Double-group element single-piston type hydraulic free piston engine

A piston engine and single-piston technology, which is applied in the field of energy and power, can solve problems such as difficulty in precise control of compression ratio, impact on engine reliability, application limitations, etc., and achieve the effect of compact structure, simple structure, and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

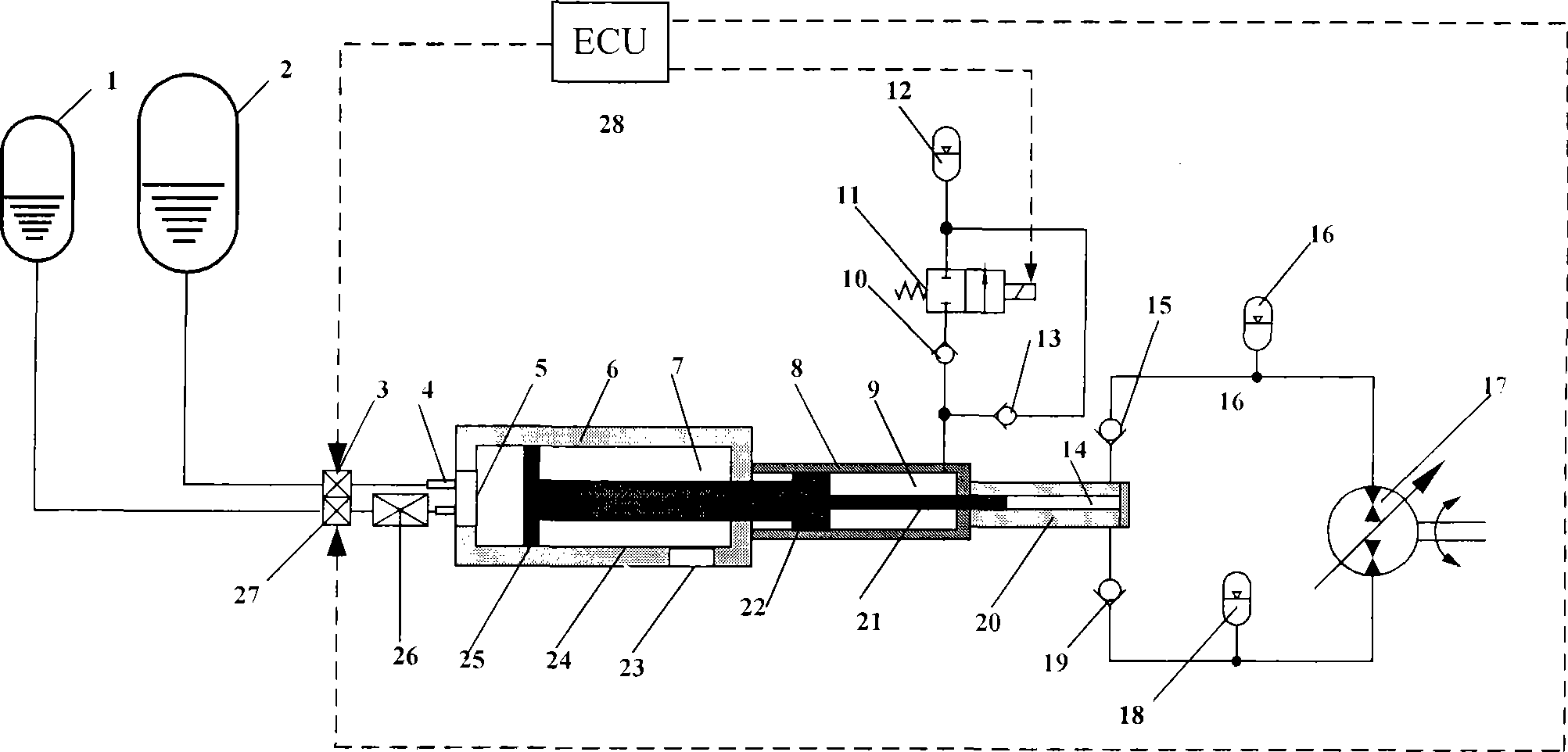

[0030] Embodiment 1: adopt the two-component single-piston hydraulic free-piston engine of catalytic ignition mode

[0031] refer to figure 1 , embodiment 1 two-component single-piston hydraulic free-piston engine comprises single-piston hydraulic free-piston engine, oxidant storage tank 1, fuel storage tank 2, oxidant control valve 27, fuel control valve 3 and electronic control unit (ECU) 28. Both the outlet port of the oxidant control valve 27 and the outlet port of the fuel control valve 3 communicate with the air inlet 5 of the power chamber of the single-piston hydraulic free-piston engine, and the inlet port of the oxidant control valve 27 communicates with the oxidant storage tank 1 is connected to the bottom end (i.e. the outlet end), the inlet port of the fuel control valve 3 is connected to the bottom end (i.e. the outlet end) of the fuel storage tank 2, the control end of the oxidant control valve 27 is connected to the control end of the fuel agent control valve 3...

