Automatic distributing system and construction method of single-line tunnel lining trolley

A lining trolley and material distribution system technology, applied in tunnel lining, tunnel, shaft lining, etc., can solve the problems of high labor intensity, unsuitable control, and concrete quality problems of layered and divided warehouses, and achieve the reduction of humps and construction cold joints , Improve the level of pouring technology, reduce the effect of manual labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

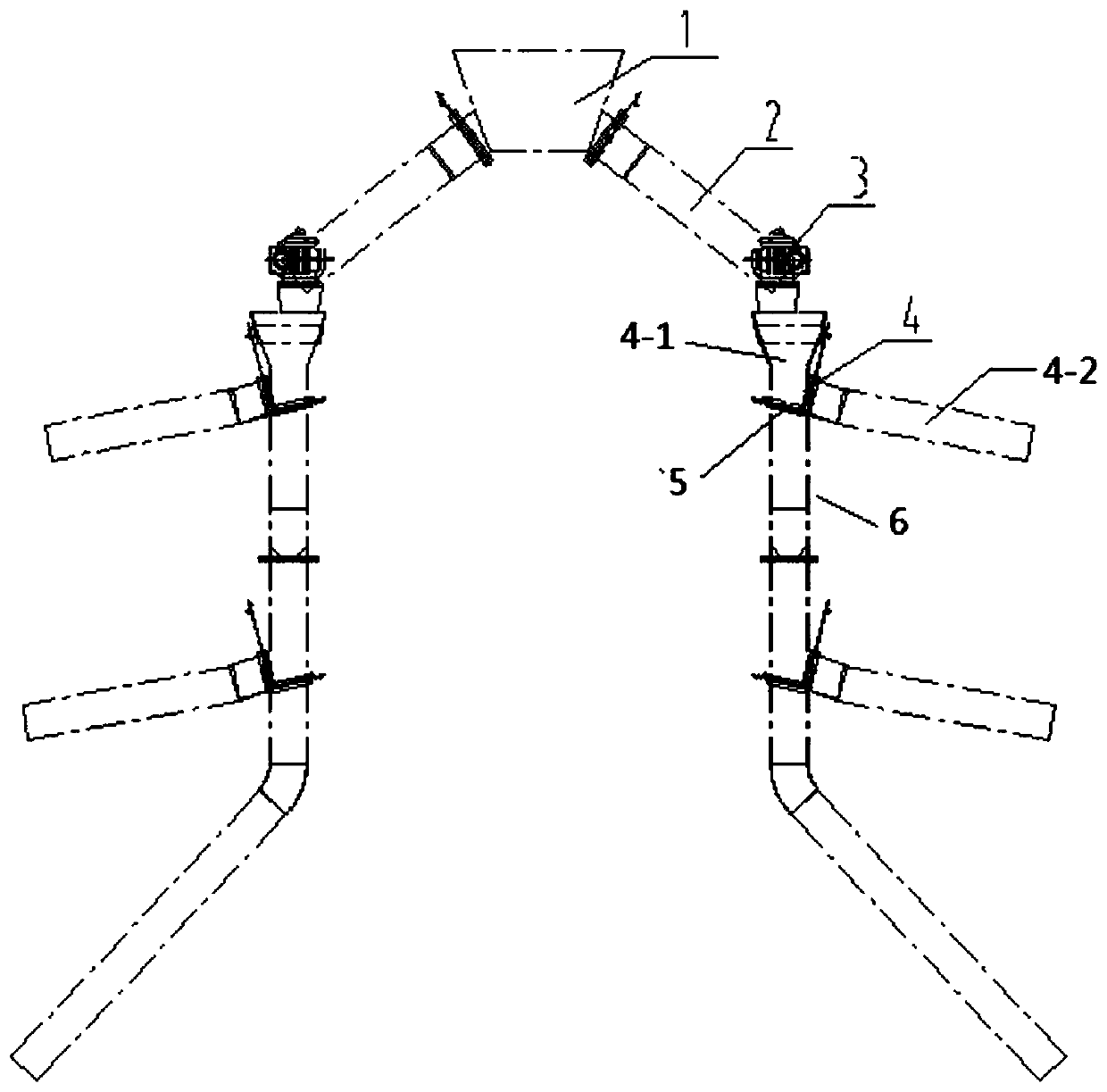

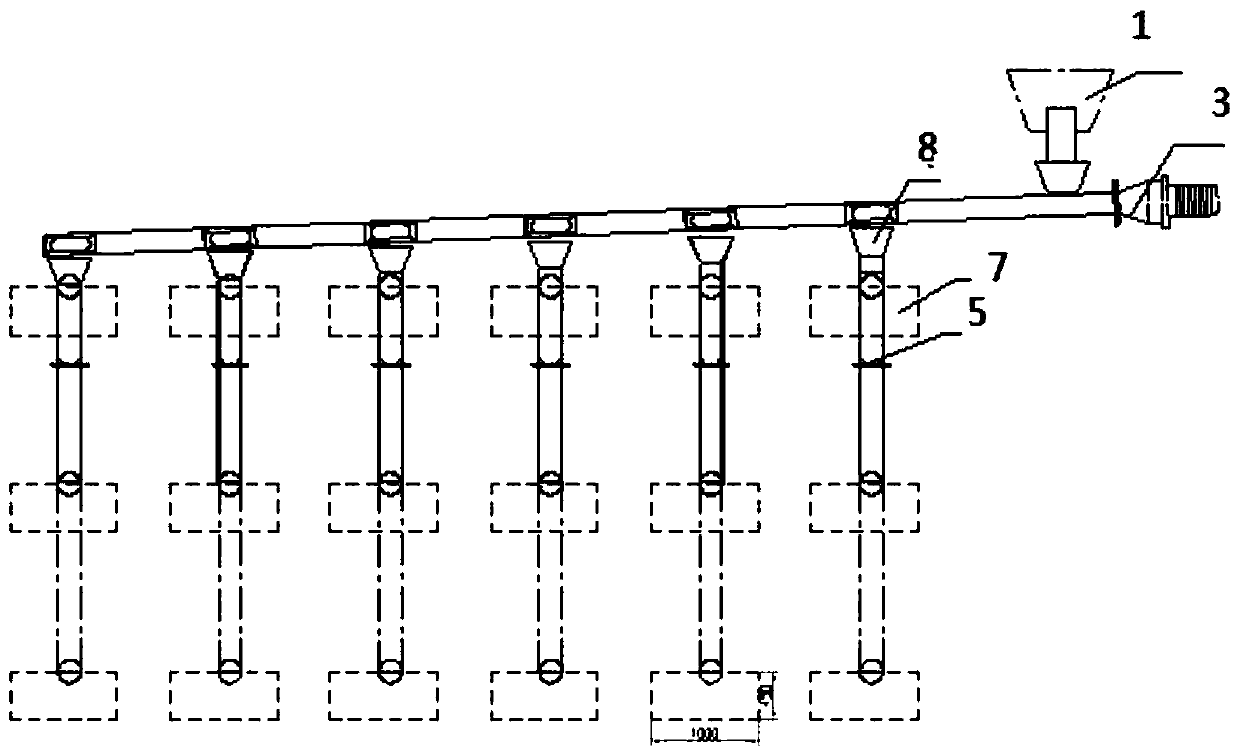

[0028] The selected shaftless screw conveyor 3 is WS350, and the diameter of the feeding pipe is 300mm; the inserting plate 5 is a steel plate with a thickness of 5mm. The diameter upper opening is 159mm, and the lower opening is the distribution pipe 2 of 125mm.

[0029] Step 1. After the formwork trolley is assembled, transport the material collection port 1 and the shaftless screw conveyor 3 to the trolley; for the convenience of processing personnel to install, welding can be done under the second window and on the third window on the left and right sides of the trolley door beam 5mm thick steel plate to add two layers of operating platform;

[0030] Step 2. Install the above-mentioned single-line tunnel lining trolley automatic distribution system;

[0031] Step 2.1. According to the position of the concentrated hopper on the top layer, add longitudinal I-beams between the two cross beams at the top of the trolley, and weld the top-layer collecting port 1 to the I-beams ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com