Speed-regulating hydraulic coupler transmission device of large-power composite gear capable of speeding up front and rear gear

A hydraulic coupling and compound gear technology, which is applied in transmission devices, fluid transmission devices, pump devices, etc., to achieve the effects of saving energy, improving operating efficiency, and improving transmission quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

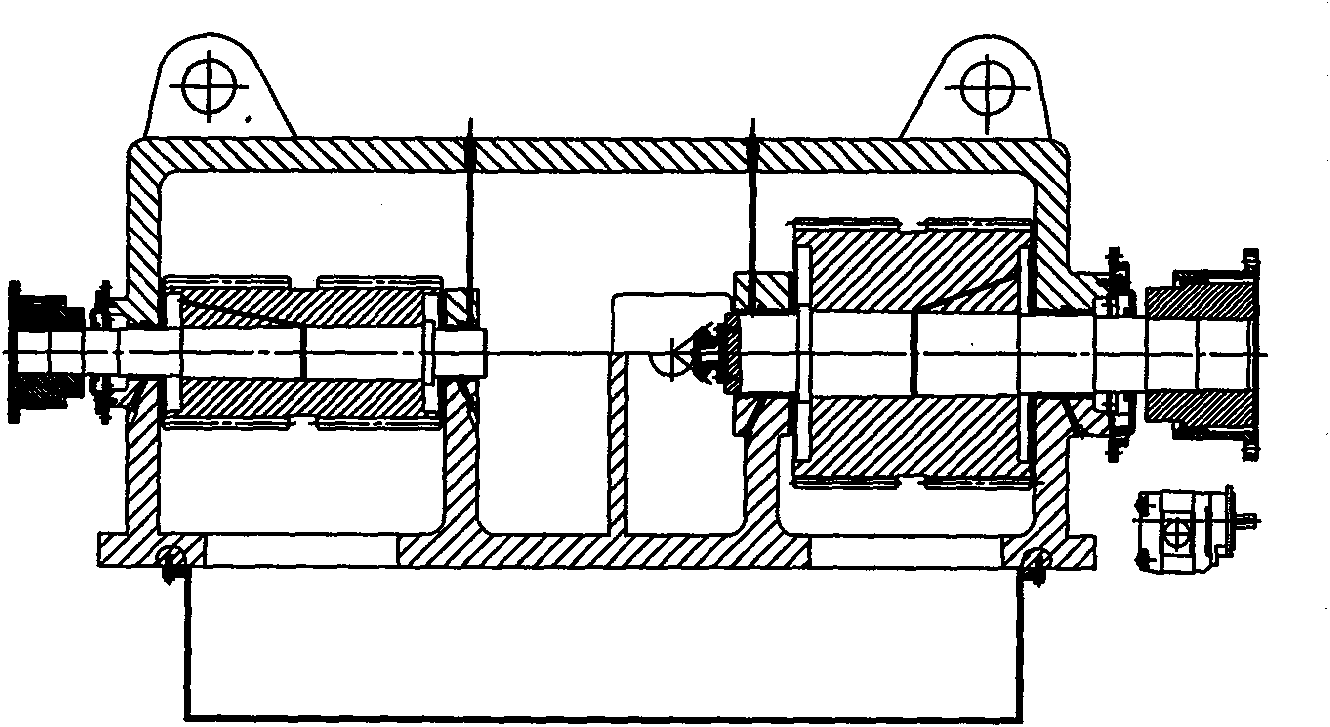

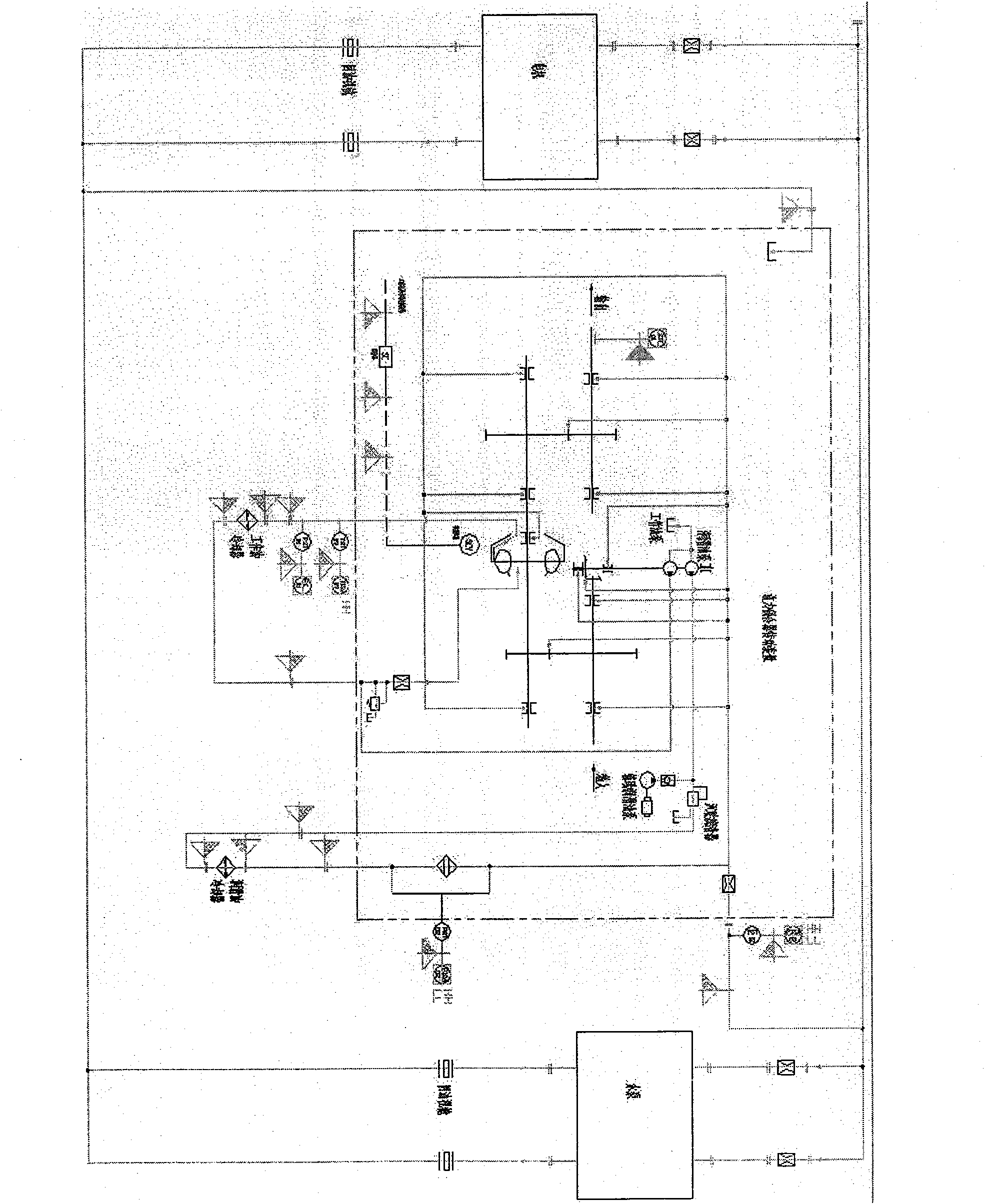

