Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1354results about How to "Less prone to failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

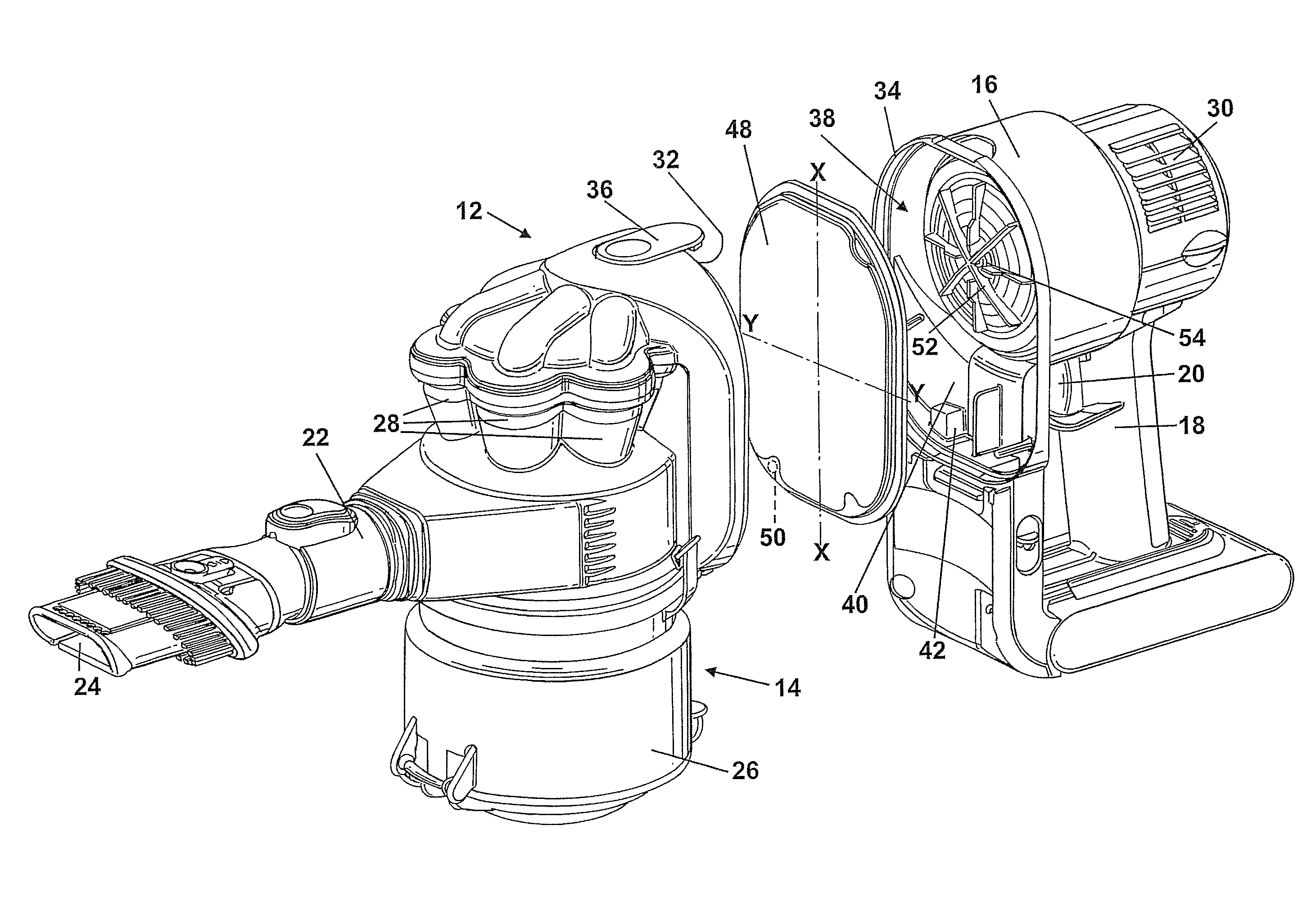

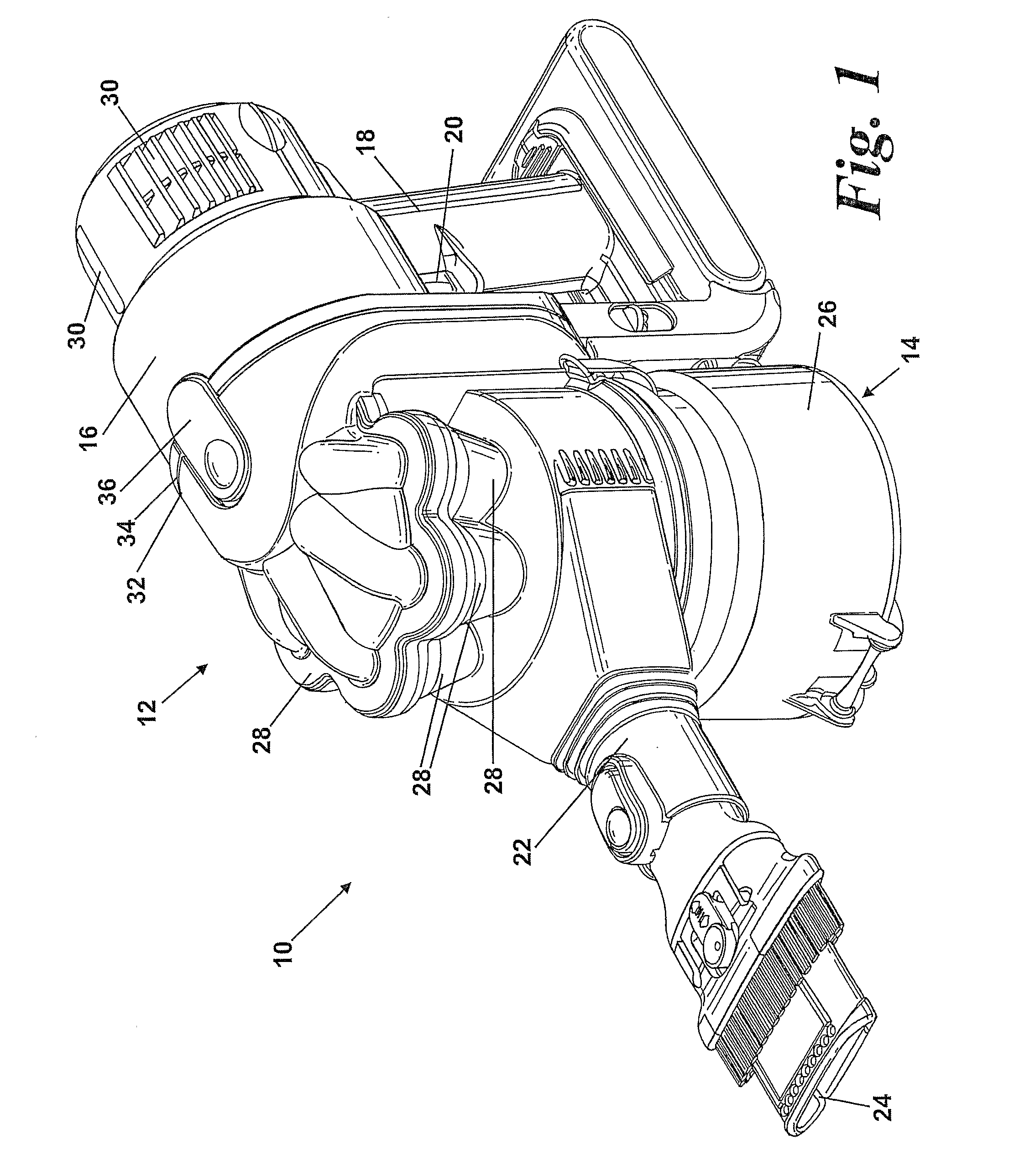

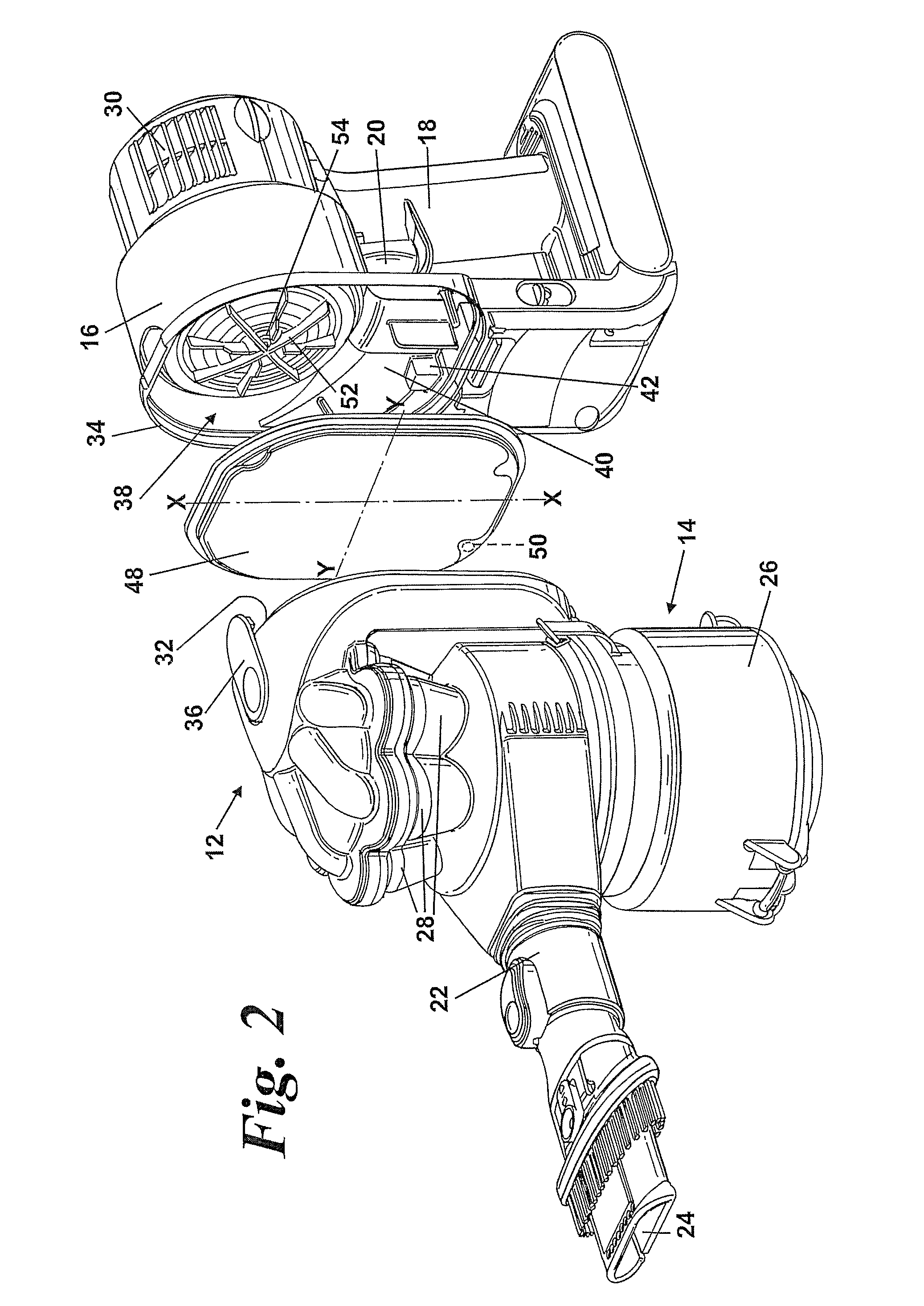

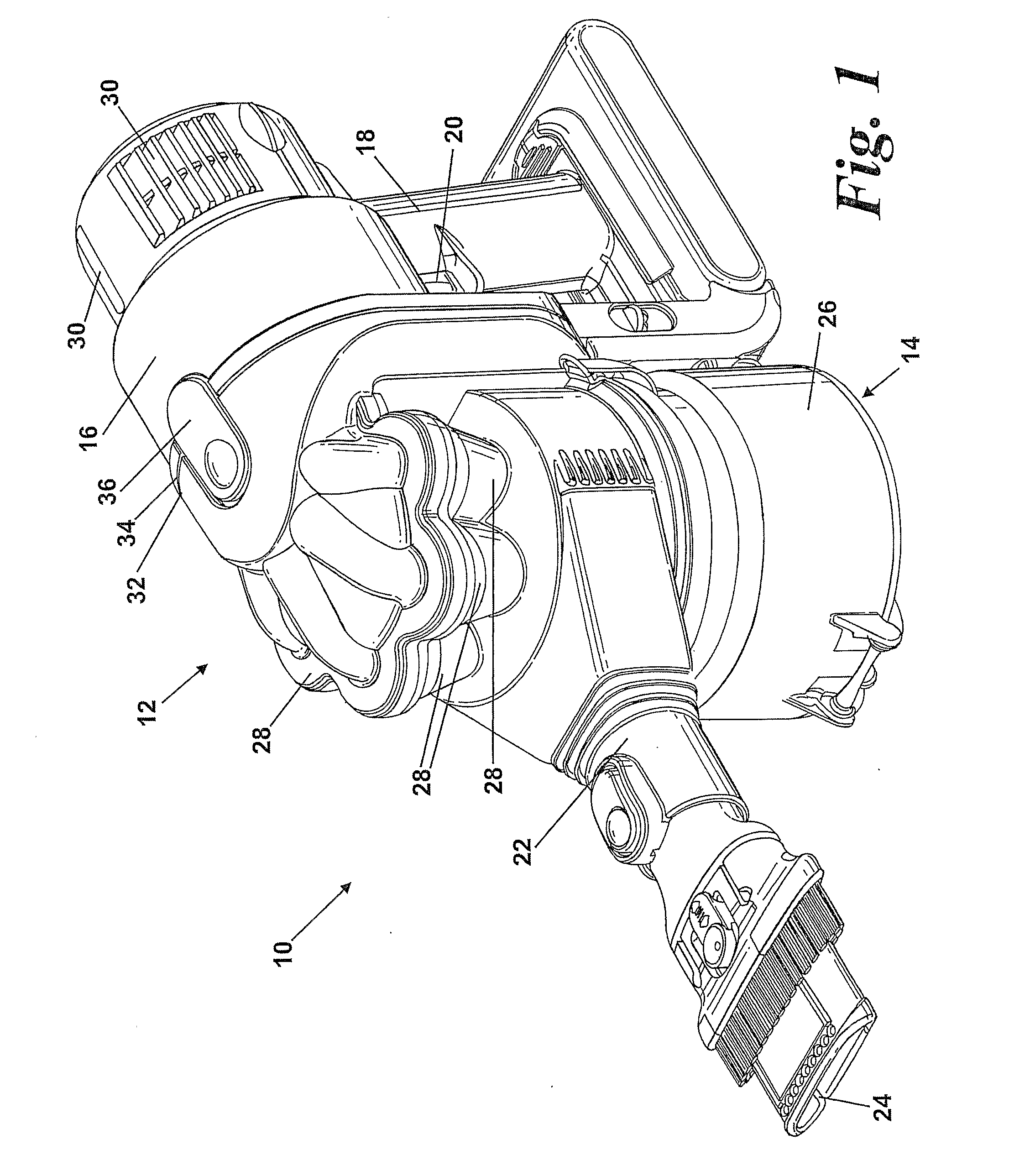

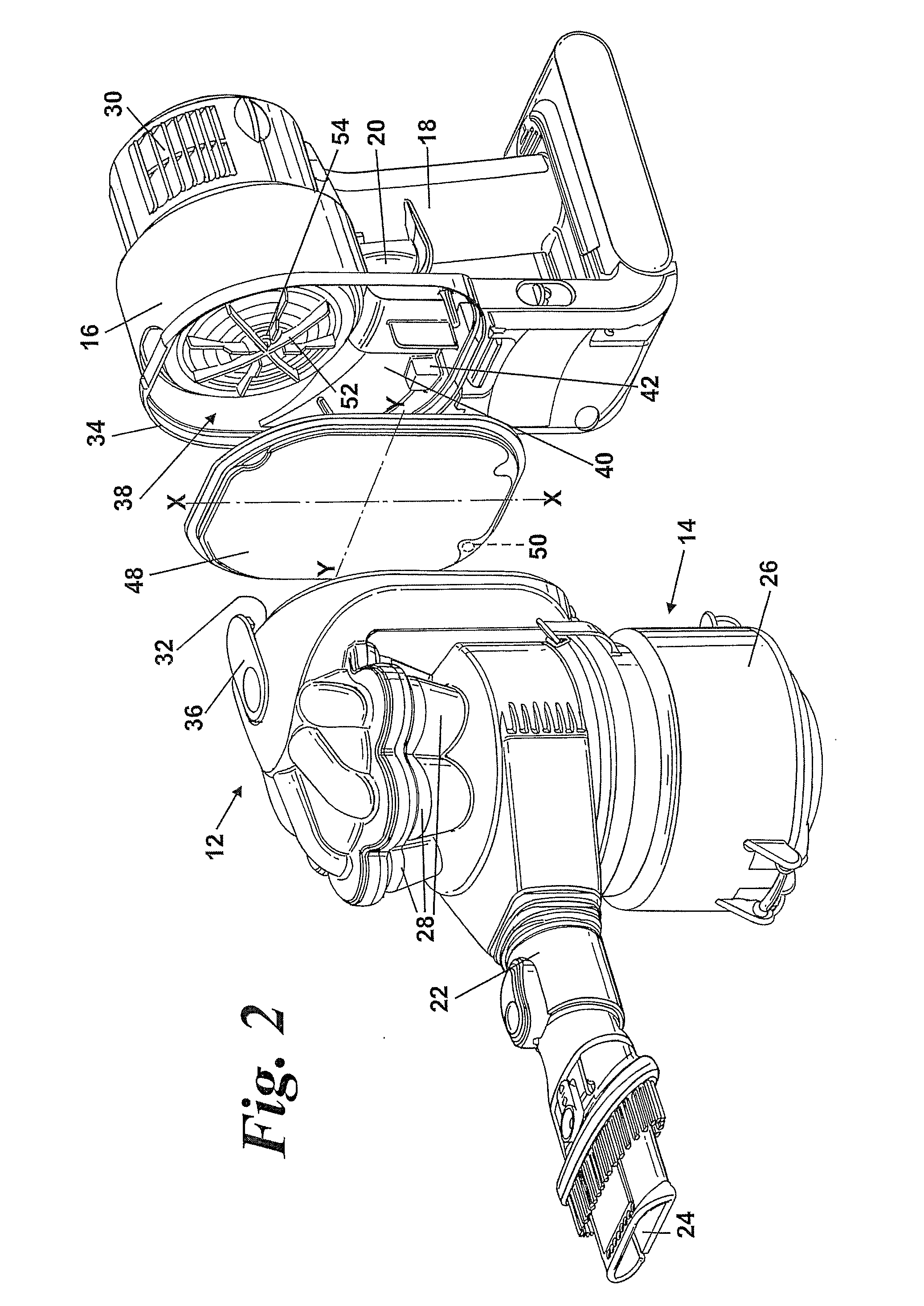

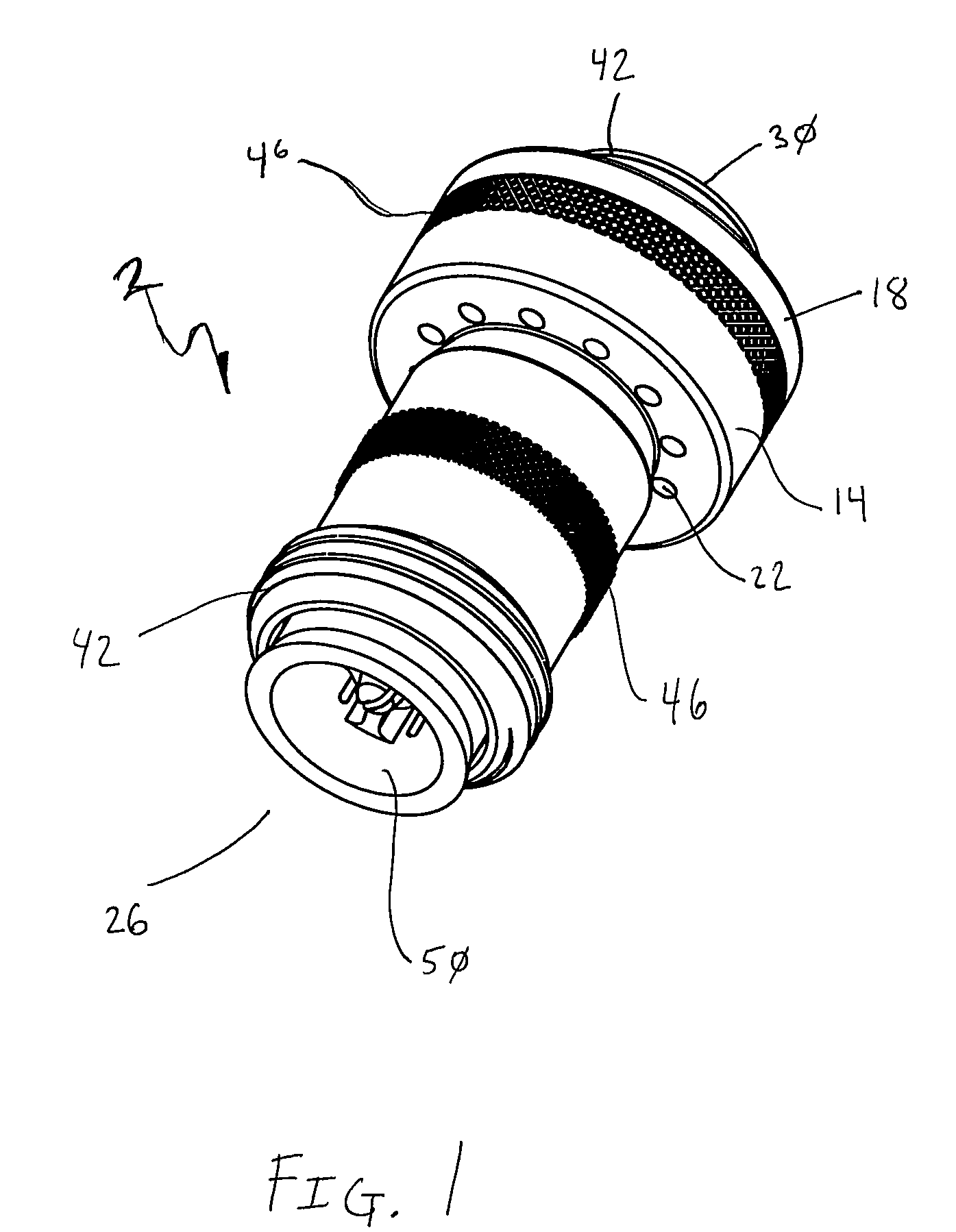

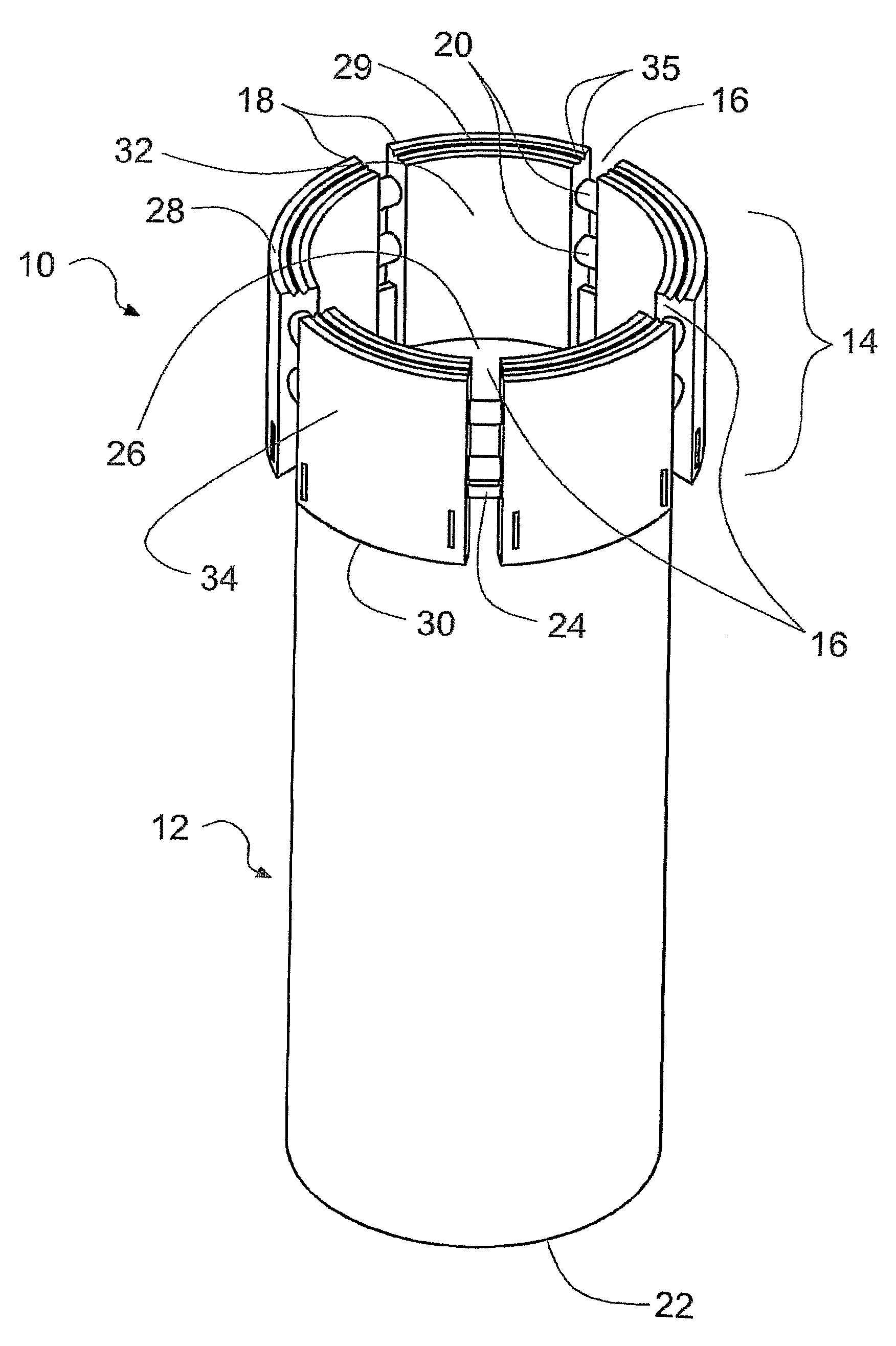

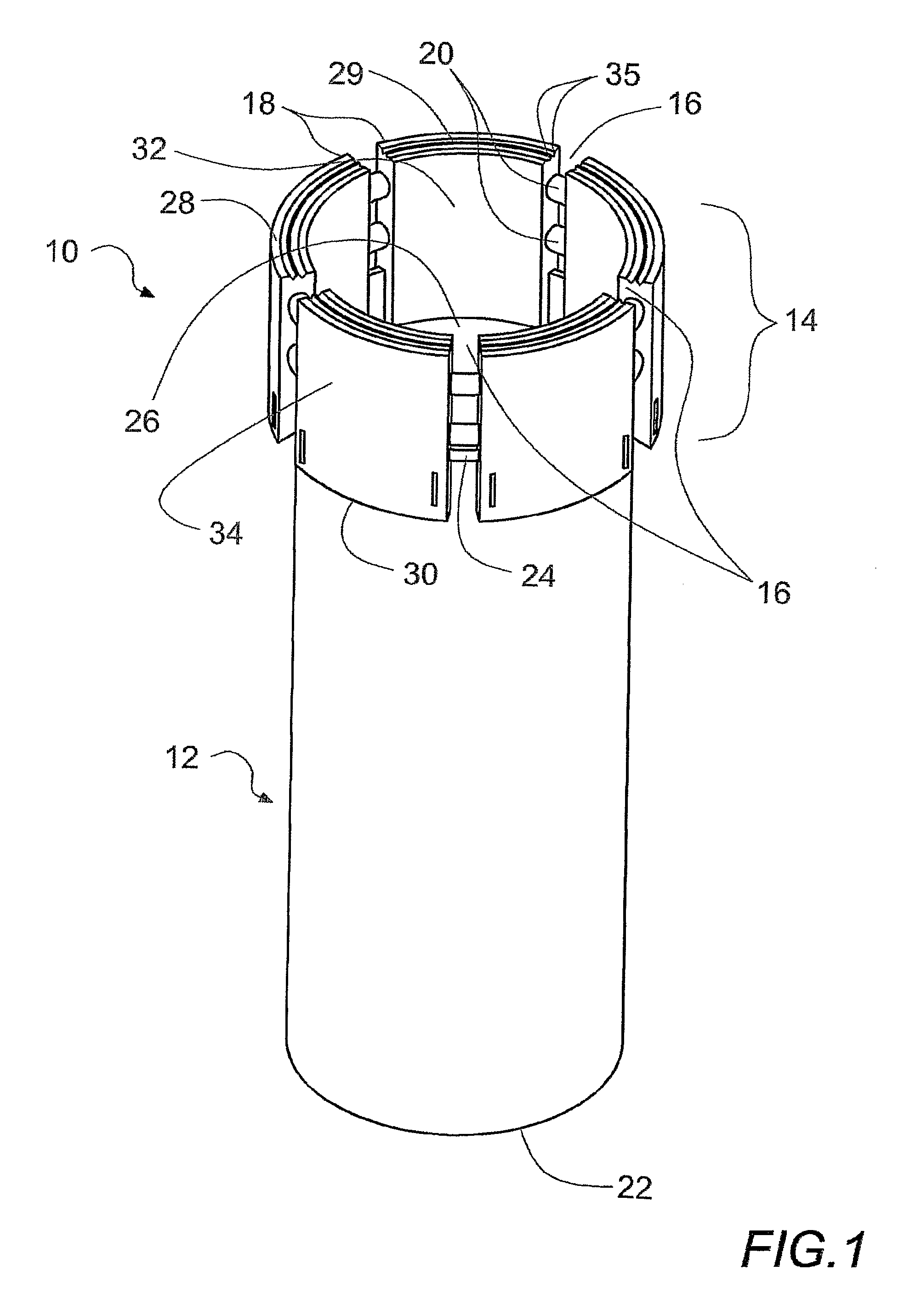

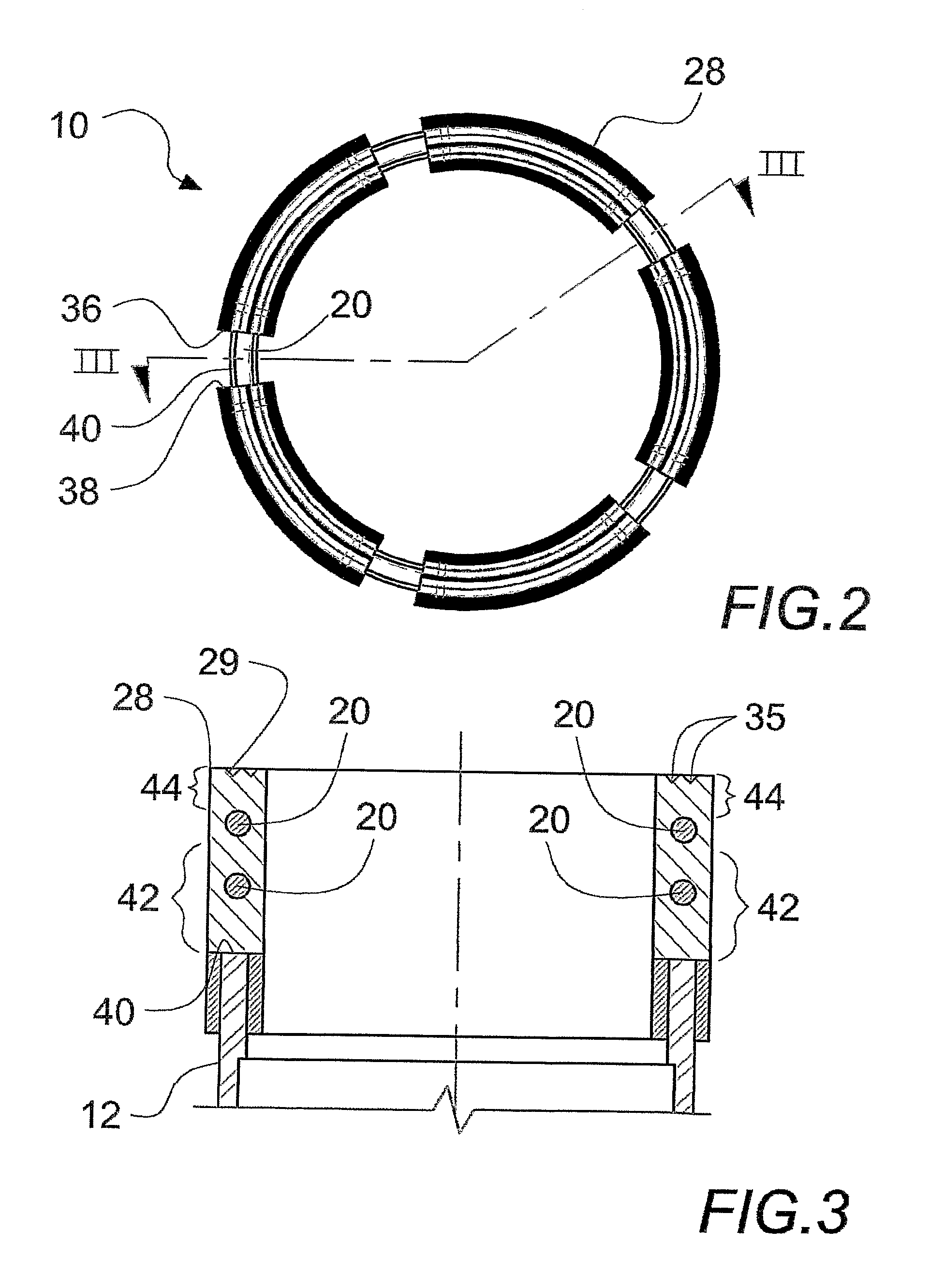

Handheld cleaning appliance

InactiveUS7931716B2Reduce cloggingLess prone to failureCombination devicesAuxillary pretreatmentHand heldWaste management

A cleaning appliance includes a main body, a filter and an interlock. The main body includes an airflow generator, a separating apparatus separating dirt and dust from an airflow, and a flowpath between the separating apparatus and the airflow generator delimited by a wall. The interlock has a first part located on the filter and a second part located on the main body outside the flowpath, arranged to communicate remotely when the filter is correctly located in the pre-determined position. The interlock is arranged selectively to allow or prevent operation of the airflow generator depending upon the relative separation between the first and second parts. By providing an interlock which has first and second parts which communicate remotely, the second part located on the main body can be isolated from the airflow path so that the second part is not subject to dirt and dust carried by the airflow.

