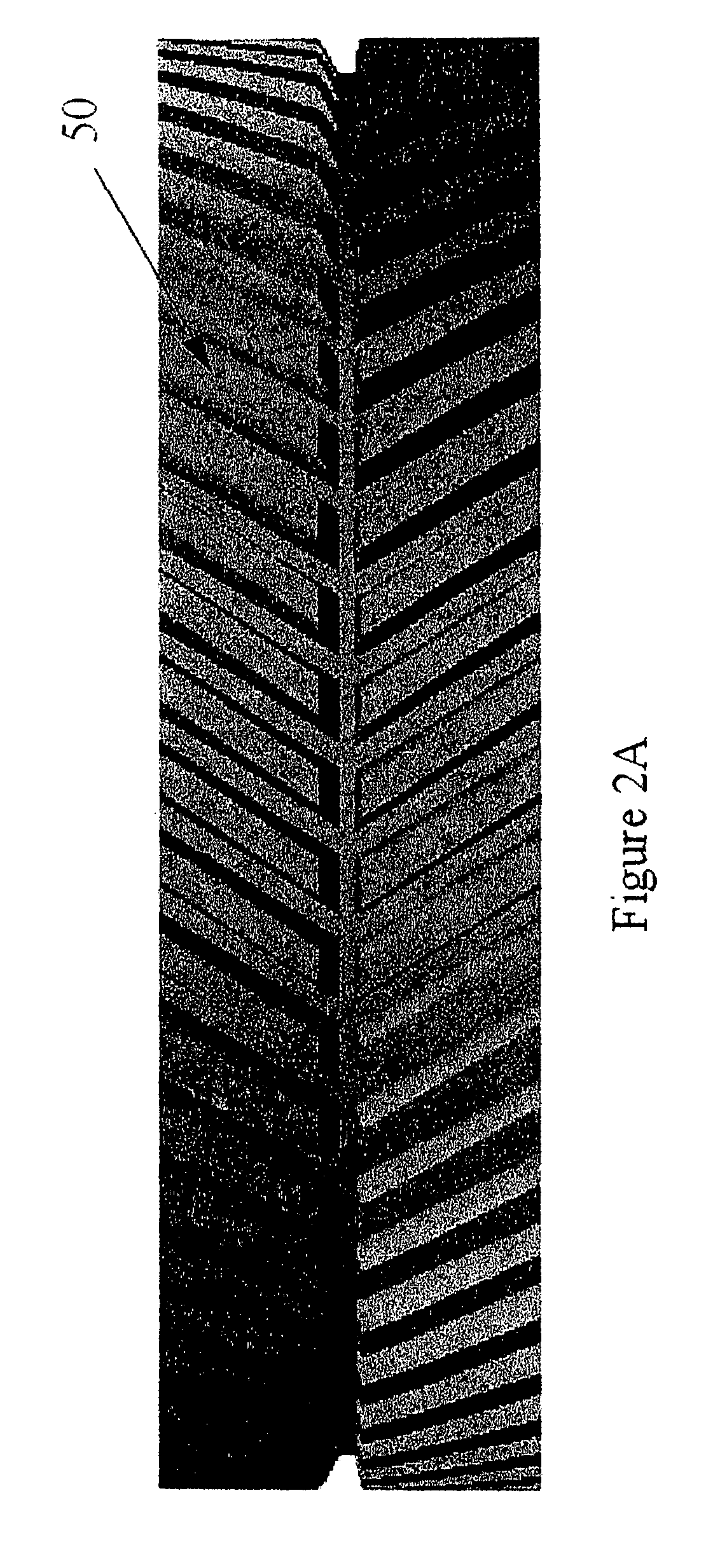

High density dual helical gear and method for manufacture thereof

ActiveUS7364803B1Low costHigh densityEngine sealsLayered productsHigh densityVolumetric Mass Density

The present invention relates to a low cost technique for manufacturing dual helical gears, such as herringbone gears, from powder metals. The dual helical gears made by this technique are of high density (greater than 92% of theoretical density) and offer superior strength. The present invention more specifically discloses a forged metal herringbone gear which is comprised of a body and a plurality of teeth wherein the metal has a density of greater than 92% of theoretical and wherein the grain in the teeth is one range higher on the ASTM E 112 grain size chart than the grain in the body of the gear. The present invention also discloses a method for manufacturing a high density forged dual helical gear.

