Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

623 results about "Torque density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torque density is a measure of the torque-carrying capability of a mechanical component. It is the ratio of torque capability to volume and is expressed in units of torque per volume. Torque density is a system property since it depends on the design of each element of the component being examined and their interconnection.

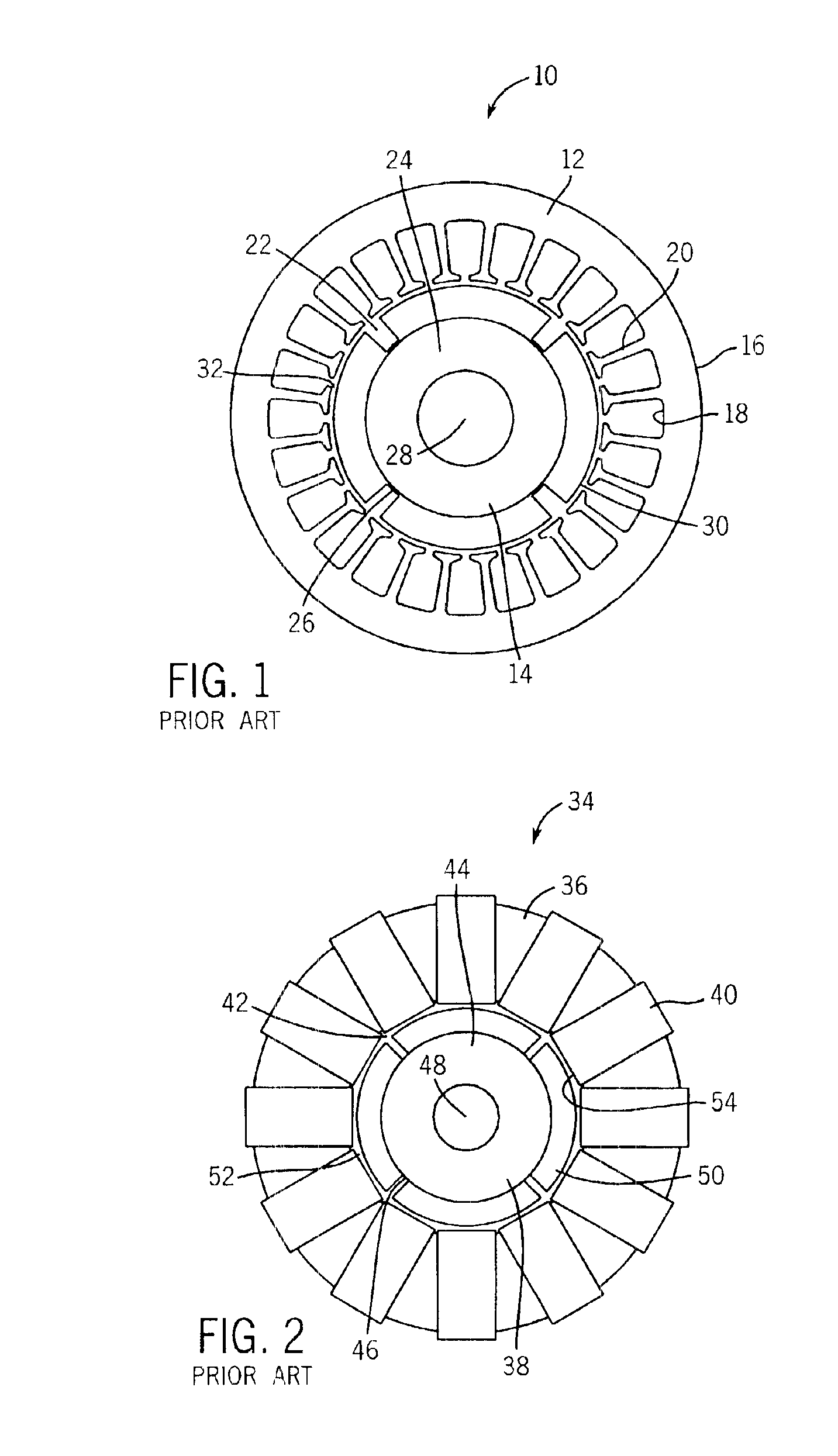

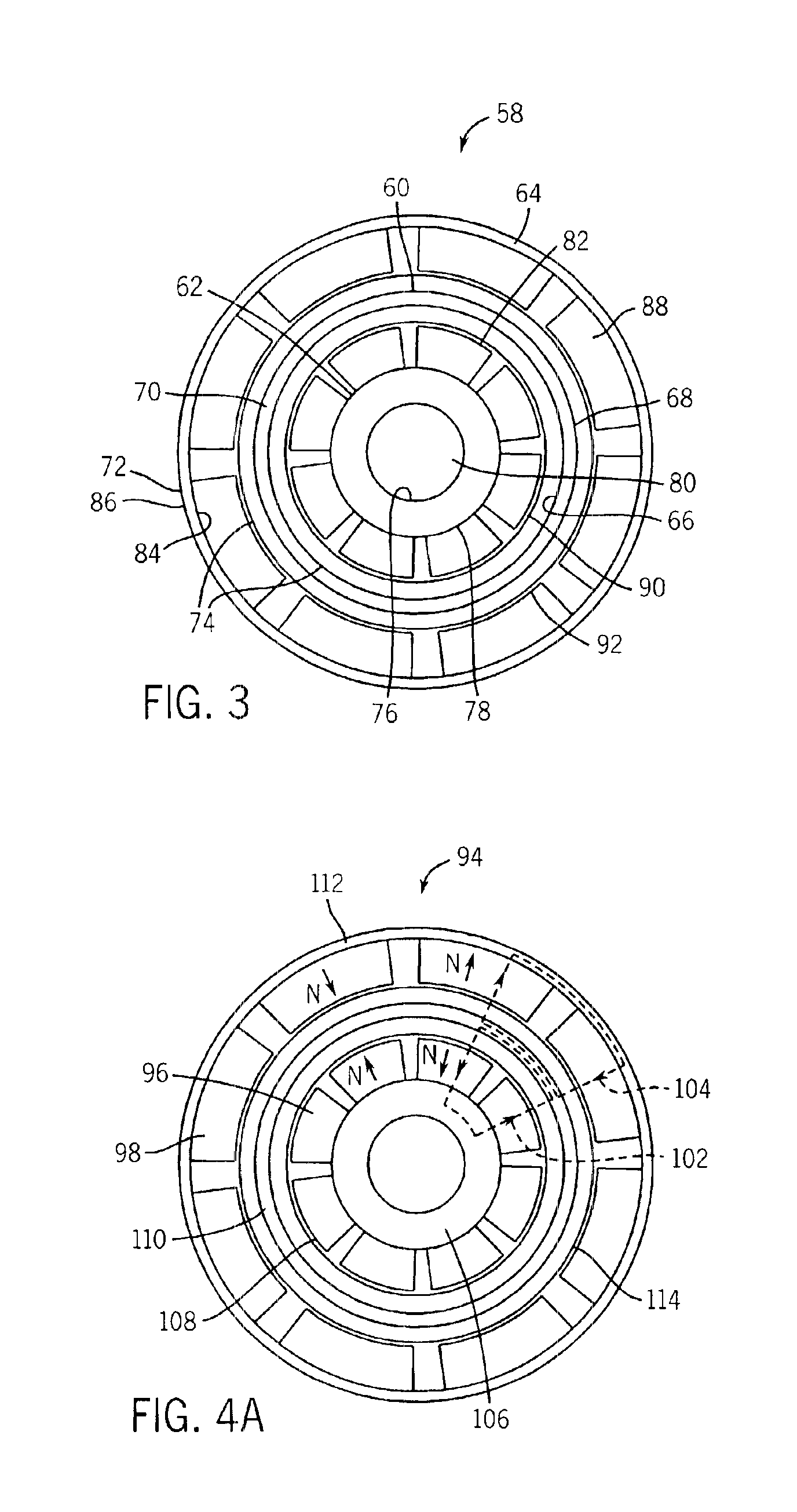

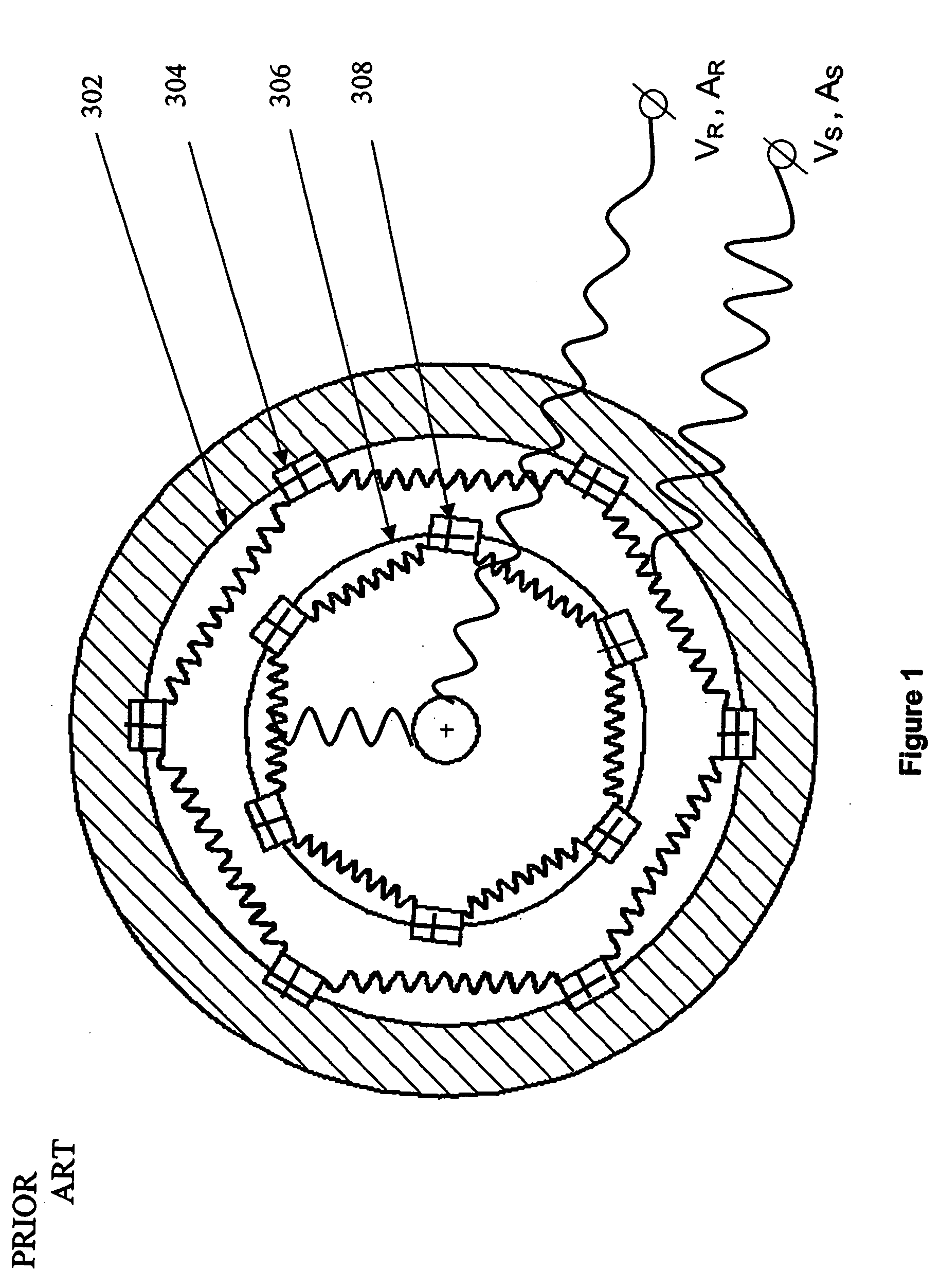

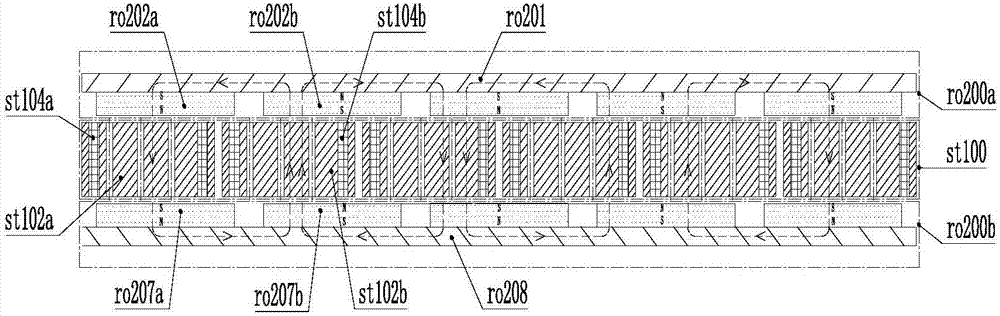

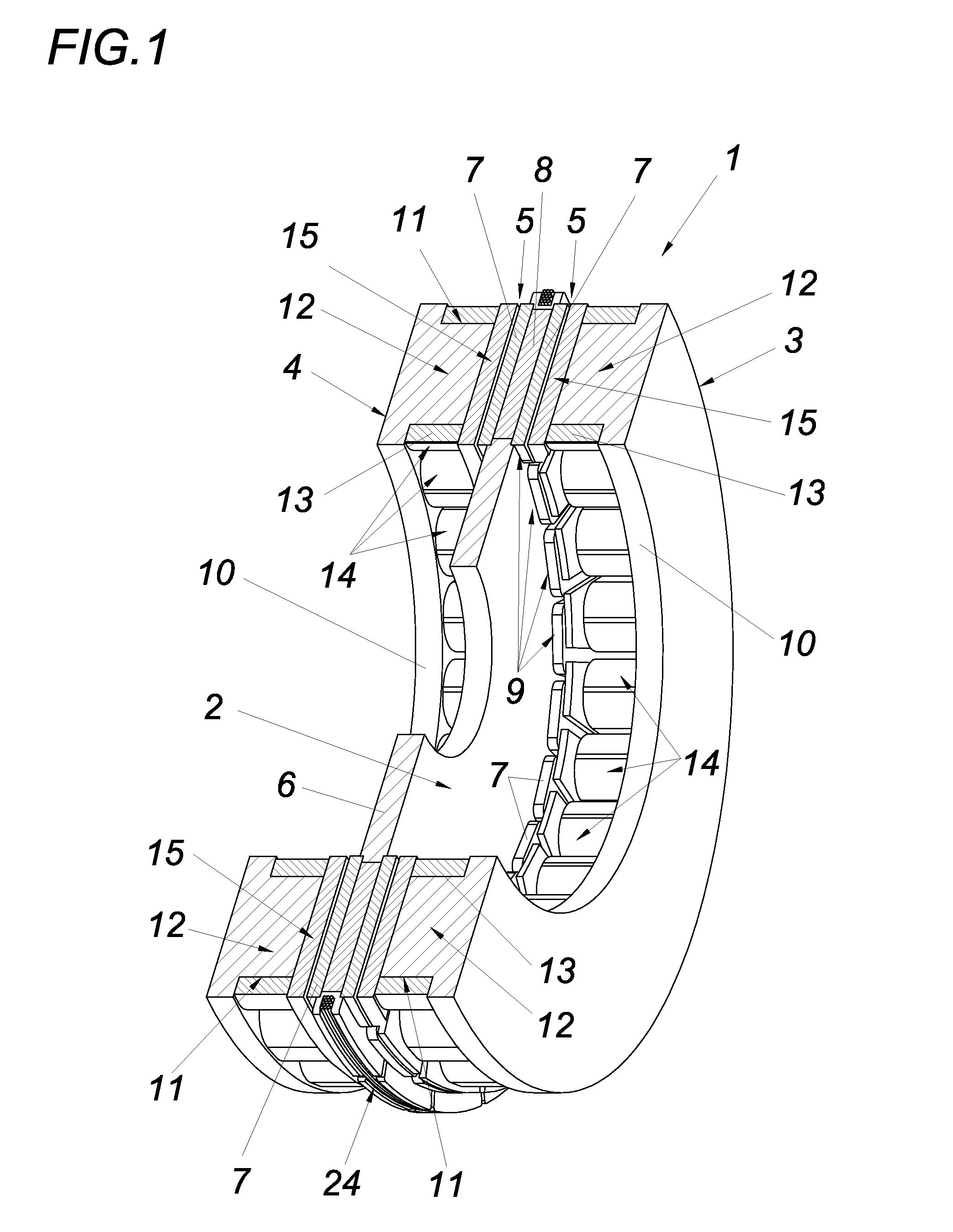

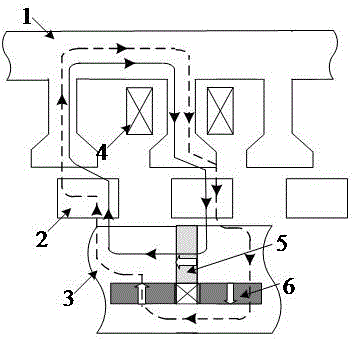

Dual-rotor, radial-flux, toroidally-wound, permanent-magnet machine

InactiveUS6924574B2Increased torque densityReduce the cost of the whole machineSynchronous generatorsMagnetic circuit rotating partsSurface mountingElectric machine

The present invention provides a novel dual-rotor, radial-flux, toroidally-wound, permanent-magnet machine. The present invention improves electrical machine torque density and efficiency. At least one concentric surface-mounted permanent magnet dual-rotor is located inside and outside of a torus-shaped stator with back-to-back windings, respectively. The machine substantially improves machine efficiency by reducing the end windings and boosts the torque density by at least doubling the air gap and optimizing the machine aspect ratio.

