Multi-zone reactor with cyclone separator

A cyclone separator and reactor technology, which is applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large gas-particle mixed medium flow rate, unfavorable medium uniform distribution, and difficulty in achieving a uniform state, and achieve medium flow rate Fast, shorten the processing cycle, reduce the effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

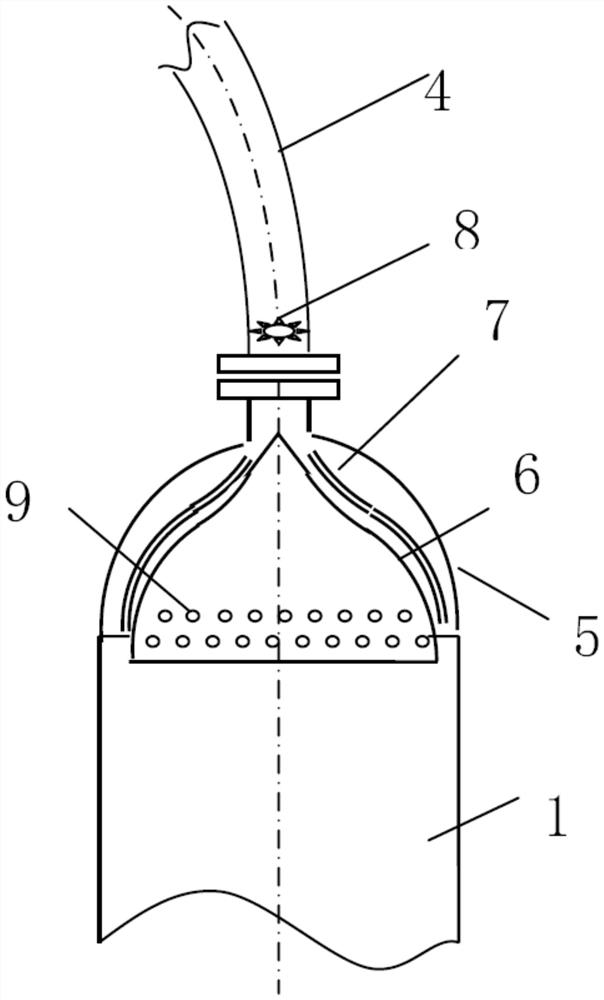

[0048] The multi-zone reactor with cyclone separator of present embodiment, as Figure 2 to Figure 4 As shown, it includes the main cylinder 1 and the auxiliary cylinder 2 arranged vertically, and the annular shell 4 for medium circulation is provided between the top of the main cylinder 1 and the top of the auxiliary cylinder 2, and the top of the main cylinder 1 and the The annular shell 4 is provided with a cyclone separator, and the cyclone separator includes a pre-rotator 8 arranged at a position close to the main cylinder 1 of the annular shell 4 and a swirler arranged on the inner top of the main cylinder 1, the pre-rotator The device 8 includes a plurality of swirl plates, which form a cage structure, and each swirl plate is in the shape of a spiral guide along the axial direction of the annular shell 4, that is, the pre-rotator 8 is comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com