Fuzzy control method for cooperating type CO2 welding circuit-shorting transition and welding machine thereof

A technology of short-circuit transition and fuzzy control, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of poor anti-interference ability, complicated operation, inability to adapt to disturbance, etc., and achieve strong anti-interference ability, simple operation process, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

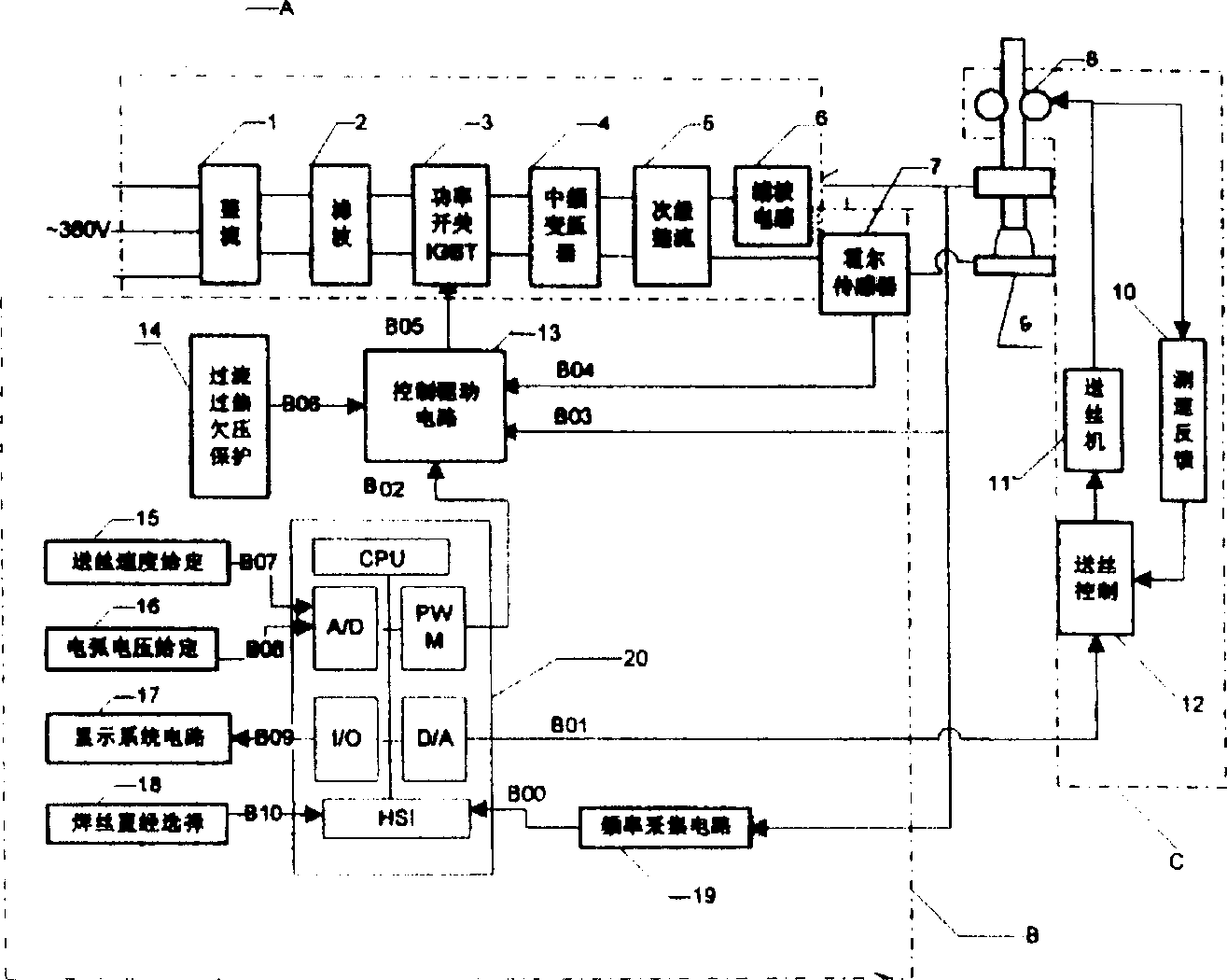

[0029] like image 3As shown, a welding machine according to a specific embodiment of the present invention is mainly composed of three parts structurally: welding power supply main circuit A, wire feeding circuit C and control circuit B with 8098 single-chip microcomputer as the control center. Among them, the main circuit A of the welding power supply adopts a full-bridge inverter circuit with IGBT as the power switching device, which is mainly composed of a rectifier circuit 1, a filter circuit 2, a switching power device (IGBT) 3, an intermediate frequency transformer 4, a secondary rectifier circuit 5, The filter inductor 6 is formed, and its working principle is as follows: After the three-phase AC 380V power supply passes through the rectifier circuit 1 and the filter circuit 2, a 540V direct current is obtained at the output end of the filter circuit 2, and then converted into a frequency of about 20KHz by the switching power device 3 intermediate frequency alternating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com