Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Uniform and symmetrical distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

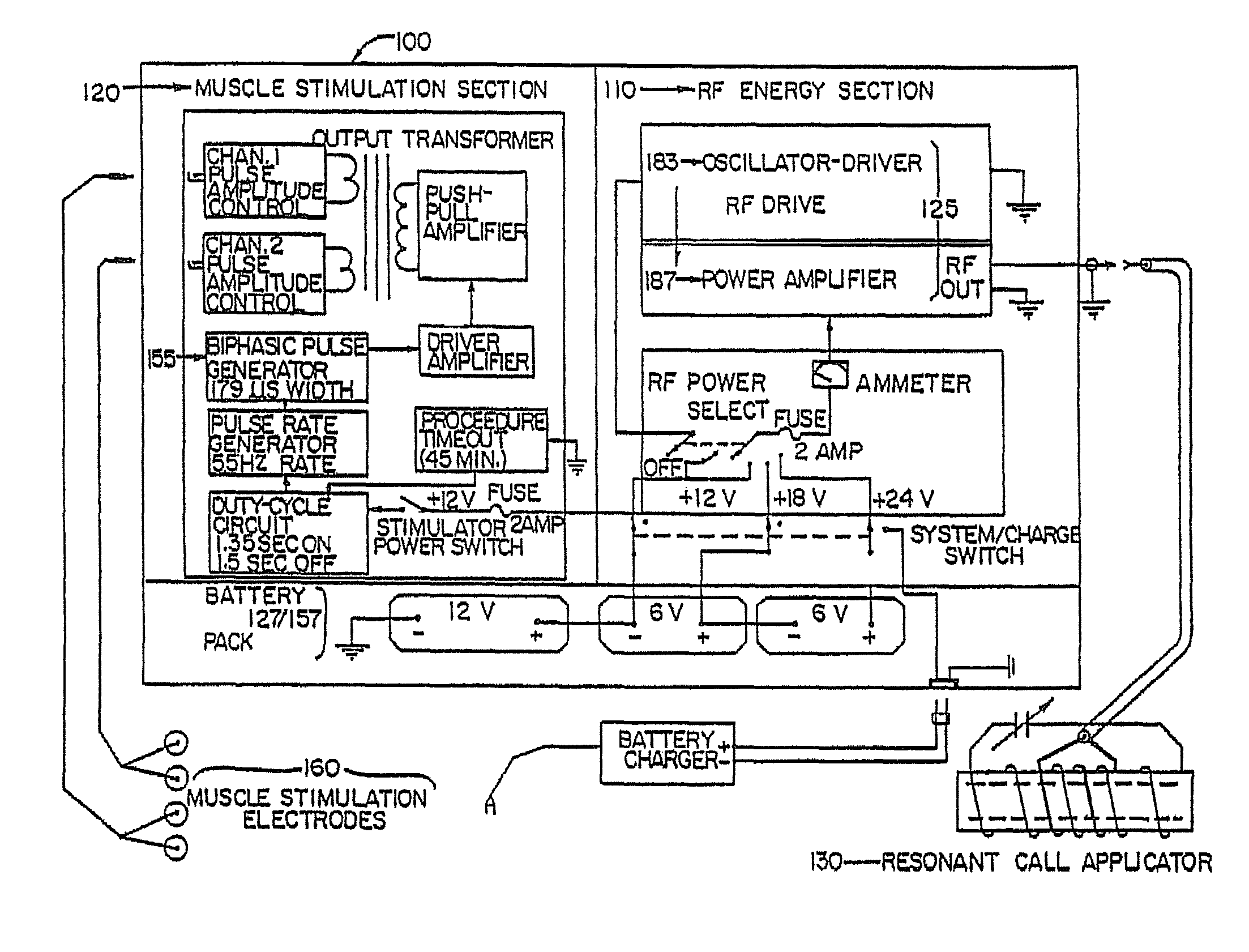

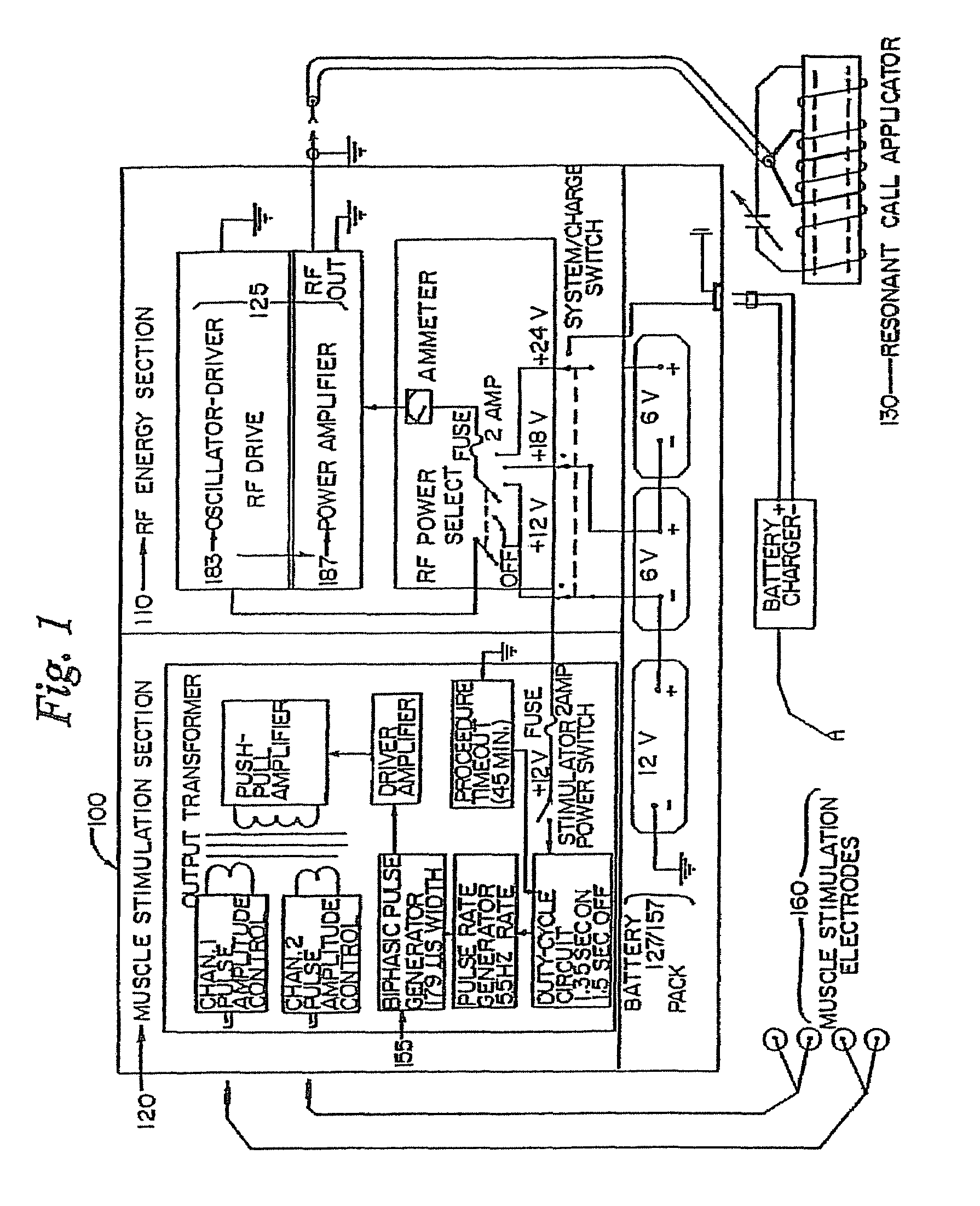

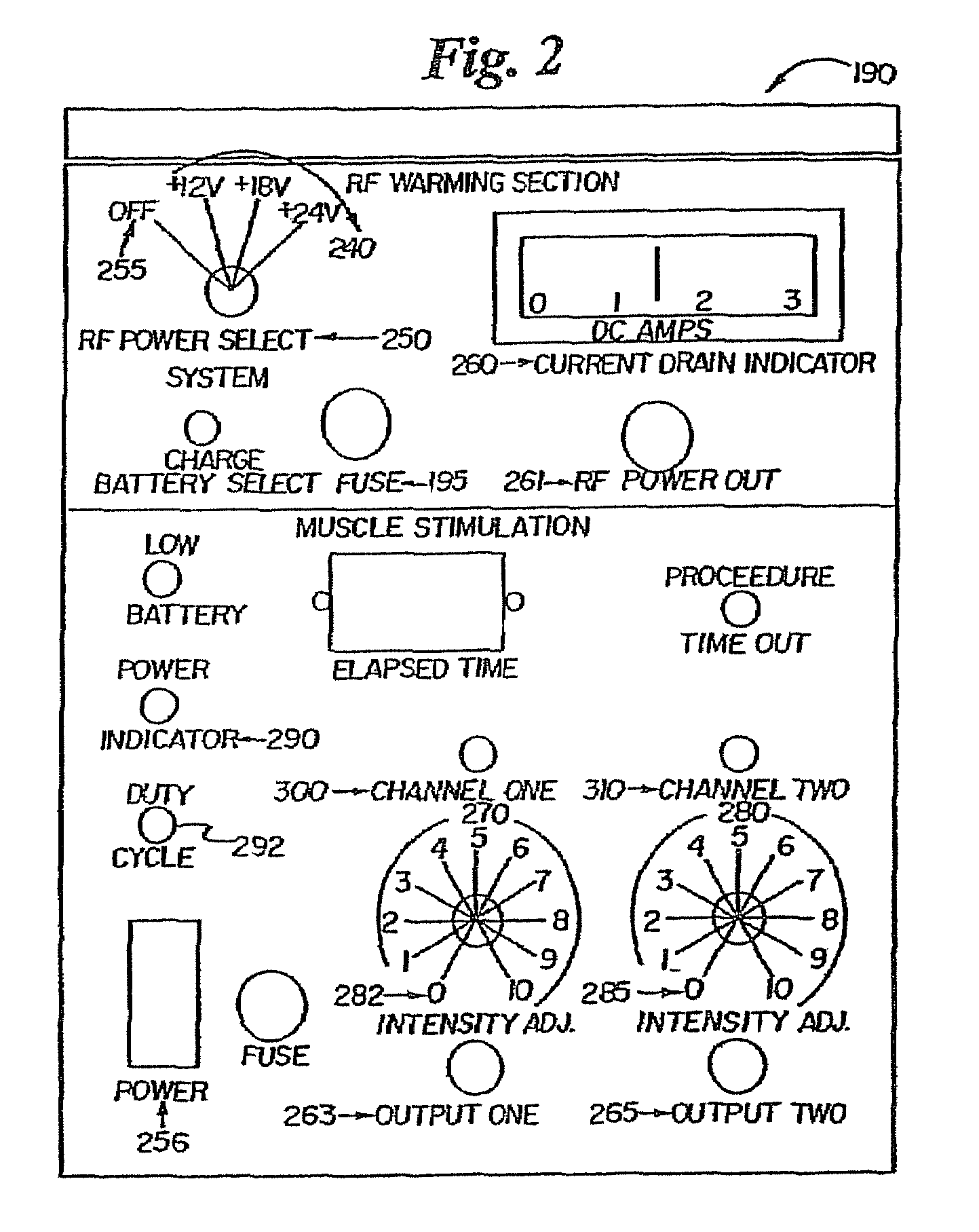

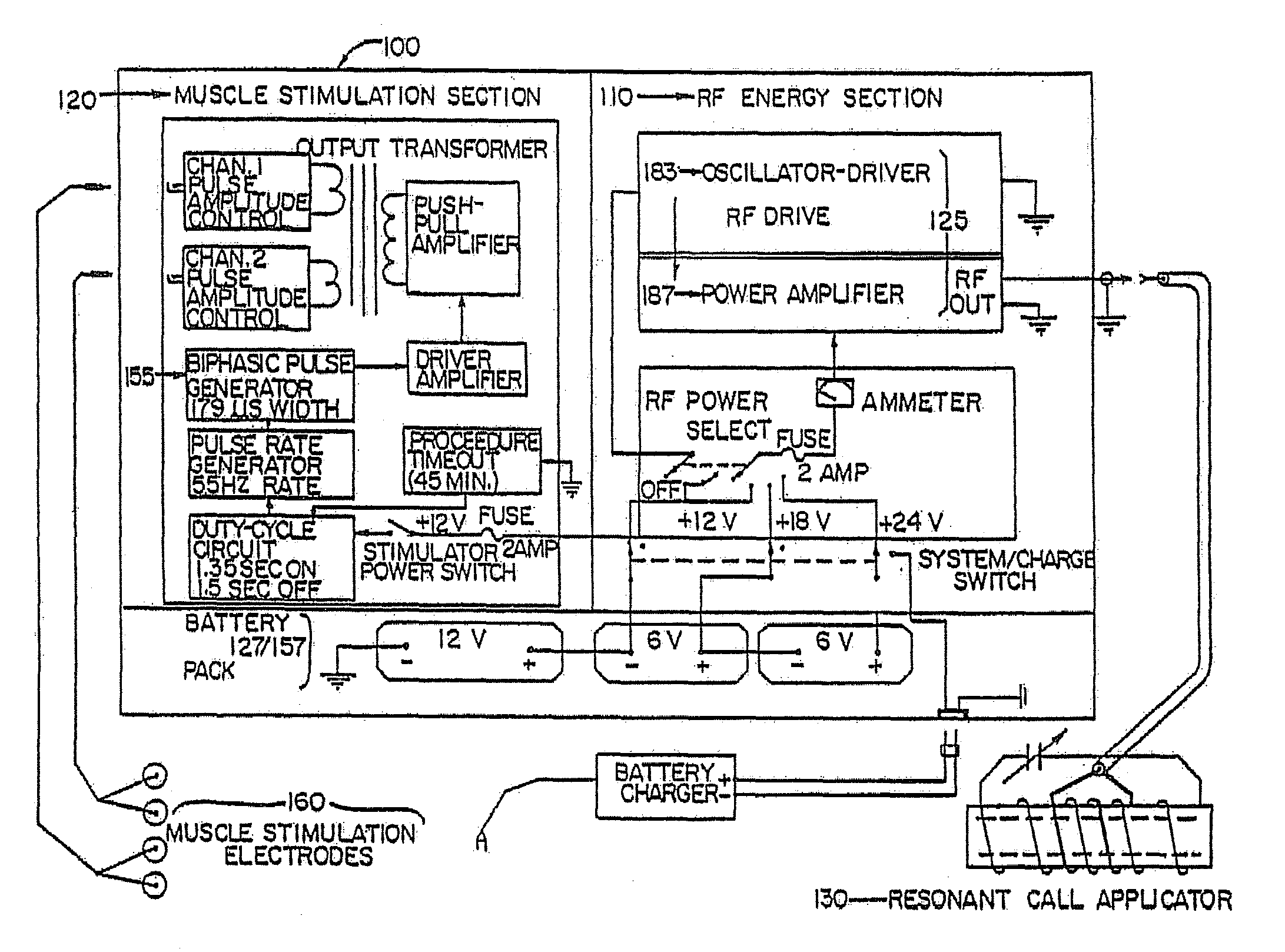

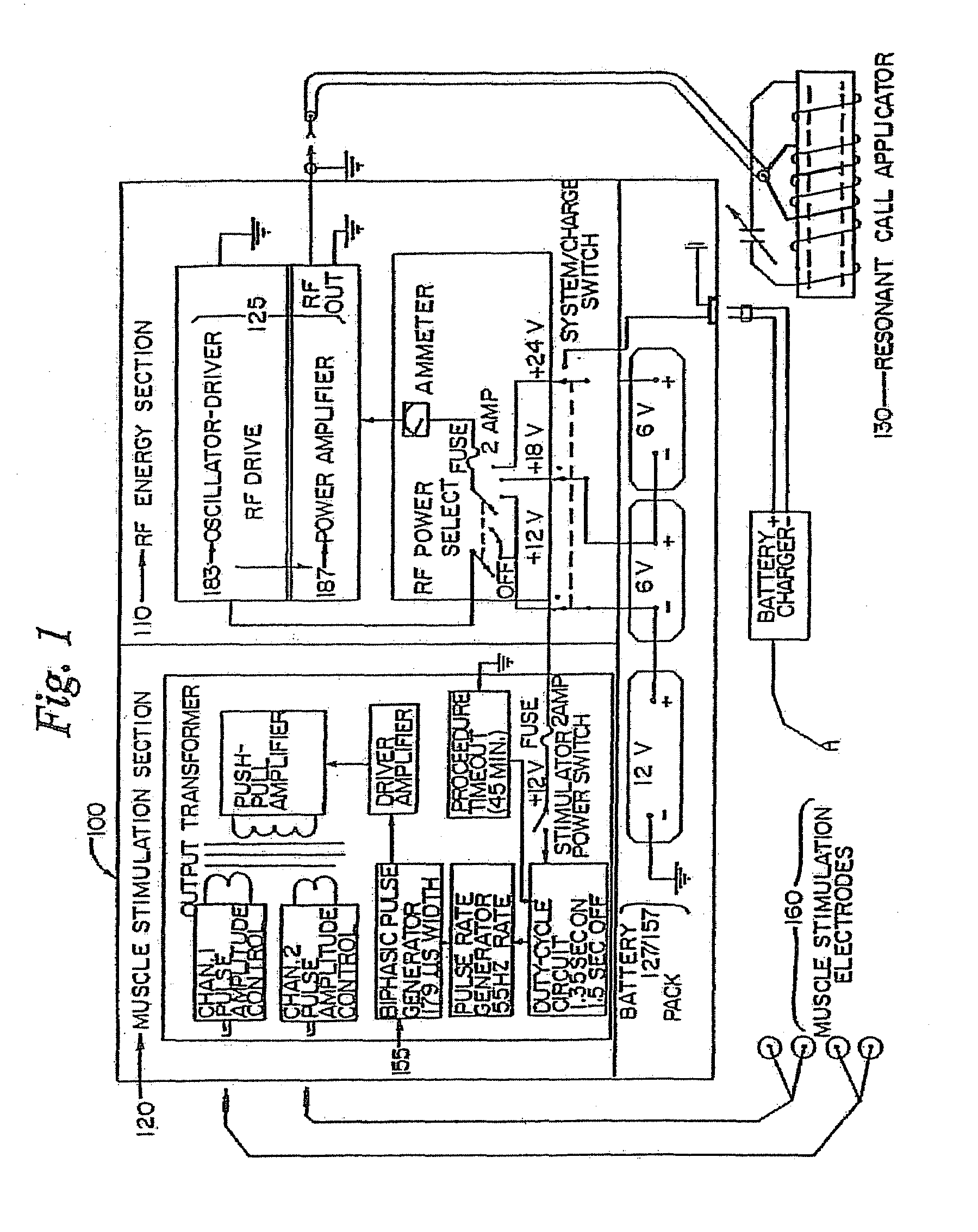

RF diathermy and faradic muscle stimulation treatment

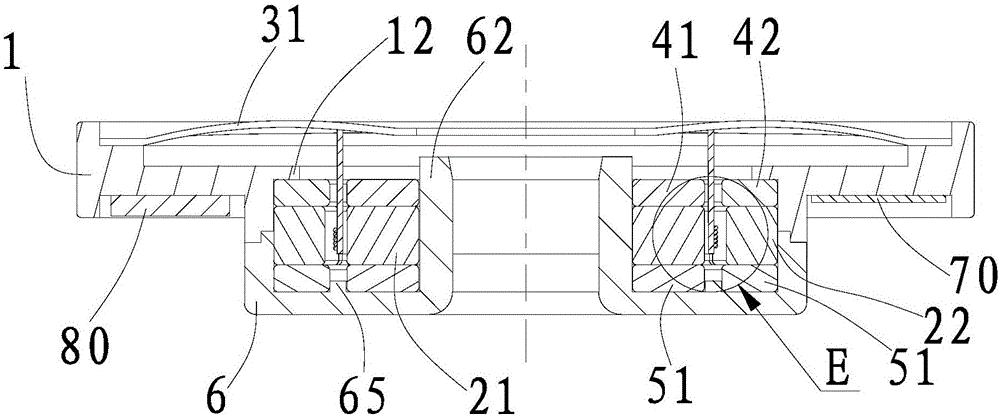

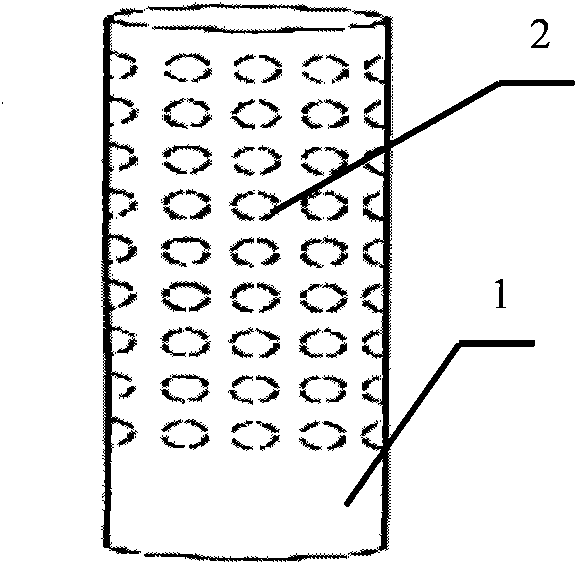

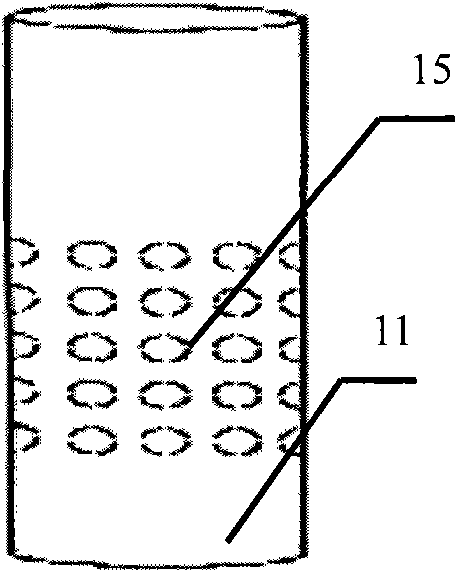

InactiveUS7953500B2Easy to changeUniform and symmetrical distributionElectrotherapyRadiation therapyEngineeringMuscle Stimulation

An RF diathermy coil assembly, including a generally elastically deformable patient conforming garment and a conductive coil secured to the garment. The conductive coil having a woven wire construction such that the coil can deform as the garment elastically deforms. The RF diathermy coil assembly can be used for wound healing in conjunction with muscle stimulation.