Owner:DYSON TECH LTD

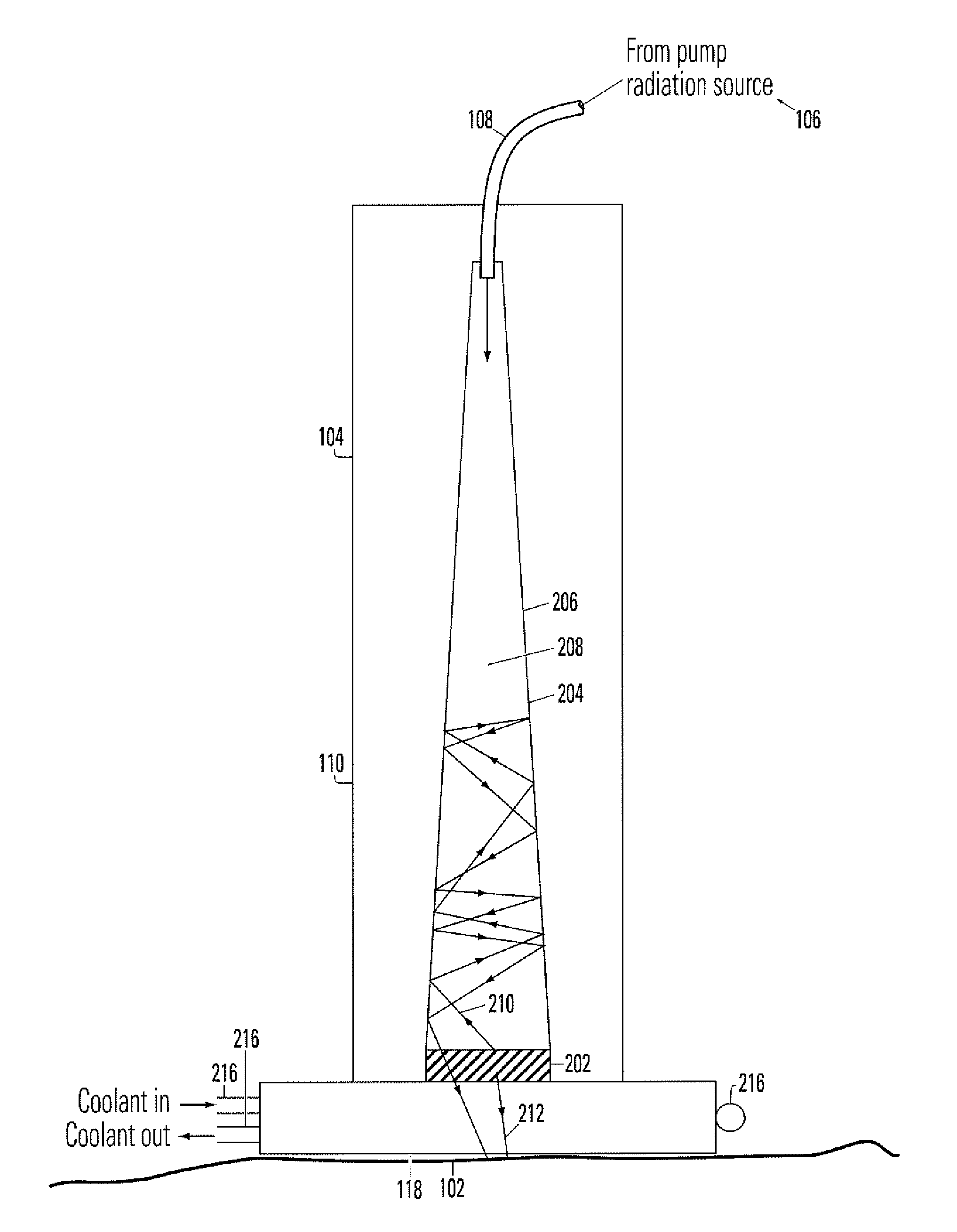

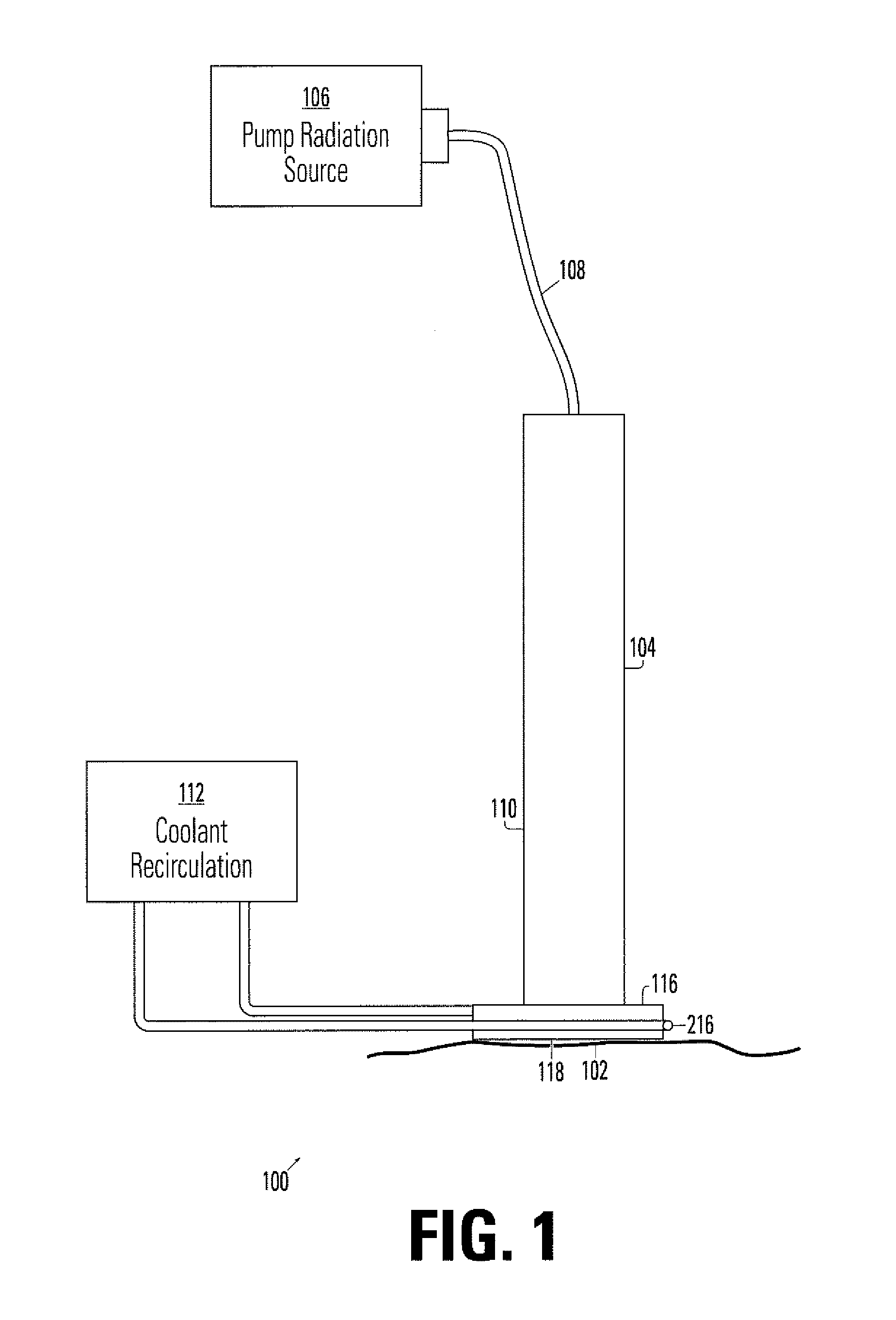

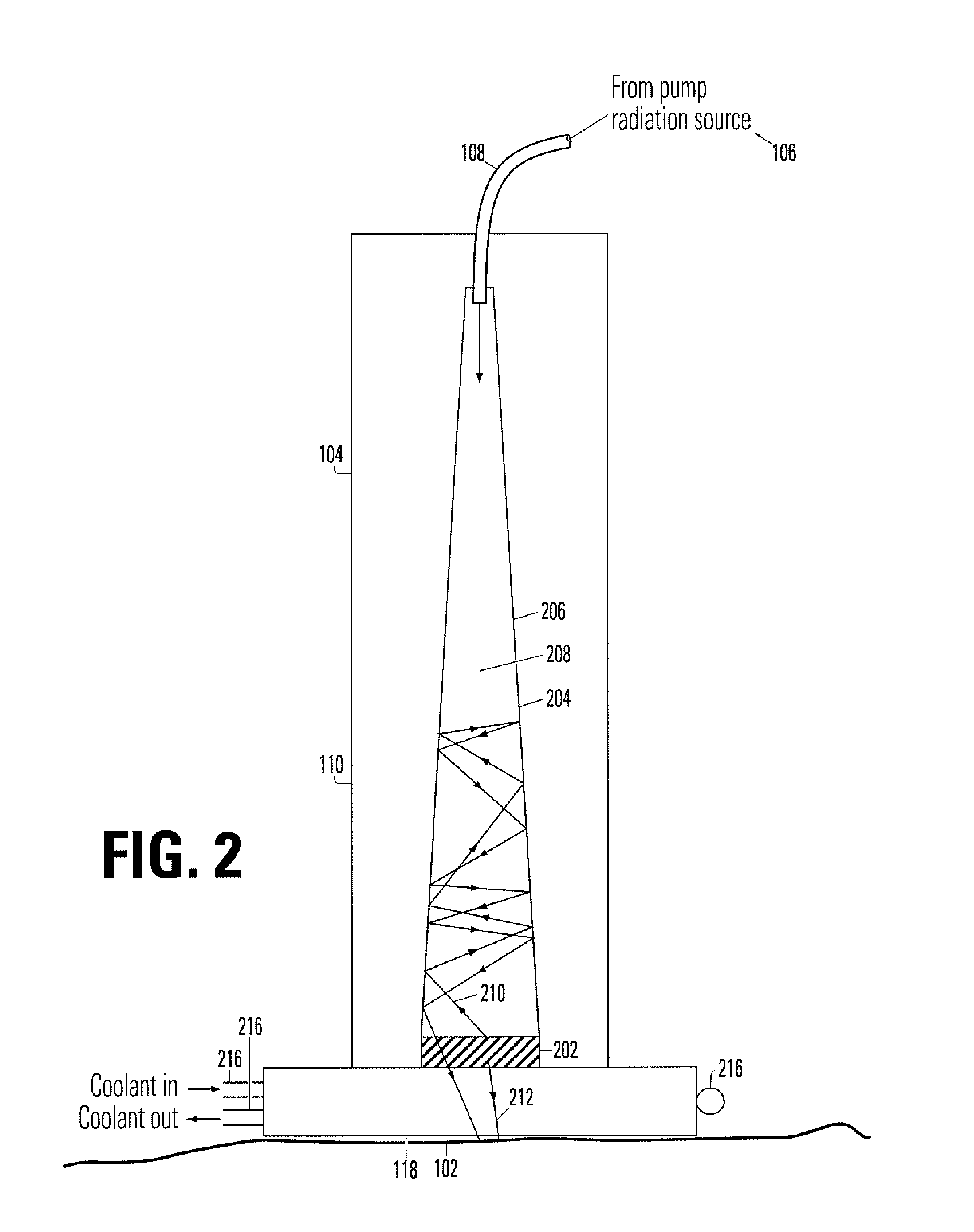

Device for irradiating tissue

InactiveUS7083610B1Minimize damageLess prone to failureSurgical instrument detailsLight therapyHair removalPhotodynamic therapy

A device for irradiating tissue includes a fluorescent element for receiving pump radiation and responsively emitting radiation having different spectral characteristics than the pump radiation. A redirector receives emitted radiation promulgated in a direction away from a tissue target and redirects the radiation toward the target. The pump radiation may be supplied, for example, by a flashlamp or frequency-doubled neodymium-doped laser. Use of the device provides an inexpensive and effective alternative to conventional dye laser-based systems for various medical therapies, including treatment of vascular and pigmented lesions, tattoo and hair removal, and photodynamic therapy (PDT).

Owner:BOSTON SCI SCIMED INC

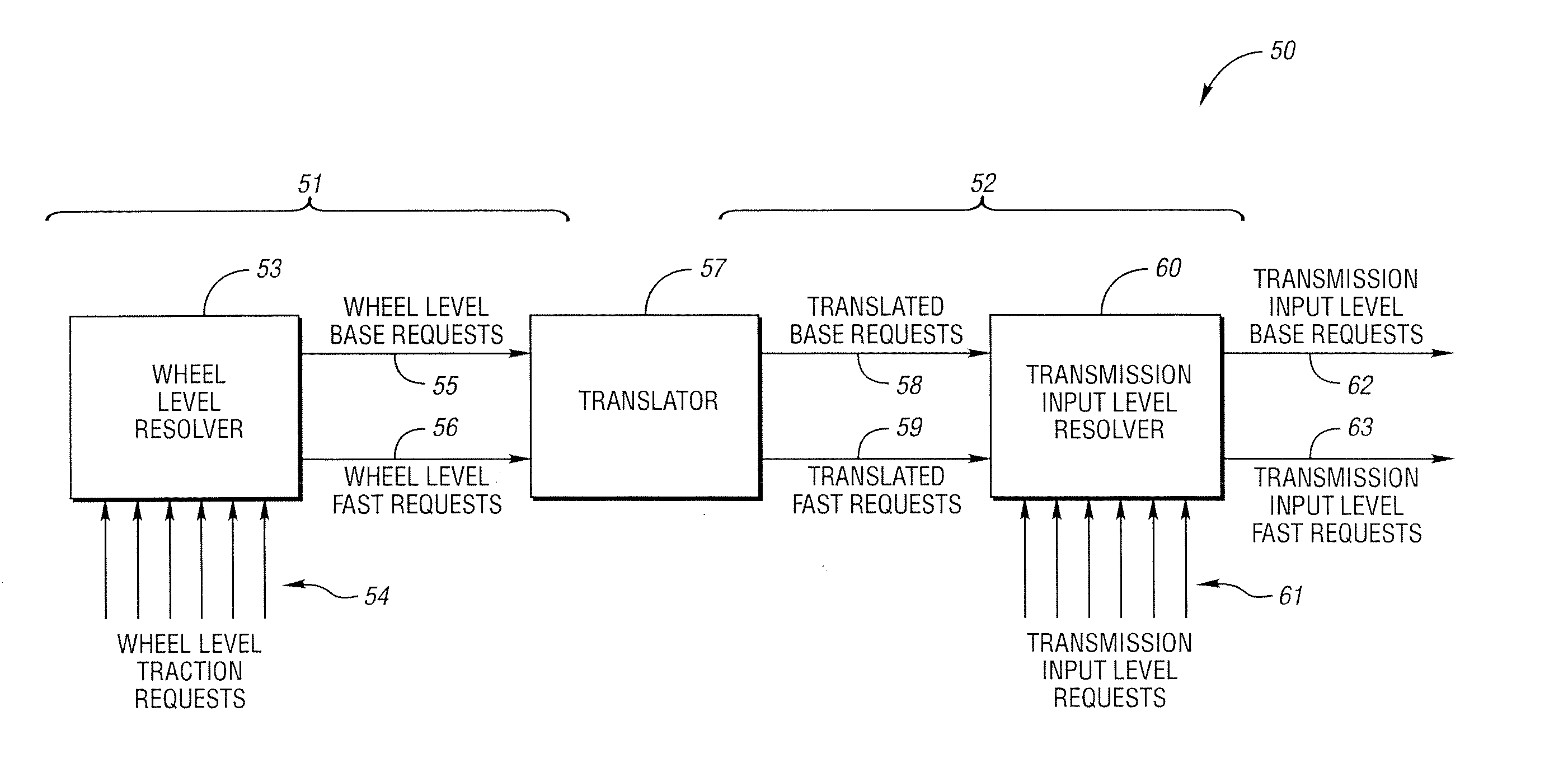

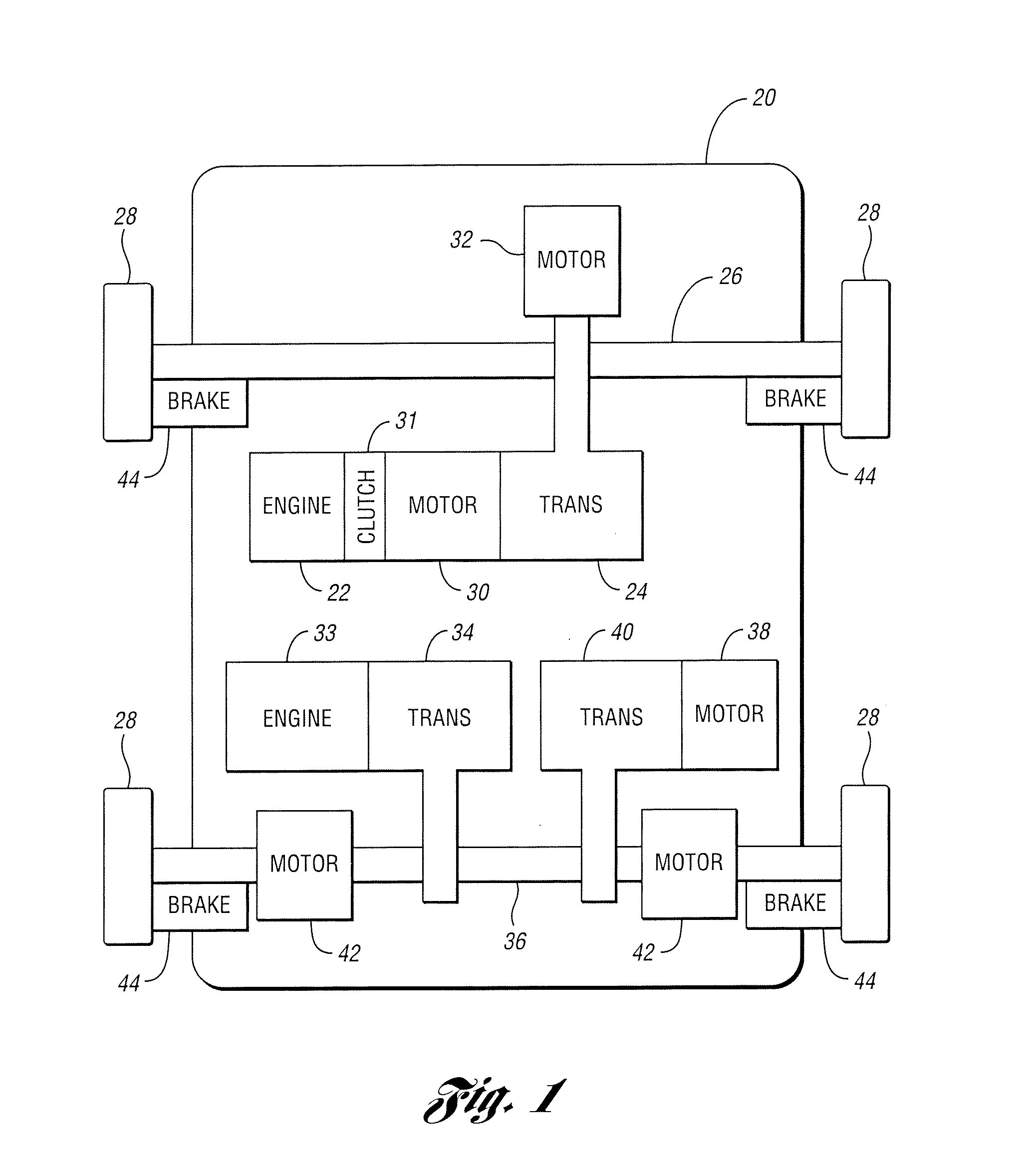

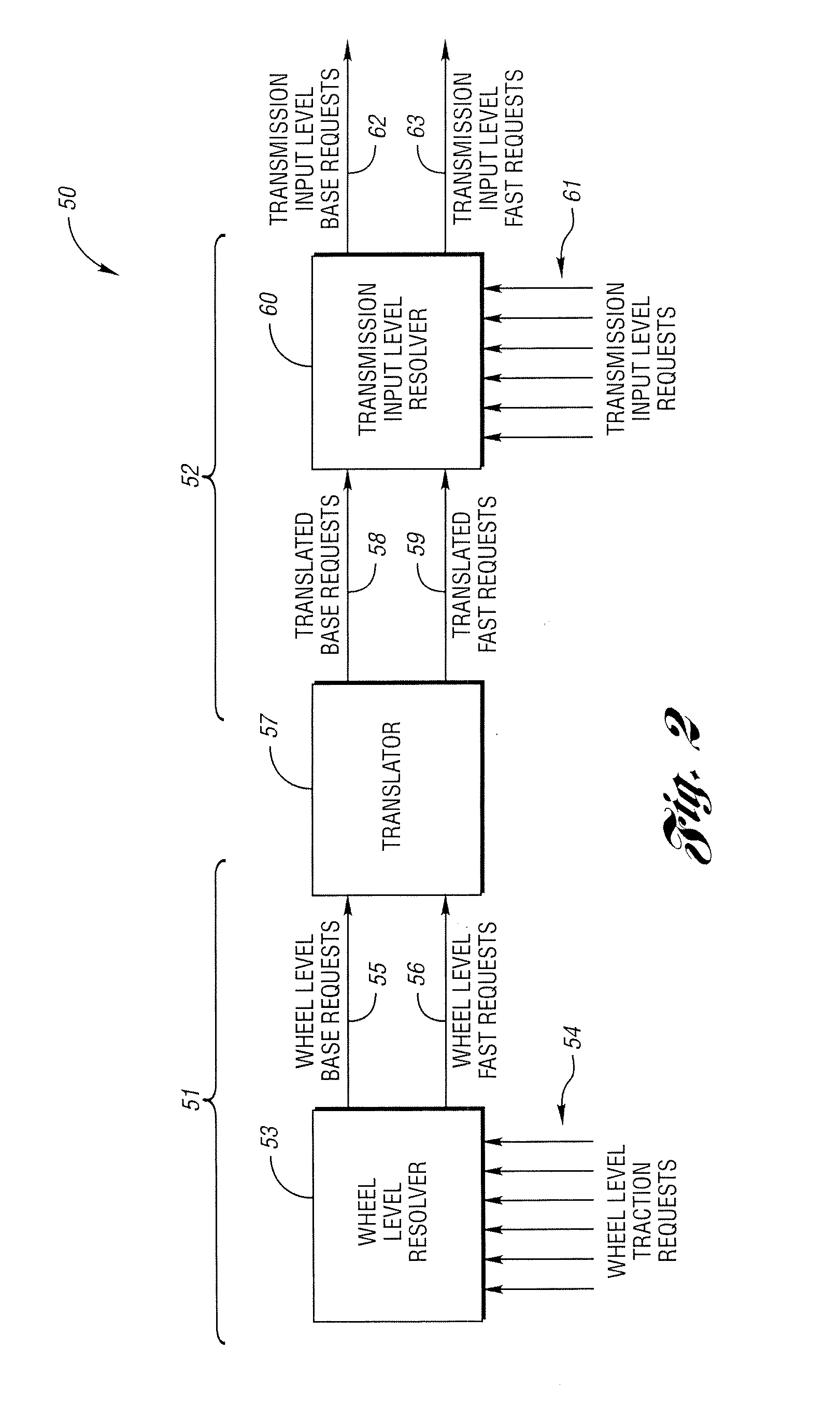

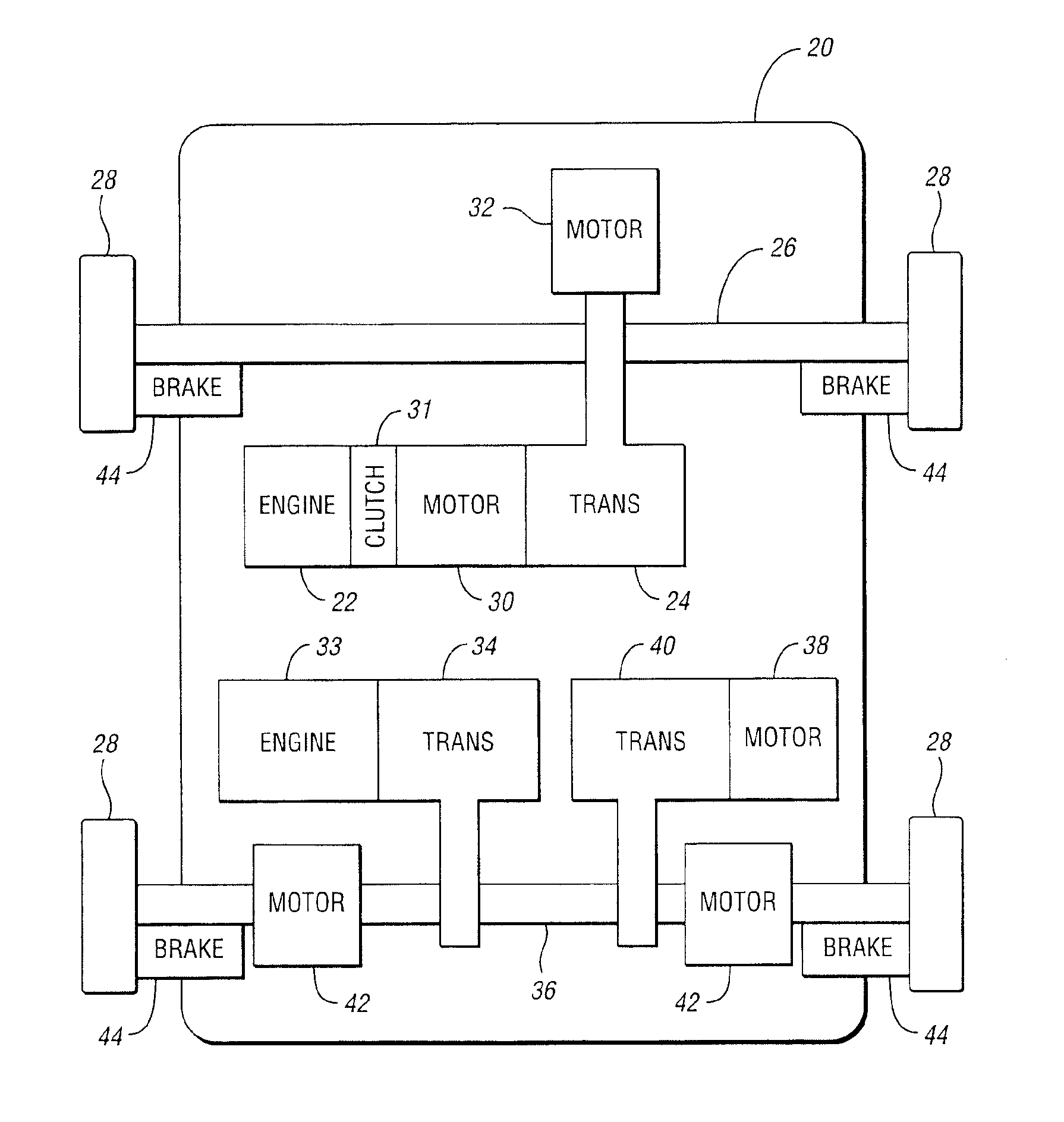

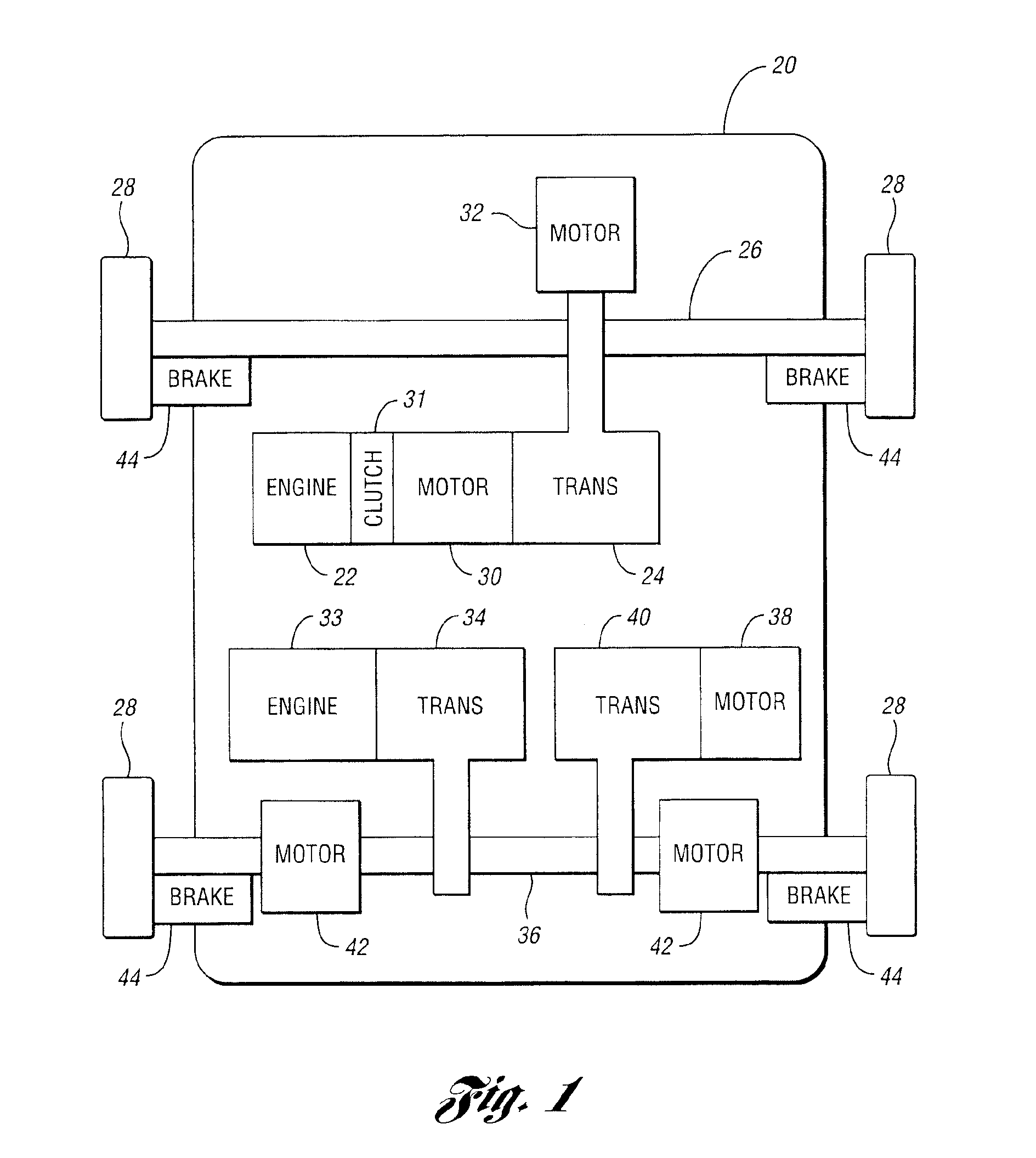

Vehicle torque coordination

InactiveUS20050060079A1More robustLess prone to failureBrake system interactionsDigital data processing detailsControl theory

