Preparation method of toughened epoxy resin and underfill adhesive

A technology of underfill glue and epoxy resin, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of insufficient balance, delamination, cracking, etc., to reduce the Tg point, improve the matching relationship, The effect of improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An underfill adhesive, which is prepared by the following steps:

[0048] (1) Preparation of high toughness epoxy resin:

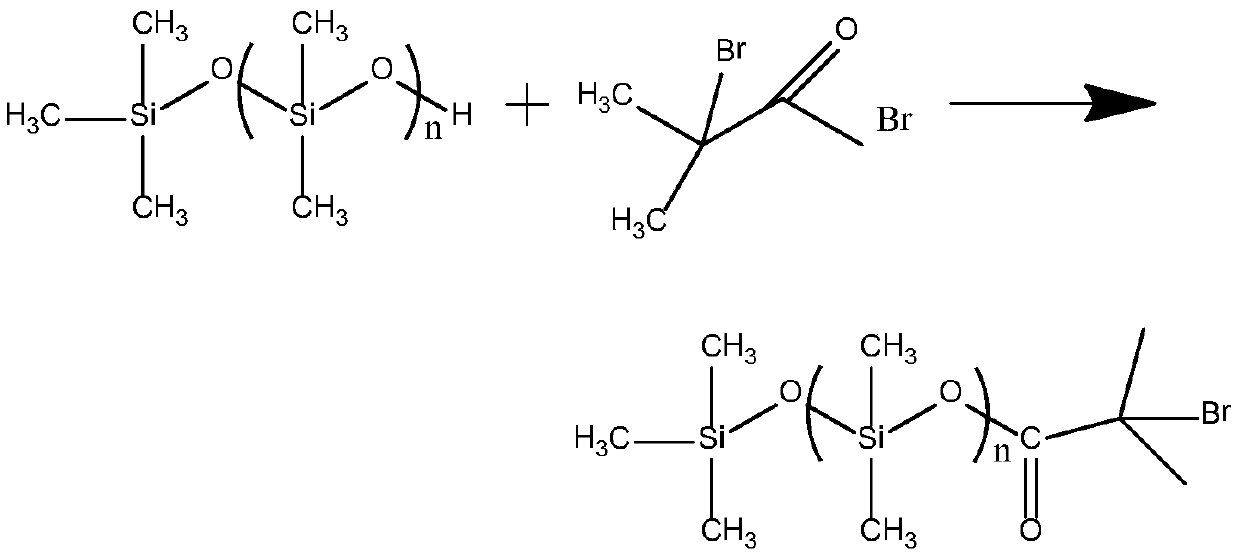

[0049] Step 1: Synthesis of polydimethylsiloxane macroinitiator: add tetrahydrofuran solution to the reaction flask, and then add polydimethylsilane / PDMS-OH, triethylamine and dimethylaminopyridine / DMAP containing monohydroxyl groups , Then vacuumize, remove the oxygen in the reactor, fill it with nitrogen or argon, and add bromoisobutyryl bromide / BiBB at a stirring speed of 20rpm, a temperature of -10°C, and a reaction time of 2 hours to obtain Macroinitiator-bromo-based polydimethylsiloxane PDMS-Br; wherein the mass ratio of THF solvent, PDMS-OH, triethylamine, DMAP, and BiBB is 100:20:5:5:1.