Owner:WISCONSIN ALUMNI RES FOUND

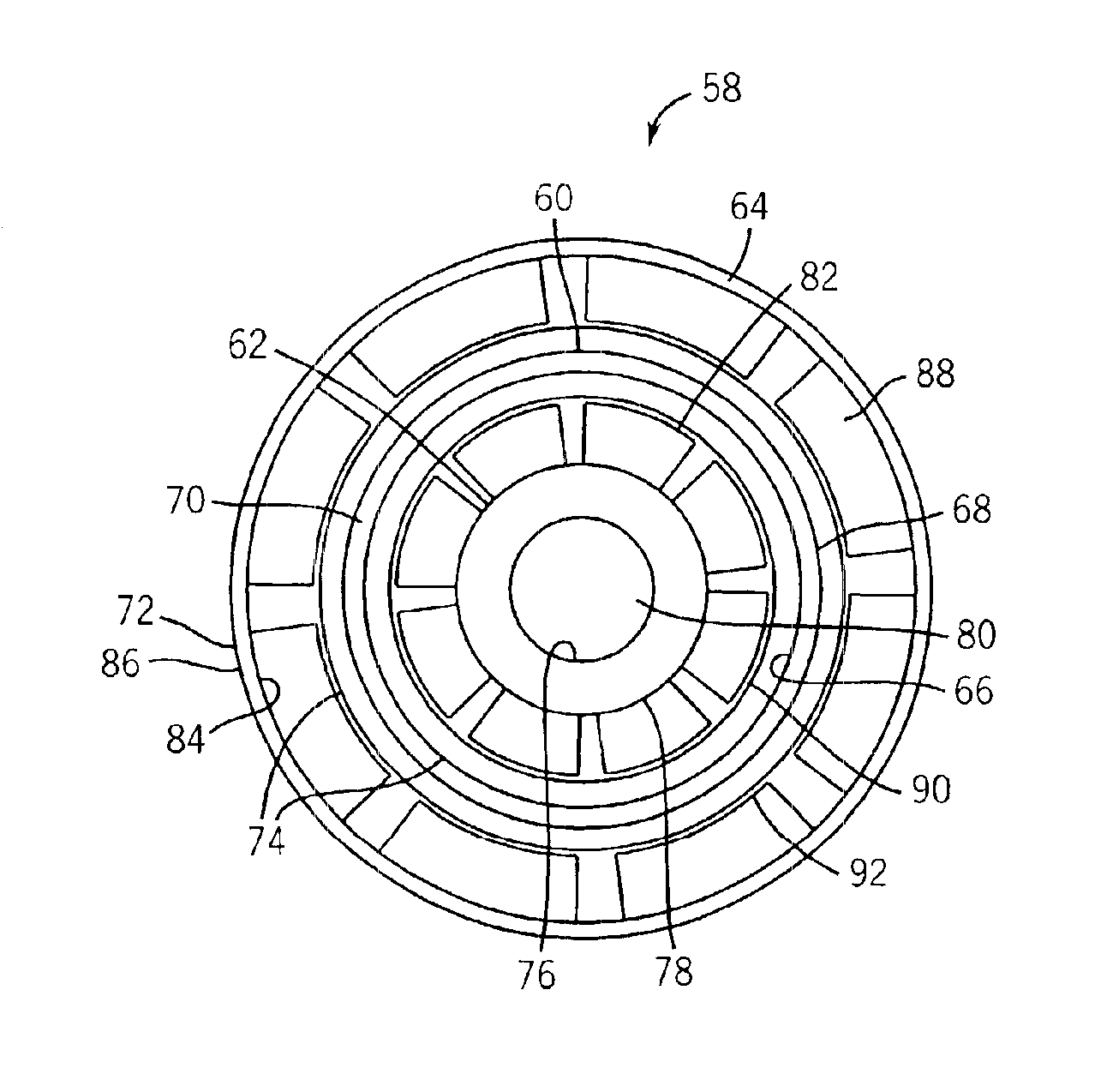

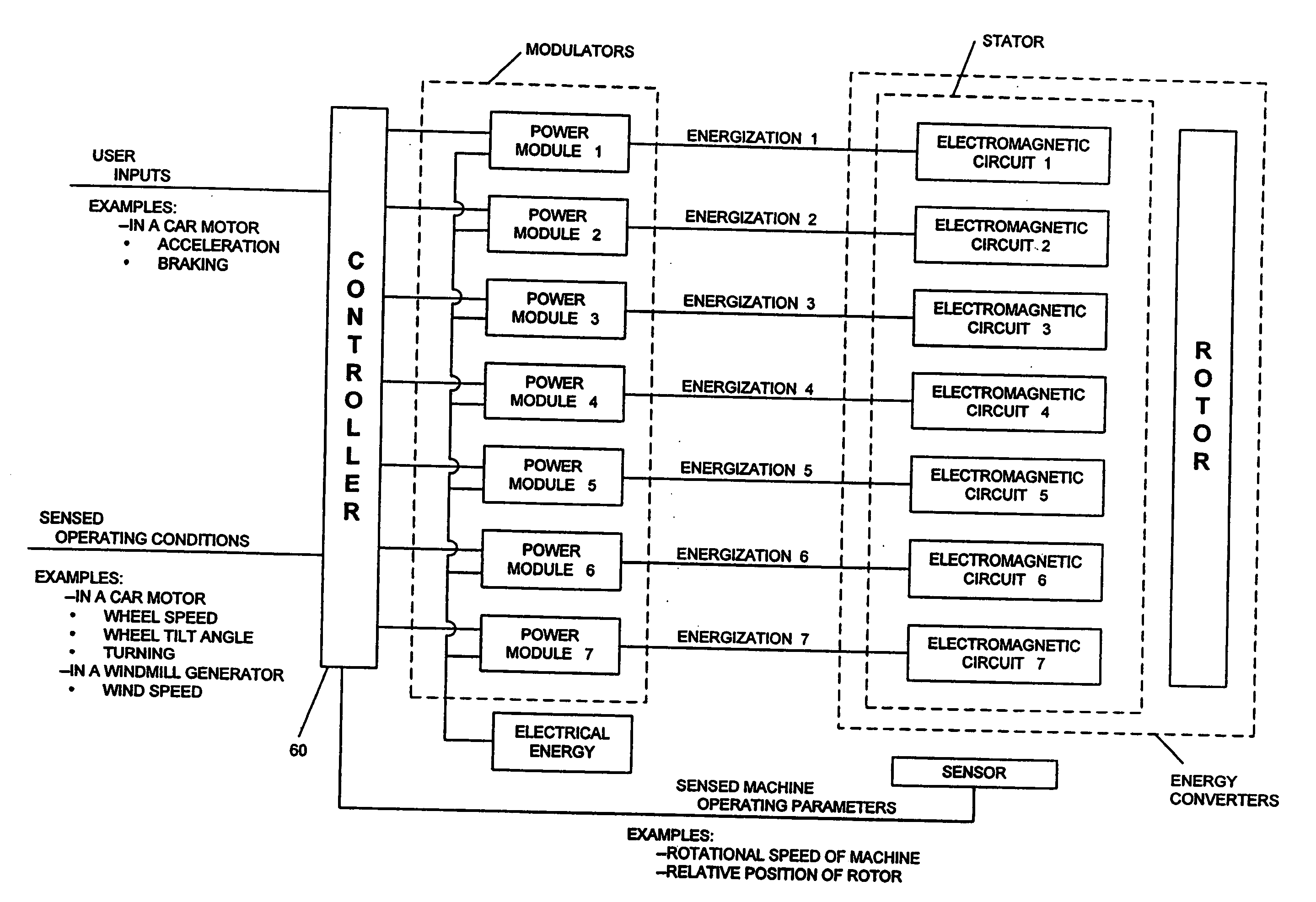

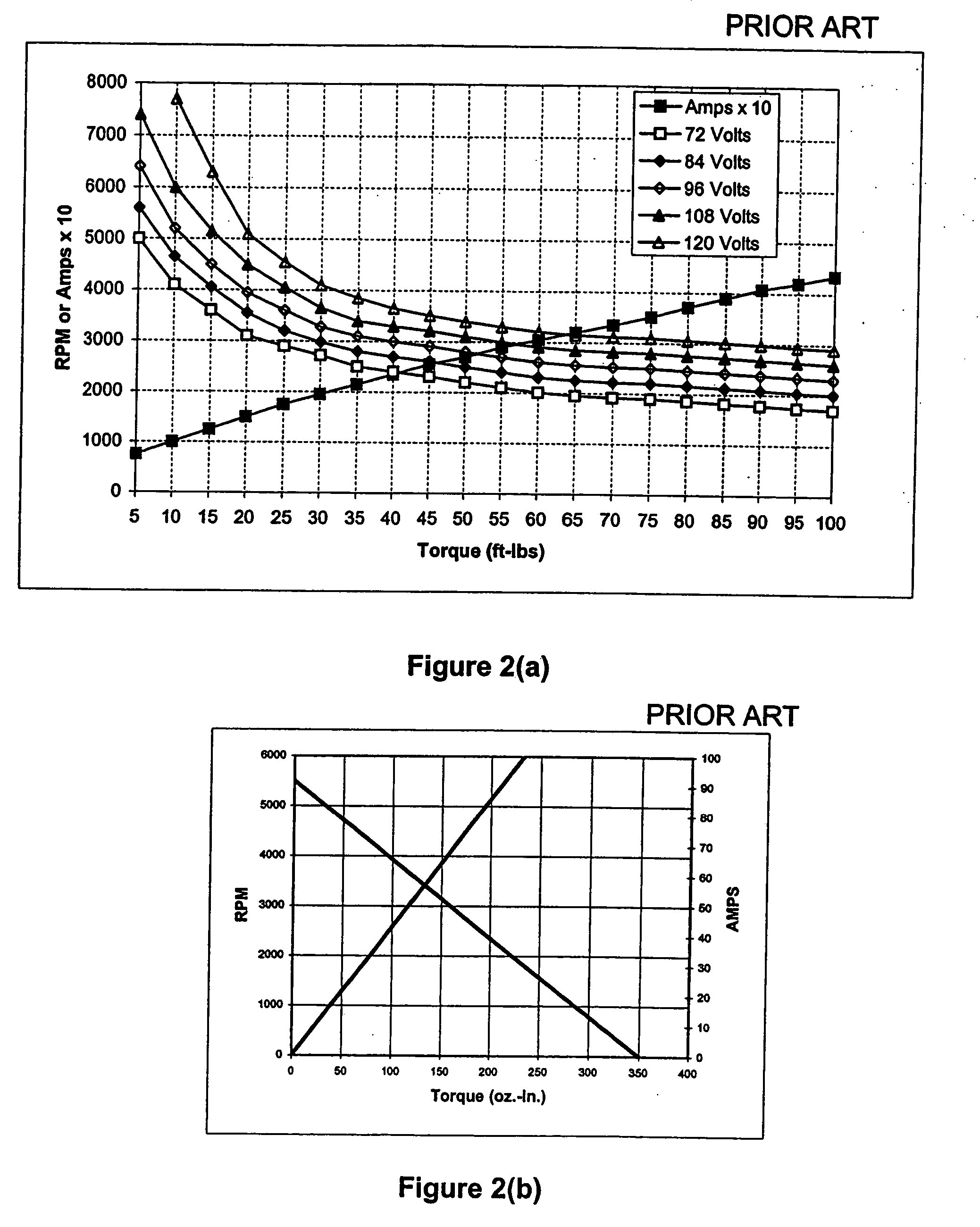

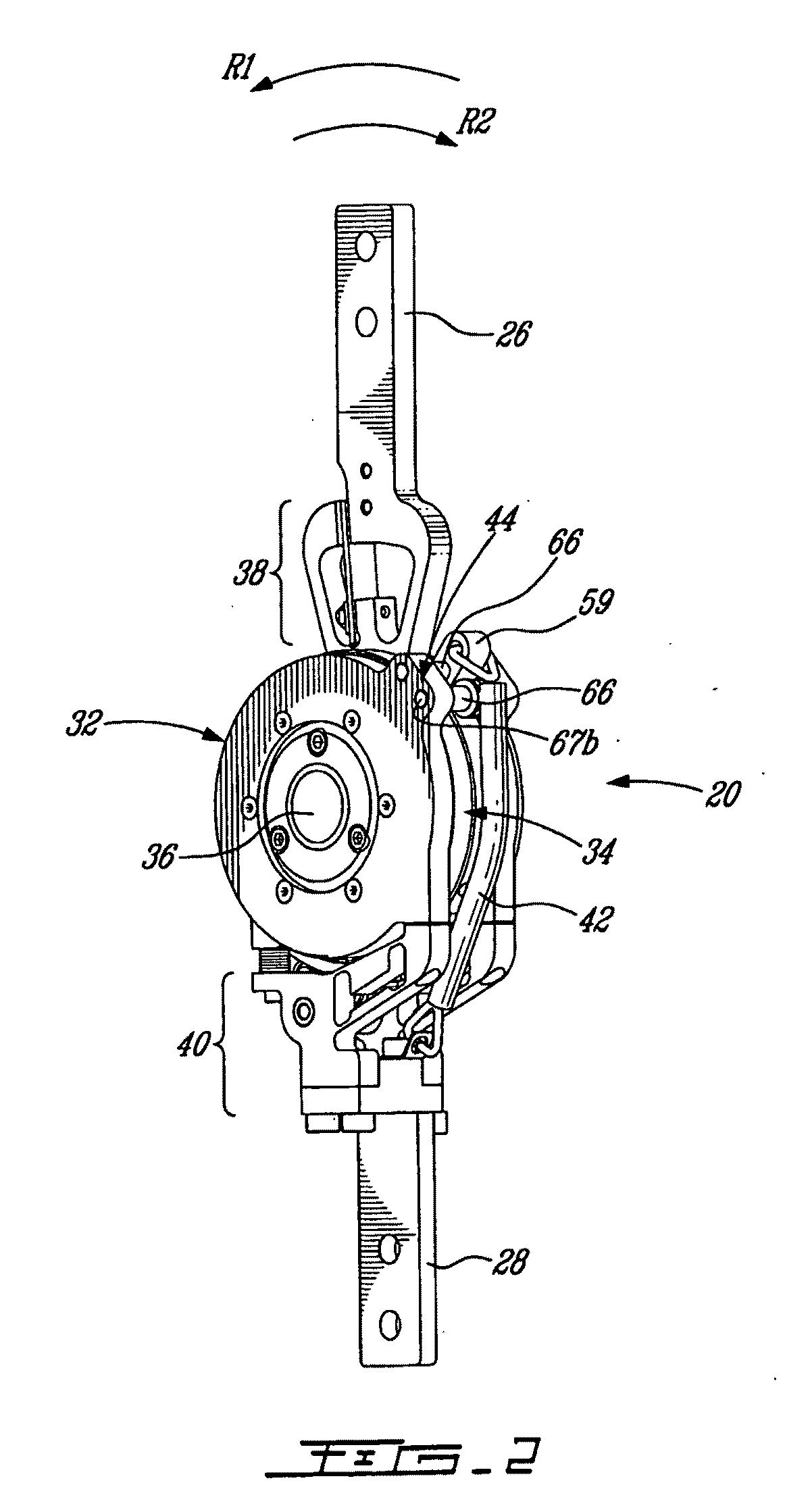

Adaptive electric motors and generators providing improved performance and efficiency

InactiveUS20050184689A1Induced currentLow reliabilityMagnetic circuitVehicular energy storageElectric vehicleHigher Power

An adaptive architecture for electric motors, generators and other electric machines. An adaptive electric machine provides optimal performance by dynamically adapting its controls to changes in user inputs, machine operating conditions and machine operating parameters. Isolating the machine's electromagnetic circuits allows effective control of more independent machine parameters, enabling greater freedom to optimize and providing adaptive motors and generators that are cheaper, smaller, lighter, more powerful, and more efficient than conventional designs. An electric vehicle with in-wheel adaptive motors enables delivery of higher power with lower unsprung mass, giving better torque-density. The motor control system can adapt to the vehicle's operating conditions, including starting, accelerating, turning, braking, and cruising at high speeds, thereby consistently providing higher efficiency. A wind powered adaptive generator can adapt to changing wind conditions, consistently providing optimal performance. An adaptive architecture may improve performance in a wide variety of electric machine applications, particularly those requiring optimal efficiency over a range of operating conditions.

