Methods of improving the elongation and shrinkage of the steering knuckle rod

A steering knuckle and elongation technology, which is applied to steering rods, steering mechanisms, vehicle components, etc., can solve problems such as high requirements on mechanical properties of steering knuckles, avoid mechanical performance degradation, reduce shear damage, and improve elongation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but the scope of implementation of the present invention is not limited thereto.

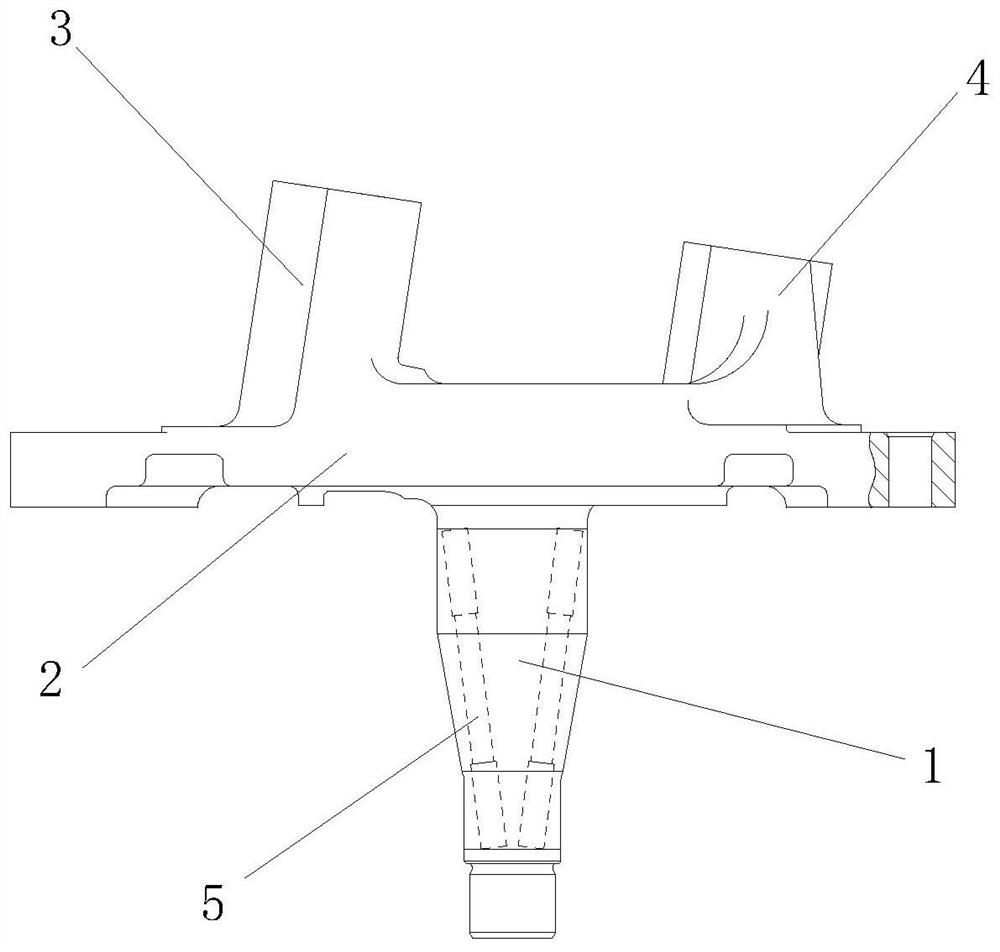

[0034] The steering knuckle processed in this embodiment is ZF 144 steering knuckle, and its structure is as follows image 3 shown. The test method for the elongation and shrinkage of the steering knuckle rod is carried out according to the detection method described above. The shape and position of the test bar 5 are as follows: image 3 shown. The steering knuckle processed according to the original technology is detected by the above-mentioned detection method, and the test rod 5 on the side close to the long ear 3 can meet the requirements, but the test rod 5 on the side near the short ear 4 does not meet the requirements. Therefore, this embodiment improves it by the following method.

[0035] Specifically, a forging blank is obtained by heating, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com