Owner:FORD GLOBAL TECH LLC

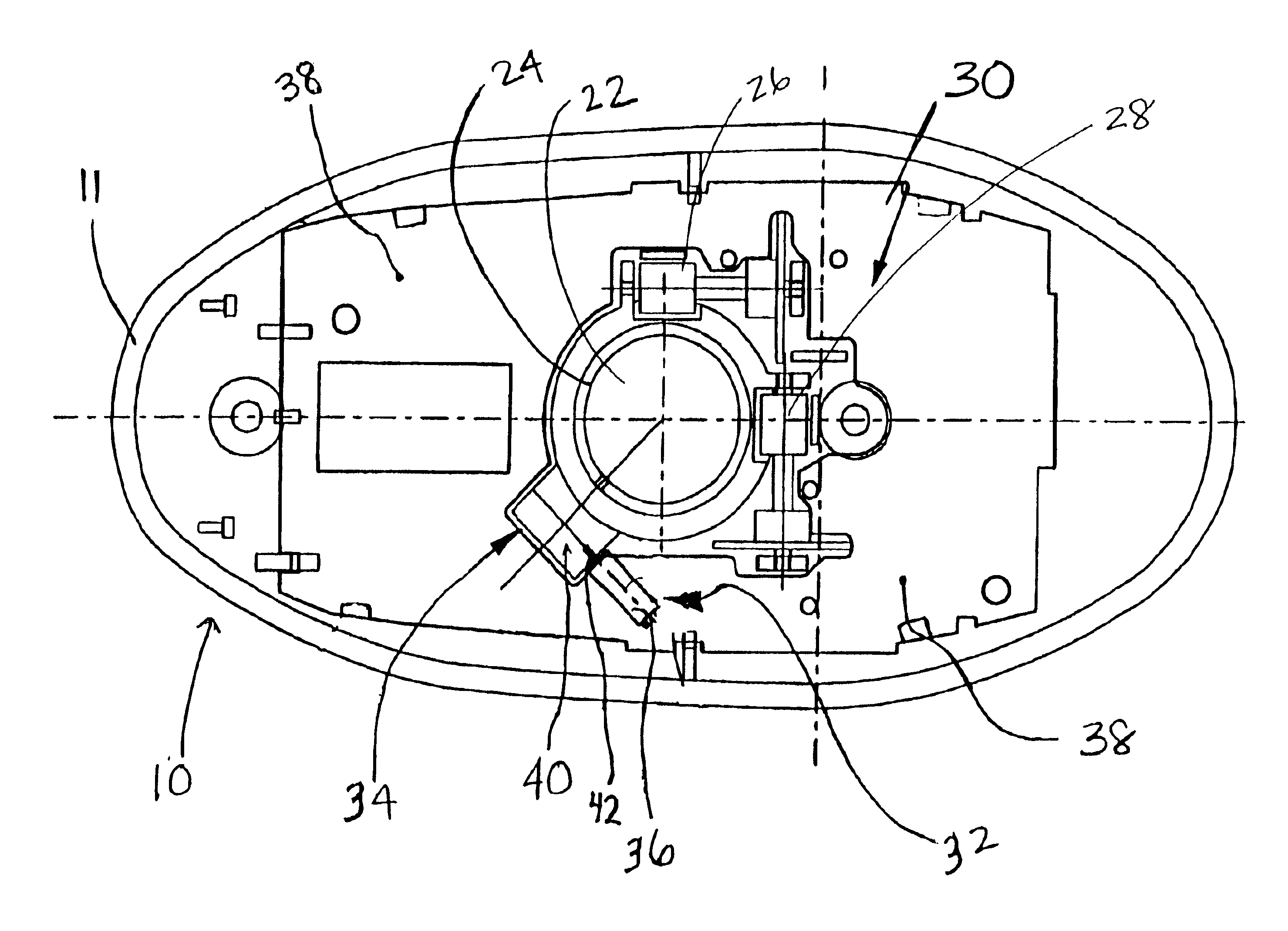

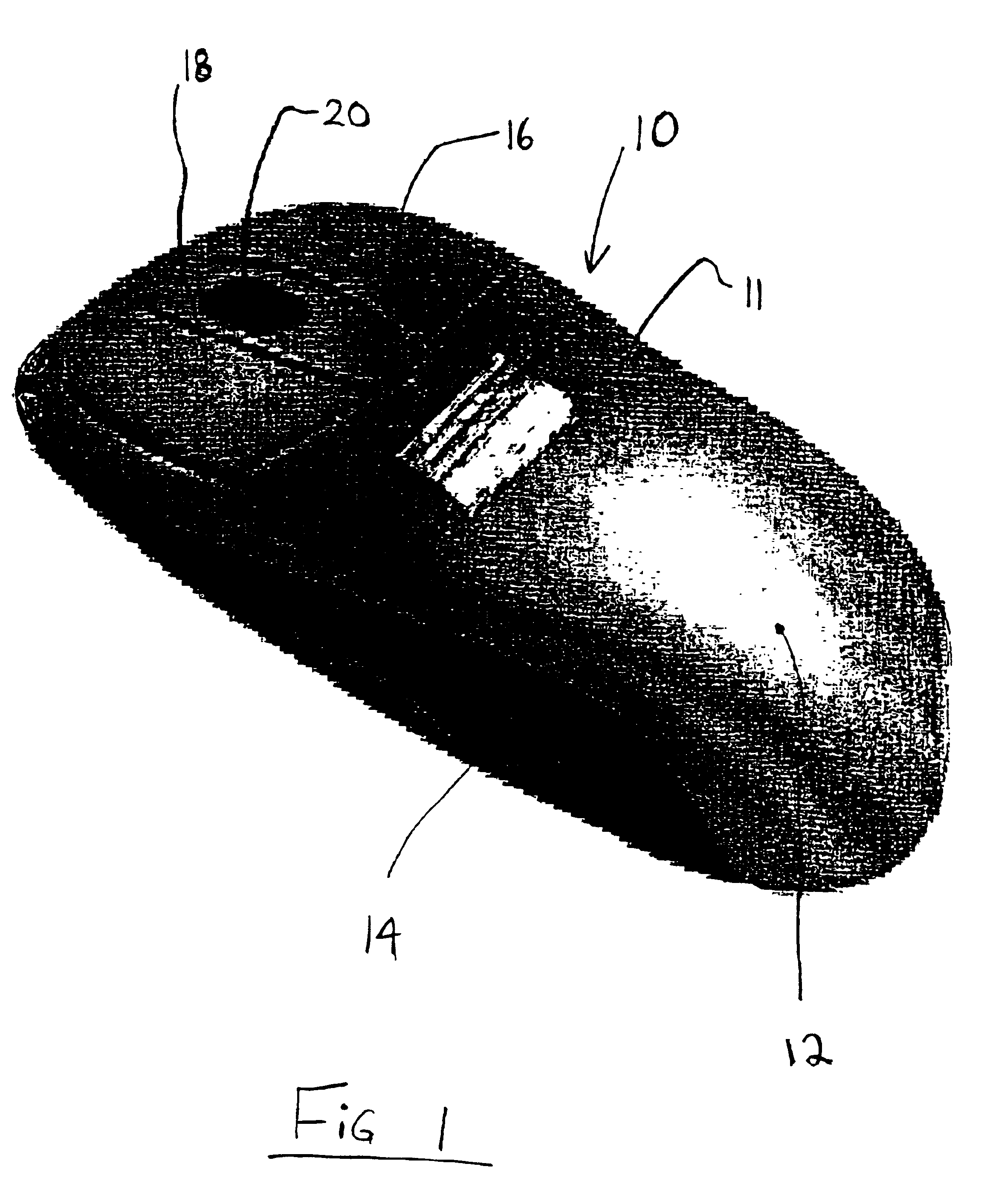

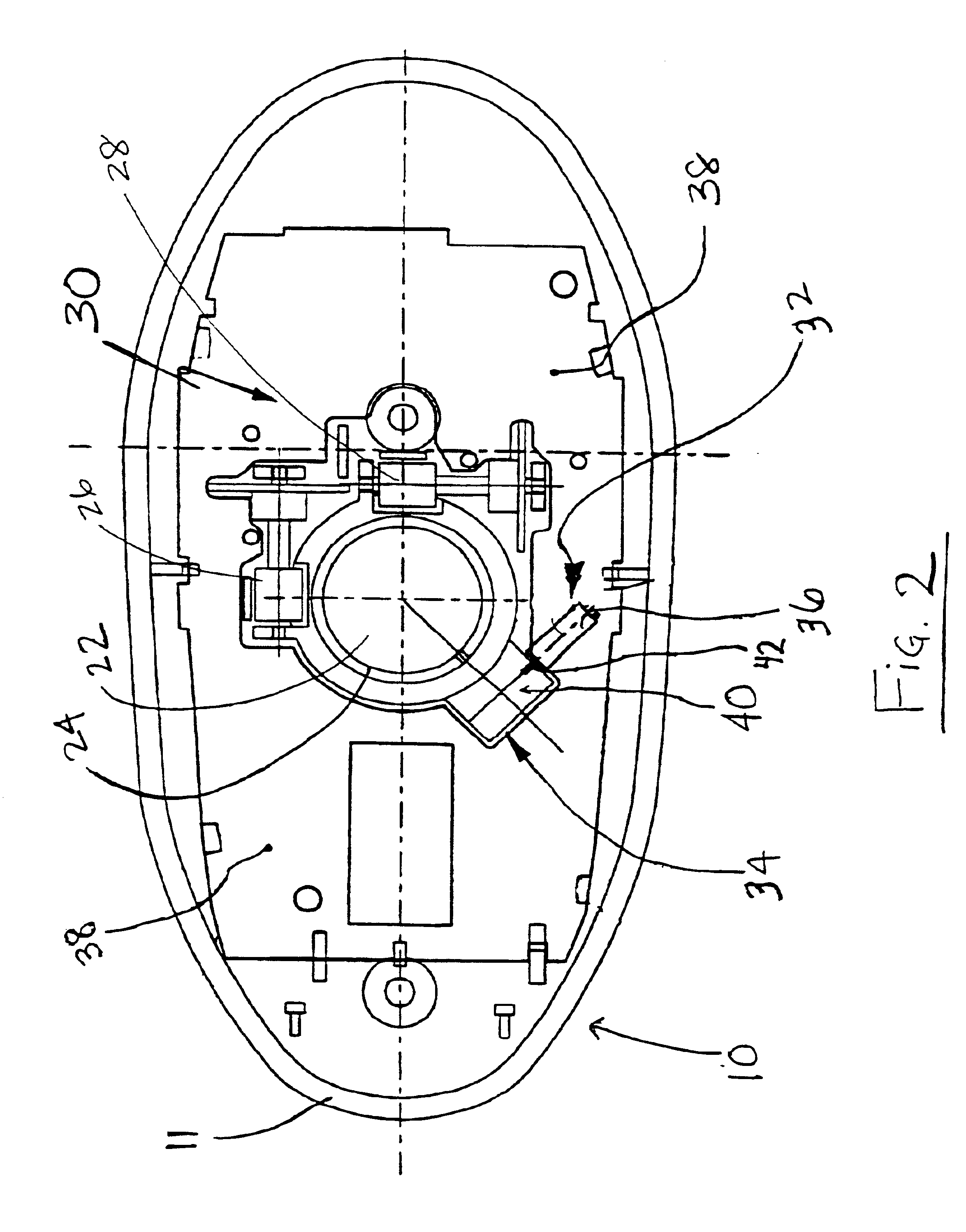

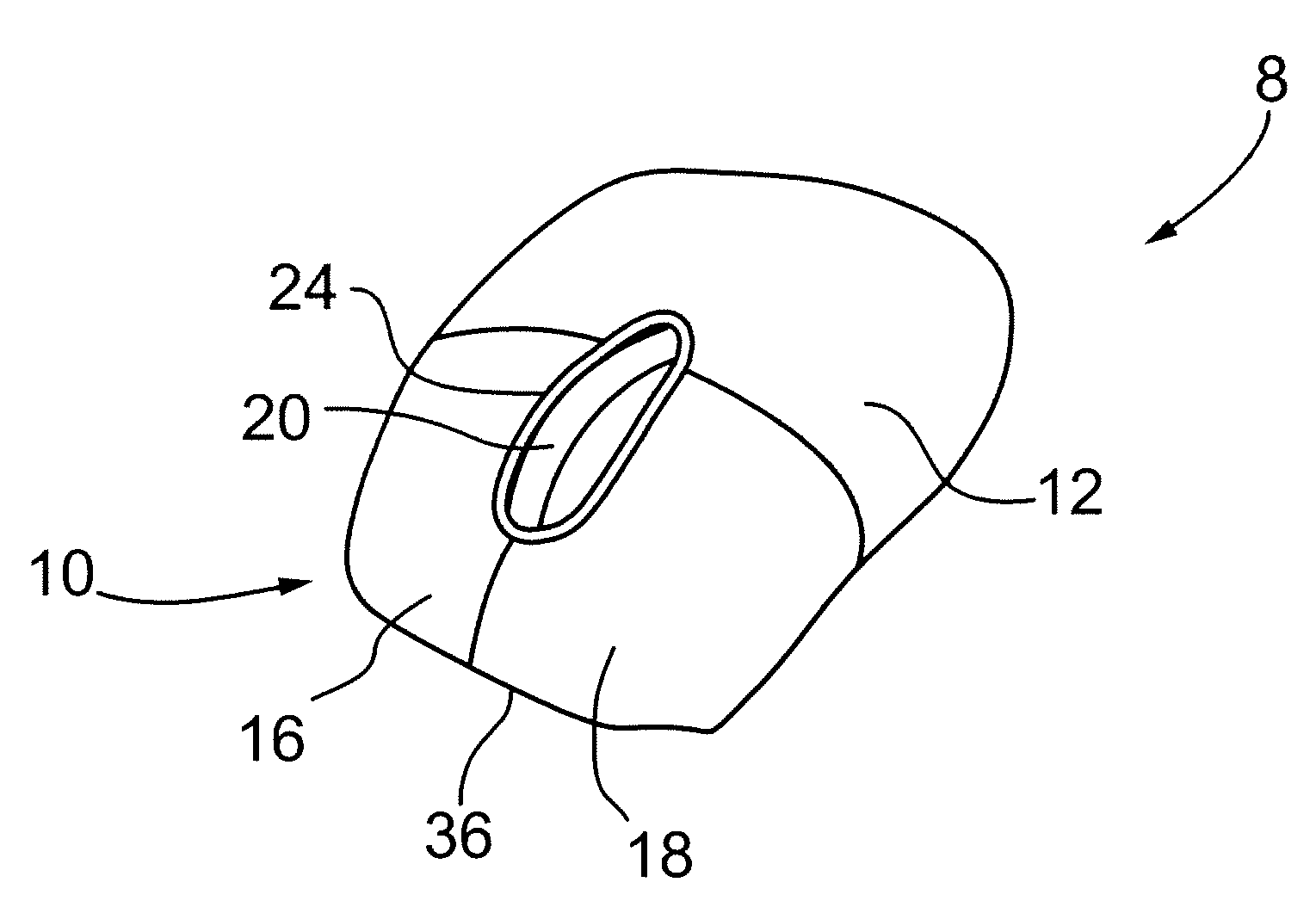

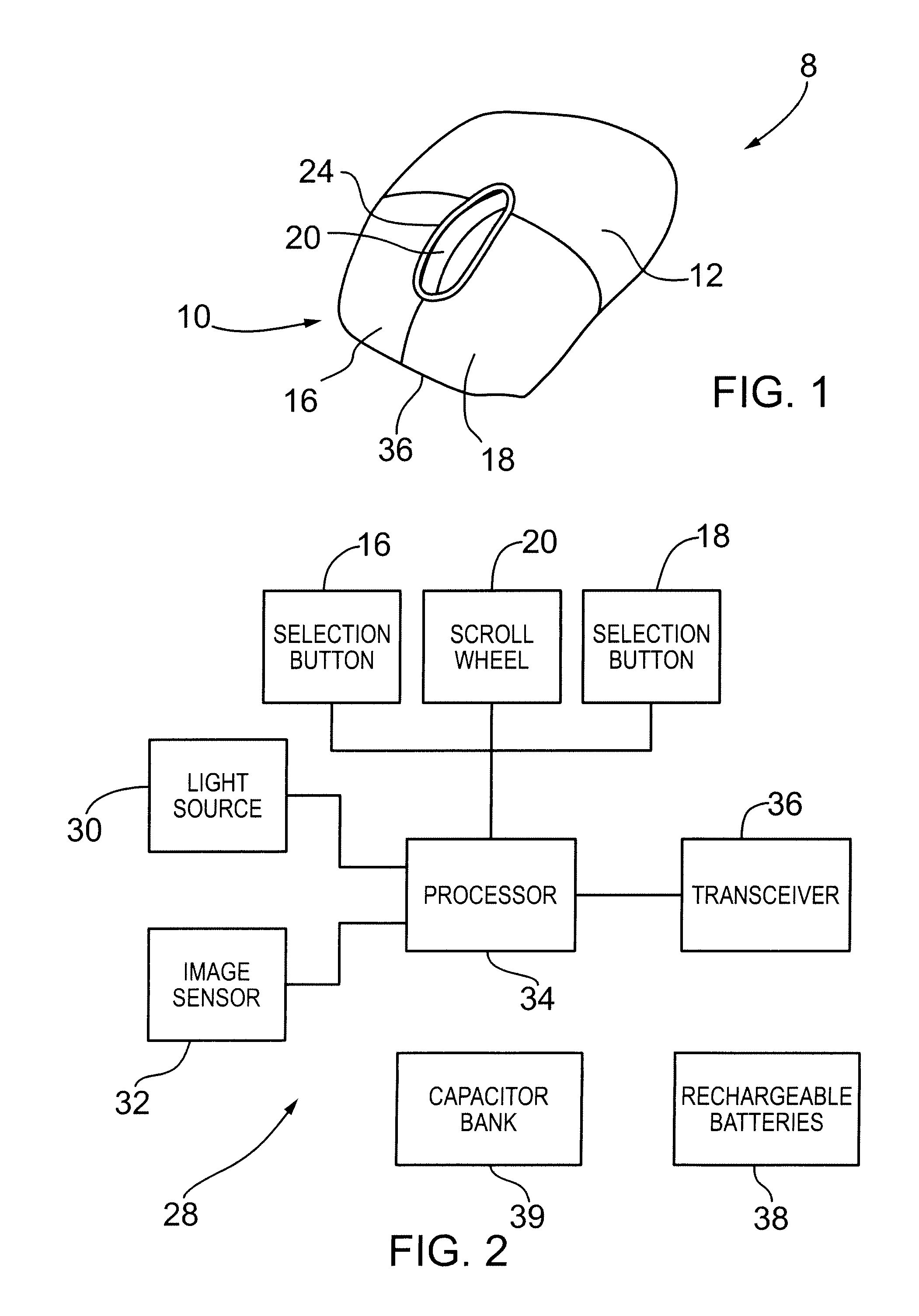

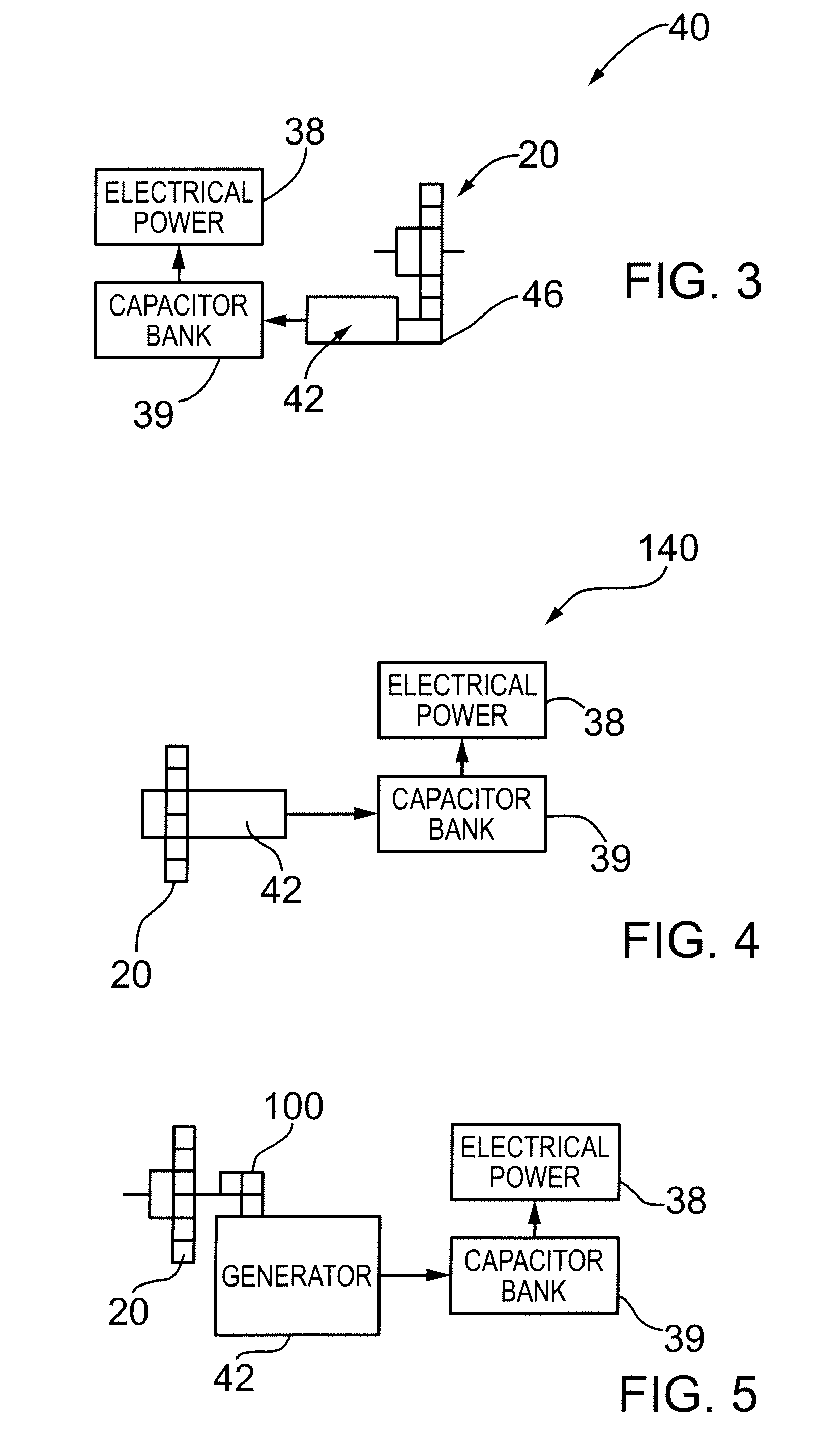

Self-powered cordless mouse

InactiveUS6903725B2Extended operating timeIncorporated into computer-pointing devices inexpensivelyCathode-ray tube indicatorsInput/output processes for data processingEngineeringPointing device

A self-powered computer-pointing device includes a housing and a roller ball accommodated within the housing. At least a portion of the roller ball is exposed through an opening in the housing to allow the roller ball to contact a surface on which the computer-pointing device rests. Movement of the computer-pointing device across the surface imparts rotation of the roller ball. A sensing mechanism senses movement of the roller ball and generates x-y movement signals corresponding to movement of the computer-pointing device across the surface. The sensing mechanism conveys the x-y movement signals to a host computer. A power generating mechanism is coupled to the roller ball and converts rotational movement of the roller ball into electrical energy that is used as power by the computer-pointing device.

Owner:NACSON SABATINO

Vehicle torque coordination

InactiveUS6862511B1Less prone to failureImprove driveabilityBrake system interactionsDigital data processing detailsControl theory

Owner:FORD GLOBAL TECH LLC

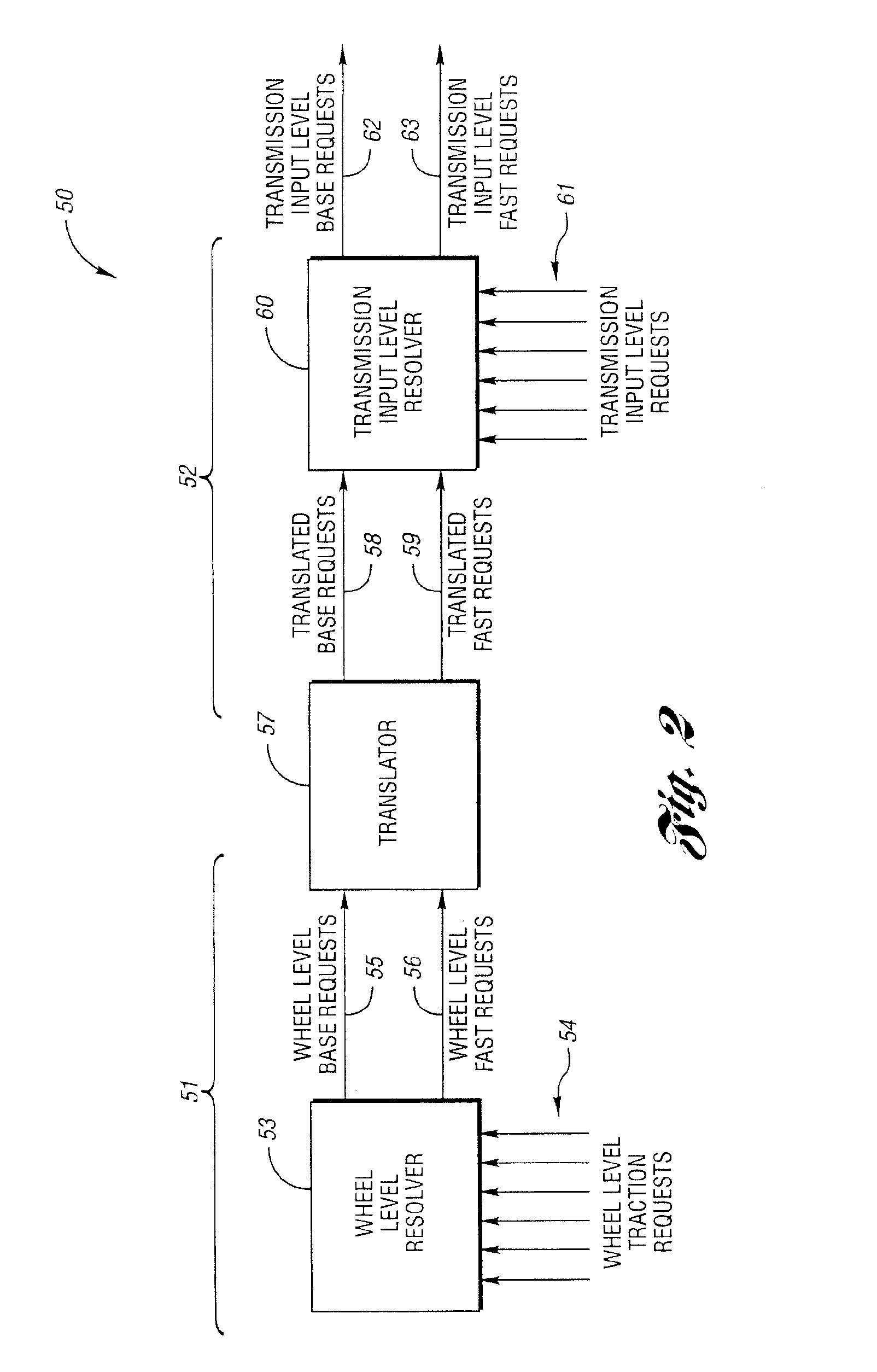

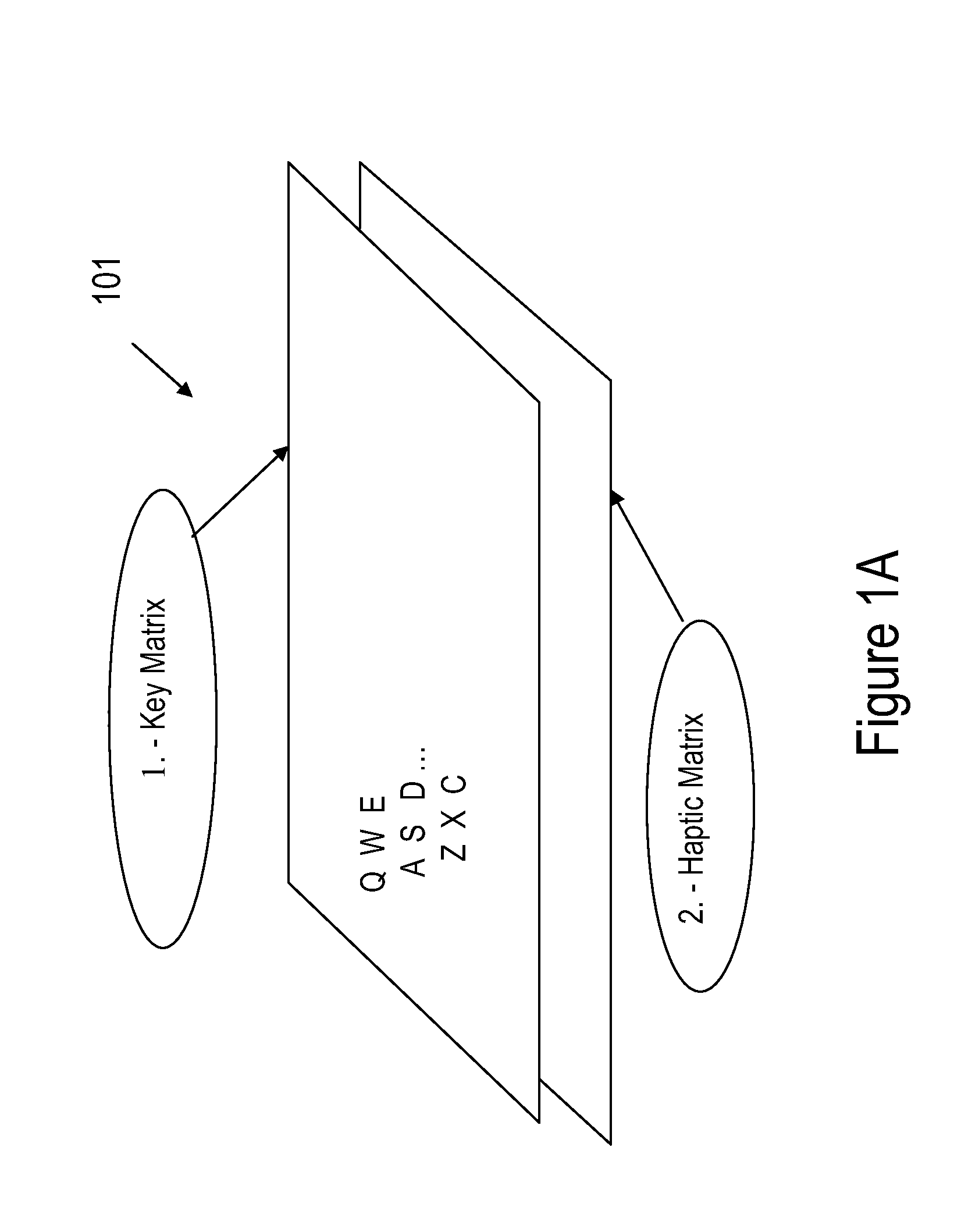

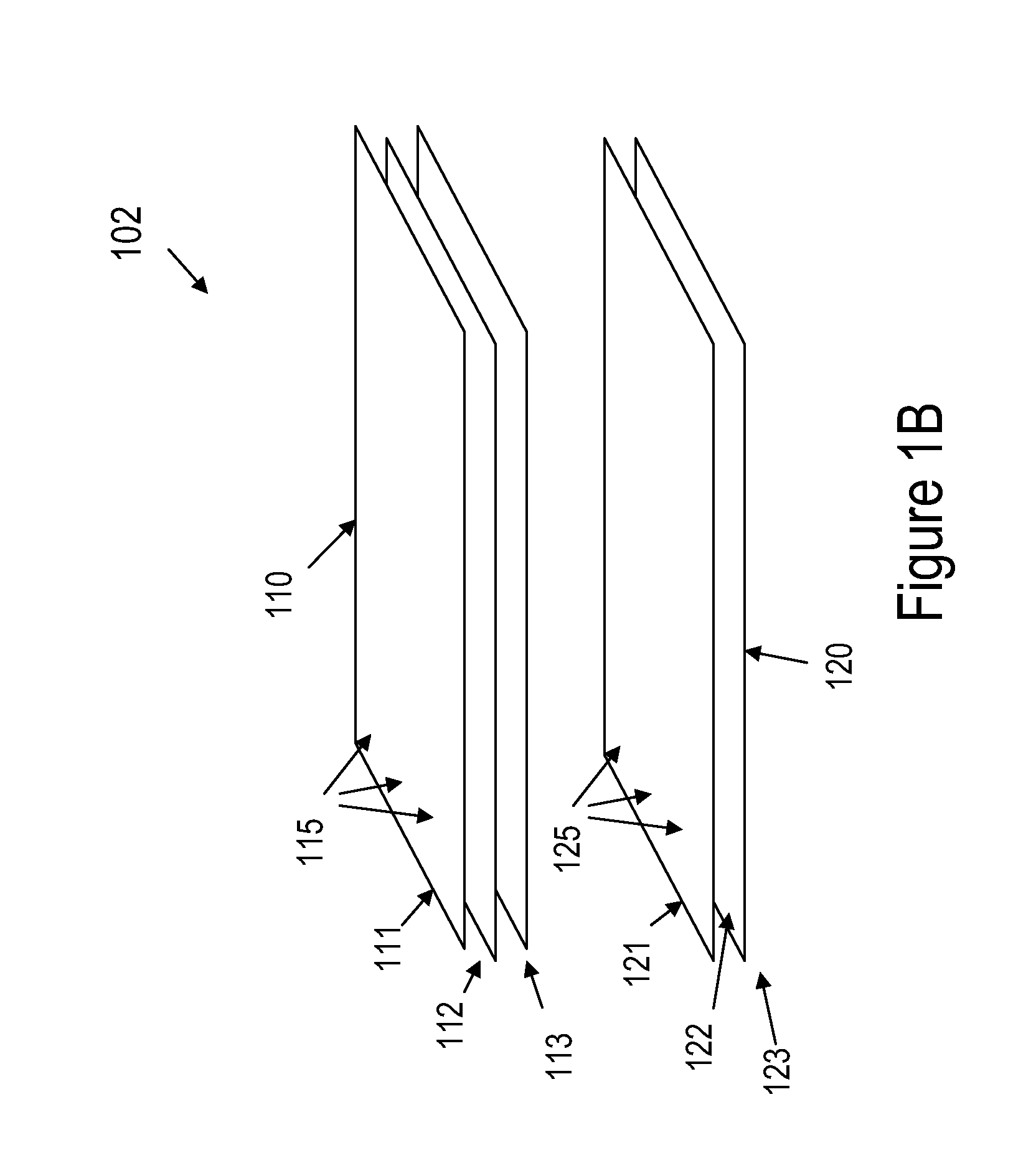

Haptic keyboard apparatus and method

InactiveUS20100089735A1Less-prone to mechanical failureQuick feedbackElectric switchesTactile feedbackControl signalTactile device

A haptic keyboard apparatus includes a membrane resistor keyboard device and a haptic device. The membrane resistor keyboard device includes a plurality of key switches, each of the key switches being responsive to touch by a user. The haptic device is coupled to the membrane resistor keyboard device. The haptic device includes a plurality of haptic cells, each of which is disposed under a corresponding key switch. Each of the haptic cells is configured to provide haptic feedback in response to the touch by the user. In a specific embodiment, the haptic keyboard apparatus also includes a processor and a haptic controller that provide control signals to the haptic device. In an embodiment, the control signals include programmable voltages and frequencies, causing the haptic cells to effect vibrational patterns in response to the control signals and provide haptic feedback to the user.

Owner:MINEBEA CO LTD

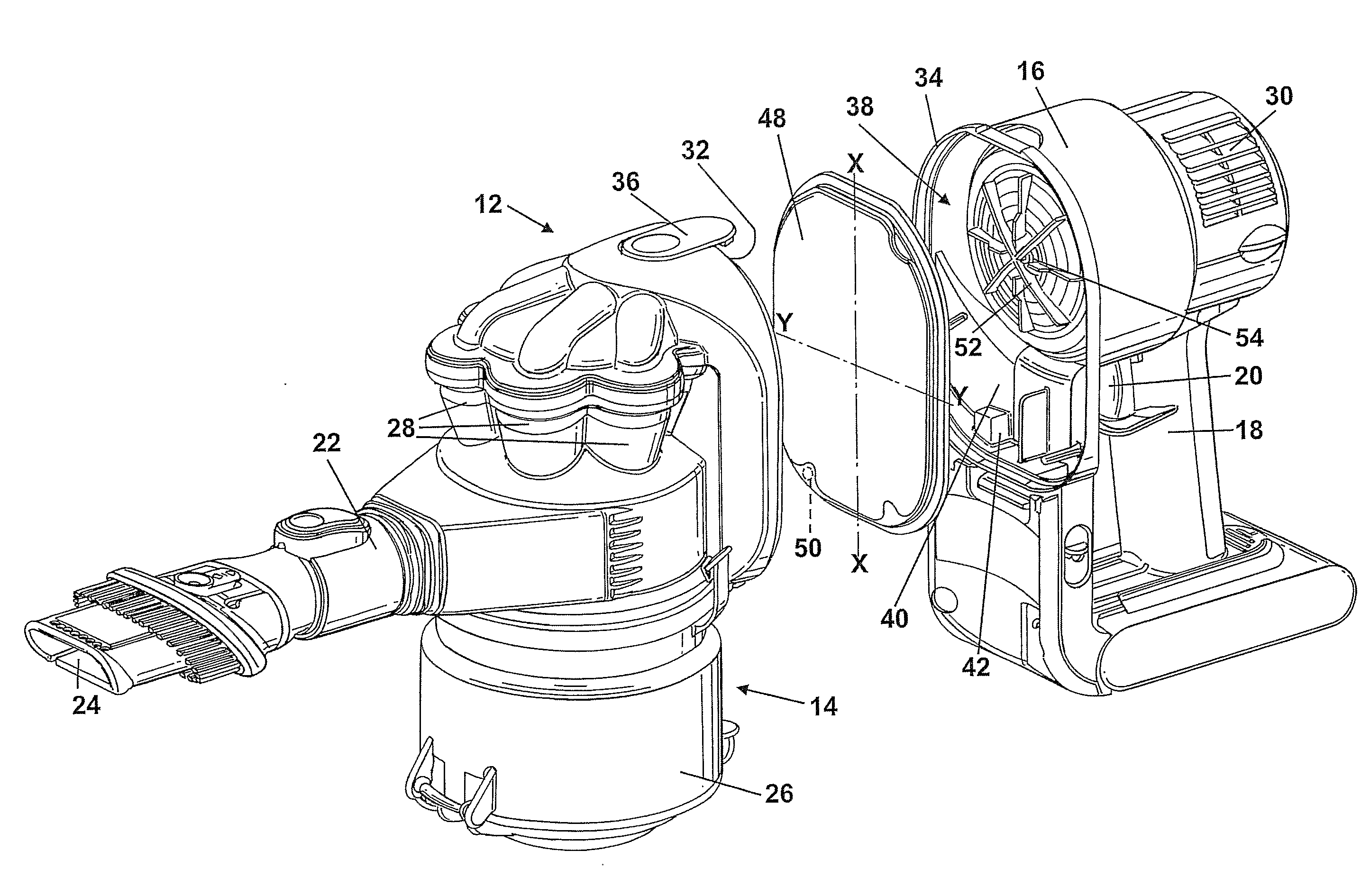

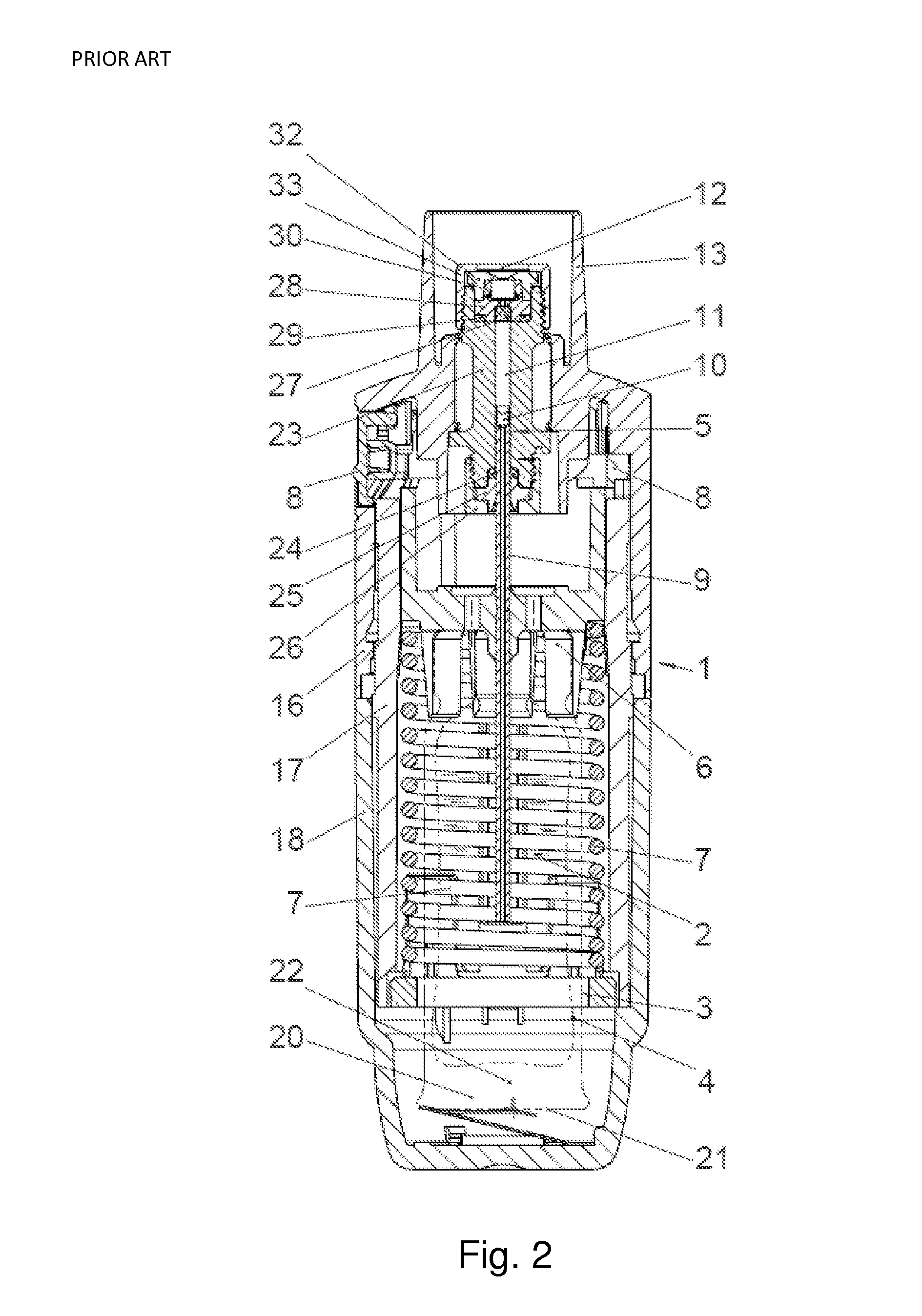

Handheld cleaning appliance

InactiveUS20090308254A1Easy to wearReduce cloggingCombination devicesSuction filtersHand heldWaste management

A cleaning appliance includes a main body, a filter and an interlock. The main body includes an airflow generator, a separating apparatus separating dirt and dust from an airflow, and a flowpath between the separating apparatus and the airflow generator delimited by a wall. The interlock has a first part located on the filter and a second part located on the main body outside the flowpath, arranged to communicate remotely when the filter is correctly located in the pre-determined position. The interlock is arranged selectively to allow or prevent operation of the airflow generator depending upon the relative separation between the first and second parts. By providing an interlock which has first and second parts which communicate remotely, the second part located on the main body can be isolated from the airflow path so that the second part is not subject to dirt and dust carried by the airflow.

Owner:DYSON TECH LTD

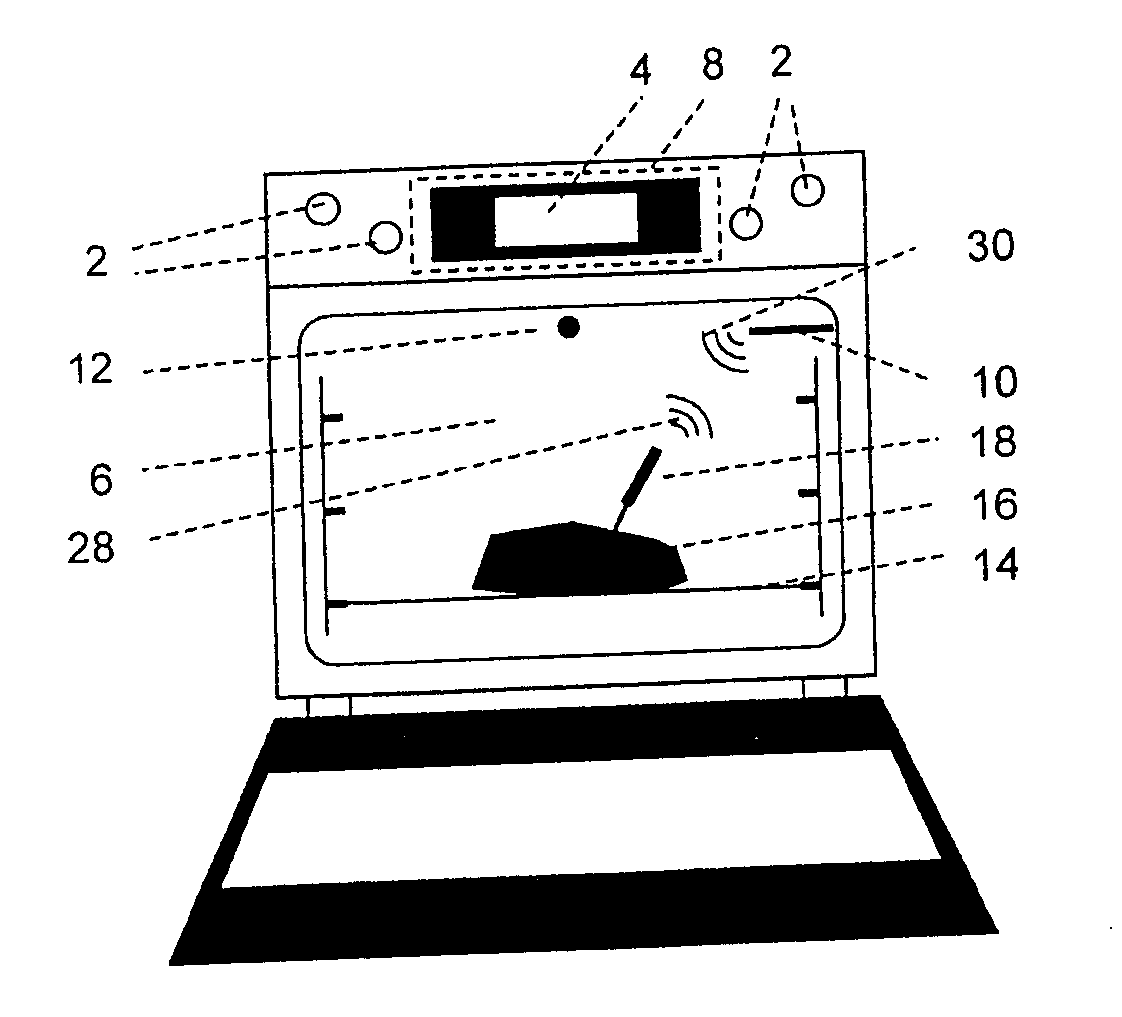

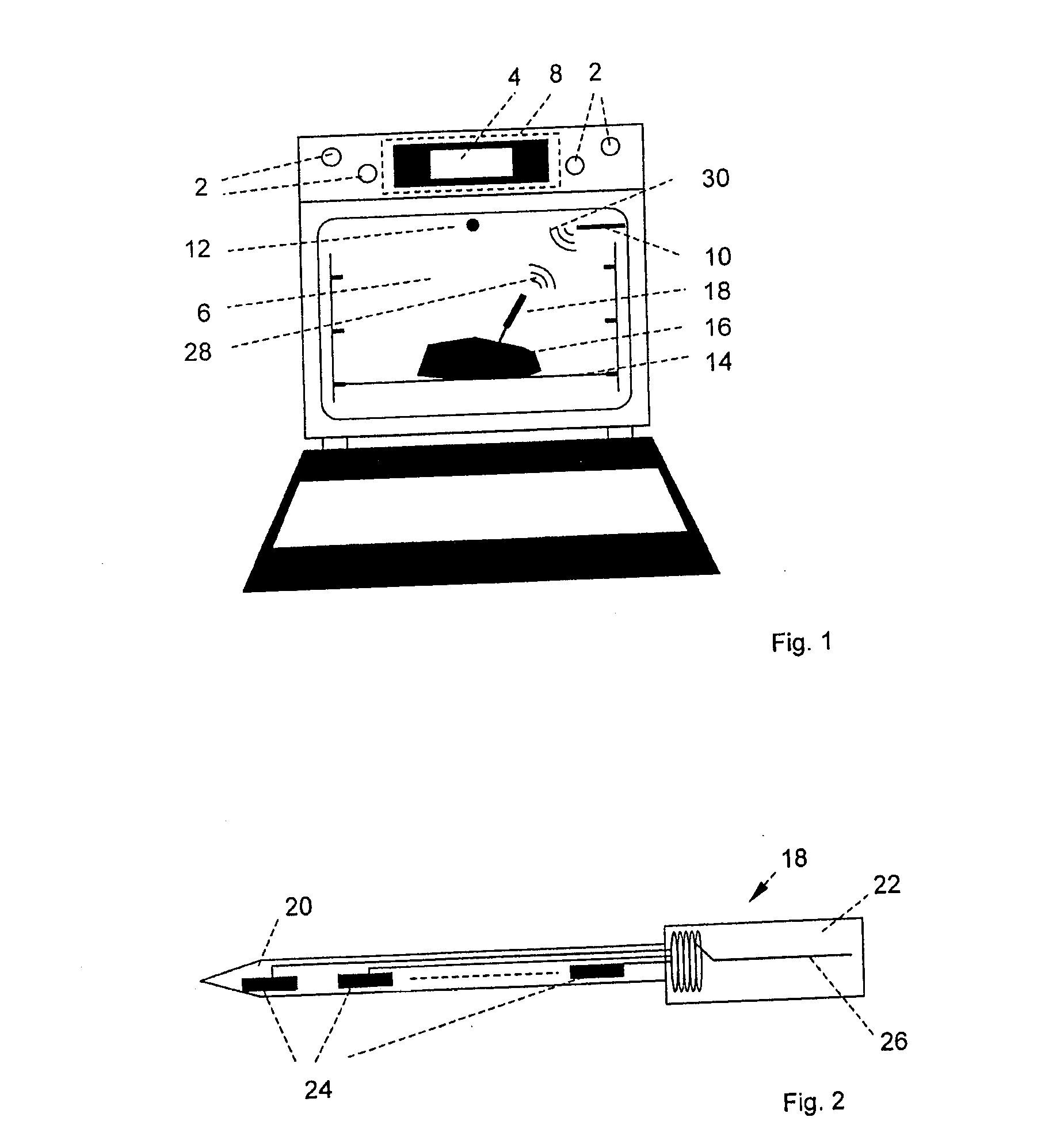

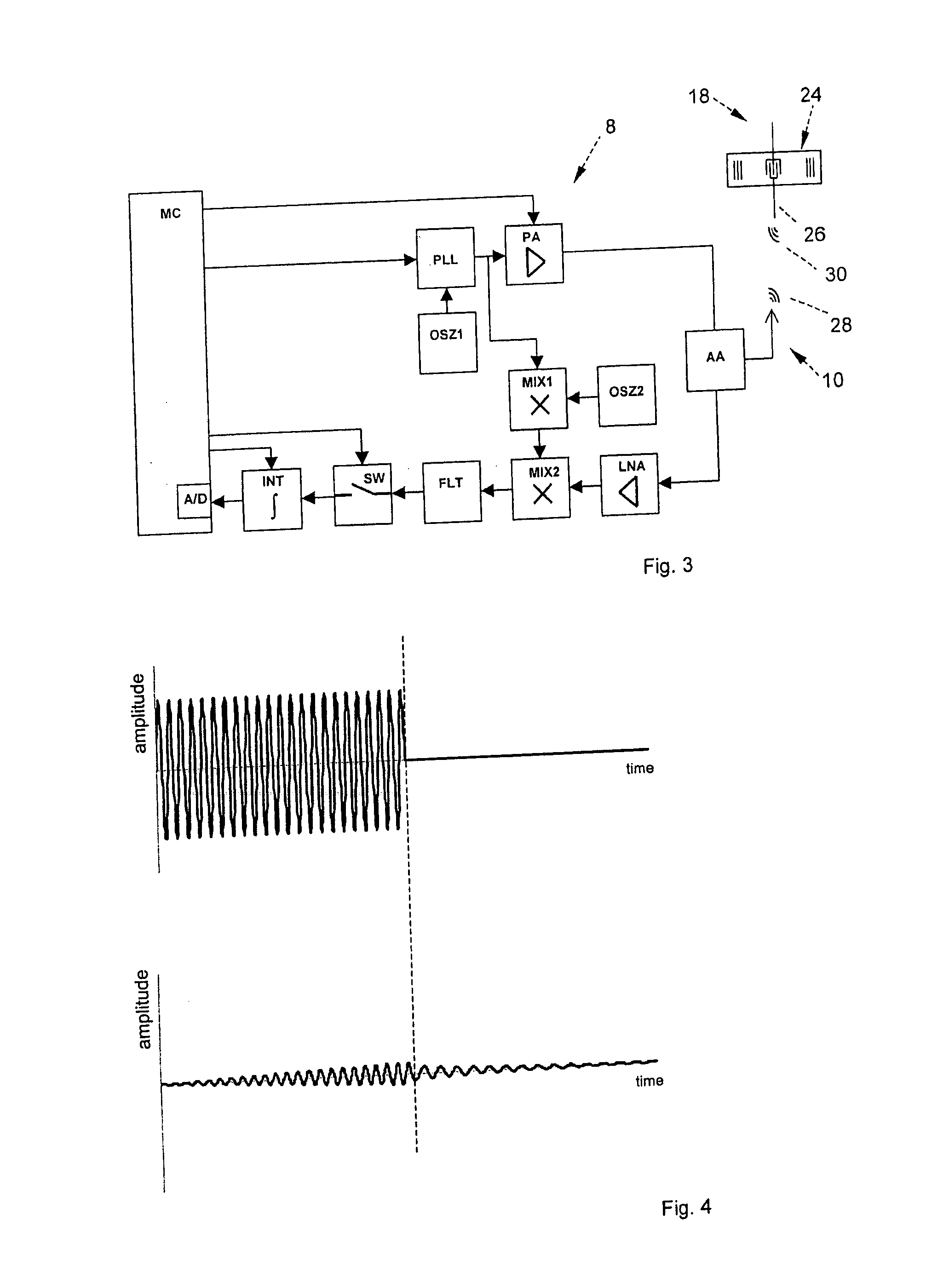

Method for temperature measurement in a household appliance

ActiveUS20060219705A1Less circuitryLess prone to failureThermometer detailsDomestic stoves or rangesElectromagnetic responseHome appliance

A method for temperature measurement in a household appliance includes generating a high-frequency electromagnetic excitation wave of a predefined transmit frequency. The transmit frequency is selected from a frequency band including temperature-dependent resonant frequencies that occur in a surface wave device incorporated in a temperature measuring probe and which respectively correspond to temperatures expected at the temperature measuring probe during operation of the household appliance. During a first phase, the excitation wave is wirelessly transmitting to the surface wave device. During a second phase following the first phase, an electromagnetic response wave generated by the excitation wave in the surface wave device is wirelessly transmitting to a processing unit. Signal levels of response signals generated from response waves of different transmit frequencies are measured and compared to determine the current temperature of the surface wave device based on the transmit frequency associated with the highest signal level.

