Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Optimize the matching relationship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

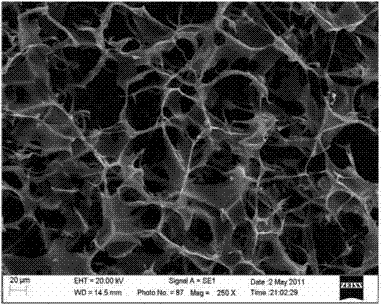

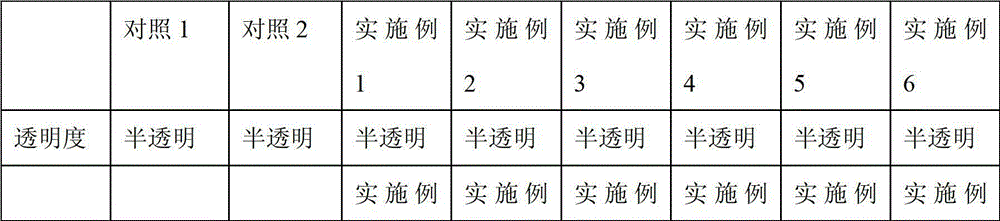

Preparation method of polysaccharide-nanometer bacterial cellulose composite wound dressing

ActiveCN102727926AGood biocompatibilityExcellent cytophileAbsorbent padsBandagesChemistryBiocompatibility Testing

Belonging to the field of biomedical materials, the invention relates to a preparation method of a polysaccharide-nanometer bacterial cellulose composite wound dressing. The method specifically consists of the steps of: taking a nanometer bacterial cellulose membrane for pretreatment and purification treatment so as to obtain purified nanometer bacterial cellulose, then preparing a polysaccharide solution with a concentration of 0.1-10%, removing part of water from the nanometer bacterial cellulose membrane, then compounding it with a polysaccharide solution by means of soaking, tape casting or spraying so as to obtain a polysaccharide-nanometer bacterial cellulose composite membrane, then conducting extrusion dewatering and ionizing radiation disinfection, thus obtaining the polysaccharide-nanometer bacterial cellulose composite wound dressing. The dressing of the invention has the advantages of good biocompatibility, cellular affinity and antibacterial property as well as mechanical property, excellent permeability, breathability or drainage, and moisture absorption effects, and has the efficacy of sterilization, inflammation diminishing, hemostasis, pain relieving, infection reduction and the like. At the same time, the dressing can promote wound surface drying, incrustation and healing, and can be used to treat burns or scalds, open wounds, ulcers, chronic wounds and stubborn infected wound surfaces, etc.

Owner:UNIV OF SCI & TECH BEIJING

A method of processing cobalt-base alloy superfine thin-walled tubes for stents

ActiveCN102363256AHigh dimensional accuracySmooth inner and outer surfacesRoll mill control devicesMetal rolling arrangementsLoad carryingControllability

The invention relates to a forming technology of superfine thin walled tubular products for vessel stents in the field of treatment, specifically to a method of processing cobalt-base alloy superfine thin walled tubes for novel coronary artery stents. The method solves the problems of great difficulty in tubular product processing and low yield of tubular products in a conventional technology. The method for forming finished products comprises the successive technological processes of smelting, forging, hot rolling, hot rolling punching, honing and cleaning of inner surfaces and outer surfaces, annealing, cold rolling / drawing, annealing, and repeated cold rolling / drawing. During overall process of the repeated cold rolling, diameter reducing deformation of the tubular products should be controlled in each pass, and match relationship between the diameter reducing deformation and wall reducing deformation should be well adjusted for guaranteeing that load carrying capability of inner walls does not exceed sigma b (breaking strength) and thus for preventing horizontal microscopic breakage. With rough blanks of the tubular products being acquired in high temperature conditions and the cobalt-base alloy tubular products being acquired through rolling at a room temperature, the processing method guarantees high dimensional precision, bright and clean inner and outer surfaces and excellent mechanical property of the tubular products; and is easy to realize and has high controllability and high economic benefit.

Owner:JIANGSU FENGYUAN MEDICAL DEVICES CO LTD

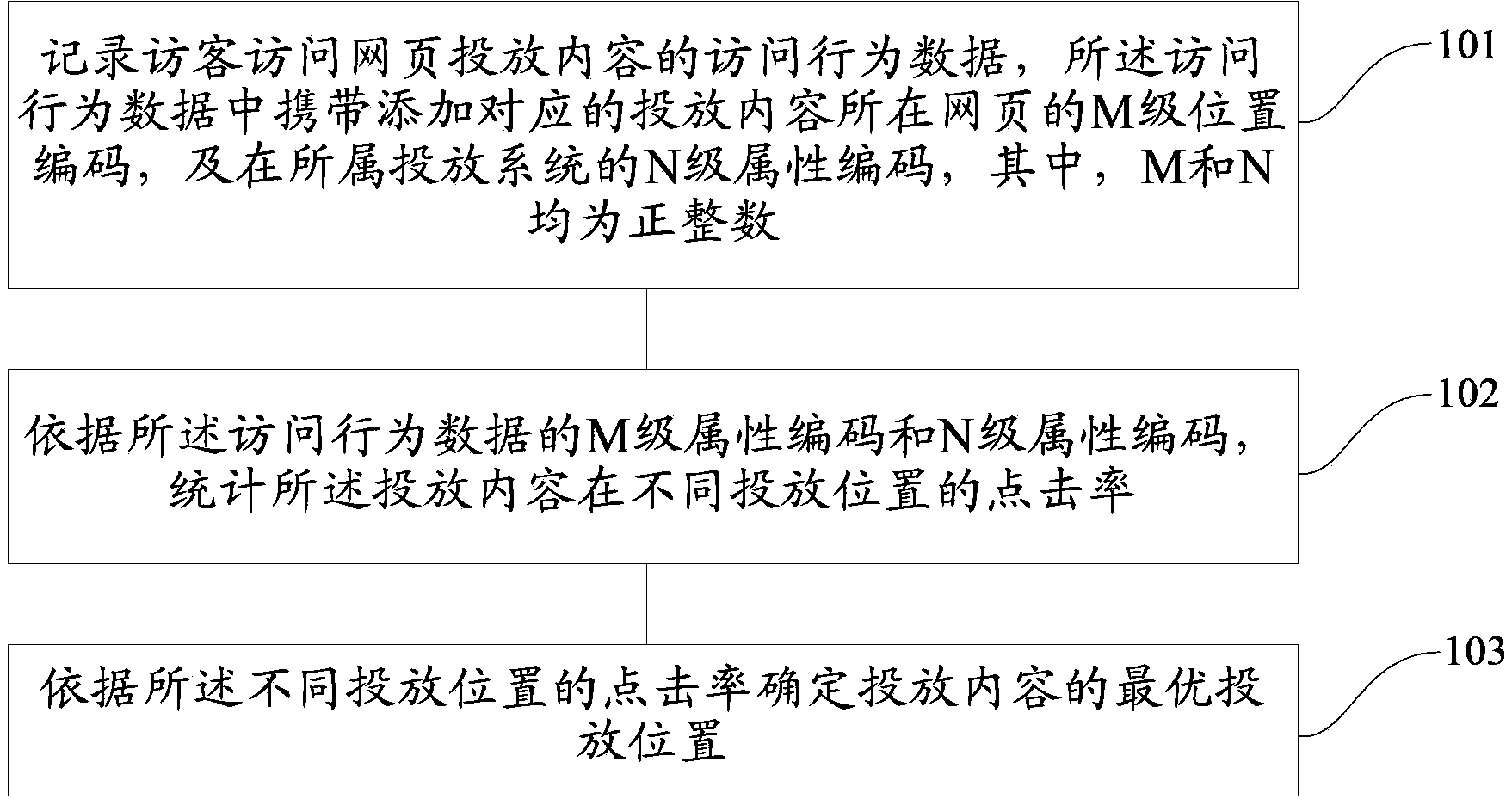

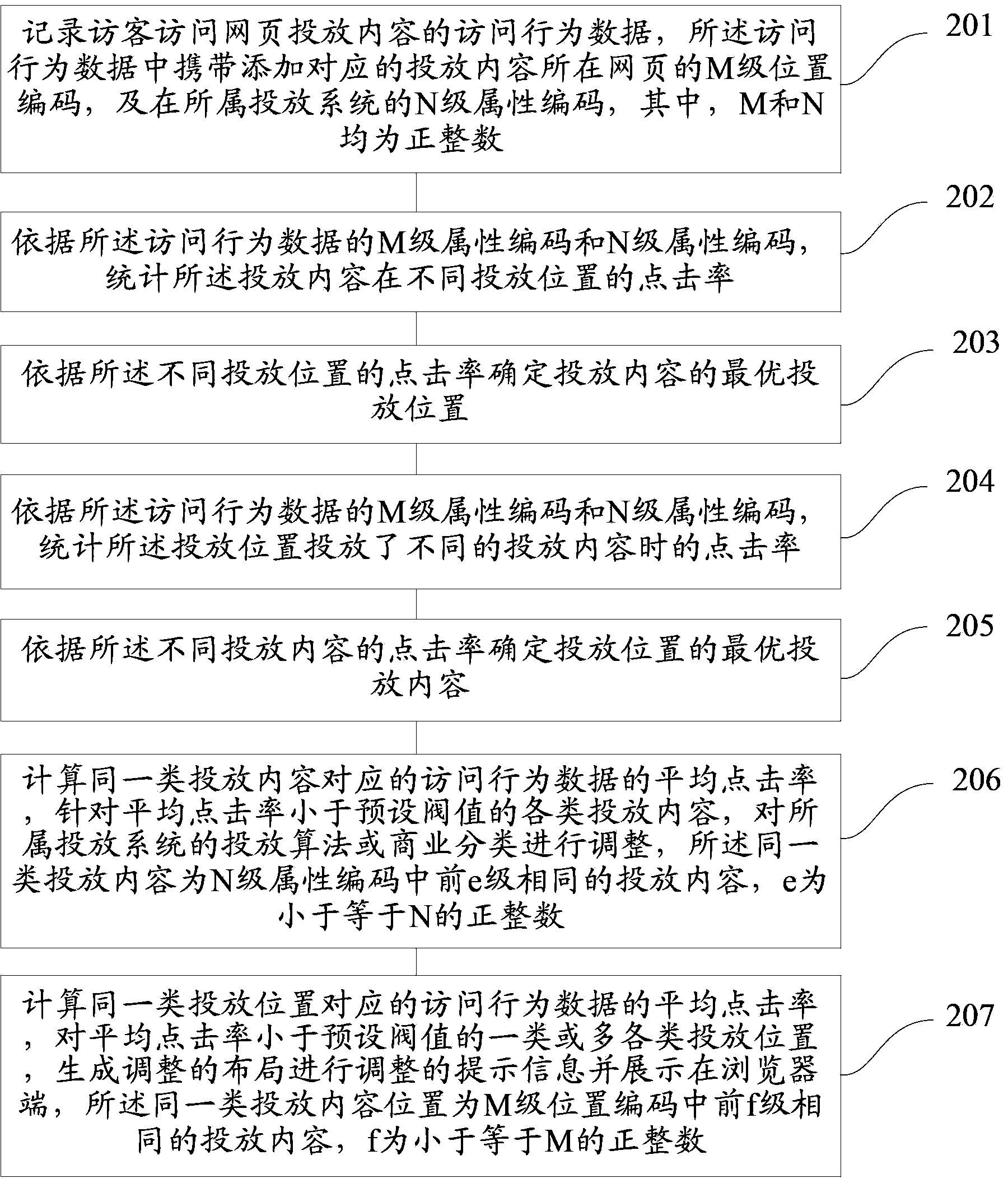

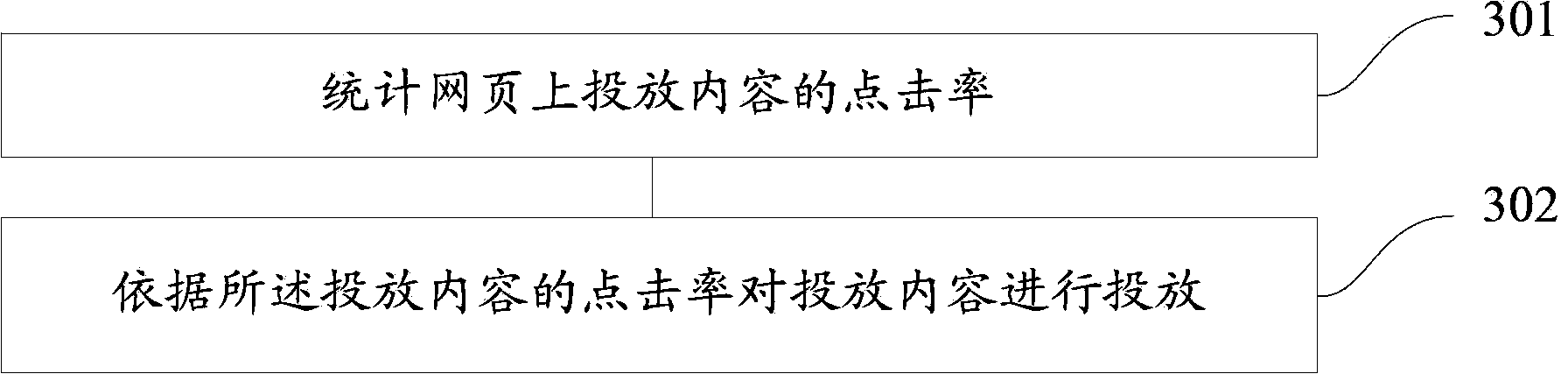

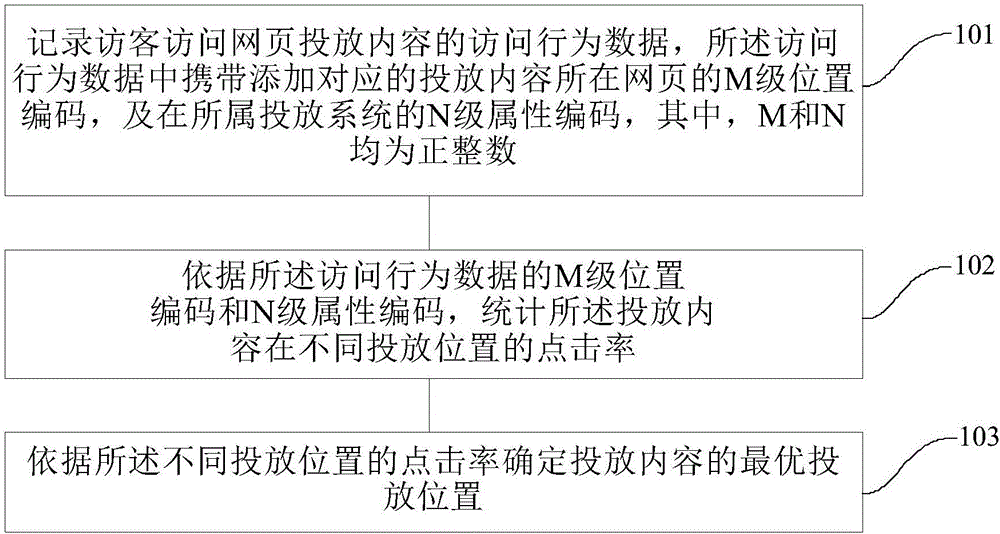

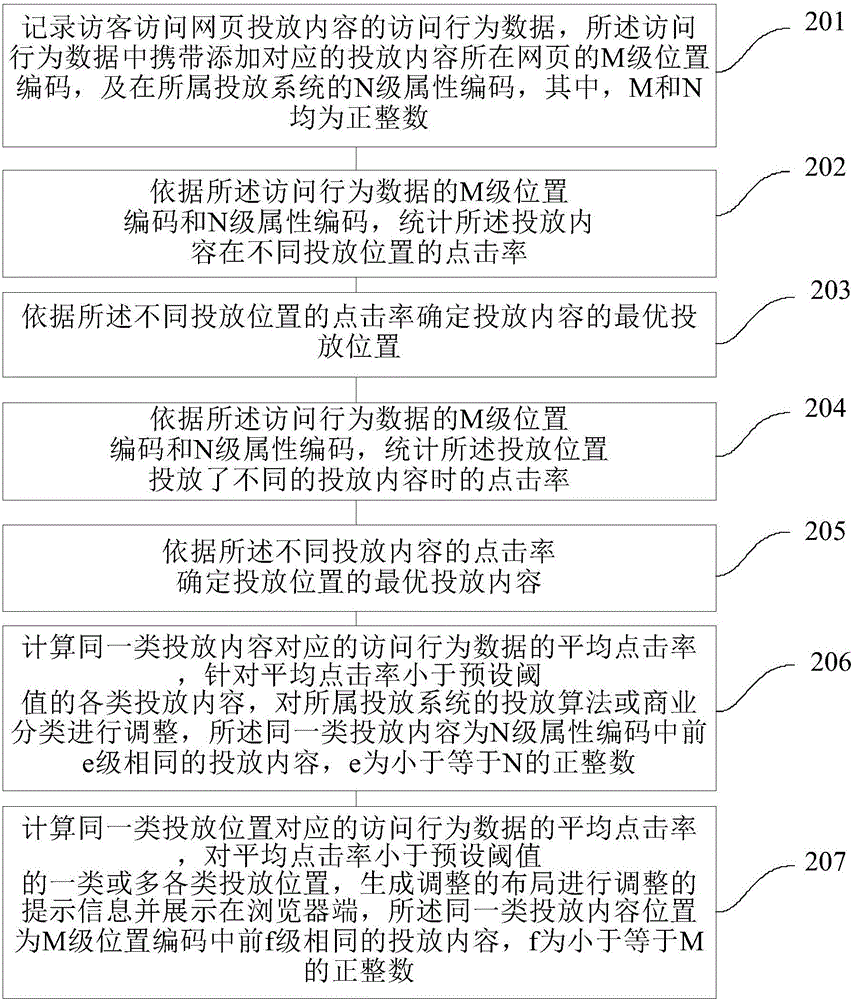

Webpage throwing content analyzing method and device and automatic throwing method and device for webpage throwing content

ActiveCN103778125AImprove click-through rateImprove delivery effectMarketingSpecial data processing applicationsWeb resourceAnalysis method

The invention provides a webpage throwing content analyzing method and device and an automatic throwing method and device for webpage throwing content. The throwing content is thrown on a plurality of webpages through a throwing system of the throwing content. The webpage throwing content analyzing method includes recording access behavior data of a visitor accessing the webpage throwing content, wherein the M-level position code of the webpage of the corresponding throwing content and the N-level attribute code of the throwing system are carried and added in the access behavior data, and M and N are positive integers; conducting statistics on the clicking rates of the throwing content at different throwing positions according to the M-level position code and the N-level attribute code of the access behavior data; determining the optimum throwing position of the throwing content according to the clicking rates at different throwing positions. By means of the method and device, the optimum throwing position of the webpage throwing content can be found, the throwing efficiency of the throwing content is improved, and relevant network resource configuration is optimized.

