Full-tooth-width line-contact helical bevel gear tooth structure

A spiral bevel gear, line contact technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, components with teeth, etc., can solve the problem of poor oil-containing performance of tooth surface lines, affecting gear transmission performance, poor bearing capacity, etc. problem, to achieve the effect of good oil-containing performance of the tooth surface, low noise, and improved transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

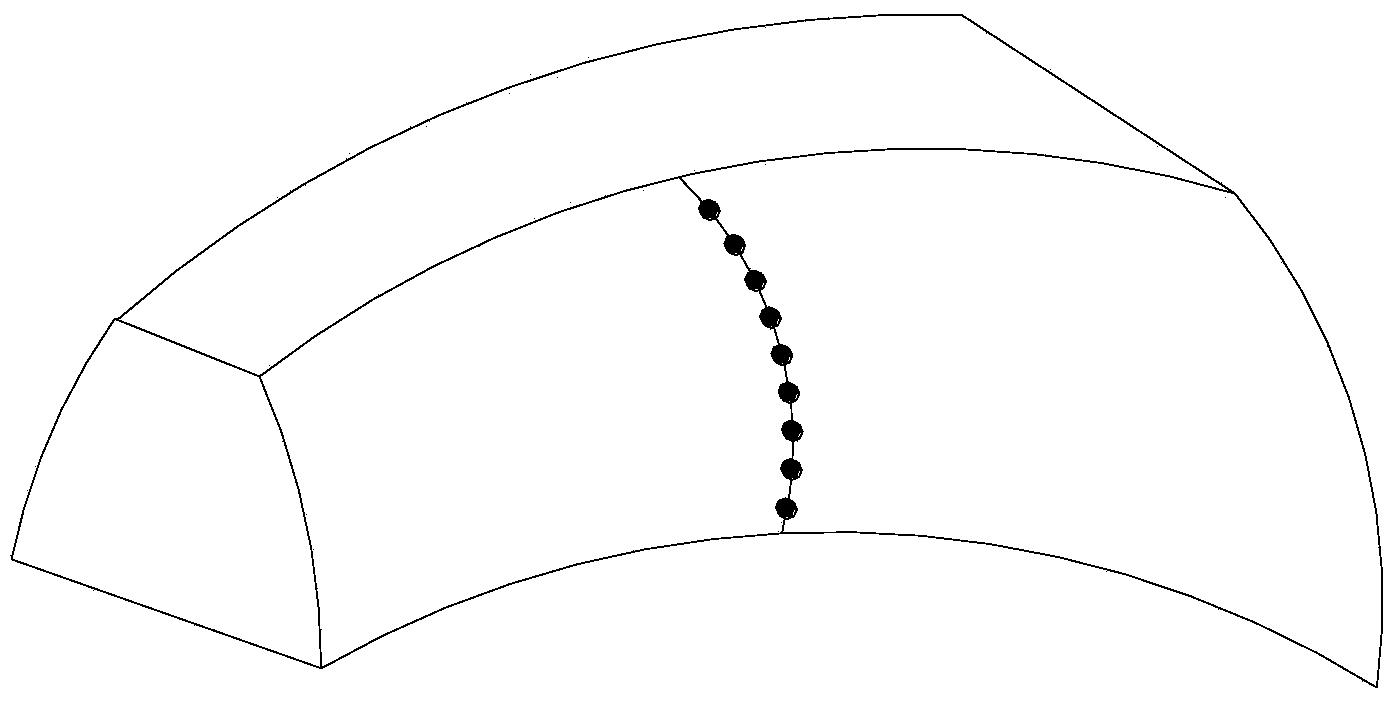

[0023] as attached figure 2 As shown, a full tooth width line contact spiral bevel gear tooth structure is characterized in that: the tooth surface of the spiral bevel gear is a full arc along the tooth length direction;

[0024] The tooth surfaces on both sides of the spiral bevel gear teeth along the tooth length direction are convex full arcs on one side, and the other side tooth surfaces are concave full arcs, which are convex along the tooth height direction. surface.

[0025] The arc of the tooth surface is a circular arc or an involute or a cycloid or a logarithmic helix.

[0026] as attached image 3 and 4 As shown, the texture of the tooth surface of the gear tooth is a well-shaped texture composed of shallow narrow grooves along the tooth length direction and intersecting shallow narrow grooves along the tooth height direction,

[0027] The well-shaped texture is rectangular or rhombus.

[0028] The distance between the grooves of the well-shaped pattern is 0.0...

Embodiment 2

[0030] as attached Figure 5 As shown, the texture on the tooth surface of the gear tooth can also be a closed circular curved texture.

[0031] The distance between the closed ring-shaped curved grooves is 0.01-3mm, and the depth of the grooves is 0.005-0.05mm.

[0032] The production process of the tooth surface with full tooth width contact of the gear is to first use the traditional spiral bevel gear milling machine to rough the tooth groove, and then generate the NC machining program according to the point data of the tooth surface and use the NC machining center to finish the tooth surface , in order to obtain tooth flanks with full tooth width contact. Among them, the well-shaped texture is processed by the numerical control machining center on the tooth surface, and then the tooth surface is processed by the tooth surface enhancement process (such as polishing, grinding, shot peening, etc.) to ensure the tooth surface is smooth.

[0033] The present invention provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com