Embodiment 2

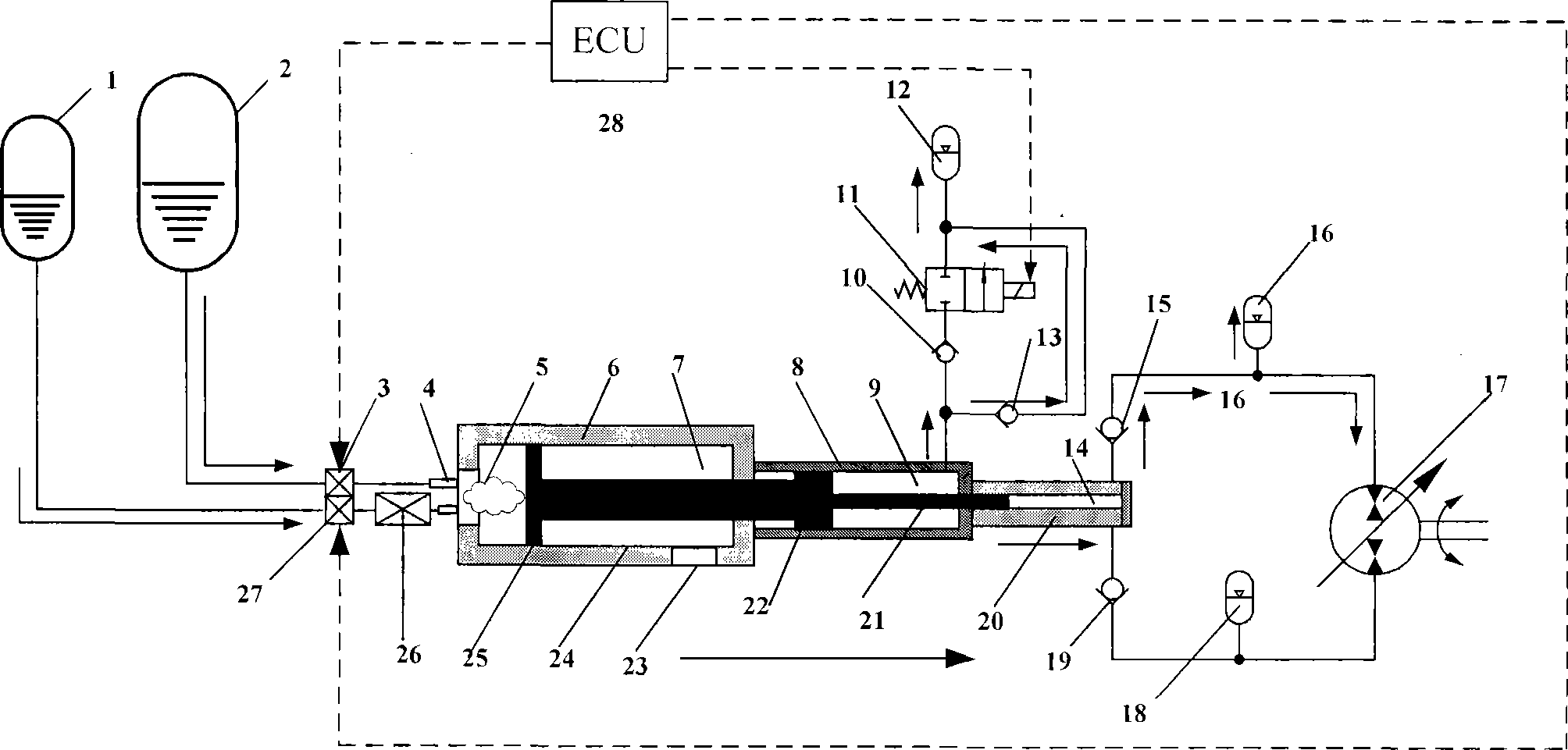

[0058] Embodiment 2: adopt the two-component single-piston hydraulic free-piston engine of homogeneous ignition mode

[0059] refer to Figure 5 , Embodiment 2 Two-component single-piston hydraulic free-piston engine comprises single-piston hydraulic free-piston engine, oxidant storage tank 1, fuel storage tank 2, oxidant control valve 27, fuel control valve 3 and electronic control unit 28, so The outlet port of the oxidant control valve 27 and the outlet port of the fuel control valve 3 are all communicated with the air inlet of the single-piston hydraulic free piston engine power chamber, and the inlet port of the oxidant control valve 27 is connected with the outlet port of the oxidant storage tank 1 ( bottom end), the inlet end of the fuel control valve 3 is connected to the outlet end (bottom end) of the fuel storage tank 2, the control end of the oxidant control valve 27 and the control end of the fuel control valve 3 are respectively connected to the electric The corr...