Owner:ALIBABA GRP HLDG LTD

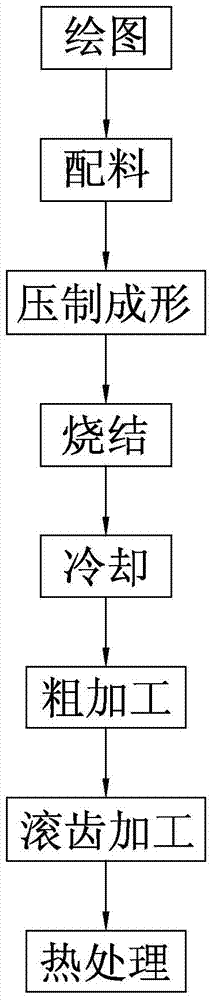

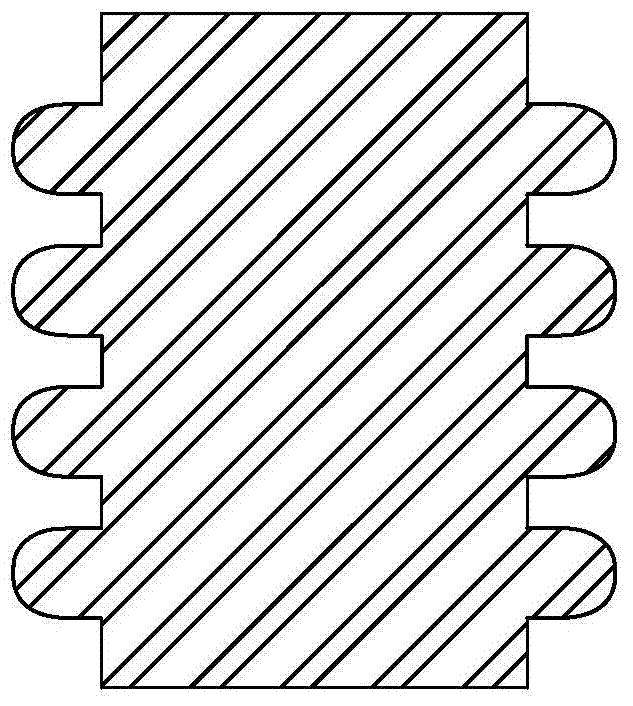

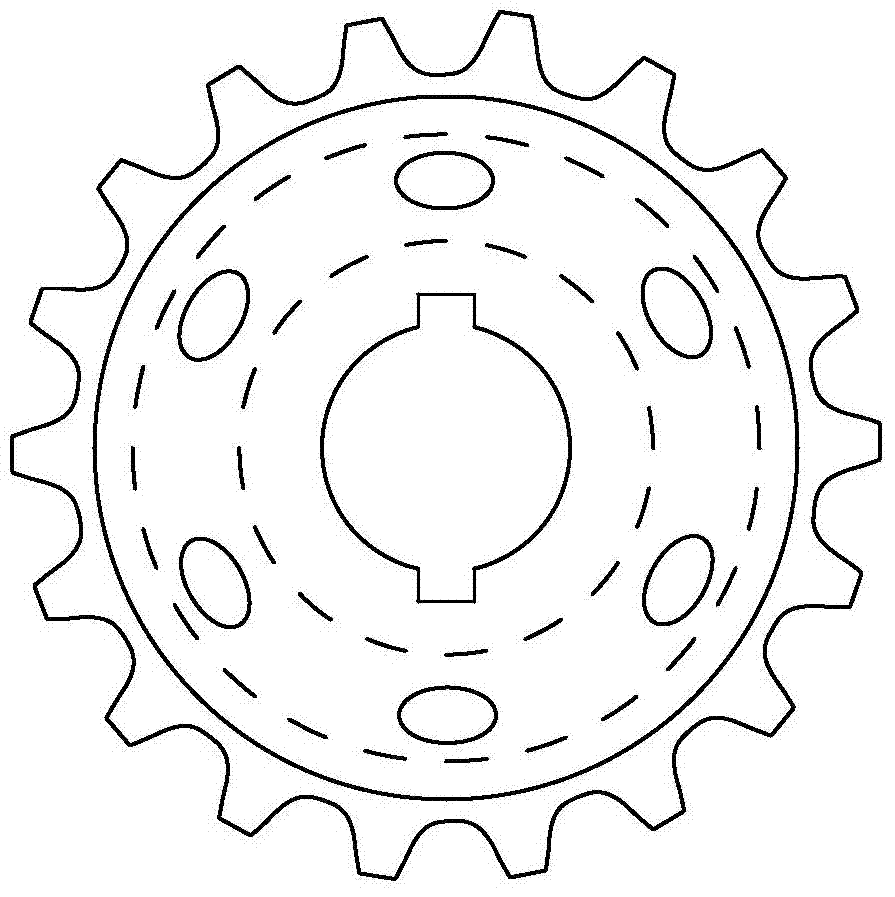

Mechanically actuated chain wheel material, and manufacturing method thereof

ActiveCN103757551AImproved mechanical properties and hardnessUniform hardness distributionAutomotive engineeringSprocket

The invention discloses a mechanically actuated chain wheel material, and a manufacturing method thereof. The mechanically actuated chain wheel material comprises following ingredients: 0.2 to 0.35 part of C, 0.35 to 0.55 part of Si, 0.6 to 0.9 part of Mn, Ni<=0.25 part, Cr<=0.20 part, S<=0.02 part, Al<=0.05 part, P<=0.03 part, Cu<=0.40 part, Mo<=0.05 part, V<=0.03 part, Nb<=0.01 part, Ti<=0.01 part, and the balance Fe. The manufacturing method comprises steps of (a) drawing; (b) material preparaing; (c) compacting and shaping; (d) sintering; (e) cooling; (f) rough machining; (g) gear hobbing processing; and (h) heat processing. According to the manufacturing method, the ingredients above are selected so as to obtain chain wheels with uniform strength. In preparation processes, the ingredients are delivered into a mould; a chain wheel blank material is obtained via upsetting extruding, and is subjected to sintering and cooling, so that the internal part of the mechanically actuated chain wheel material is compact, is high in strength, and is not easily fractured; gear hobbing processing is adopted, so that cost is reduced, and processing cycle is shortened; and phenolic aldehyde cloth base laminates are used, so that wear resistance and corrosion resistance of the chain wheels are increased.

Owner:中山舜人机械制造有限公司

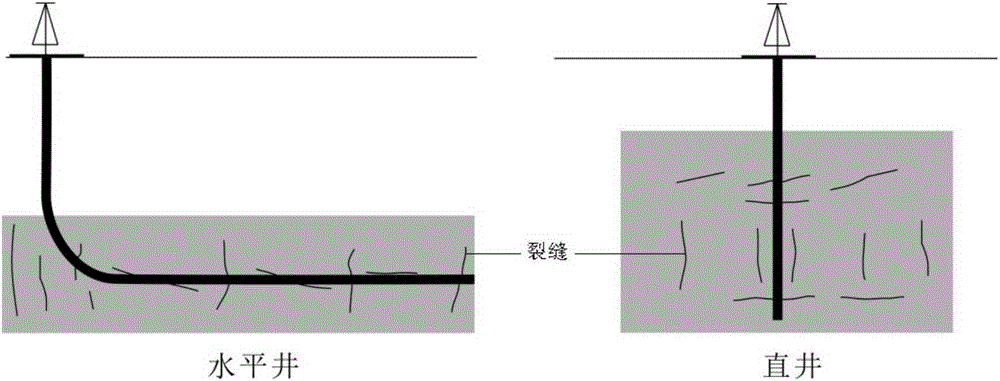

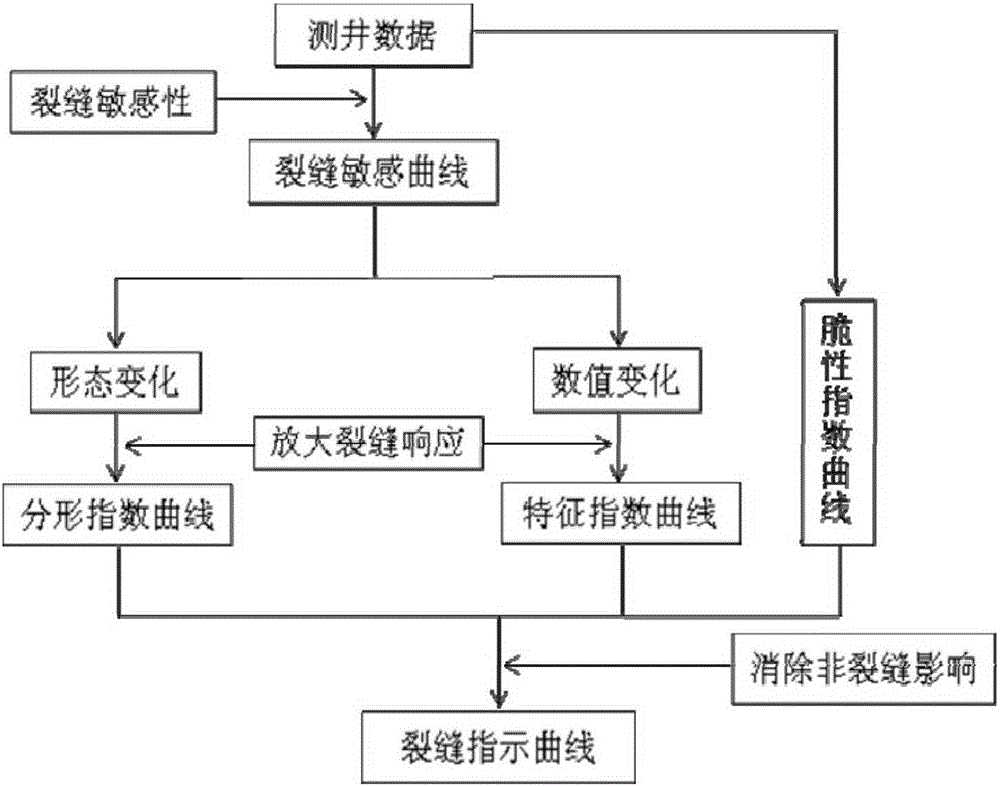

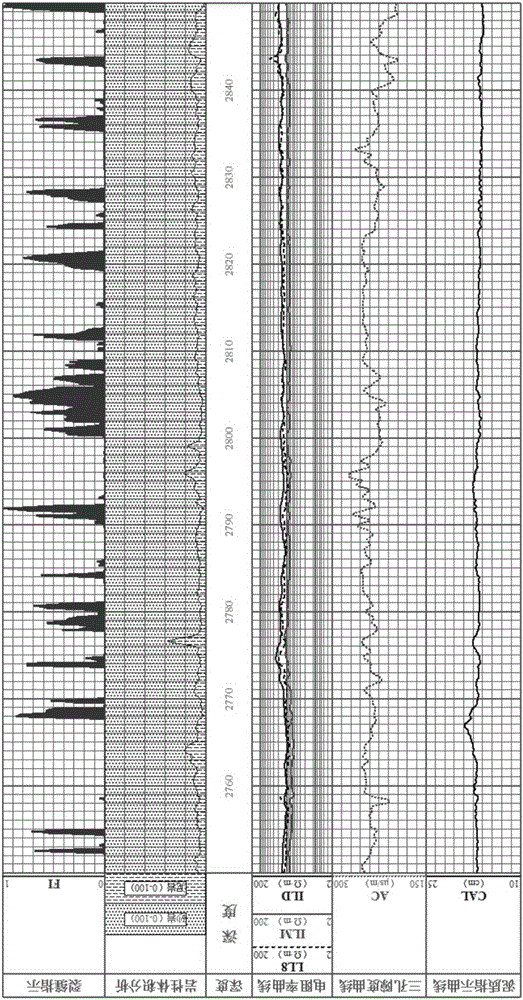

Horizontal well crack recognition method

ActiveCN105317435AOptimize the matching relationshipBorehole/well accessoriesDensity curveWell logging

The invention relates to a horizontal well crack recognition method. The horizontal well crack recognition method comprises the following steps: detecting a horizontal section of a horizontal well to obtain a well logging curve which is sensitive to a crack and a rock density curve, and further reconstructing to obtain a crack fractal index curve, a crack feature index curve and a stratum brittleness index curve; obtaining a crack index curve according to the various curves obtained by reconstruction; and recognizing development degree of the crack of the horizontal well in the horizontal direction according to the crack index curve, wherein the development degree of the crack is increased along with increasing of crack indexes. According to the method provided by the invention, response strength of the crack is amplified by well logging data, non-crack influences are eliminated, crack information is extracted comprehensively from the well logging data, and cracks of the stratum surrounding the horizontal well are recognized accurately.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