Owner:MIELE & CIE KG

Butterfly valve

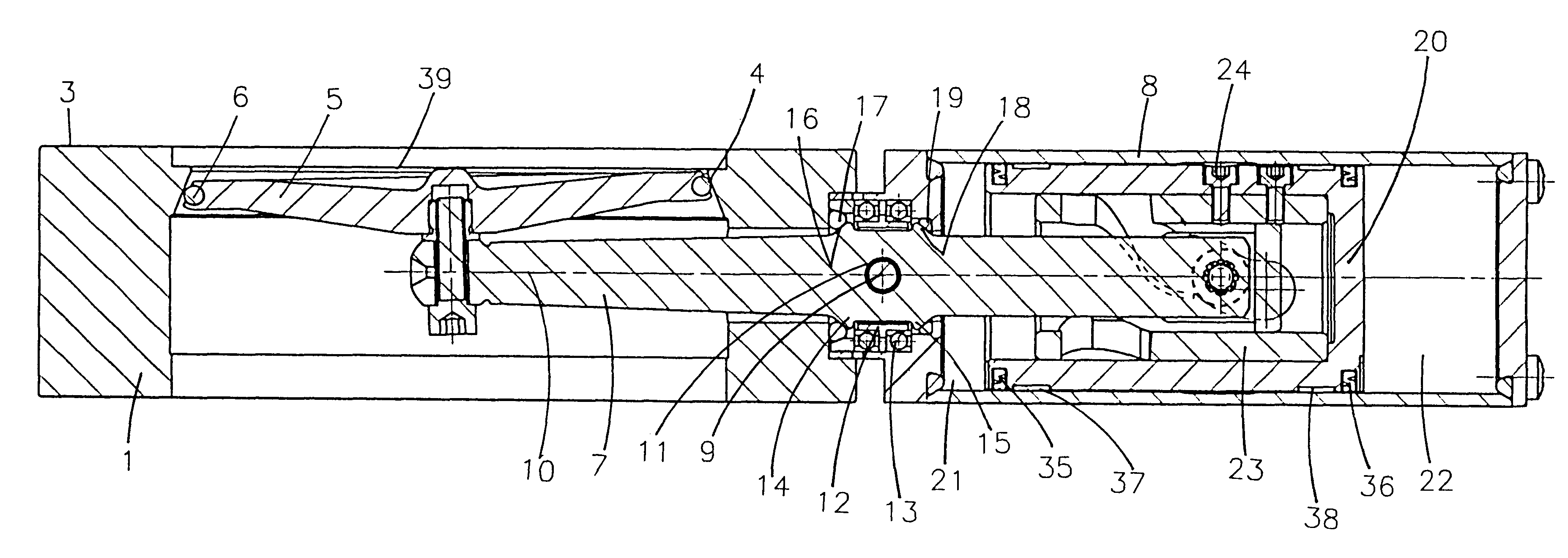

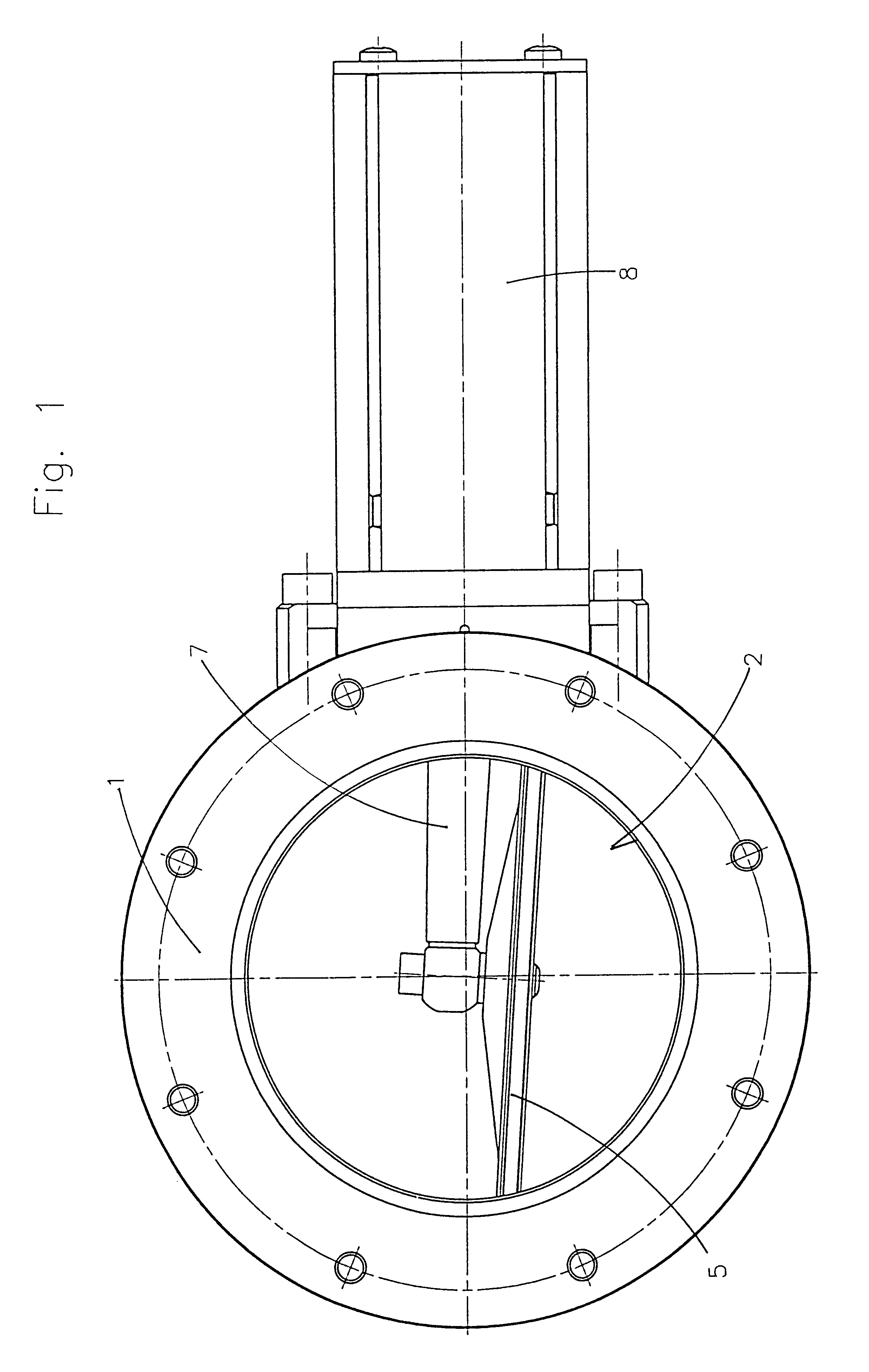

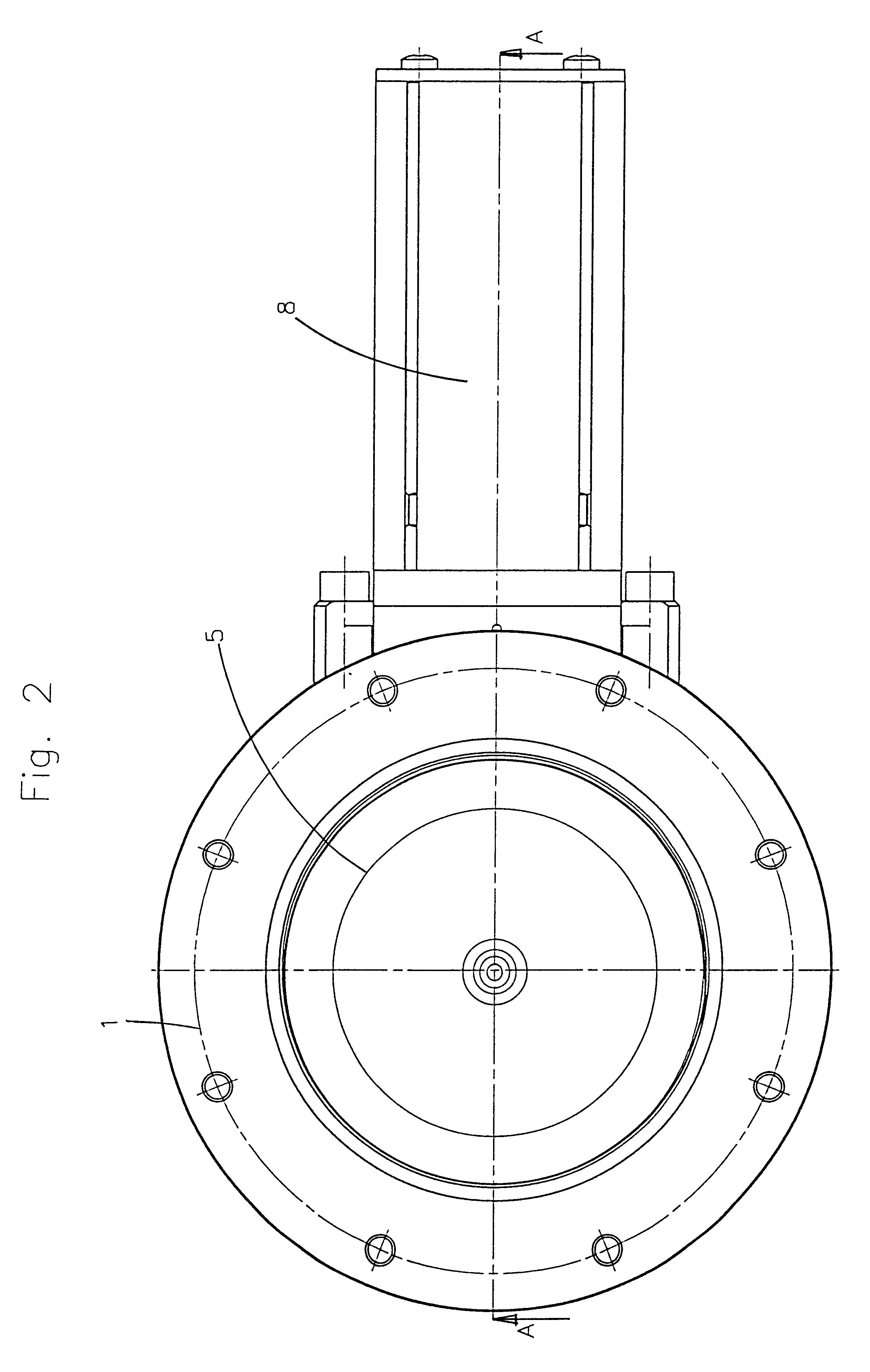

InactiveUS6494434B1Less prone to failureSolution to short lifeOperating means/releasing devices for valvesGearingEngineeringButterfly valve

A butterfly valve comprises a valve housing with a valve opening and a valve seat, this valve housing enclosing a vacuum area of the valve; a valve plate which is mounted at a valve rod guided through the valve housing and which is pressed against the valve seat in a closed position of the valve, tilted relative to the valve seat in a partially open position of the valve through tilting of the valve rod about a tilting axis, and tilted and rotated relative to the valve in a completely open position of the valve by subsequent rotation of the valve rod about its longitudinal axis; wherein the valve rod has portions extending on both sides of the tilting axis, the portion located on one side of the tilting axis acting centrally at the valve plate and the portion located on the other side of the tilting axis being connected, via a link guide which is located outside the vacuum area and which has a link with a part extending at an inclination to the longitudinal axis of the valve rod and a helical surface-shaped part and a journal which is guided in the link, to an actuating member which is mounted so as to be displaceable in axial direction of the valve rod.

Owner:VAT HLDG AG

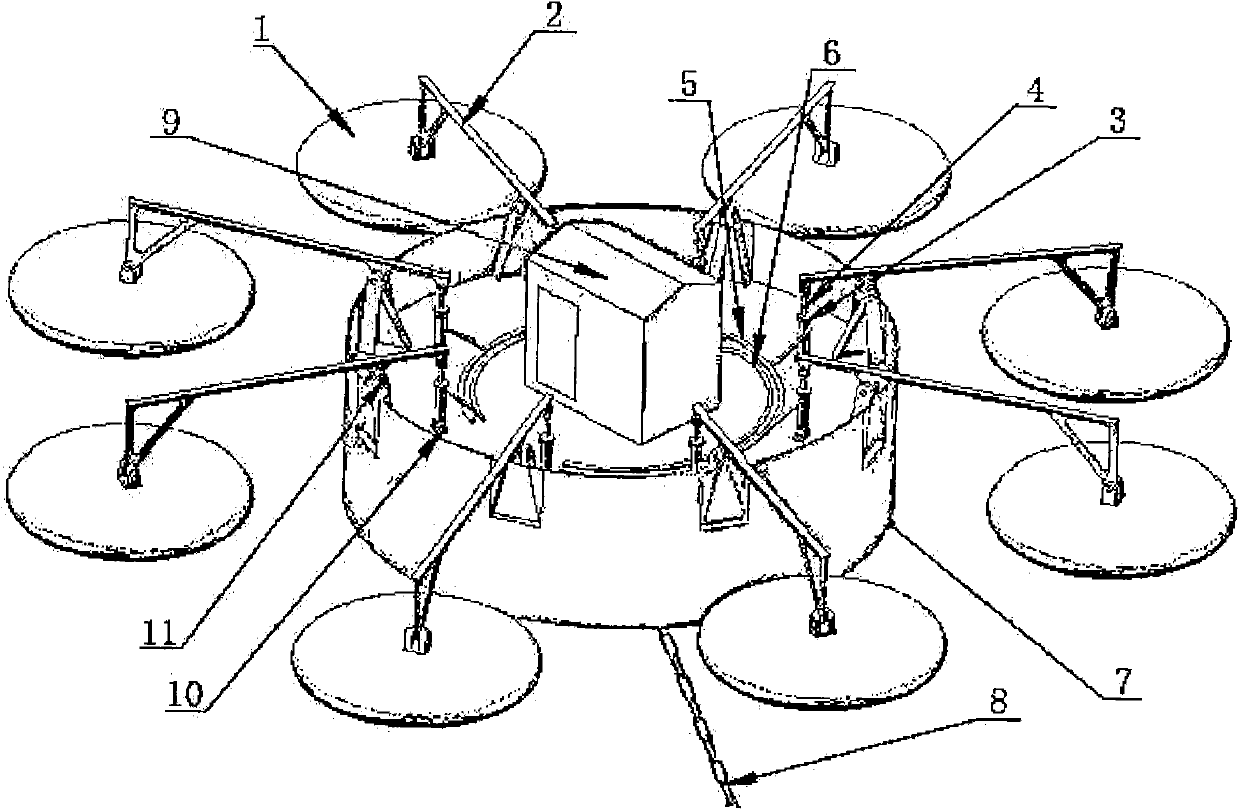

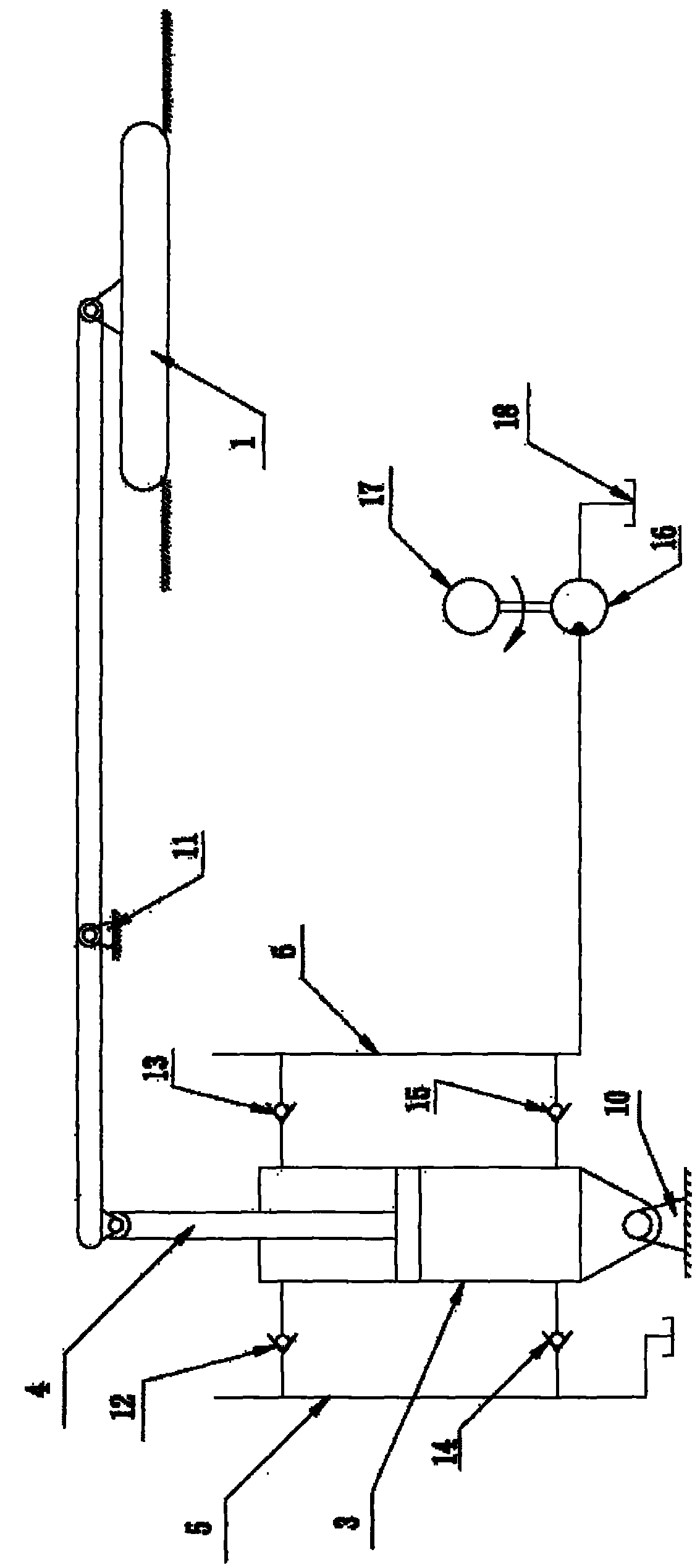

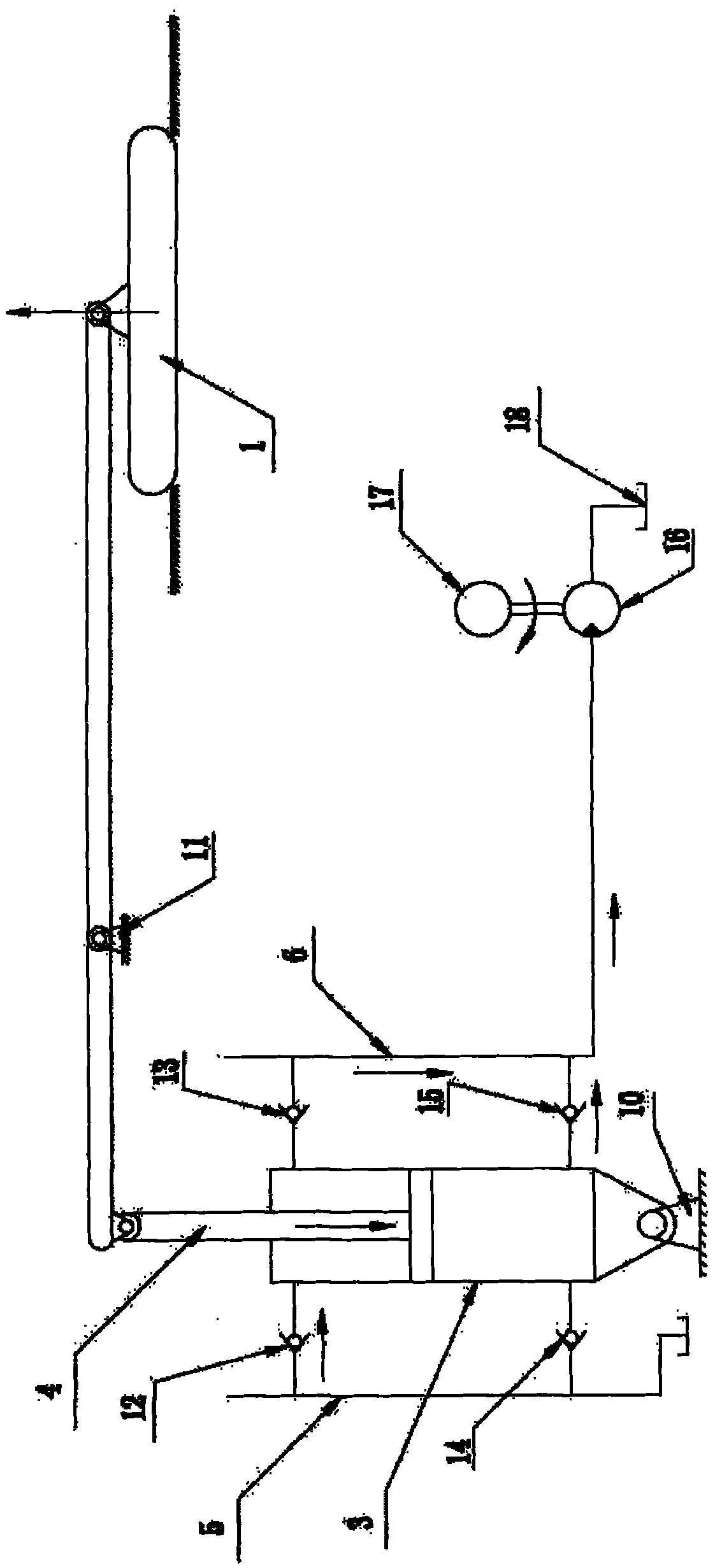

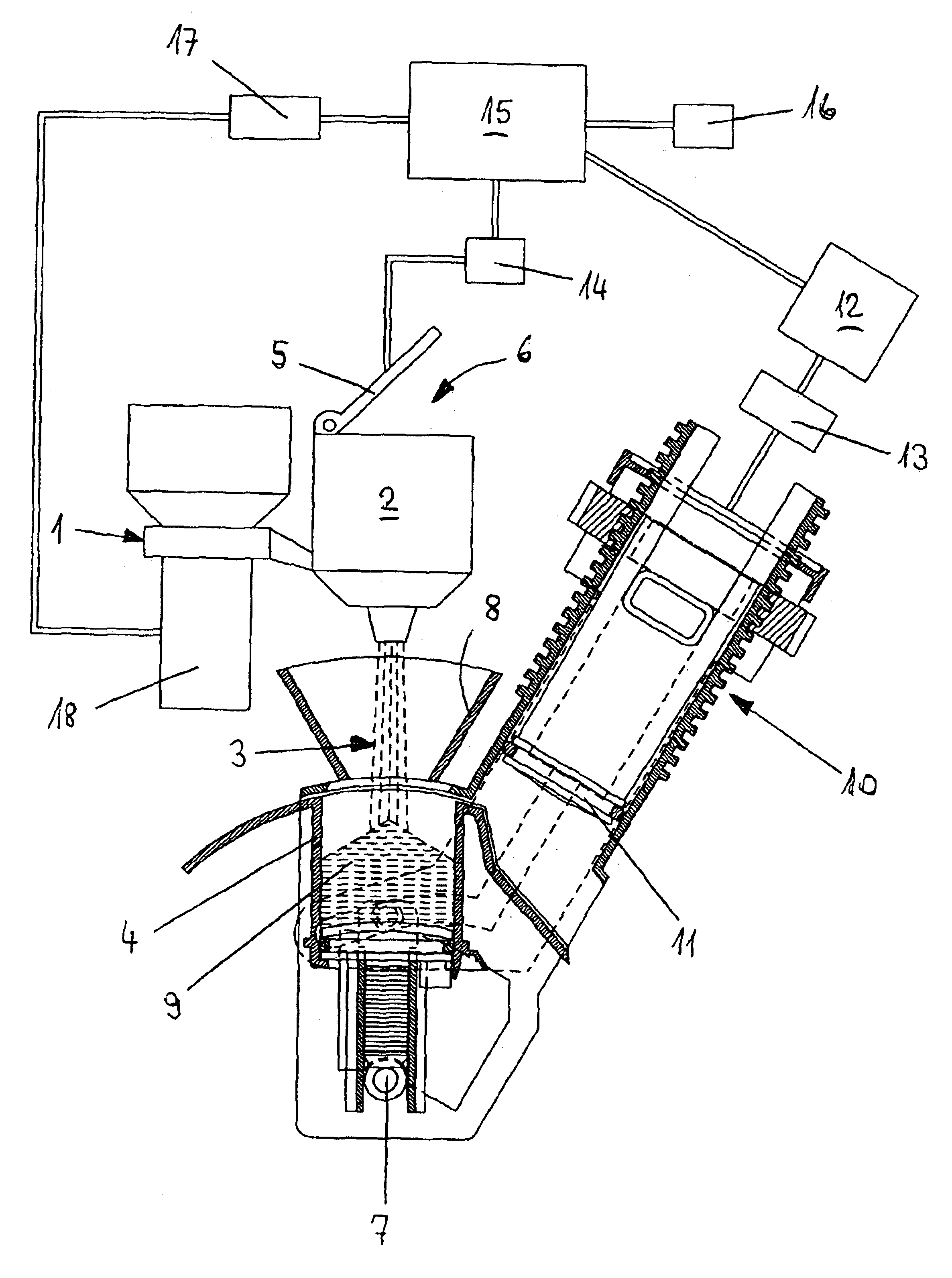

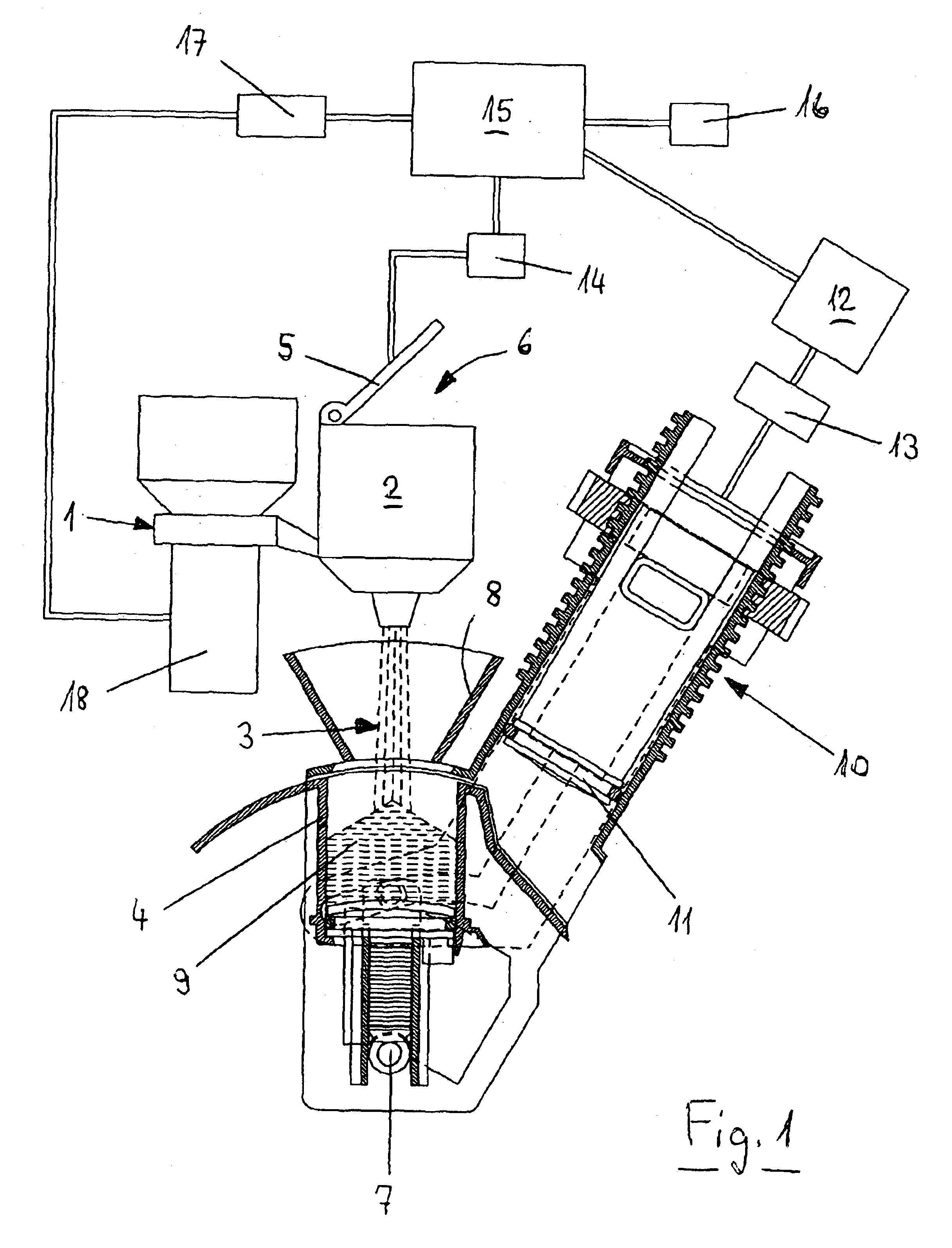

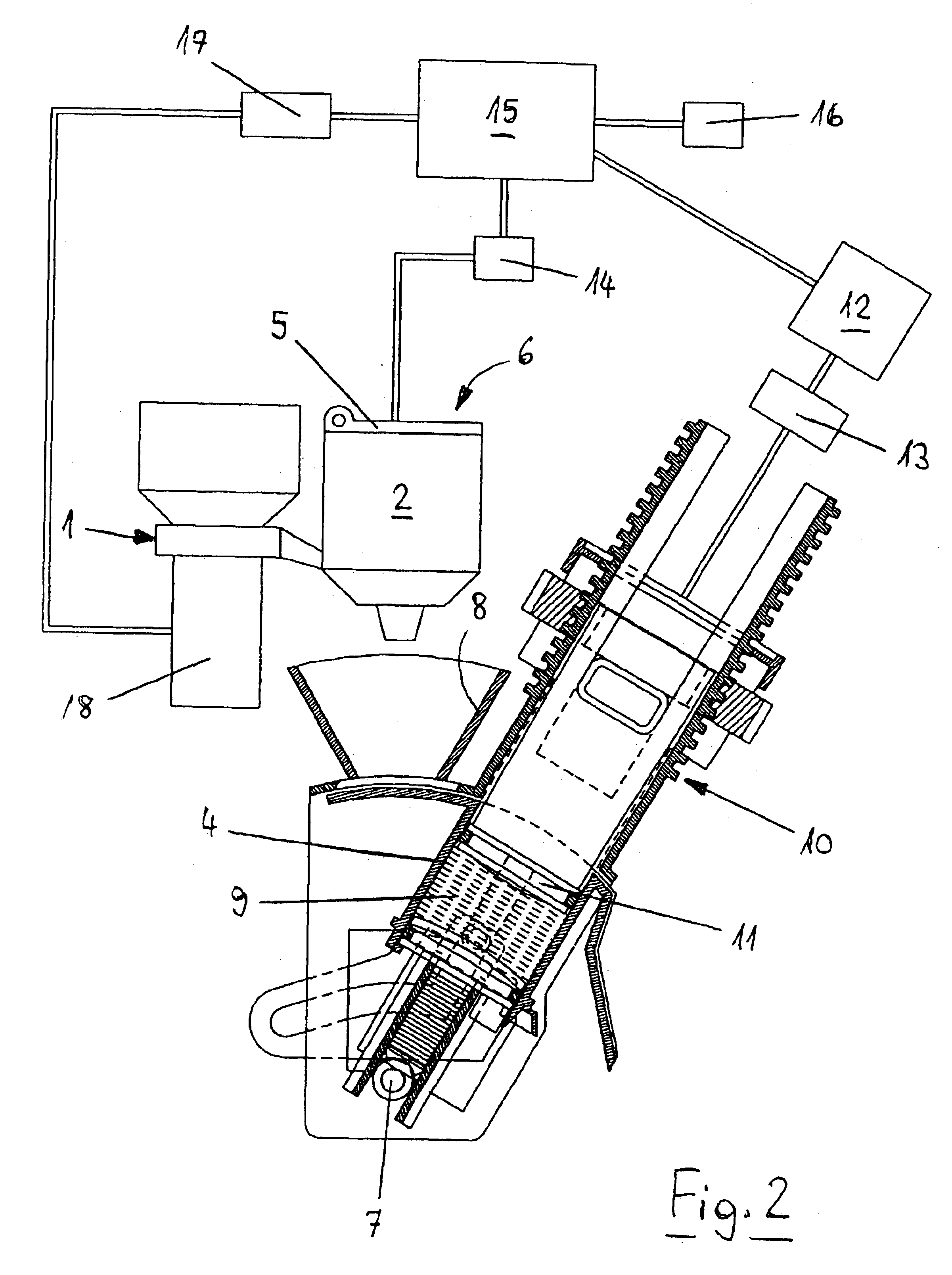

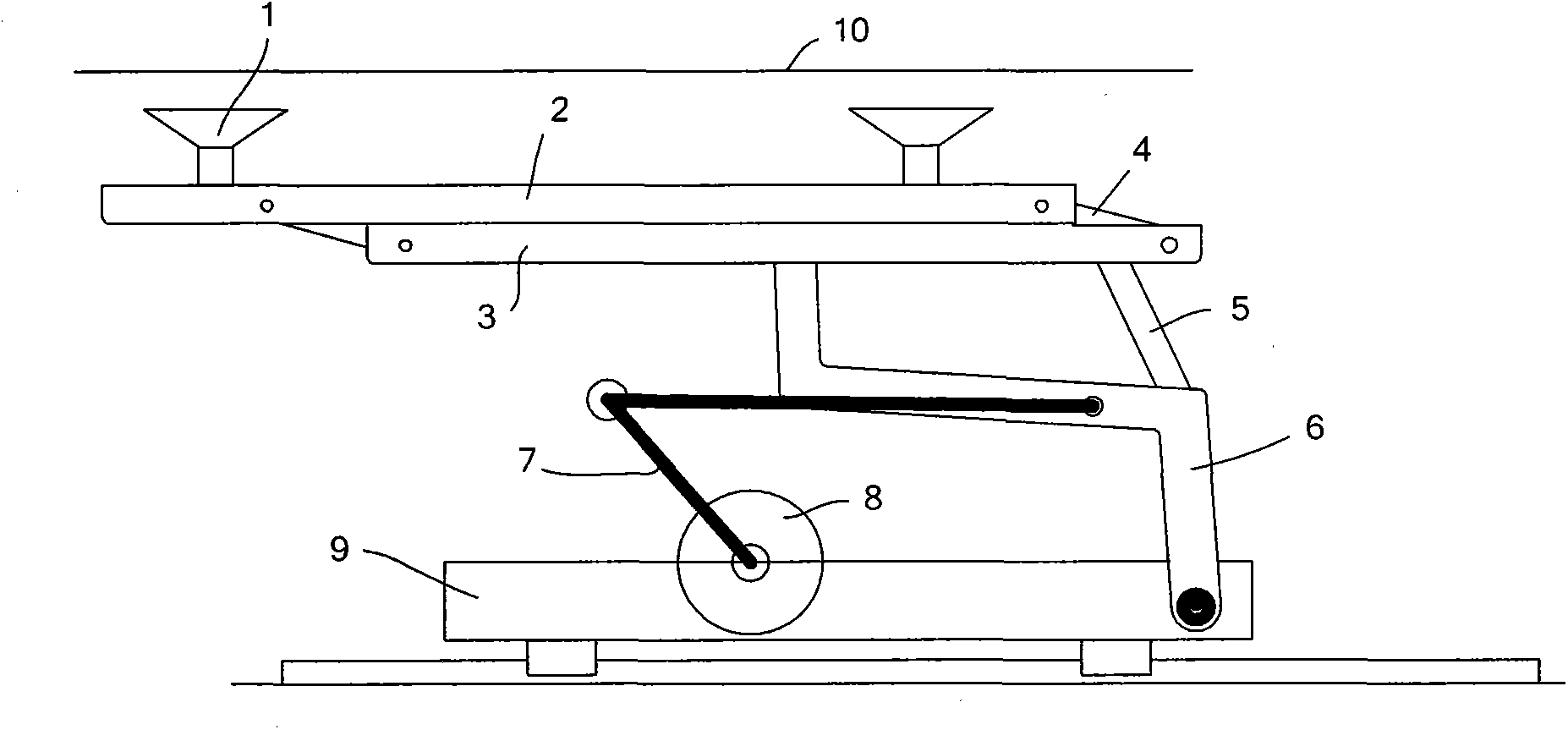

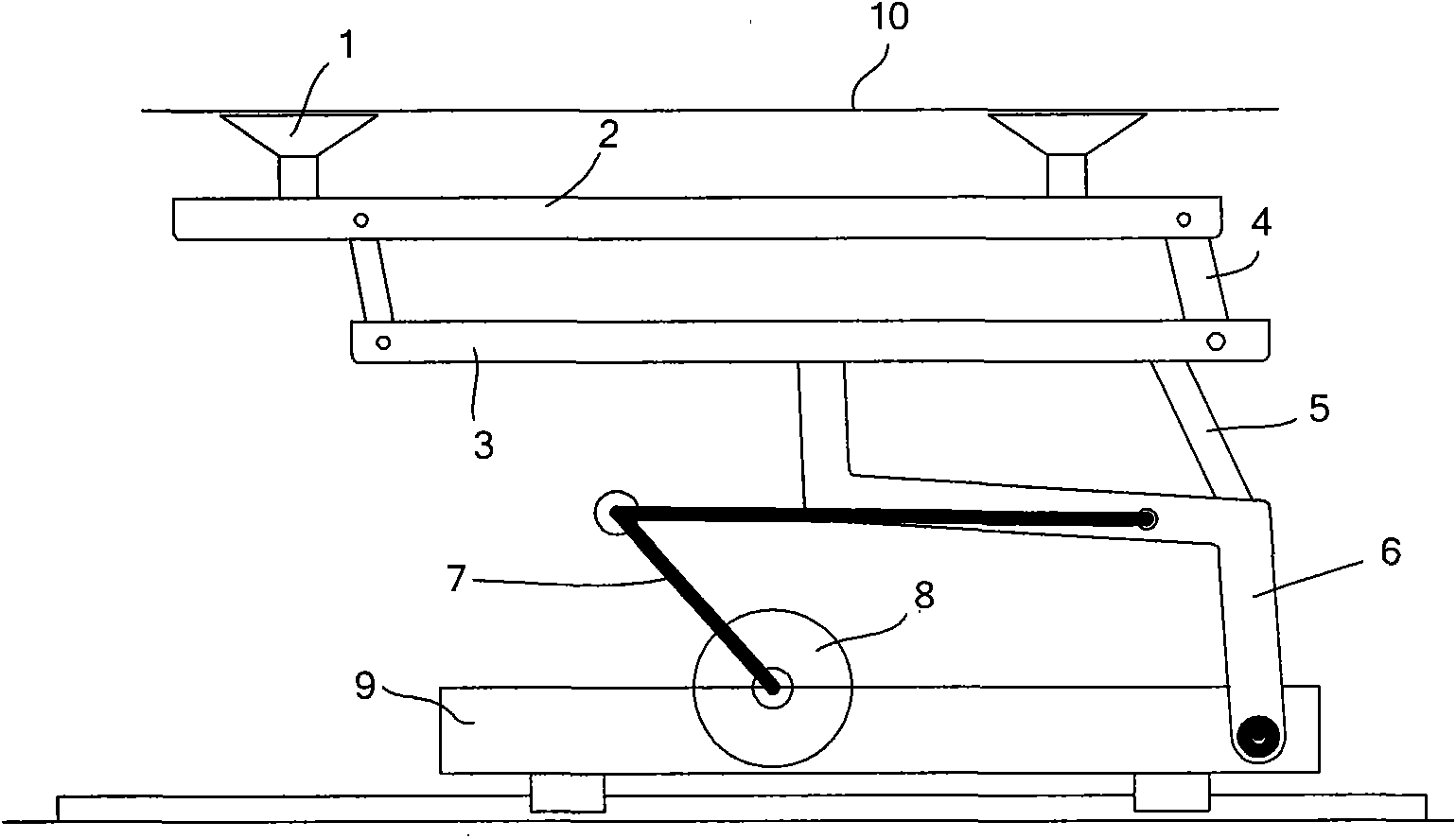

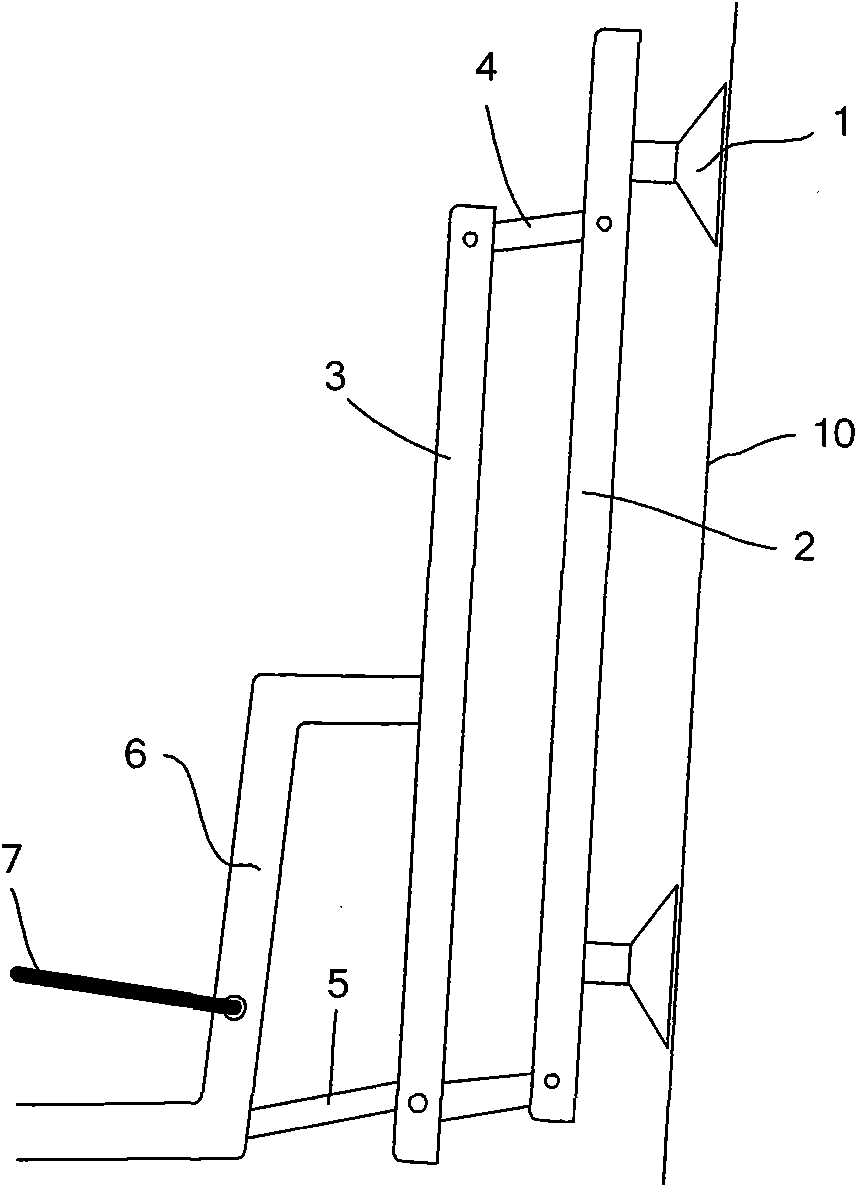

A floating type wave power generation system

InactiveCN102022248AEfficient captureControllable outputMachines/enginesEngine componentsWave power generationMechanical energy

A floating type wave power generation system is characterized in that the system consists of eight sets of lever-type floating bodies and a hydraulic energy accumulation converter with the hydraulic pump function. On a floating workbench 7, eight sets of levers 2 and a floating body 1 are connected through supporting hinge bearers 10 and 11; in this way, the highly undulating displacement caused by waves can be converted to relatively lesser displacement of a piston rod 4, and the minor force that the floating body bears can be converted through the lever to the major force on the piston rod. The piston rod drives a hydraulic tank 3 to switch and transmit the hydraulic energy through a connecting oil pipe5, a high-pressure oil pipe6, a hydraulic oil tank and four no-return valves of each set to a hydraulic motor in a hydraulic power generation control chamber 9; in this way the generator is driven to work. The present system can absorb, convert and accumulate the intermittent unstable wave energy in a highly effective way and can buffer the destructive effect of waves. The floating platform can be suitable to different marine space by adjusting the length of an anchor chain 8. And in various sea conditions, kinetic energy and potential energy possessed by waves in the sea surface can be converted and accumulated as hydraulic mechanical energy by utilization of the wave drop; thus the generator is driven to unremittingly provide electric power.

