Method of improving Al-Cu spot welding quality

A spot welding, quality technology, applied in welding media, welding/cutting media/materials, welding equipment, etc., can solve problems such as inability to obtain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

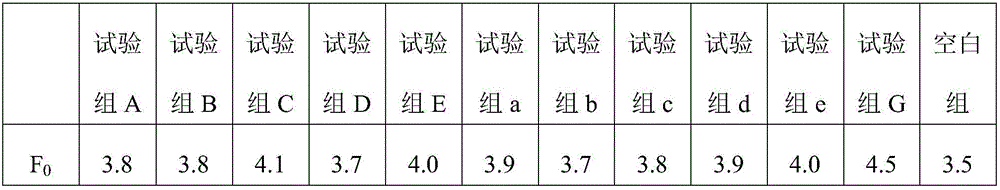

Examples

Embodiment Construction

[0016] One, the present invention will be further described below in conjunction with embodiment.

[0017] A method for improving Al-Cu spot welding quality, characterized in that it proceeds in the following steps:

[0018] Step 1, weighing Mn powder and Zn powder according to the mass ratio of 6~10:1~3;

[0019] Step 2, mixing the Mn powder and the Zn powder evenly in proportion, adding a volatile solvent to prepare an alloy powder, and the volatile solvent is acetone;

[0020] Step 3. Stir the alloy powder. When the viscosity is 0.5 to 0.55 Pa·s, scrape the alloy powder on the lap joint between the Al material and the Cu material to be welded. Alloy powder group layer is formed between the joints, the thickness of the alloy powder group layer on the surface of the Al material is 2 times the thickness of the alloy powder group layer on the surface of the Cu material, and the thickness of the alloy powder group layer on the surface of the Al material is the same as that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com