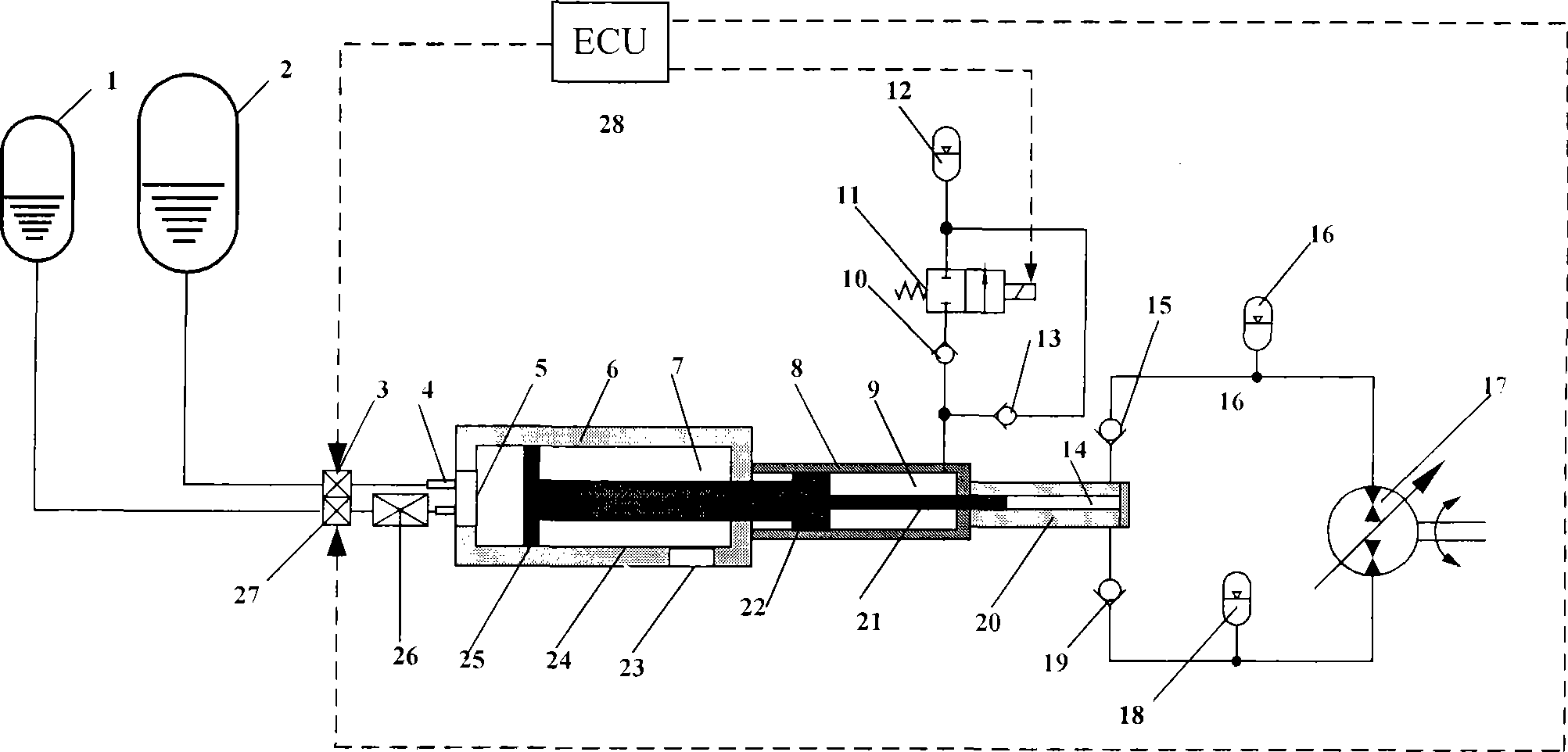

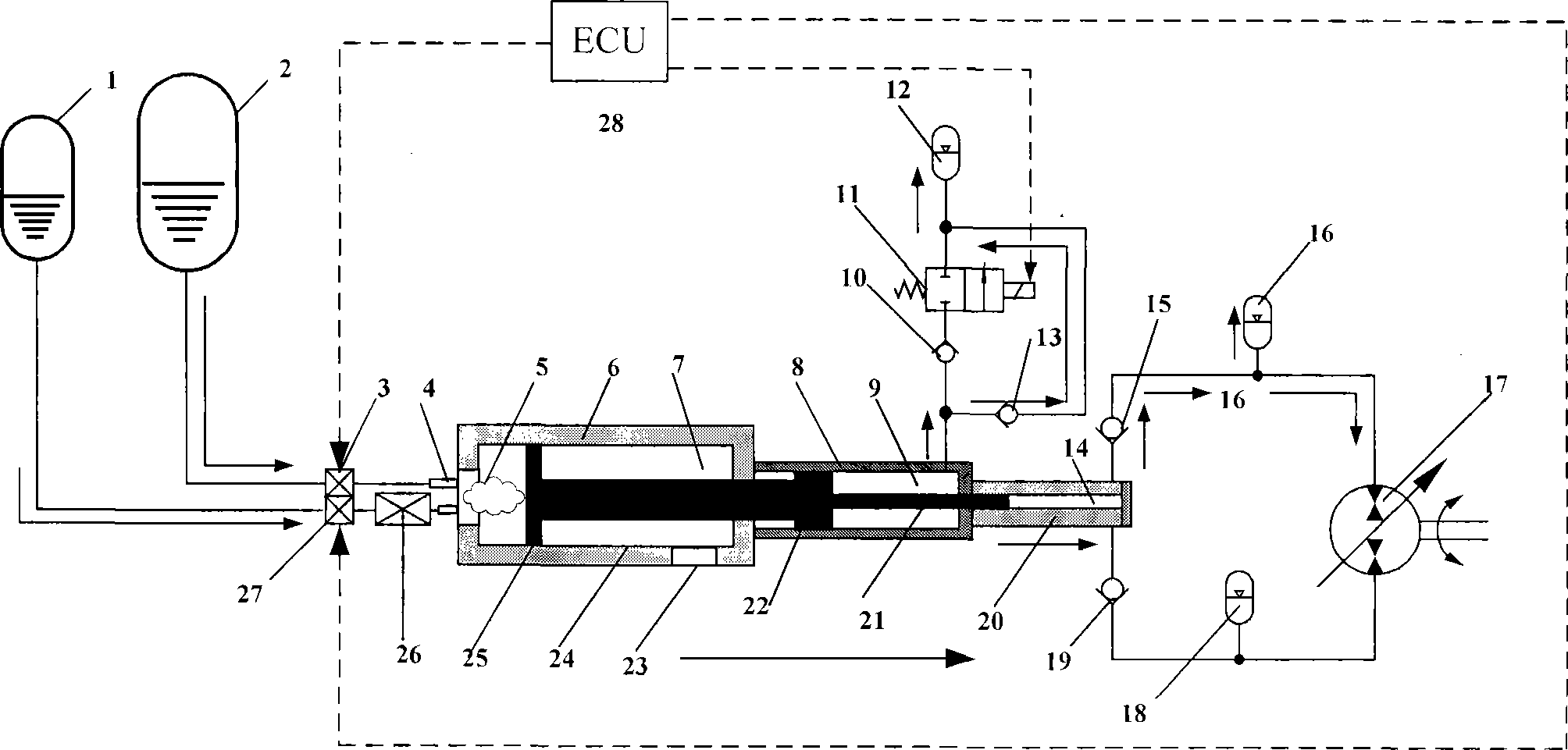

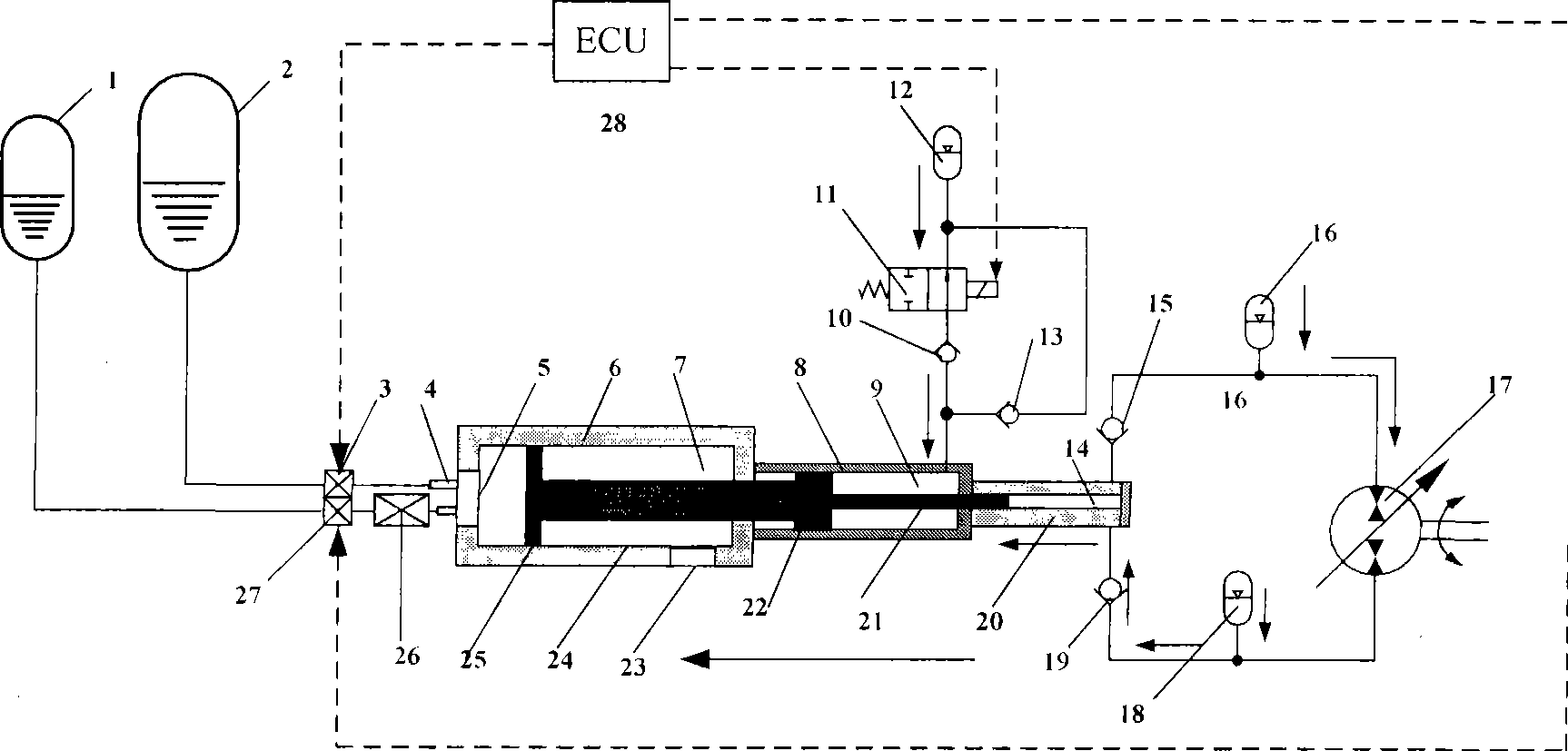

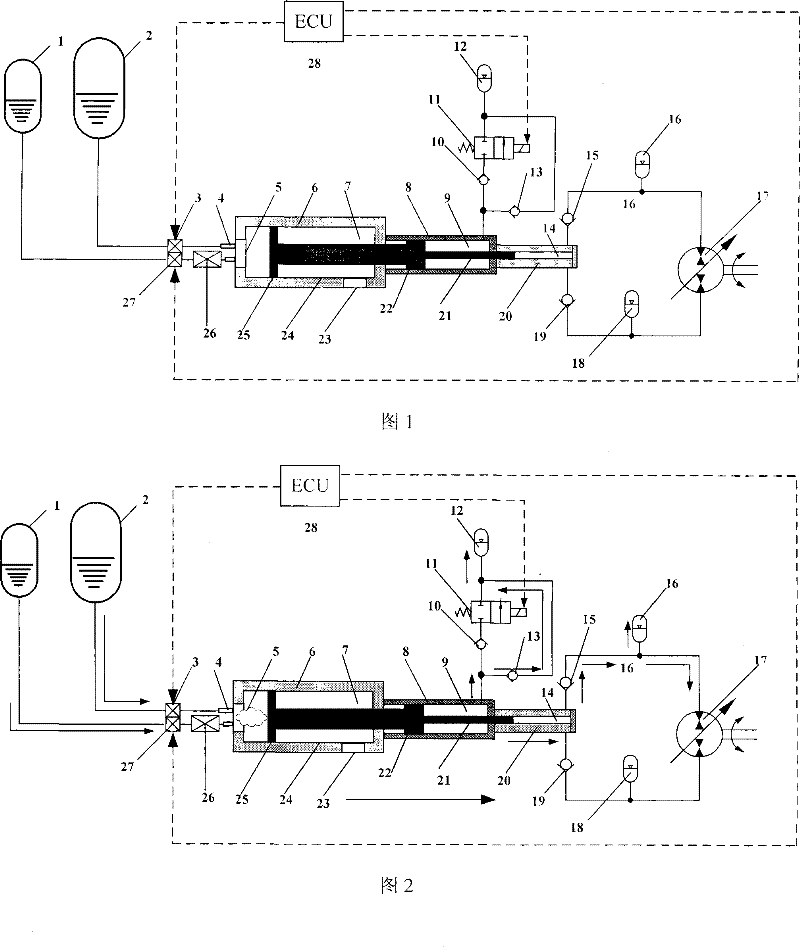

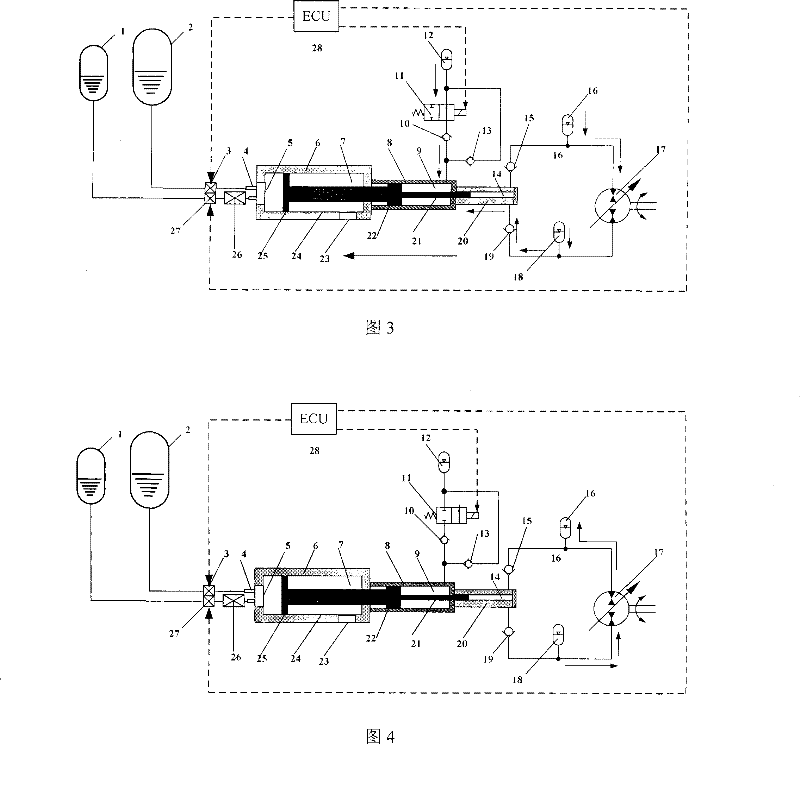

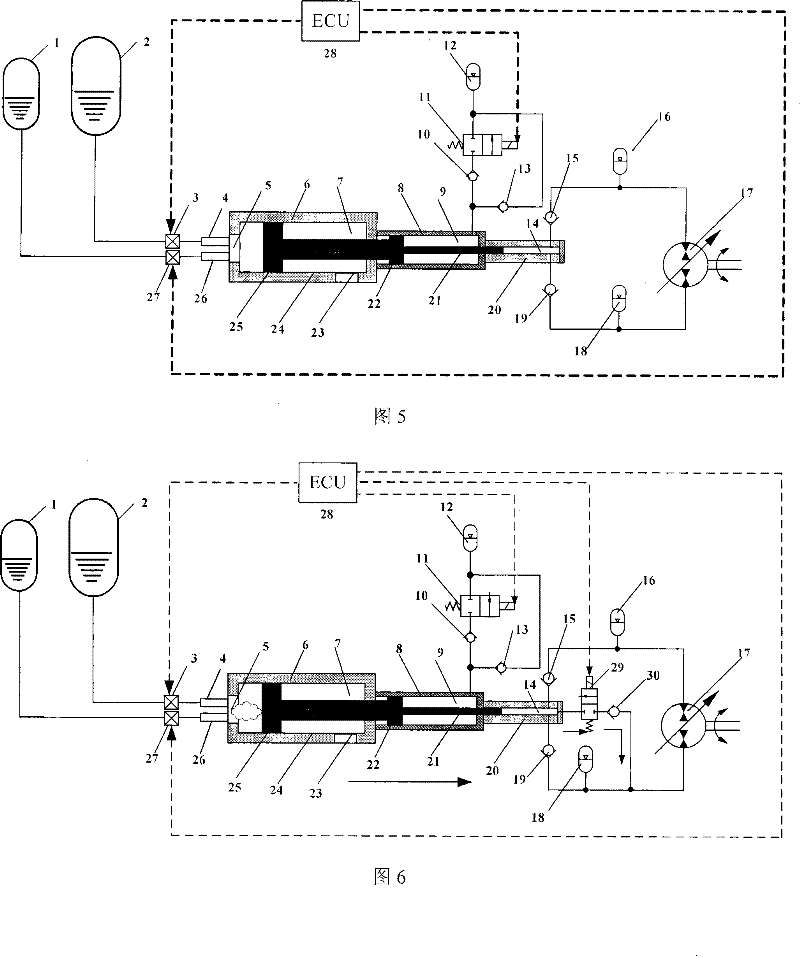

Double-group element single-piston type hydraulic free piston engine

InactiveCN101377150AHigh calorific valueSimple structureFree piston enginesFree-piston engineHigh energy

The present invention relates to a double-component single-piston type hydraulic free-piston engine, which comprises a single-piston hydraulic free-piston engine, an oxidizer storage tank, a fuel agent storage tank, an oxidizer control valve, a fuel agent control valve and an electronic control unit; wherein, both the outlet end of the oxidizer control valve and the outlet end of the fuel agent control valve are communicated with the air inlet of the power cavity of the single-piston hydraulic free-piston engine; the inlet end of the oxidizer control valve is connected with the outlet end of the oxidizer storage tank; the inlet end of the fuel agent control valve is connected with the outlet end of the fuel agent storage tank; and the control end of the oxidizer control valve and the control end of the fuel agent control valve are respectively connected with the corresponding output ends of the electronic control unit. The double-component single-piston type hydraulic free-piston engine, which is characterized by simple structure, reliable operation, wide application range, high energy density, high power density, little moving parts, etc., can operate under various oxygen-deficient or oxygen-free environments, such as plateaus, underwater and outer space, and can realize stroke control and regenerative braking.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Double-sheet spot welding hot stamping method and welding structure thereof

InactiveCN101862947APrevent up and down movementGuaranteed flatnessWelding/cutting auxillary devicesAuxillary welding devicesHot stampingSpot welding

The invention discloses a double-sheet spot welding hot stamping method, which comprises the following steps: firstly, welding two sheets made of the same material together to enable the two sheets to be completely attached; secondly, heating two welded sheets to be over 900DEG C to enable the two sheets to form an austenite structure; and finally placing the two heated sheets in the same die for hot stamping to form a part and carrying out pressure maintaining and cooling on the formed part in the die to enable the part to become the austenite structure. For the double-sheet spot welding hot stamping method, the two sheets are welded before hot stamping and the two welded sheets are subject to hot stamping in only one die, thereby saving a stamping die, reducing operation steps and reducing the production cost.

Owner:上海赛科利汽车模具技术应用有限公司

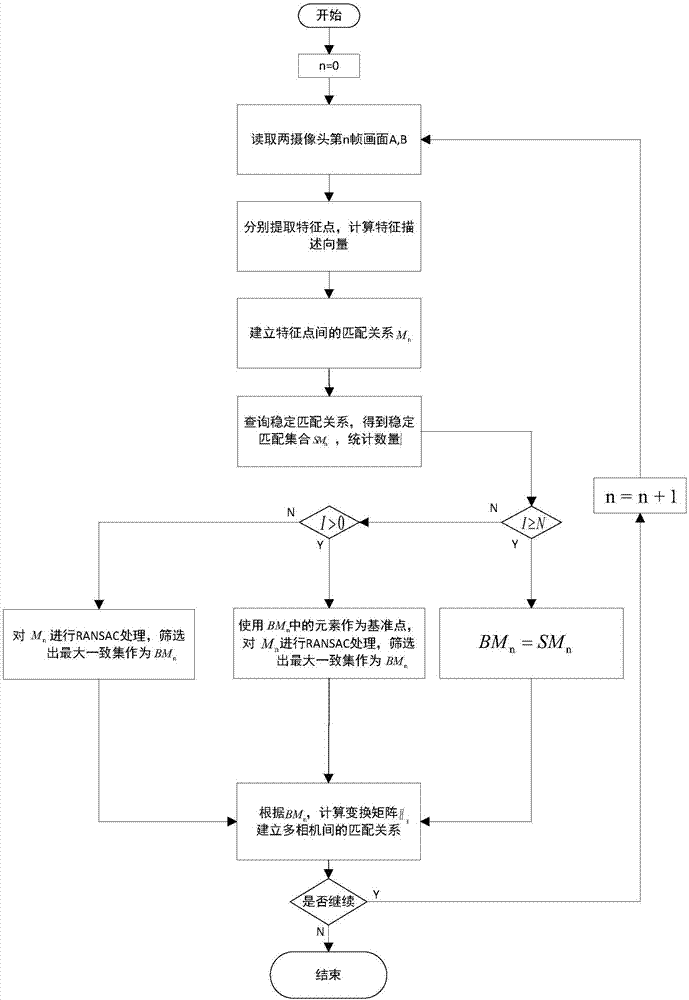

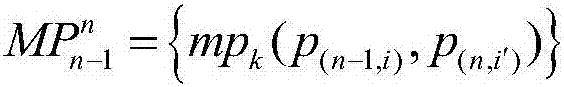

Unrestraint multi-camera picture matching method based on space-time consistency

ActiveCN106887015AOptimize the matching relationshipChanges smoothly and accuratelyImage enhancementImage analysisMulti cameraPrior information

The invention discloses an unrestraint multi-camera picture matching method based on space-time consistency. The method comprises the following steps of reading pictures captured by a reference camera and an auxiliary camera; extracting characteristic points of a current picture; calculating the characteristic description vector of each characteristic point; performing similarity comparison of the characteristic description vectors and establishing matching relations of corresponding characteristic points; querying stable matching relations in the matching relations, and according to the number of the stable matching relations, screening characteristic point sets used for calculating a transformation matrix; according to the matching relation of the screened characteristic point sets, calculating the transformation matrix to obtain the matching relation between pictures of the two cameras; and reading a next picture and repeating the abovementioned steps till the end. During the screening of the matching relations, the space-time consistency is fully considered. The effective prior information is obtained by retrieving the stable matching relations and is used for screening the current matching relation, so that the stability of image matching between adjacent frames of the unrestraint camera can be effectively enhanced, and the matching precision and efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

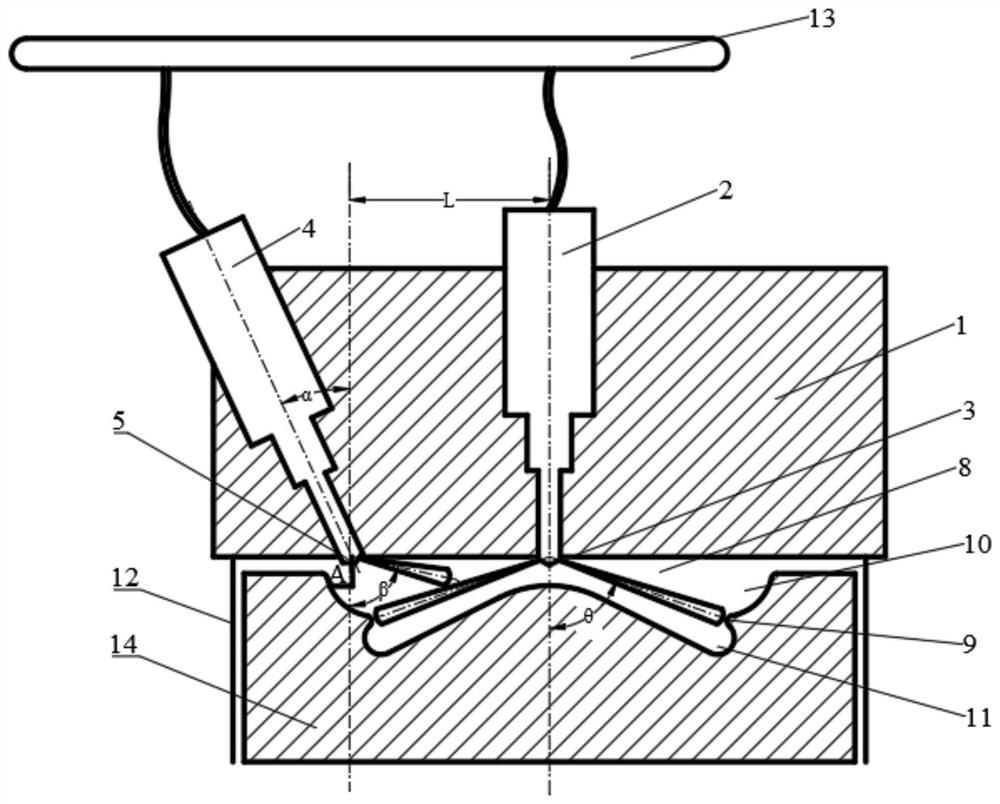

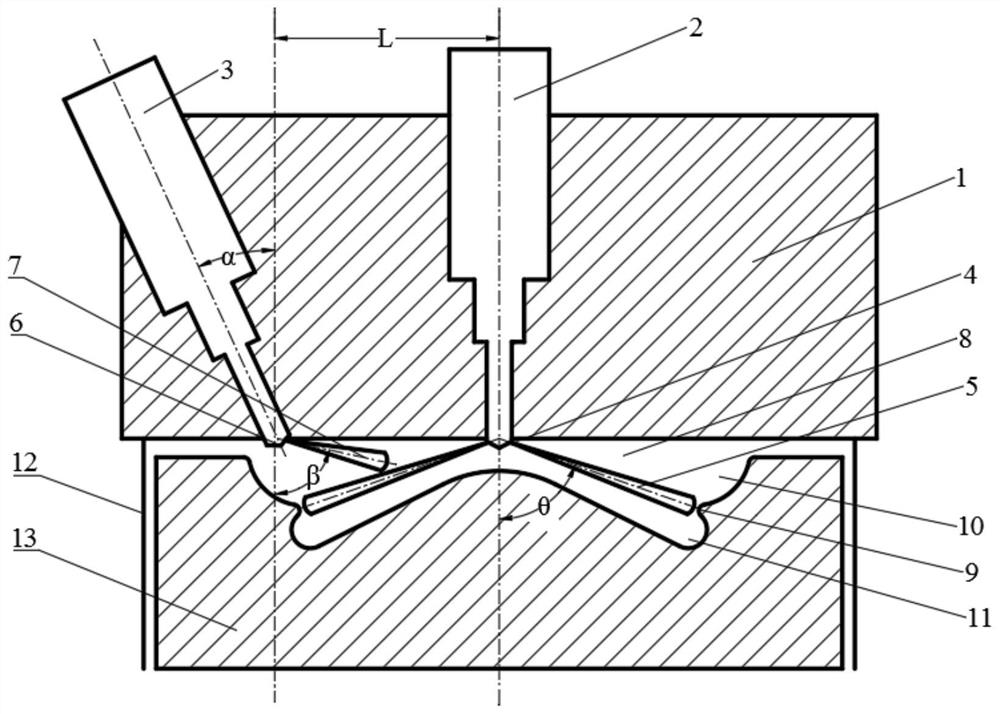

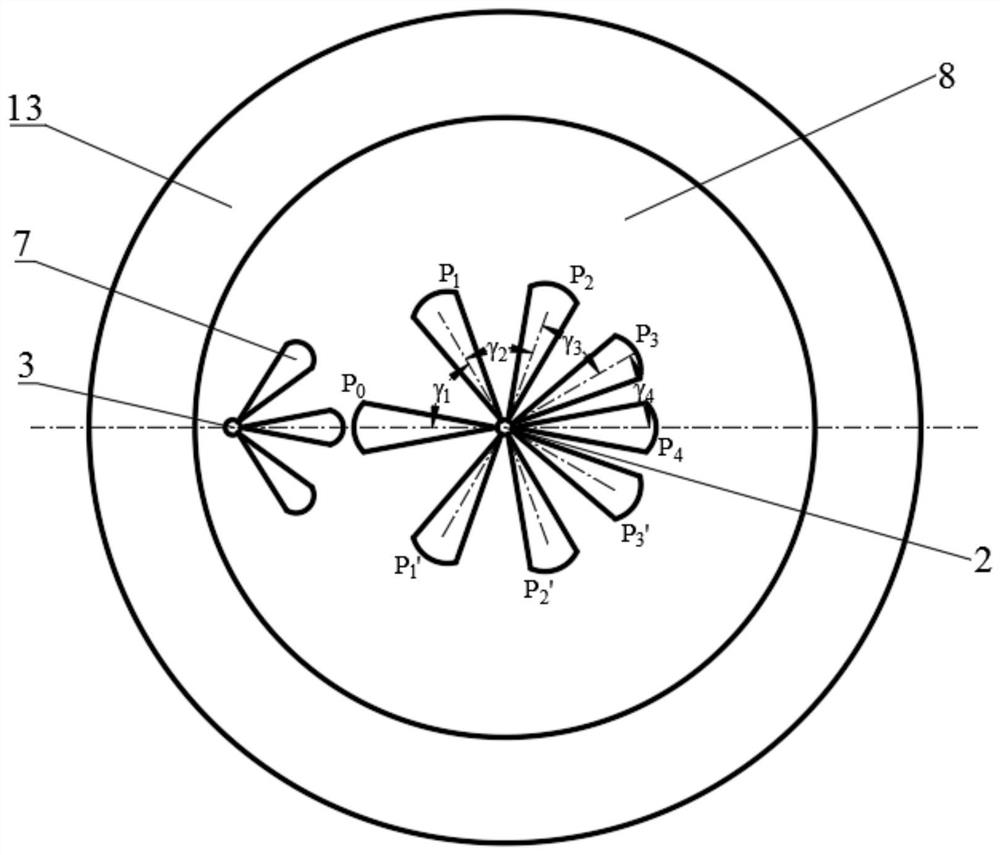

Main and auxiliary oil injection system of high-power-density diesel engine

InactiveCN112879146ASolve the problem of insufficient fuel injection rateHigh power indexInternal combustion piston enginesFuel injection apparatusCombustion chamberInjector nozzle