Owner:HK MEDICAL TECH +1

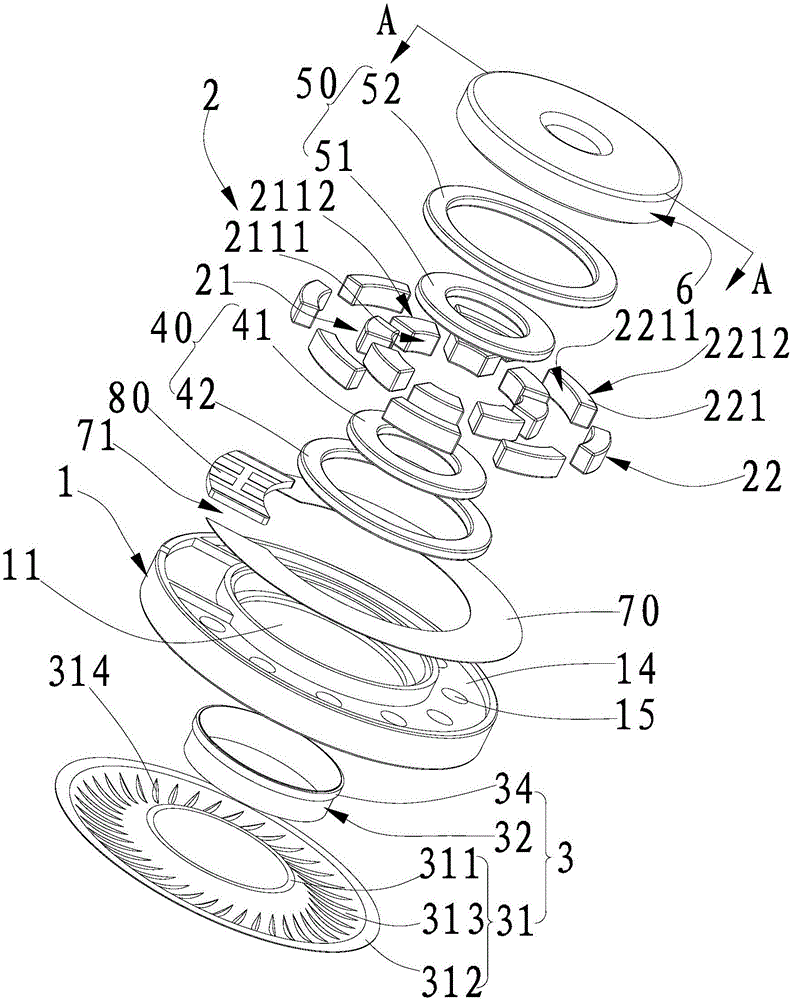

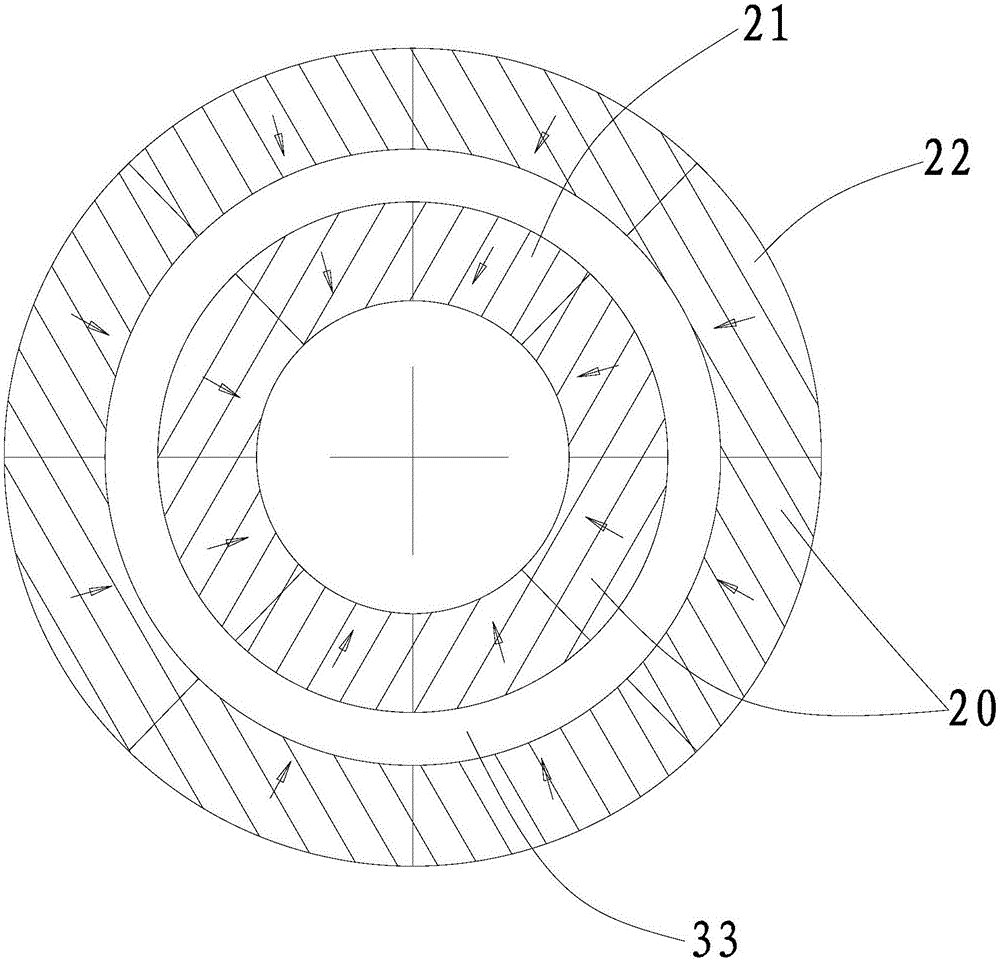

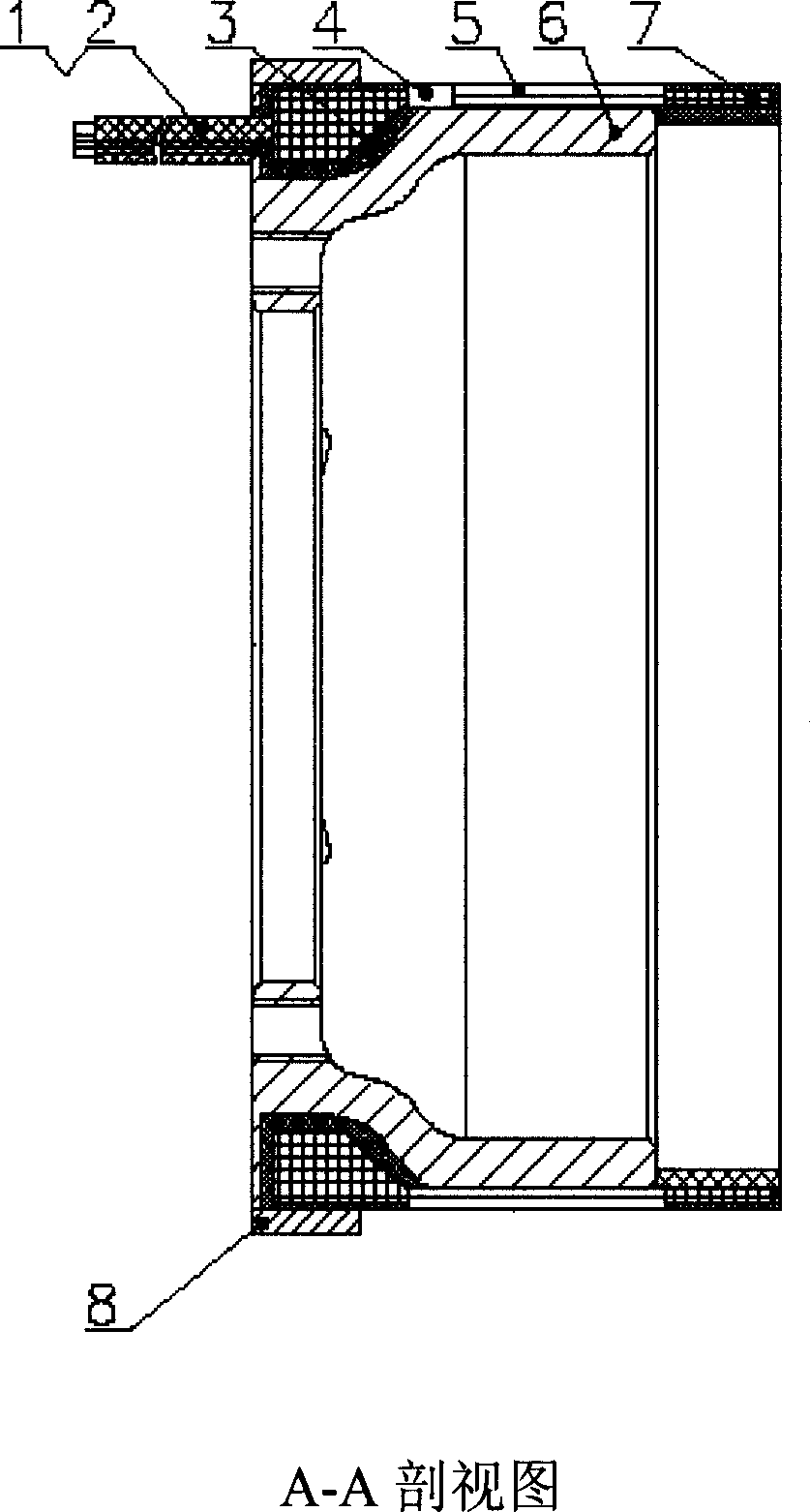

Loudspeaker and headset

PendingCN106375915AReduce magnetic flux leakage and hysteresis lossUniform and symmetrical distribution of magnetic field linesLoudspeakersFrequency/directions obtaining arrangementsDistortionLoudspeaker

The invention relates to the technical field of electronic products, and provides a loudspeaker and a headset. A horn bracket, a magnetic circuit system and a vibration system are comprised. The horn bracket is used for providing a through hole used for accommodating the magnetic circuit system. The magnetic circuit system comprises an inner magnetic ring and outer magnetic ring which sleeves the inner magnetic ring. The inner magnetic ring and the outer magnetic ring share the same axis. A gap is between the inner ring surface of the outer magnetic ring and the outer ring surface of the inner magnetic ring. The magnetic poles of the inner magnetic ring and the outer magnetic ring are different. Magnetic force lines formed by the inner magnetic ring and the outer magnetic ring in the gap are radially arranged. The vibration system comprises a sound film, a voice coil with one end connected with the sound film, and a coil which is connected with the other end of the voice coil. The coil is placed in the gap. The sound film is connected with one end part of the horn bracket. According to the design of the magnetic circuit system, magnetic flux leakage and hysteresis loss are reduced; the magnetic force lines are uniformly and symmetrically distributed; distortion is reduced; and true sound is restored to show the sense of reality.

Owner:SHENZHEN GRANDSUN ELECTRONICS

RF Diathermy and Faradic Muscle Stimulation Treatment

InactiveUS20080215115A1Easy to changeUniform and symmetrical distributionElectrotherapyArtificial respirationWound healingEngineering

An RF diathermy coil assembly, including a generally elastically deformable patient conforming garment and a conductive coil secured to the garment. The conductive coil having a woven wire construction such that the coil can deform as the garment elastically deforms. The RF diathermy coil assembly can be used for wound healing in conjunction with muscle stimulation.