Owner:KEYSTONE INVESTMENT CORP

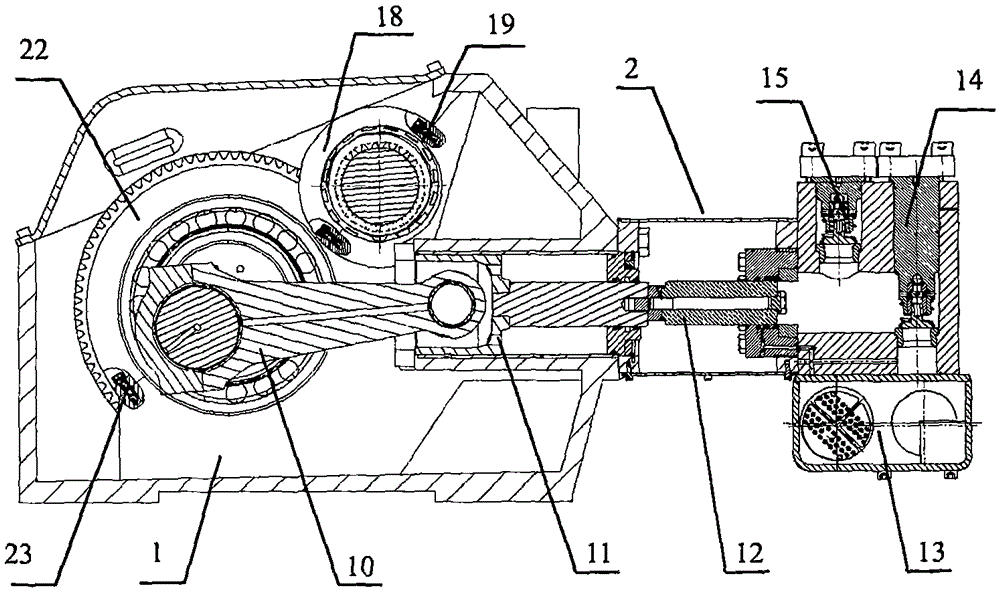

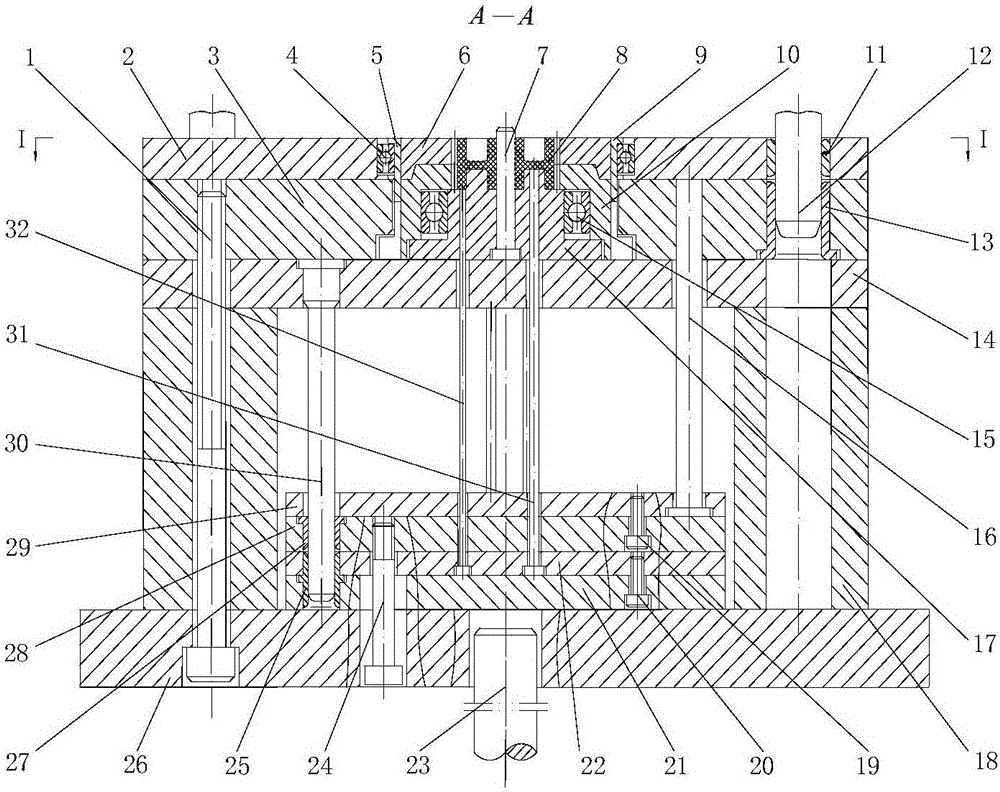

Eccentric shaft-connecting rod combined type load averaging method and speed reducer adopted in method

InactiveCN104373517ASolve assembly difficultiesSolve the technical problem of uneven load distributionToothed gearingsGearing detailsAuto regulationNeedle roller bearing

The invention discloses an eccentric shaft-connecting rod combined type load averaging method and a speed reducer adopted in the method. The method and the speed reducer are characterized in that a whole high-speed shaft is a herringbone gear shaft, planet gears are herringbone gears overall, an annular gear A and an annular gear B are both oblique-tooth annular gears, particularly, a herringbone gear transmission system comprises an automatic load averaging structure and can conduct automatic adjustment when multiple planet gear loads are unequal, the automatic load averaging structure is composed of a planet shaft, a needle bearing, a load averaging connecting rod and a round load averaging ring, the planet shaft is an eccentric shaft, the eccentric distance is specially designed for the situation that the loads among the planet gears are unequal due to manufacture and installation errors of a compensation system, the center distance between each planet gear and a sun gear and the center distance between each planet gear and the corresponding annular gear are not constant and can be changed slightly due to the eccentric distance, and the loads among the planet gears are adjusted and redistributed so as to be equal. The method and the speed reducer have the advantages that the load averaging effect of the system is greatly improved, vibration and noise are lowered, reliability is high, and the application prospects are wide.