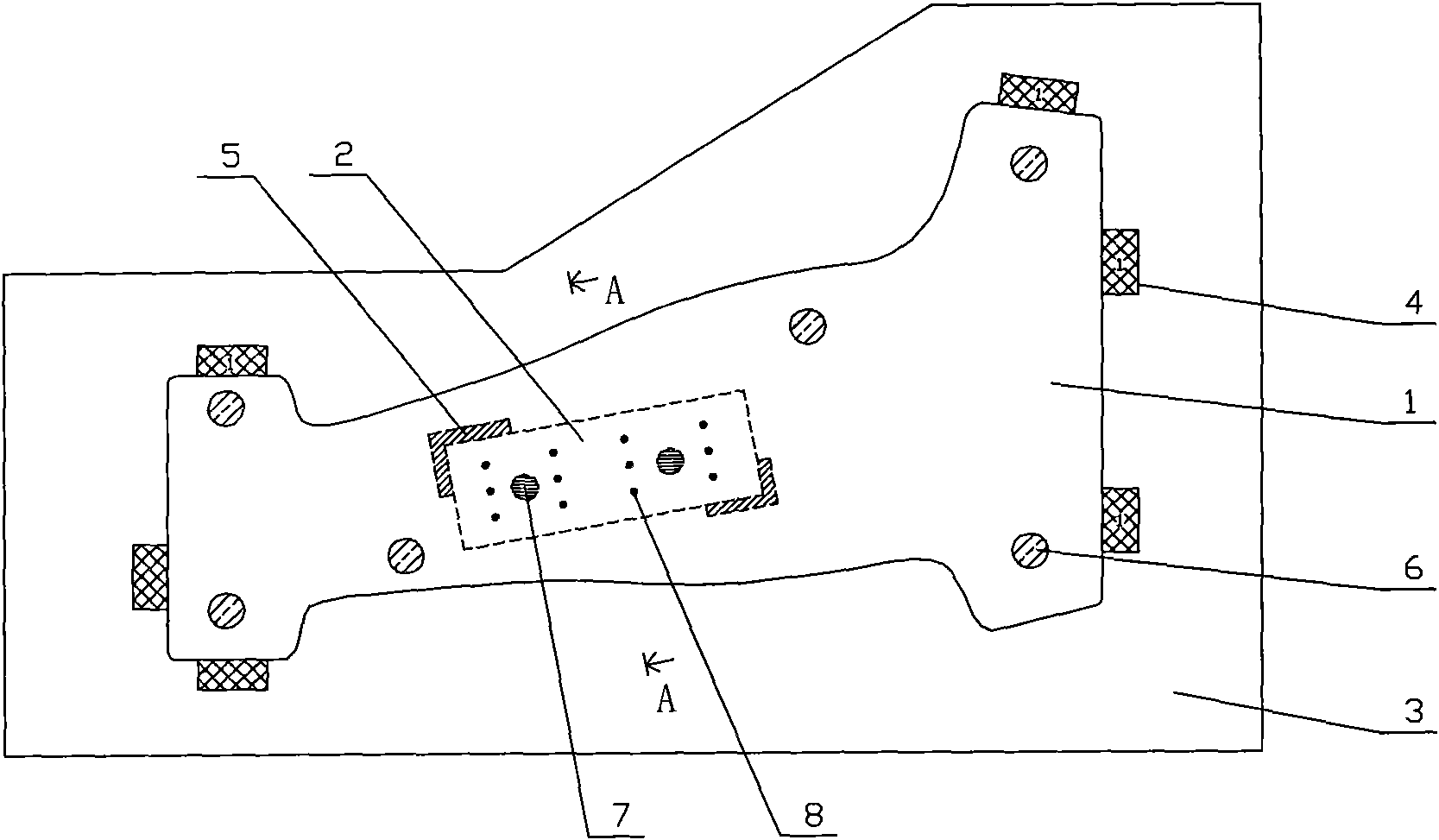

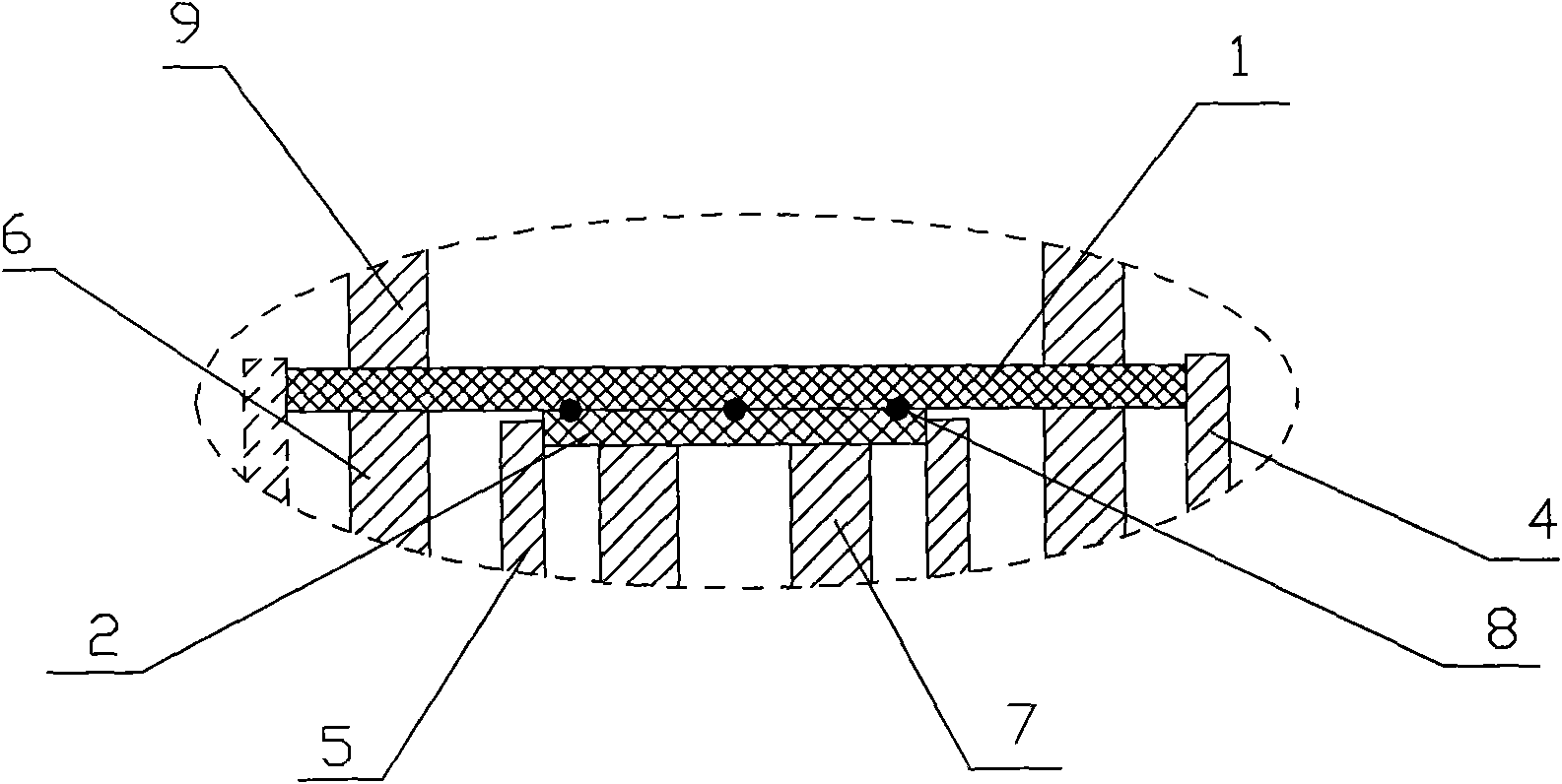

The invention discloses a main and auxiliary oil injection system of a high-power-density diesel engine, and belongs to the related technical field of diesel engines. The main and auxiliary oil injection system comprises a main oil injector, an auxiliary oil injector and a combustion chamber. The main oil injector is arranged on an air cylinder cover, and the central axis of the main oil injector is superposed with the central axis of an air cylinder. The auxiliary oil injector is obliquely arranged on the air cylinder cover, and the central axis of the auxiliary oil injector and the central axis of the air cylinder are located on the same plane. The main oil injector comprises a main oil injection nozzle, and a plurality of oil injection holes are formed in the circumferential direction of the main oil injection nozzle. The auxiliary oil injector comprises an auxiliary oil injection nozzle, and a plurality of oil injection holes are formed in the side close to the main oil injector, so that auxiliary oil injector fuel oil mist beams sprayed out of the auxiliary oil injection nozzle point to the central area of the combustion chamber. The system comprises the main oil injector and the auxiliary oil injector, the two oil injectors inject oil simultaneously, the oil injection rate can be increased, the oil injection duration is shortened, the problem that the oil injection rate of a single oil injector in the high-power-density diesel engine is insufficient is effectively solved, and therefore rapid combustion and a higher index of power per liter are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

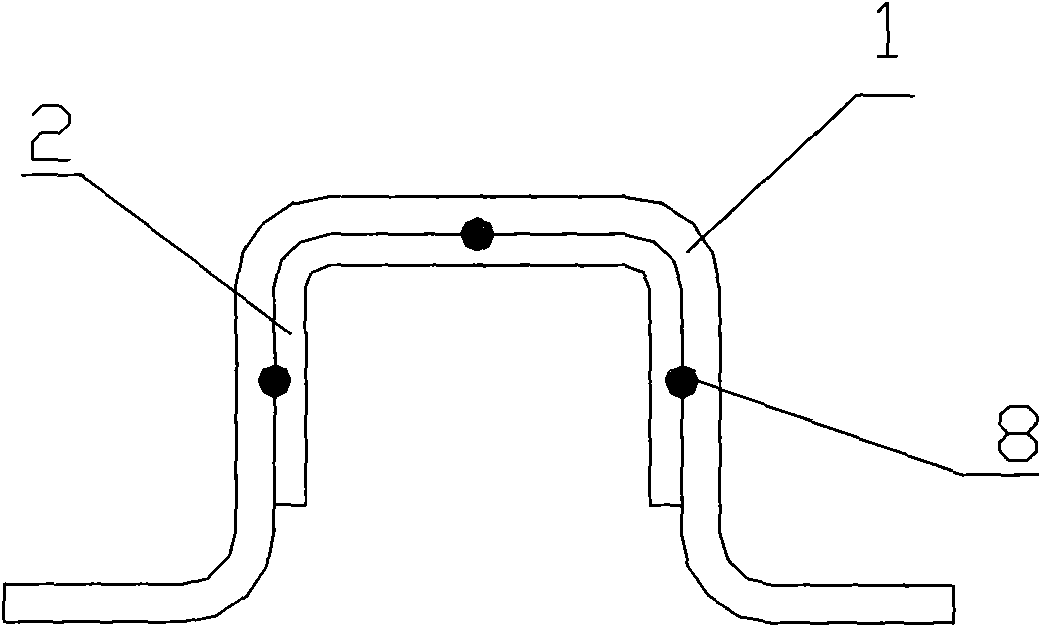

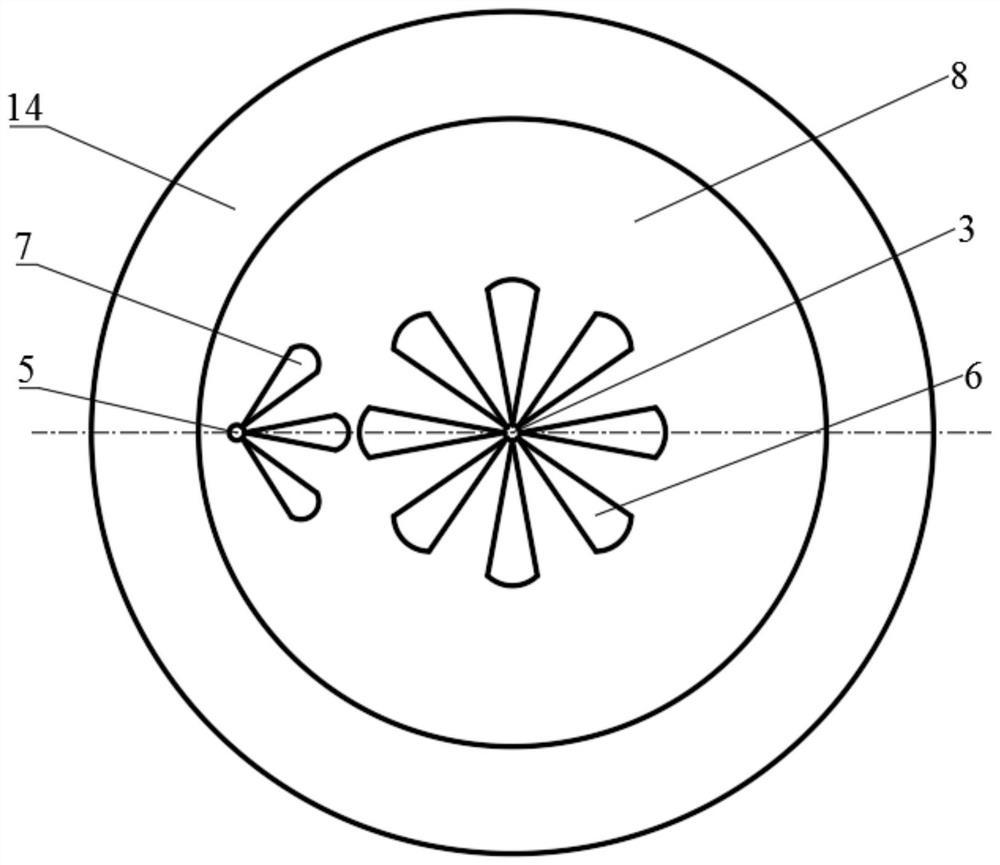

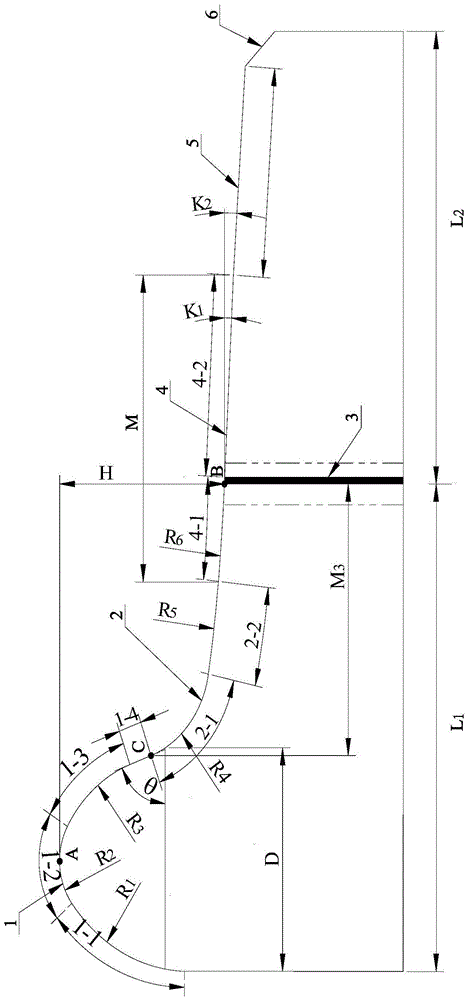

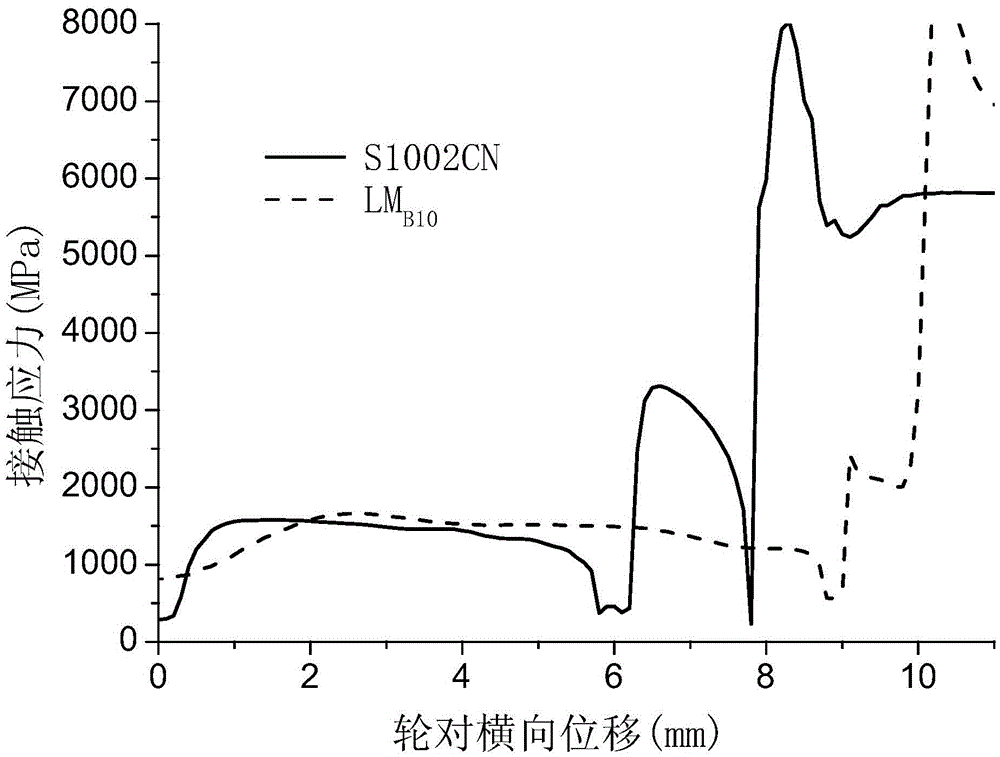

Novel wheel tread structure of high-speed motor train unit

The invention relates to a novel wheel tread structure for a high-speed motor train unit, and belongs to the field of railway vehicle wheel tread structures. The wheel tread structure can be completely matched with and completely adapt to the profile of CN60 novel railways, and a small curvature radius of a first arc segment end surface of a throat root circle high taper region is adopted to avoid the destabilization of train wheels produced by that the equivalent taper of a tread is too high, and avoid the rocking of motor trains caused by that the equivalent taper of the tread is too low. A normal operating region cooperates with a low taper region at the outer side of an end part of the tread to have the effect of enlarging the contacting area of the tread and the railways, and the wheels can be allowed to bear a higher axle weight load under the same contact stress. According to the novel wheel tread structure disclosed by the invention, the purposes that the tread wear is retarded and the wheel rotating period is prolonged are achieved through optimizing the optimal position of a rolling circle, and the adaptability of the tread structure to the change of a steel rail profile is greatly improved through the given parameter settings which are calculated and preferred, and the purpose of obtaining the ideal effects of concurrently considering and balancing two aspects of restraining snaking motion and prolonging the wheel rotating period is achieved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD +2

Machining method for magnesium alloy thin-walled pipe for degradable and absorbable support

The invention belongs to the technical field of biomaterials, and discloses a machining method for a magnesium alloy thin-walled pipe for a degradable and absorbable support. The technological processof the method comprises the steps of smelting, casting, extruding, extruding punching, boring and cleaning of the inner surface and the outer surface, annealing, drawing, repeated conduction of annealing and drawing and obtaining of finished products. In the whole repeated drawing process, the reducing deformation amount of the pipe needs to be controlled during each pass, and the matching relation between the reducing deformation amount and the wall reduction deformation amount is well adjusted at the same time. The pipe obtained through the process is high in precise, the inner surface andthe outer surface are smooth and clean, the mechanical performance is excellent, and the whole process is simple, good in controllability and high in economic benefits.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Double-group element single-piston type hydraulic free piston engine

InactiveCN101377150BHigh calorific valueSimple structureFree piston enginesFree-piston engineHigh energy

The present invention relates to a double-component single-piston type hydraulic free-piston engine, which comprises a single-piston hydraulic free-piston engine, an oxidizer storage tank, a fuel agent storage tank, an oxidizer control valve, a fuel agent control valve and an electronic control unit; wherein, both the outlet end of the oxidizer control valve and the outlet end of the fuel agent control valve are communicated with the air inlet of the power cavity of the single-piston hydraulic free-piston engine; the inlet end of the oxidizer control valve is connected with the outlet end of the oxidizer storage tank; the inlet end of the fuel agent control valve is connected with the outlet end of the fuel agent storage tank; and the control end of the oxidizer control valve and the control end of the fuel agent control valve are respectively connected with the corresponding output ends of the electronic control unit. The double-component single-piston type hydraulic free-piston engine, which is characterized by simple structure, reliable operation, wide application range, high energy density, high power density, little moving parts, etc., can operate under various oxygen-deficient or oxygen-free environments, such as plateaus, underwater and outer space, and can realize stroke control and regenerative braking.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

