A hydraulic design method for reducing a multi-stage pump lift curve hump

A head curve and hydraulic design technology, which is applied to components, pumps, and calculations of pumping devices used for elastic fluids, can solve problems such as reducing system reliability and pumps cannot operate normally, and reduce losses and energy Loss, effect of good matching relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

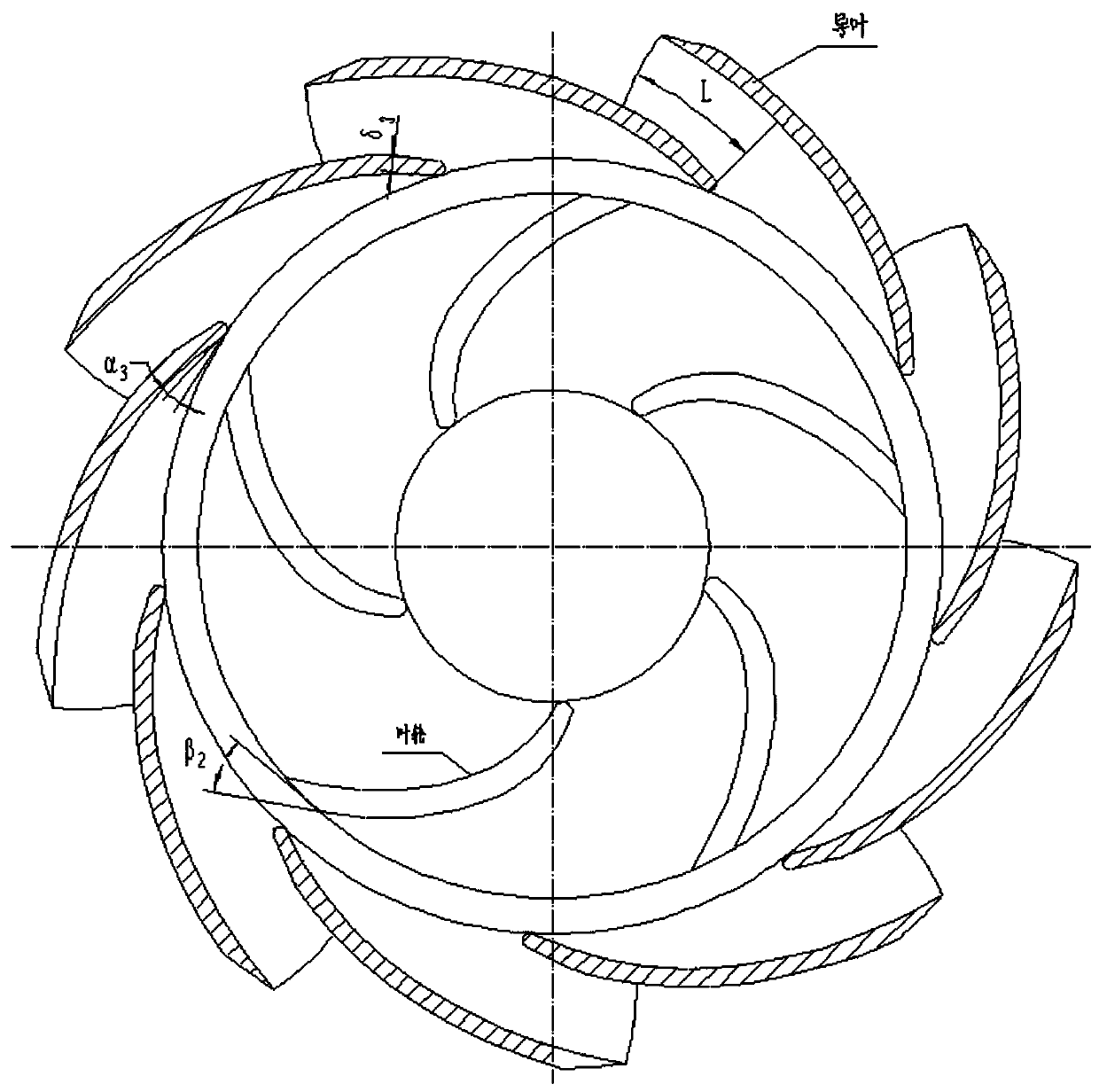

[0074] Embodiment: select multi-stage pump product performance parameter flow rate Q=85m 3 / h, head H=80m, speed n=2950r / min, gravity acceleration g=10m 2 / s, take β 2 =23°,δ 3 =3mm, calculate the hydraulic parameters of impeller and guide vane according to the above-mentioned content of the invention as follows:

[0075] Specific speed n s Calculated as follows:

[0076]

[0077] In the formula:

[0078] no s — specific speed;

[0079] Q—flow rate, cubic meter per second;

[0080] H—head, m;

[0081] n—rotational speed, rev / per minute;

[0082] no s =((3.65×2950×(85 / 3600)^0.5) / (80^0.75))=62;

