In fact, in order to ensure the uniform load of the gear teeth, the

gear manufacturing needs to include the modification of the tooth direction and even the tooth profile, which can increase the cost by at least 3 times. Gear Manufacturers Association Standard) 10 and a half to 12 and a half or DIN (German Industrial Standard) 6 to 4 meshing precision, that is, gears, shafts, bearings and housings of corresponding precision levels are required to achieve, which is compared with the so-called "standard" "Accuracy grade" is DIN7 grade (corresponding to AGMA9 and a half or Chinese

national standard grade 7), the cost of the rear transmission box is at least 3 times higher, making the high-torque traditional parallel co-rotating intermeshing twin-screw machine very expensive

[0053] Second, the driven gear on the shorter overhanging shaft itself is a high-load final gear, and the smaller

pitch circle

diameter causes its wear time life to be insufficient in the "one-to-one"

gear transmission. Compared with "one-to-one"

gear transmission, the "many-to-one"

gear transmission has double (2-3 times) increase in the number of gear teeth meshing per revolution, that is, the double (2-3 times) increase in wear time and shortened

life expectancy. , making the gear conspicuously less durable

In order not to reduce the life, the load on the

tooth surface must be reduced, thereby reducing the

torque density (M / a 3 ), which becomes the prior art

high torque density (M / a 3 ) The technical contradiction of the power distribution shaft (wheel)

system and another significant technical shortcoming

[0054] Thirdly, it is known that the

pitch circle

diameter of the gears on the shorter outrigger shaft is severely limited by the center distance a and is smaller, and due to the space occupied by the longer outrigger shaft, it is reasonable to arrange symmetrically or roughly symmetrically Described " many to one " can only reach " three to one " at most, so screw rod 1 has limited described prior art

high torque density (M / a 3 ) The power distribution shaft (wheel)

system continues to increase the

torque density (M / a 3 )

[0055] Fourth, so far, the continuous improvement of the torque

bearing capacity of the two outstretched shafts (as the shaft itself) has been achieved by continuously replacing them with special steels with higher and higher heat treatment strengths (—— two screw rods similar situation), which leads to a substantial increase in the cost of steel and / or tooling for the two outrigger shafts and is yet another reason why

high torque tailside transmissions become expensive

However, the adoption of the two synchronous transmission gears requires high gear transmission accuracy due to the requirement of

load sharing, that is, the drive components are more expensive at this time

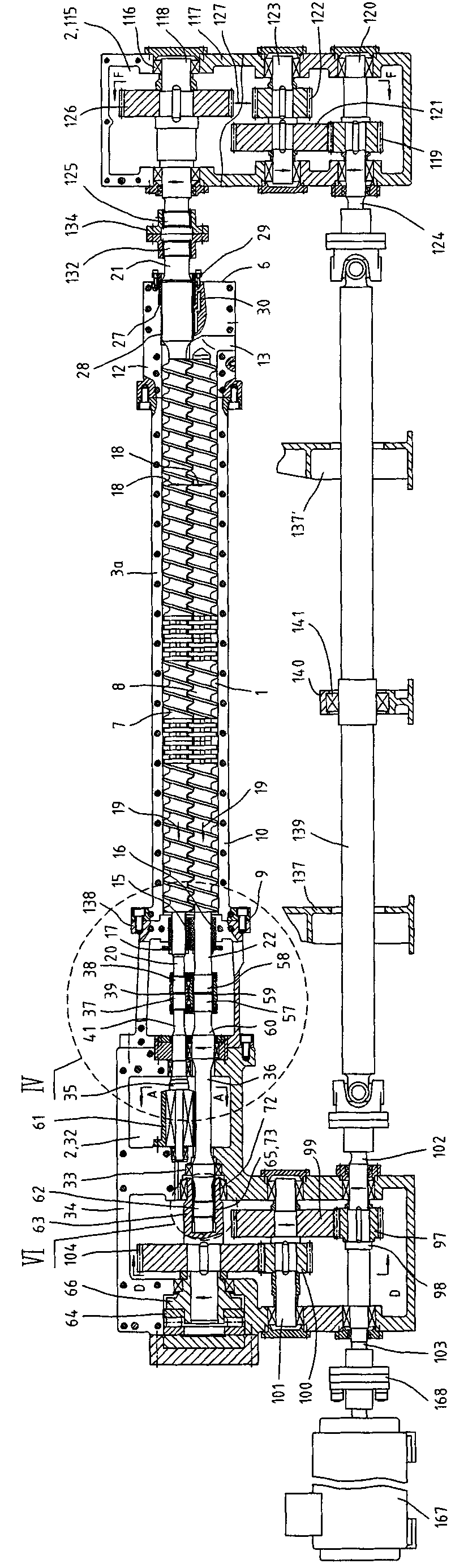

[0091] In summary, the traditional parallel co-rotating intermeshing twin-screw machines for compounding or compounding extrusion of plastic materials such as plastics, and the anti-traditional ones suggested by German patent applications DE2040065-A, DE102006060739-A1 and DE102008029130-A1 Parallel co-rotating intermeshing twin-screw machines, due to the inherent technical defects of parallel co-rotating intermeshing continuous compounding or compounding extrusion devices and their drive components, it is difficult to economically and durably achieve large torque densities (M / a 3 ), that is, 10Nm / cm 3 Above, and continue to increase the torque density (M / a 3 ) For the complete machine that adopts the drive

assembly of the prior art power distribution shaft (wheel)

system and the integral screw or the downstream modularized screw of the

processing section, the complete machine faces three structural bottlenecks or a fatigue strength

bottleneck—the structural

bottleneck That is, the

bottleneck of the gear transmission capacity of the power distribution shaft (wheel) system, the minimum outer

diameter d of the backward overhanging section of the two screw rods and the forward overhanging section of the two overhanging shafts R Minimum outside diameter d on bottleneck, longer outrigger shaft LA

Bottleneck, the fatigue strength bottleneck is the strength obstacle formed by the concentration of tensile stress at the dangerous section, which leads to a significant decrease in the

fatigue limit; while continuing to increase the torque density (M / a 3 ) For the drive

assembly of the prior art power distribution shaft (wheel) system and the complete machine of the full-length modular screw in the

processing section, at least the drive

assembly faces three structural bottlenecks or one fatigue strength bottleneck—namely The bottleneck of the gear transmission capacity of the power distribution shaft (wheel) system, the minimum outer diameter d of the forward extension section of the two extension shafts R Minimum outside diameter d on bottleneck, longer outrigger shaft LA

Bottleneck, the fatigue strength bottleneck is the strength barrier formed by the concentration of tensile stress at the dangerous section, which leads to a significant decrease in the

fatigue limit Login to View More

Login to View More  Login to View More

Login to View More