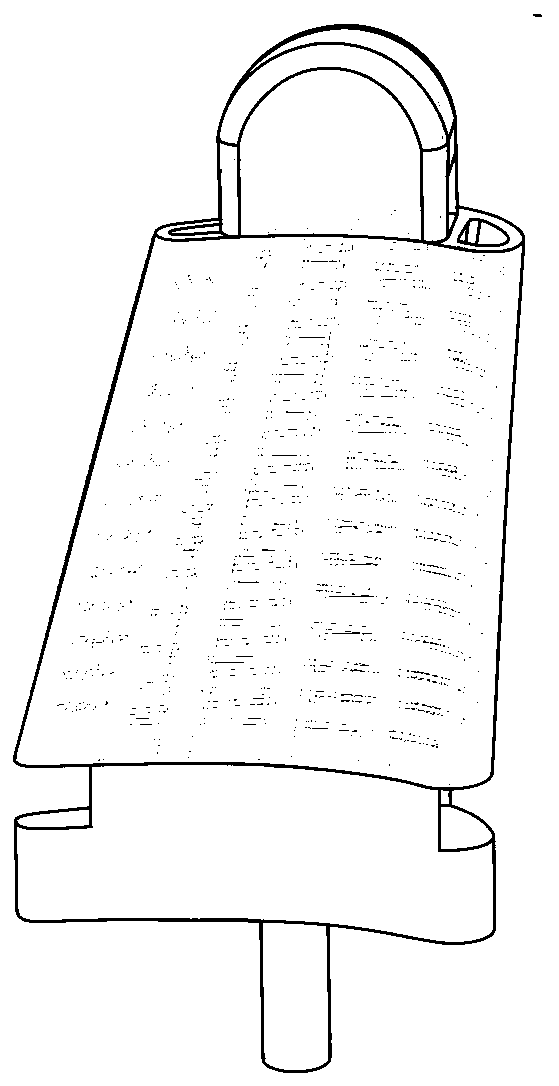

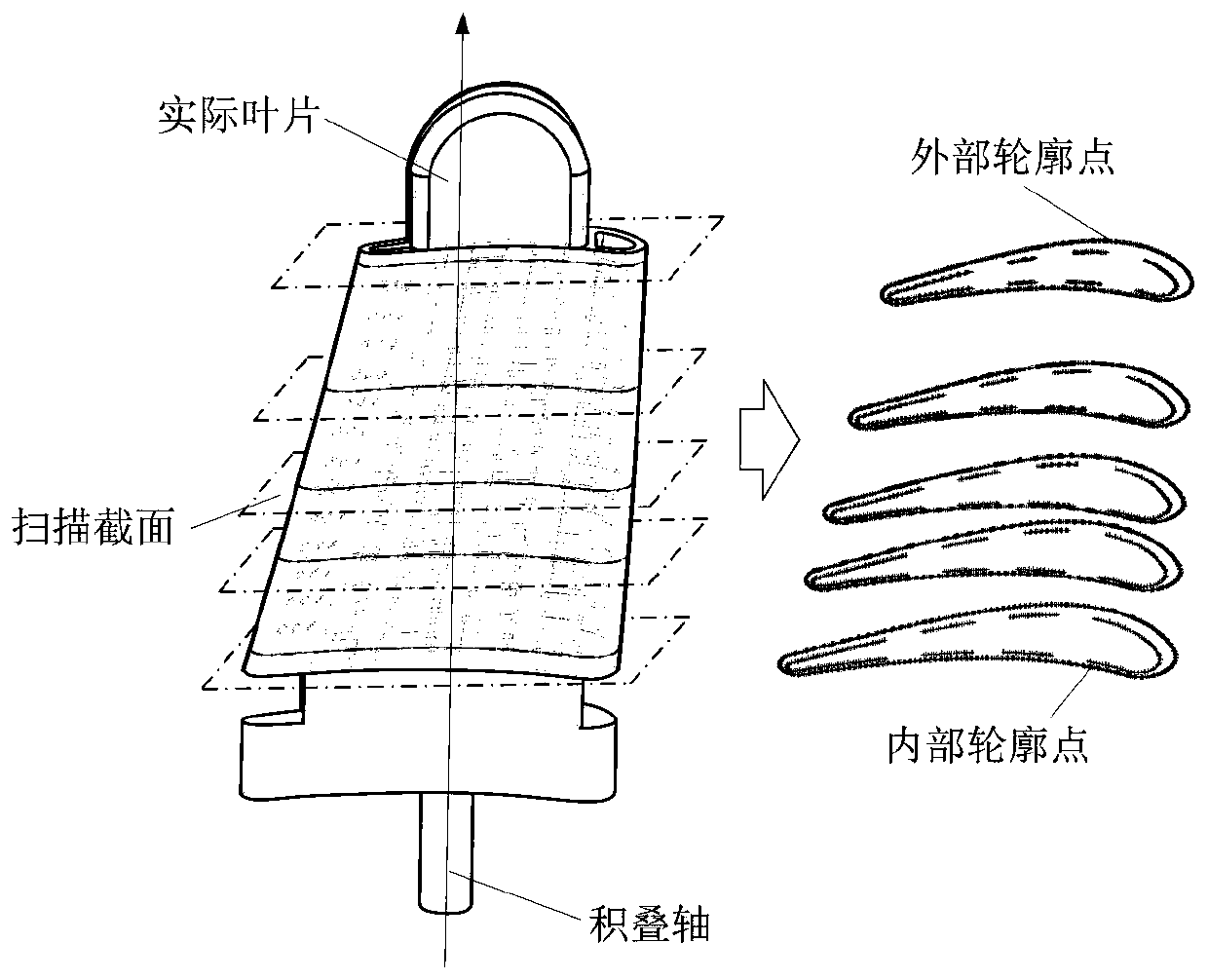

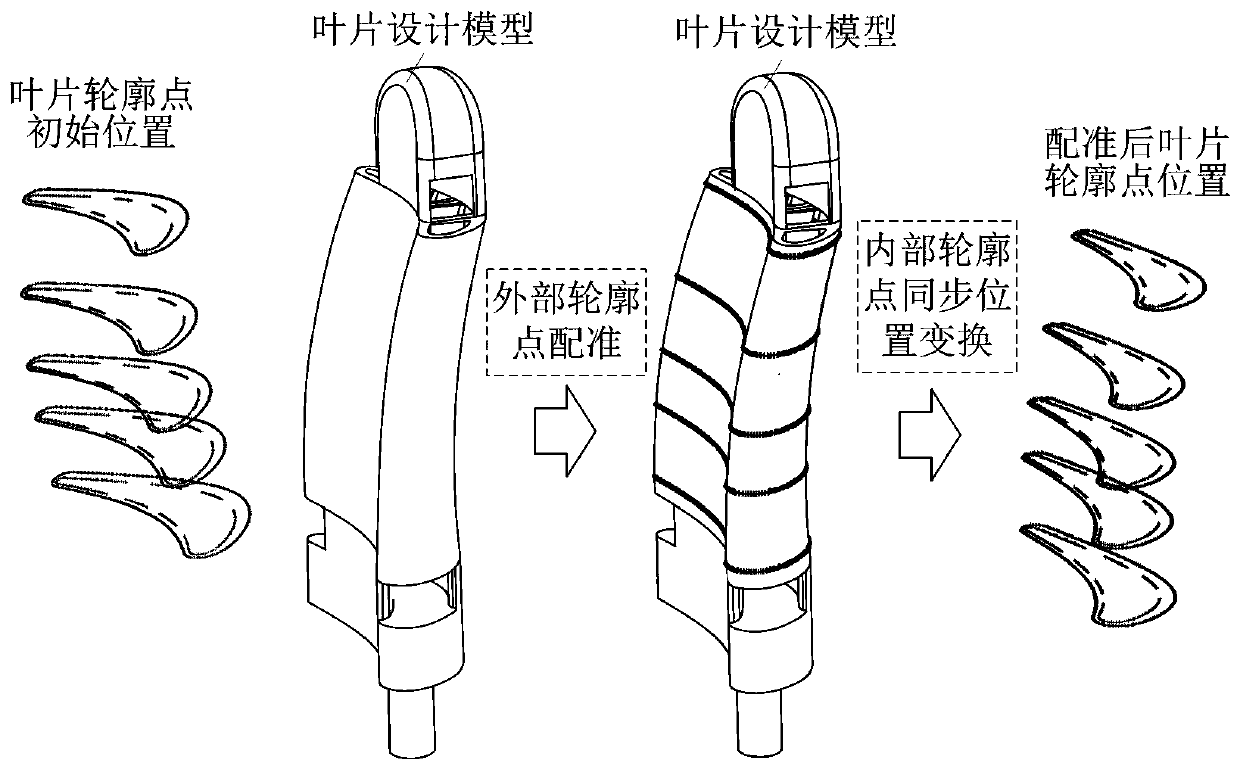

Hollow turbine blade wall thickness deviation reverse regulation and control method based on ceramic core positioning compensation

ActiveCN111259557APrecise control of wall thickness accuracyOptimize the matching relationshipGeometric CADHydro energy generationTurbine bladeCeramic

The invention belongs to the technical field of aeroengine hollow turbine blade investment precision casting, and particularly relates to a hollow turbine blade wall thickness deviation reverse regulation and control method based on ceramic core positioning compensation. The method comprises the following steps: 1) acquiring data of inner and outer contour points of an actual hollow turbine blade;2) carrying out three-dimensional iterative registration on the outline points of the blade and a design model; 3) calculating the pose drift amount of the ceramic core in the precision casting process; 4) calculating the reverse offset of the ceramic core; 5) reversely biasing the ceramic core design model; and 6) adjusting the size of the wax mold ceramic core positioning element. The problem that the wall thickness size of an existing aero-engine hollow turbine blade is out of tolerance seriously is solved. From the perspective of ceramic core pose regulation and control, the spatial poseof a ceramic core in a wax pattern is changed by adjusting the size of a ceramic core positioning element in the wax pattern mold, then a core shift wax pattern is formed, and finally the purposes ofimproving the position matching relation between a shell and the ceramic core and achieving accurate control over the wall thickness precision of the hollow turbine blade are achieved.

Owner:SHANXI UNIV

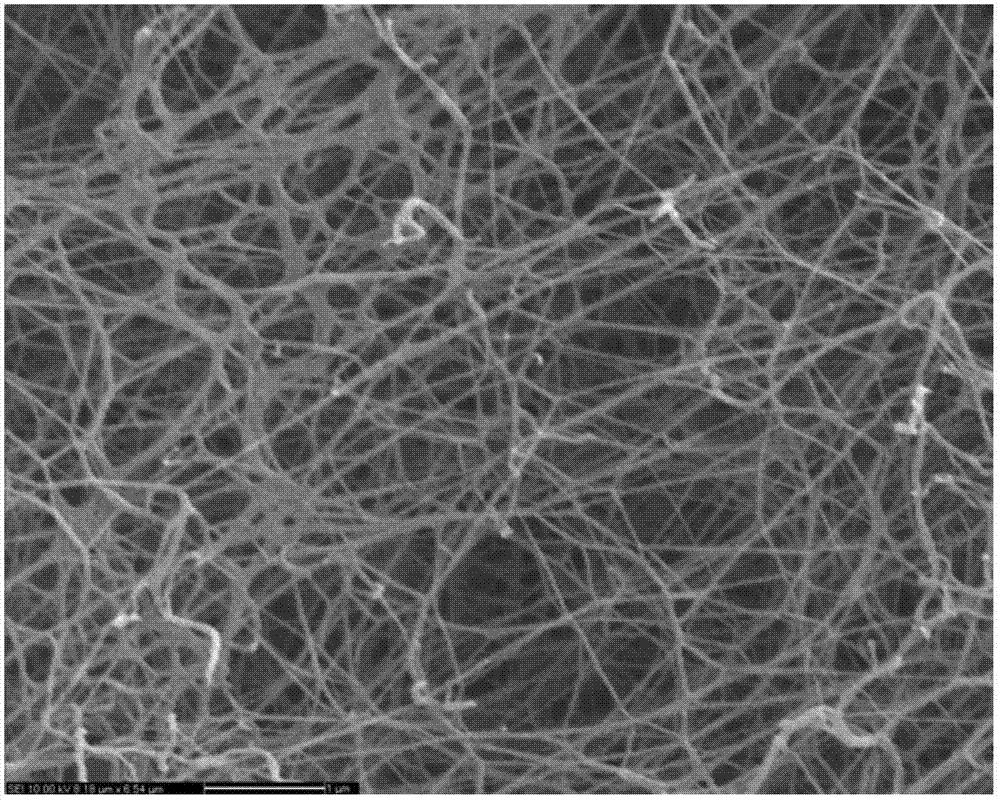

Preparation method of bacterial cellulose capable of removing endotoxin

InactiveCN102977392AUnique three-dimensional porous network structureLarge specific surface areaWater bathsEndotoxin removal

The invention discloses a preparation method of bacterial cellulose capable of removing endotoxin. The preparation method comprises the following steps of: pretreating a bacterial cellulose membrane and preparing a PEG (polyethylene glycol) water solution or chitosan solution; putting the bacterial cellulose membrane in the PEG water solution or chitosan solution, heating to above 80 DEG C and maintaining at 80-100DEG C under a water bath for 0.5-1.5h; and washing the cooked bacterial cellulose membrane with purified water to obtain the bacterial cellulose. The method for removing the endotoxin is simple without considering the removal of the endotoxin in the bacterial cellulose culture process; and the preparation method is simple in preparation process and is suitable for industrial production of composite bacterial cellulose dressing.

Owner:SHANGHAI DIVINE MEDICAL TECH

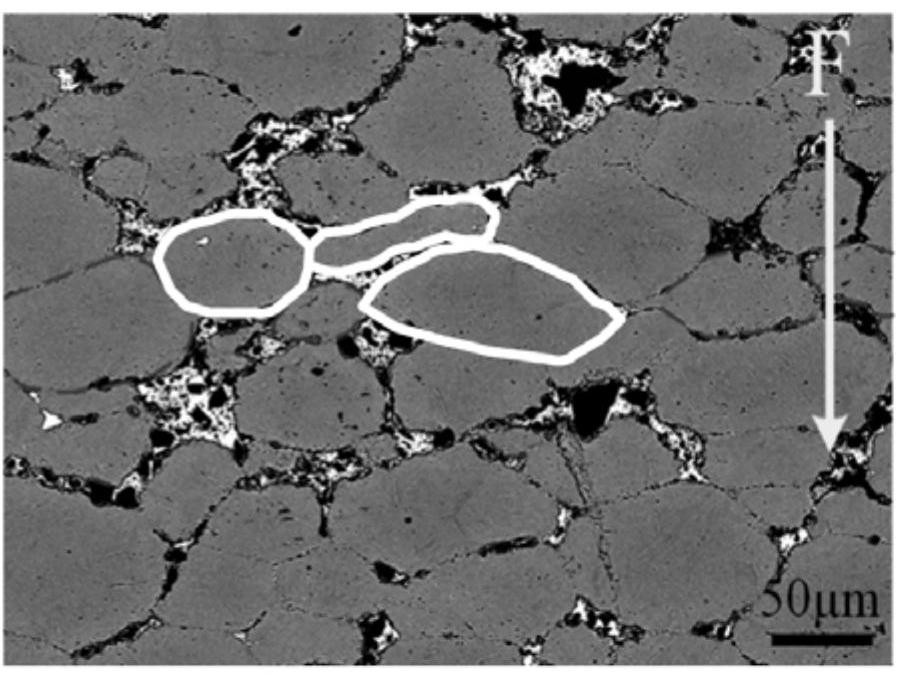

Multi-scale fracture modeling method for fracture-cavity type carbonate rock oil reservoir

PendingCN111695228AOptimize the matching relationshipConform to developmental characteristicsDesign optimisation/simulation3D modellingFracture controlGeophysics

The invention provides a multi-scale fracture modeling method for a fracture-cavity type carbonate rock oil reservoir. The method comprises the following steps: firstly, identifying a scale accordingto cracks; dividing cracks into large-scale cracks, medium-scale cracks and small-scale cracks; secondly, aiming at a fracture-vug type carbonate rock fracture forming mechanism, subdividing small-scale cracks into fracture control cracks and karst cave control cracks; establishing a fracture model by adopting a deterministic modeling method according to characteristics of large-scale and medium-scale fractures, establishing a fracture model by adopting a random indication point method according to small-scale fractures, and finally forming a multi-scale fracture model through fusion, so thatthe fracture modeling precision of the fracture-cavity type oil reservoir is effectively improved, and the geological modeling method of the fracture-cavity type oil reservoir is perfected.

Owner:CHINA PETROLEUM & CHEM CORP +1

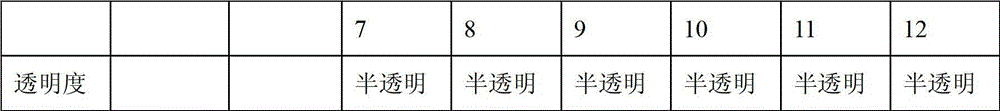

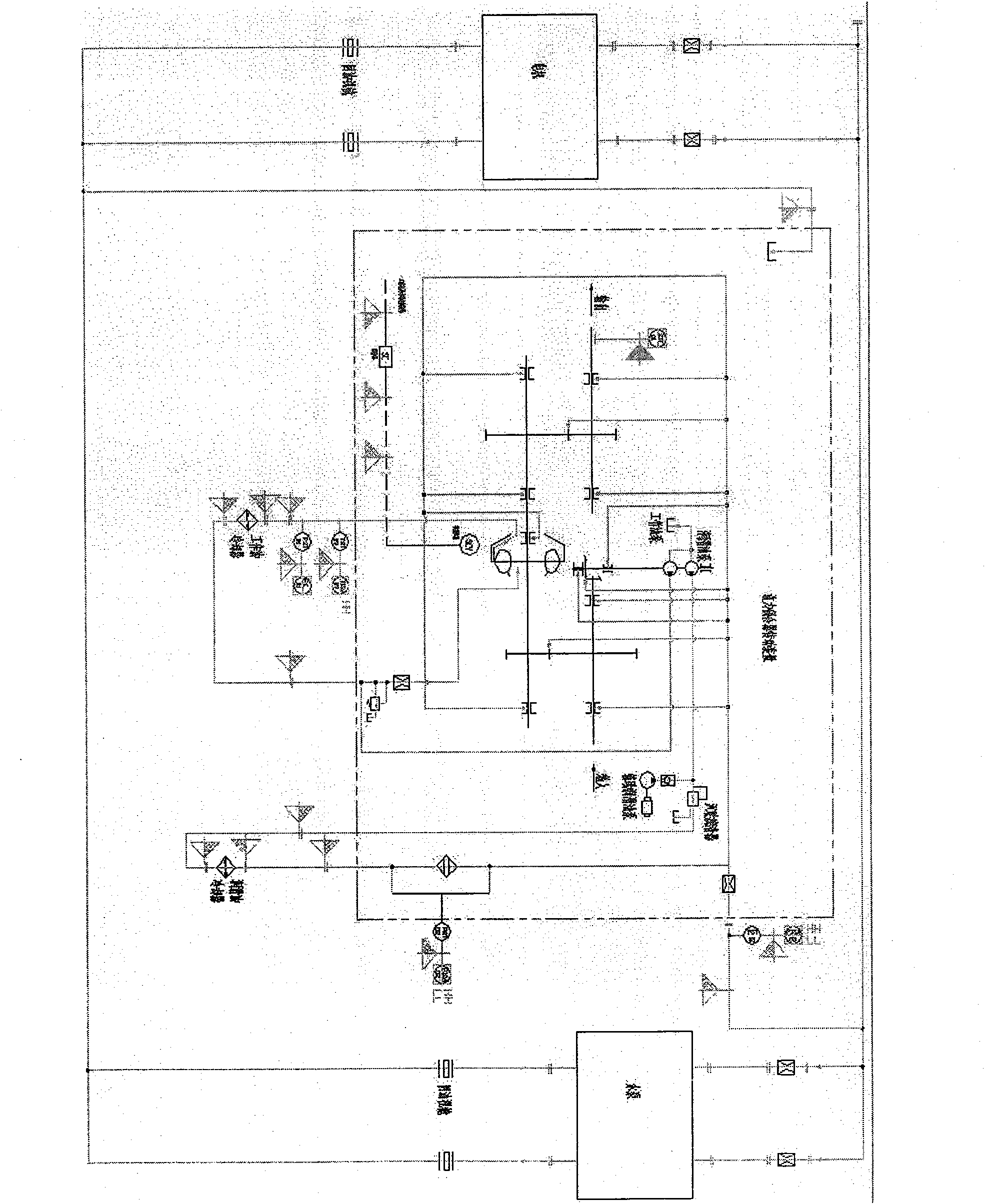

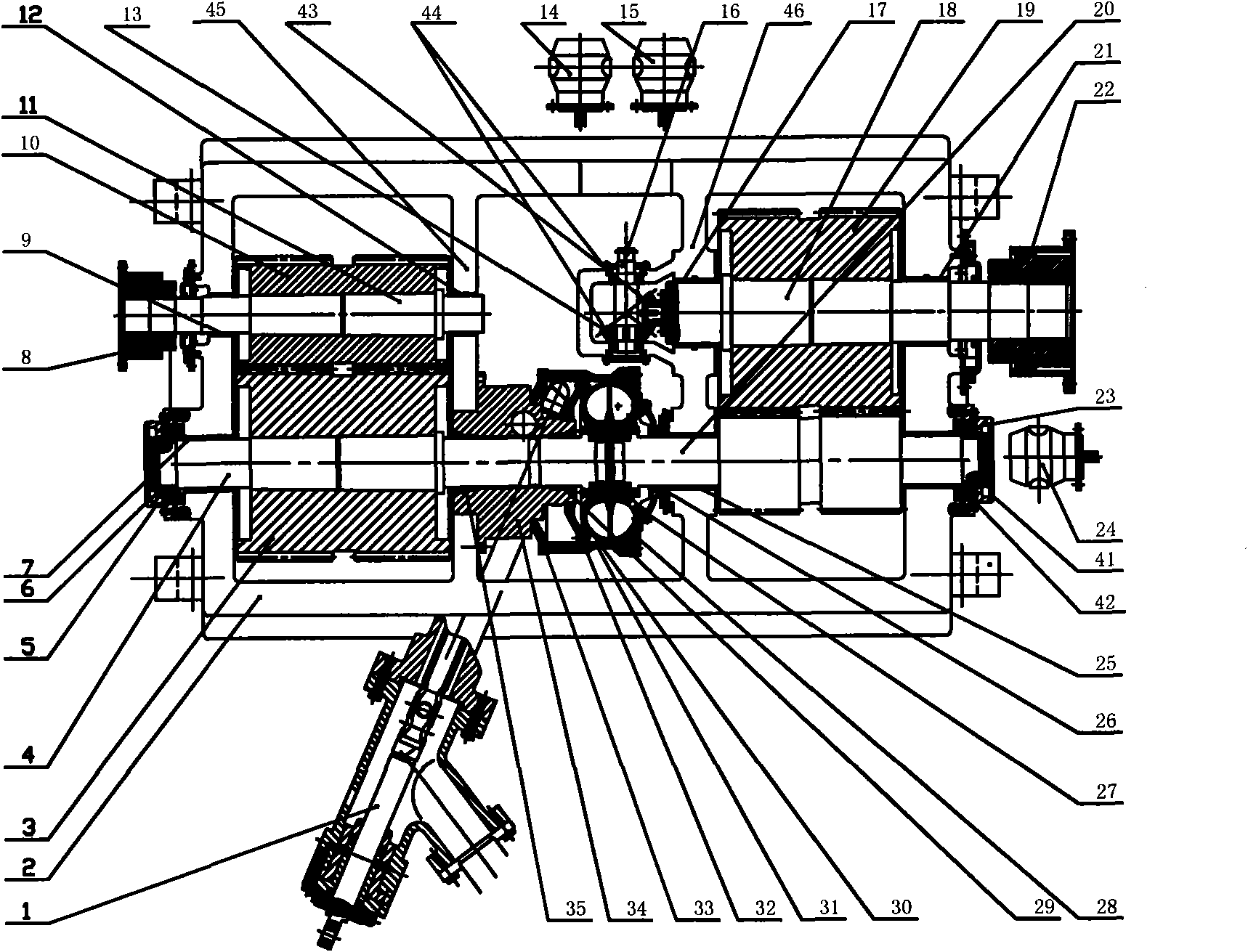

Intelligent high-power mechatronic speed adjusting device

InactiveCN103742620AImprove boot performanceOptimize the matching relationshipGearboxesToothed gearingsFluid couplingThrough transmission