Owner:BEIHANG UNIV

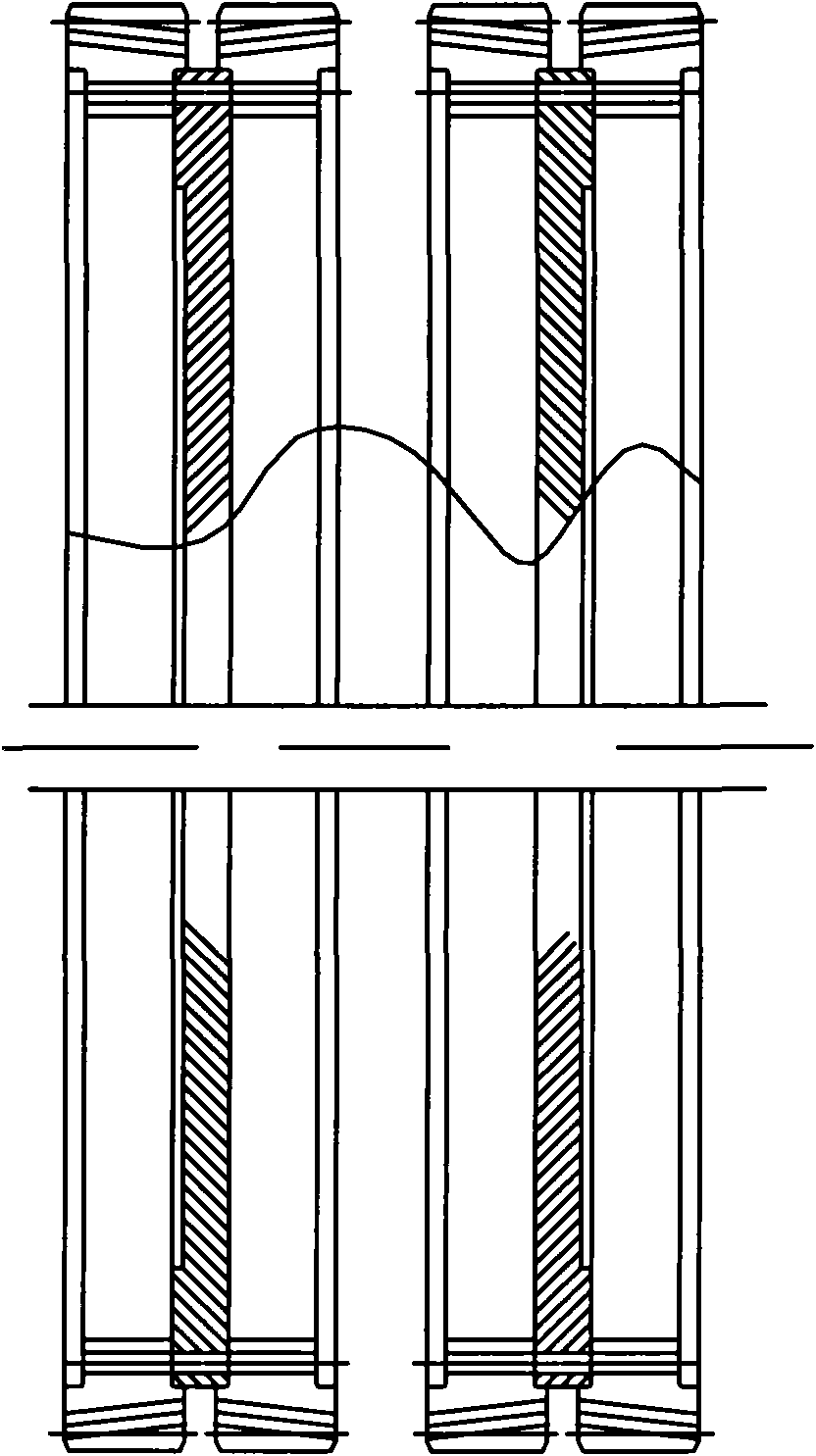

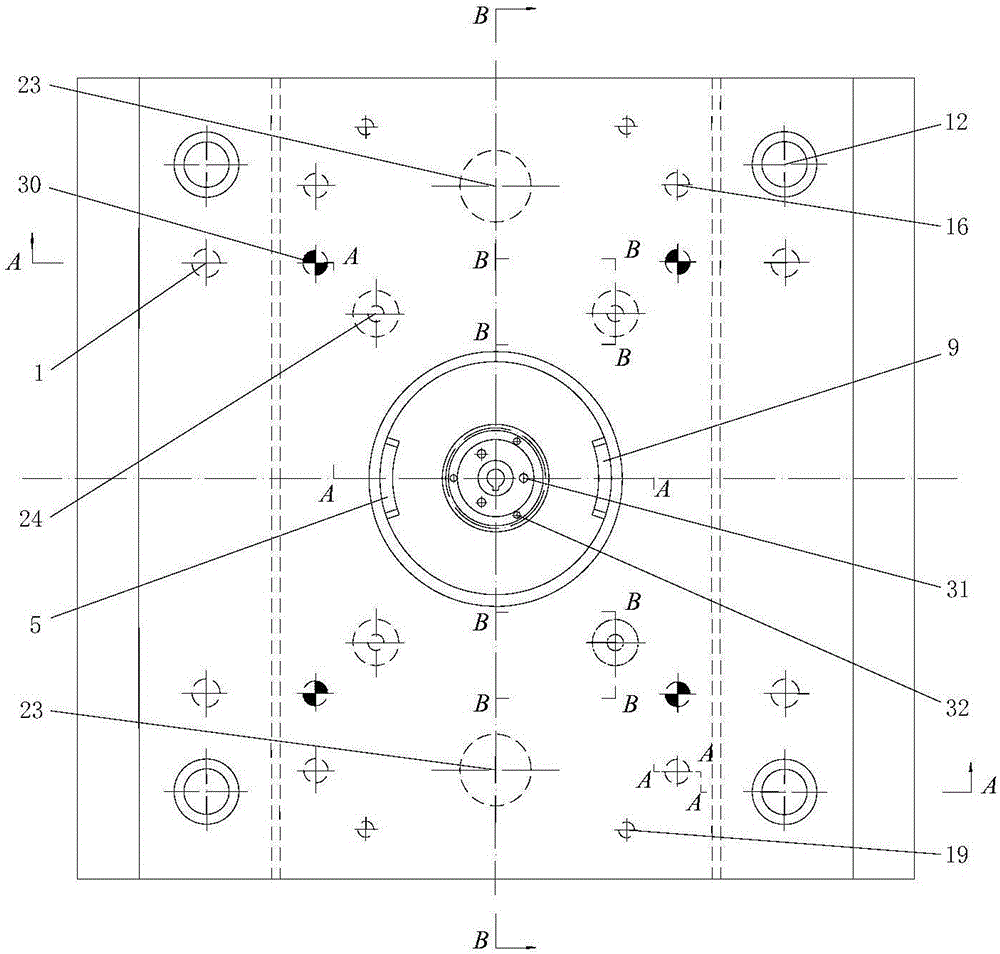

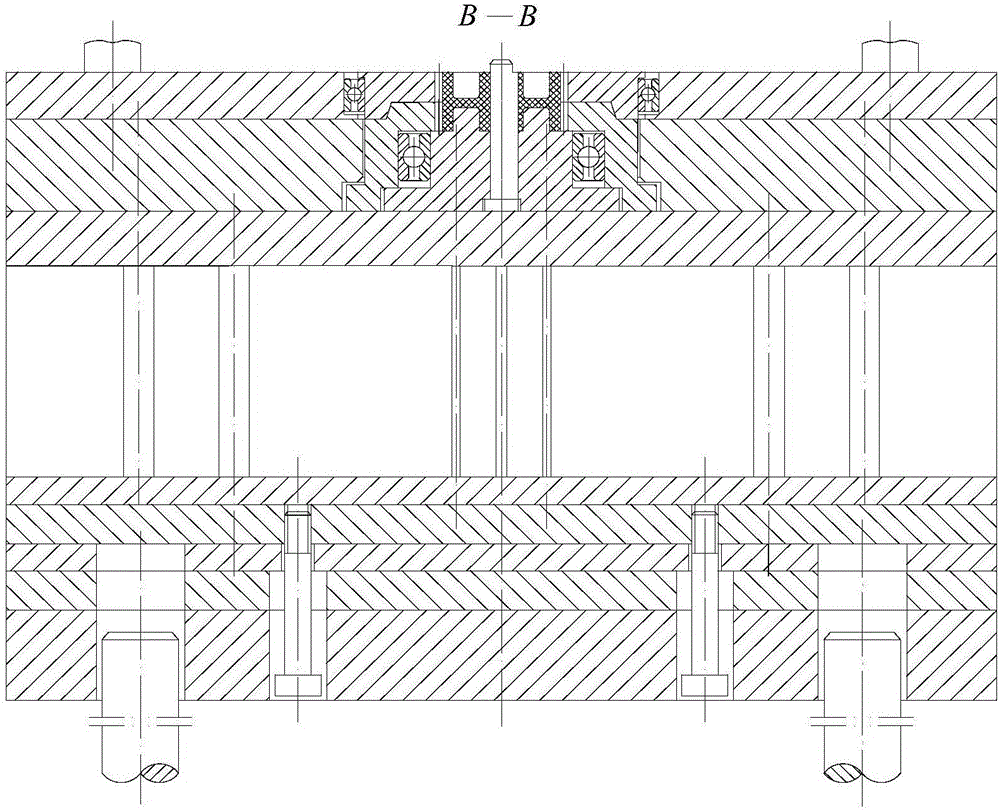

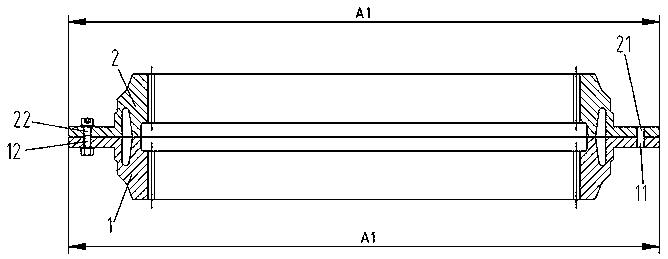

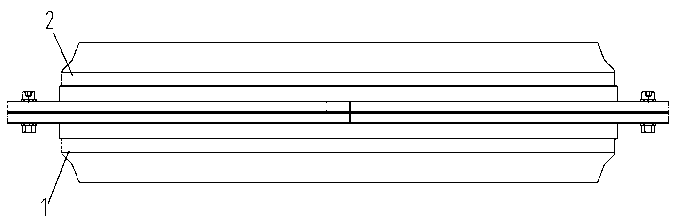

De-molding and resetting device for injection molding of herringbone gear

The invention discloses a de-molding and resetting device for injection molding of a herringbone gear. The de-molding and resetting device sequentially comprises a cavity fixing plate, a movable mold plate, a bearing plate, cushion blocks and a movable mold base plate from up to down; a front-section centripetal thrust bearing is arranged in a mounting hole of the cavity fixing plate; a front-section helical gear cavity is formed in the inner side of the front-section centripetal thrust bearing; the movable mold plate internally comprises a rear-section helical gear cavity; positioning inserts are arranged on the side surface of the front-section helical gear cavity and are matched with positioning grooves formed in the corresponding position of the outer side of the rear-section helical gear cavity; a movable mold core insert is arranged in the rear-section helical gear cavity; a rear-section centripetal thrust bearing is arranged between the rear-section helical gear cavity and the movable mold core insert; a mold core with a forming center hole is arranged in the movable mold core insert; and a two-stage sequential pushing mechanism is arranged on a movable mold base plate and between the cushion blocks on the two sides of the movable mold base plate. According to the de-molding and resetting device, the two-section helical gear cavities rotate sequentially so that the herringbone gear can be smoothly de-molded, and two helical tooth grooves opposite in the rotating direction are enabled to be aligned to the forming position in the mold-closing and resetting processes by means of the positioning inserts.