Owner:杨超

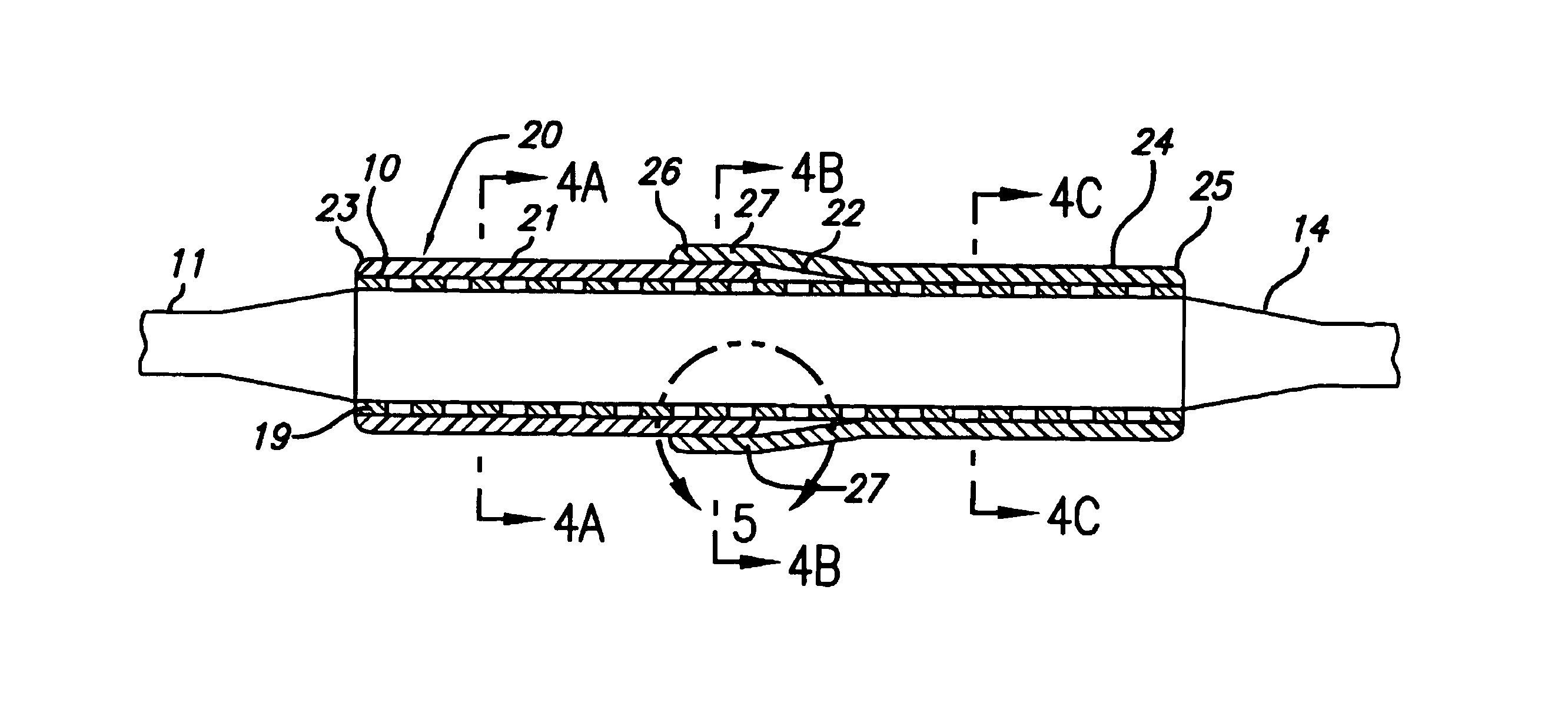

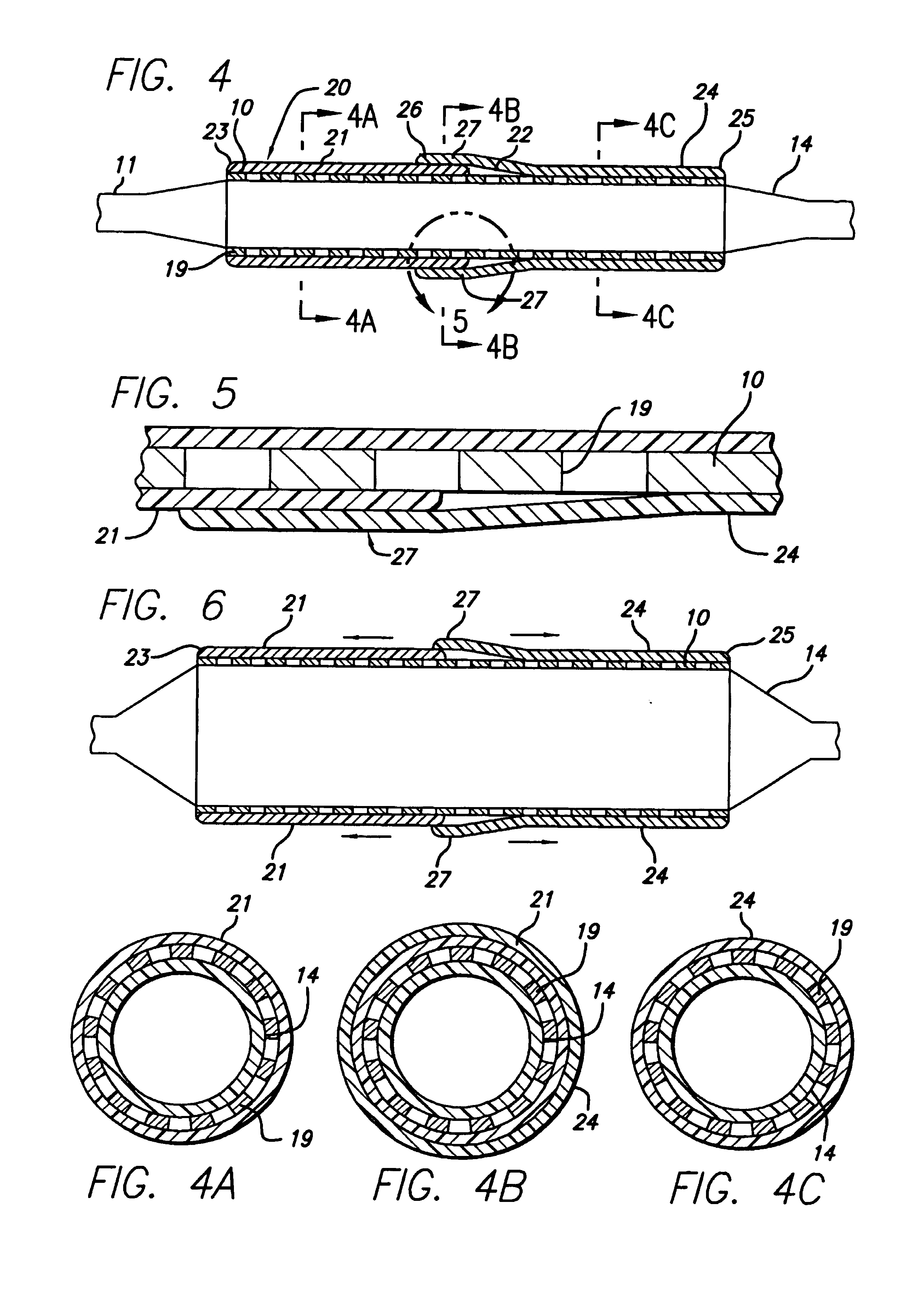

Covered stent assembly for reduced-shortening during stent expansion

InactiveUS7118592B1SpeedMinimize covered stent shrinkageStentsSurgeryInsertion stentIntravascular stent

A polymeric material such as polyurethane, PET, or ePTFE is used to cover an intravascular stent. The cover material has an overlapping portion which is slidable upon itself so that when the stent is expanded, the cover material does not contribute to stent foreshortening, if any. The cover material can be provided with holes to permit endothelialization and can be drug loaded to facilitate repair of a damaged vessel.

Owner:ABBOTT CARDIOVASCULAR

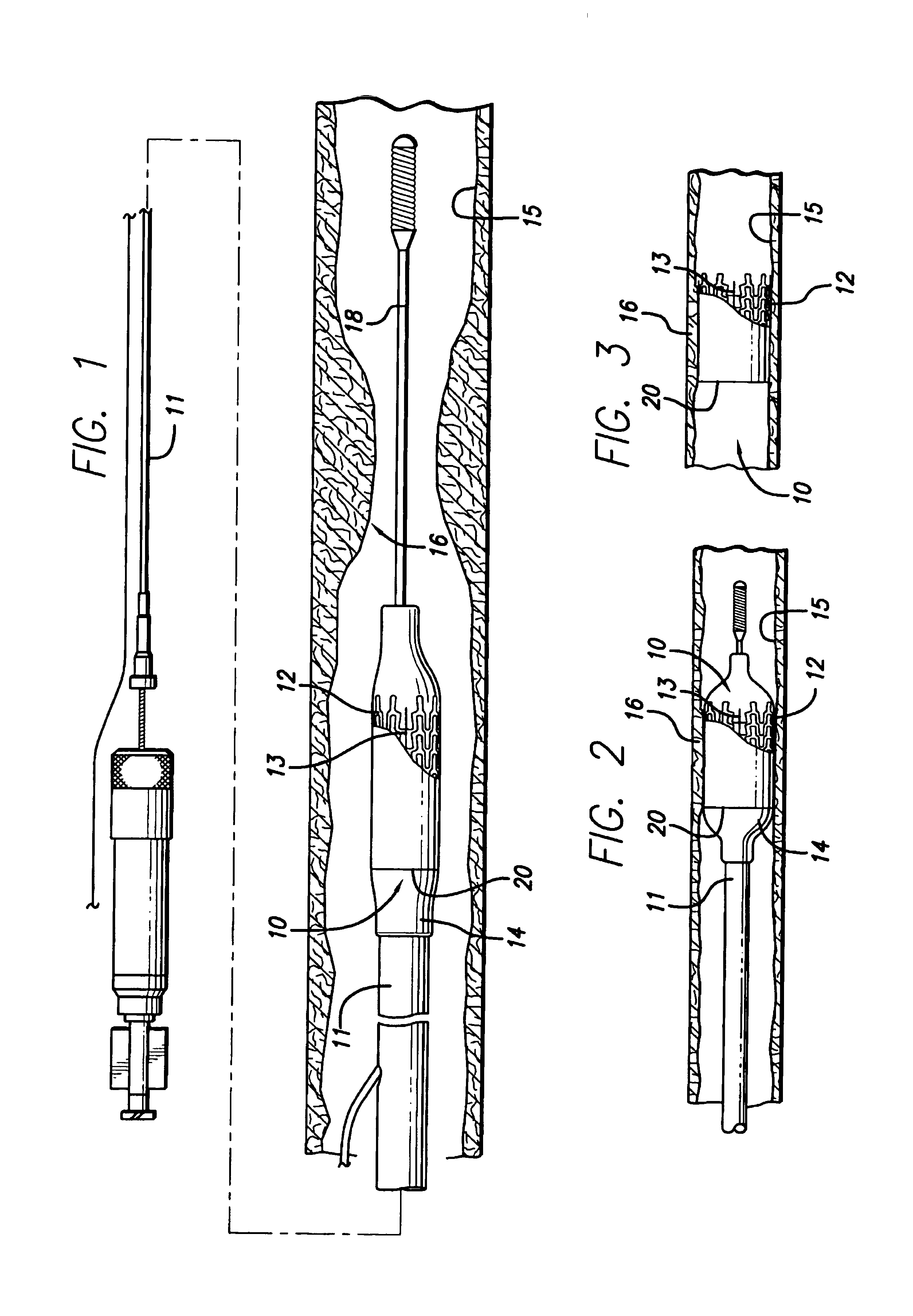

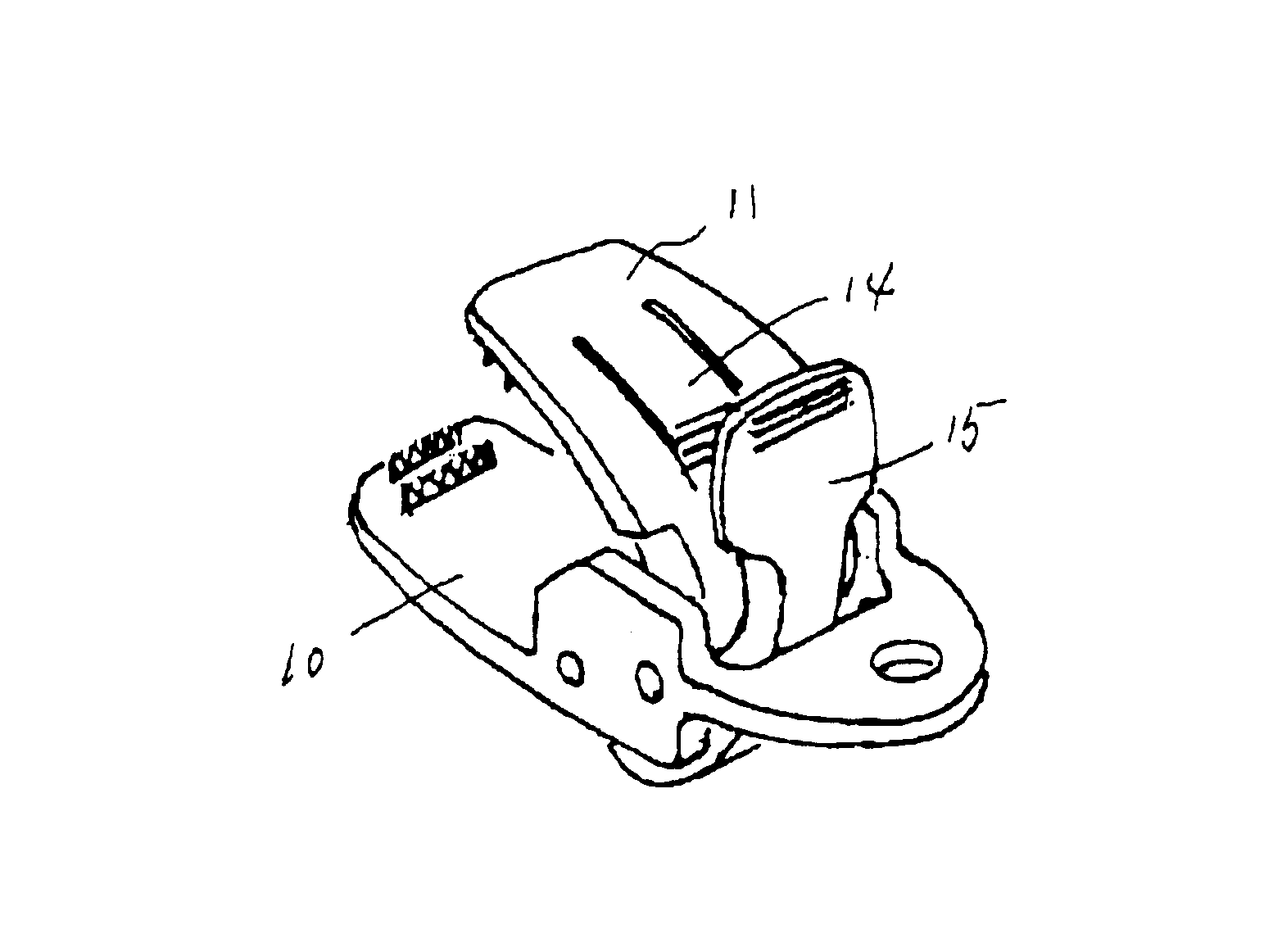

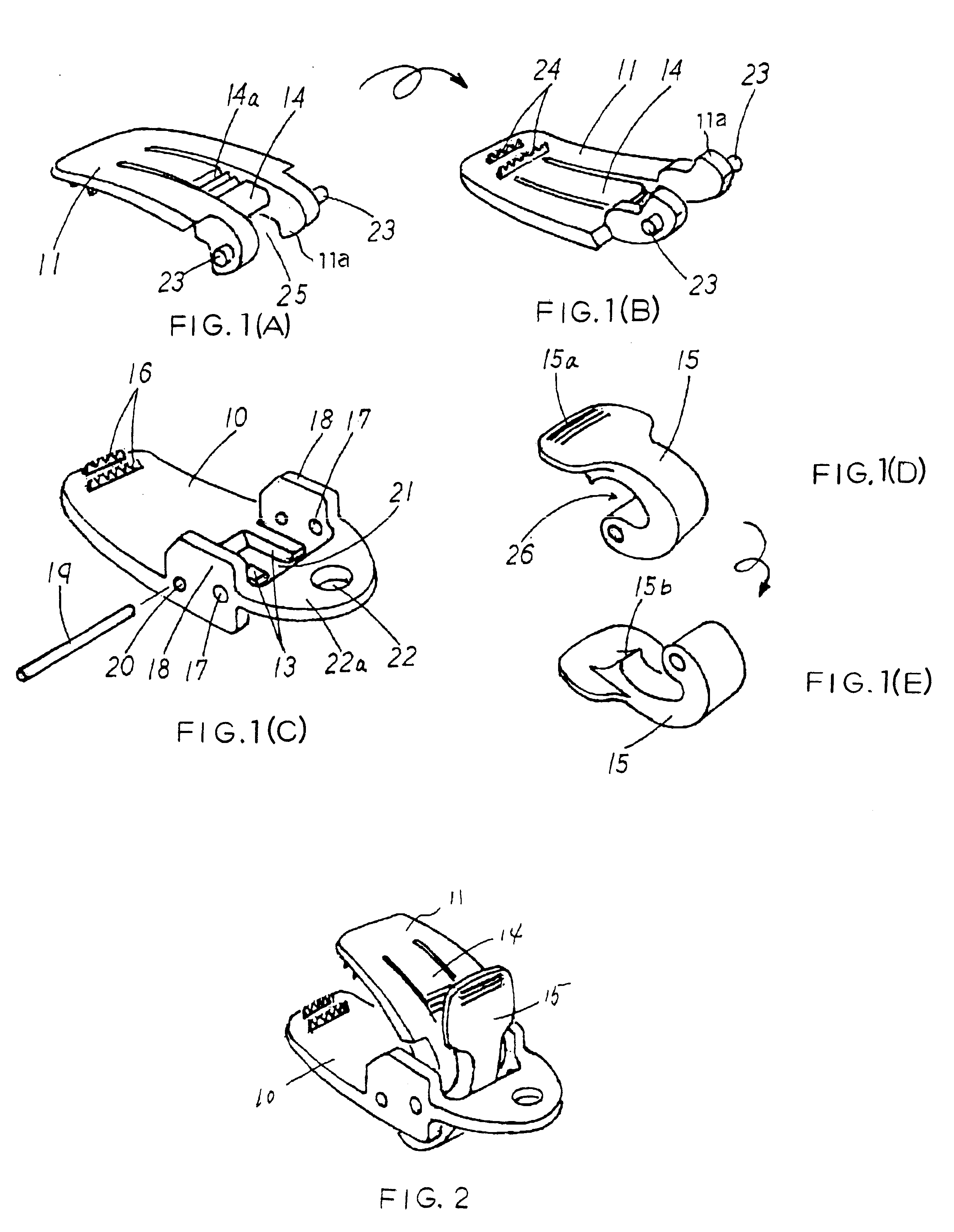

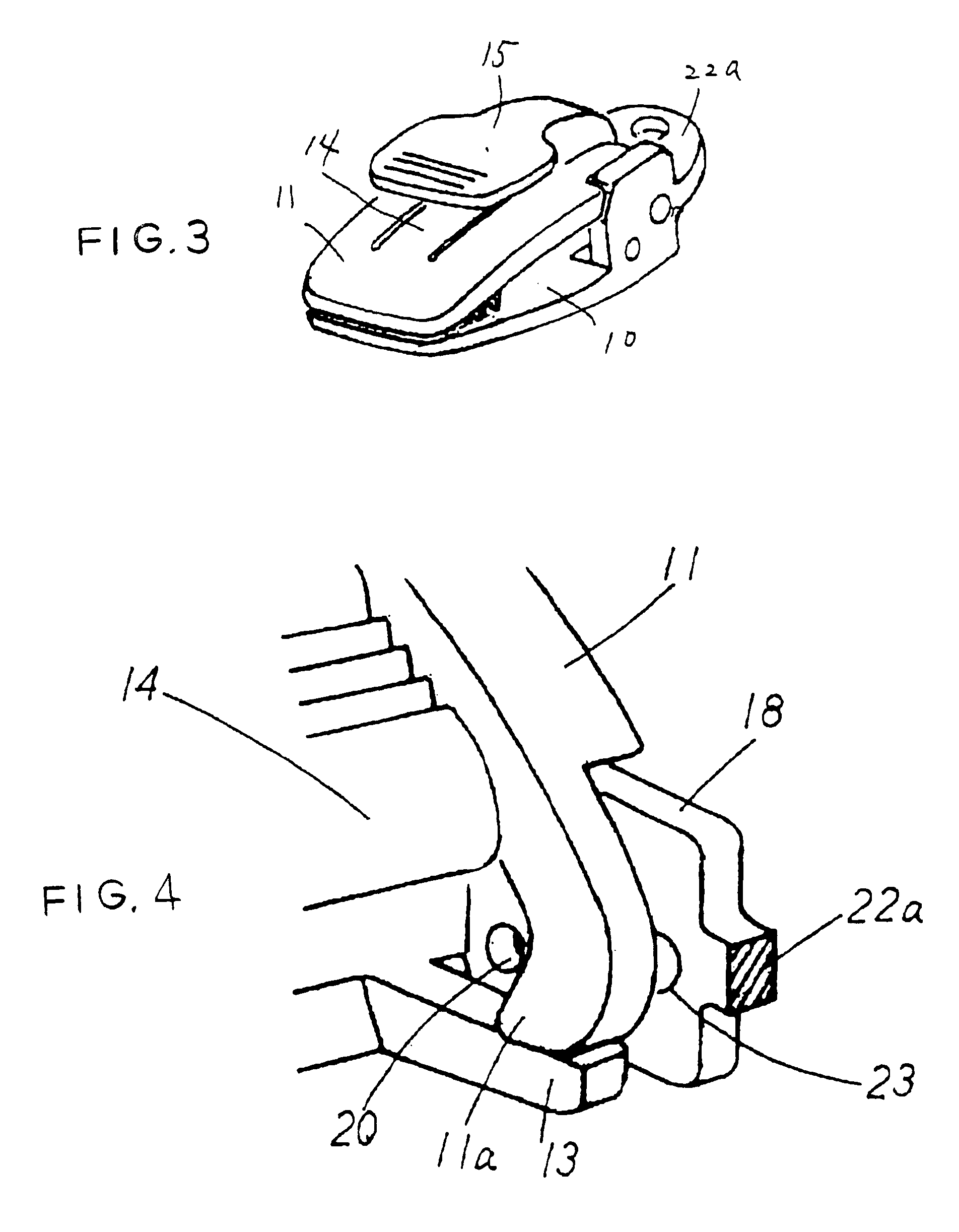

Plastic clipping device

InactiveUS6516500B2Less prone to failureEasy to operateSnap fastenersStockingEngineeringMechanical engineering

The present invention is to provide a clipping device made of plastic and which can surely grasp any good regardless a thickness thereof and which comprises a first clamping member 10, a second clamping member 11 rotatably supported at a part of the first clamping member 10, an elastically resilient member 13 integrally formed on a part of the first clamping member 10 and giving the second clamping member 11 a bias force to cause the second clamping member 11 to be moved to a direction whereby the second clamping member 11 to be opened, a coupling piece member 14 integrally formed on a part of the second clamping member 11, and an operation member 15 rotatably supported on a part of the first clamping member 10, and in that by coupling the coupling piece member with the operation member, the first and the second clamping members are fixed to each other.

Owner:FIRST CREATE

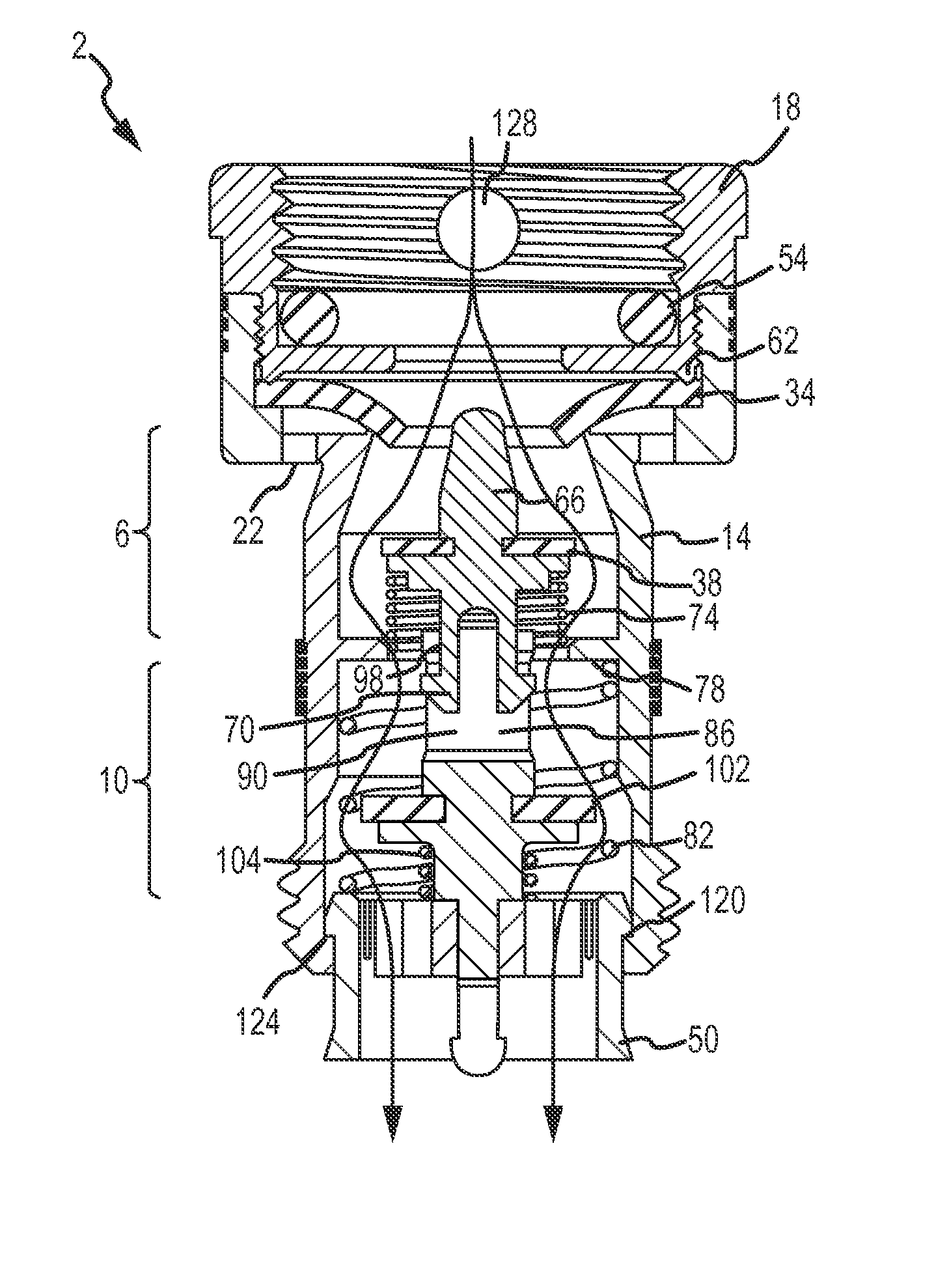

Double check back flow prevention device

ActiveUS8042565B2Prevent backflowEasy and less-expensive to manufactureCheck valvesDomestic plumbingDouble check valveEngineering

A double check valve is provided that includes an in-line inlet check valve and an outlet check valve that cooperate to prevent back flow of fluid through the valve. The check valve also includes at least one vent that allows for fluid trapped within the check valve to drain, thereby preventing freezing of the check valve and hydrant to which it is interconnected. The check valve provided omits many superfluous components and thus is smaller and easier to install than check valves of the prior art.

Owner:WCM IND INC

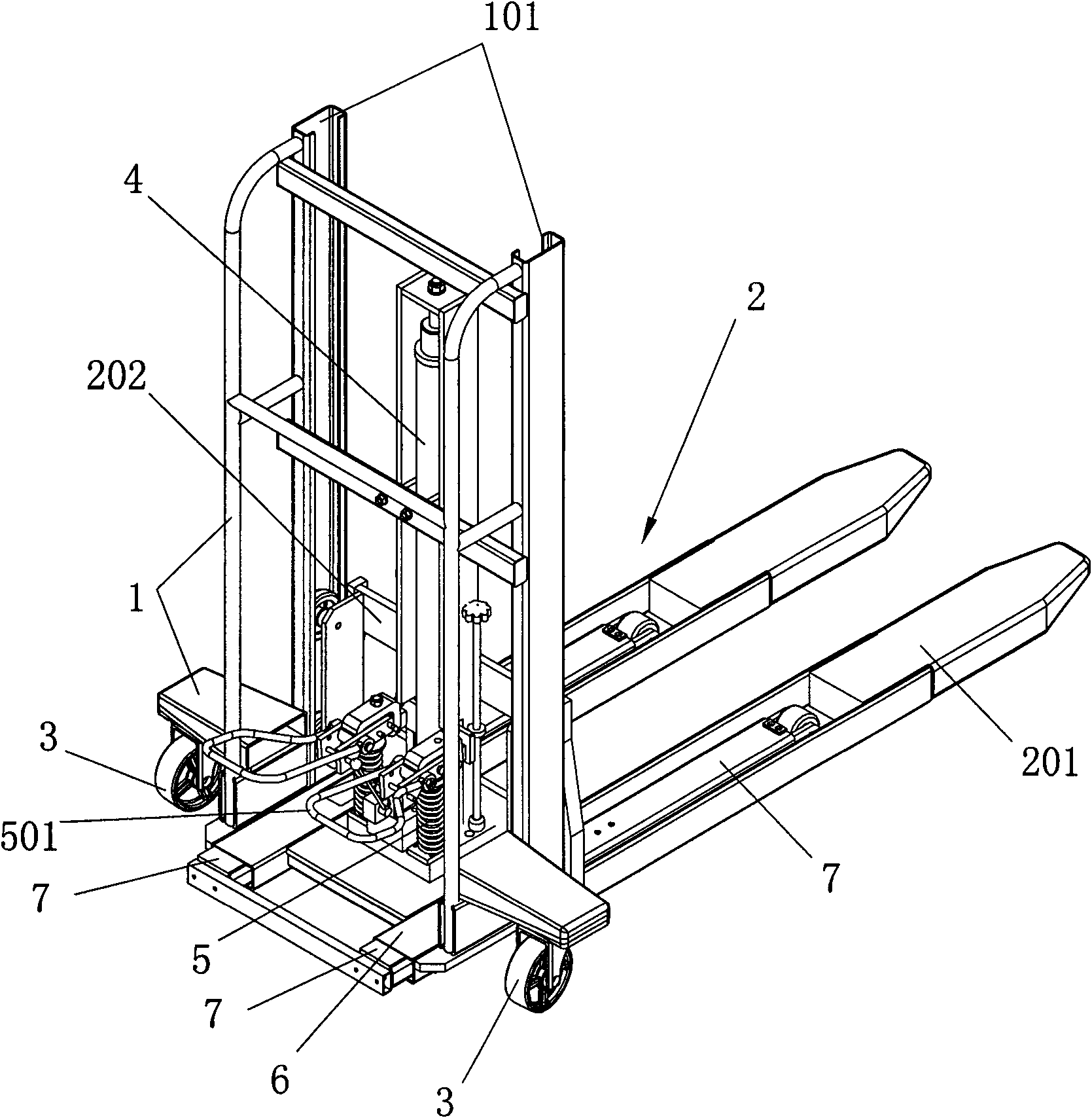

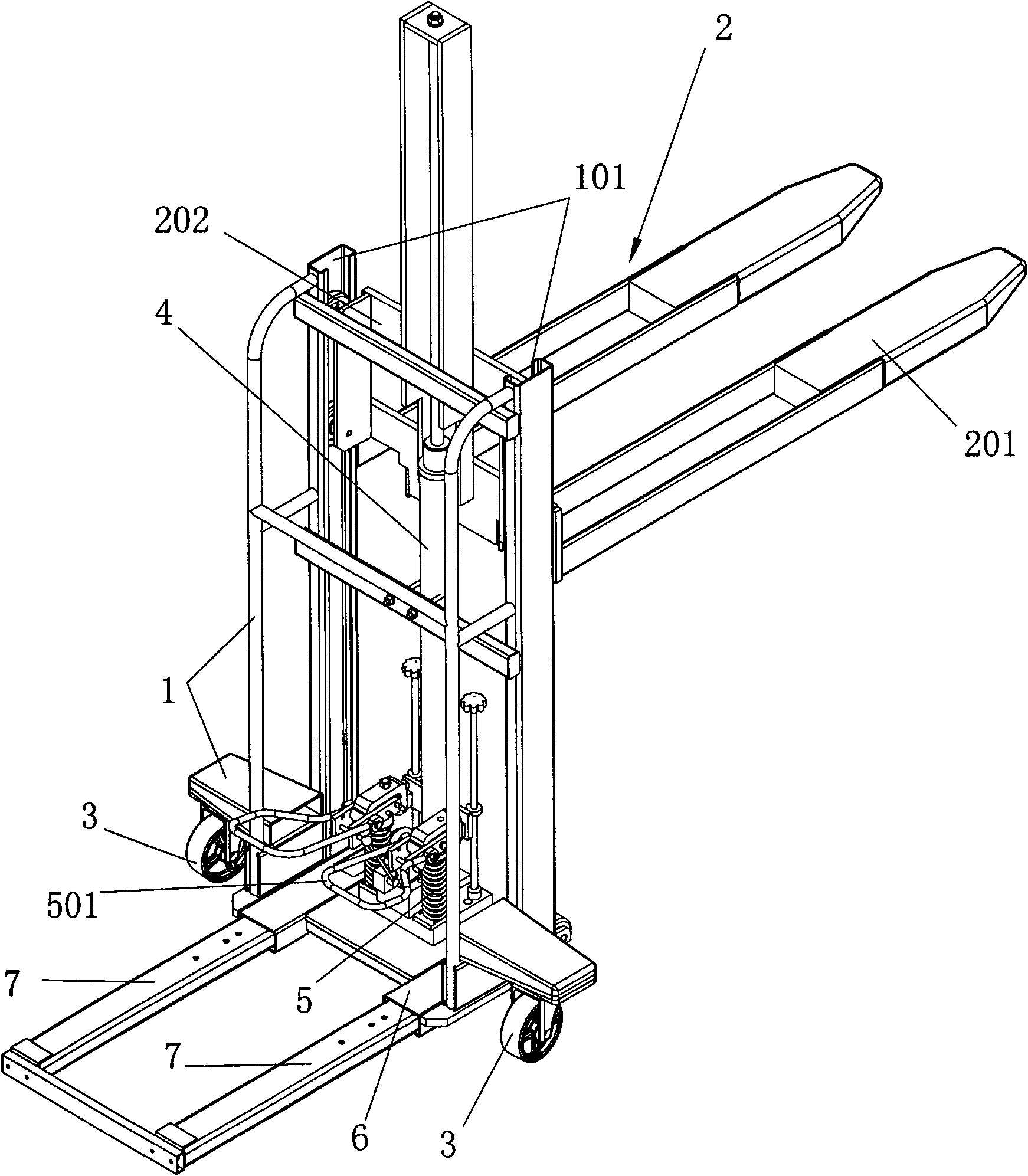

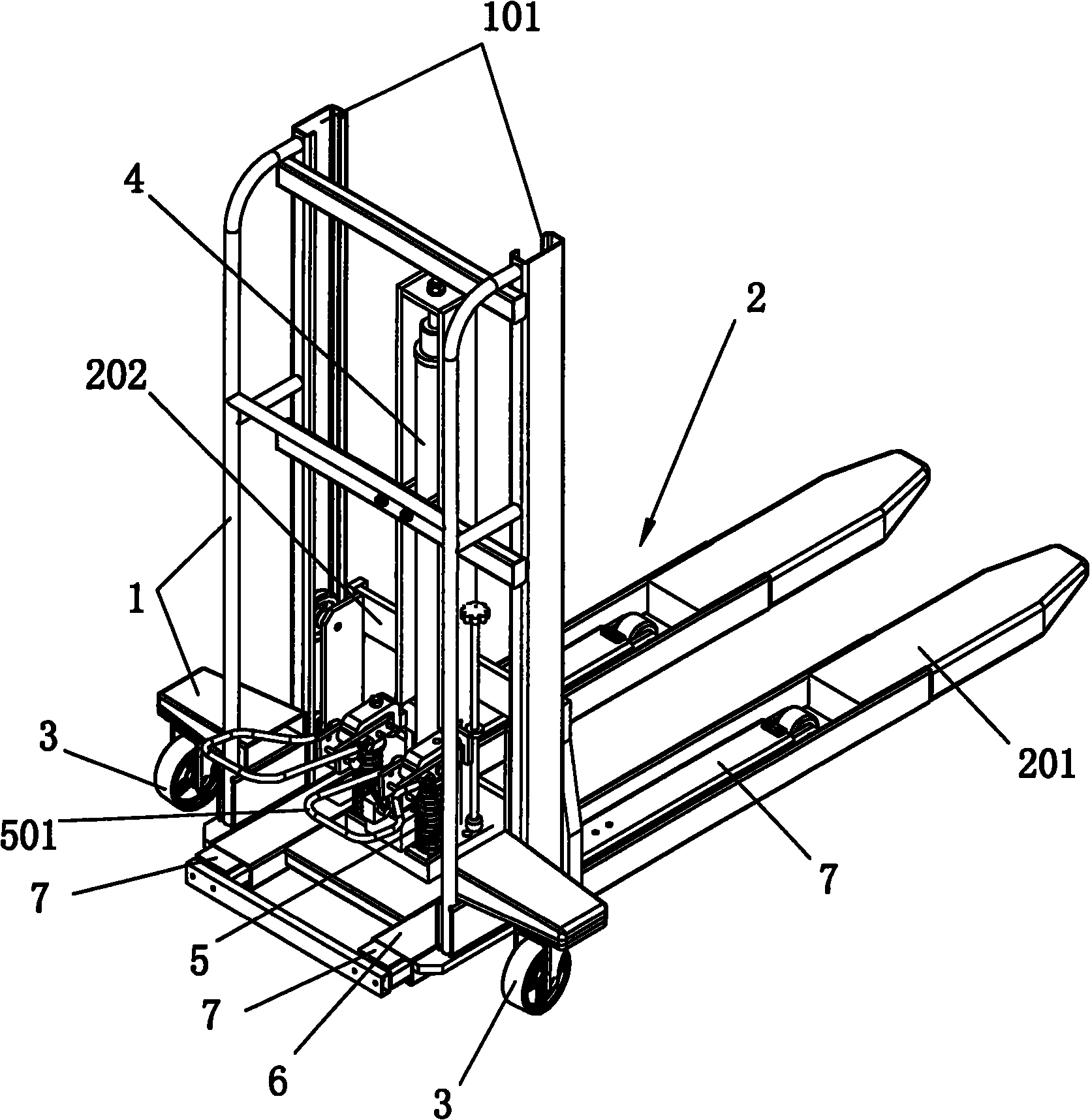

Manual self-elevating pallet truck

The invention discloses a manual self-elevating pallet truck, which comprises an upright post bracket and an elevating pallet fork. A manual hydraulic drive device is arranged on the upright post bracket, and comprises a hydraulic oil cylinder and a hydraulic oil pump, wherein the hydraulic oil pump is a manual oil pump and is provided with a drive handle which can be pressed by hands or pedaled; and one of a hydraulic cylinder body and a piston rod of a difunctional hydraulic cylinder which is the hydraulic oil cylinder is fixedly connected with the upright post bracket, and the other of the hydraulic cylinder body and the piston rod is in drive connection with a pallet fork sliding bracket. Caster stand sliding chutes are formed at the lower end of the upright post bracket, and telescopic caster stands are arranged in a matching way in the caster stand sliding chutes. Front and rear support casters are arranged at the front and rear ends of each telescopic caster stand. The manual self-elevating pallet truck provided by the invention has a simple structure and a small volume, works stably, and is well designed and easy to operate and maintain and difficult to fail when working.