The invention relates to an intelligent high-power mechatronic speed adjusting device which comprises a front-end planetary speed increaser, a speed-adjusting fluid coupling, a rear-end planetary speed changer and an intelligent control system. A speed adjustment mode of a telescopic outlet adjusting guide pipe is adopted by the fluid coupling, revolving speed input and power transmission capabilities of the fluid coupling are improved through transmission of a planetary gear of the front-end planetary speed increaser, and accordingly, the size of the coupling is reduced; three gears of the two-freedom-degree planetary speed changer arranged in the rear portion of the fluid coupling are acquired through two brakes and a clutch; the intelligent control system automatically determines the gears of the planetary speed changer and liquid charging quantity of the speed-adjusting fluid coupling according to given revolving speed or flow requirements of pumps and fans, so that operation efficiency of a working machine is improved, the fans and the pumps of power plants are enabled to work at high-efficiency areas, starting current can be remarkably reduced, working efficiency of the pumps and the fans is improved, electric energy is saved, and energy consumption is remarkably reduced.

Owner:WUHAN UNIV

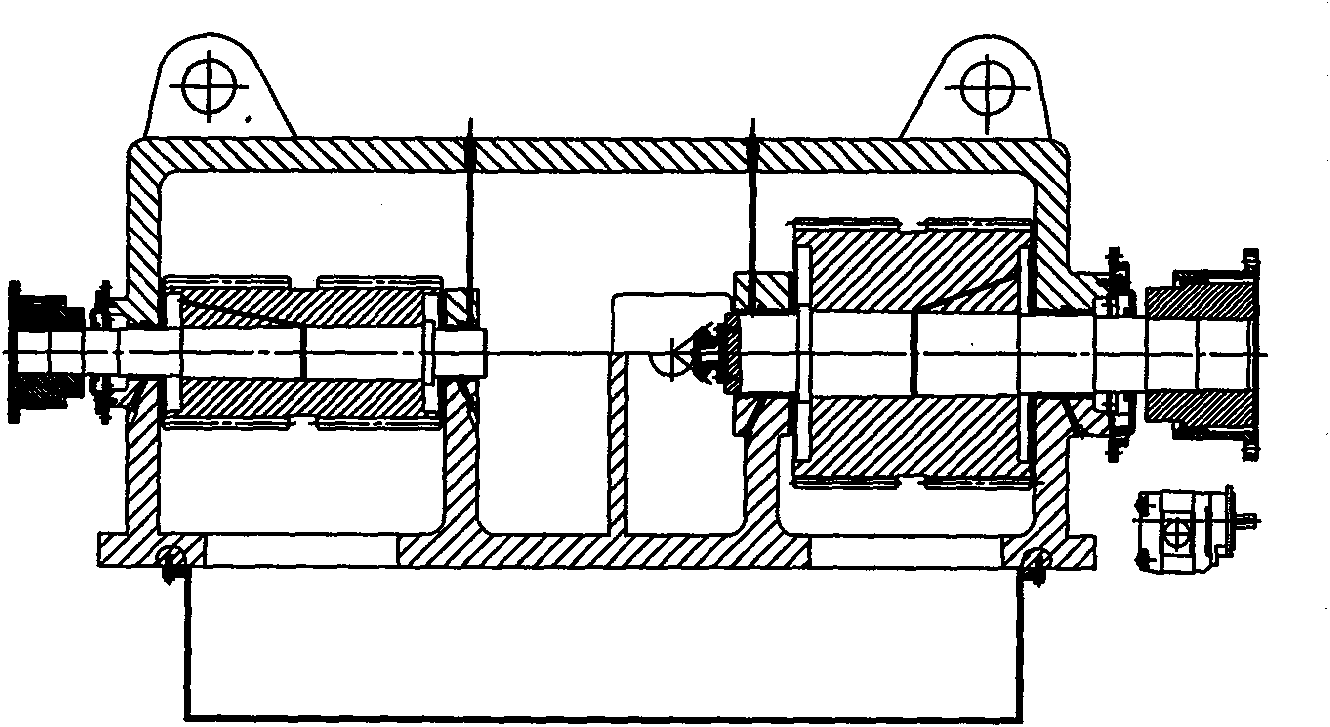

Speed-regulating hydraulic coupler transmission device of large-power composite gear capable of speeding up front and rear gear

InactiveCN101660596BOptimize the matching relationshipImprove operational efficiencyFeed water supplyFluid gearingsGear wheelTransmitted power

The utility model relates to a speed-regulating hydraulic coupler transmission device of a large-power compound gear capable of speeding up front and rear. The device consists of a hydraulic coupler, a front speed-up herringbone gear, a rear speed-up herringbone gear and an oil line system; the hydraulic coupler adopts a speed regulation mode of adjusting a telescopic conduit at an outlet; the front part and the rear part of the hydraulic coupler are provided with a primary herringbone gear speed-up transmission mechanism respectively; the input rotating speed and capability for transmitting power of the hydraulic coupler are improved by the front speed-up gear transmission, thus reducing the specification of the coupler; the oil line system comprises a working oil pump, a main lubricating oil pump and an auxiliary lubricating oil pump that are gear oil pumps. The device leads a motor and a working machine to match well, improves the transmission quality, improves the running efficiency of the working machine, leads a water supply pump of a boiler to work at a high-efficiency area all the time, greatly improves the working efficiency of the water supply pump of the boiler by the hydraulic speed regulation, saves a large amount of electric energy, and greatly reduces the consumption of energy resource.

Owner:JILIN UNIV

Oil injection system suitable for high-power-density diesel engine

PendingCN112879147AUniform and symmetrical distributionIncrease the fuel injection rateInternal combustion piston enginesFuel injection apparatusInjector nozzleFuel oil

The invention discloses an oil injection system suitable for a high-power-density diesel engine, and belongs to the related technical field of diesel engines. The oil injection system comprises a main oil injector vertically arranged in the center of a cylinder cover and an auxiliary oil injector obliquely arranged on the cylinder cover. The main oil injector and the auxiliary oil injector are provided with a plurality of oil injection holes. The auxiliary oil injector is provided with a plurality of oil injection holes. One oil injection hole of the main oil injector and one oil injection hole of the auxiliary oil injector are oppositely arranged. The multiple oil injection holes of the main oil injector are symmetrically distributed in the circumferential direction of the main oil injector through the center axis of the oil injection hole opposite to the auxiliary oil injector, and the angles between the adjacent oil injection holes are gradually increased in the direction away from the auxiliary oil injector. According to the oil injection system, the oil injection holes of the main oil injector are distributed sparsely in the side provided with the auxiliary oil injector, the oil injection holes of the main oil injector are distributed densely in the side away from the auxiliary oil injector, the problem that overall fuel oil distribution is uneven and asymmetric due to existence of the auxiliary oil injector can be balanced and compensated, and fuel oil in a diesel engine cylinder is evenly and symmetrically distributed integrally.

Owner:HUAZHONG UNIV OF SCI & TECH

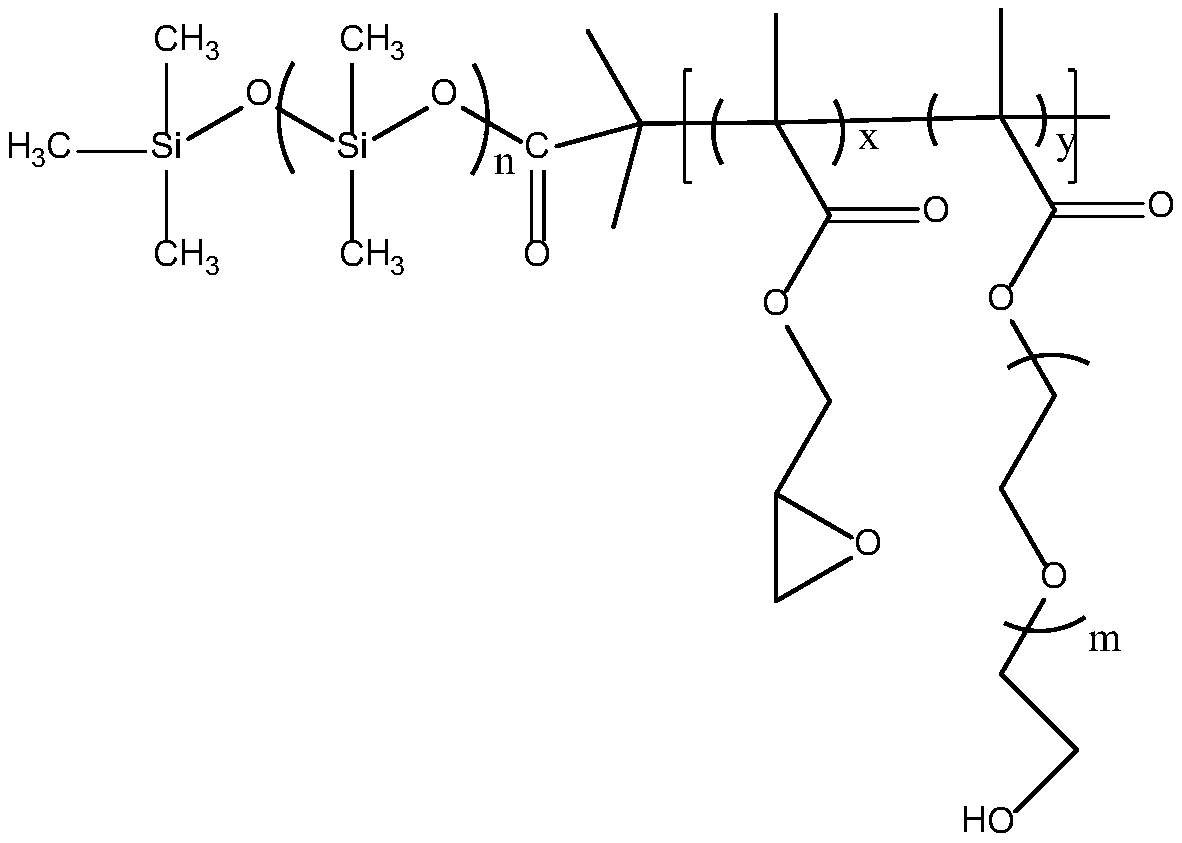

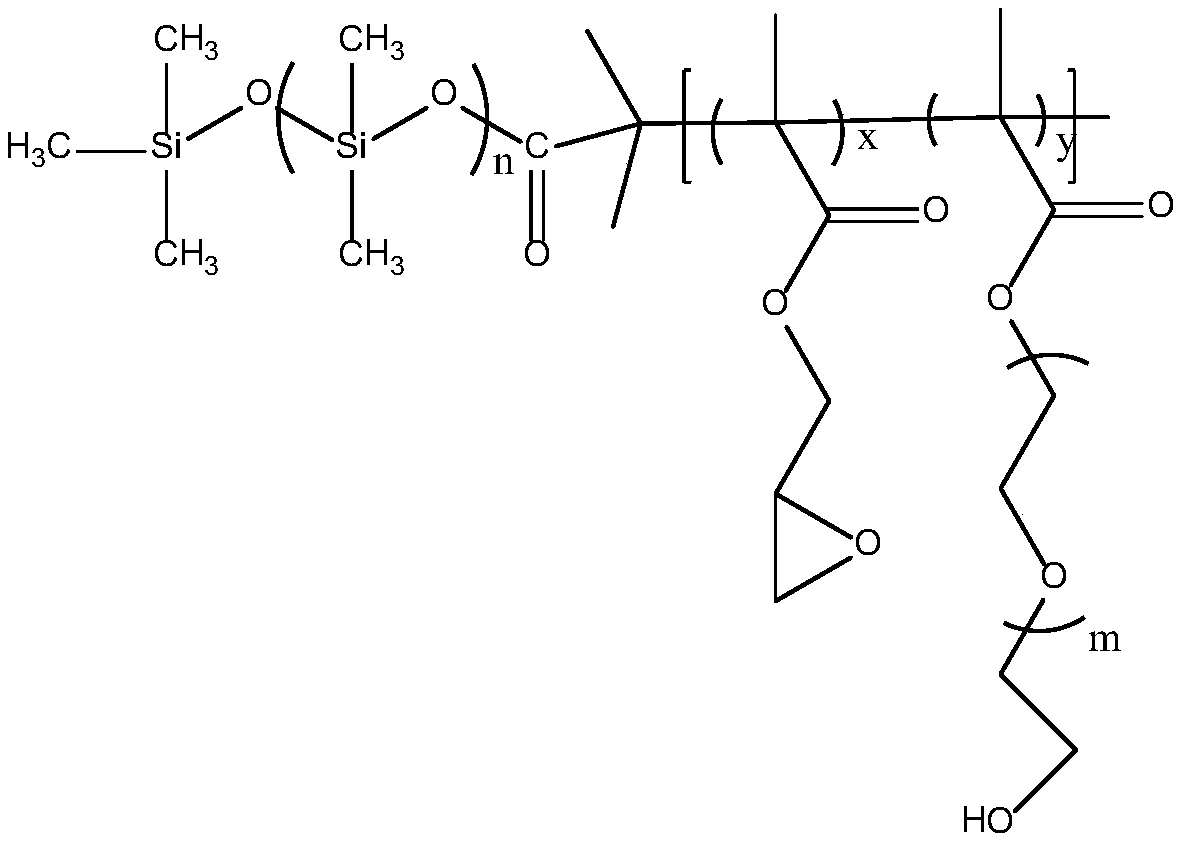

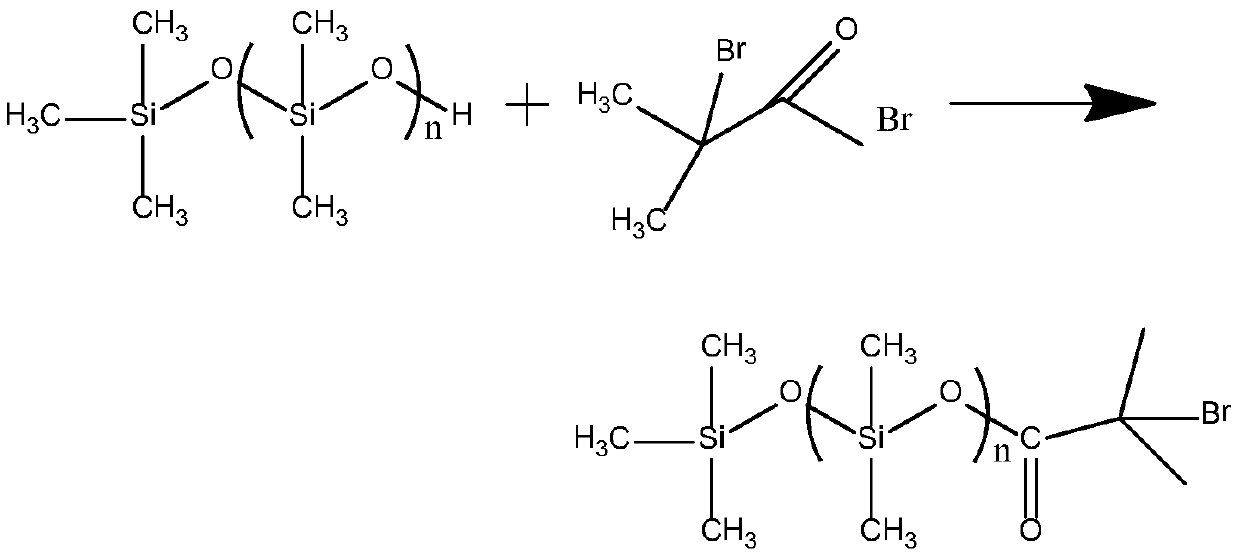

Preparation method of toughened epoxy resin and underfill adhesive

ActiveCN111171253AModulus improvementImprove liquidityNon-macromolecular adhesive additivesEpoxy resin adhesivesThermal dilatationPolymer science

The invention provides a preparation method of toughened epoxy resin and an underfill adhesive. The structural formula of the toughened epoxy resin is a polydimethylsiloxane-block-poly(glycidyl methacrylate-random-hydroxyl-terminated polyethylene glycol methyl methacrylate) copolymer. The toughened epoxy resin is synthesized by adopting a block / random controllable active polymerization method; coordination among four characteristics of modulus, thermal expansion coefficient, glass-transition temperature and fluidity of the underfill adhesive can be realized; the toughened epoxy resin is mixedand reacted with bisphenol epoxy resin, a curing agent and the like to prepare the high-performance underfill adhesive. According to the invention, the compatibility between the glue and the chip, thesubstrate and the soldering flux can be improved, and the filling performance of the glue at the bottom of the chip is improved, so that a good bottom filling effect is finally realized, and the reliability problem existing in bottom filling of a large-size chip is solved.