Owner:CHANGZHOU INST OF TECH

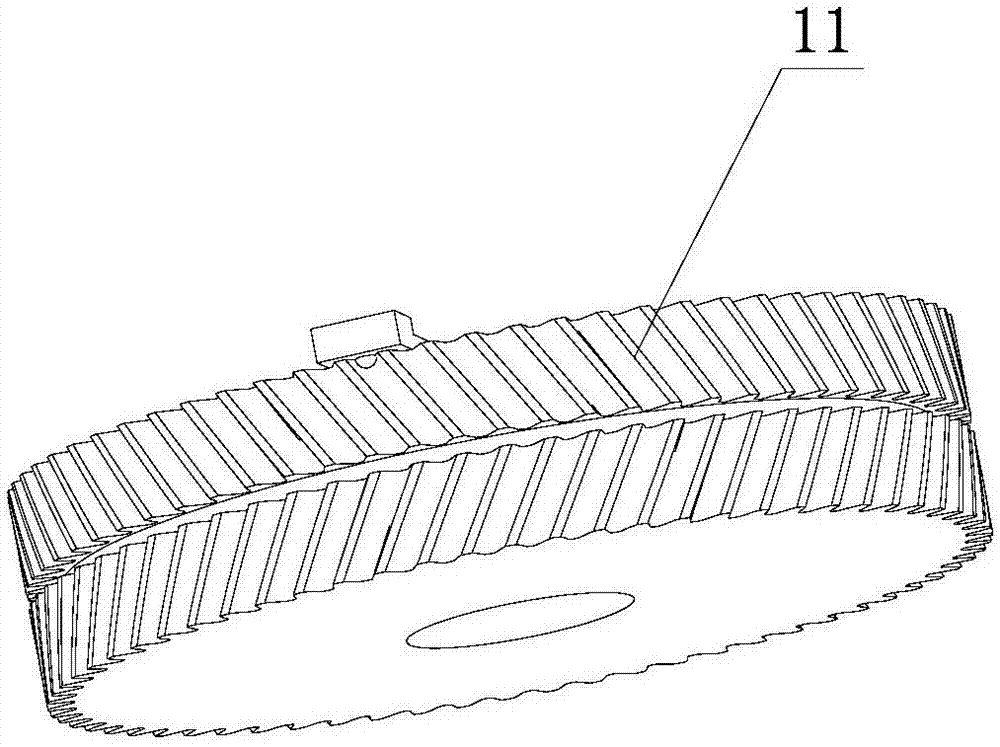

Technology for combining left-handed ring gear and right-handed ring gear into high-precision herringbone gear

ActiveCN111022610ARod spacing error is smallHigh speedPortable liftingGearing elementsGear grindingStructural engineering

The invention provides a technology for combining a left-handed ring gear and a right-handed ring gear into a high-precision herringbone gear. The technology comprises the following steps of gear grinding machining conducted on the left-handed ring gear and the right-handed ring gear, the combining technology for combining the left-handed ring gear and the right-handed ring gear into the high-precision herringbone gear and the specific adjustment process and a technique for recovering the high-precision herringbone gear again after disassembly. The technology improves the adjustment method forcombining the left-handed ring gear and the right-handed ring gear into the high-precision herringbone gear, improves the centering degree and tooth portion precision of the herringbone gear and guarantees the precision of the reassembled herringbone gear after disassembly.