Owner:上海海资国际贸易有限公司

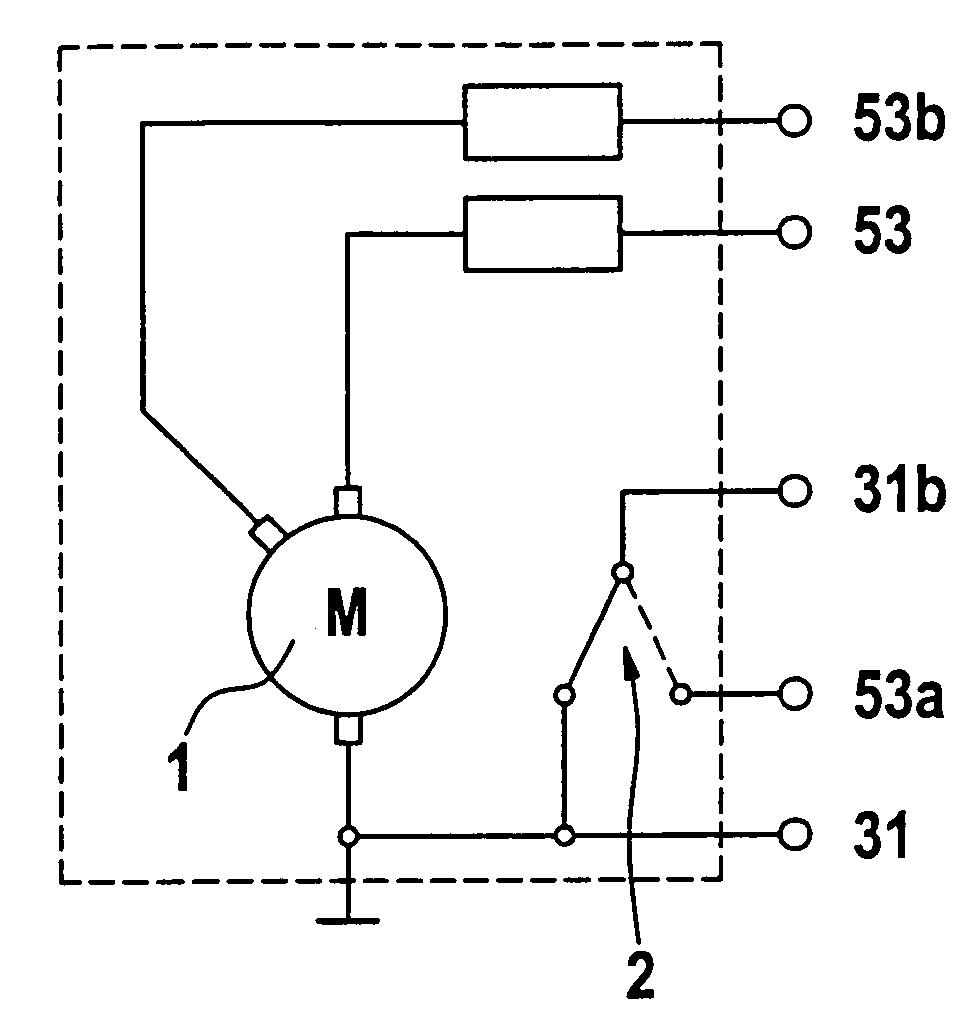

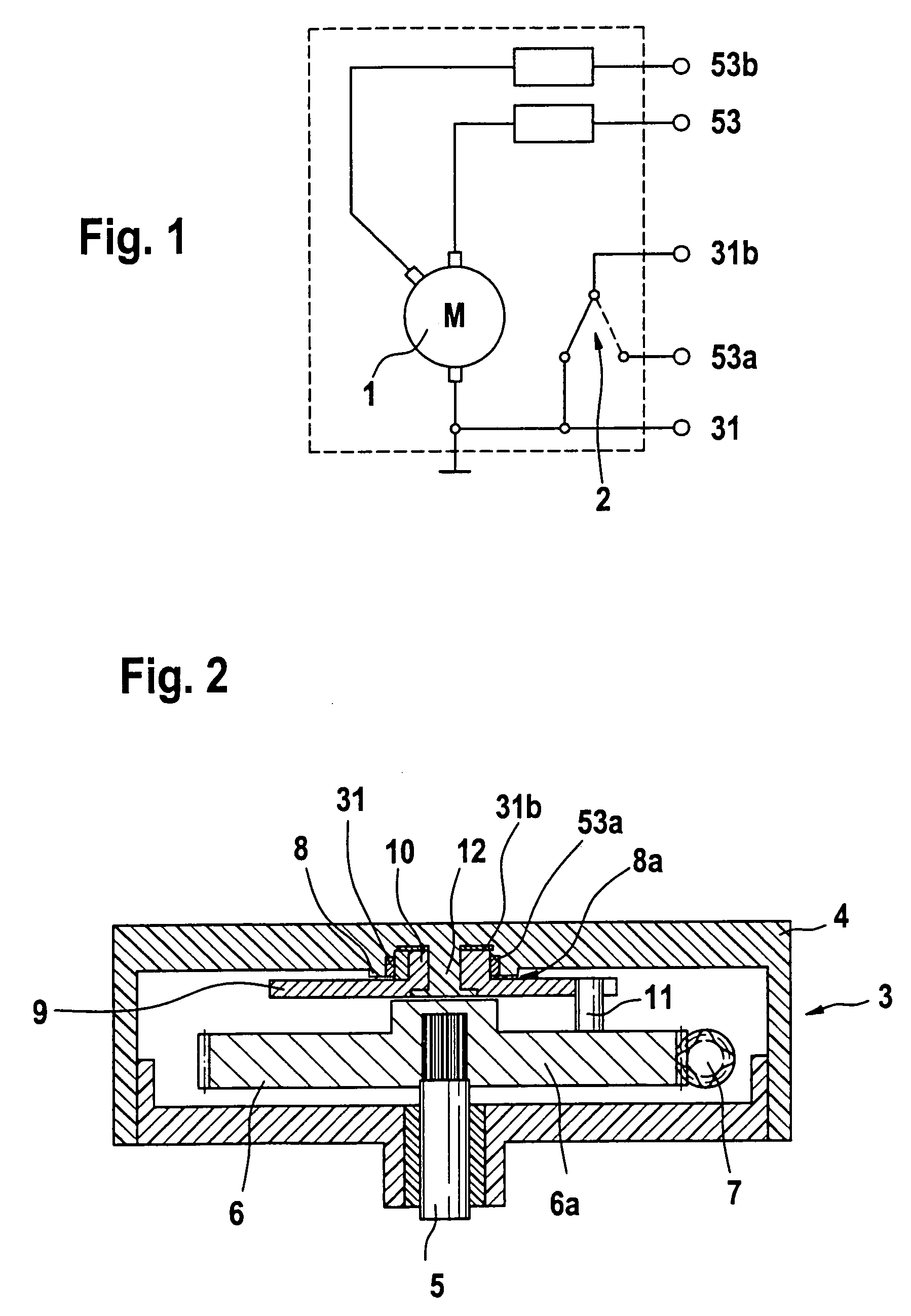

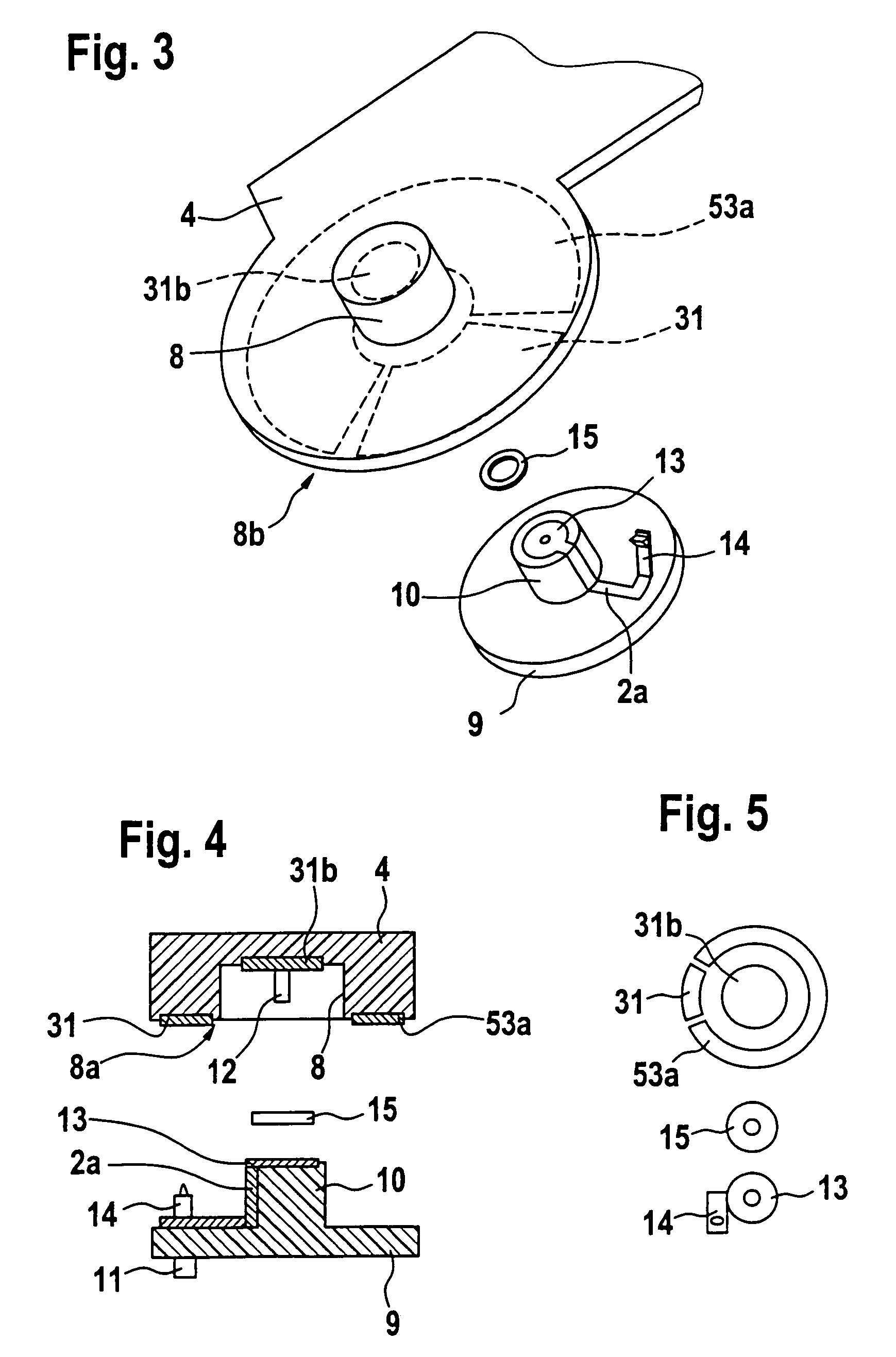

Drive device for window wipers with a parking position switch

InactiveUS7707680B2Design variableImprove contact stabilityMotor/generator/converter stoppersDC motor speed/torque controlGear wheelEngineering

The device comprises an output gearwheel (6), a gear cover (4) having a plastic sleeve open toward the output gearwheel (6) and a park position switch having first contacts mounted for rotation and second contacts fixed to the gear cover (4) and a driving means. The invention provides that the sleeve is embodied as a contact sleeve (8) having contact tracks (31b, 53a, 31), particularly along the inner surface of the contact sleeve (8). To enable sliding contact on rotation, the cylindrical member (10) of a driving disk (9) extends into the contact sleeve (8).

Owner:ROBERT BOSCH GMBH

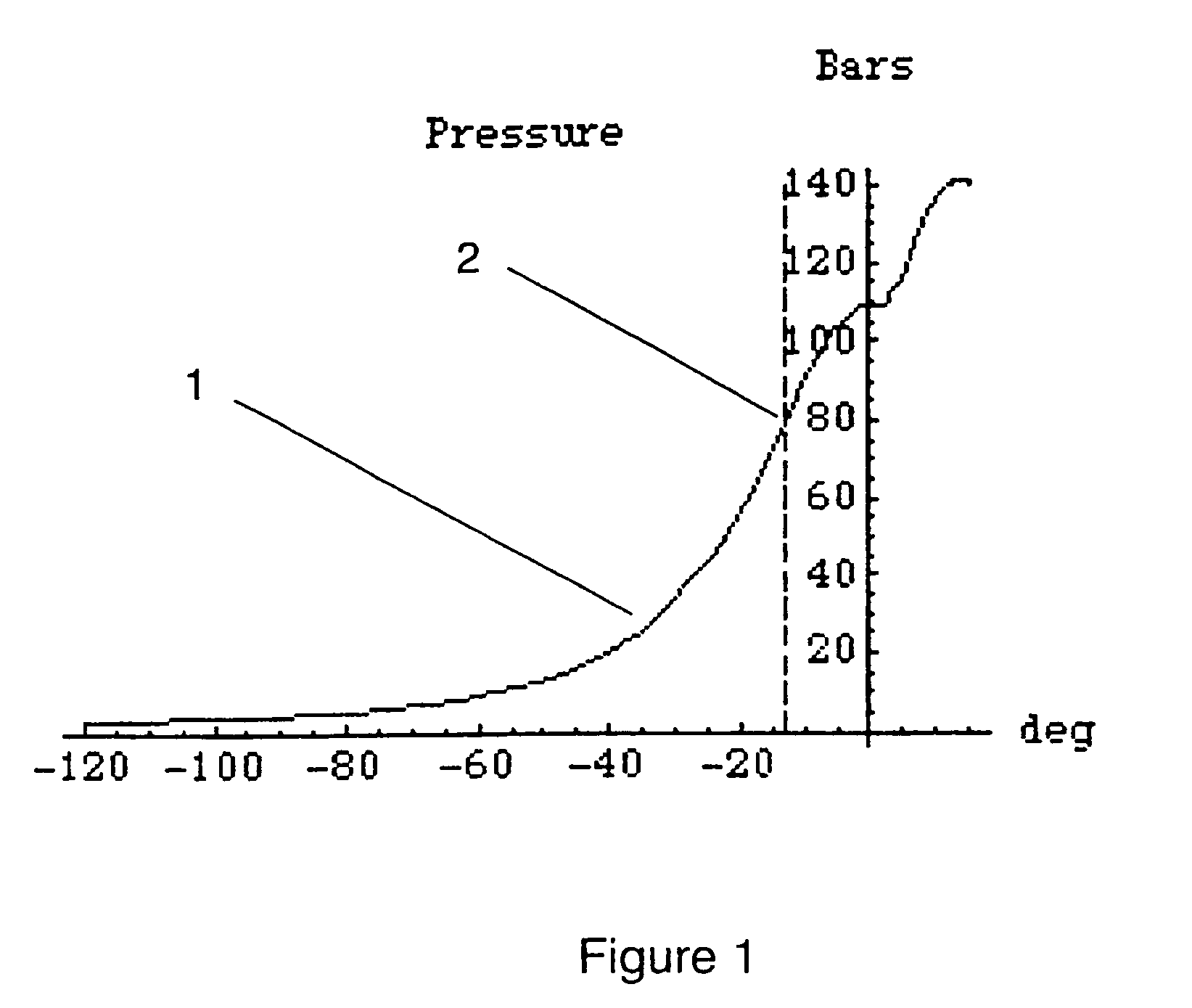

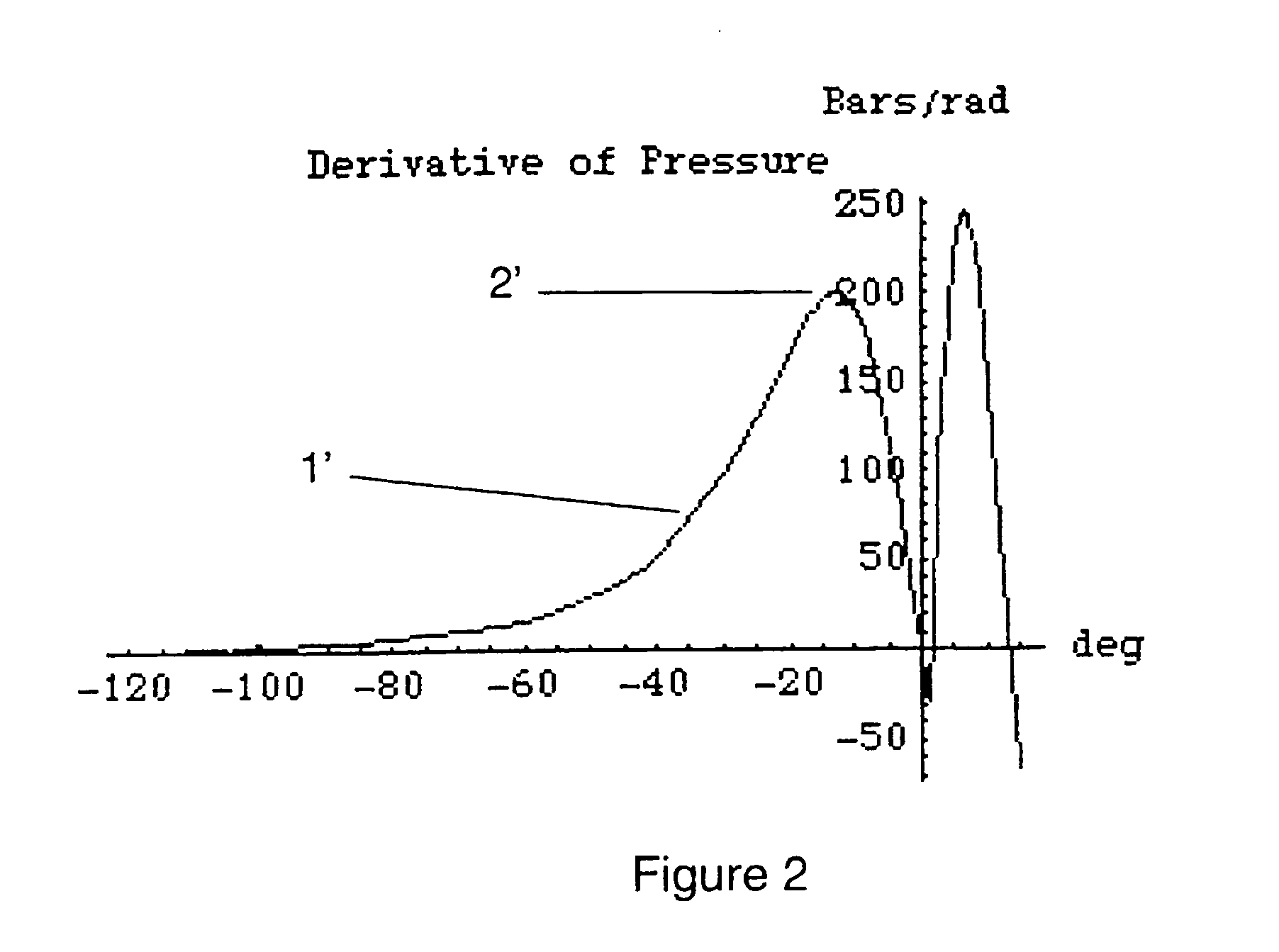

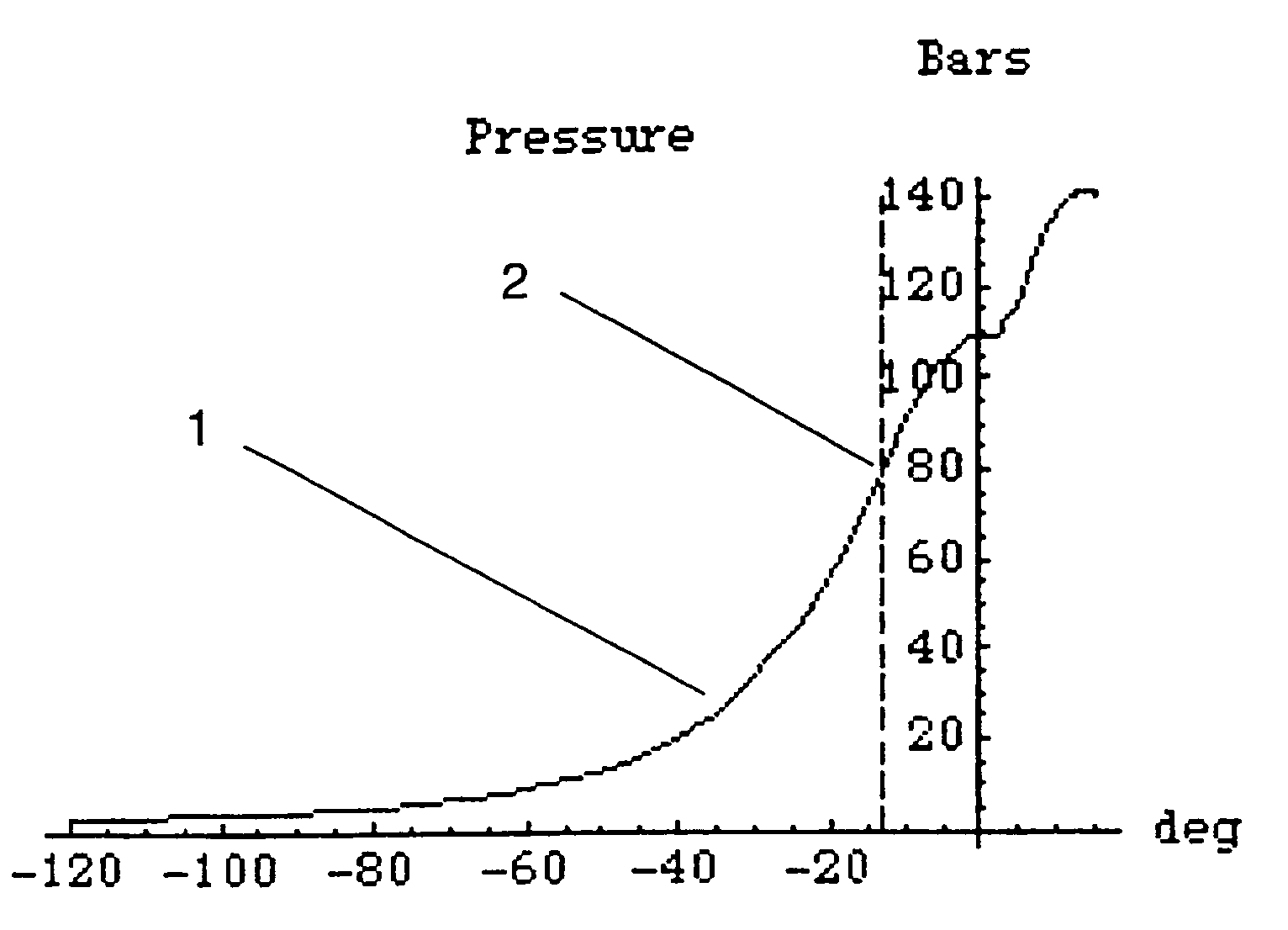

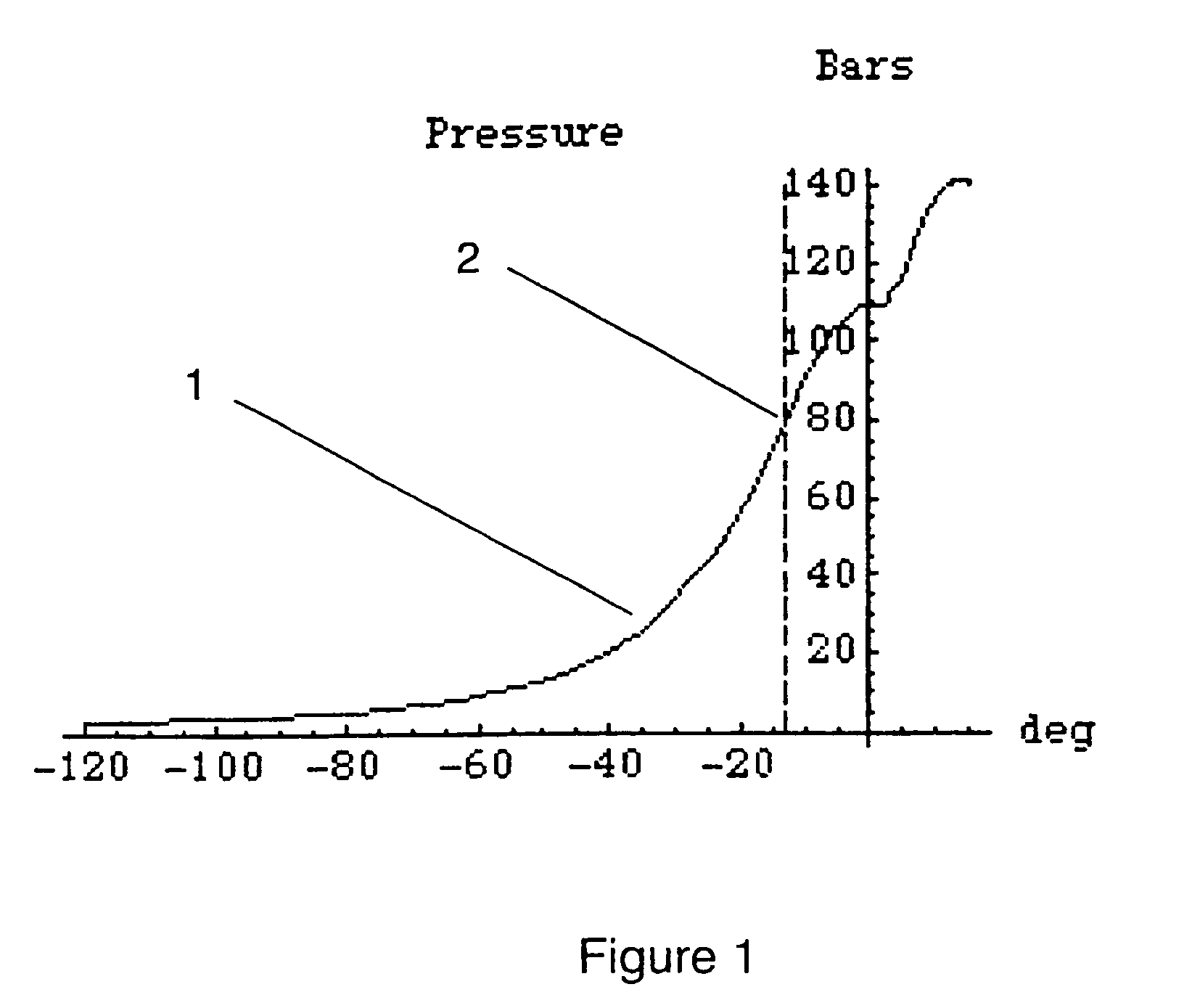

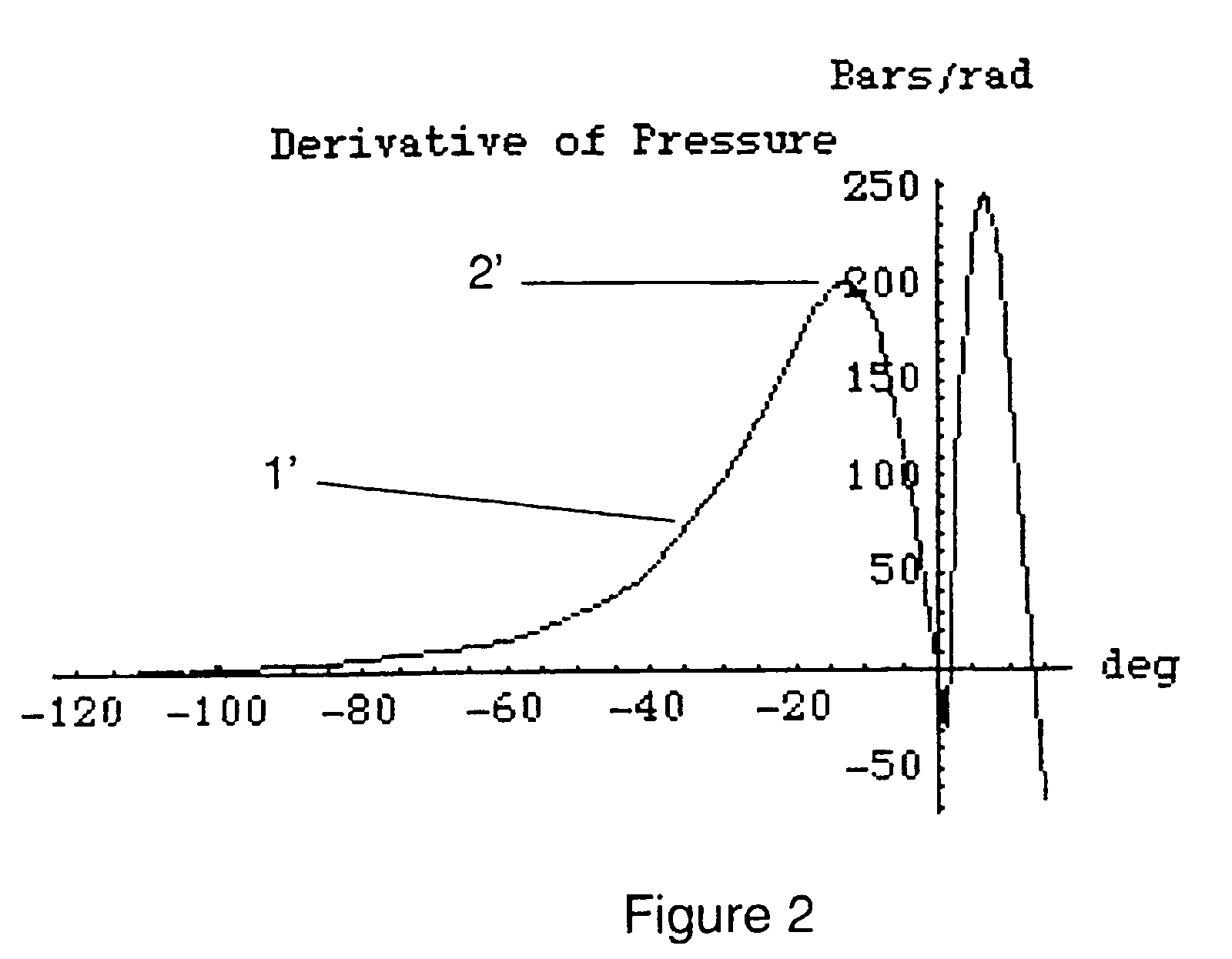

Method to determine tdc in an internal combustion engine

InactiveUS20040236496A1Efficient developmentReduce fuel consumptionInternal-combustion engine testingAnalogue computers for vehiclesFlywheelInternal combustion engine

A method and apparatus for accurately determining TTX: in a cylinder of an internal combustion engine. Gas pressure is measured in the cylinder relative to crank angle, giving rise to a curve of gas pressure with crank angle. An offset is found by first computing the angular position of an inflexion point of the compression pressure curve measured as a function of the crank angle, and then computing the offset as the difference between the angular position of a piston in the cylinder and a theoretical value for said angular position of the piston dependent on a known or measured flywheel angle. The value of TDC corrected by the offset is then used to calculate a value of work output such as the indicated Mean Effective Pressure (IMEP) which may be used for diagnostic and / or control purposes.