Owner:深圳市勇泰运科技有限公司

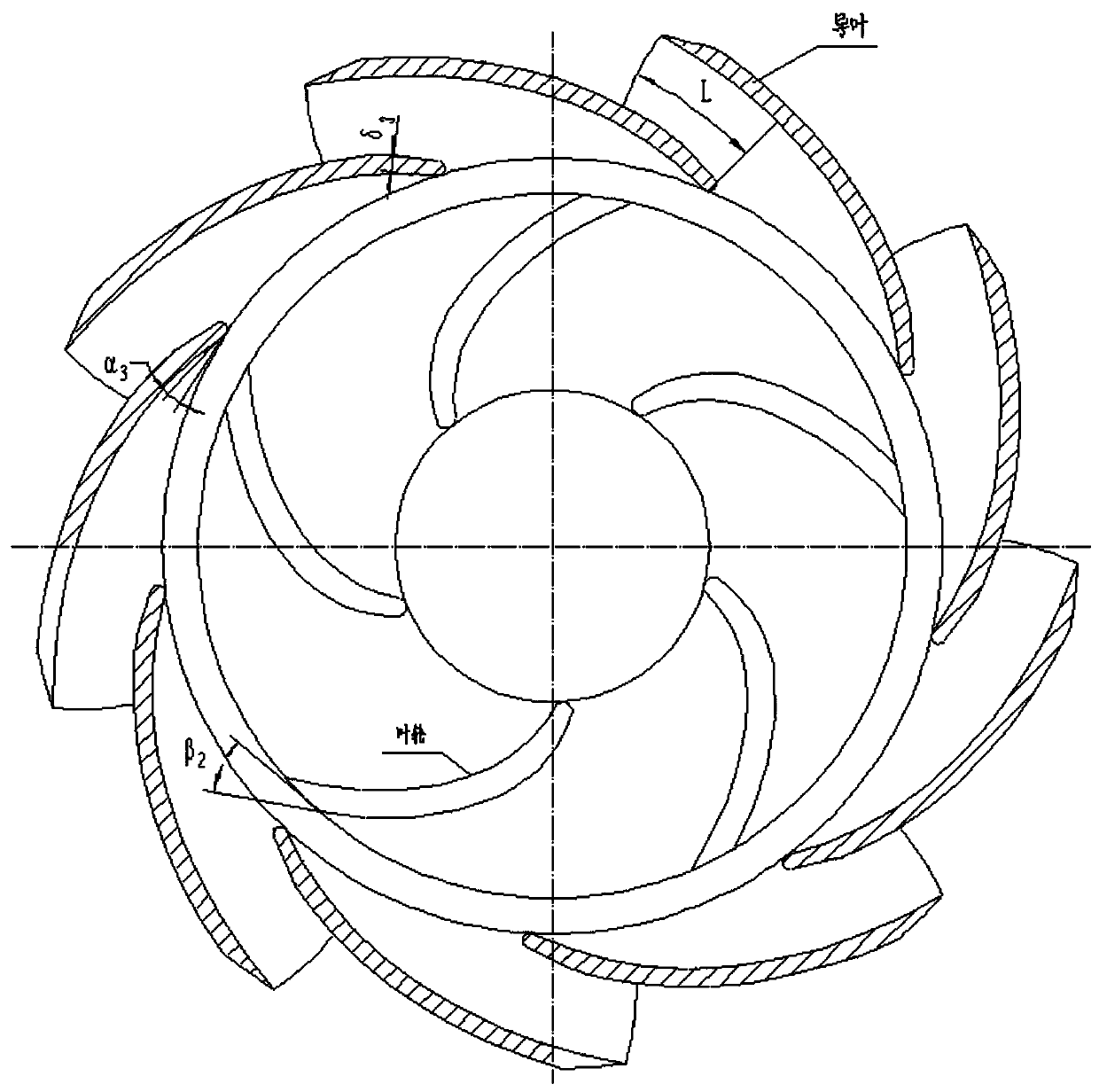

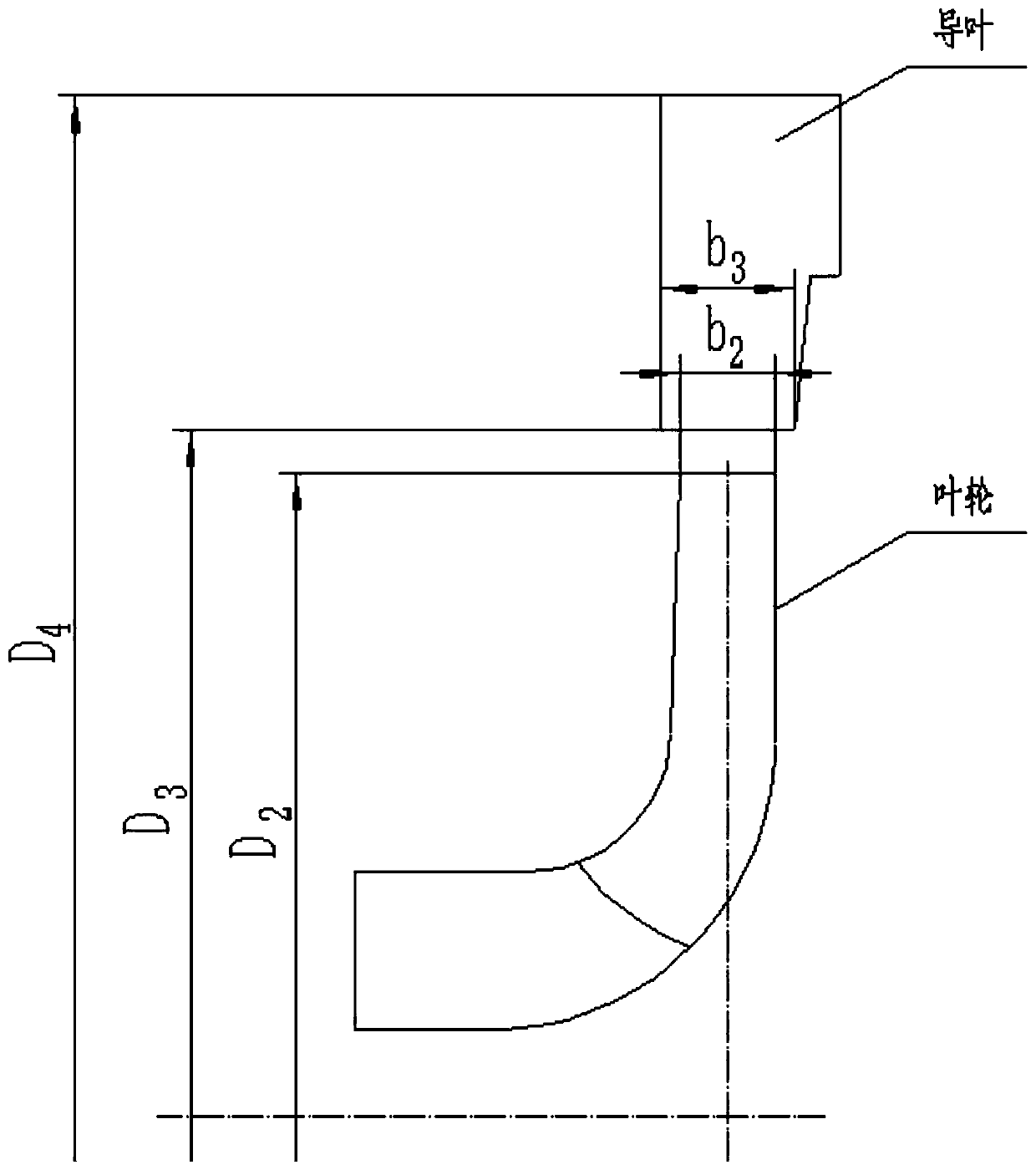

A hydraulic design method for reducing a multi-stage pump lift curve hump

ActiveCN109885886AReduce humpOptimize the matching relationshipPump componentsPumpsImpellerEngineering

The invention provides a hydraulic design method for reducing a multi-stage pump lift curve hump, and relates to the technical field of water pumps. The method is mainly used for solving the problem that a multistage pump has a hump phenomenon in a small-flow area, the main positive guide vane hydraulic parameters are derived from the main hydraulic parameters of the impeller according to a certain mathematical algebraic relationship; the outlet width of the impeller is defined; the outlet diameter of the impeller and the outlet placement angle of the impeller blade are parent item derivationto design the inlet diameter of the child item positive guide blade; the inlet width, the guide vane placing angle, the guide vane outlet diameter and the guide vane diffusion section length are improved, the permeability between the impeller and the guide vanes is improved, the impeller and the guide vanes have a good matching relation, and therefore the loss in the guide vanes under the small-flow working condition is reduced, and the hump degree of a lift curve is reduced.

Owner:SANLIAN PUMP IND CO LTD

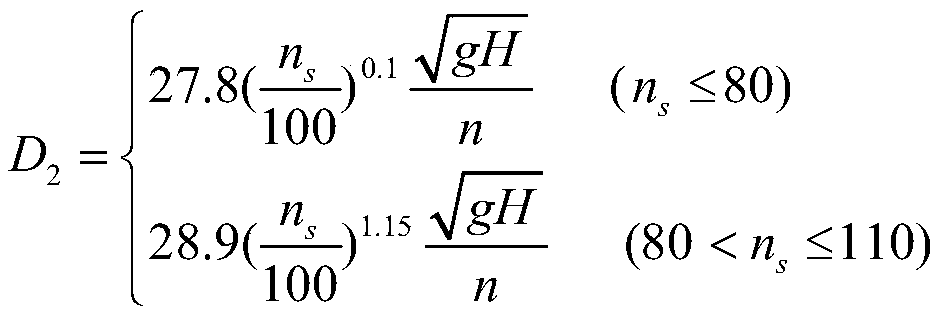

Fuzzy control method for cooperating type CO2 welding circuit-shorting transition and welding machine thereof

InactiveCN1113723CBest synergistic matching relationshipGuaranteed stabilityArc welding apparatusInterference resistanceClosed loop

The present invention relates to a fuzzy control method for CO2 short-circuiting transfer welding and its welding machine. It is characterized by that it adopts a closed-loop control method combining parameters-matched coordinate control and parameters-regulated fuzzy control, on the basis of the real-time detection on short circuiting transfer frequiency of reflecting stability of welding process, according to the coordinate relationship between all welding parameters and short circuiting transfer frequencies, it makes fuzzy treatment to detected data to define the regulating quantity of all parameters to make real-time regulation to make short circuiting transfer frequency keep stable in a certain range to ensure the optimum matching relationship between all parameters. Said invention possesses the advantages of good parameter matching property, strong anti-interference capacity and stable welding course.

Owner:BEIJING UNIV OF TECH +1

Automotive engine piston made of novel material

InactiveCN104632456AImprove solid solubilityImprove performanceMachines/enginesPistonsHeat resistanceAlloy

The invention discloses an automotive engine piston made of a novel material and belongs to the field of automotive engine components. The novel material is rapid set high-silicon aluminum alloy, a certain novel tissue structure characteristic, namely ultra-fine microstructure is obtained through the rapid set technique, the solid solubility limit of the alloy is improved, the heights of components are even, segregation is nearly or completely avoided, a novel metastable phase is formed, and defect density is improved. The material has the advantages of being light, high in strength, high in corrosion resistance and heat resistance, low in thermal expansivity and the like, the solid solubility of Si in an aluminum matrix can be improved, grains are refined, the material is well matched with the matrix, and the performance of the alloy is improved remarkably.

Owner:QINGDAO LIBO AUTO PARTS PRECISION CASTING

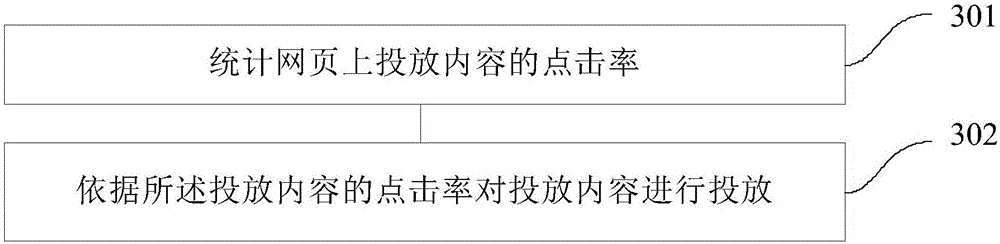

High-temperature high-strength wear-resistant self-lubricating material and preparation method thereof

The invention discloses a high-temperature high-strength wear-resistant self-lubricating material and a preparation method thereof, and belongs to the field of metal material manufacturing and powdermetallurgy. The preparation method comprises the following steps of (1) taking Ag powder and TiB2 powder as a lubricating phase and a reinforcing phase, and taking Ti2AlNb powder as matrix powder; (2)ultrasonically dispersing powder in a solution to obtain slurry; (3) putting the pre-ultrasonic slurry and grinding balls into a ball milling tank for ball milling, so that the powder is fully mixedand the particle size is uniform; (4) drying the ball-milled slurry in a vacuum drying oven; (5) crushing the dried powder by using a wall breaking machine; and (6) putting the crushed mixed powder into a graphite mold, carrying out spark plasma sintering, carrying out furnace cooling to room temperature, and taking out to obtain the high-temperature high-strength wear-resistant self-lubricating material; the problem that the high-temperature friction performance of the aviation titanium alloy is poor is solved, process is simple; the lubricating phase and the reinforcing phase are tightly combined with the matrix, and the material density is high; and the hardness, high-temperature strength and high-temperature wear resistance of the material are obviously enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

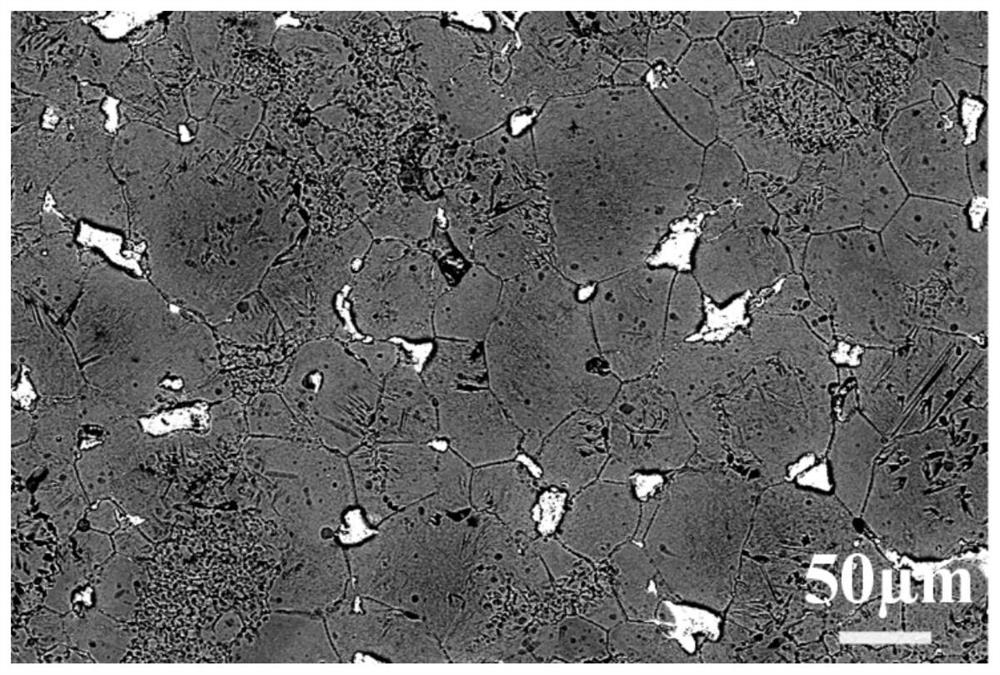

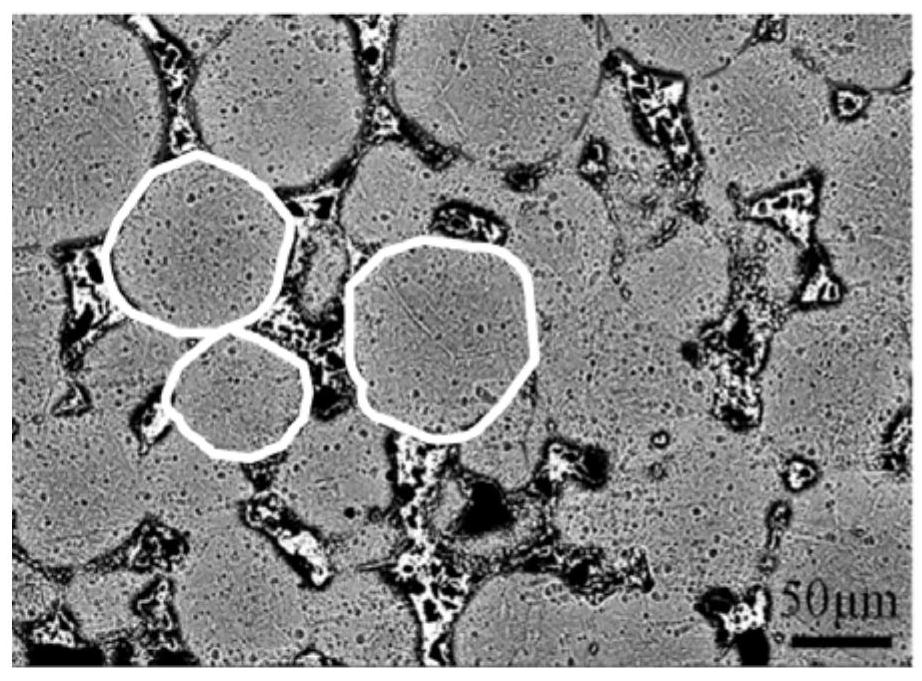

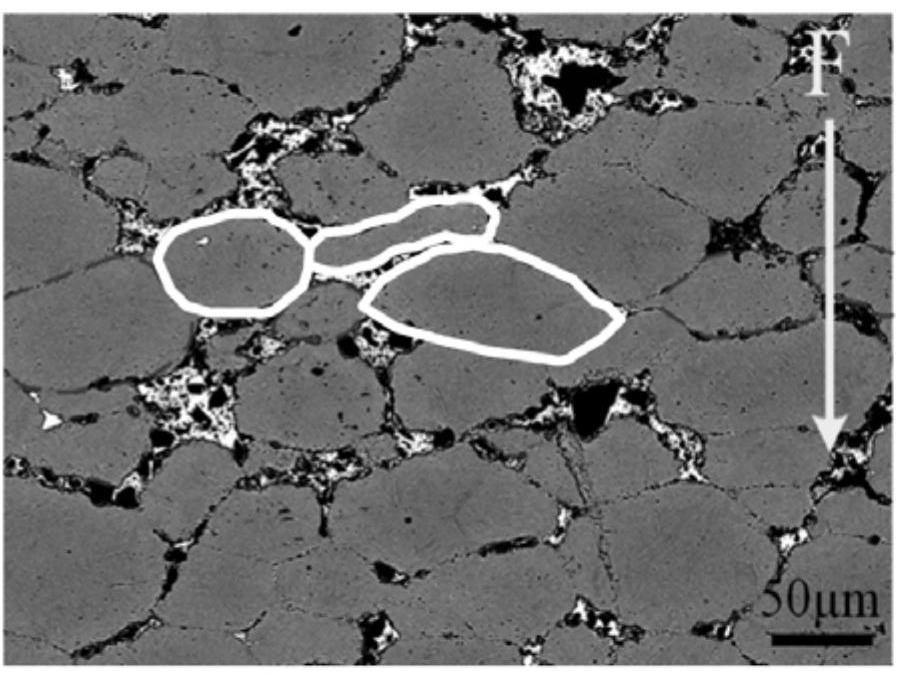

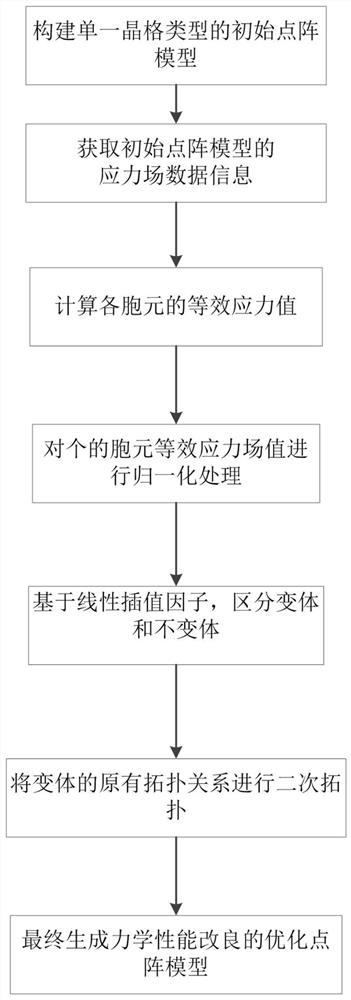

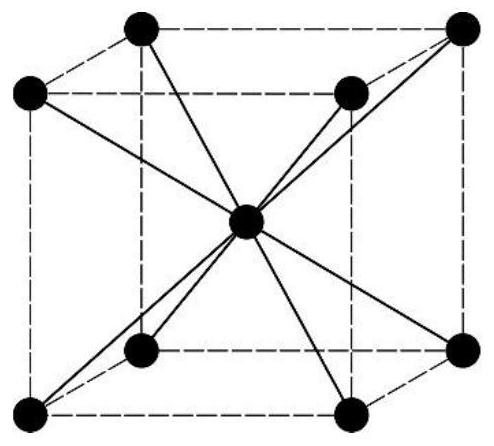

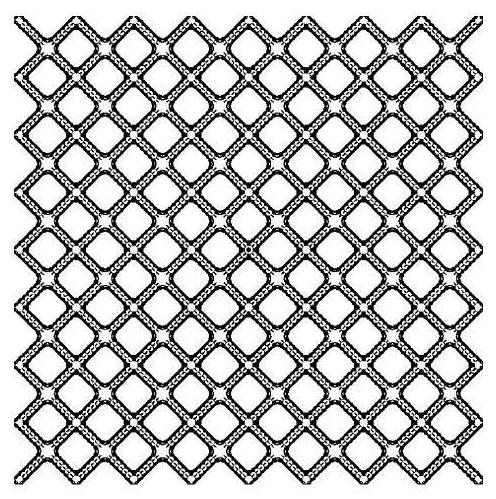

Lattice model multiphase reinforcement optimization method based on field data driving

PendingCN112257310AImprove structural mechanical propertiesInhibit and hinder dislocation slip phenomenonDesign optimisation/simulationSpecial data processing applicationsDot matrixEngineering