Owner:HK MEDICAL TECH +1

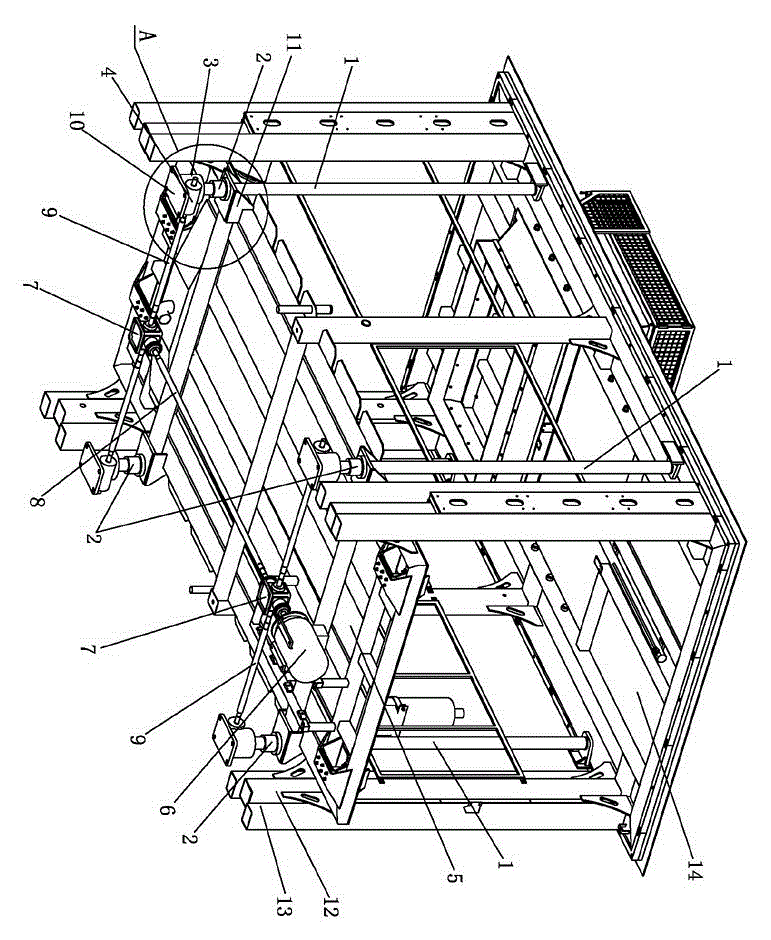

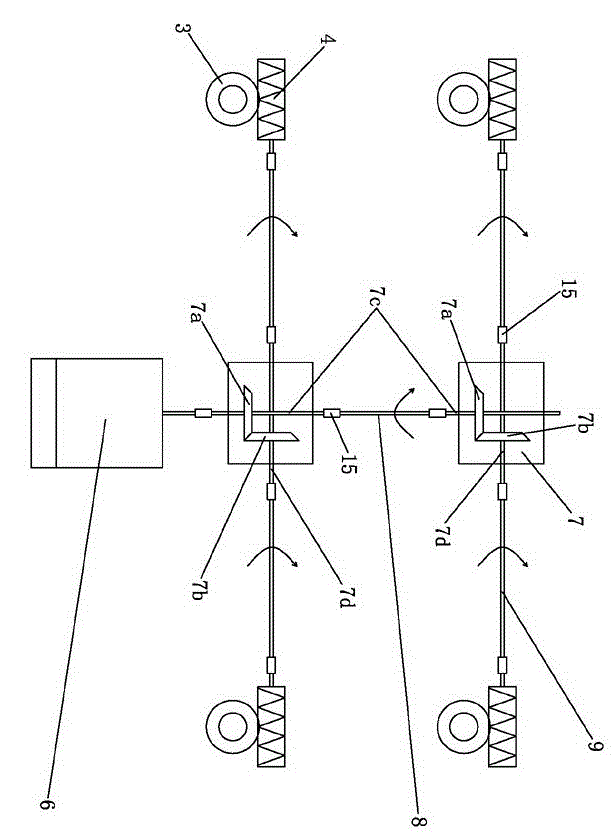

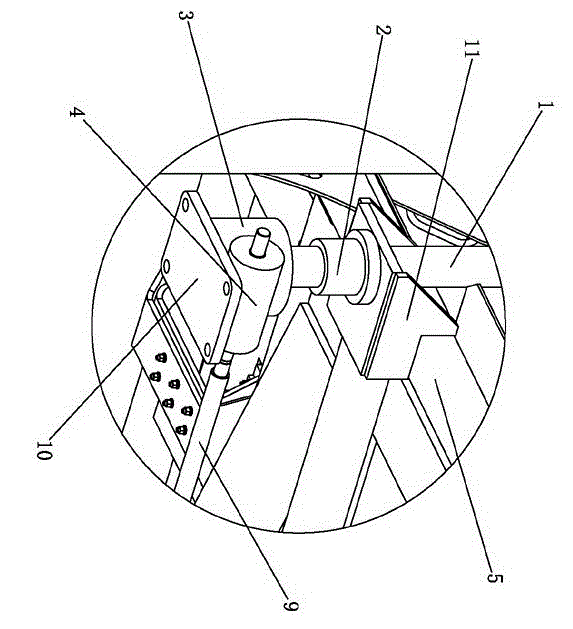

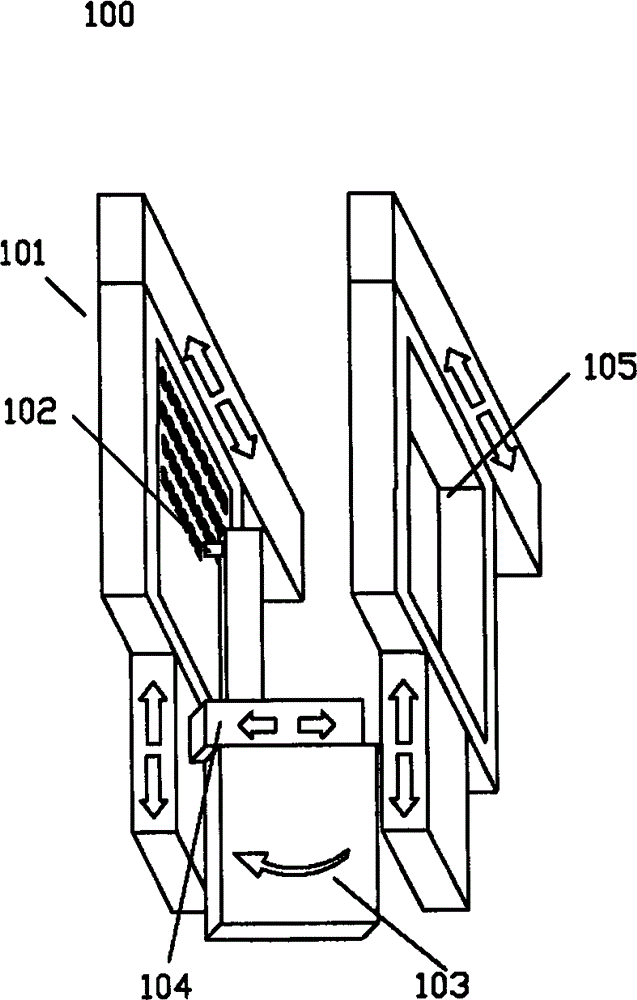

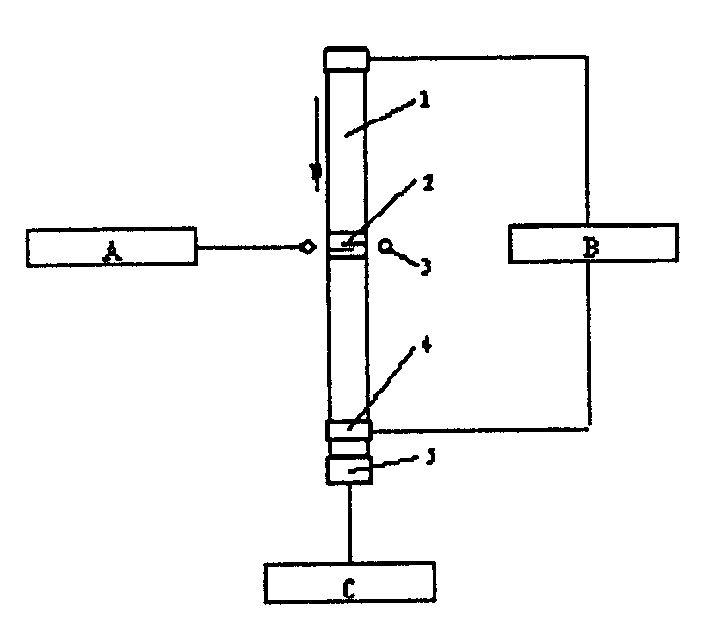

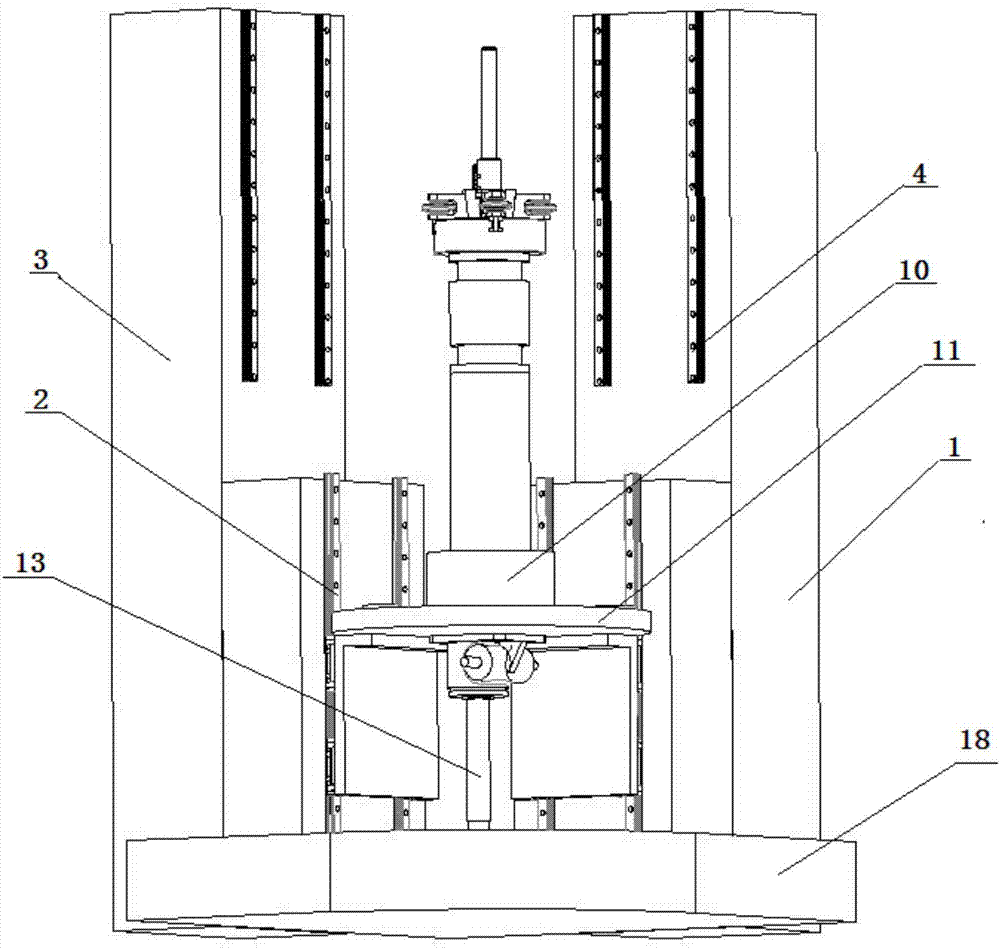

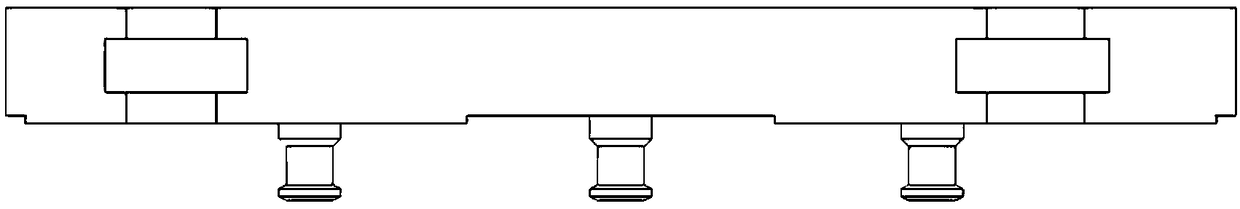

Buried type movable garbage disposal equipment based on worm gear and lead screw transmission

ActiveCN104944032AHigh precisionGuaranteed accuracyLifting devicesRefuse gatheringMechanical engineeringGarbage disposal

The invention discloses buried type movable garbage disposal equipment based on worm gear and lead screw transmission in the technical field of garbage disposal equipment. The buried type movable garbage disposal equipment based on worm gear and lead screw transmission comprises a main framework, a lifting platform and a jacking transmission mechanism, wherein the lifting platform is further provided with a vertical lifting guide mechanism; the jacking transmission mechanism comprises lead screws, nuts and a bottom supporting base; the nuts are fixedly installed on the lifting platform; the axial length direction of the lead screws is consistent with the lifting direction of the lifting platform; the head portions of the lead screws are rotationally installed on the main framework; the foot portions of the lead screws are rotationally installed on the bottom supporting base; at least four sets of the lead screws and the nuts, and the number of sets is an even number; the lead screws and the nuts are symmetrically arranged; the foot portions of the lead screws are fixedly sleeved with worm gears; a rotation acting mechanism capable of driving the lead screws to rotate is arranged on a ground foundation below the lifting platform and comprises a worm meshed with the worm gears and a drive system capable of driving the worm to rotate. The synchronism of the lifting action of the lifting platform can be accurately controlled, and the structure is simple and reasonable.

Owner:YANGZHOU JINWEI ENVIRONMENTAL PROTECTION TECH CO LTD

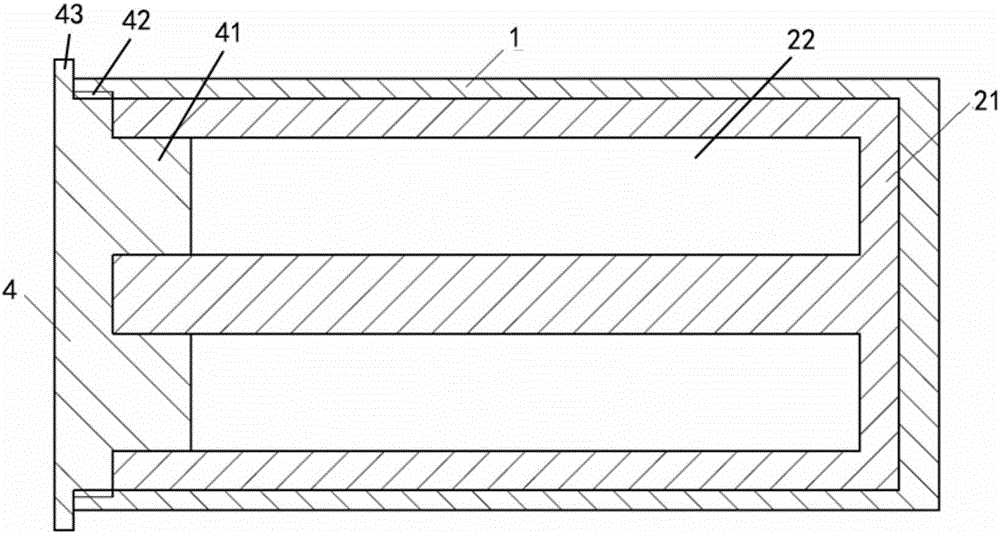

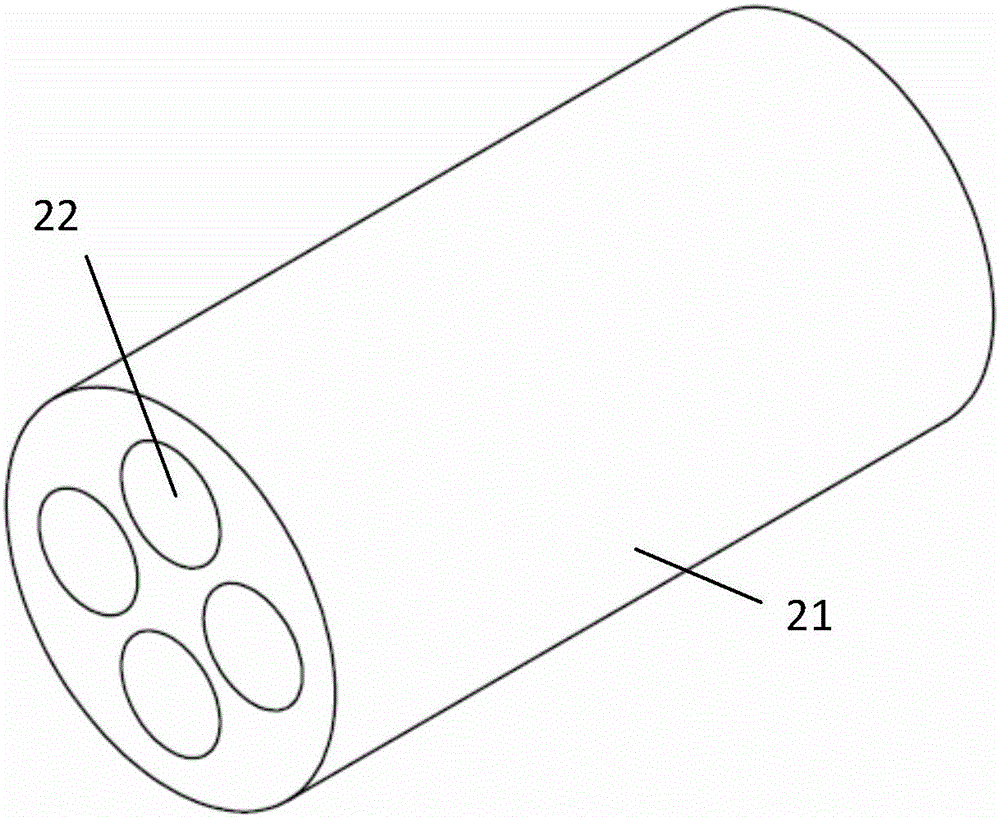

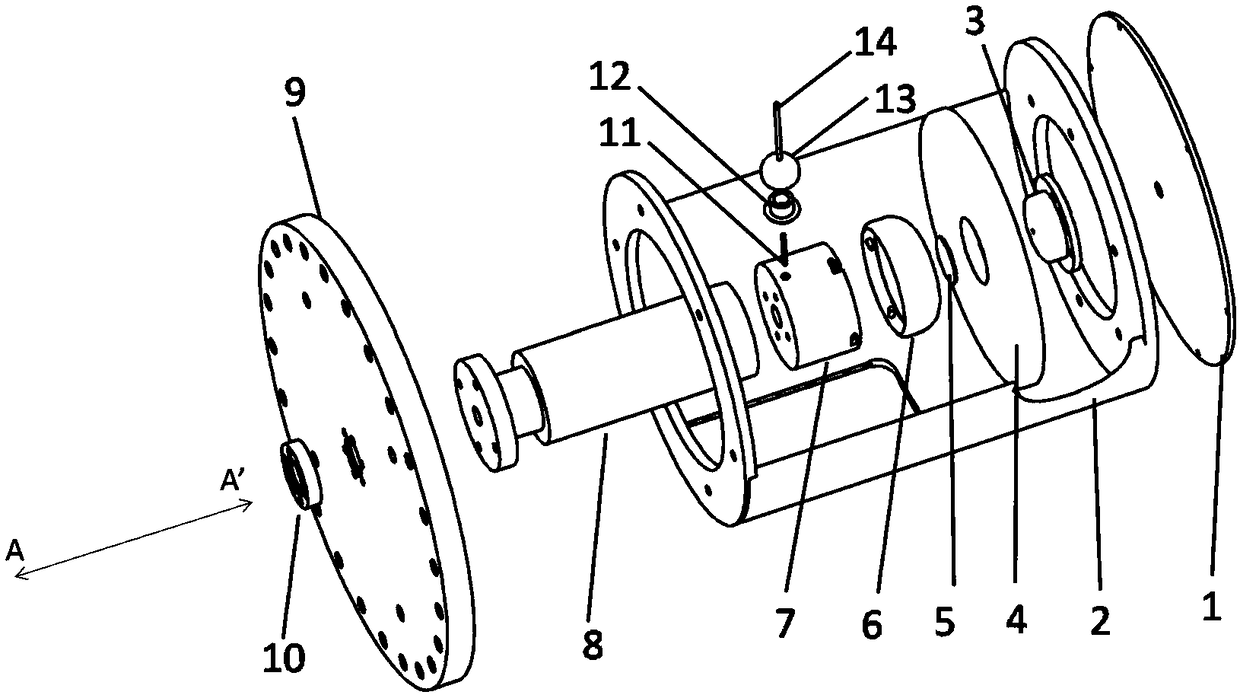

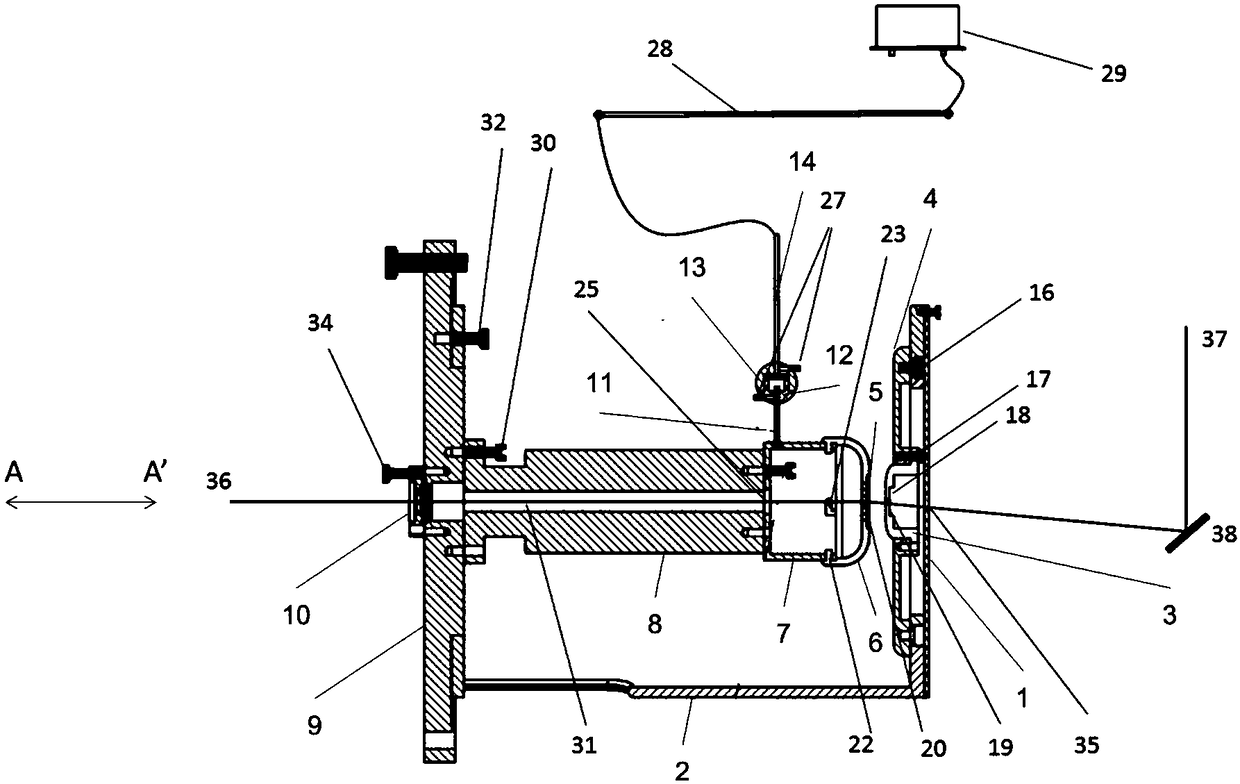

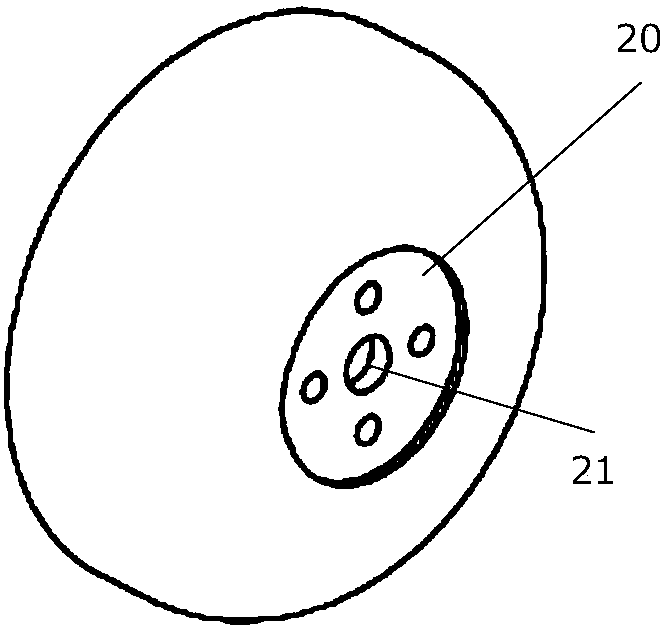

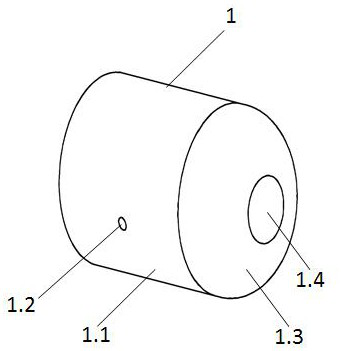

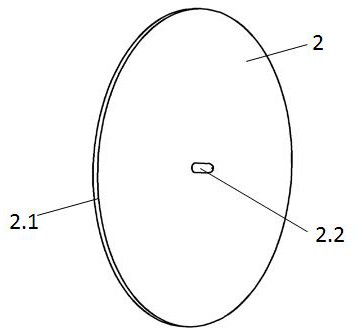

Multi-cavity shaft system particle damper

InactiveCN106195088ALess dynamic imbalanceImprove stabilityFriction dampersEngineeringNoise reduction

The invention discloses a multi-cavity shaft system particle damper and relates to a shaft system of a power device. A cylinder is arranged, and at least two axial cavities are formed in the cylinder. A fixed cover plate is arranged at the opened ends of the axial cavities, and the axial cavities are filled with particles. An end cover is arranged at the front end of the fixed cover plate, shafts matched and connected to the axial cavities are arranged at the back end of the fixed cover plate, a connecting part is arranged between the end cover and the shafts, and an external thread is arranged in the connecting part. An original single shaft hole is separated into a plurality of cavities, and each cavity is filled with particles. As the positions of the particles after modification are balanced relative to the centroids, the dynamic unbalance phenomenon of the particle damper is greatly reduced, so that generation of extra work is not caused or a small part of extra work is generated, and the vibration and noise reduction stability of the particle damper is enhanced. Vibration and noise generated when the shaft system operates are reduced, and meanwhile, extra work generated by dynamic unbalance is reduced, and the vibration and noise reduction stability of the particle damper is improved.