Owner:BLUWAV SYST LLC

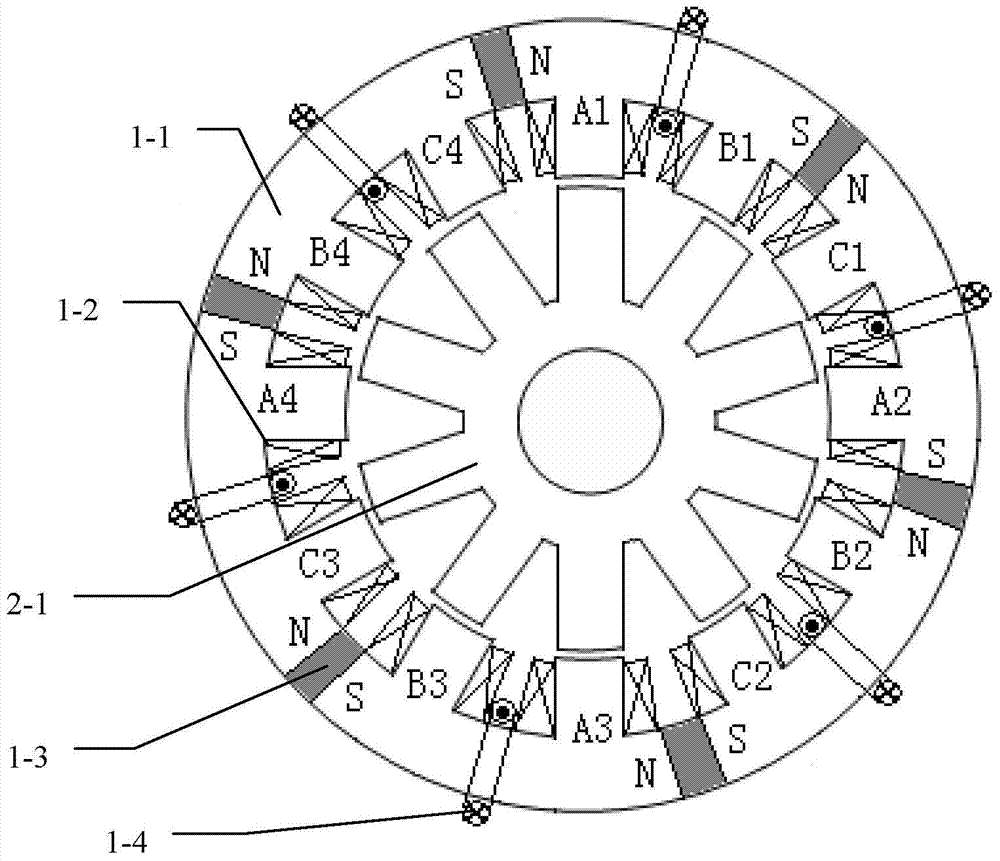

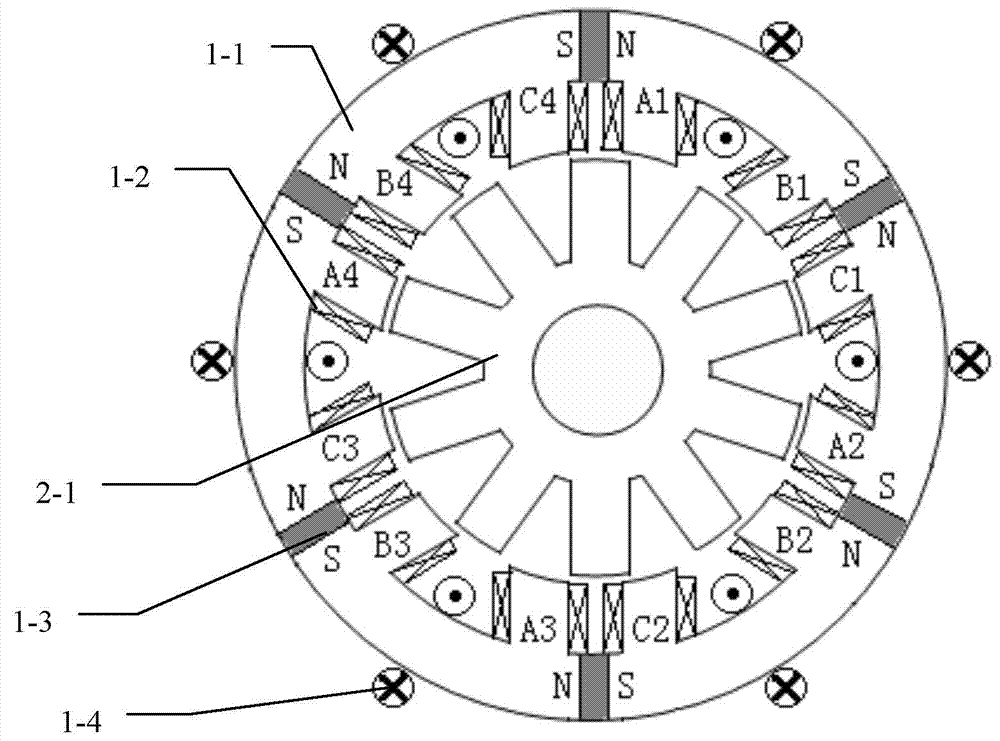

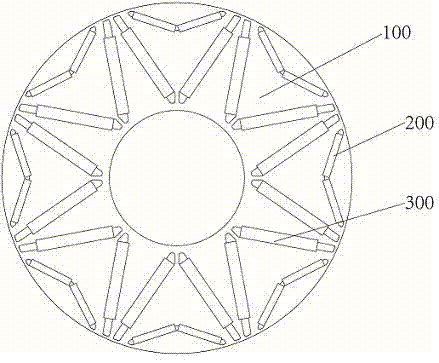

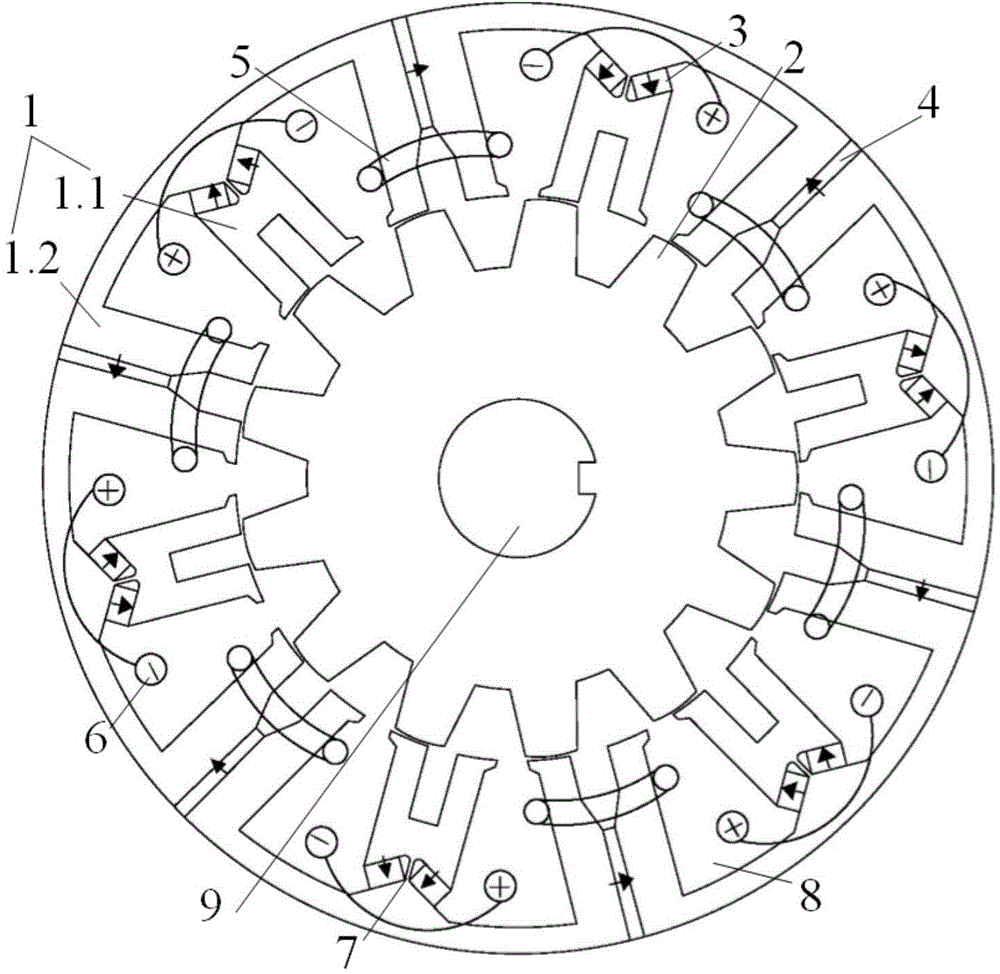

Multi-phase reluctance machine

ActiveCN104218763AReduce copper consumptionAchieve vibrationMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineTorque density

The invention belongs to the technical field of motors, discloses a multi-phase reluctance machine and solves the problem that only works for a half electric cycle, the conventional switch reluctance machine can acquire the one-way torque, thus the torque density of the motor is low. An armature core is in a cylinder shape. A plurality of axial slots are formed in the side surface of an airspace of the armature core to form a structure in which stator poles and stator slots are spaced along a peripheral direction. Each stator pole is wounded by an armature coil. Along the peripheral direction of the armature core, co-phasal armature coils are sequentially connected to for a phase armature winding, and a multi-phase winding, composed of the phase armature windings, is an armature winding. Excitation units are arranged on a yoke portion of the armature core or the stator poles. A rotator comprises a rotator core. A plurality of axial slots are formed in the side surface of an air gap of the rotator core to form a structure in which rotator poles and rotator slots are spaced along the peripheral direction.