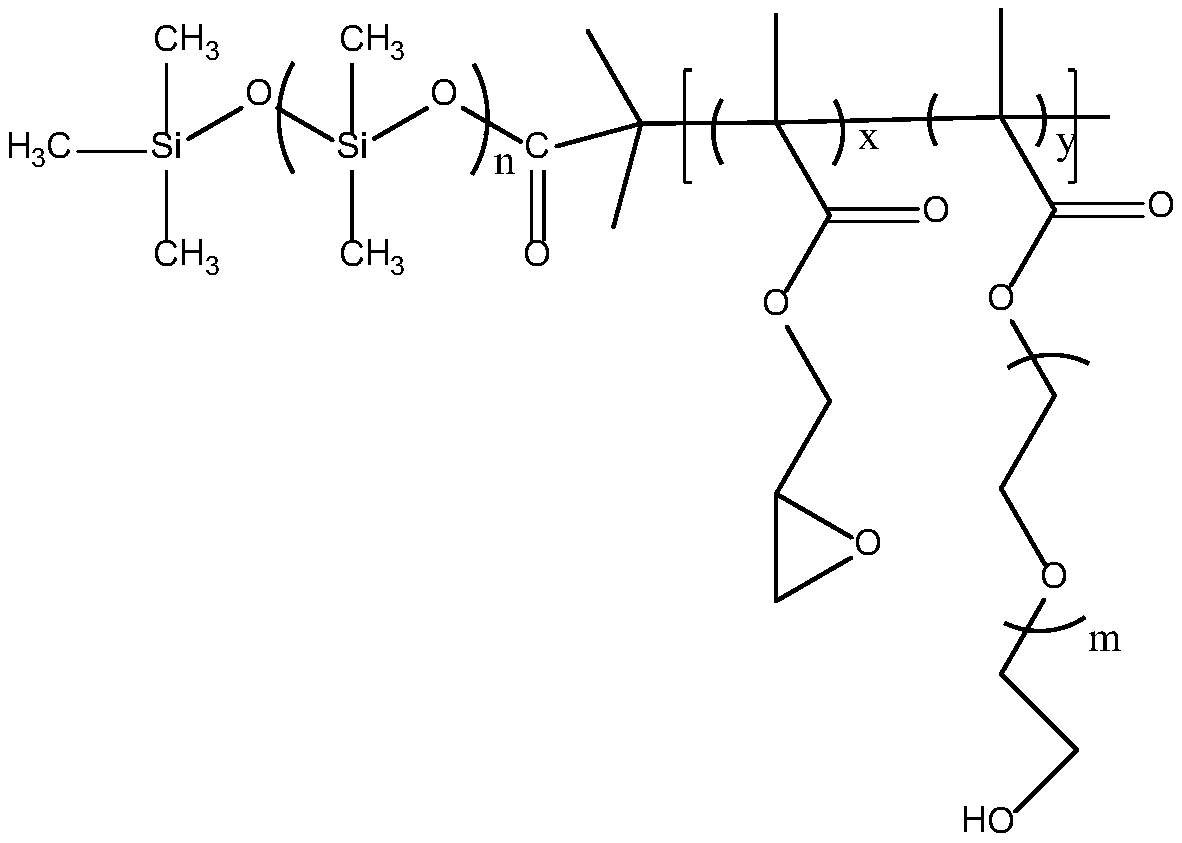

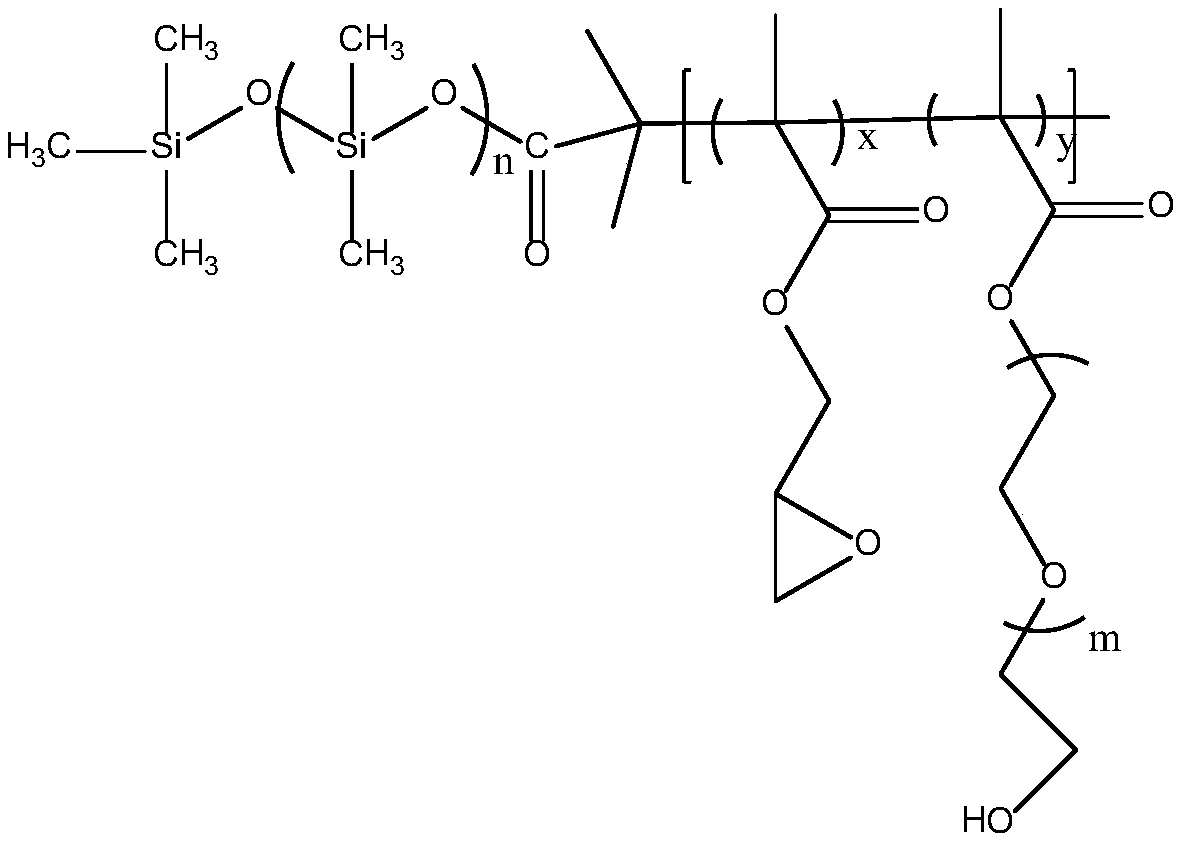

[0050] Step 2: Synthesis of highly toughened epoxy copolymer: PDMS-Br prepared in (Step 1) is used as a macroinitiator, and a block / random copolymer PDMS-bP (GMA-r-PEG-OH) is prepared by atom transfer method , That is, the macroinitiator PDMS-Br, monomer glycidy...

Embodiment 2

[0056] An underfill adhesive, which is prepared by the following steps:

[0057] (1) Preparation of high toughness epoxy resin:

[0058] The high-toughness epoxy resin has a structural formula of polydimethylsiloxane-block-poly(glycidyl methacrylate-random-hydroxy-terminated polyethylene glycol methyl methacrylate) PDMS-bP(GMA -r-PEG-OH) copolymer, the polydimethylsiloxane-block-poly(glycidyl methacrylate-random-hydroxy-terminated polyethylene glycol acrylate) copolymer adopts the following steps Prepared:

[0059] Step 1: Synthesis of polydimethylsiloxane macroinitiator: Add tetrahydrofuran solution to the reaction flask, then add polydimethylsilane containing monohydroxyl group / PDMS-OH, triethylamine and dimethylaminopyridine / DMAP, vacuum, remove oxygen in the reactor, fill with nitrogen or argon, add bromoisobutyryl bromide / BiBB, stirring speed 200rpm, temperature 10℃, reaction time 5 hours, you can get Macroinitiator-bromopolydimethylsiloxane / PDMS-Br; wherein the mass ratio o...

Embodiment 3

[0066] An underfill adhesive, which is prepared by the following steps:

[0067] (1) Preparation of high toughness epoxy resin:

[0068] The high-toughness epoxy resin has the structural formula: polydimethylsiloxane-block-poly(glycidyl methacrylate-random-hydroxy-terminated polyethylene glycol methyl methacrylate) PDMS-bP (GMA-r-PEG-OH) copolymer, which is prepared by the following steps:

[0069] Step 1: Synthesis of polydimethylsiloxane macroinitiator: Add tetrahydrofuran solution to the reaction flask, then add polydimethylsilane containing monohydroxyl group / PDMS-OH, triethylamine and dimethylaminopyridine / DMAP, then vacuum, remove oxygen in the reactor, fill with nitrogen or argon, then add bromoisobutyryl bromide / BiBB, stirring speed 100rpm, temperature 5℃, reaction time 4 hours, you can get The macromolecular initiator-bromopolydimethylsiloxane / PDMS-Br; wherein the mass ratio of THF solvent, PDMS-OH, triethylamine, DMAP, and BiBB is 100:30:8:8:2.

[0070] Step 2: Synthesis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com