Owner:XIAMEN UNIV

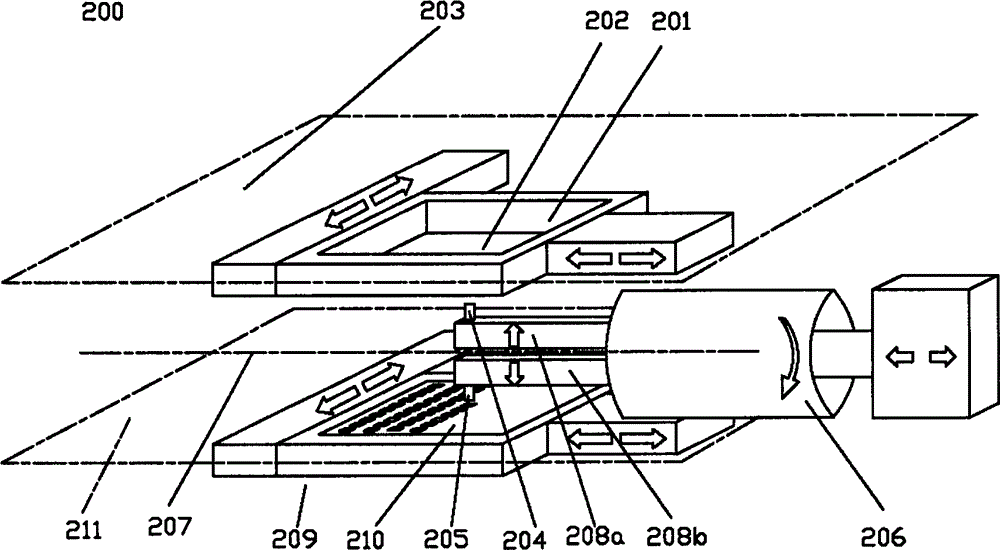

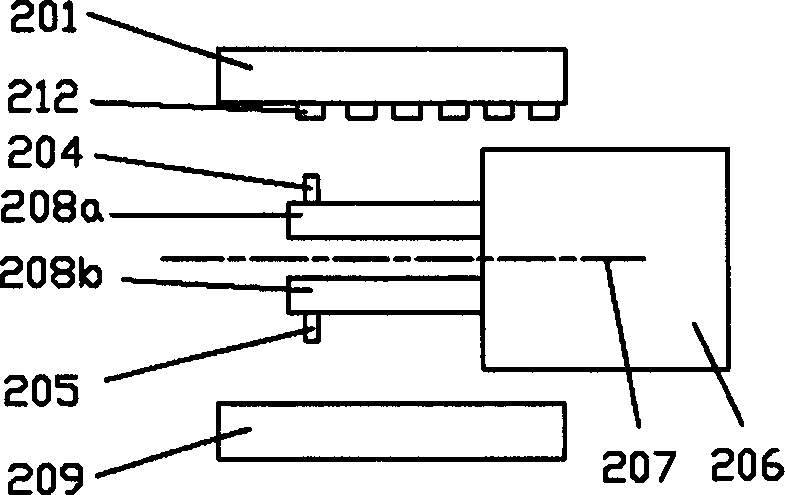

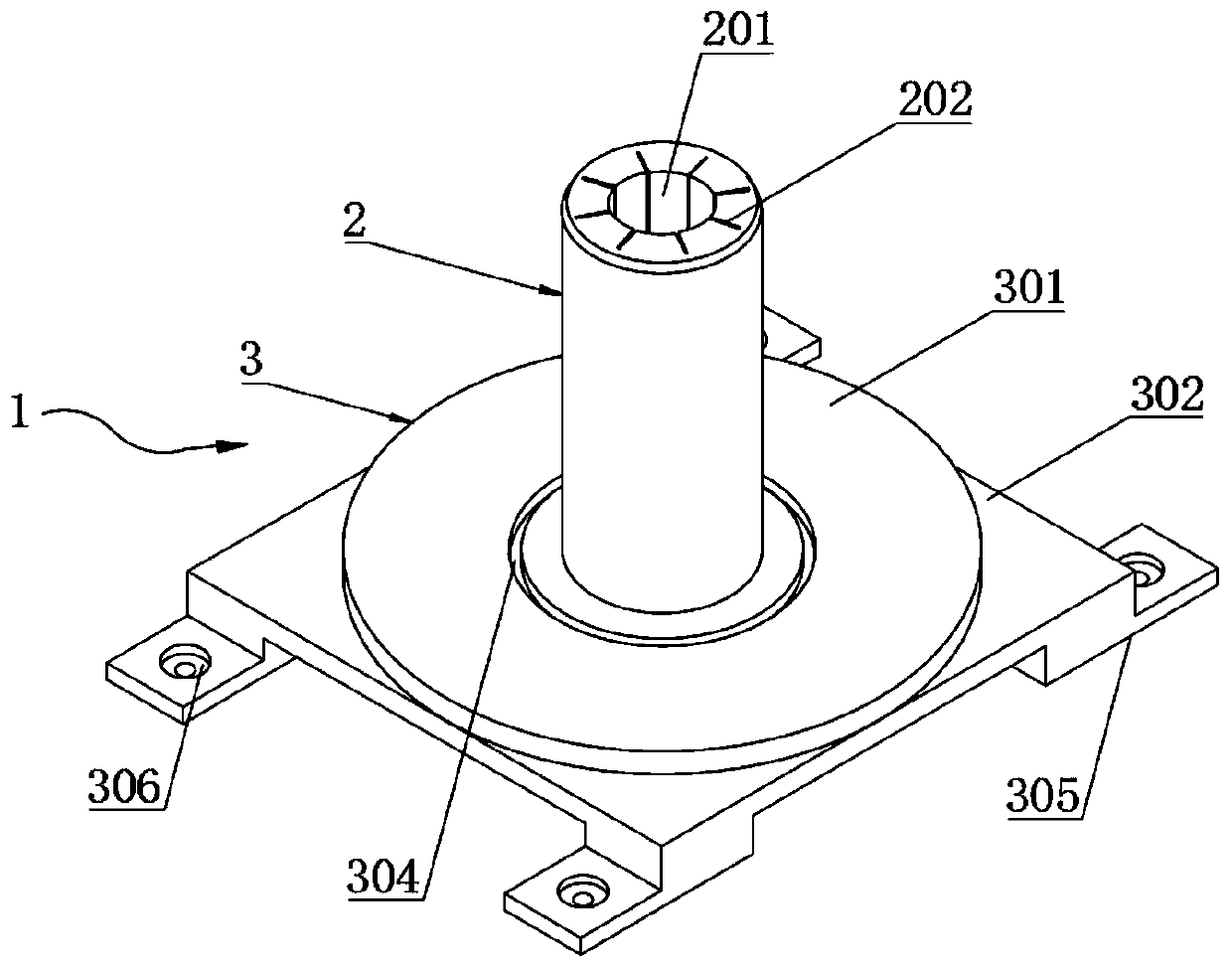

Chip taking and placing device

InactiveCN102751169AImprove pick-and-place efficiencyIncrease productivitySemiconductor/solid-state device manufacturingSemiconductor devicesLight-emitting diodeNozzle

The invention provides a chip taking and placing device which can be used for technologies including a preparation technology of light-emitting diodes and the like which require chip movement. The chip taking and placing device comprises a chip storage area, a chip placing area, a rotating shaft, a first sucking nozzle and a second sucking nozzle, wherein the first sucking nozzle and the second sucking nozzle are arranged on the rotating shaft, and the rotating shaft rotates to drive the first sucking nozzle and the second sucking nozzle to place chips from the chip storage area to the chip placing area. The chip taking and placing device is characterized in that the first sucking nozzle and the second sucking nozzle are in even symmetry around the axis of the rotating shaft and on the same plane perpendicular to the axis of the rotating shaft and are distributed corresponding to the chip storage area and the chip placing area. The chip taking and placing device can perform sucking-taking and placing simultaneously, thereby effectively improving the overall production efficiency.

Owner:EVERLIGHT ELECTRONICS (CHINA) CO LTD +1

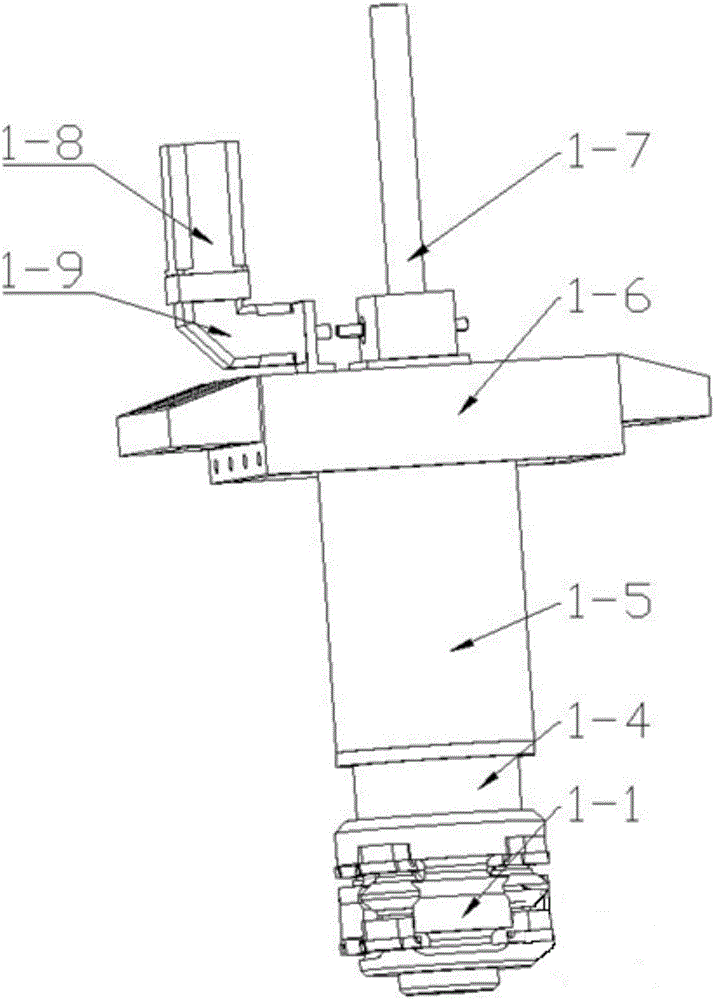

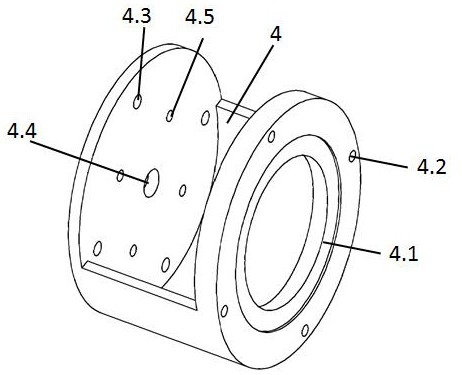

Internal rotation feeding device for large thin-wall cylindrical part pair wheel spinning equipment

ActiveCN106180341AReduce manufacturing costShorten the manufacturing cycleReduction driveEngineering

The invention discloses an internal rotation feeding device for large thin-wall cylindrical part pair wheel spinning equipment, relates to an internal rotation feeding device, and aims to solve the problems of high mold cost, weak generality and long manufacturing period in traditional mold spinning equipment. A conical wedge block coats a feeding lead screw; multiple internal rotation wheel bases are annularly and uniformly mounted on the conical wedge block; one rotating shaft is vertically and rotationally mounted in each internal rotation wheel base; one internal rotation wheel is mounted on each rotating shaft; cross chutes are respectively formed in a rotating base guide sleeve and a wedge block guide sleeve, and are mutually aligned and buckled up and down; a transition sleeve coats the feeding lead screw, and is positioned at the upper end of the wedge block guide sleeve; an upper cross beam is mounted on the transition sleeve; an internal rotation motor is mounted on a speed reducer for transferring power to a speed reducer; and the speed reducer drives the feeding lead screw to rotate. The internal rotation feeding device is suitable for the thin-wall cylindrical part pair wheel spinning equipment.

Owner:HARBIN INST OF TECH

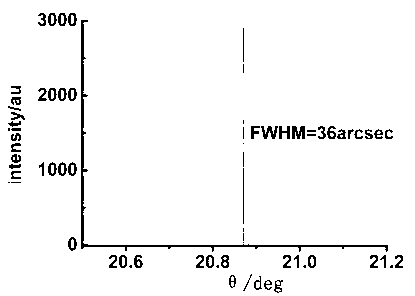

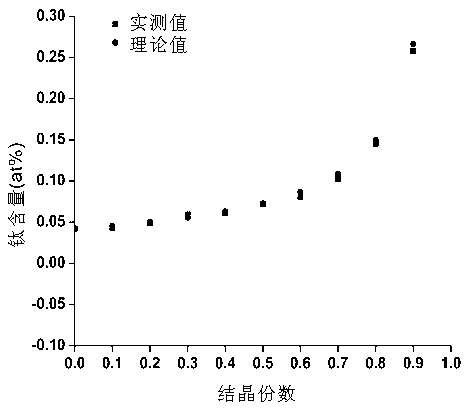

Large-size and high-quality factor carbon-doped titanium gem laser crystal and preparation method thereof

InactiveCN103060911AReduce IR Residual Absorption CoefficientBalance oxidationPolycrystalline material growthActive medium materialPhysical chemistryHost material

The invention provides a large-size and high-quality factor carbon-doped titanium gem laser crystal. The crystal comprises an Al2O3 host material, wherein the doping content of carbon in the carbon-doped titanium gem laser crystal is 0.05-1 wt% of total mass; and the doping content of titanium in the carbon-doped titanium gem laser crystal is 0.1-0.5 at%. The invention further discloses a preparation method for the crystal. The method comprises the following steps: raw materials are mixed, grinded, formed and sintered by proportioning to prepare crystal growth block materials; and then the kyropoulos method technology is adopted to grow. The carbon-doped titanium gem laser crystal has high quality factor (FOM (Figure of Merit) value). The titanium gem laser crystal with large size, high optical quality and high quality factor can efficiently grow; the FOM value is higher than 300; and the method can be used for producing ultrafast high-energy lasers.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

