Method for increasing size of resistance spot weld nugget on thin-plate side of multilayer plates in different thickness

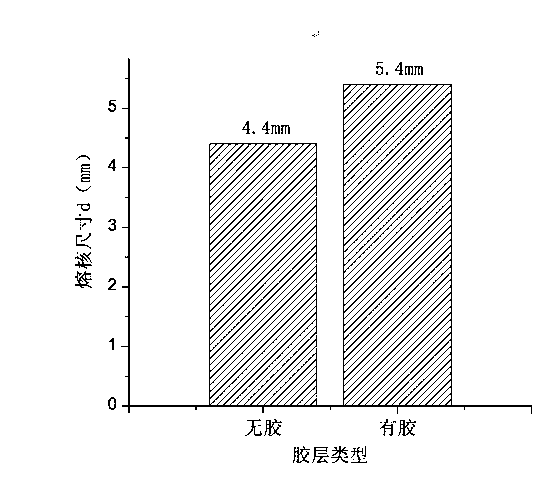

A technology of resistance spot welding and multi-layer boards, which is applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of undiscovered side nugget size of three-layer board and thin plate, and achieve the goal of increasing the nugget size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0030] The specific parameters of the material selected in this embodiment are as follows:

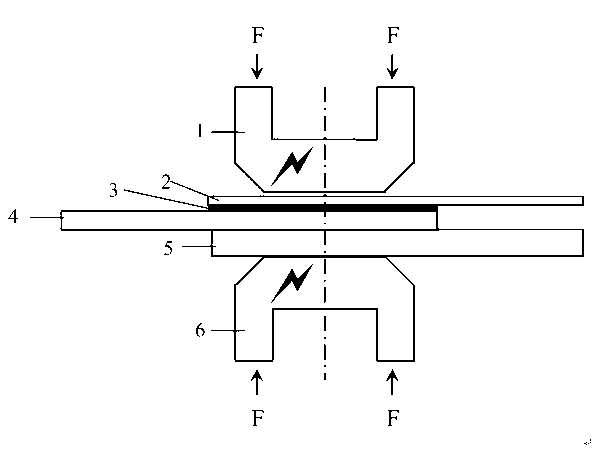

[0031] Both the upper electrode 1 and the lower electrode 6 are chromium-zirconium copper electrodes, and the diameter of the electrode end face is 5 mm.

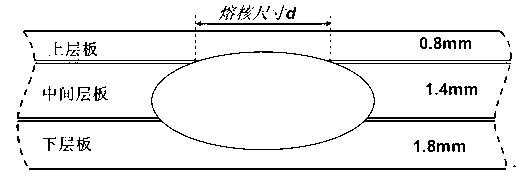

[0032] The upper steel plate 2 to be welded is double-sided galvanized low-carbon steel plate (mass percentage C: 0.037, Si: 0.018, Mn: 0.21, P: 0.01, S: 0.02, Al: 0.04, and the balance is Fe), and the thickness of the steel plate is 0.8 mm , double-sided coating thickness is 60g / m 2 。

[0033] The steel plate 4 to be welded in the middle layer is a doubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com