Method for processing large combination type herringbone gear

A processing method and combined technology, used in metal processing equipment, manufacturing tools, components of boring machines/drilling machines, etc., can solve the problems of difficult to control deformation and deformation of heat treatment, unguaranteed processing quality, and reduced production efficiency. The effect of precision assurance, work efficiency improvement and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

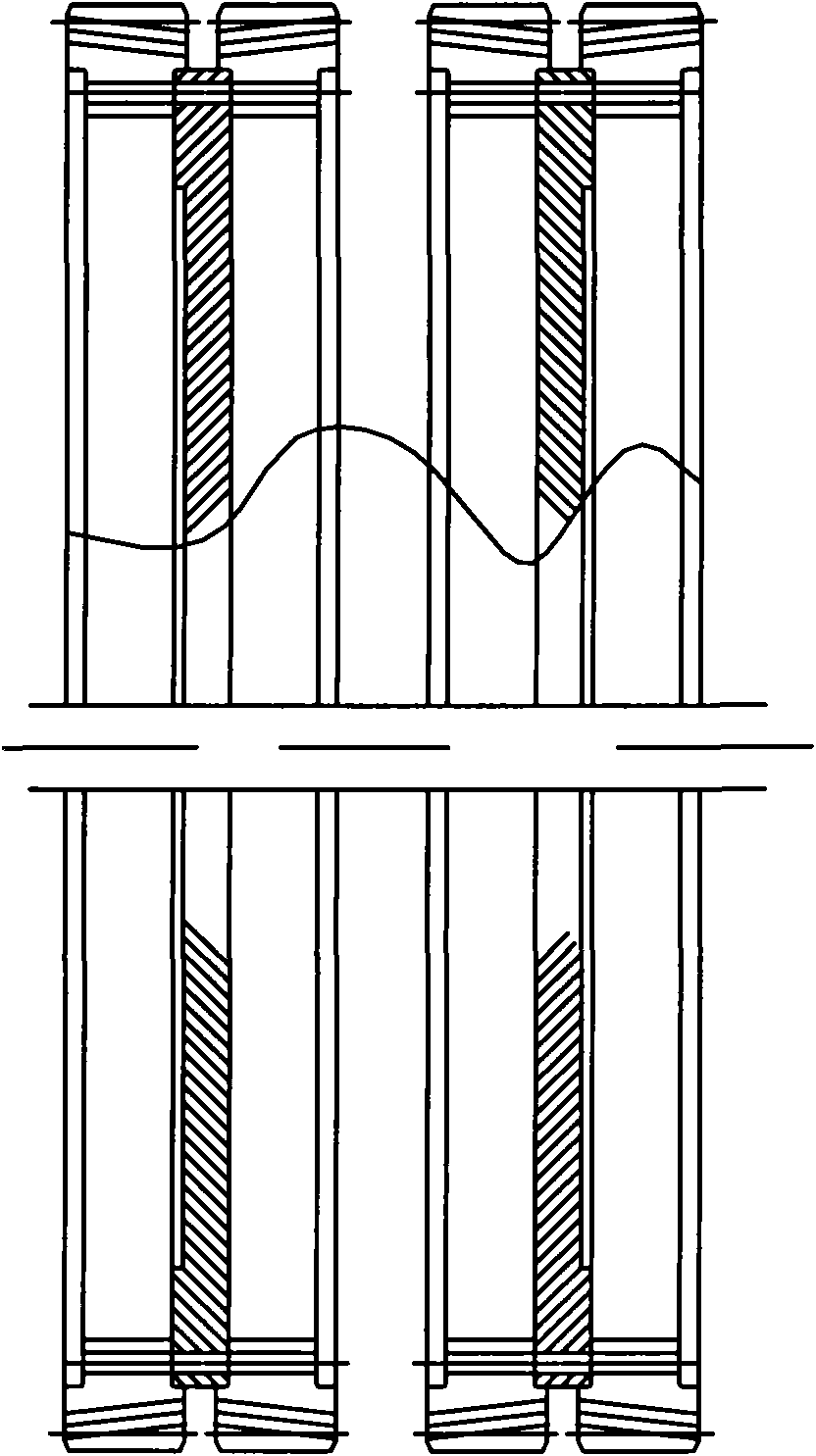

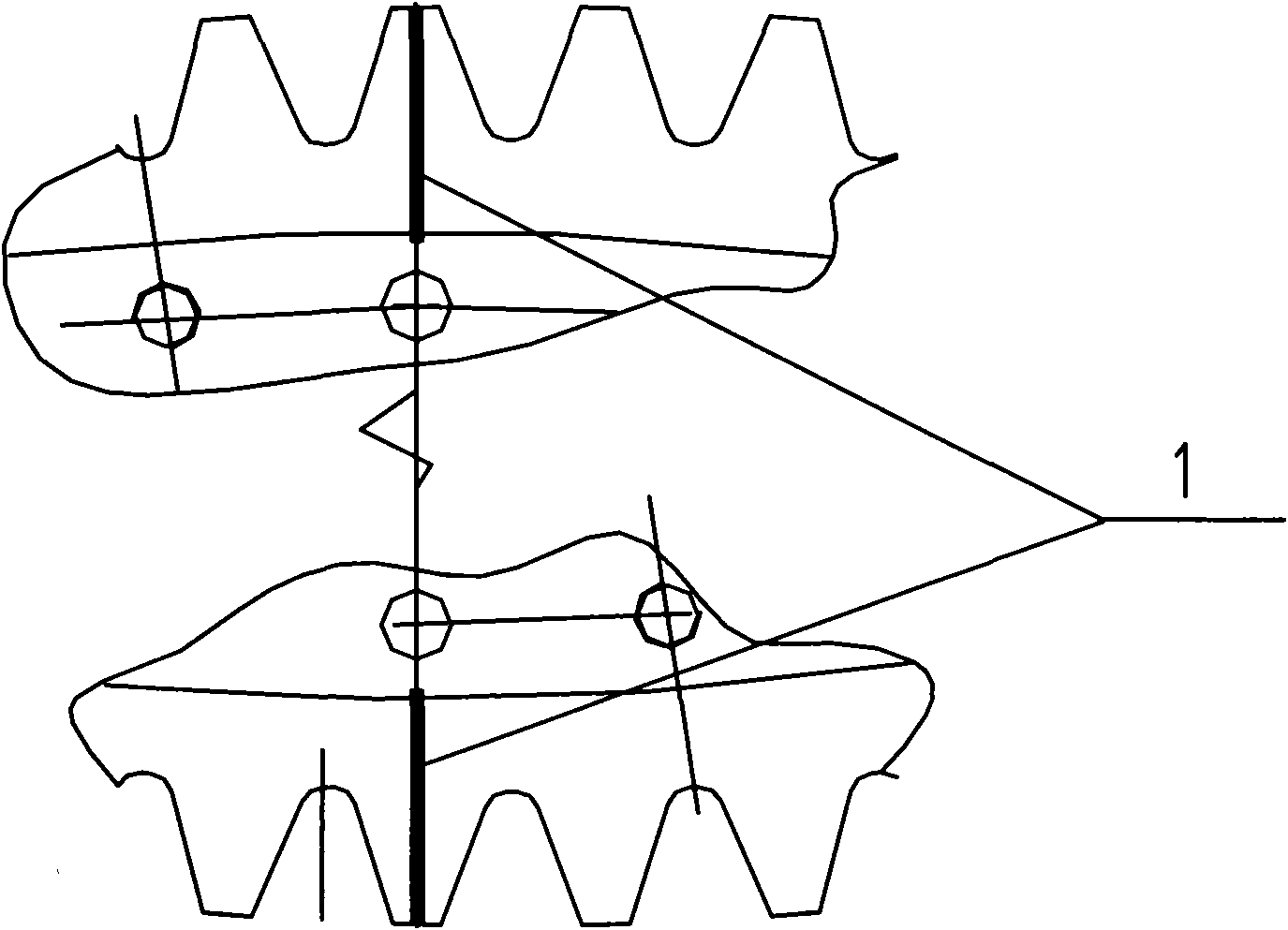

[0028] Such as figure 1 , figure 2 ,with image 3 A specific embodiment of the processing method of a large combined herringbone tooth of the present invention is shown, comprising the following steps:

[0029] A. Forging: Ring forging will be carried out on the prepared materials, and normalizing treatment will be carried out after forging, and a material inspection report will be provided;

[0030] B. Use the lathe for the rough machining of the end face and the inner and outer circles of the prepared materials after processing, and leave a margin of 5mm on each side when turning the inner and outer circles, and leave an allowance of 8mm on both sides when turning the end face;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com