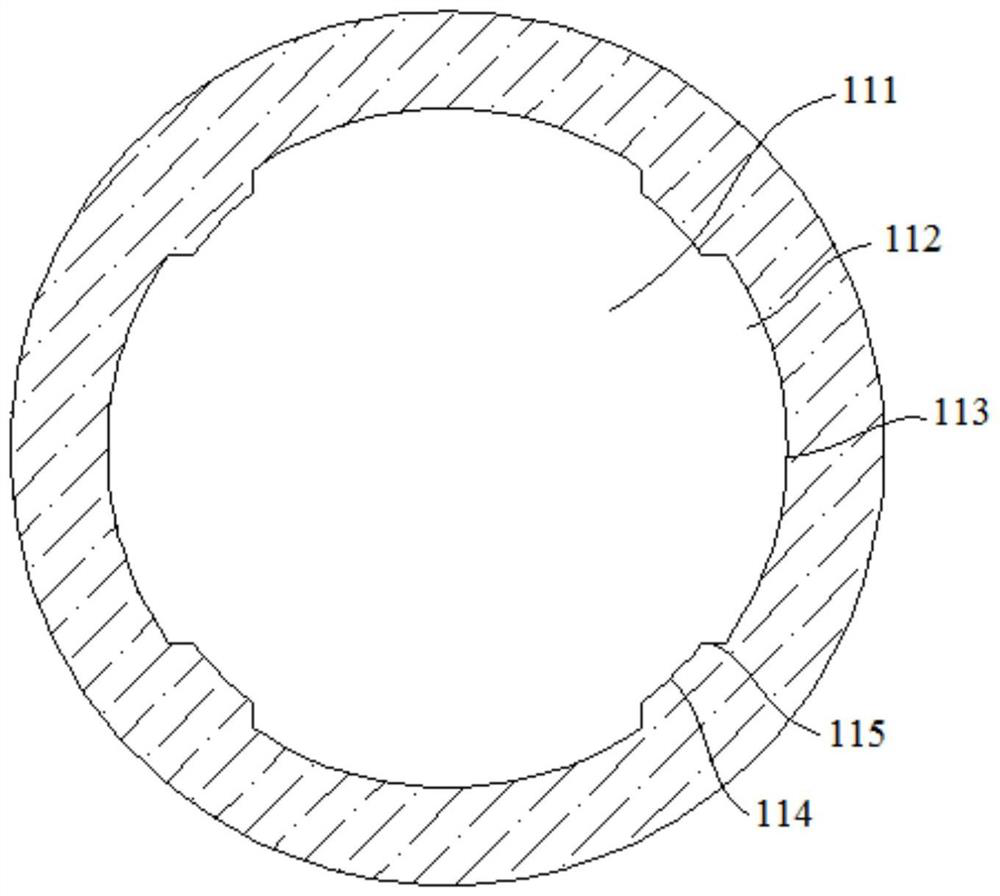

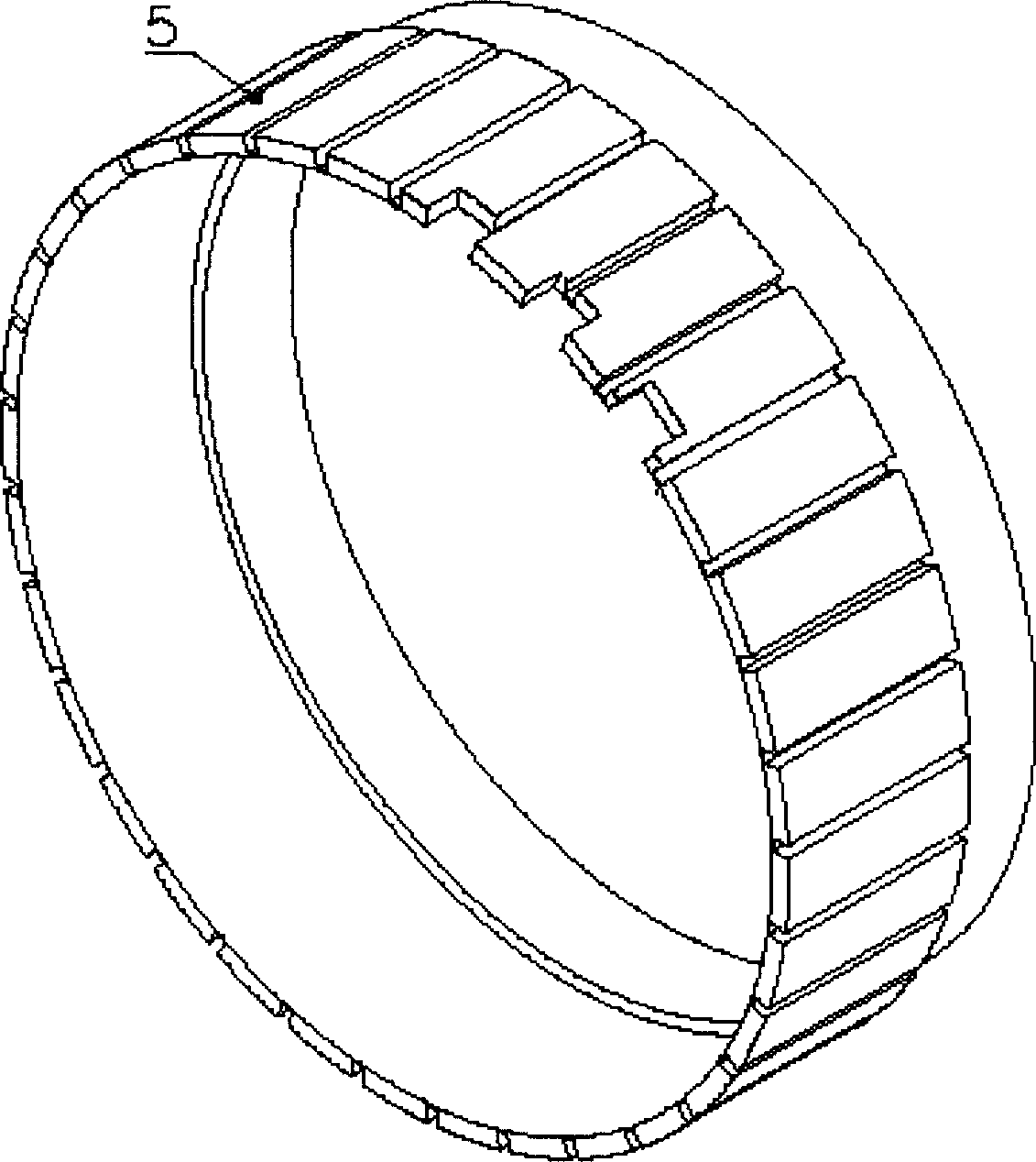

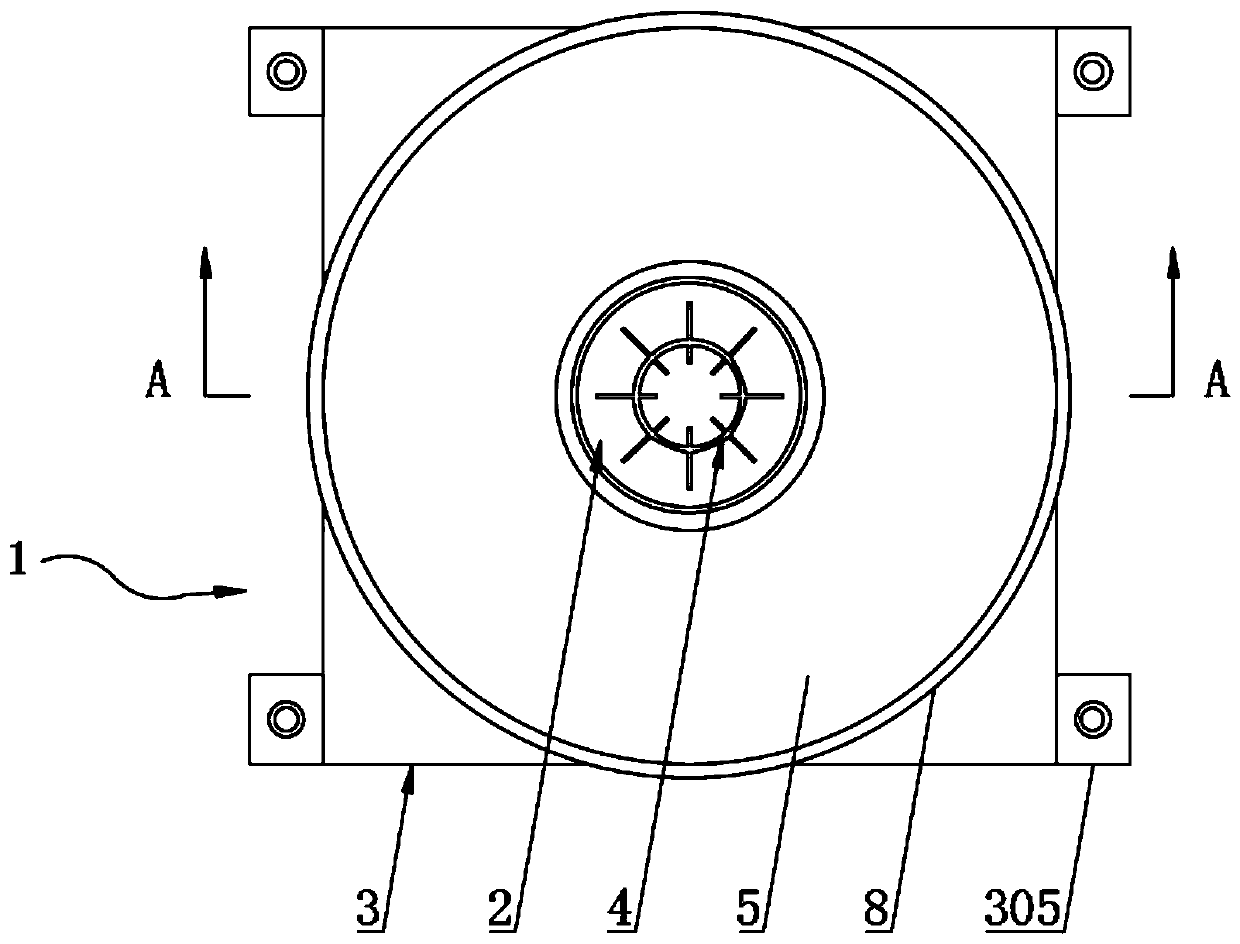

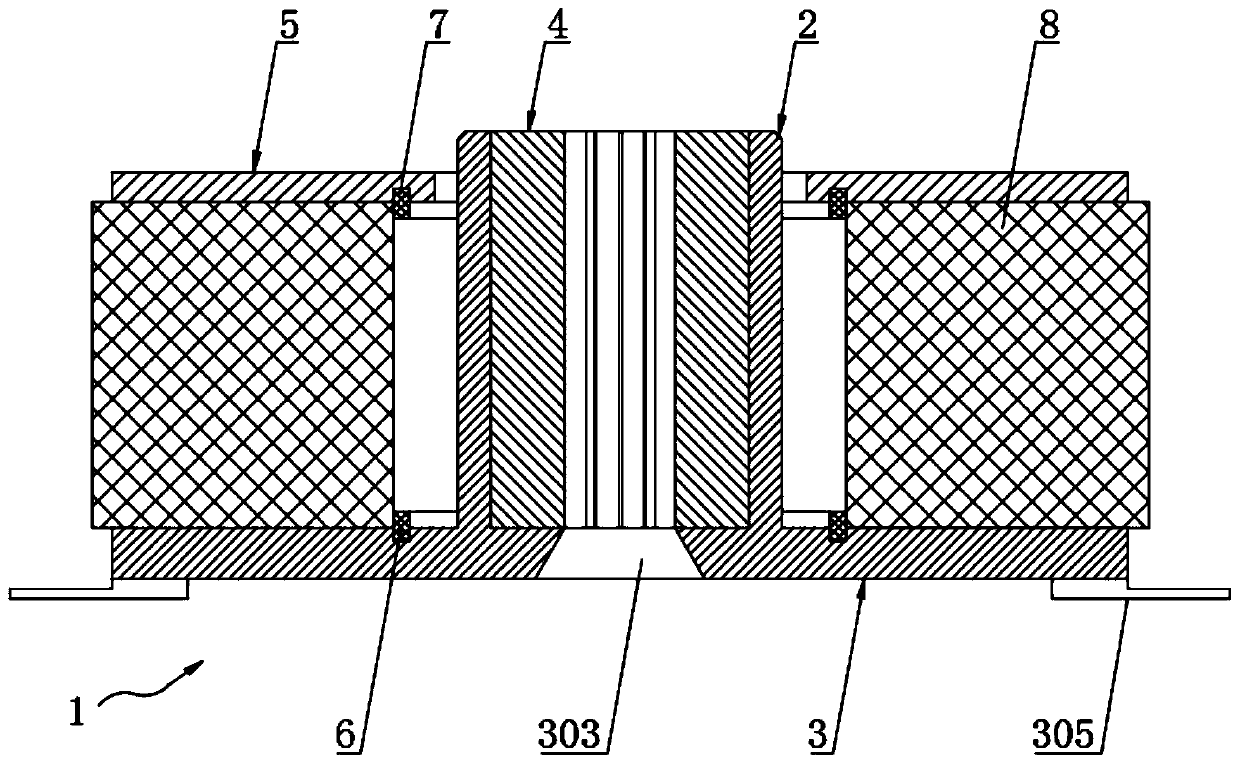

Manufacturing method of small-size sintered NdFeB multi-pole magnetic ring

ActiveCN112164575AEfficient manufacturingImprove magnetic propertiesInductances/transformers/magnets manufactureMagnetic materialsMetallurgyMagnetic loop

The invention discloses a manufacturing method of a small-size sintered NdFeB multi-pole magnetic ring, and belongs to the technical field of permanent magnet material preparation. According to the method, a pneumatic pressing device is adopted for pressing and forming sintered neodymium-iron-boron powder, then a pressed blank is taken out and subjected to isostatic pressing treatment, high-temperature sintering, tempering treatment and trepanning and grinding treatment, and the sintered NdFeB multi-pole magnetic ring is obtained. The pneumatic pressing device comprises an orientation mechanism and a pressing die, the orientation mechanism is composed of an even number of sintered NdFeB magnetic shoes which are evenly distributed in the circumferential direction at intervals, a die installation cavity is formed among the sintered NdFeB magnetic shoes in a surrounding mode, and the pressing die is correspondingly installed in the die installation cavity. By the adoption of the technicalscheme, the small-size sintered NdFeB multi-pole magnetic ring can be effectively manufactured, the manufacturing process is convenient, the equipment investment cost is low, the manufactured multi-pole magnetic ring is good in magnetic performance, and meanwhile the pressing percent of pass and the overall efficiency of the multi-pole magnetic ring are improved.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

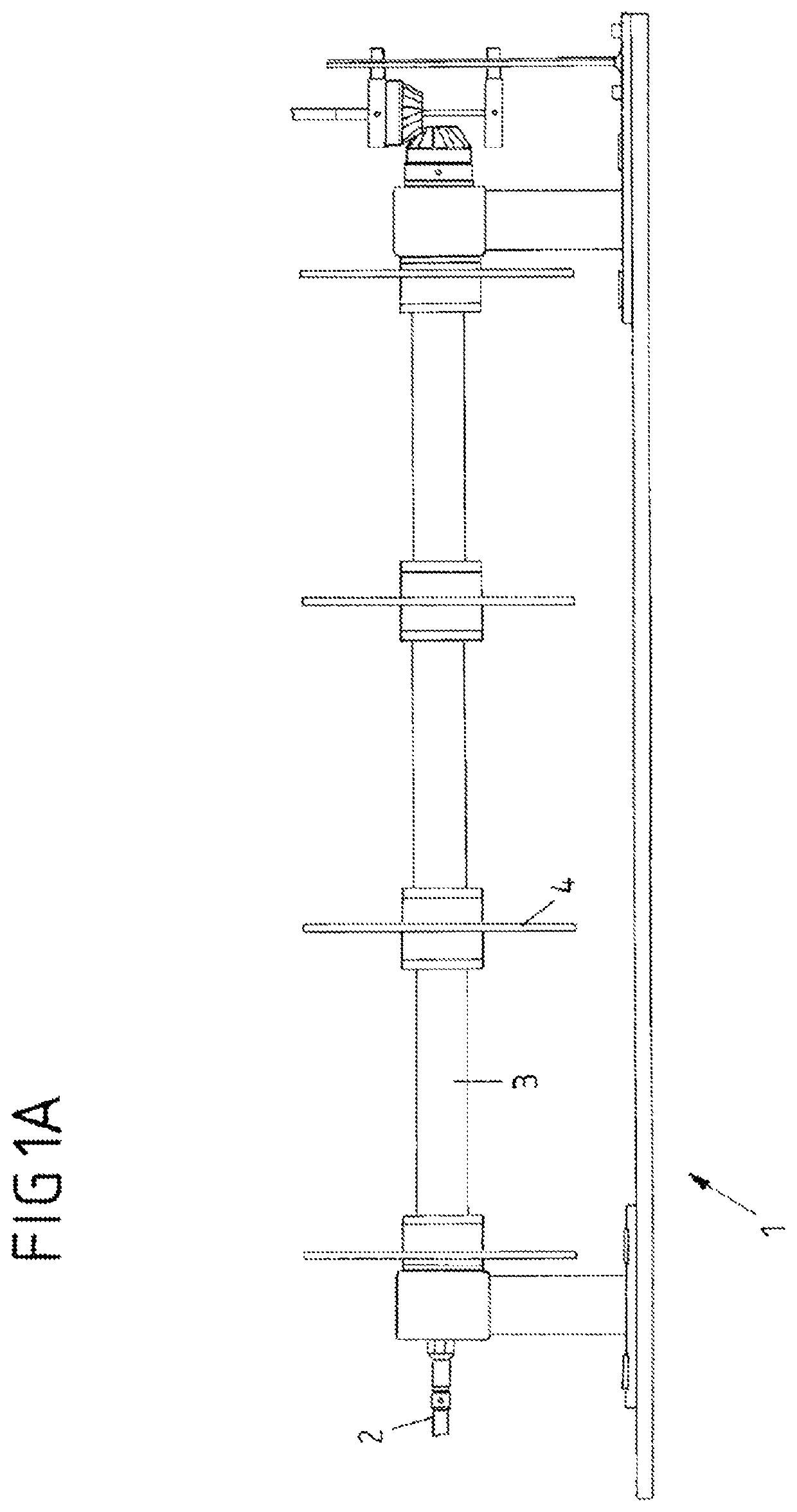

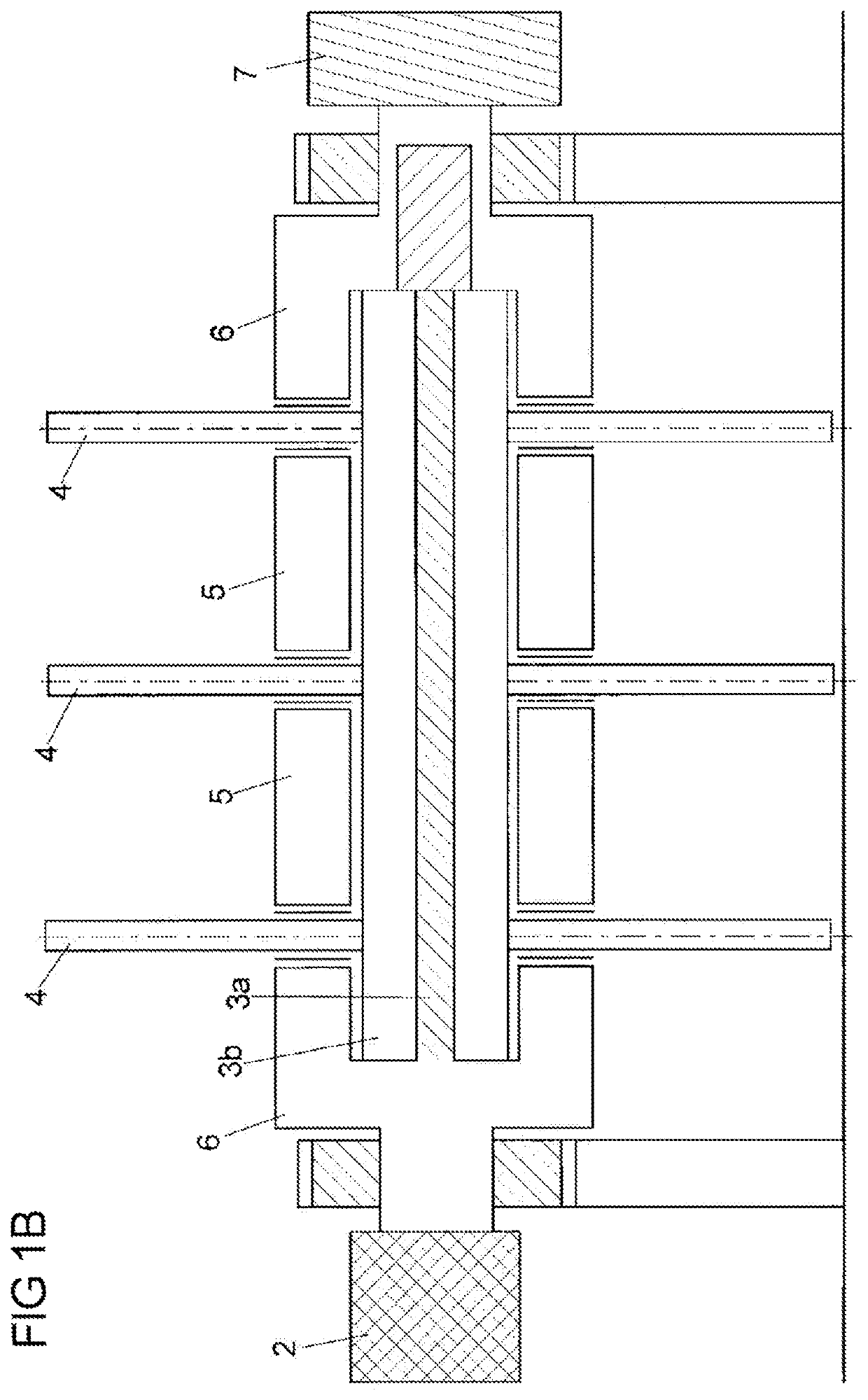

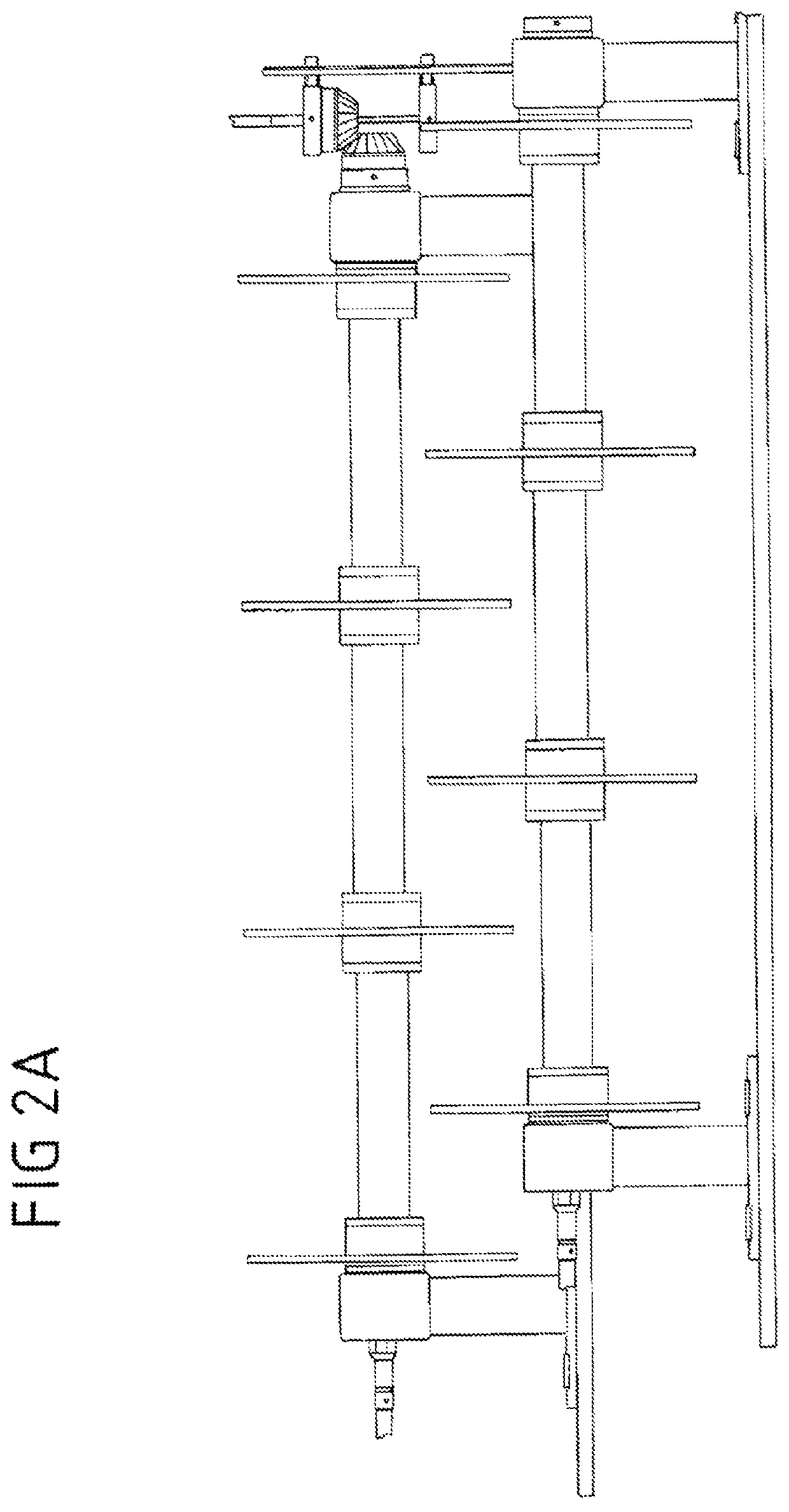

Device and method for generating gas bubbles in a liquid

ActiveUS10898867B2Uniform productUniform and symmetrical distributionTransportation and packagingMixing methodsLine tubingEngineering

The invention relates to a device for generating gas bubbles in a liquid in a container, including at least one rotatable hollow shaft arranged horizontally in at least one container; at least one gassing disc arranged vertically on the at least one hollow shaft; and at least one feed line for supplying at least one compressed gas to the interior of the at least one hollow shaft, said compressed gas being brought into the feed line and hollow shaft directly, without a liquid carrier.