Owner:HARBIN INST OF TECH

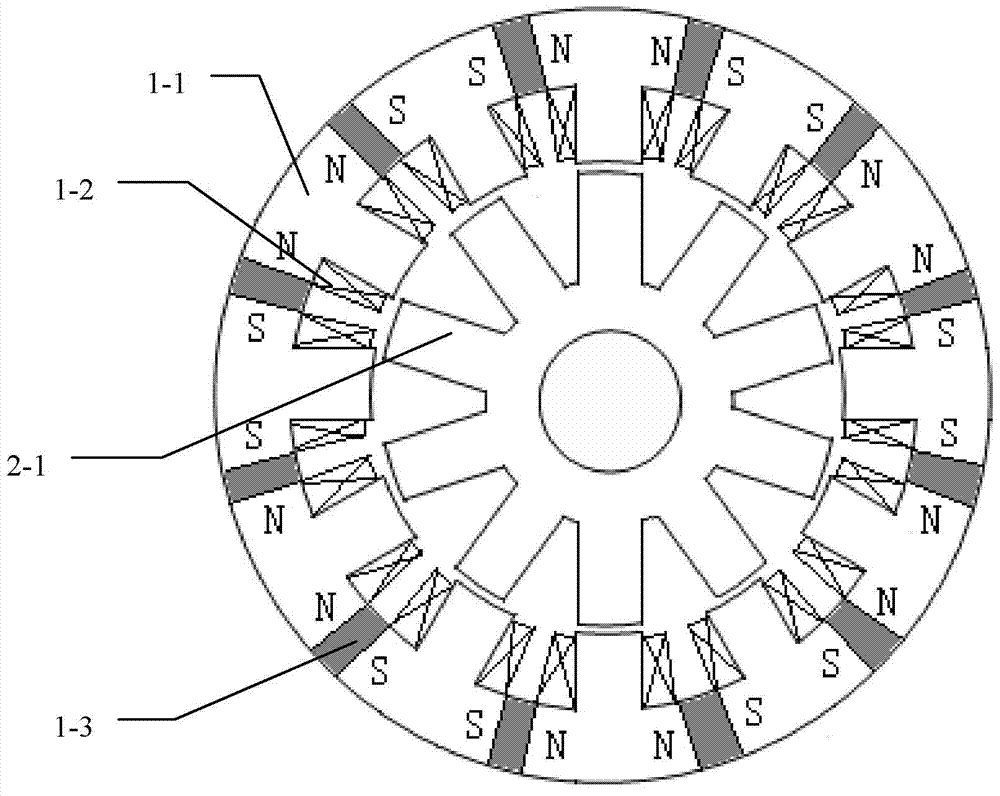

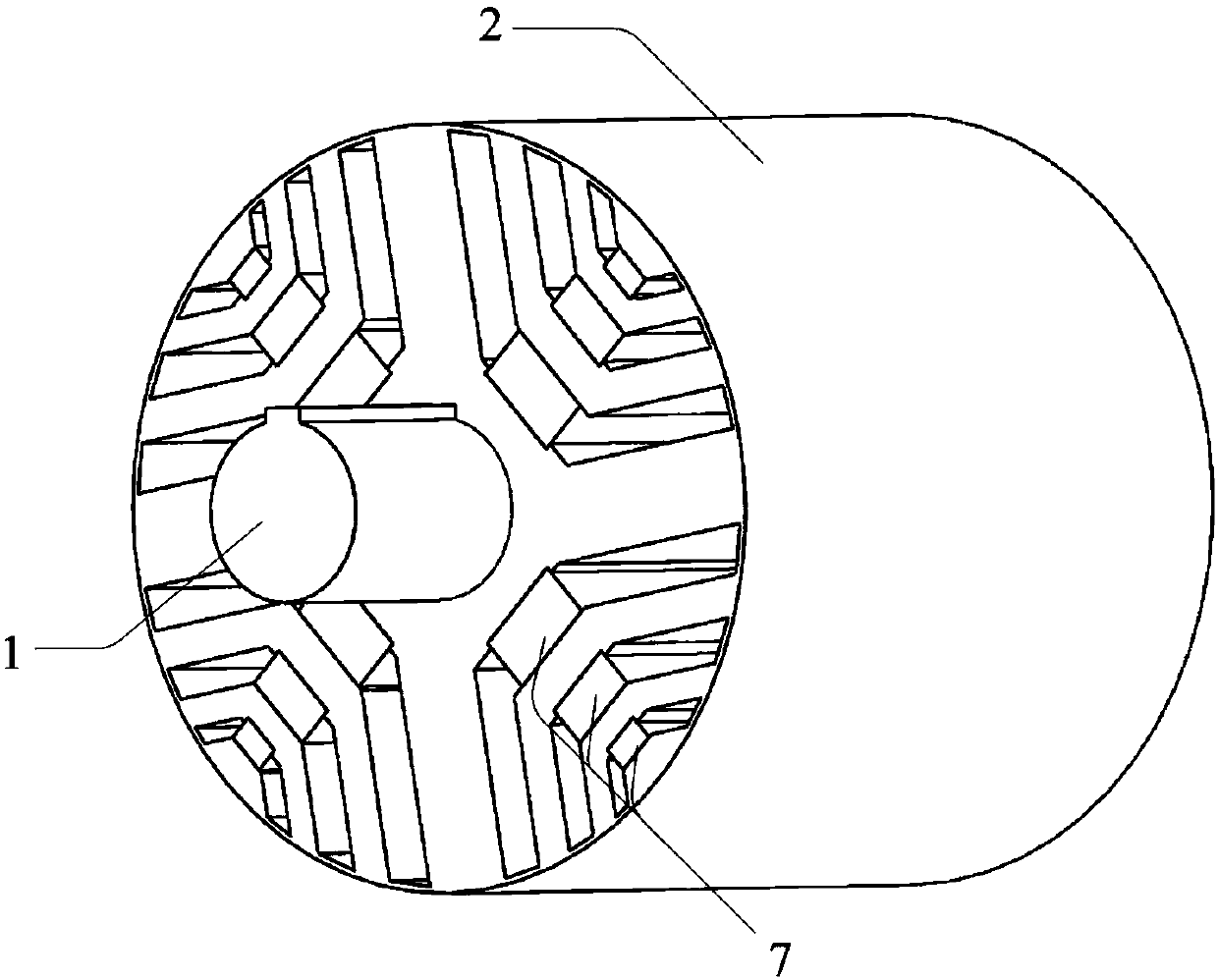

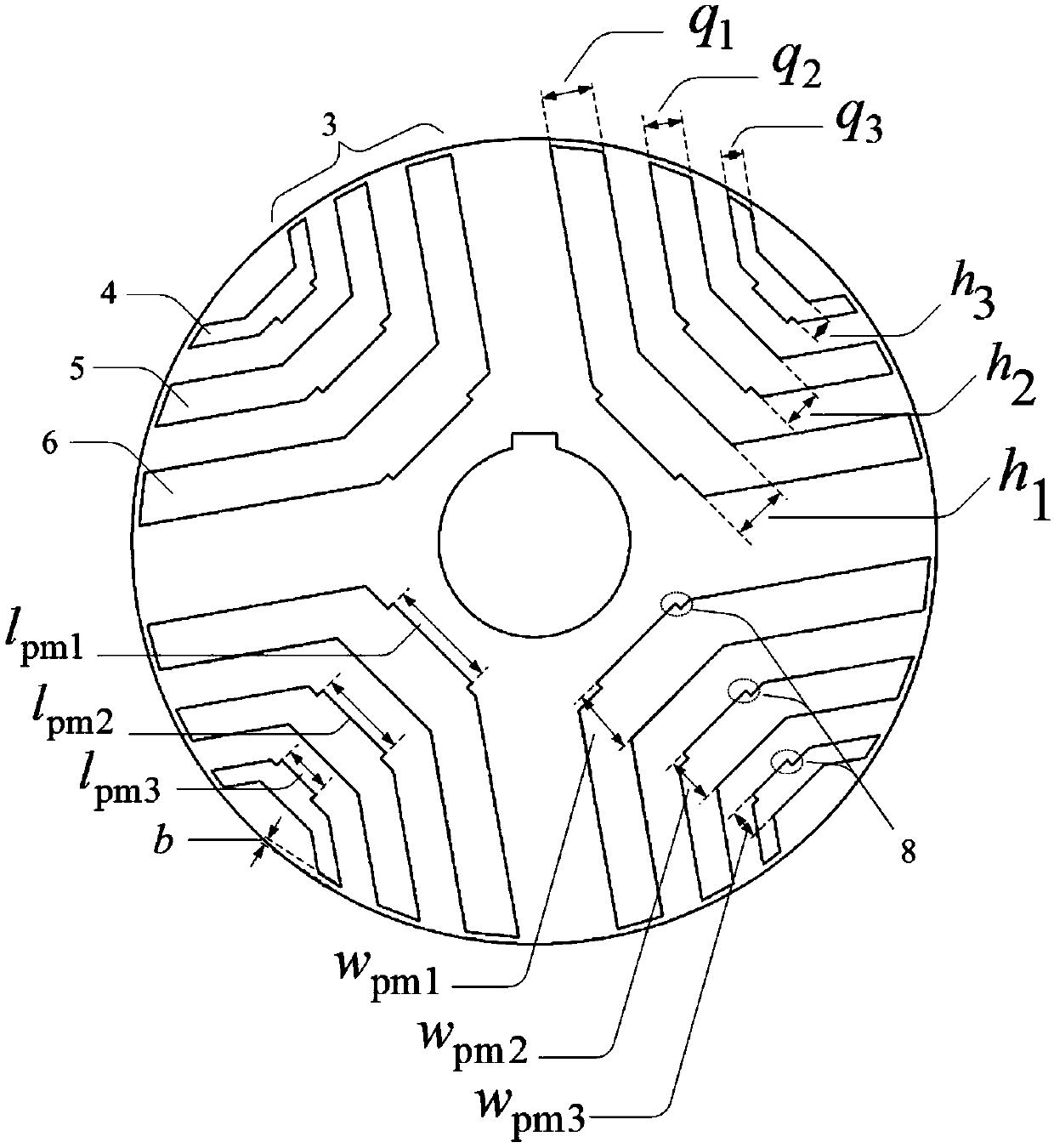

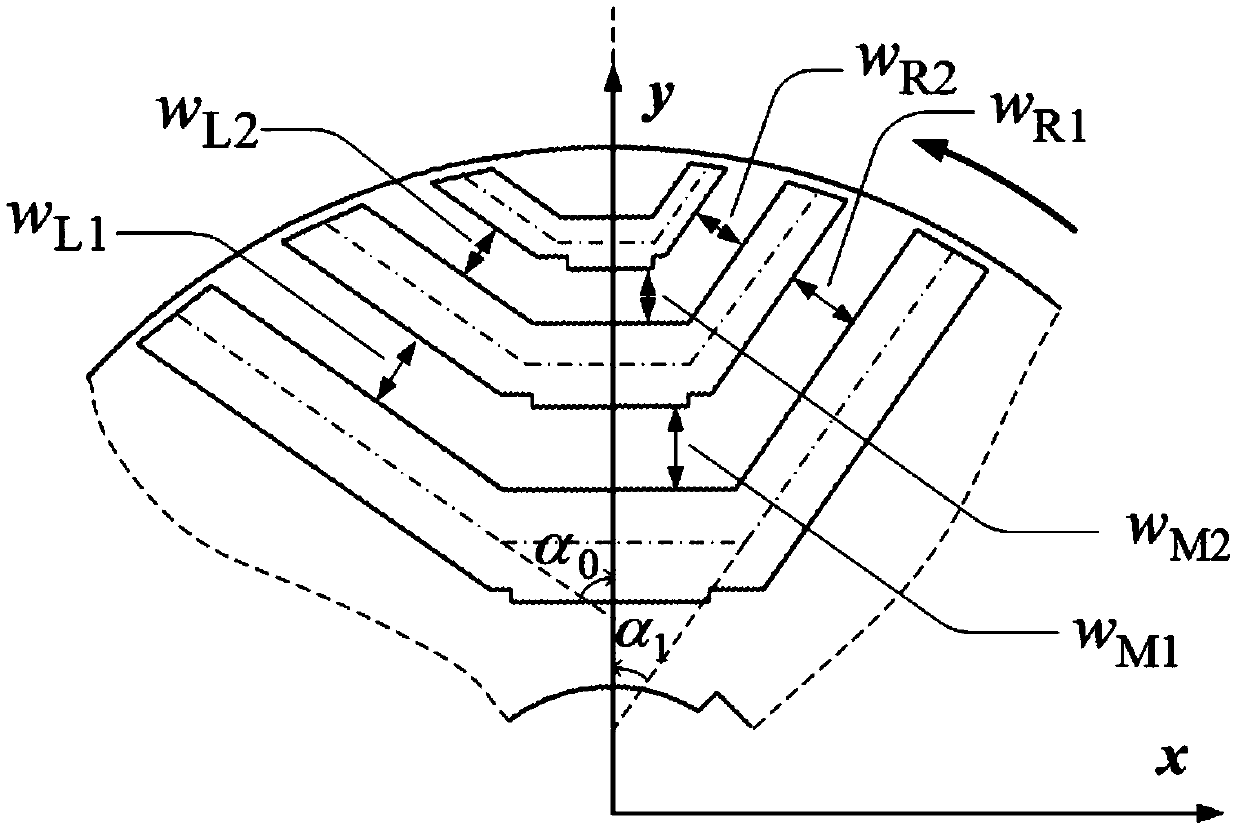

High-torque-density permanent magnet reluctance synchronous motor rotor structure

ActiveCN105914925AReduce manufacturing costReduce consumptionMagnetic circuit rotating partsSynchronous motorTorque density

The invention discloses a high-torque-density permanent magnet reluctance synchronous motor rotor structure, which comprises a central rotating shaft and a rotor core, wherein P groups of through slots are evenly formed in the rotor core along the circumferential direction, each group of through slots includes three layers of U-shaped through slots formed along a radial direction of the rotor core at intervals, and a permanent magnet is embedded in each of two wings of the middle U-shaped through slot; and the middle U-shaped through slot among the three layers of U-shaped through slots is of a symmetric structure, and the outer-layer and inner-layer U-shaped through slots are each of asymmetric structure. The high-torque-density permanent magnet reluctance synchronous motor rotor structure can change torque characteristics of a built-in permanent magnet synchronous motor, makes the maximum synthesized torque fully utilize a permanent-magnet torque component and a reluctance torque component, and increases torque density of a motor.

Owner:江苏仪能电机有限公司 +1

Rotor of permanent magnetic composite excitation synchronous motor

ActiveCN104242509AReduce the effect of the air gap magnetic fieldImproving Salient Pole Torque UtilizationMagnetic circuit rotating partsSynchronous motorTorque density

The invention aims at disclosing a rotor of a permanent magnetic composite excitation synchronous motor. The rotor comprises a double-layer embedded type rotor sheet, first magnetic steel grooves are formed in the outer side of the rotor sheet, second magnetic steel grooves are formed in the inner side of the rotor sheet, magnetic bridges are arranged between the second magnetic steel grooves, and magnetic steel is arranged in the first magnetic steel grooves and the second magnetic steel grooves. Compared with the prior art, different permanent materials are embedded in the rotor sheet according to a certain rule to form the rotor, the usage number of rare-earth permanent magnetic materials is effectively reduced, the effect of the temperature on a motor air-gap magnetic field is reduced, the excitation stability is improved, the utilization rate of salient pole torque of the motor is increased, the torque density of the motor is increased, and the purpose of the rotor is achieved.