Owner:HUNAN NANFANG AVIATION HIGH ACCURATE DRIVE

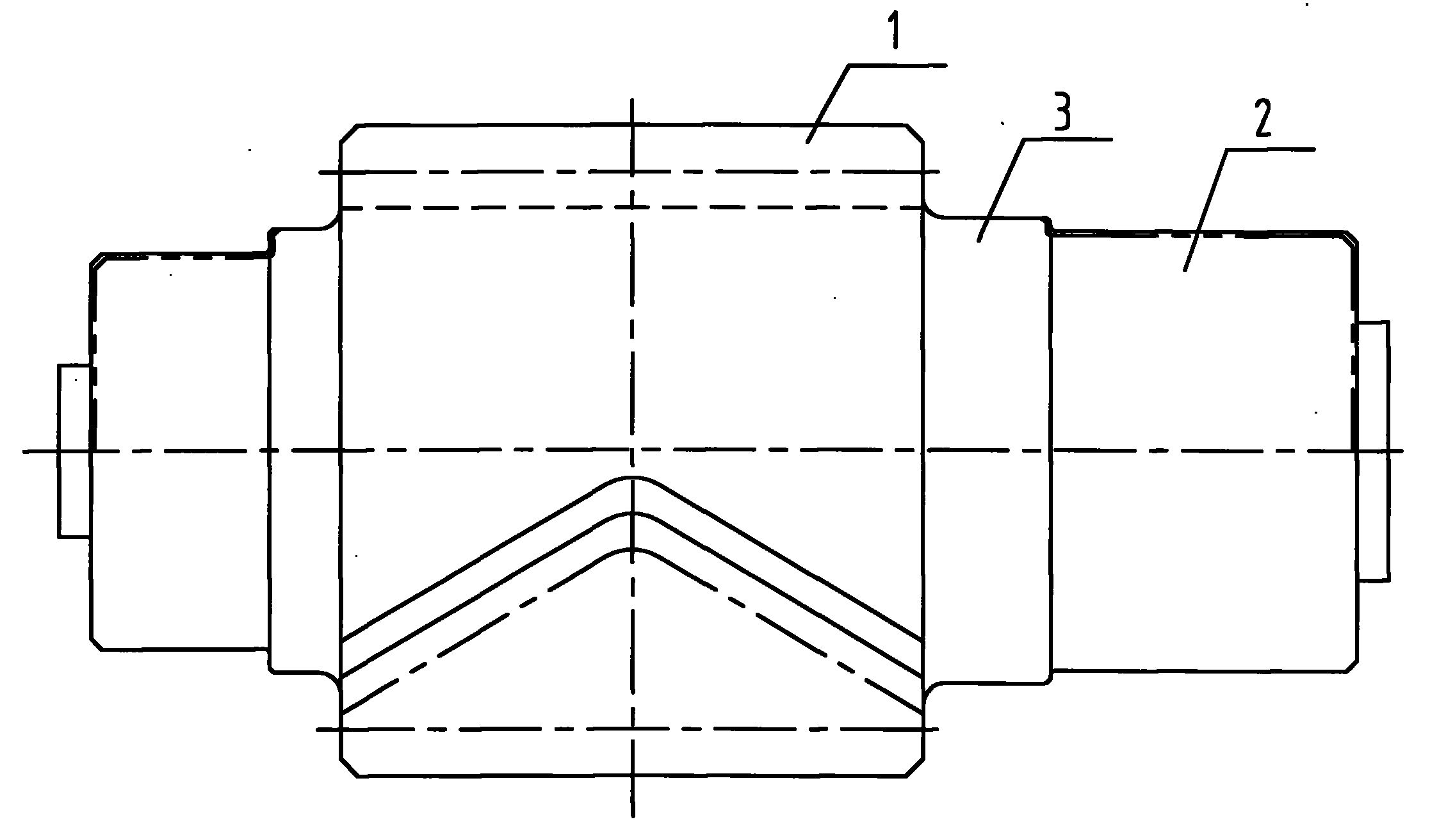

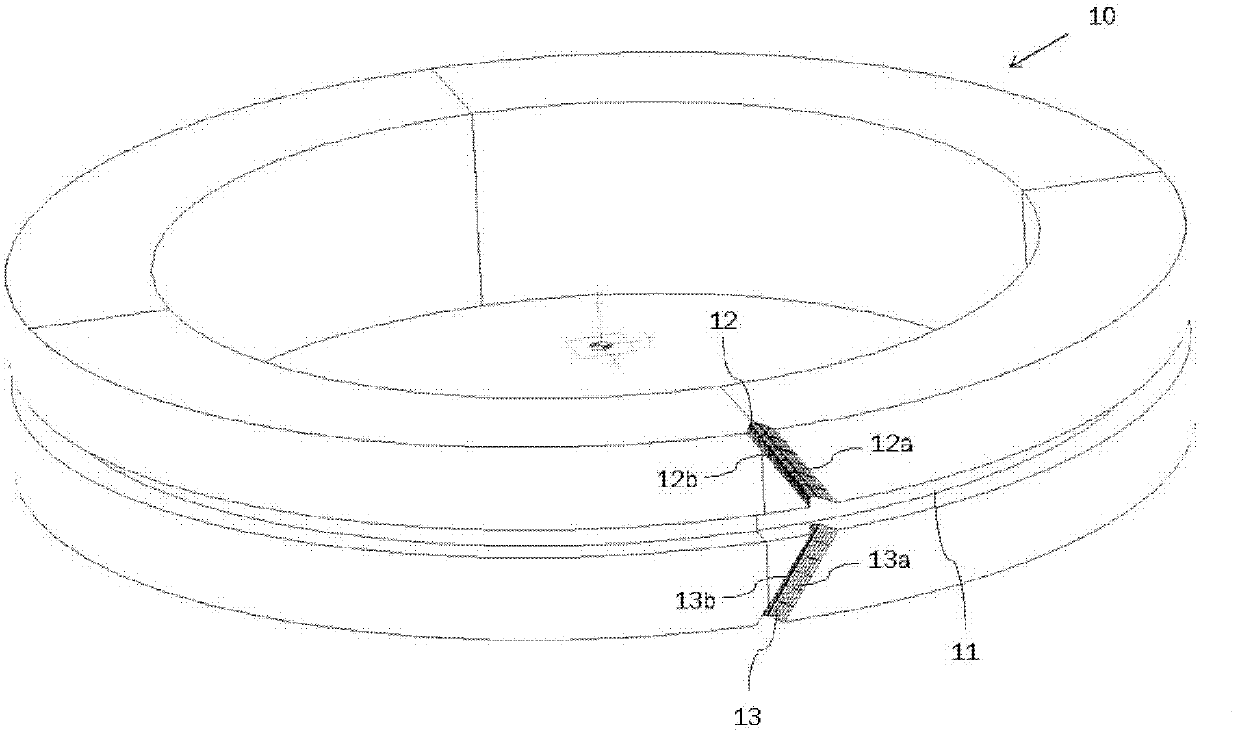

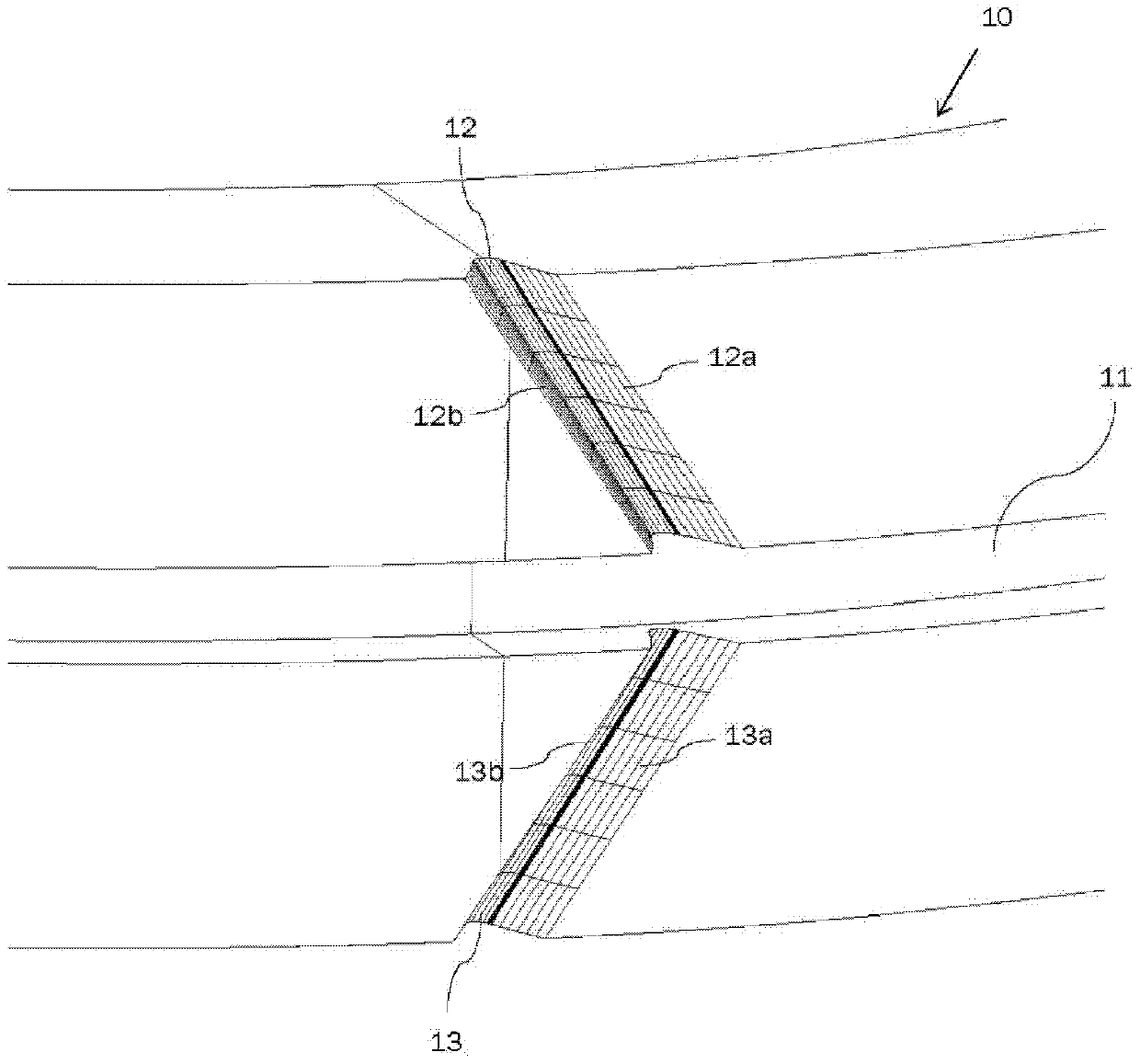

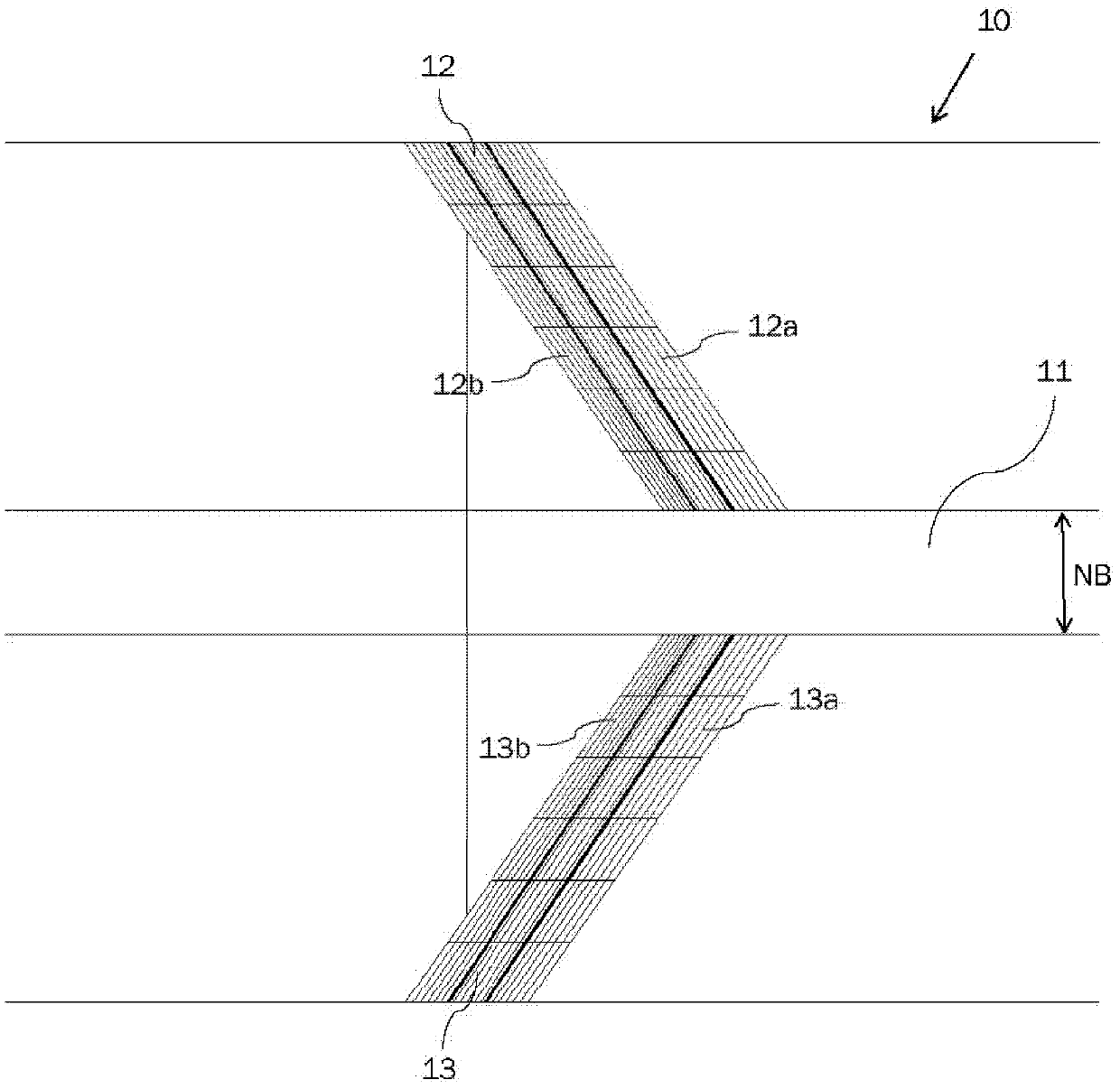

Method for producing cogged wheel with herringbone gearing and method and device for generating control data

ActiveCN102416507AReduce processing timeStrongProgramme controlTotal factory controlNumerical controlControl data

The invention relate to a method which is used to generate a cogged wheel with a herringbone gearing 10. The invention includes a device for producing control data comprising a geometry modeling unit, a numerically controlled, 4-axle machine tool comprising a control data producing device a computer program product comprising a computer program for executing a method for producing control data. A process and an apparatus for generating control data, wherein a first tooth flank geometry 12b is determined which corresponds to a geometry of a first tooth flank of the herringbone gearing, a second tooth flank geometry 13b is determined which corresponds to a geometry of a second tooth flank of the herringbone gearing, a transition section geometry 14b is determined which corresponds to a geometry of a transition section between the first tooth flank and the second tooth flank, an overall tooth flank geometry 12b, 13b, and 14b is determined which comprises the first tooth flank geometry 12b, the transition section geometry 14b and the second tooth flank geometry 13b, and the control data is generated based on the overall tooth flank geometry 12b, 13b, and 14b and machining paths are indicated, each extending transversely to the profile direction of the tooth flanks and along the first tooth flank geometry 12b, the transition section geometry 14b and the second tooth flank geometry 13b.