Owner:AKVOLA TECH GMBH

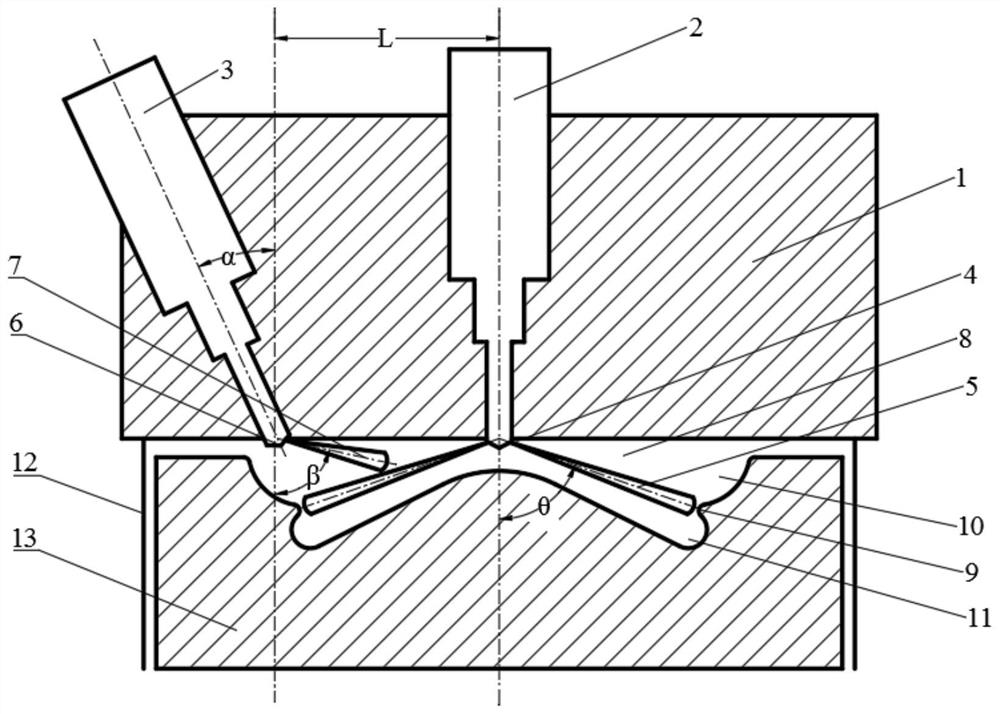

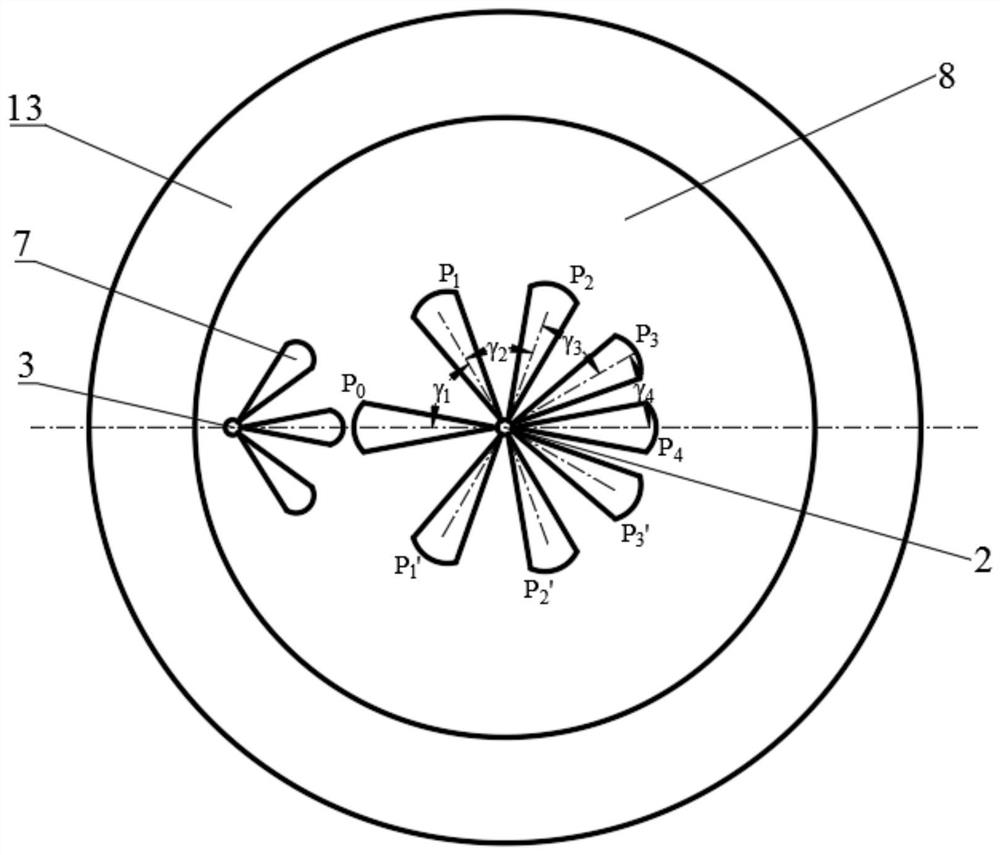

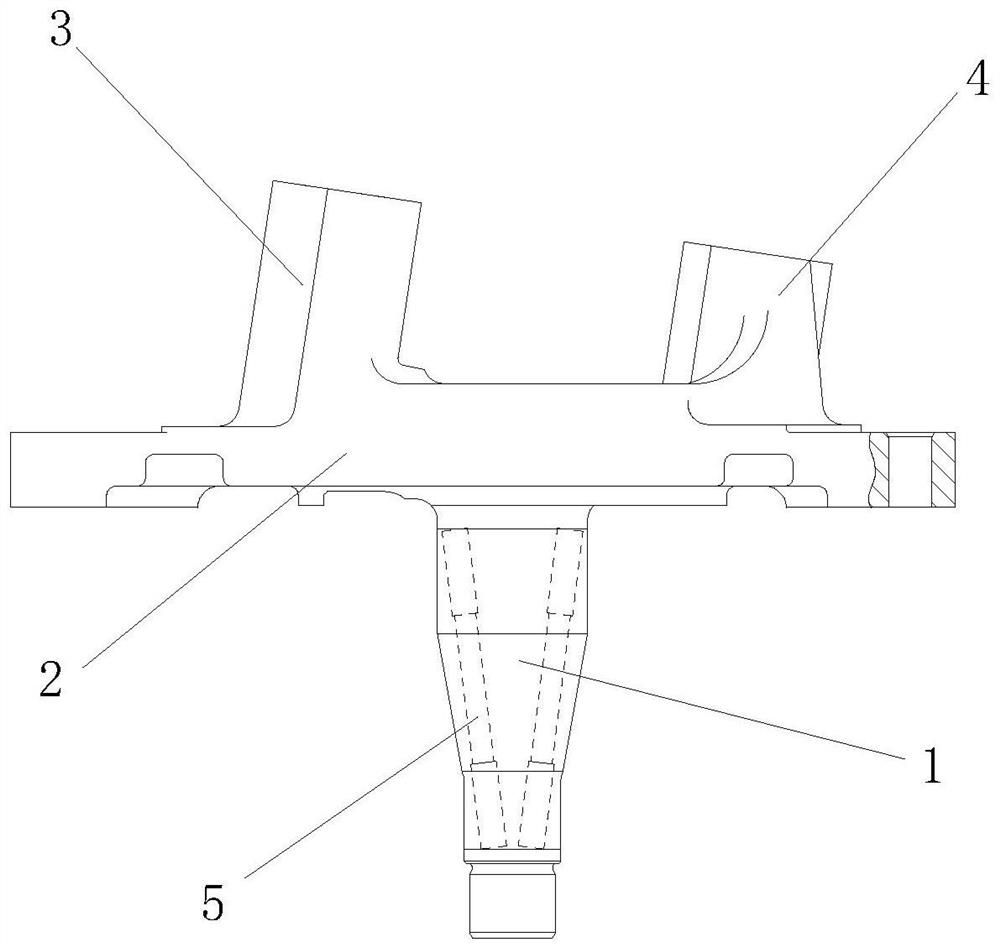

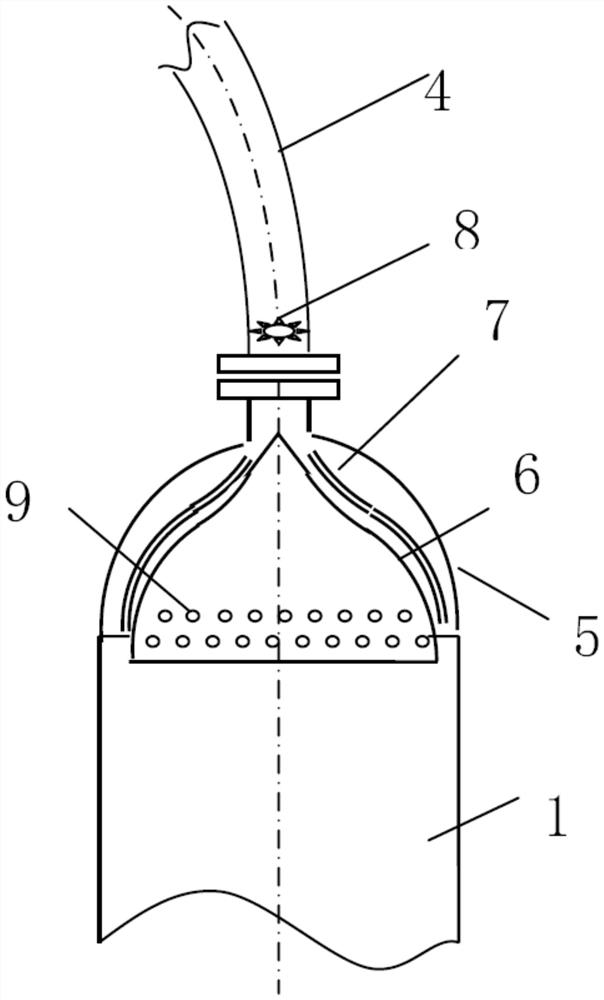

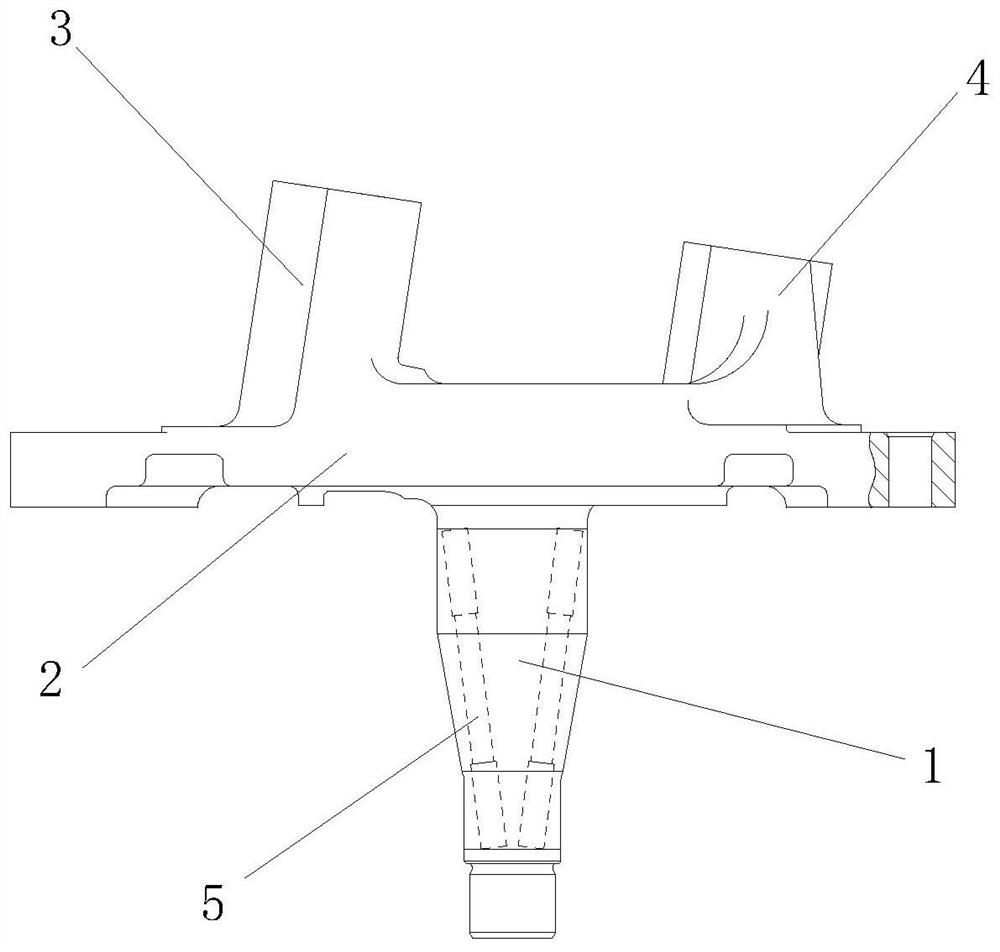

Oil injection system suitable for high-power-density diesel engine

PendingCN112879147AUniform and symmetrical distributionIncrease the fuel injection rateInternal combustion piston enginesFuel injection apparatusInjector nozzleFuel oil

The invention discloses an oil injection system suitable for a high-power-density diesel engine, and belongs to the related technical field of diesel engines. The oil injection system comprises a main oil injector vertically arranged in the center of a cylinder cover and an auxiliary oil injector obliquely arranged on the cylinder cover. The main oil injector and the auxiliary oil injector are provided with a plurality of oil injection holes. The auxiliary oil injector is provided with a plurality of oil injection holes. One oil injection hole of the main oil injector and one oil injection hole of the auxiliary oil injector are oppositely arranged. The multiple oil injection holes of the main oil injector are symmetrically distributed in the circumferential direction of the main oil injector through the center axis of the oil injection hole opposite to the auxiliary oil injector, and the angles between the adjacent oil injection holes are gradually increased in the direction away from the auxiliary oil injector. According to the oil injection system, the oil injection holes of the main oil injector are distributed sparsely in the side provided with the auxiliary oil injector, the oil injection holes of the main oil injector are distributed densely in the side away from the auxiliary oil injector, the problem that overall fuel oil distribution is uneven and asymmetric due to existence of the auxiliary oil injector can be balanced and compensated, and fuel oil in a diesel engine cylinder is evenly and symmetrically distributed integrally.

Owner:HUAZHONG UNIV OF SCI & TECH

Slotless permanent magnet motor

InactiveCN1756031AAvoid Hysteresis LossAvoid eddy current lossMagnetic circuit stationary partsWindings conductor shape/form/constructionHysteresisPunching

The invention relates to a slotless permanent-magnet machine comprising stator components. The invention is characterized in that: said stator components comprise a false stator (5); an iron core (6) and a stator winding (7). Wherein, said false stator (5) is sheathed outside the iron core (6); said stator winding (7) is arranged of wire outside the false stator (5); and said false stator (5) is made from insulation material. The invention replaces the groove and tooth on the punching sheet of stator iron core with insulated false stator (5) to effectively solve the problem of slot electric machine as slot effect, hysteresis loss, eddy current loss and eddy current loss. The invention has higher load efficiency, continuous speed regulation, better acceleration property, higher overload capacity, smaller volume, stable operation, small torque fluctuation and simple manufacture process.

Owner:BYD CO LTD

Chromatographic column temperature control device and control method of chromatographic instrument

PendingCN111089927AHeating fastReduce heating lagComponent separationTemperature controlElectric machinery

The invention relates to a chromatographic column temperature control device and control method of a chromatographic instrument, and belongs to the technical field of chromatographic column temperature control of the chromatographic instrument. The aim is to provide improvement of a hardware structure of the chromatographic column temperature control device of the chromatographic instrument and the chromatographic column temperature control method of the chromatographic instrument. According to the technical scheme, the control device comprises a column box body, the column box body is a peripherally sealed box body, and a column box heat preservation layer is arranged on the inner side of the column box body; the column box body is internally provided with a first temperature measuring resistance sensor, a chromatographic column, a heating device, a second temperature measuring resistance sensor, a heat dissipation motor, a blower motor and an electric appliance control box, the bottom of the column box body is provided with a heat dissipation hole, and the heat dissipation hole is also provided with a hollow heat dissipation sheet; and the chromatographic column is arranged in the middle of the column box body through a support, the upper side of the chromatographic column is separately provided with the first temperature measuring resistance sensor, and the lower side of thechromatographic column is provided with the heating device. The control device and the control method are applied to the chromatographic instrument.

Owner:SINOGREEN ENVIRONMENTAL PROTECTION SCI & TECH

Fireworks inner tank for displaying caption pattern in the sky

Owner:LIUYANG YUSHI TECH ENVIRONMENTAL PROTECTIONFIREWORKS FACTORY

Method for improving elongation and shrinkage of rod part of steering knuckle

ActiveCN112498476AImprove elongationReduced shear damageSteering linkagesKnuckleStructural engineering

The invention relates to the technical field of steering knuckles, and in particular relates to a method for improving the elongation and the shrinkage of a rod part of a steering knuckle. The methodcomprises the steps of heating round steel, upsetting, extruding, pre-forging and finish-forging to obtain a forging blank, and during pre-forging, arranging a transition arc at the joint of the rod part and a disc part of the steering knuckle, and the transition arc forming an annular face around the axis of the rod part. The radius of the transition arc on the side, close to a steering knuckle long lug, of the annular face is R1, R1 is a fixed value, the radius of the transition arc on the side, close to a steering knuckle short lug, of the annular face is R2, the plane where the axis of therod part of the steering knuckle and the axis of a main pin hole are located serves as a datum plane, and R2 is evenly reduced to R1 along with the angle deviating from the datum plane. According tothe method, rod part mold filling can be facilitated, shear damage of an internal metal flow line in the forming process of the rod part of the steering knuckle is reduced, and reduction of the mechanical performance of the rod part is avoided; the rod part can be uniformly distributed, and two sides of the flow line are uniformly and symmetrically distributed; and the stress distribution at the joint of the rod part and the disc part of the steering knuckle is improved.

Owner:HUBEI TRI RING FORGING

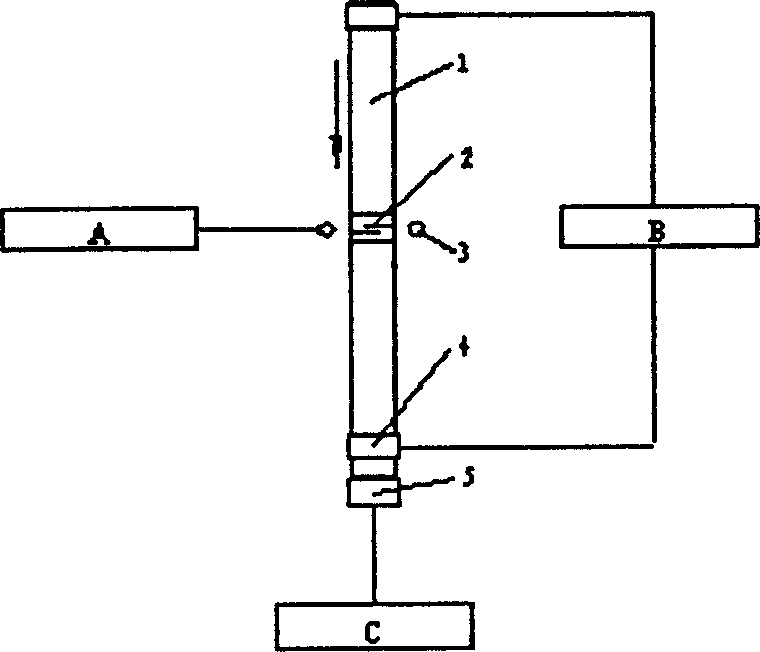

Metal bar continuous zone smelting and solidification grain-refining process

InactiveCN1219897CNo pollutionSolve solidification and fine grain processingIncreasing energy efficiencyPeak valueFinings

The present invention provides one kind of continuous metal bar zone refining and crystal fining process, and belongs to the field of metal material heat processing technology. The present invention features that the descending or ascending metal bar is made to pass through induction heating system for continuous zone smelting, while pulse current is applied to the metal bar via the pulse power source connected to the ends of the metal bar, with pulse current frequency being 1-10 KHz, applied voltage 50-1000 V, current peak value 50-5000 A, metal bar diameter 5-100 mm and moving rate of the metal bar 0.1-10 mm / s.

