Buried type movable garbage disposal equipment based on worm gear and lead screw transmission

A technology of garbage disposal equipment and worm gear screw, which is applied in the direction of garbage collection, lifting devices, household appliances, etc. It can solve the problems of scratching and wear between the lifting platform and the main frame, the asynchronous lifting platform, and the error of the lifting stroke, etc., to achieve The effect of improved motion synchronization, improved motion accuracy, and small torque error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

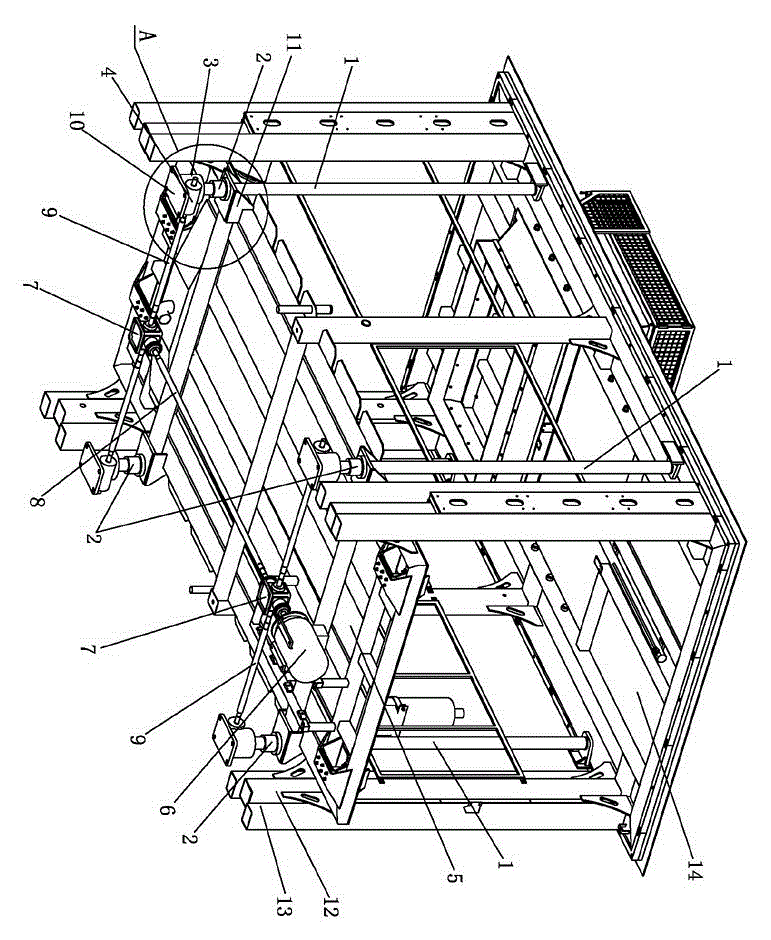

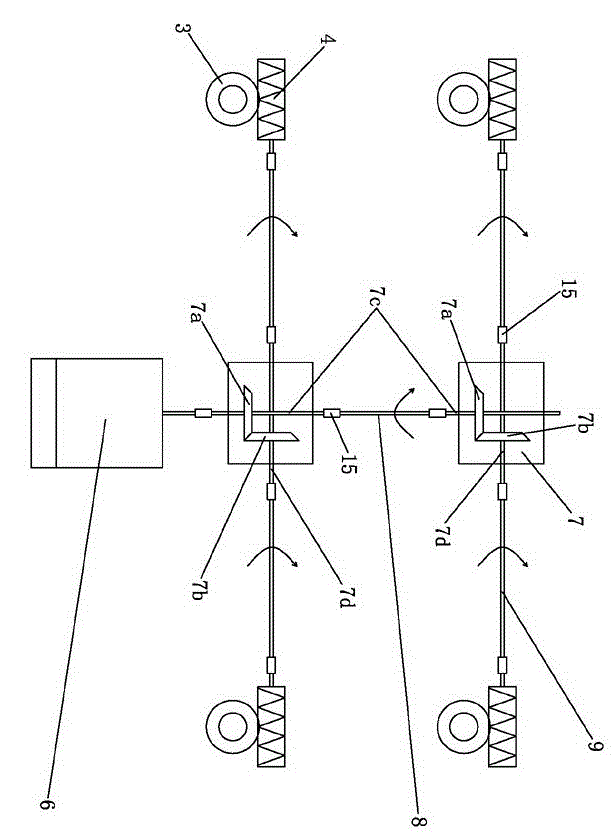

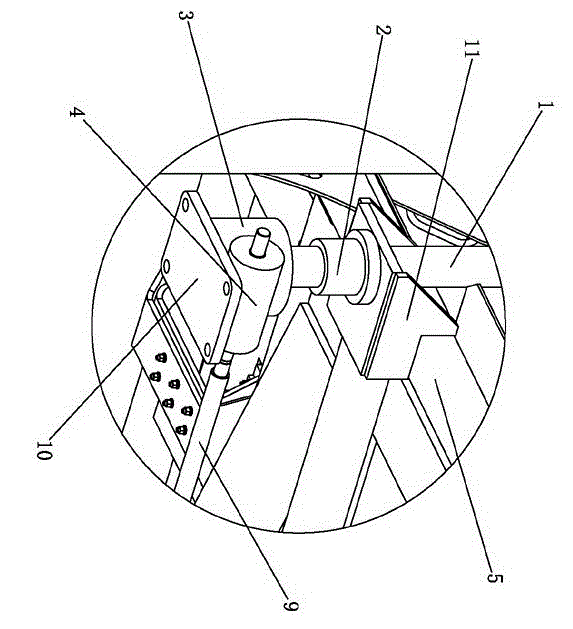

[0018] Such as Figure 1-3 As shown, the buried mobile garbage disposal equipment based on worm gear screw transmission includes a main frame 14, a lifting platform 5 for placing garbage disposal boxes, and a jacking transmission mechanism. Under the control of the main frame 14 for vertical lifting movement, the lifting platform 5 is also equipped with a vertical lifting guide mechanism to guide the lifting movement of the lifting platform 5. The jacking transmission mechanism includes a screw rod 1, which is sleeved on the screw rod 1 The screw nut 2, the bottom support seat 10 fixed on the ground foundation below the lifting platform 5; the screw nut 2 is fixedly installed on the lifting platform 5, and the axial length direction of the screw rod 1 is consistent with the lifting direction of the lifting platform 5, And the head of the screw mandrel 1 is rotatably installed on the main body frame 14, and the foot of the screw mandrel 1 is rotatably installed on the bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com