Owner:ABB (SCHWEIZ) AG

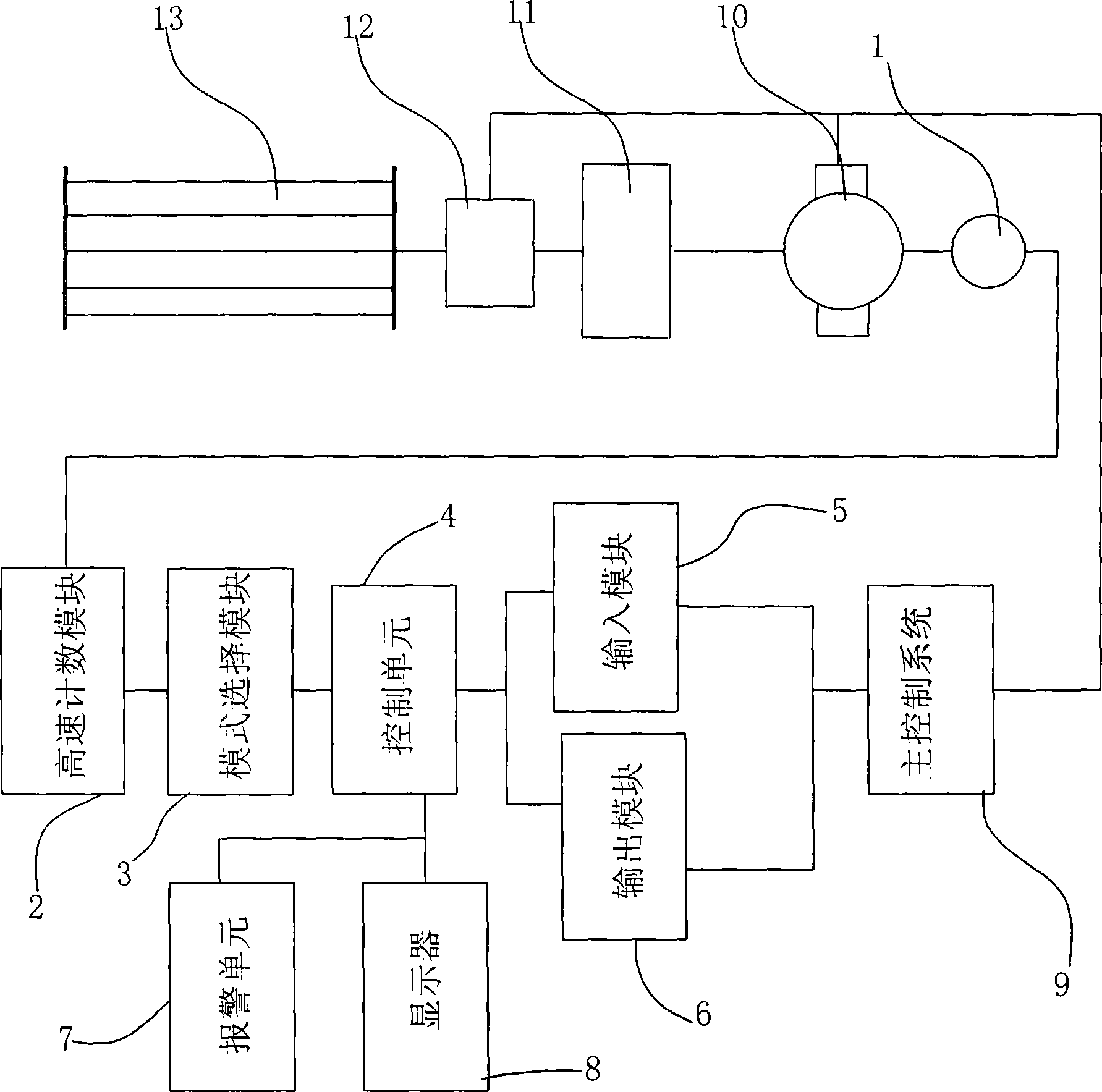

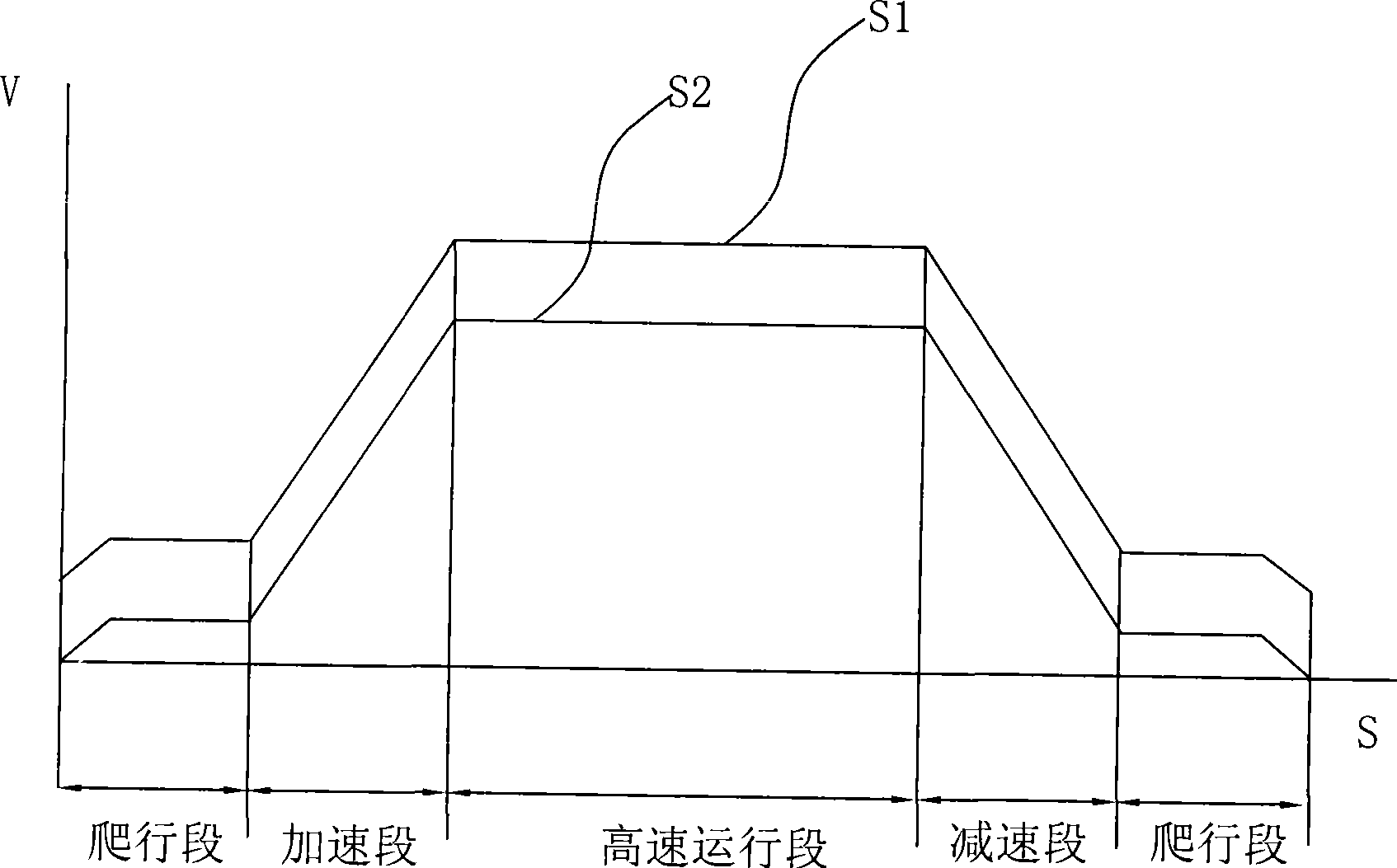

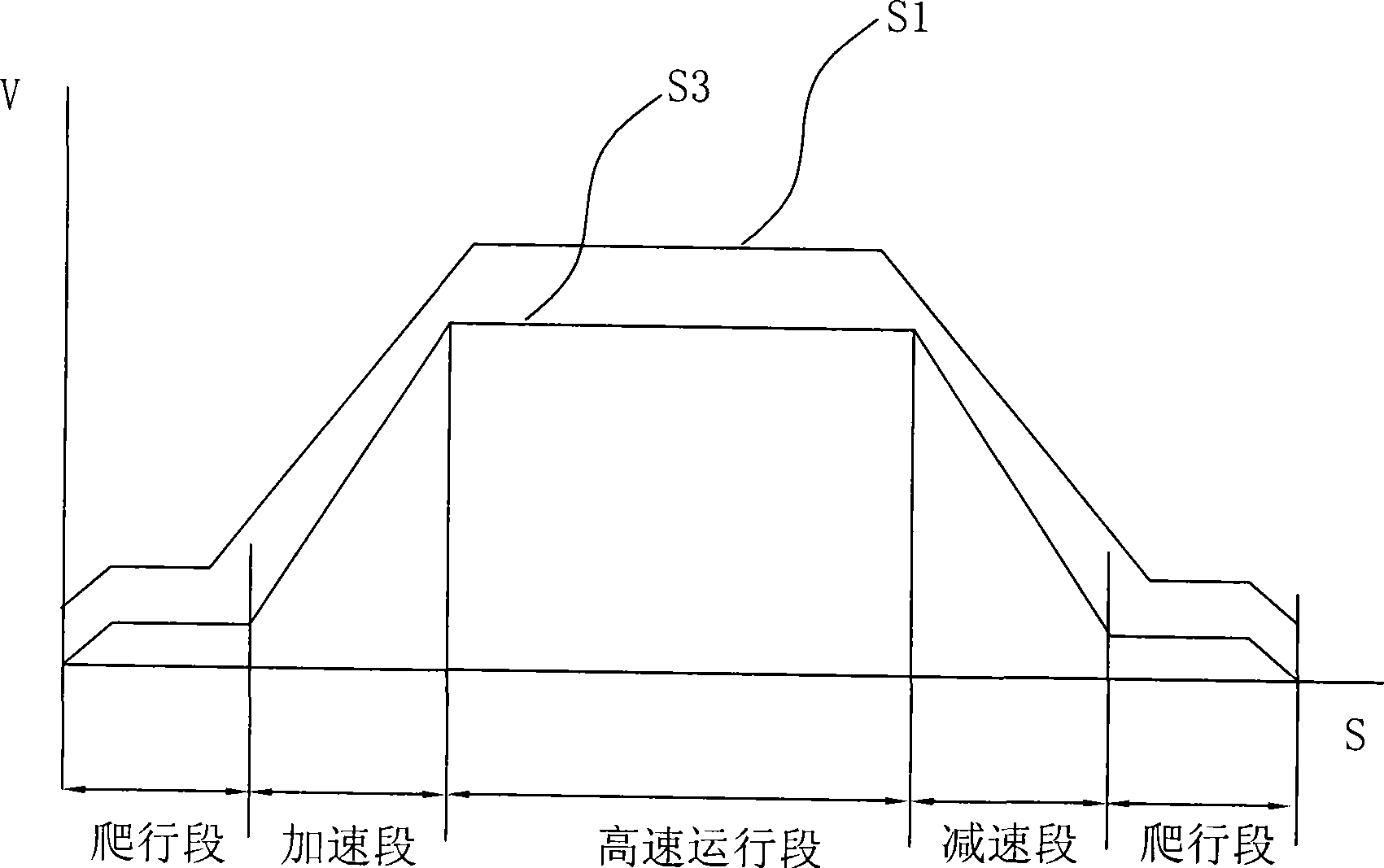

Monitoring apparatus for lifting machine

The invention relates to a monitor for a hoisting machine, which comprises a rotary encoder for detecting displacement of the hoisting machine and outputting impulse signals corresponding to the displacement of the hoisting machine, a control unit for calculating speed of the hoisting machine by using the impulse signals received from the rotary encoder, and a mode selecting module for switching the control unit between a standard mode and an actual operational mode, wherein in the standard mode, the control unit records the calculated speed of the hoisting machine as standard speed, and in the actual operational mode, the control unit compares actual speed of the hoisting machine calculated at a preset position with the standard speed corresponding to the preset position, so that the control unit sends out stop signals to stop the hoisting machine when a difference value of the actual speed and the standard speed is larger than a first threshold value. The monitor has the advantages of simple structure, high precision and wide appliance range.

Owner:CHINA ENFI ENGINEERING CORPORATION

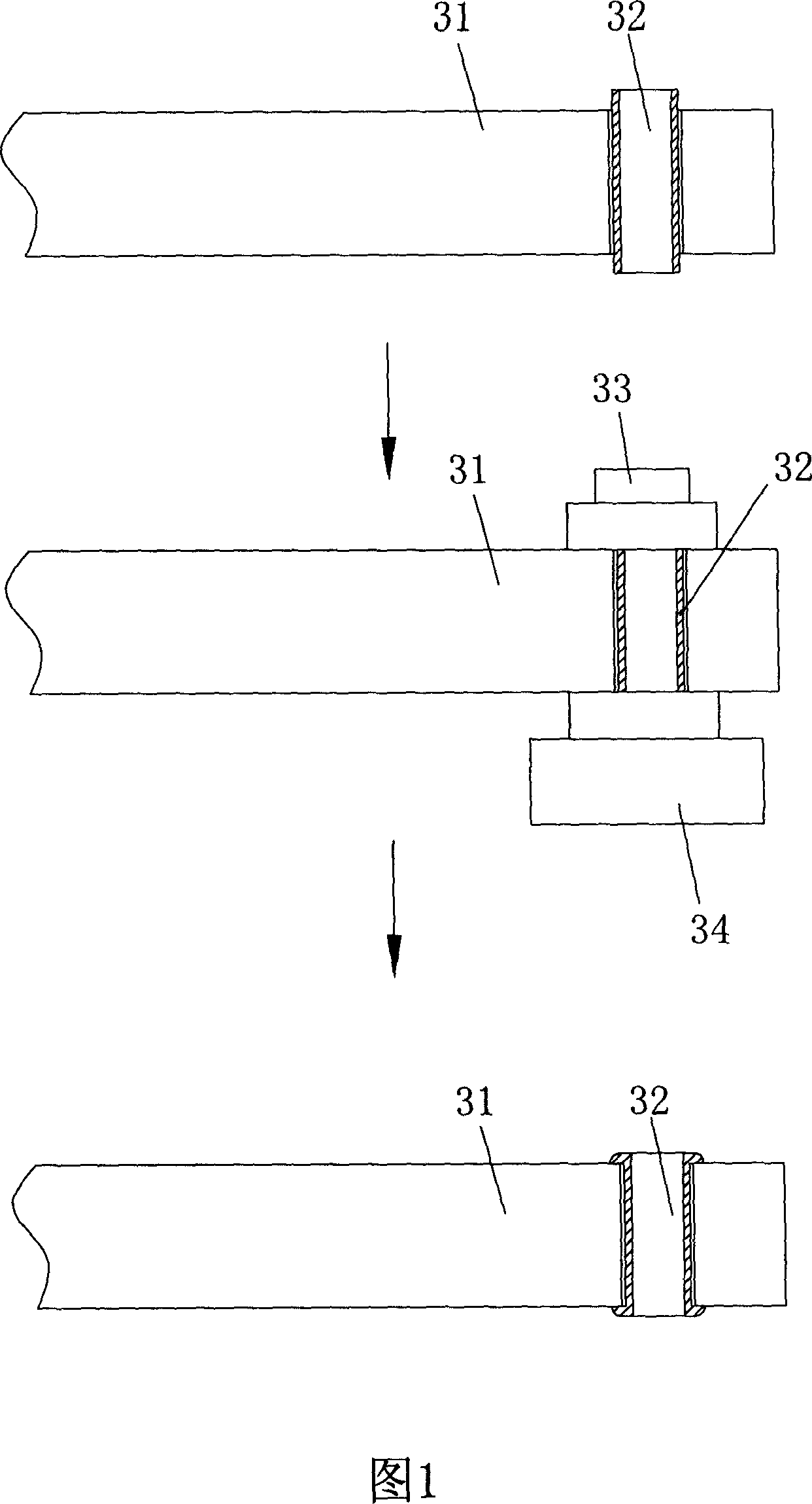

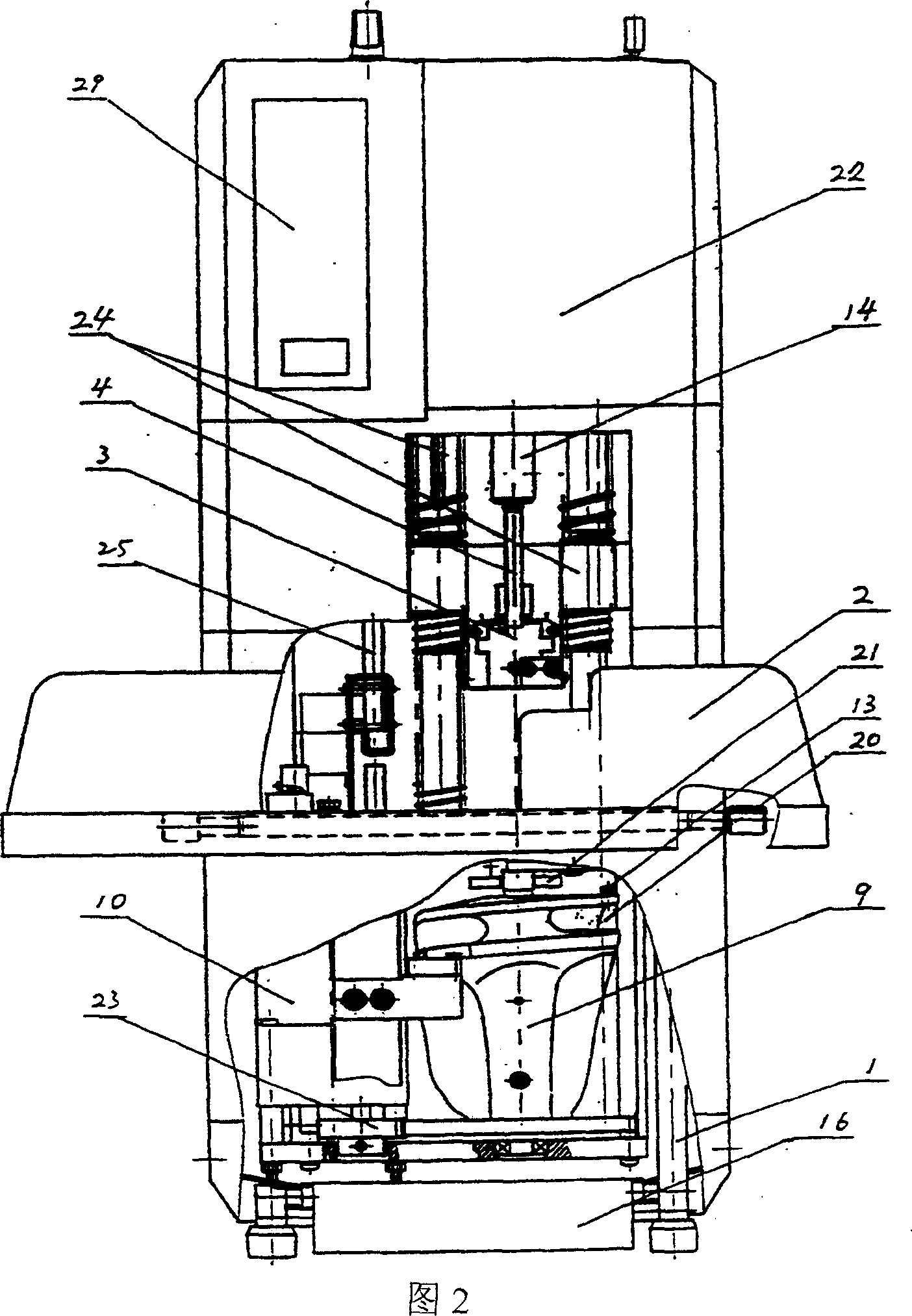

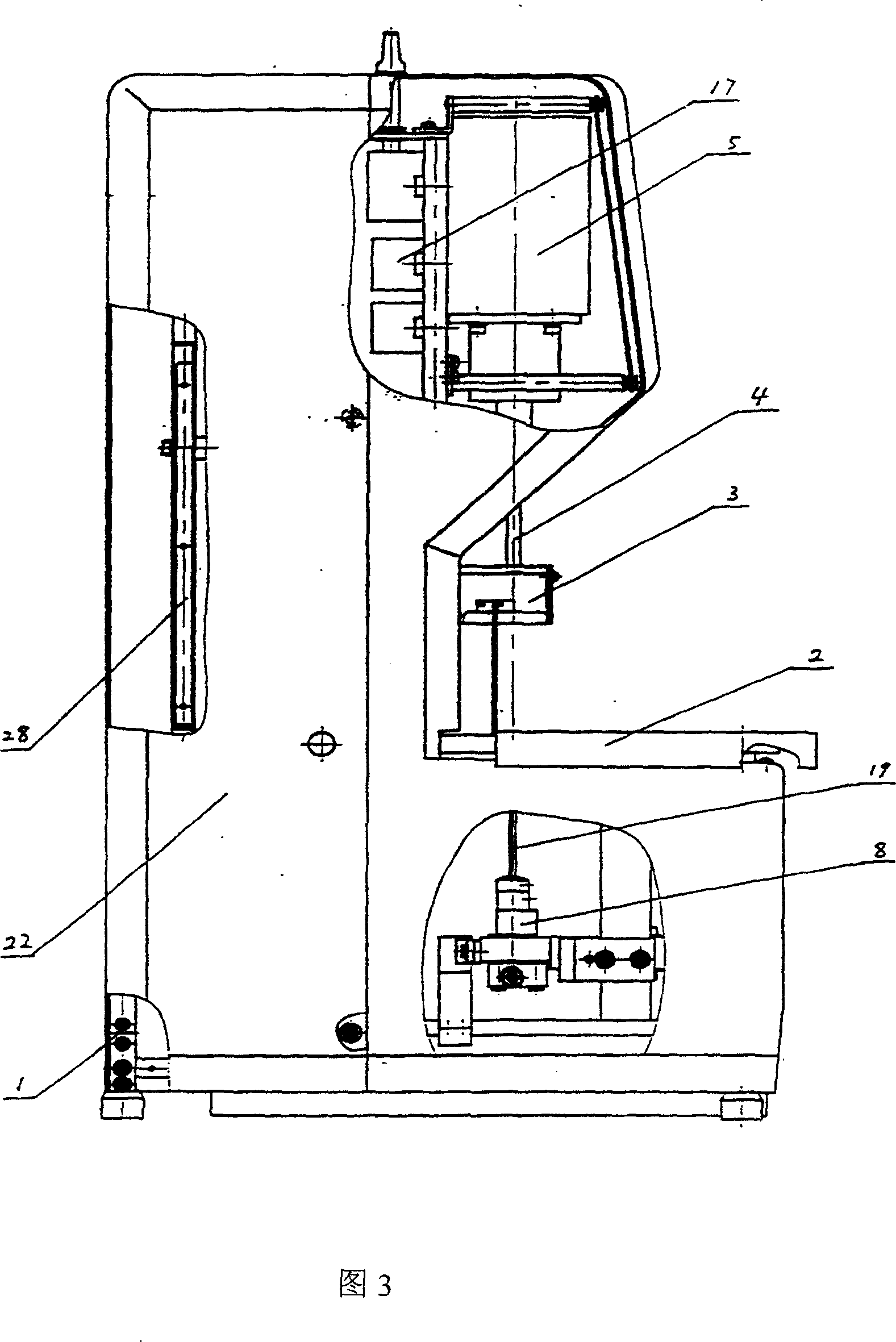

Omnibearing full automatic binding machine

The omnibearing full automatic binding machine consists of a frame, a casing, a bench, a paper holding mechanism, a hole drilling mechanism, a tube setting mechanism, a tube cutting mechanism, a rotary tube feeding mechanism, a pressing and riveting mechanism and a control circuit device mainly. It has also bearer fixed behind the bench, two guide shafts on the bearer, punching motor, shifting motor, walking motor, upper pressing spring, lower pressing spring and other parts. It has small size, light weight, smooth driving, accurate position and other advantages and may be used widely in binding various kinds of files.

Owner:北京亚博通科技发展有限公司

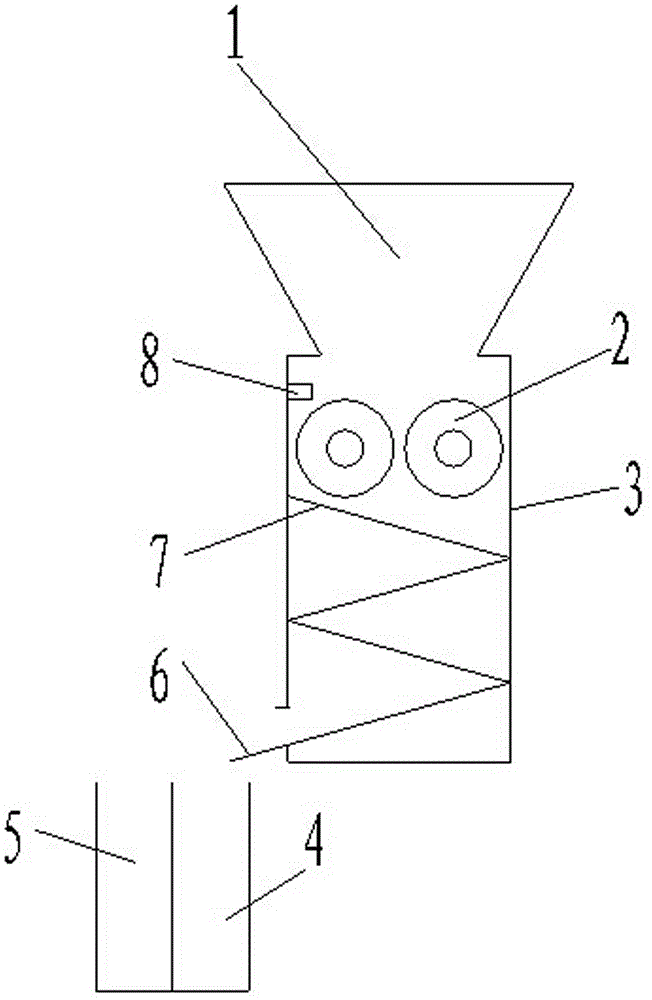

Dust-free peanut sheller

InactiveCN104397837AAvoid it happening againGood for healthHuskingHullingEngineeringMechanical engineering

The invention discloses a dust-free peanut sheller. The dust-free peanut sheller comprises a box body, a feed inlet is opened at one side of the top end of the box body, two shell smashing rollers are arranged below the feed inlet in a parallel mode, a sprinkler head is formed between the shell smashing roller and the feed inlet, a discharge plate inclining downward is arranged below the shell smashing rollers, a shell collecting bucket and a peanut collecting bucket are mounted below one end of the discharge plate extending out the box body, the shell collecting bucket is close to the end of the discharge plate extending out the box body. The dust-free peanut sheller can avoid the dust during the peanut production process, protect the environment and is beneficial to the good health for workers, the structure is simple and beneficial to produce and maintain and is not easy to break down.

Owner:GUANGXI GAONONG MACHINERY

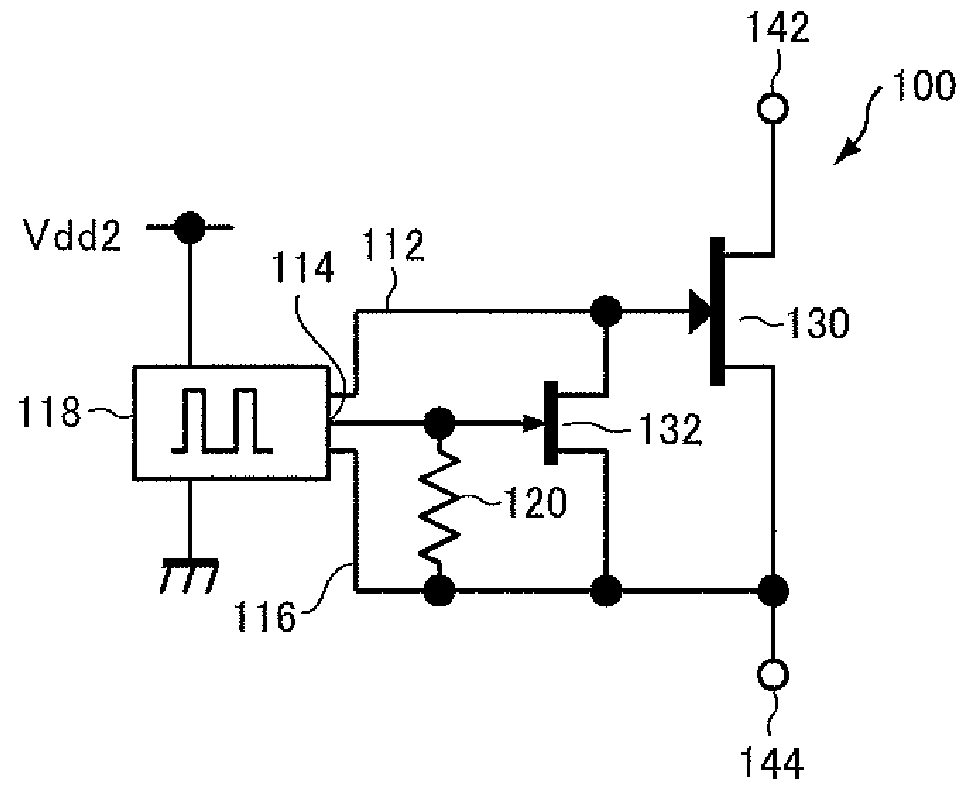

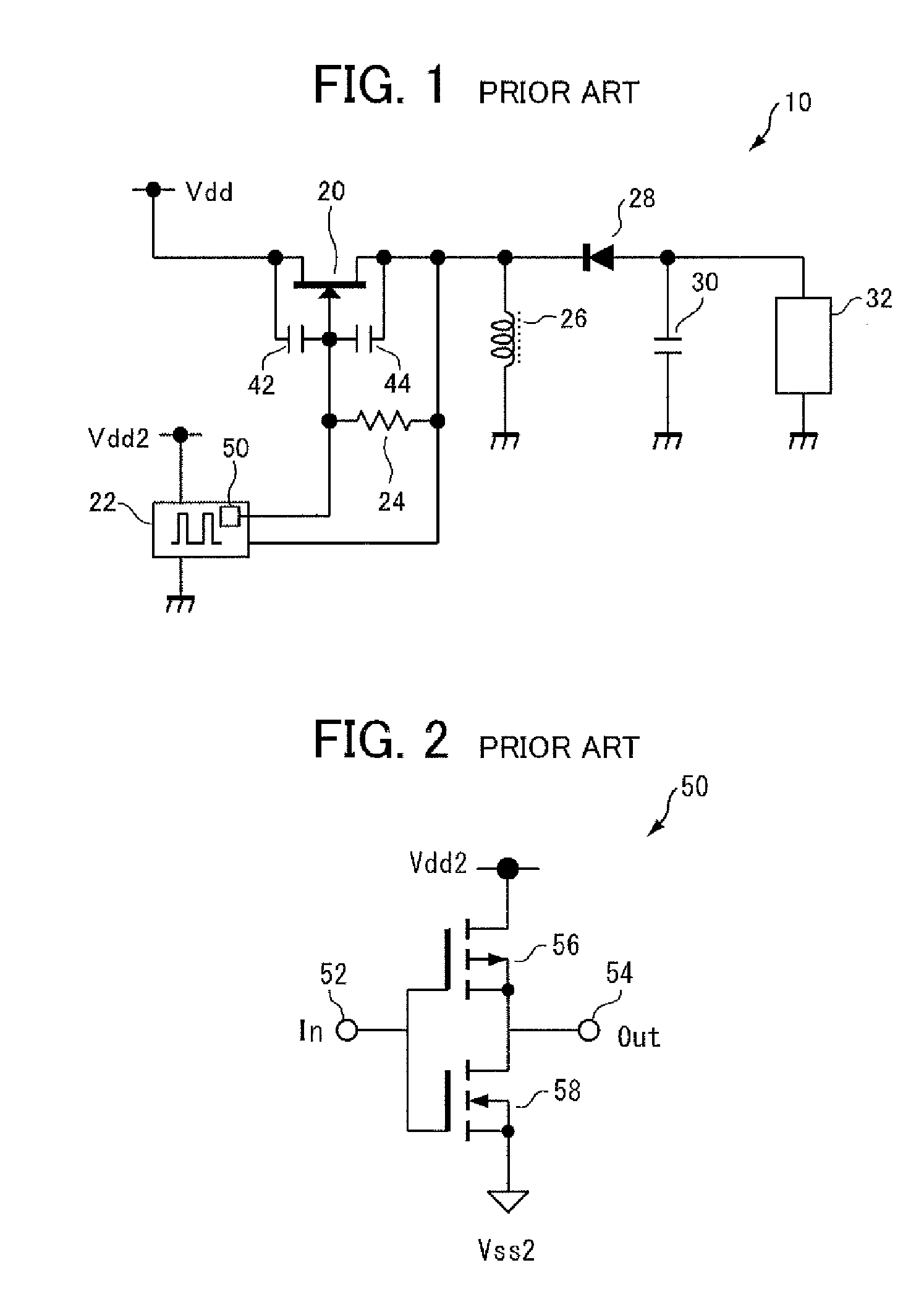

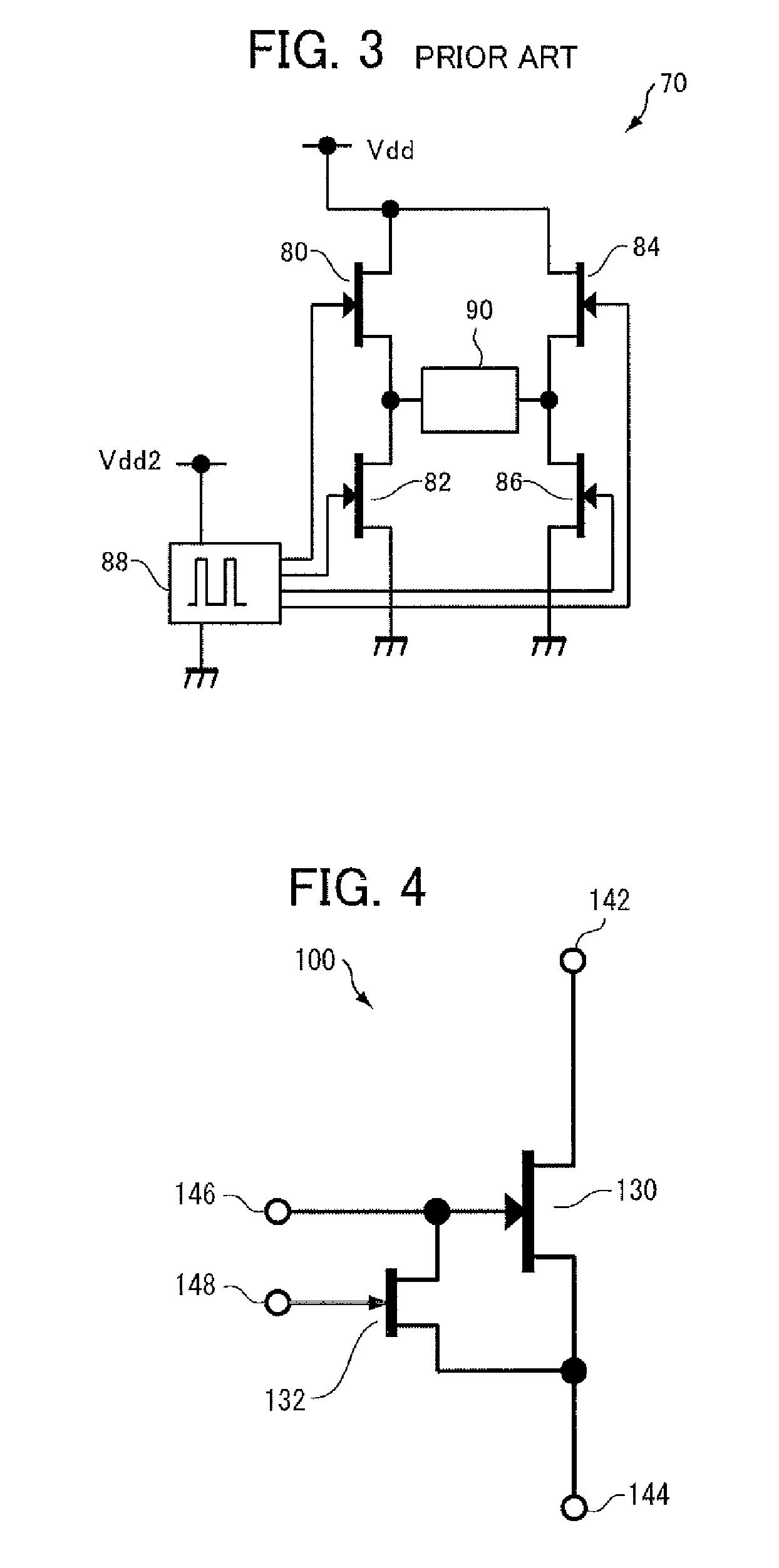

Switching circuit having low threshold voltage

ActiveUS7782099B2Solve the large power consumptionLower on-resistanceTransistorElectronic switchingDevice formEngineering

A switching circuit for preventing malfunction of a switching device formed of a wide band-gap semiconductor used for switching a high-power main power supply includes a normally-off type FET having a gate electrode, a source electrode connected to the ground, and a drain electrode connected to a power supply potential Vdd, and a normally-on type FET having drain and source electrodes connected to the gate and source electrodes of the FET, respectively, and a gate electrode. In the absence of any power supply, the normally-on type FET turns on. As a result, the gate / source potential of FET attains to 0V, and FET is kept off.

Owner:MURATA MFG CO LTD

Method to determine TDC in an internal combustion engine

InactiveUS7117080B2Efficient developmentHigh in technologyInternal-combustion engine testingAnalogue computers for vehiclesInternal combustion engineFlywheel

A method and apparatus for accurately determining TDC in a cylinder of an internal combustion engine. Gas pressure is measured in the cylinder relative to crank angle, giving rise to a curve of gas pressure with crank angle. An offset is found by first computing the angular position of an inflexion point of the compression pressure curve measured as a function of the crank angle, and then computing the offset as the difference between the angular position of a piston in the cylinder and a theoretical value for said angular position of the piston dependent on a known or measured flywheel angle. The value of TDC corrected by the offset is then used to calculate a value of work output such as the Indicated Mean Effective Pressure (IMEP) which may be used for diagnostic and / or control purposes.

Owner:ABB (SCHWEIZ) AG

Coffee machine with a manually operated lid of an inlet for special coffee and a method for monitoring the position of this lid

InactiveUS6857354B2Less prone to failureEasy to operateCoffee millsSpice millsMinimum timeEngineering

A coffee machine with an integrated coffee grinder and a powder chute, which serves the purpose of feeding ground coffee from the coffee grinder to a movable brewing cylinder, has an inlet with a manually operated lid for already ground special coffee. A sensor detects the position of the lid. The detection signal of the sensor is passed on to a processor controlling the coffee machine, and the signal is used to differentiate between a normal operating mode and an operating mode for producing special coffee. If the lid is opened for a certain minimum time span, a subsequent coffee preparation cycle in the operating mode for producing special coffee is initialized. Since, to that end, no separate pre-selection is required any longer, the operation of the coffee machine is simplified and the susceptibility to problems is reduced.

Owner:JURA ELEKTROAPPARATE AG

Bit For Drilling A Hole

ActiveUS20080066969A1Improve robustnessLess prone to failureDrill bitsTurning toolsEngineeringDistal segment

A bit for drilling a hole. The bit includes a support member, the support member having a passageway extending substantially longitudinally therethrough; a substantially annular crown defining a crown distal end and a crown proximal end, a radially inwardly located crown inner surface and a radially outwardly located crown outer surface, the crown extending from the support member; a slot extending between the crown inner and outer surfaces from the crown distal end substantially longitudinally towards the crown proximal end, the slot defining a slot first side wall, a substantially circumferentially opposed slot second side wall and a slot proximal wall extending therebetween substantially opposed the crown distal end; and a reinforcing member extending substantially circumferentially across the slot between the slot first and second walls; wherein the slot includes a slot proximal segment extending between the reinforcing member and the slot proximal wall and a slot distal segment extending between the reinforcing member and the crown distal end.

Owner:GROUPE FORDIA

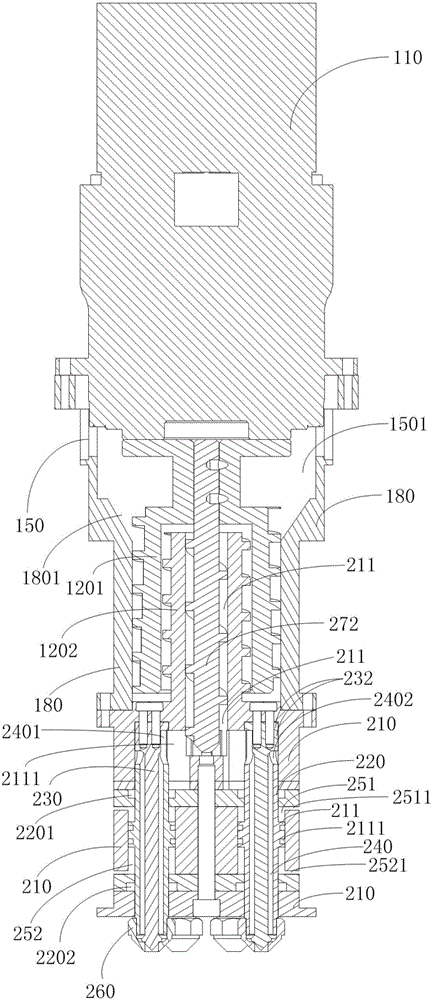

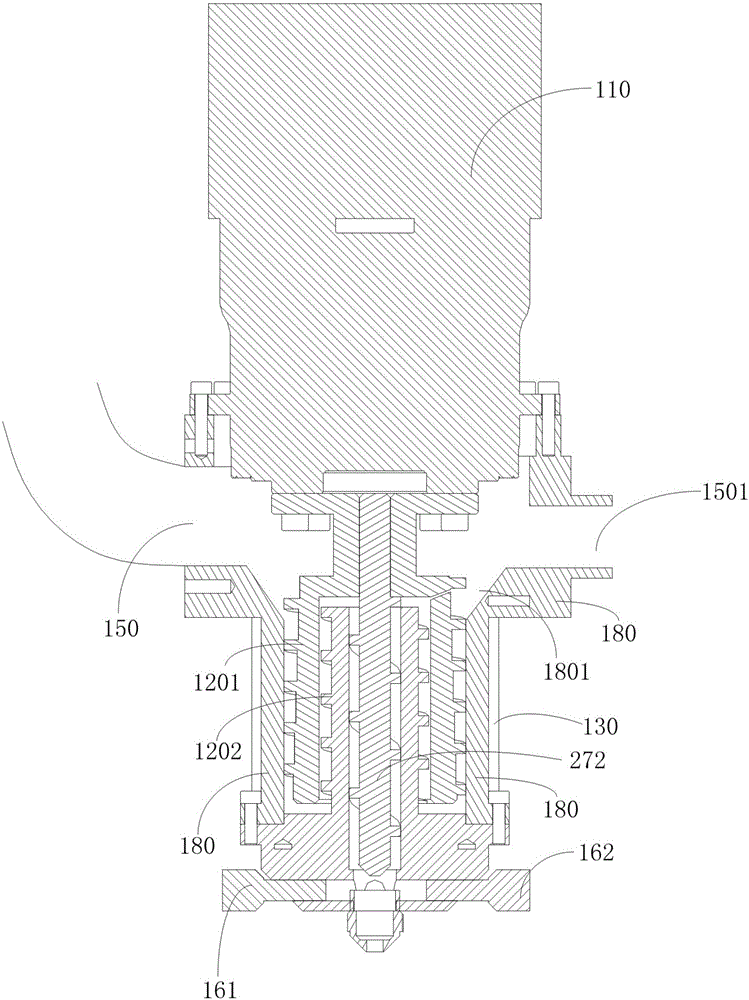

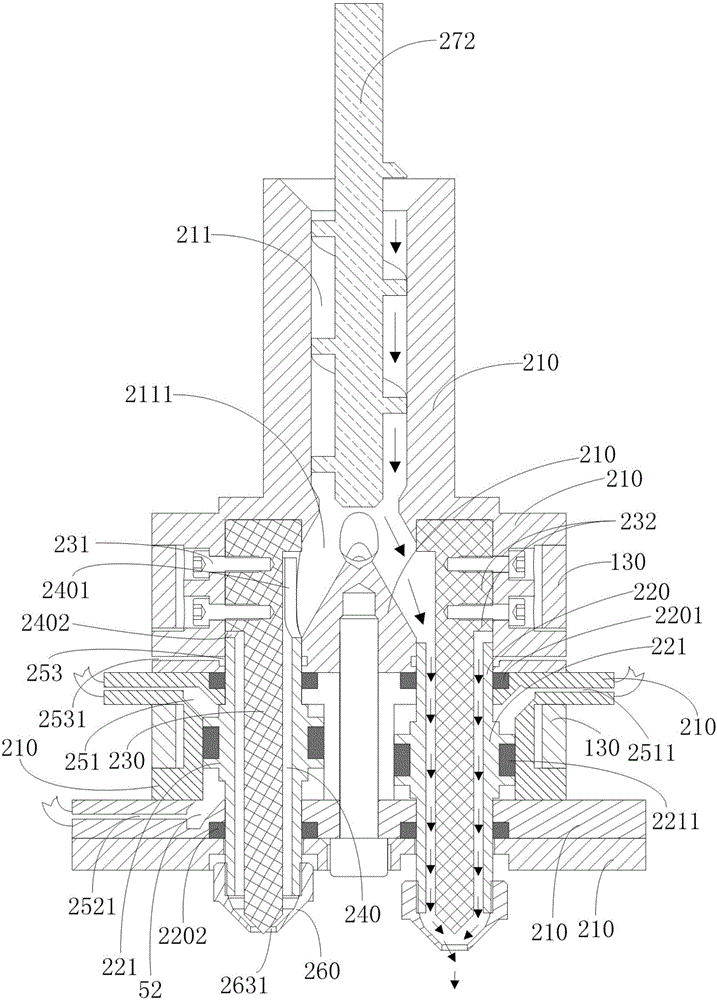

Printing head for 3D printing, control system, 3D printer and printing method

The invention discloses a printing head for 3D printing. The printing head comprises a machine shell, a screw extruding system, an installation seat, barrels, valve needles and spray nozzles. A drive system is arranged at one end of the machine shell. The screw extruding system is arranged in the machine shell and is composed of at least two screws which are embedded internally and externally, and at least one screw is driven by the drive system. The installation seat is mounted below the screw extruding system. One or more inner holes are distributed in the installation seat in the axial direction, and a discharge outlet is formed in the top or the side face of each inner hole. The barrels are mounted in all the inner holes of the installation seat correspondingly, the barrels extend out from one end of the installation seat, and barrel feeding openings are formed in the top ends of the barrels. Valve cavities are formed in the barrels. The valve needles penetrate through all the valve cavities of the barrels to be mounted on the installation seat, and the gaps between the valve needles and the valve cavities form discharging channels communicating with the feeding openings of the barrels. The spray nozzles are arranged at the tail ends of all the barrels. The printing head for 3D printing is light in weight, small in size, capable of achieving high printing precision and printing speed, novel in design, high in practicability and high in economic value.