The invention discloses a lattice model multiphase reinforcement optimization method based on field data driving. The method specifically comprises the following steps: 1) constructing an initial lattice model of a single lattice type; 2) acquiring stress field data information of the dot matrix model; 3) calculating an equivalent stress value of each cell element in the initial lattice model; 4)normalizing the equivalent stress value of each cell element; and 5) distinguishing the cell elements needing strengthening treatment from the cell elements not needing strengthening treatment, performing secondary topology on the topological relation of the cell elements needing strengthening treatment, and maintaining the original topological relation of the cell elements not needing strengthening treatment, thereby realizing strengthening of the dot matrix model. According to the invention, a good matching relationship is established between the attribute characteristics of each cell element in the optimization model and the stress field data information of the initial lattice model when the initial lattice model is loaded, and the multiphase reinforced lattice model designed by the invention provides a novel visual angle for the optimization of the mechanical properties of the homogeneous lattice structure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A kind of processing method of magnesium alloy thin-walled tube for degradable absorption stent

The invention belongs to the technical field of biomaterials, and discloses a machining method for a magnesium alloy thin-walled pipe for a degradable and absorbable support. The technological processof the method comprises the steps of smelting, casting, extruding, extruding punching, boring and cleaning of the inner surface and the outer surface, annealing, drawing, repeated conduction of annealing and drawing and obtaining of finished products. In the whole repeated drawing process, the reducing deformation amount of the pipe needs to be controlled during each pass, and the matching relation between the reducing deformation amount and the wall reduction deformation amount is well adjusted at the same time. The pipe obtained through the process is high in precise, the inner surface andthe outer surface are smooth and clean, the mechanical performance is excellent, and the whole process is simple, good in controllability and high in economic benefits.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

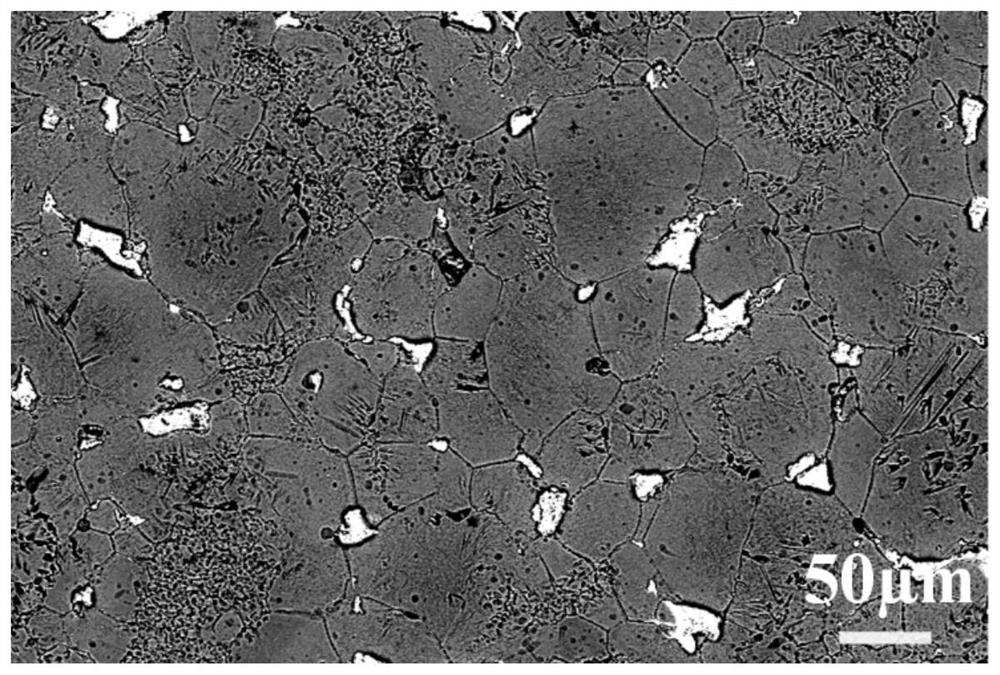

A kind of ti-39nb-6zr biomedical porous titanium alloy and preparation method thereof

ActiveCN106801163BOptimize the matching relationshipEasy to prepareTransportation and packagingMetal-working apparatusAdhesiveNiobium

The invention relates to a Ti-39Nb-6Zr biomedical porous titanium alloy and a preparation method thereof, belonging to the field of biomedical materials and porous materials. The alloy is composed of niobium, zirconium and titanium, wherein niobium is 39w%, zirconium is 6w%, and the balance is titanium; the porosity of the titanium alloy is 19.4%-42.1%. Prepare Ti-39Nb-6Zr alloy ingot by vacuum self-consumption melting method, and use rotating electrode atomization method to obtain spherical powder particles; select 100-150 mesh alloy powder, add binder, or ammonium bicarbonate pore-forming agent and bond agent, fully mixed, and pressed into a compact; the compact is sintered in an argon tube sintering furnace to completely remove the binder, or the pore-forming agent and the binder, and obtain a porous alloy. The elastic modulus of the alloy is 3.6GPa-12.4GPa, the tensile strength is 123.8MPa-347.5MPa, and has the advantages of low elastic modulus and good biocompatibility.

Owner:GRIMAT ENG INST CO LTD

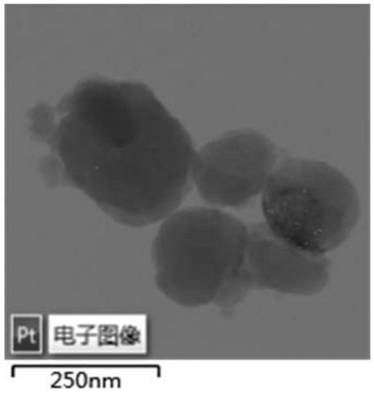

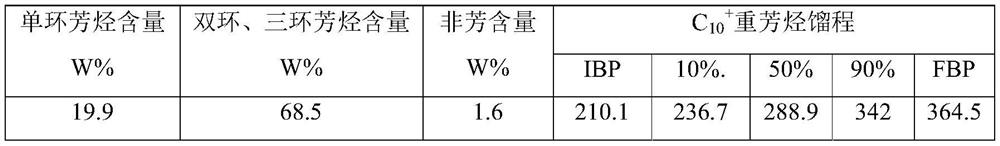

A kind of high-activity heavy aromatics lightening catalyst and preparation method thereof

ActiveCN110465327BSolve the problem of not being able to effectively orient the loadHigh purityMolecular sieve catalystsCatalyst activation/preparationPtru catalystCarbon deposit

The invention discloses a high-activity heavy aromatic hydrocarbon lightening catalyst and a preparation method thereof. The high-activity heavy aromatics lightening catalyst in the present invention is prepared by loading a precious metal precursor on a composite carrier through drying and roasting; the precious metal precursor is made of at least one of sponge platinum or chloroplatinic acid as a raw material, dissolved in Prepared platinum(IV) complex. The noble metal precursor can realize the directional quantitative impregnation on the composite support, and optimize the bifunctional matching relationship of the catalyst. The catalyst of the invention can efficiently process C under low pressure conditions 10 + The heavy aromatics have higher yields of light aromatics such as BTX, thereby solving the problems of low conversion depth of heavy aromatics, fast deactivation rate of catalyst carbon deposition and low yield of light aromatics in the prior art. Compared with the prior art, the catalyst of the present invention has higher activity and stability for lightening heavy aromatic hydrocarbons, and is especially suitable for processing inferior C. 10 + Heavy aromatics.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

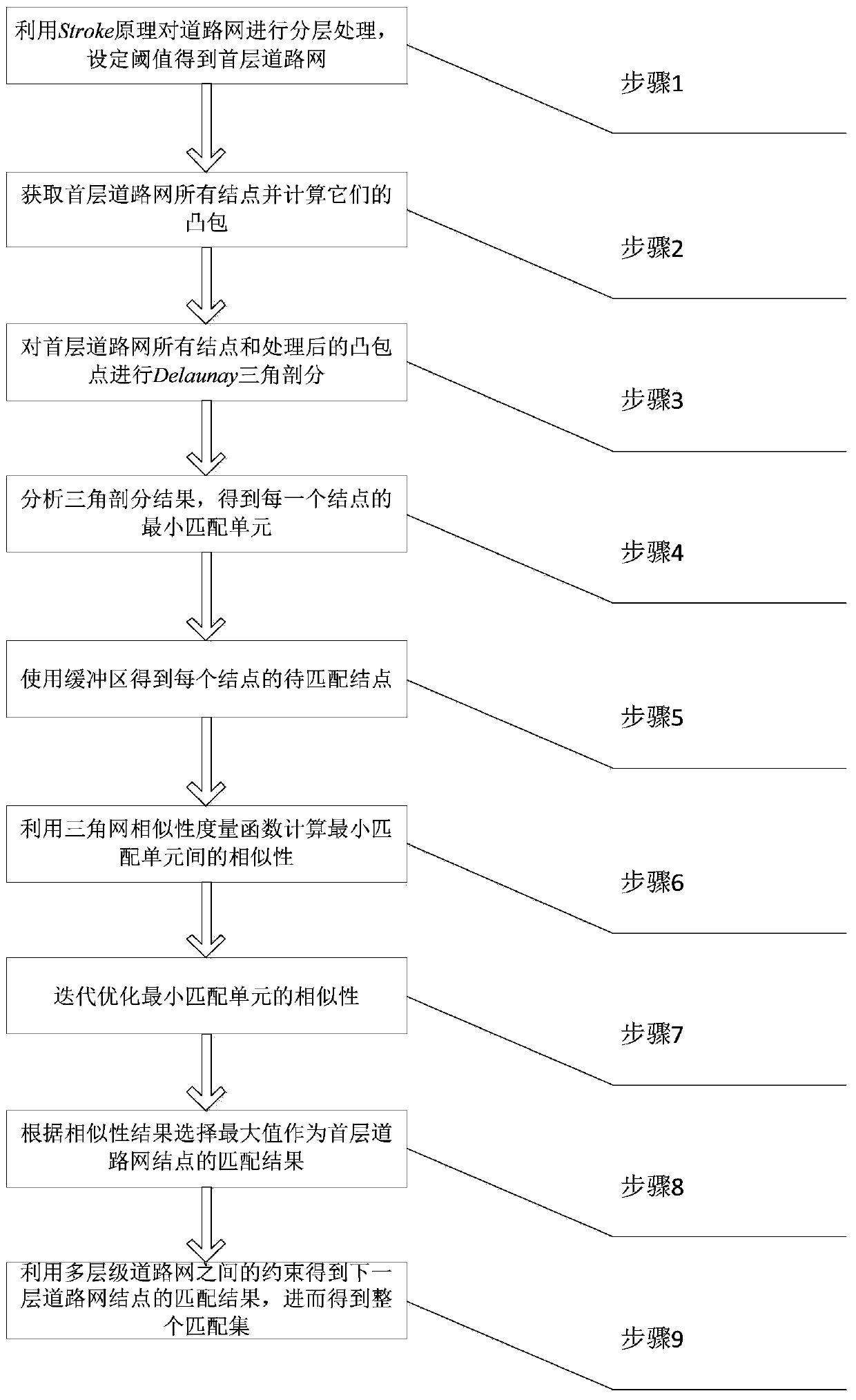

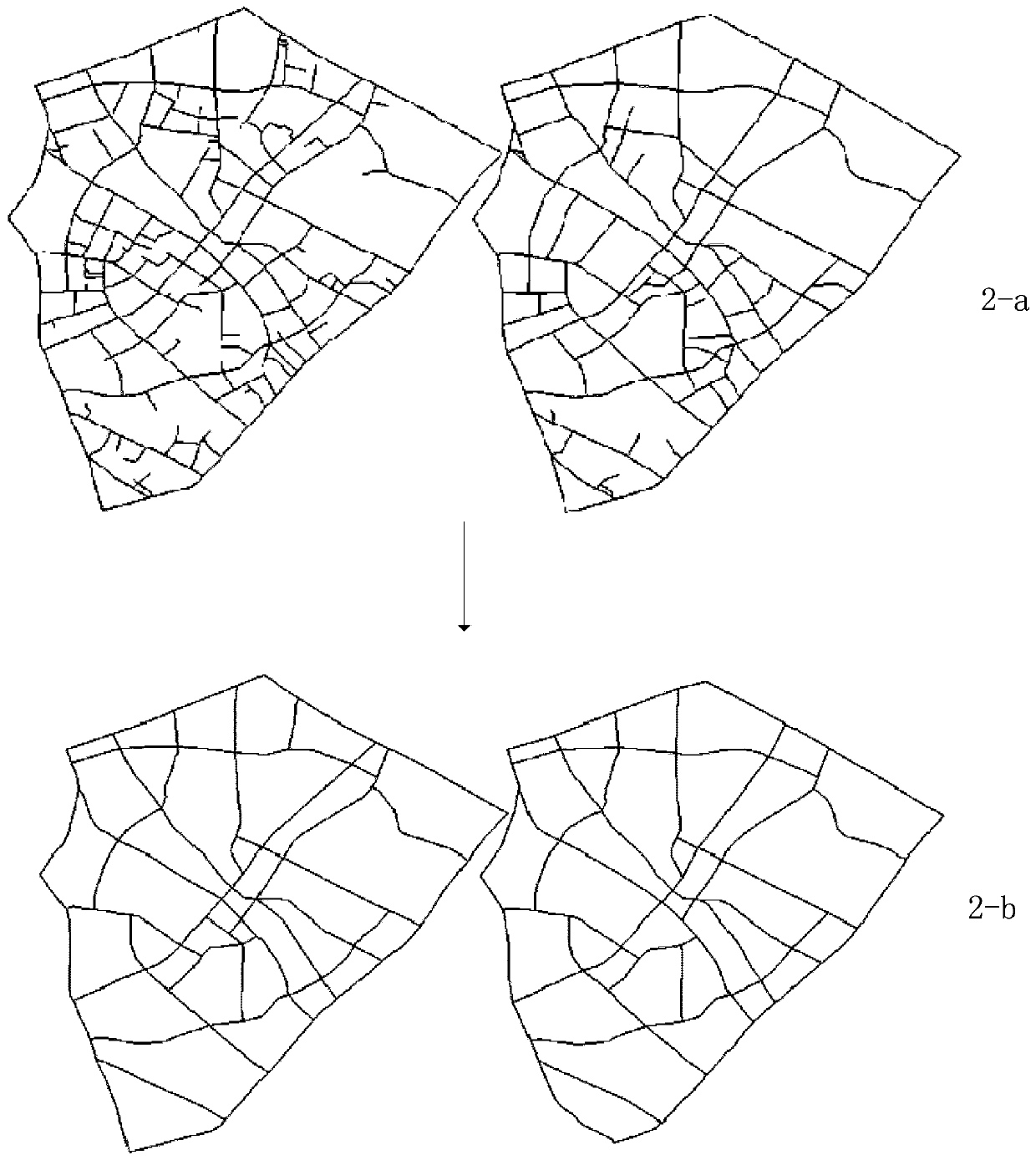

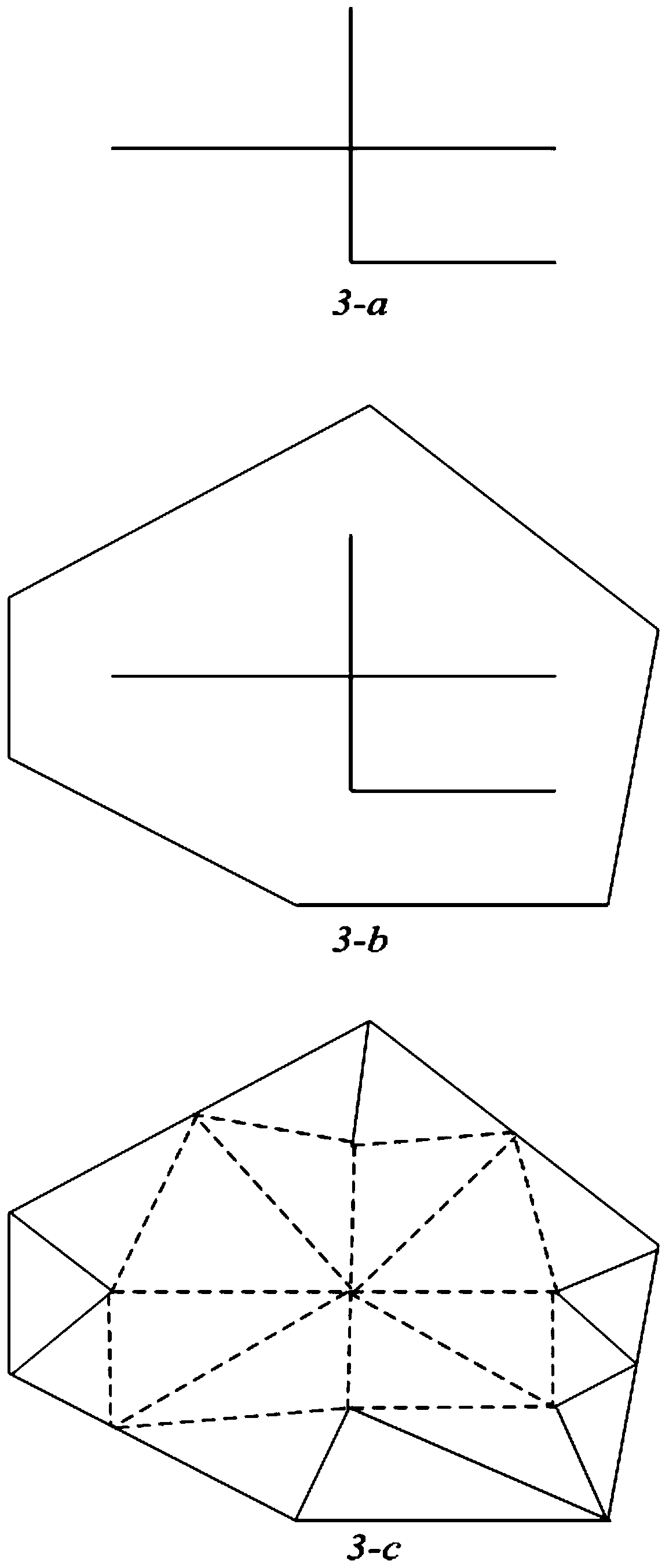

A Multi-level Vector Road Network Matching Method Based on Delaunay Triangulation

InactiveCN108074253BSimilarity calculationOptimize the matching relationshipImage enhancementImage analysisRoad networksEngineering

The invention discloses a multi-layer vector road network matching method based on Delaunay triangulation. The method comprises the steps of utilizing the Stroke principle for performing layering processing on a road network, and setting a threshold value to obtain a first-layer road network; calculating convex hulls of all nodes in the road network, and processing the convex hulls; performing triangulation; obtaining the minimum matching unit of each node; utilizing a buffer region method for obtaining a node to be matched of each node; obtaining the similarity of the minimum matching unit ofthe corresponding node; performing iterative optimization on the similarity of the minimum matching units; selecting the node with the highest similarity of the minimum matching unit in the nodes tobe matched as the matched node; utilizing the constraint among different layer roads for calculating the matching relation of the next layer road nodes, and then obtaining the final matching set. Thegood vector road element matching relation can be obtained.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method and device for analyzing webpage delivery content and automatic delivery method and device

ActiveCN103778125BImprove click-through rateImprove the delivery effectMarketingSpecial data processing applicationsAnalysis methodWeb page

The invention provides a webpage throwing content analyzing method and device and an automatic throwing method and device for webpage throwing content. The throwing content is thrown on a plurality of webpages through a throwing system of the throwing content. The webpage throwing content analyzing method includes recording access behavior data of a visitor accessing the webpage throwing content, wherein the M-level position code of the webpage of the corresponding throwing content and the N-level attribute code of the throwing system are carried and added in the access behavior data, and M and N are positive integers; conducting statistics on the clicking rates of the throwing content at different throwing positions according to the M-level position code and the N-level attribute code of the access behavior data; determining the optimum throwing position of the throwing content according to the clicking rates at different throwing positions. By means of the method and device, the optimum throwing position of the webpage throwing content can be found, the throwing efficiency of the throwing content is improved, and relevant network resource configuration is optimized.

Owner:ALIBABA GRP HLDG LTD

A high-temperature, high-strength wear-resistant self-lubricating material and its preparation method

The invention discloses a high-temperature, high-strength wear-resistant self-lubricating material and a preparation method thereof, belonging to the fields of metal material manufacturing and powder metallurgy. Described preparation method comprises: (1) with Ag powder and TiB 2 Powder as lubricating and reinforcing phase, Ti 2 AlNb powder is used as matrix powder. (1) Put the powder into the solution and ultrasonically disperse it into a slurry; (3) Put the pre-ultrasonic slurry and grinding balls together into a ball milling tank for ball milling, so that the powder is fully mixed and the particle size is uniform; (4) Ball milling The final slurry is dried in a vacuum oven; (5) the dried powder is crushed with a wall breaker; (6) the crushed mixed powder is put into a graphite mold for discharge plasma sintering, and the furnace is cooled to room temperature and taken out. That is, the high-temperature high-strength wear-resistant self-lubricating material of the present invention is obtained. The invention solves the problem of poor high-temperature friction performance of the aviation titanium alloy. Simple process. The lubricating phase and reinforcing phase are closely combined with the matrix, and the material has high density. The hardness, high temperature strength and high temperature wear resistance of the material are all significantly improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com