Embodiment 3

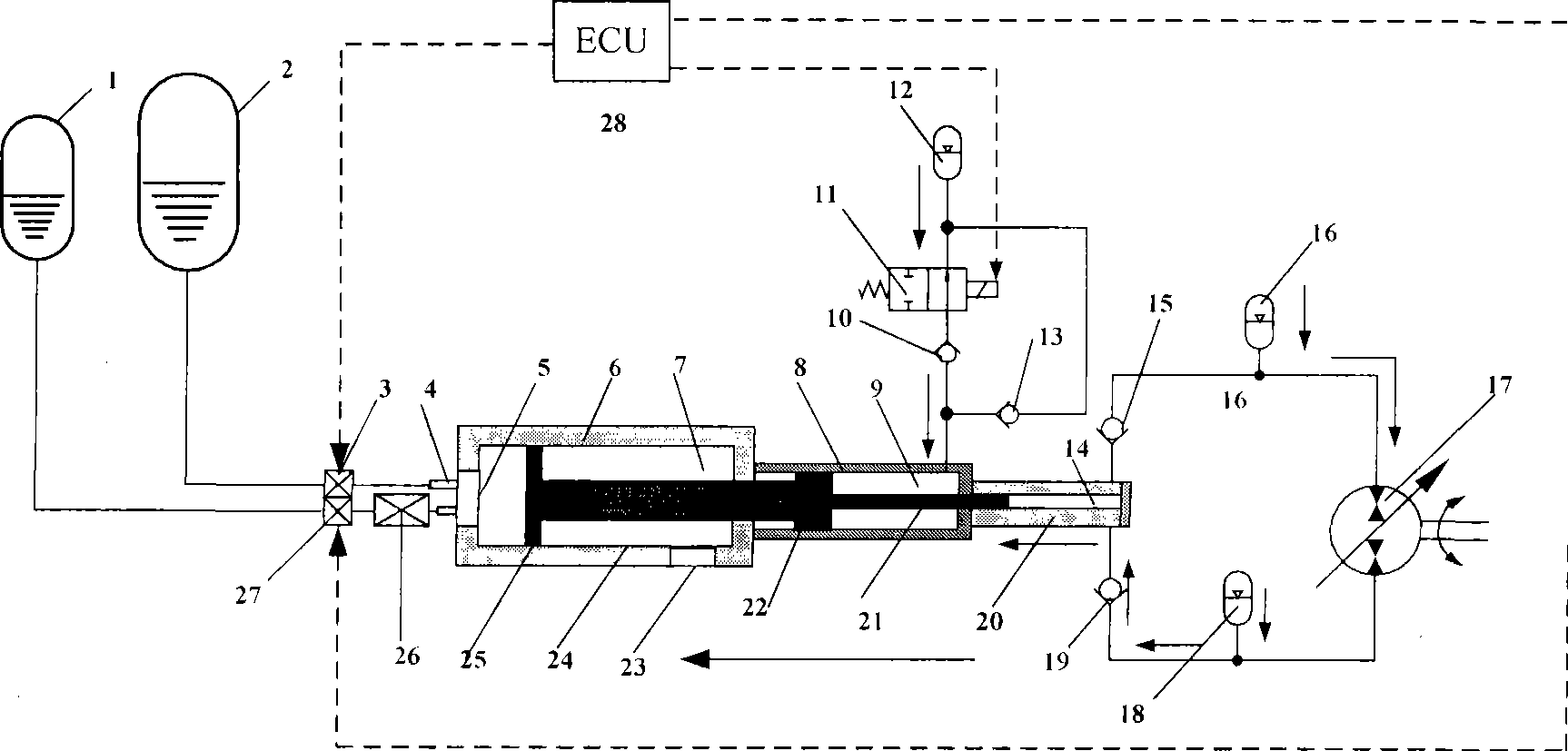

[0068] Embodiment 3: Adopt homogeneous ignition mode and contain the two-component single-piston hydraulic free-piston engine of stroke regulating circuit

[0069] refer to Figure 6 , embodiment 3 adds a stroke adjustment loop on the basis of embodiment 2 dual-component single-piston hydraulic free-piston engine, so that the engine can work in a variable-range working mode under the control of the electronic control unit 28 to realize stroke adjust. The stroke adjustment loop includes a variable range control valve 30 and an unloading check valve 29. The control end of the variable range control valve 30 is connected to the output end of the electronic control unit 28, and the inlet port of the variable range control valve 30 is connected to the hydraulic pump chamber 14 of the engine. , the outlet end of the range control valve 30 is connected to the inlet end of the unloading check valve 29 , and the outlet end of the unloading check valve 29 is connected to the low-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com