Owner:SHANGHAI UNIV

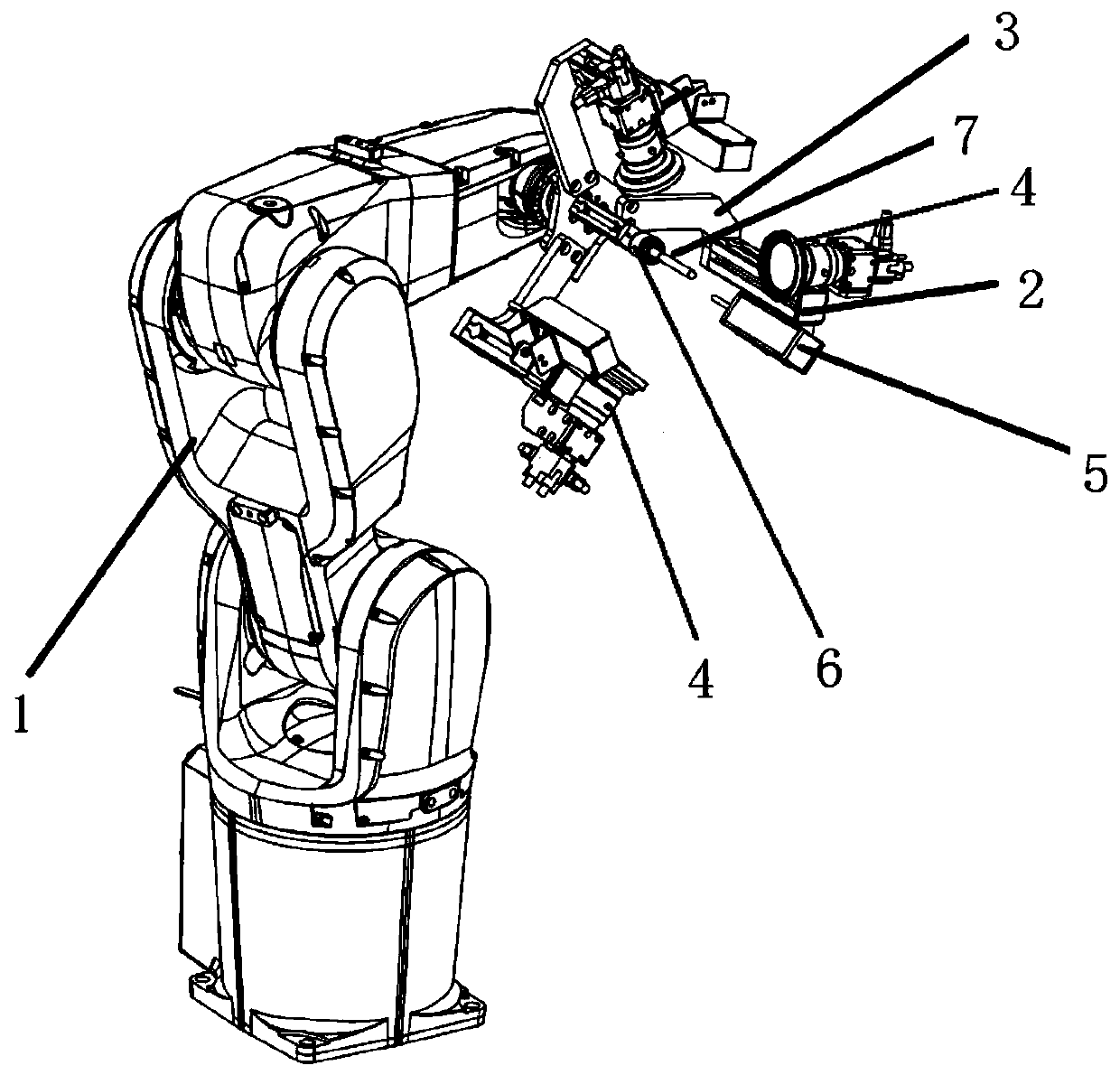

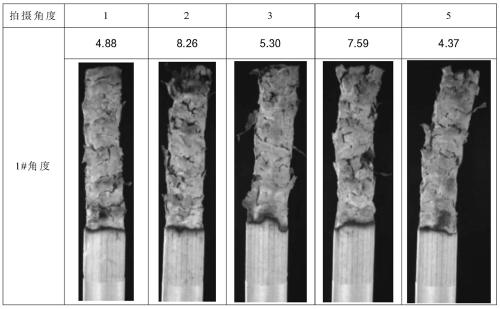

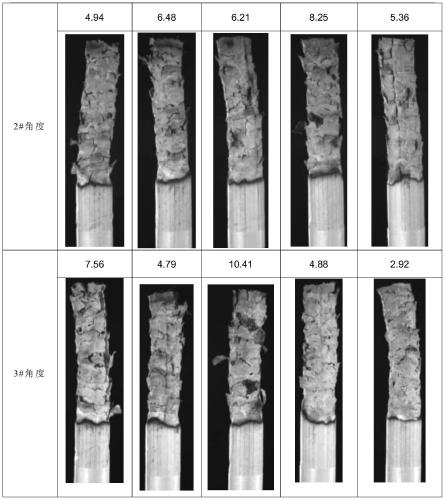

Image acquisition device of smoking path simulation system

PendingCN111426787AHigh precisionEnsure consistencyProgramme-controlled manipulatorChemical analysis using combustionPhysicsManipulator

The invention relates to an image acquisition device of a smoking path simulation system, which belongs to the technical field of cigarette detection equipment. The device comprises a manipulator, a frame body which is fixedly connected with the working end of the manipulator and is provided with N supporting rods, N cameras which are fixedly connected to the different supporting rods respectively, and N supplementary lighting lamps which are fixedly connected to the different supporting rods respectively, wherein lenses of the cameras face the working end of the manipulator, and light sourcesurfaces of the supplementary lighting lamps face the working end of the manipulator. N is greater than or equal to 2. According to the device, the supplementary lighting lamps are utilized; images are dynamically collected in real time through the cameras under the action of the smoking path of the manipulator; and the cigarette combustion ash wrapping characteristic detection precision is effectively improved. The device is suitable for image acquisition of smoking path simulation systems of various cigarettes.

Owner:CHINA TOBACCO YUNNAN IND

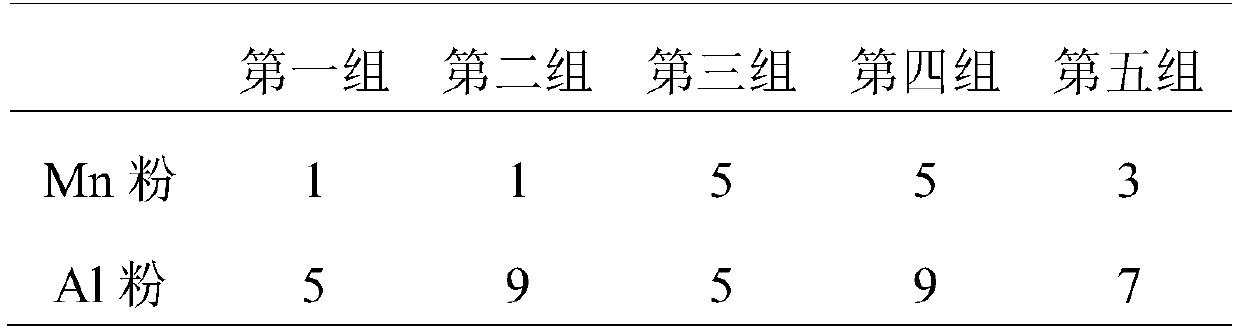

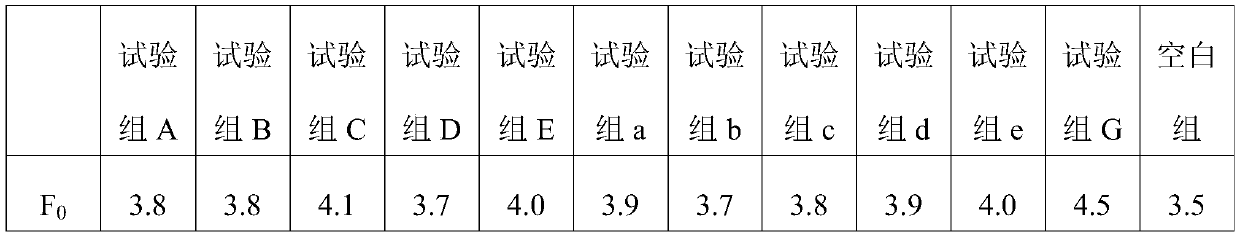

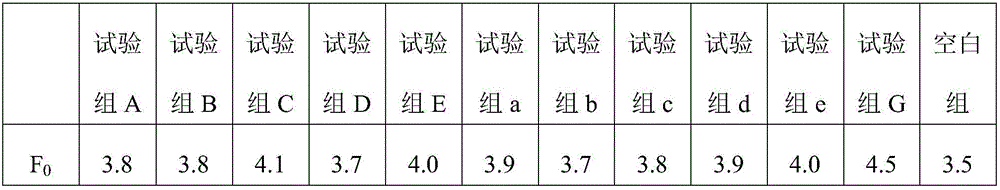

Microalloying improves the quality of mg-fe spot welding of dissimilar metals

ActiveCN107138841BIncrease nugget sizeImprove shear resistanceResistance welding apparatusAlloyViscosity

The invention discloses a technology for improving the dissimilar metal Mg-Fe spot welding quality through microalloying. The technology comprises the steps that firstly, Mn powder, Al powder and a volatile solvent serve as raw materials to prepare an alloy pulp cluster; secondly, when the alloy pulp cluster has proper viscosity, the alloy pulp cluster is scraped to the lap joint connector position of a to-be-welded Mg material and a to-be-welded Fe material, and accordingly the to-be-welded materials are subjected to pretreatment; and thirdly, a lap joint connector of the Mg material and the Fe material is subjected to spot welding. Adoption of the technology for improving the dissimilar metal Mg-Fe spot welding quality through microalloying has the obvious beneficial effects that the size of molten cores between the dissimilar metal Mg and Fe after spot welding is increased, distribution of the molten cores between Mg and Fe is uniform and symmetric, the anti-shearing performance between the dissimilar metal Mg and Fe after spot welding is obviously improved, and the spot welding quality between the dissimilar metal Mg and Fe is improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

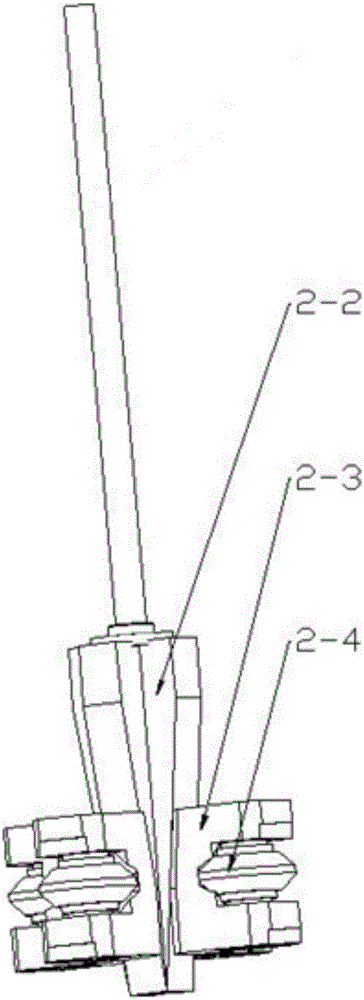

A pair of wheel spinning equipment for forming large thin-walled cylindrical parts

The invention relates to opposite roller spinning equipment, in particular to opposite roller spinning equipment for forming a large thin-walled cylindrical part, and aims to solve the problems that existing die spinning equipment is high in cost, poor in universality and long in manufacturing period as a core die is needed. A chuck substrate fixing base is installed on a rack between an internal rotation guide rail and an external rotation guide rail, a chuck substrate is installed on the chuck substrate fixing base, an external rotation mechanism fixing base is installed on the external rotation guide rail in a sliding mode, and an external rotation disc is installed on the external rotation mechanism fixing base; a bottom plate is installed on an internal rotation guide rail, a lifting motor is installed at the lower end of the bottom plate, one end of a lifting lead screw penetrates through the bottom plate, and the other end of the lifting lead screw is connected with a base; an internal rotation device fixing base is installed on the bottom plate, a worm and gear assembly is installed on the chuck substrate, a three-claw chuck is installed on the worm and gear assembly, multiple pull rods are connected with the external rotation disc, the chuck substrate and the base, an internal rotation device is installed in the internal rotation device fixing base, and the external rotation device is installed in the external rotation disc. The opposite roller spinning equipment is suitable for carrying out opposite roller spinning on the large thin-walled cylindrical part.

Owner:HARBIN INST OF TECH

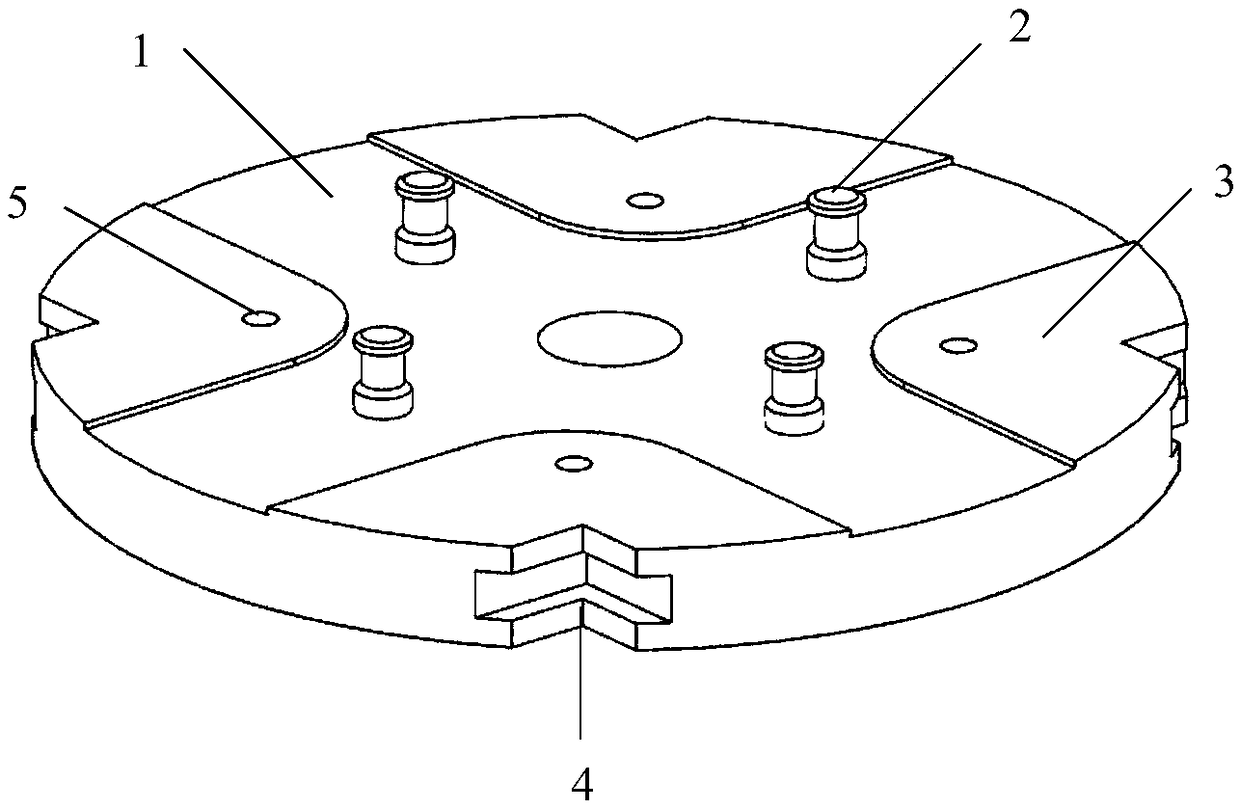

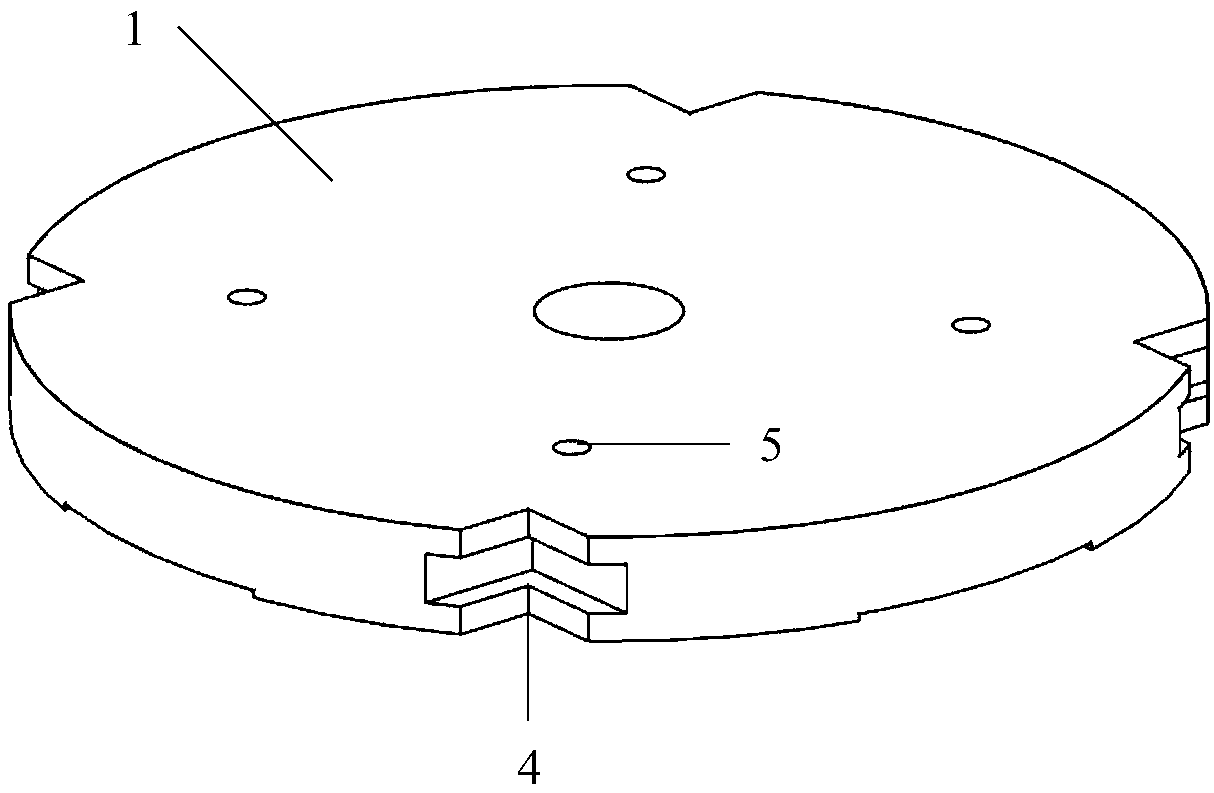

Quick replacement sub-board for impeller part

InactiveCN108907768AImprove contact stiffnessHigh positioning accuracyPositioning apparatusMetal-working holdersImpellerEngineering

The invention discloses a quick replacement sub-board for an impeller part. A concave surface is processed in the middle portion of the sub-board to form a mounting surface matched with a mother board. Pop-rivets mounted with the mother board in a matched mode are fixed on the concave surface, the pop-rivets are evenly distributed along the circumference, the center of the circumference which thepop-rivets are along and the center of the sub-board coincide, and the outer circumference of the sub-board is provided with a clamping groove for an external mechanical hand to capture. The quick replacement sub-board can improve the contact rigidity and the positioning precision of the sub-board and the mother board in the process of quick replacement of the impeller part, and the repeated positioning precision of quick replacement of the impeller part is ensured.