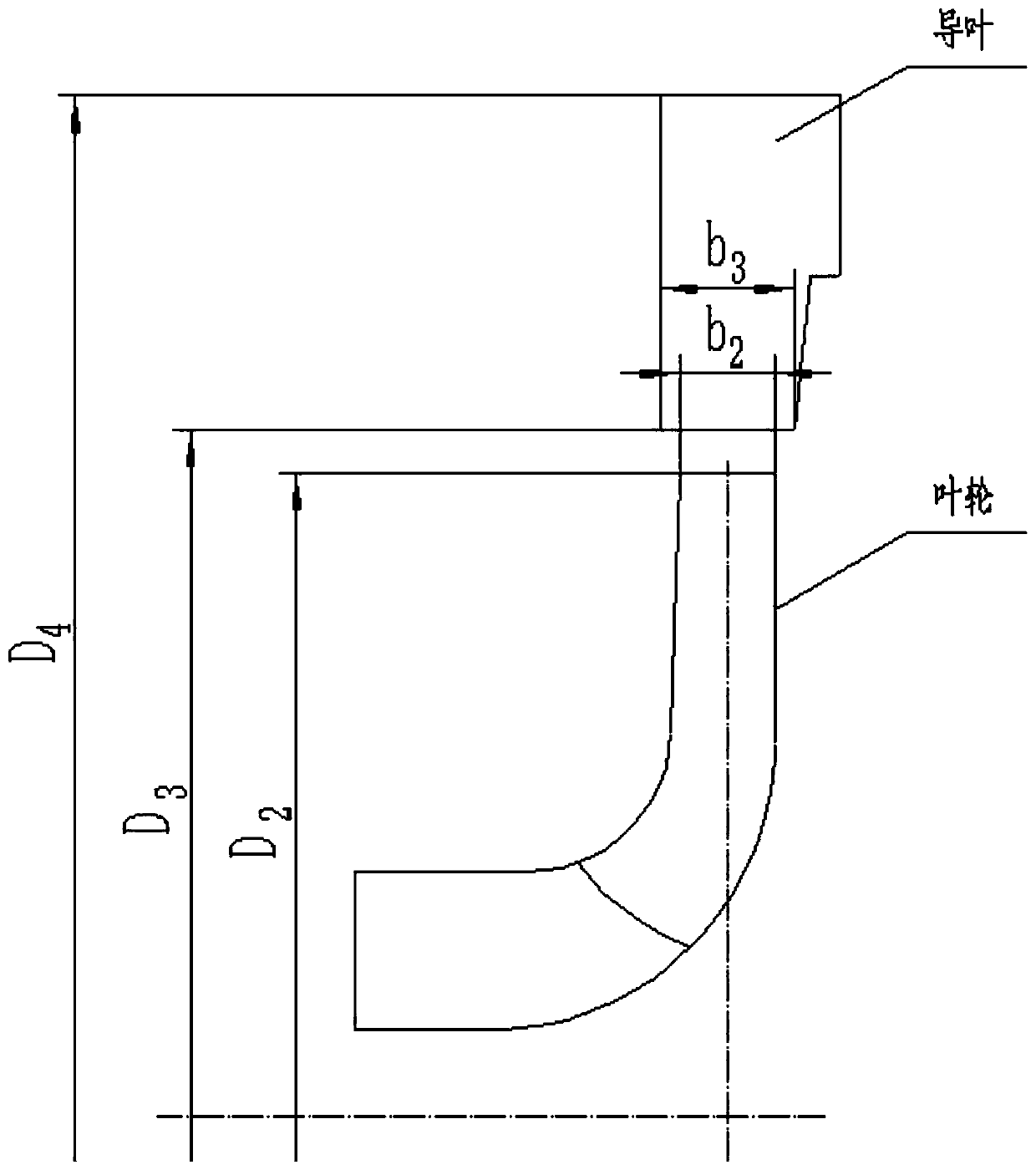

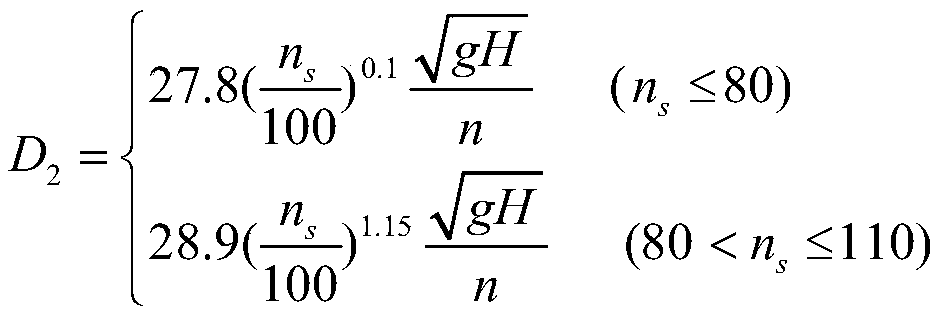

[0083] Impeller outlet diameter D 2 Calculated as follows:

[0084]

[0085] In the formula:

[0086] D. 2 —Impeller outlet diameter, m;

[0087] no s — specific speed;

[0088] g—gravitational acceleration, m / square second;

[0089] H—head, m;

[0090] n—rotational speed, rev / per minute;

[0091] D. 2 =(27.8×((62 / 100)^0.1)×(10×80)^0.5) / 2950=0.255m;

[0092] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com