Owner:DECKEL MAHO PFRONTEN GMBH

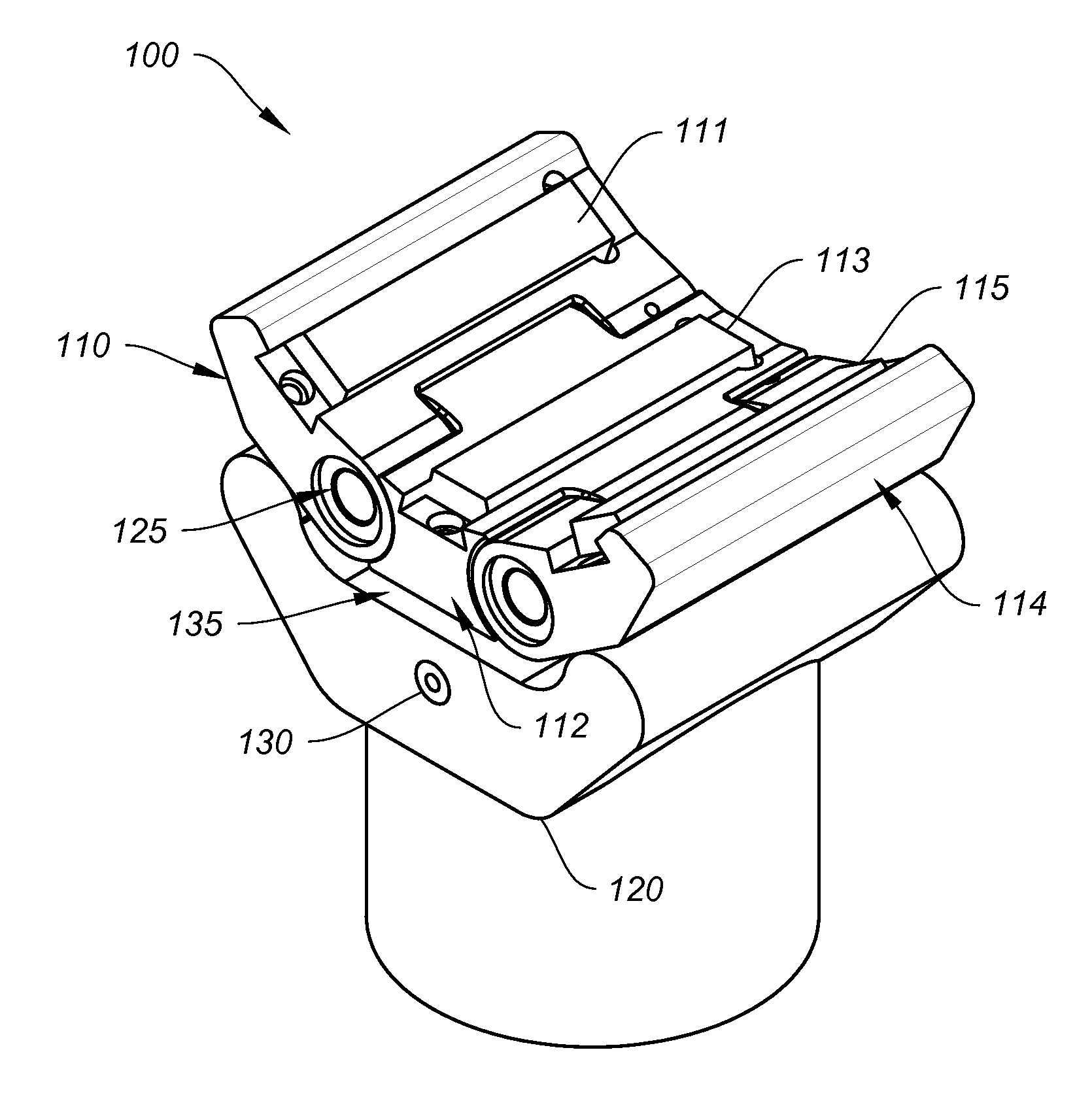

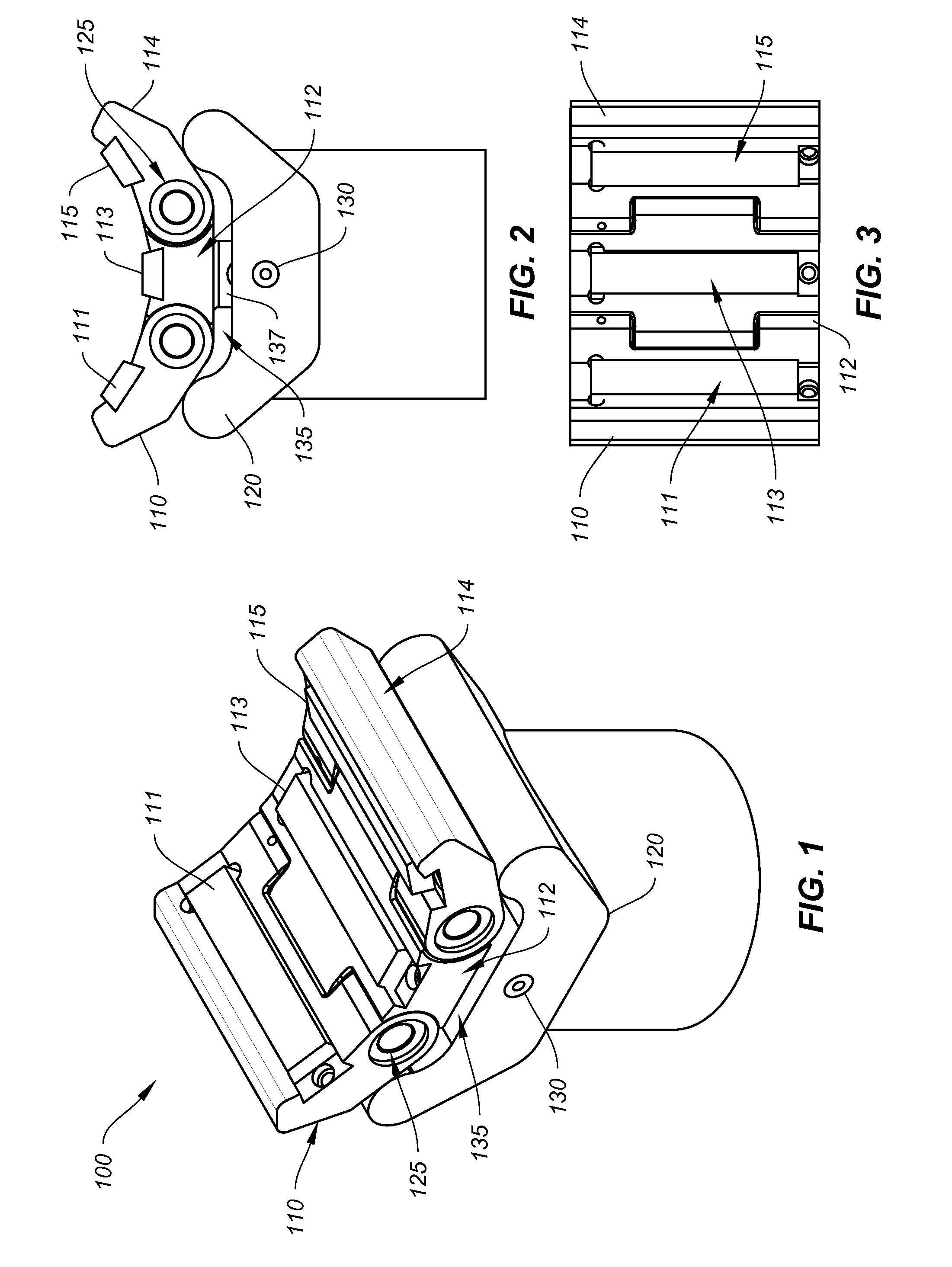

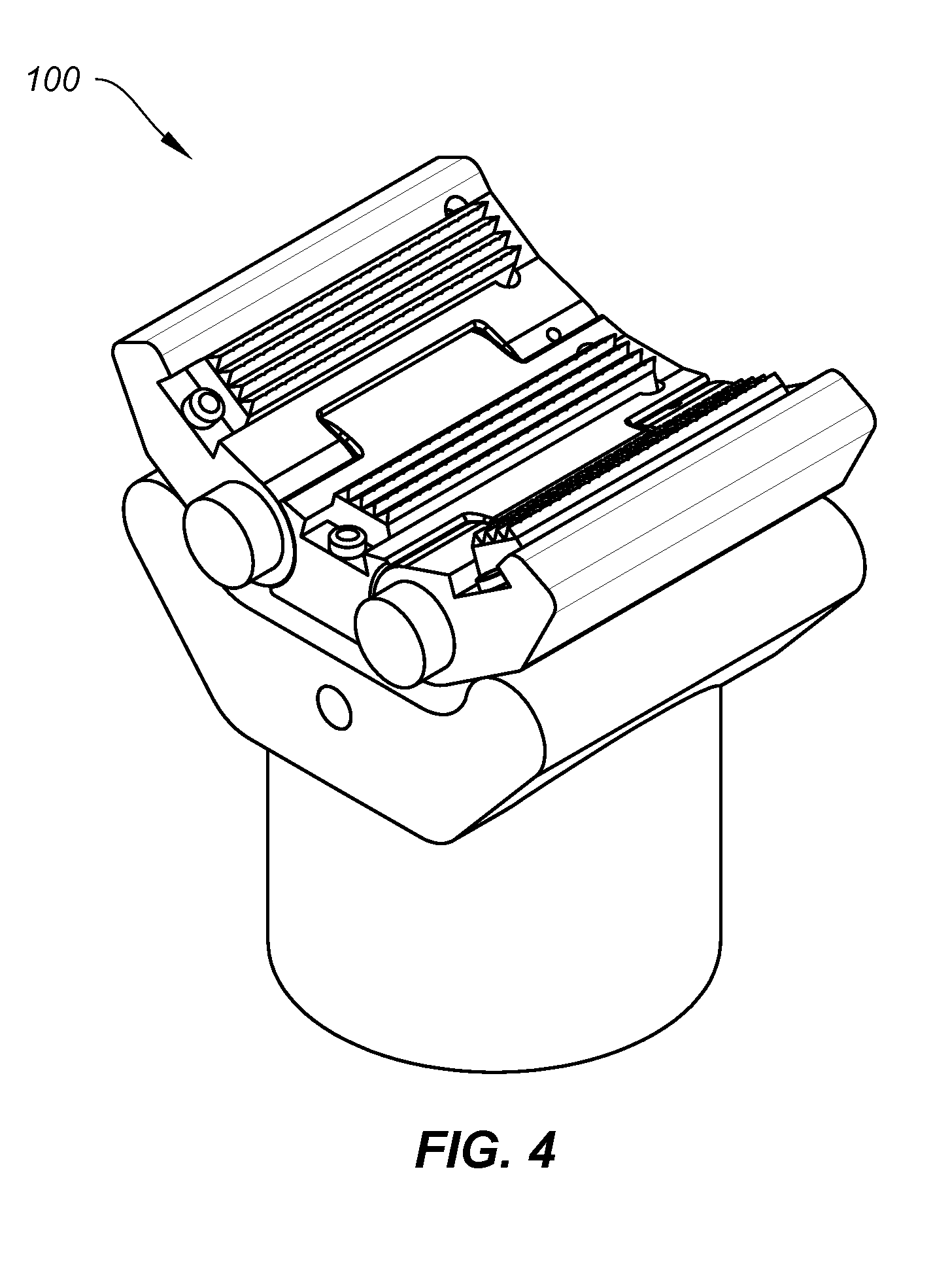

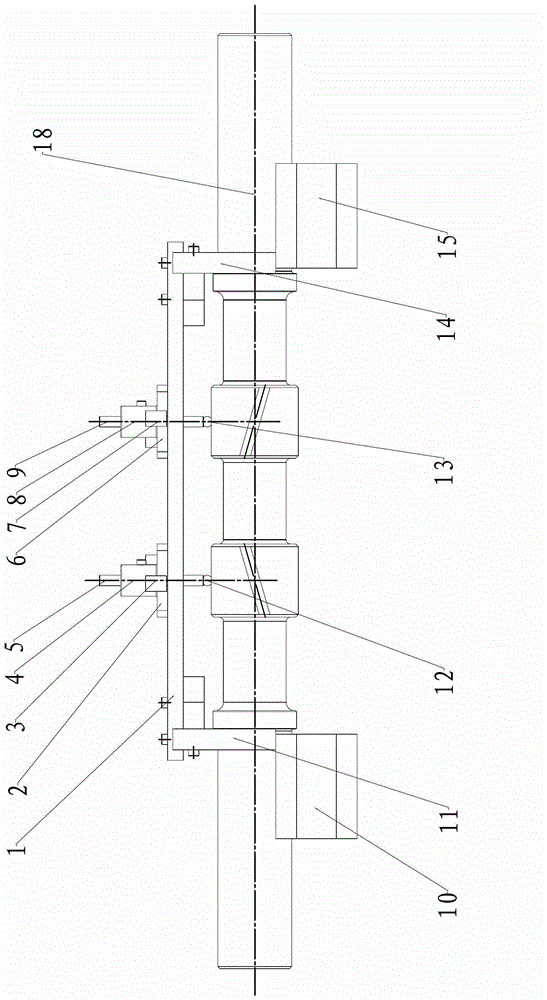

Variable diameter pipe clamp apparatus and torque module therefor

A combination for making up and breaking out pipe at an oil rig site includes a torque module and at least one pipe clamp apparatus. The torque module includes a pair of hydraulic motors, a torque transmission driven by the motors, a herringbone gear segment driven by the transmission to rotate the torque module, and a pair of clamp cylinders actuated by the transmission. The at least one pipe clamp apparatus is actuated by at least one of the clamp cylinders to apply a uniform gripping load around a pipe that is pipe diameter independent.

Owner:BERTELSEN JEFFREY LEE

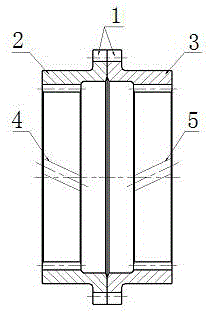

Symmetry degree measurement device for herringbone gears

ActiveCN102944167AReasonable structureQuick measurementAngles/taper measurementsMeasurement deviceHerringbone gear

The invention relates to a symmetry degree measurement device for herringbone gears, particularly relates to a device used for measuring the symmetry degree of two herringbone gears on a herringbone gear shaft, and belongs to the technical field of herringbone gear symmetry degree measurement. The device comprises a beam plate, a first sliding block, a first locking block, a first guide column sleeve, a first guide column, a second sliding block, a second locking block, a second guide column sleeve, a second guide column, a first V-shaped block, a first positioning plate, a first measuring head, a second measuring head, a second positioning plate and a second V-shaped block. The first guide column sleeve is fixed on the first sliding block, and the first guide column is installed in the first guide column sleeve in a sliding mode. The lower end of the first guide column is connected with the first measuring head. The second guide column sleeve is fixed on the second sliding block, and the second guide column is installed