Owner:BEIJING POWER MACHINERY INST

A DC Photocathode Ultrafast Electron Gun

ActiveCN106816349BImprove stabilityAvoid elevationDischarge tube electron gunsPhotocathodeEngineering

The invention provides a photocathode ultrafast electron gun wherein the cathode is of an axis-symmetrical structure and comprises a first cylindrical side face, a round bottom face and a first connection face to have the first cylindrical side face connected with the round bottom face. The center of the round bottom face is provided with a light penetration hole. The outer side of the round bottom face is provided with a round groove to hold a metal film. The anode is of an axis-symmetrical structure and comprises a round top face, a second cylindrical side face, a round bottom face and a second connection face to have the round top face and the second cylindrical side face connected. The round bottom face extends outwardly in the radius direction of the lower edge of the second cylindrical side face. The center of the round top face is provided with a through hole and the first connection face is provided with a round chamfer angle, and the second connection face is provided with an elliptical chamfer angle.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

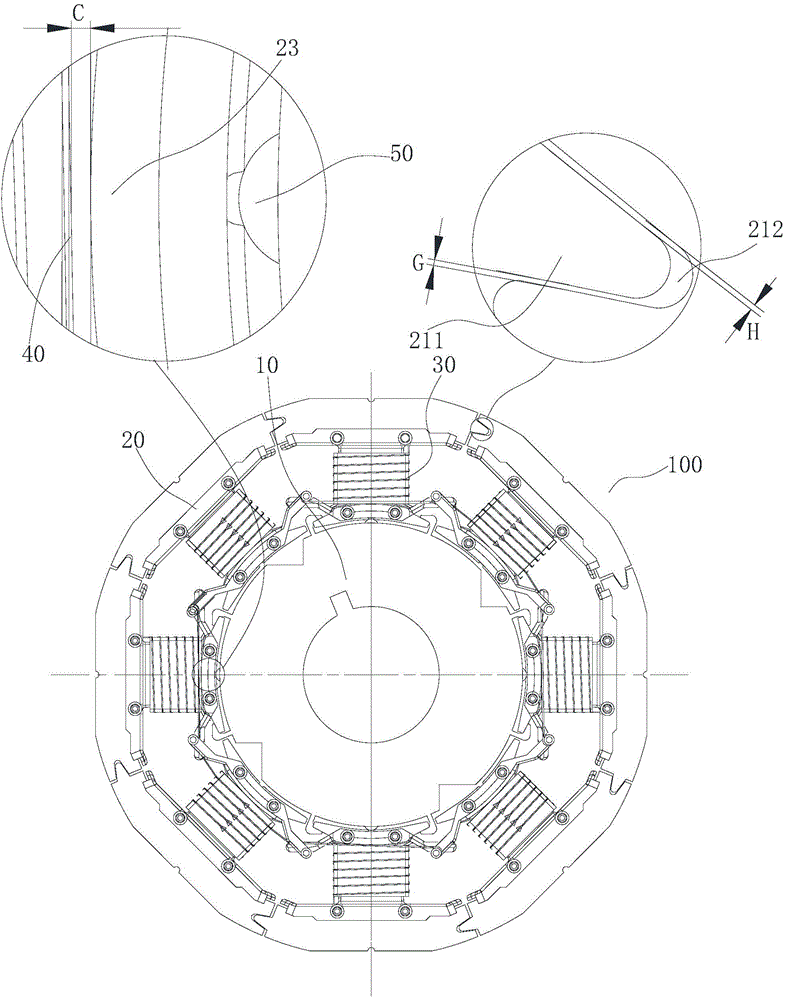

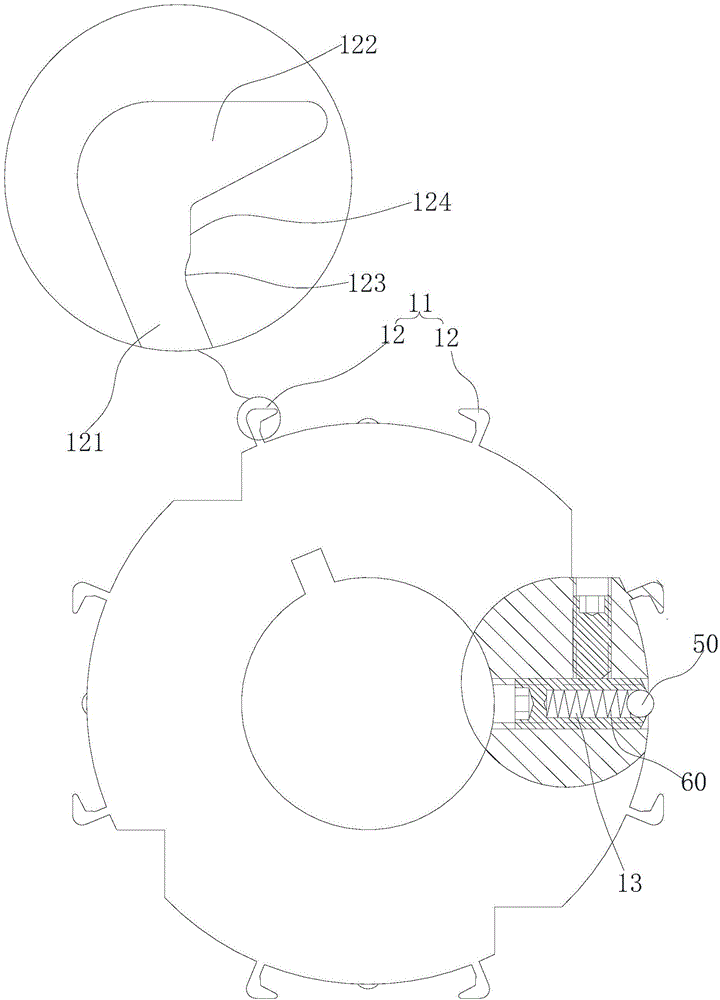

Partitioned motor

ActiveCN104868669AEasy to installWith correction functionMagnetic circuit stationary partsWindings conductor shape/form/constructionMechanical engineeringStator

The invention discloses a partitioned motor, which comprises a connection block, multiple coils, and an elastic piece, wherein the periphery of the connection block is provided with multiple mounting parts, and each mounting part comprises two hooks respectively; multiple partitioned stators are arranged at intervals along the circumferential direction of the connection block and connected with the mounting parts respectively; the multiple coils are wound on the multiple partitioned stators respectively, a mounting groove is arranged between the two hooks of each mounting part respectively, and each mounting groove is internally provided with a mobile abutting ball along the axial direction of the mounting groove; and two ends of the elastic piece abuts against the bottom wall of the mounting groove and the abutting ball so as to enable the abutting ball to abut against the partitioned stator. According to the partitioned motor of the embodiment of the invention, mounting of the partitioned stator on the connection block is firmer, an alignment function is provided, coils wound on the multiple partitioned stator can be easily combined via the connection block, the partitioned stators can be uniformly and symmetrically distributed, and the partitioned stator combination success rate is improved.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

Technology for improving dissimilar metal Mg-Fe spot welding quality through microalloying

ActiveCN107138841AIncrease nugget sizeImprove shear resistanceResistance welding apparatusAl powderLap joint

The invention discloses a technology for improving the dissimilar metal Mg-Fe spot welding quality through microalloying. The technology comprises the steps that firstly, Mn powder, Al powder and a volatile solvent serve as raw materials to prepare an alloy pulp cluster; secondly, when the alloy pulp cluster has proper viscosity, the alloy pulp cluster is scraped to the lap joint connector position of a to-be-welded Mg material and a to-be-welded Fe material, and accordingly the to-be-welded materials are subjected to pretreatment; and thirdly, a lap joint connector of the Mg material and the Fe material is subjected to spot welding. Adoption of the technology for improving the dissimilar metal Mg-Fe spot welding quality through microalloying has the obvious beneficial effects that the size of molten cores between the dissimilar metal Mg and Fe after spot welding is increased, distribution of the molten cores between Mg and Fe is uniform and symmetric, the anti-shearing performance between the dissimilar metal Mg and Fe after spot welding is obviously improved, and the spot welding quality between the dissimilar metal Mg and Fe is improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Direct-current photocathode ultrafast electron gun with immersed electrostatic lens

ActiveCN112563098AUniform and symmetrical distributionEnsure accelerationElectric discharge tubesPhotocathodeMaterials science

The invention provides a rear-mounted direct-current photocathode ultrafast electronic gun with an immersed electrostatic lens. The rear-mounted direct-current photocathode ultrafast electronic gun comprises a cathode, an anode and an electrostatic lens electrode determined by an electric field and a particle simulation program, and a ceramic disc, a fine ceramic column, an electrostatic lens electrode ceramic support and an electron gun support which are suitable for rear mounting. and the cathode comprises a hollow cylinder, a circular top surface and an arc-shaped connecting surface. The anode comprises two smooth discs and a cylindrical protrusion on the back side, and a through hole is formed in the center of the anode. The electrostatic lens electrode comprises a circular top surface, a cylindrical side surface and an arc-shaped connecting surface, and a through hole is formed in the center. A cylindrical protrusion is arranged in the center of the circular top face, and the topannular face of the protrusion is chamfered. The electronic gun support is of a double-disc connecting structure, a top disc is connected with the fine ceramic column and the ceramic disc, the cathodeis fixed to the ceramic disc, and the anode is placed in a groove in the top disc. The electrostatic lens electrode is fixed on the ceramic support, and the ceramic support is fixed on a disc at thebottom of the support.

Owner:GANNAN NORMAL UNIV

Multi-zone reactor with cyclone separator

PendingCN113117611AImprove the forceMaintain structural rigidityChemical/physical processesEngineeringPetrochemical

The invention relates to the technical field of petrochemical industry production devices, in particular to a multi-zone reactor with a cyclone separator. The multi-zone reactor comprises a main cylinder and an auxiliary cylinder which are vertically arranged, and an annular shell is arranged between the top of the main cylinder and the top of the auxiliary cylinder. The cyclone separator comprises a pre-cyclone device arranged at the position, close to the main cylinder, of the annular shell and a cyclone guide device arranged at the inner top of the main cylinder, the cyclone guide device comprises an end socket located at the top of the main cylinder, a jacket and a plurality of flow guide partition plates, an annular flow channel is formed between the jacket and the inner wall of the end socket, and the flow guide partition plates are distributed in the annular flow channel in the circumferential direction; and the flow guide partition plate is in a spiral flow guide shape longitudinally. A pre-swirler can enable the flowing fluid to generate a rotating flow state around the bending central axis of the large annular shell, and the flow deviation state caused by centrifugal force when the flowing fluid flows through the annular shell is broken. And the flow guide device at the top of the main cylinder body can enable the fluid entering from the pre-swirler to generate a rotating flow state which is uniformly distributed in the circumferential direction around the central vertical axis of the main cylinder body, so that the effect of further strengthening the rotational flow is achieved.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

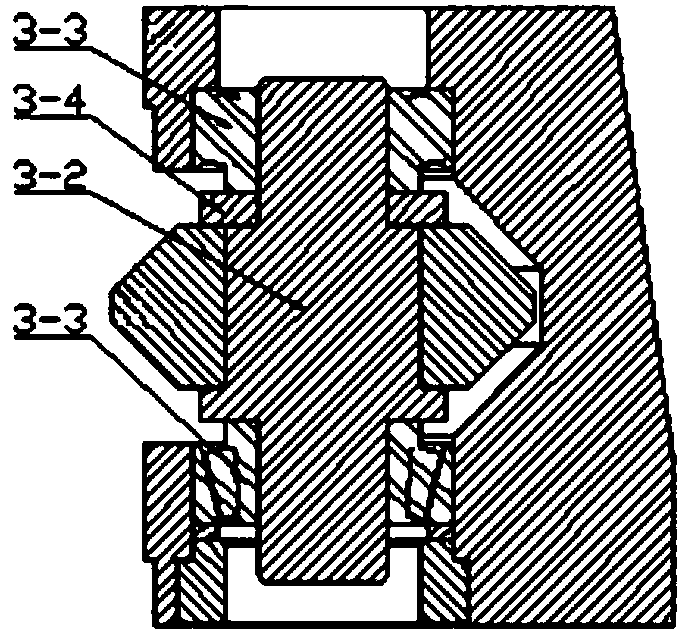

Double-station-diameter square loudspeaker T-yoke

ActiveCN111405435AIncrease cooling areaImprove cooling effectElectrical transducersLoudspeakerMechanical engineering

The invention relates to the technical field of loudspeakers, in particular to a double-station-diameter square loudspeaker T-yoke. T-yoke comprising a T-yoke body, a mandrel is arranged at the top ofthe T-yoke body; a cylindrical cavity is formed in the center of the mandrel; the mandrel is further provided with a plurality of positioning grooves. A copper pipe is arranged in cylindrical cavity,outer ridges are arranged on the outer wall of the copper pipe; the outer ridges are embedded into the positioning grooves; inner ridges are arranged on the inner wall of the copper pipe; a lower clamping plate is arranged at the bottom of the T-yoke body, a heat dissipation hole is formed in the center of the lower clamping plate, the lower clamping plate is integrally formed by a circular plateand a square plate, a first limiting ring is arranged on the upper surface of the circular plate, magnetic steel sleeves the periphery of the first limiting ring, an upper clamping plate is arrangedat the top of the magnetic steel, and a cushion block is arranged on the lower surface of the square plate. The copper pipe with the inner and outer double-ridge structure is arranged, the heat dissipation area of the mandrel and the outside is increased, the magnetic steel and the upper clamping plate are positioned through the first limiting ring and the second limiting ring, and it is guaranteed that magnetic gaps between the upper clamping plate and the mandrel are uniform and symmetrical.

Owner:ZHEJIANG OUSAI ELECTRONICS CO LTD

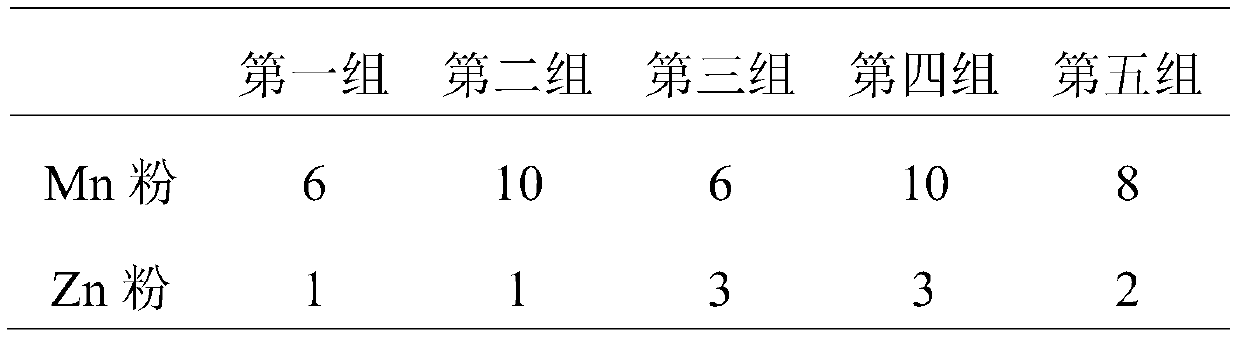

The method of improving the quality of al-cu spot welding

ActiveCN107175395BIncrease nugget sizeImprove shear resistanceWelding/cutting media/materialsWelding/soldering/cutting articlesMass ratioAlloy

The invention discloses a method of improving Al-Cu spot welding quality. The method comprises the following steps: one, Mn powder and Zn powder are weighed according to a mass ratio of (6-10):(1-3); two, the Mn powder and the Zn powder are proportionally mixed uniformly, a volatile solvent is added, and an alloy powder paste is formed through blending; three, the alloy powder paste is stirred, after the viscosity of the alloy powder paste is 0.5-0.55Pa.s, overlap joints of a Al material and a Cu material which are to be welded are subjected to knife coating with the alloy powder paste, and alloy powder paste layers are formed at the Al material and the Cu material; and four, the overlap joints of the Al material and the Cu material are subjected to spot welding. The method has the significant effects that the cast nugget size of dissimilar metal Al-Cu is increased, cast nuggets are distributed uniformly and symmetrically between Al and Cu, the shearing resistance of the dissimilar metal Al-Cu is improved significantly, and thus the spot welding quality of the dissimilar metal Al-Cu is improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method of improving Al-Cu spot welding quality

ActiveCN107175395AIncrease nugget sizeImprove shear resistanceWelding/cutting media/materialsWelding/soldering/cutting articlesAlloySpot welding

The invention discloses a method of improving Al-Cu spot welding quality. The method comprises the following steps: one, Mn powder and Zn powder are weighed according to a mass ratio of (6-10):(1-3); two, the Mn powder and the Zn powder are proportionally mixed uniformly, a volatile solvent is added, and an alloy powder paste is formed through blending; three, the alloy powder paste is stirred, after the viscosity of the alloy powder paste is 0.5-0.55Pa.s, overlap joints of a Al material and a Cu material which are to be welded are subjected to knife coating with the alloy powder paste, and alloy powder paste layers are formed at the Al material and the Cu material; and four, the overlap joints of the Al material and the Cu material are subjected to spot welding. The method has the significant effects that the cast nugget size of dissimilar metal Al-Cu is increased, cast nuggets are distributed uniformly and symmetrically between Al and Cu, the shearing resistance of the dissimilar metal Al-Cu is improved significantly, and thus the spot welding quality of the dissimilar metal Al-Cu is improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Methods of improving the elongation and shrinkage of the steering knuckle rod

ActiveCN112498476BHigh elongationImprove shrinkageSteering linkagesShrinkage rateMechanical engineering

The invention relates to the technical field of steering knuckles, in particular to a method for improving the elongation rate and shrinkage rate of a steering knuckle rod. , a transition arc is provided at the junction of the rod part of the steering knuckle and the disk part, and the transition arc forms an annular surface around the axis of the rod part, and the radius of the transition arc on the side of the annular surface close to the long ear of the steering knuckle is R 1 , the R 1 is a fixed value, the radius of the transition arc on the side of the annular surface close to the short ear of the steering knuckle is R 2 , taking the plane where the shaft axis of the steering knuckle and the axis of the king pin hole are located as the reference plane, the R 2 uniformly decreases to R with the deviation from this reference plane 1 , the present invention can facilitate the filling of the rod part, reduce the shear damage of the internal metal streamline during the forming process of the steering knuckle rod part, and avoid the reduction of the mechanical performance of the rod part; Symmetrical; improved stress distribution at the junction of the knuckle stem and disc.

Owner:HUBEI TRI RING FORGING

A kind of internal rotation feeding device used for large-scale thin-walled cylindrical piece counter-wheel spinning equipment

The invention discloses an internal rotation feeding device for large thin-wall cylindrical part pair wheel spinning equipment, relates to an internal rotation feeding device, and aims to solve the problems of high mold cost, weak generality and long manufacturing period in traditional mold spinning equipment. A conical wedge block coats a feeding lead screw; multiple internal rotation wheel bases are annularly and uniformly mounted on the conical wedge block; one rotating shaft is vertically and rotationally mounted in each internal rotation wheel base; one internal rotation wheel is mounted on each rotating shaft; cross chutes are respectively formed in a rotating base guide sleeve and a wedge block guide sleeve, and are mutually aligned and buckled up and down; a transition sleeve coats the feeding lead screw, and is positioned at the upper end of the wedge block guide sleeve; an upper cross beam is mounted on the transition sleeve; an internal rotation motor is mounted on a speed reducer for transferring power to a speed reducer; and the speed reducer drives the feeding lead screw to rotate. The internal rotation feeding device is suitable for the thin-wall cylindrical part pair wheel spinning equipment.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com