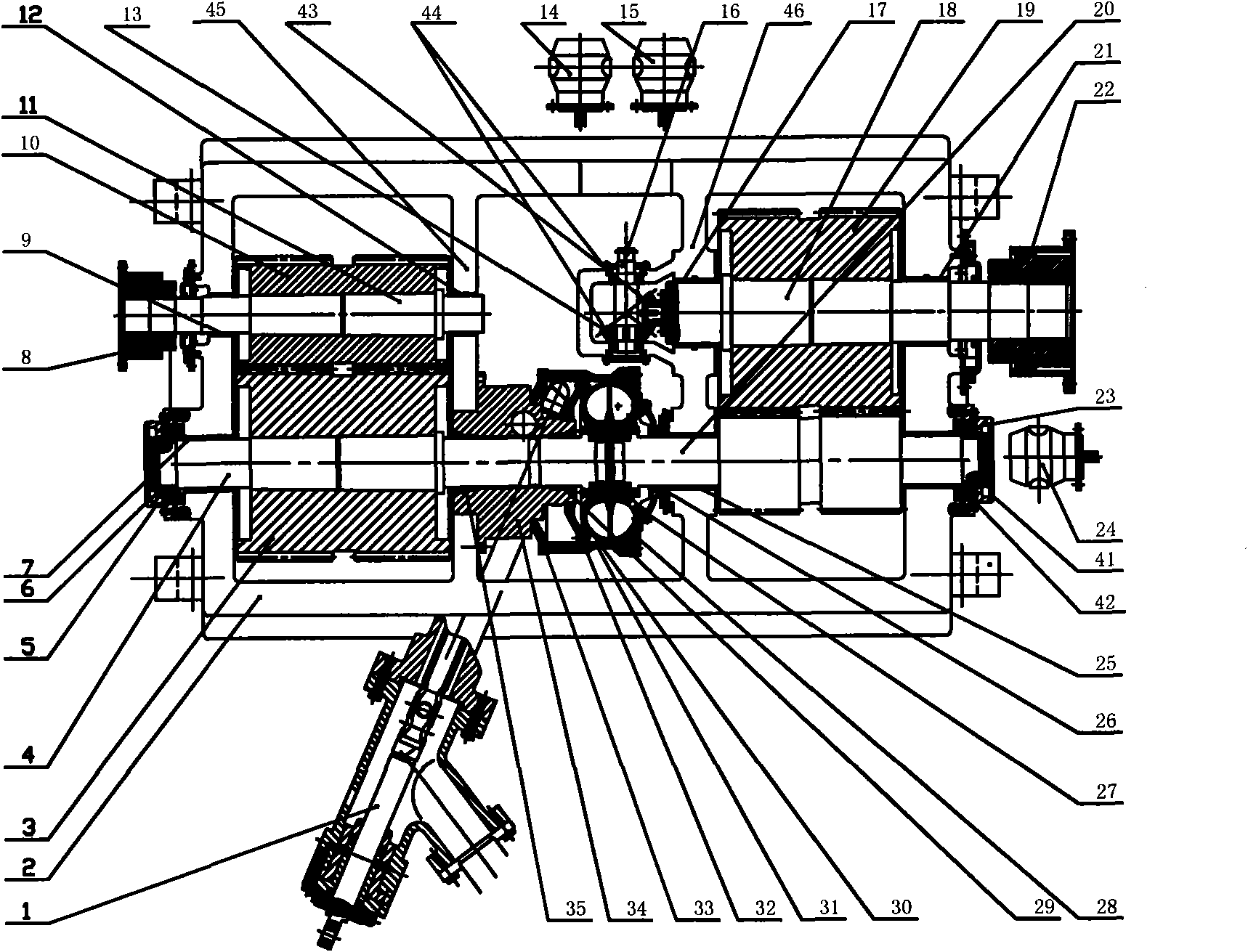

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] According to the performance parameters of the KSB type motor and the large-scale boiler water supply pump, the transmission scheme of the speed-regulating hydraulic coupling is determined as the compound gear speed-up before the speed-up and the speed-up after the speed-up. The rated power transmitted by the invention is 12000kw, the rated input speed is 3000r / min, and the rated output speed is 10000r / min. The purpose of this transmission scheme is to improve the input speed and transmission power capacity of the hydraulic coupling, while reducing the specification of the coupling and meeting the requirements of the input speed of the boiler water pump.

[0020] Determine the original design parameters of the hydraulic coupling based on the performance parameters of the KSB type motor and the large boiler water supply pump: rated transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com