in the second guide column sleeve in a sliding mode. The lower end of the second guide column is connected with the second measuring head. The symmetry degree measurement device is reasonable in structure and quick in measurement, and improves the measuring efficiency; measurement results are accurate and reliable; the device cost is low; and the usage range is wide.

Owner:WUXI WEIFU CHINA ITAL GEAR

Machining method of internal herringbone gear

InactiveCN105563059AGood precisionStable quality and good consistencyGear-cutting machinesGear teethHerringbone gearEngineering

The invention relates to a machining method of an internal herringbone gear. The machining method is characterized in that a centering clamp is machined according to the size of the internal herringbone gear, a gear blank is machined, internal oblique teeth are inserted, machined gear rings are assembled into the internal herringbone gear through the centering clamp, and the internal herringbone gear is placed on a three-coordinate detector so that the centering degree can be metered; and external teeth are rolled and milled at the same time under the combination state, and a mark is made to serve as a mark for assembling. By means of the machining method, the internal teeth are inserted firstly, a sleeve and pressing plate combined tool is adopted to clamp the two gear rings opened oppositely to a sleeve, centering accuracy and precision are high, the working procedures of rolling and milling the external teeth are completed at a time, machining efficiency is improved and labor intensity is relieved. The clamp is simple in structure, easy to manufacture and convenient to assemble and disassemble. The machined internal herringbone gear is high in precision, stable in quality and good in uniformity, the centering degree after the internal herringbone gear is assembled is increased and operation reliability and stability of the herringbone gear in a transmission system are improved.

Owner:HUNAN NANFANG AVIATION HIGH ACCURATE DRIVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com