Owner:浙江光镀智造科技有限公司

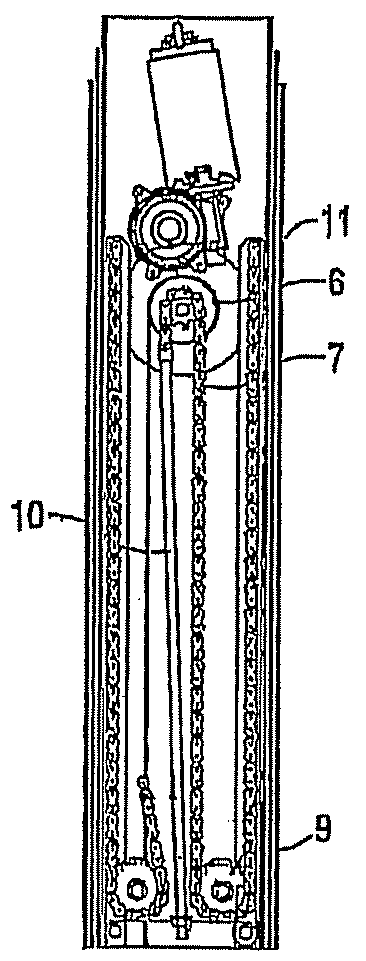

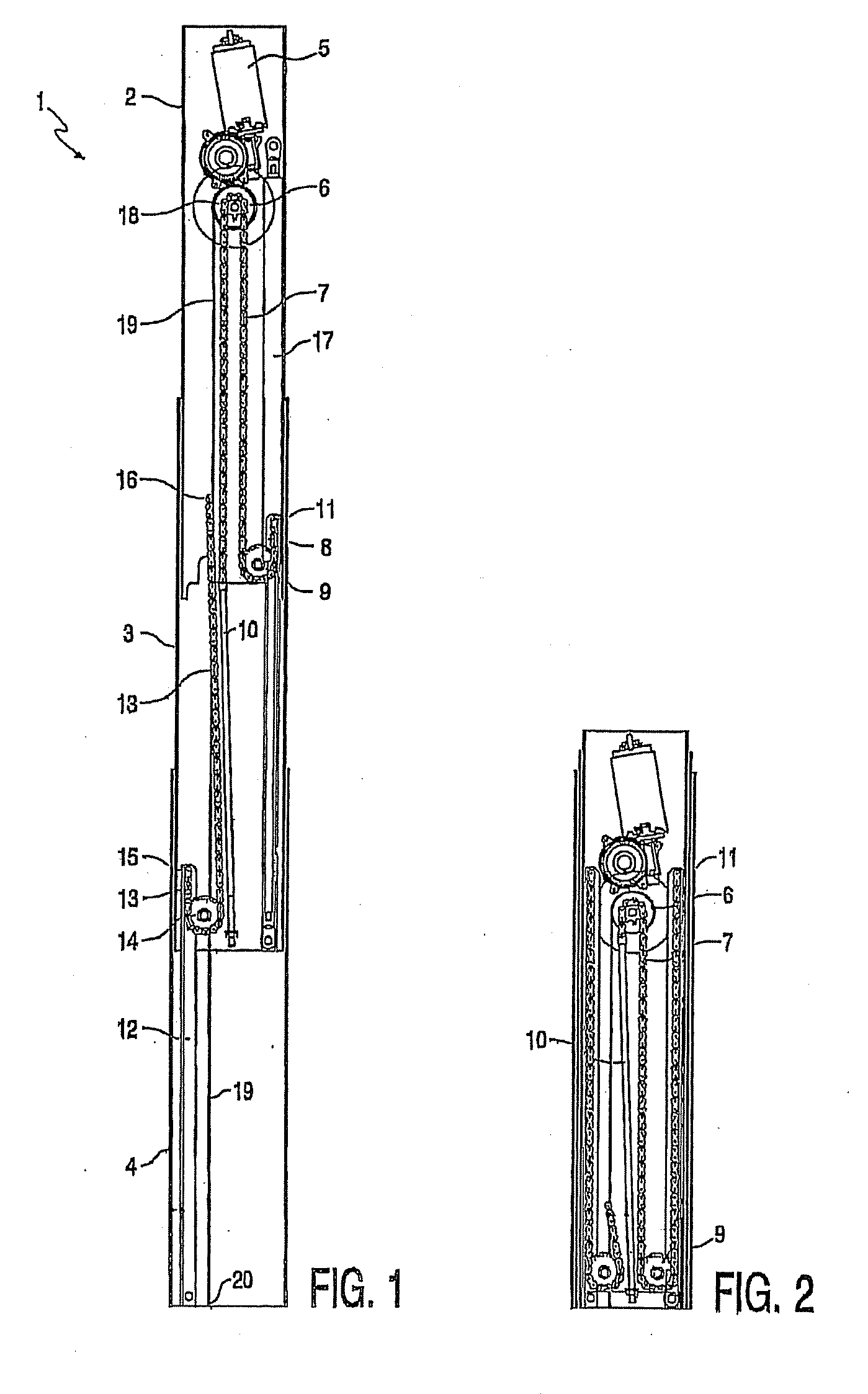

Drive for displacing profile parts relative to each other via a flexible material strip, length-adjustable housing and article of furniture

ActiveUS20090072101A1Increase motivationSimple and inexpensive constructionStands/trestlesKitchen equipmentDrive wheelEngineering

A drive for displacing and positioning at least two profile parts relative to each other, includes: a rotatable drive wheel, a motor coupled to a first profile part and to the drive wheel, a flexible material strip which is rigidly connected on at least one side to a second profile part, which material strip also engages on the drive wheel, and a guide for the flexible material strip connected in at least substantially stationary manner to the first profile part, wherein the distance between the guide and the drive wheel is greater than the distance between the point of engagement of the flexible material strip on the second profile and the drive wheel. The invention also includes a length-adjustable housing provided with the aforementioned drive and to an article of furniture, in the legs of which such drives are accommodated.

Owner:ACTIFORCE INT BV

Charging/Powering Device for an Electronic Device and Electronic Device Incorporating Same

InactiveUS20100060234A1Simple designLess prone to failureBatteries circuit arrangementsPower supply for data processingElectronic equipmentElectric energy

A charging / powering device comprises at least one manually rotatable element, a power generating mechanism coupled to the at least one rotatable element, the power generating mechanism converting rotational movement of said at least one rotatable element into electrical energy and an energy harvesting module collecting and storing the electrical energy generated by the power generating mechanism, the energy harvesting module further being operable to output stored electrical energy.

Owner:NACSON SABATINO

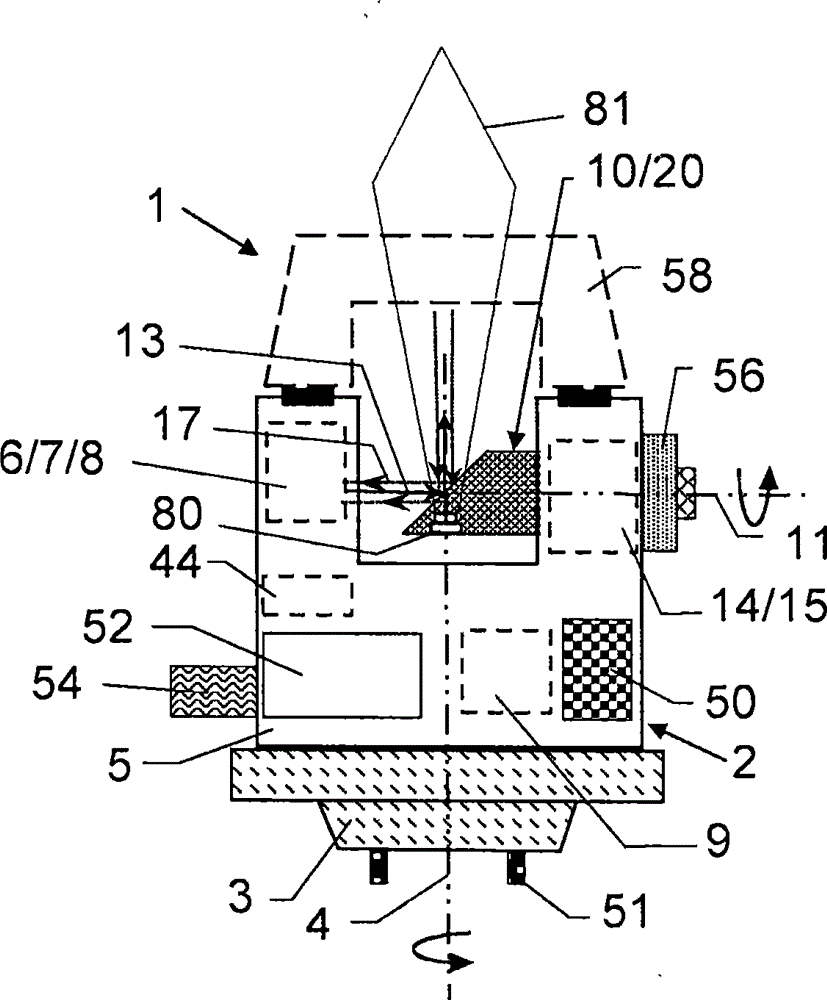

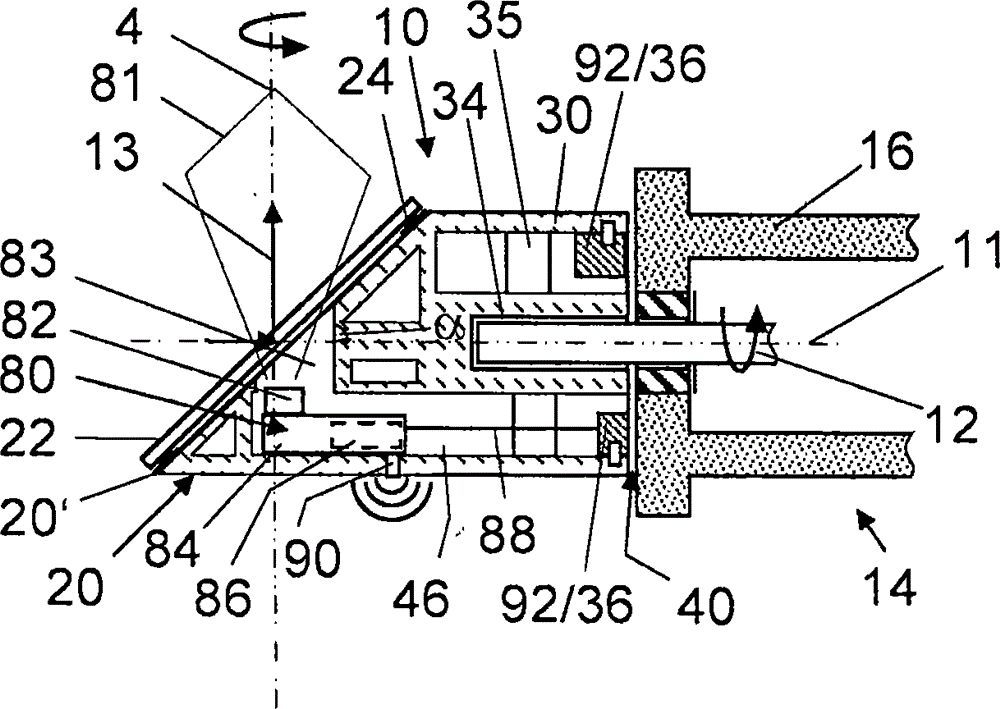

Scanner for space measurement

ActiveCN104567668ALess computing performanceFast trackUsing optical meansElectromagnetic wave reradiationOptics

Some embodiments of the invention relate to a surveying apparatus in the form of a scanner comprising a beam deflection unit, such a beam deflection unit and a measuring method to be carried out with said surveying apparatus. The surveying apparatus comprises a radiation source for generating measurement radiation and a detector for receiving reflected measurement radiation, called reflection radiation for short, which was reflected at an object of interest, wherein measurement radiation and reflection radiation have substantially the same optical path. Situated in said optical path there is a beam deflection unit mounted rotatably about a rotation axis and serving for adjustably aligning the measurement radiation and for capturing the reflected radiation

Owner:HEXAGON TECH CENT GMBH

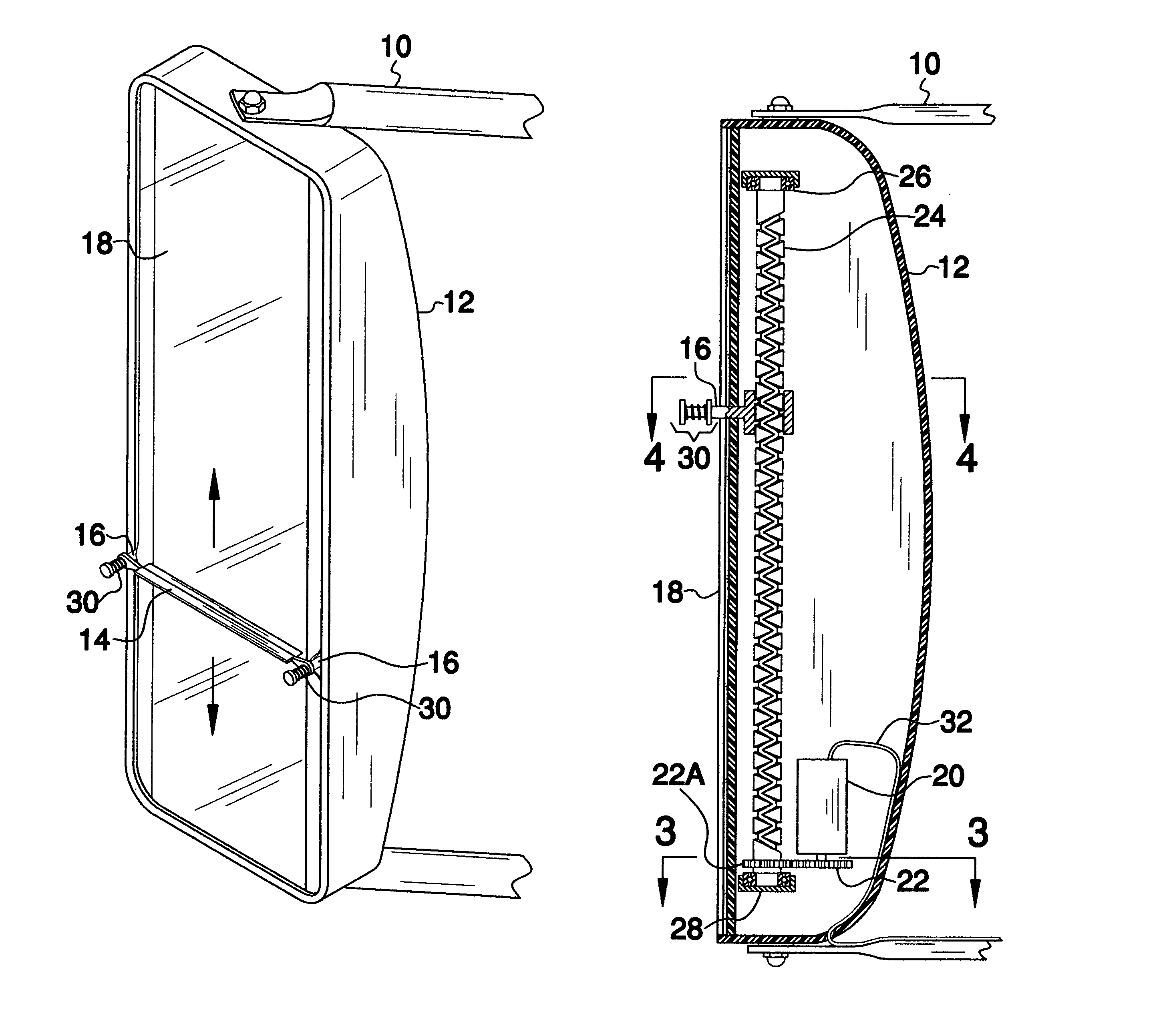

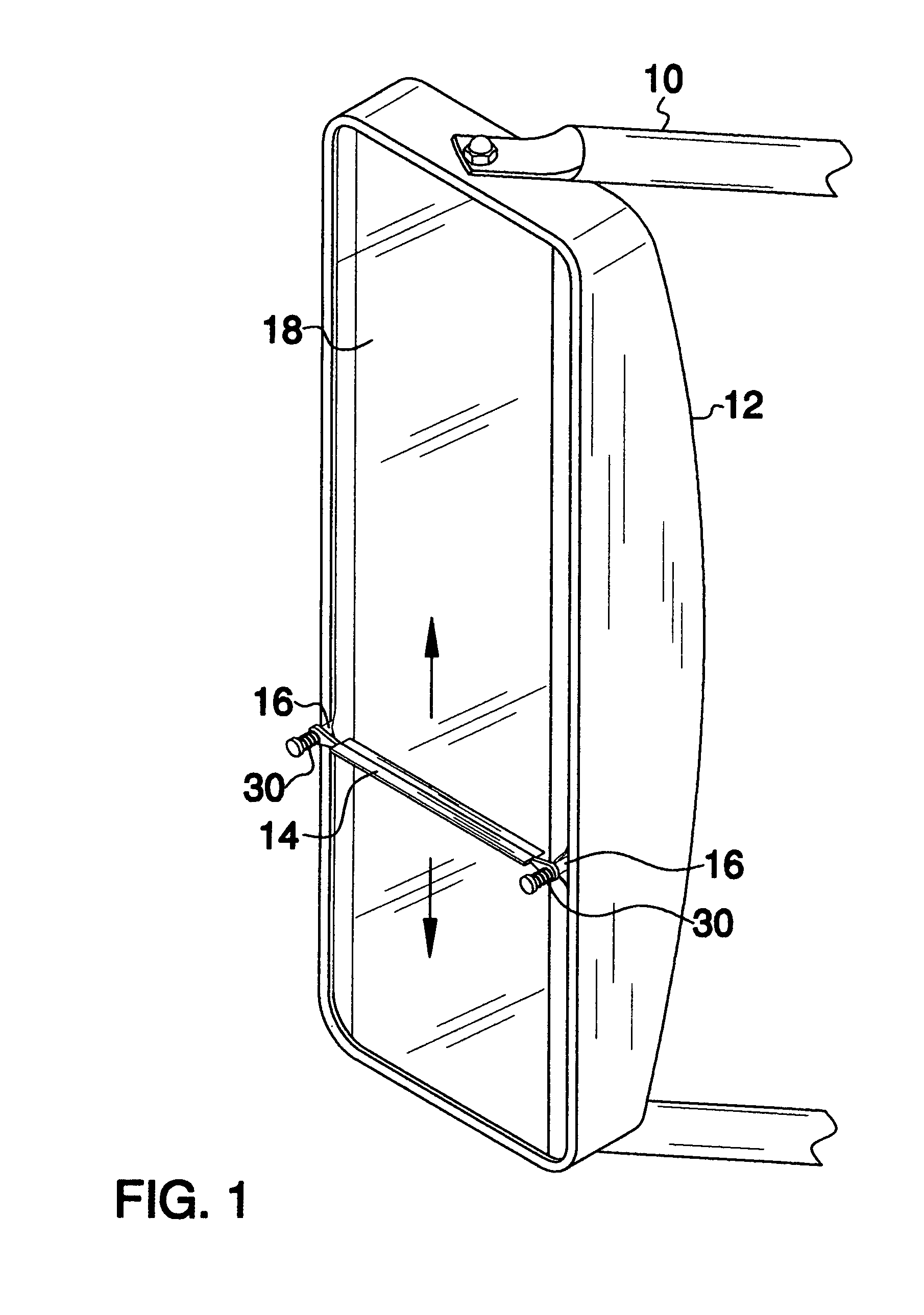

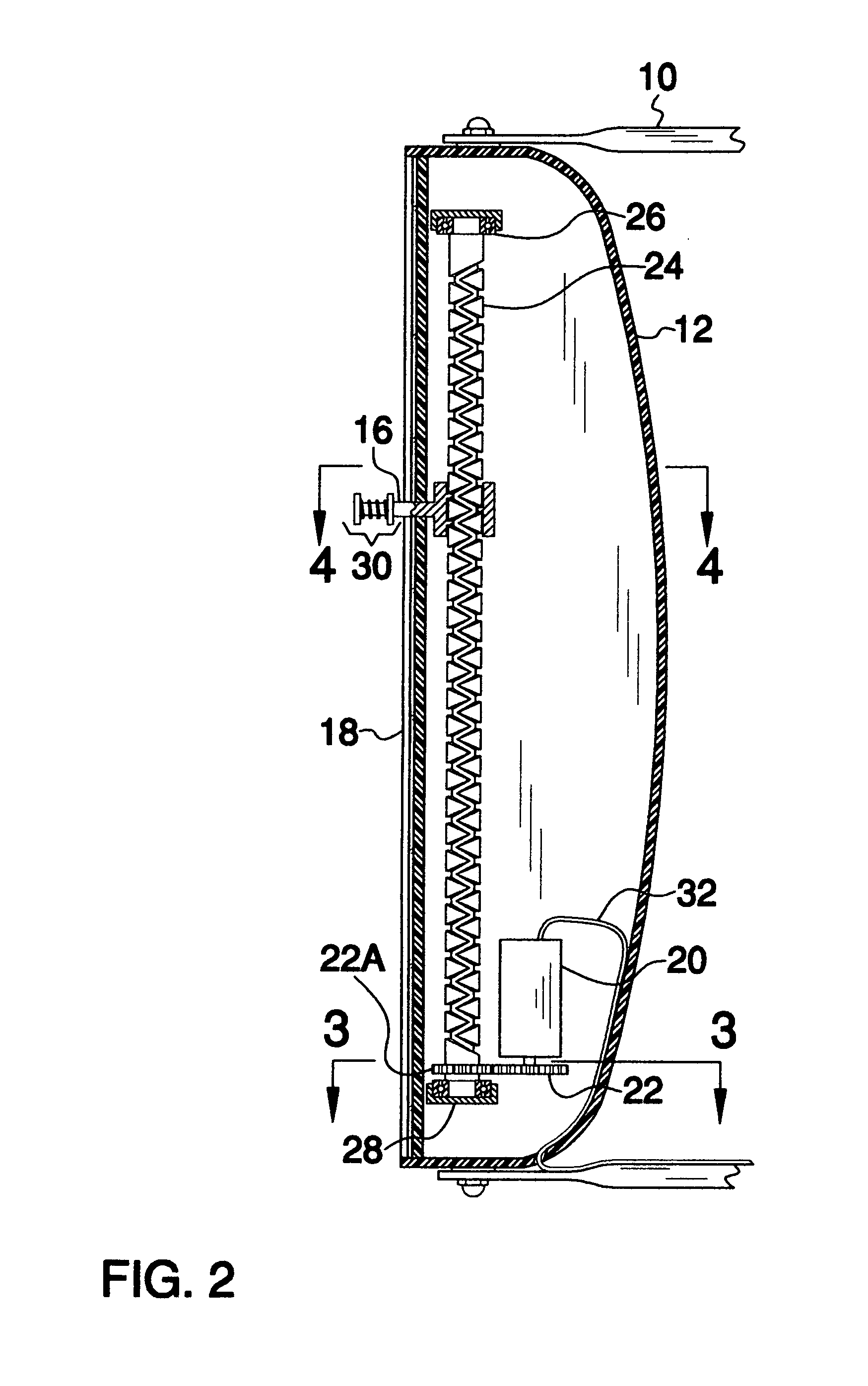

Rearview mirror wiper system

InactiveUS7574769B1Easy maintenanceLess susceptible to icingWindow cleanersVehicle cleaningMobile vehicleMotor home

In one aspect, the invention relates a rearview mirror wiper system suitable for use on, for example, large tractor-trailer trucks, delivery trucks, vans, motor homes, cars and other motor vehicles. The rearview wiper system of the present invention has many advantages over prior art systems. It ensures an even and adjustable pressure over the entire wiping surface, has a minimum of parts exposed to the elements so that it is less susceptible to icing and is easy for the user to maintain.

Owner:NEMETH GLENN

Automatic sheet fetching sheet fetching and stacking equipment of photovoltaic thin glass production line

ActiveCN103935765AEasy to moveRealize the function of picking and palletizingStacking articlesConveyor partsProduction lineThin glass

The invention discloses automatic sheet fetching sheet fetching and stacking equipment of a photovoltaic thin glass production line. The automatic sheet fetching sheet fetching and stacking equipment of the photovoltaic thin glass production line comprises a suction cup rack, a landing gear, a roll-over rack and a moving device. The roll-over rack can be arranged on the moving device in a rolling over mode, the landing gear can be arranged on the roll-over rack in a lifting mode, the suction cup rack is arranged on the landing gear, and the top of the suction cup rack is provided with a sucker cup. According to the equipment, the suction cup rack, the landing gear, the roll-over rack and the moving device can conduct sheet fetching on the photovoltaic glass from the bottom, and movement is convenient, roll-over sheet fetching and stacking is conducted, so that the sheet fetching sheet fetching and stacking function is reliably achieved.

Owner:山东元凯恒盛玻璃科技有限公司

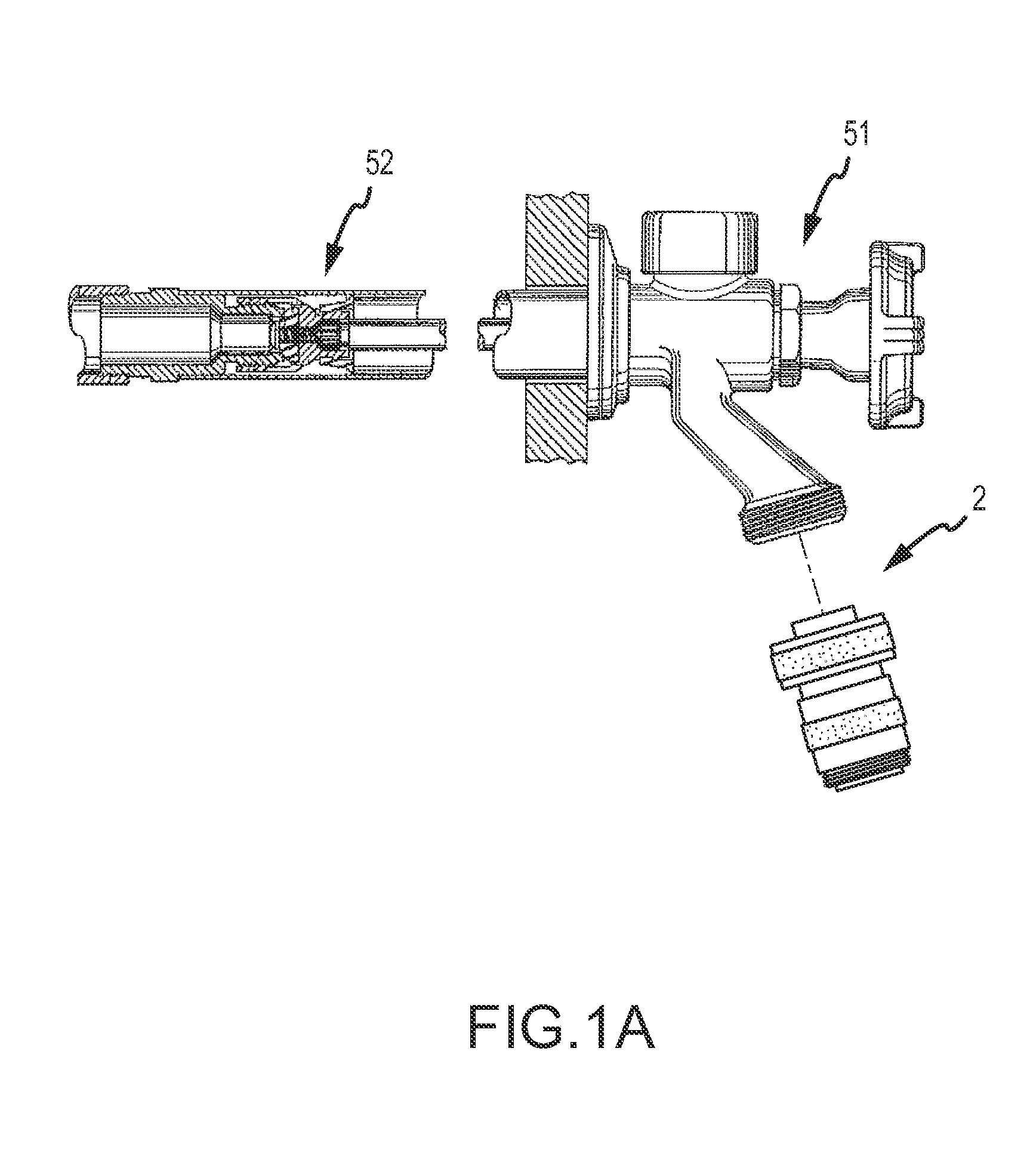

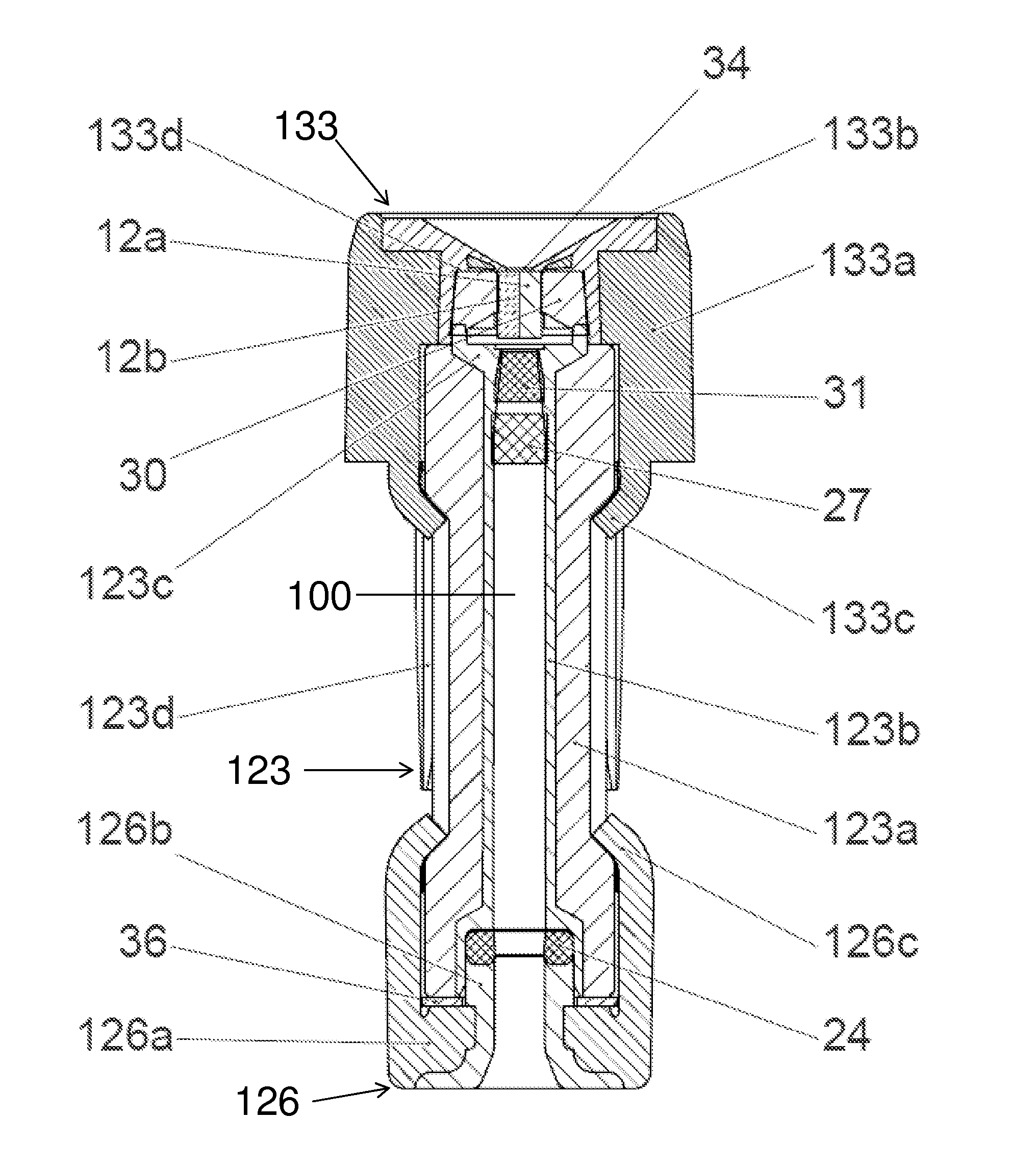

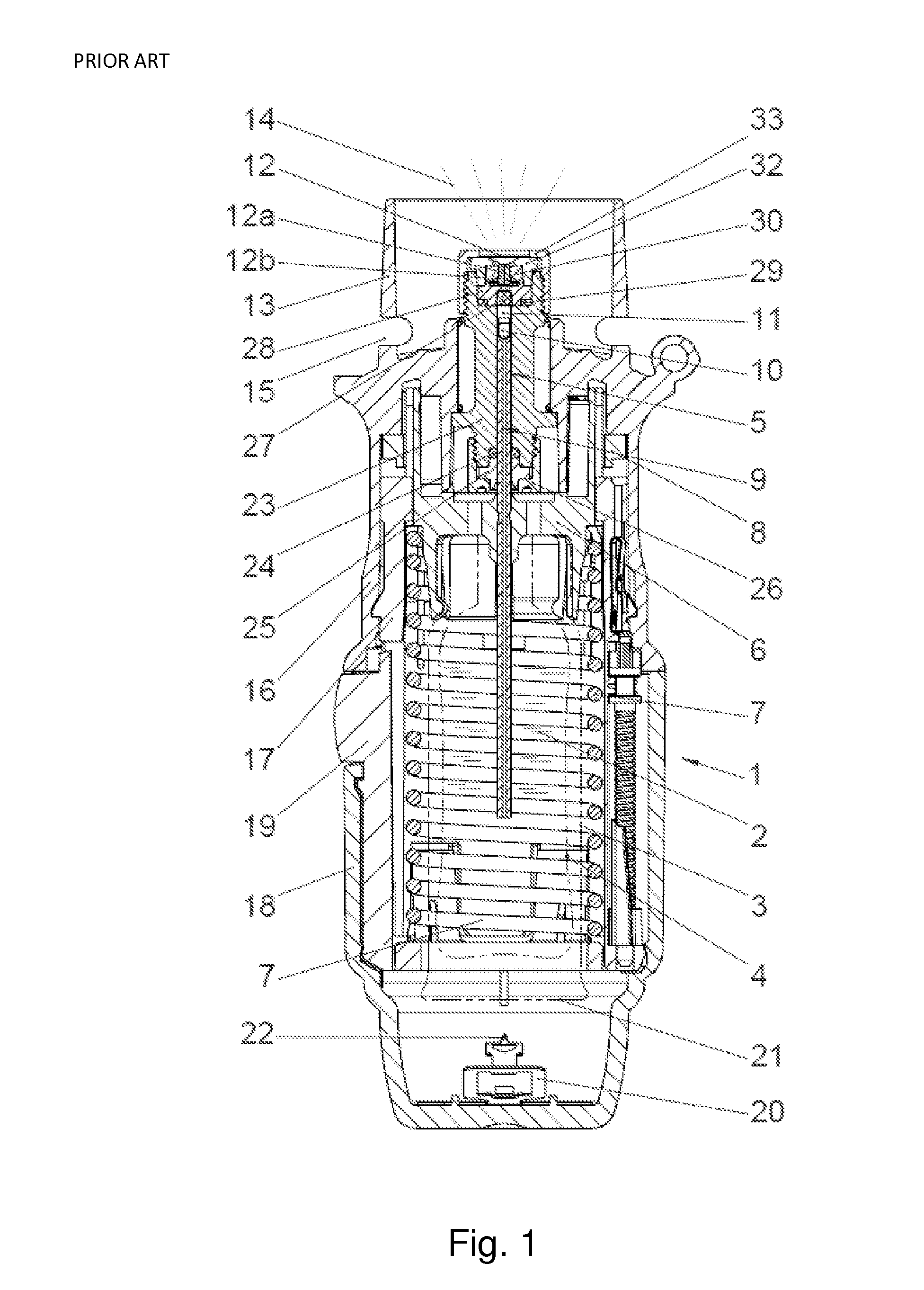

High-pressure chamber

ActiveUS9192734B2Achieves compatibilityAccurately meterSpray nozzlesMedical devicesCorrosionHigh pressure chamber

The invention relates to a high-pressure chamber for preferably atomizing or injecting metered amounts of fluid, such as pharmaceutical preparations. The components of the high-pressure chamber determining the strength thereof are made of a sintered metal body having plastic regions directly attached thereto. The plastic regions allow corrosion resistance and material compatibility of the interior of the high-pressure chamber and fluids placed under pressure therein. The shape of the sintered metal body provides the entire system with the rigidity required for high-pressure operation and with directly molded connection elements prescribing the type of connection to other components. The components of the high-pressure chamber determining the strength thereof are thereby deformed or crimped to each other, so that inexpensive and quick overall assembly processes are available.

Owner:BOEHRINGER INGELHEIM INT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com