Owner:ZHEJIANG LOONGSON ELECTRIC DRIVE TECH CO LTD

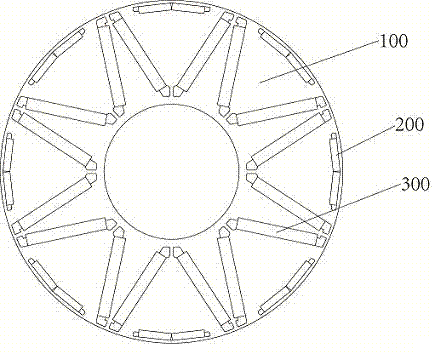

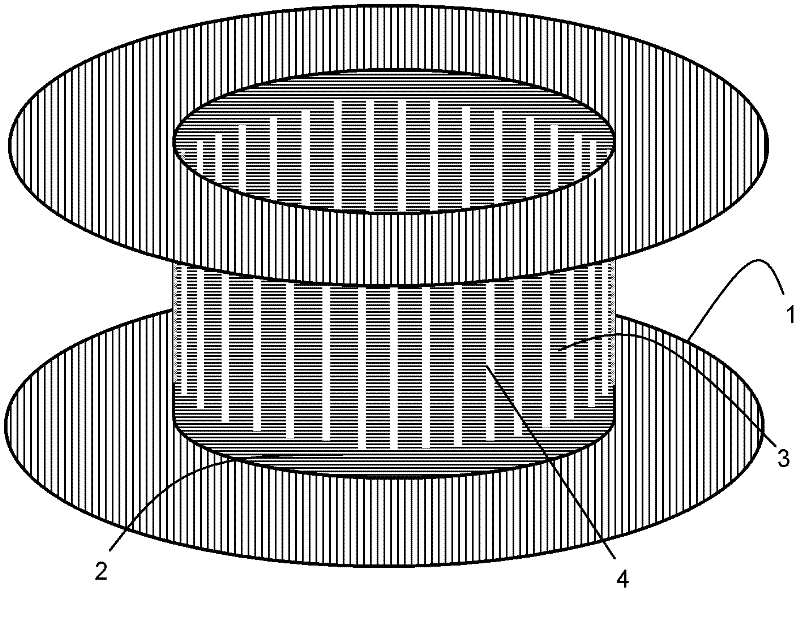

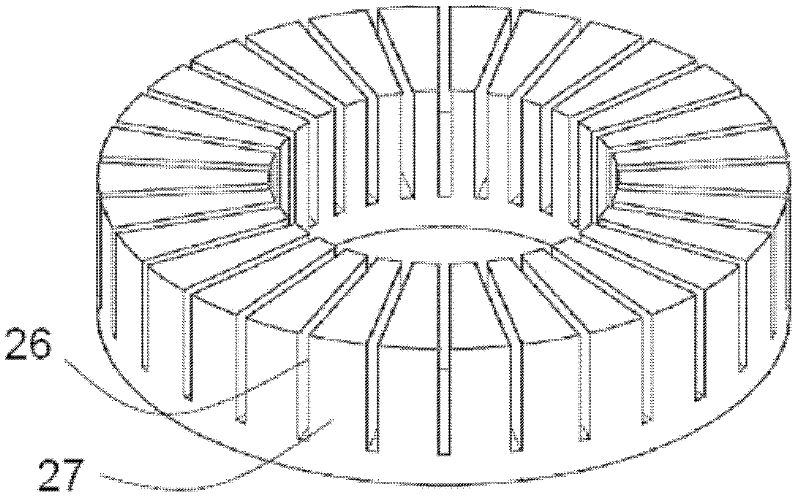

Amorphous, microcrystalline or nano-crystalline alloy stator iron core for axial magnetic flux motor and manufacture method for stator iron core

ActiveCN102510141AImprove production efficiency and core yieldEliminate resin thermosetting molding processMagnetic circuit stationary partsManufacturing stator/rotor bodiesHigh power densityMagnetic flux

The invention discloses an amorphous, microcrystalline or nano-crystalline alloy stator iron core for an axial magnetic flux motor and a manufacture method for the stator iron core. The manufacture method includes the steps: firstly, rolling and cutting a coiled amorphous, microcrystalline or nano-crystalline alloy wide band into an alloy strip coil (6) which is twice as high as that of the finished iron core, then uniformly punching a plurality of strip slots (17) in the middle of the alloy strip coil at intervals with the same equipment, performing insulation coating treatment and further coiling the alloy strip coil on an inner core (24) of the iron core, wherein the strip slots (17) are as same as open slots (26) in width, and the length of each strip slot (17) is twice of the depth of each open slot (26); next, adding an iron core outer-circumference protecting layer on the outer circumference face of the coiled alloy strip coil, then transversely halving the alloy strip coil into two identical alloy iron cores along the axial perpendicular plane of the alloy strip coil; and finally, carrying out high-temperature annealing treatment on the iron cores formed by processing. The stator iron cores prepared by the method are more excellent in performance, and particularly applicable to a high-speed motor, a high-power density motor and a high-torque density motor.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

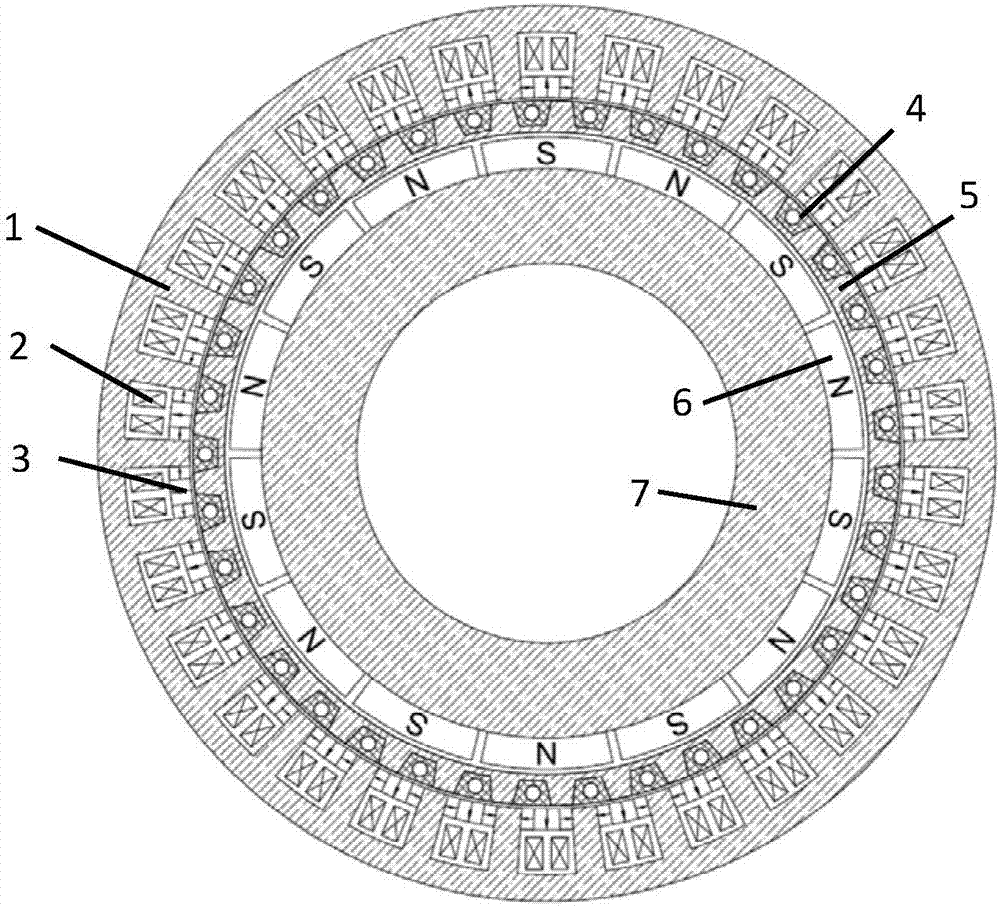

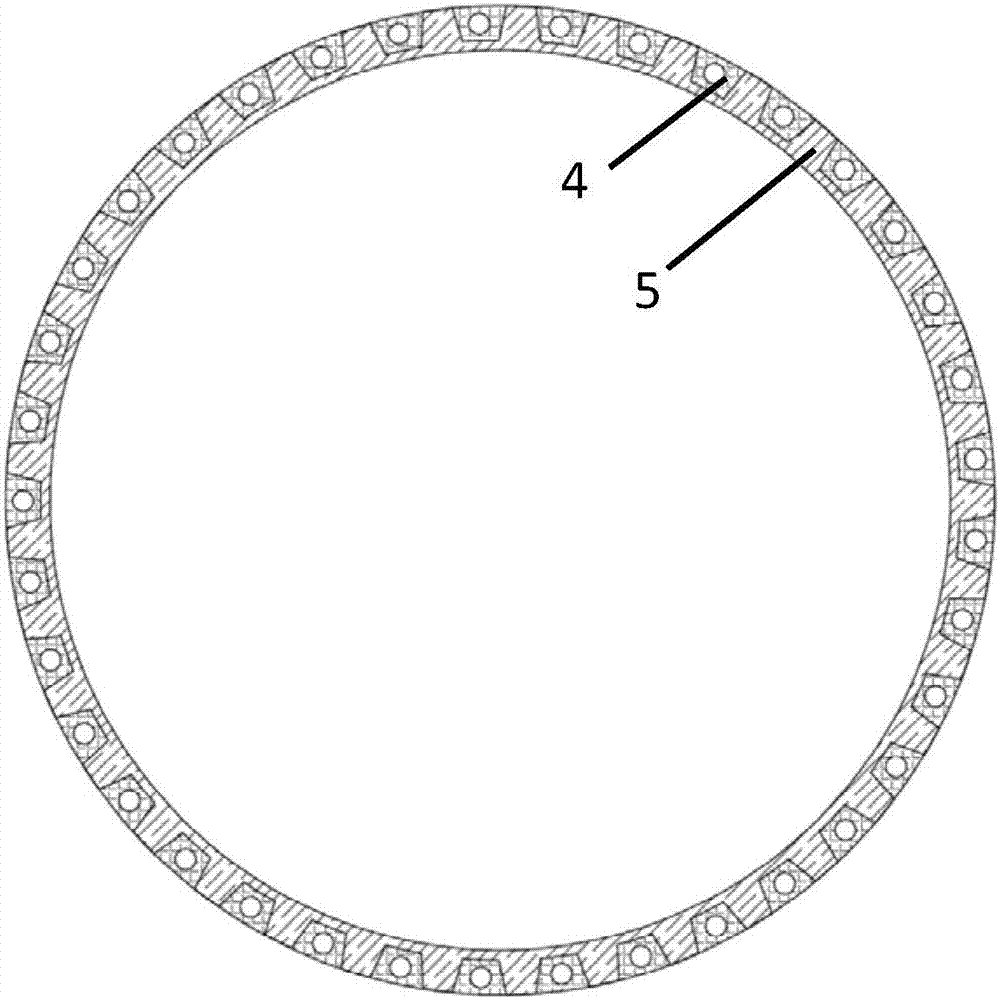

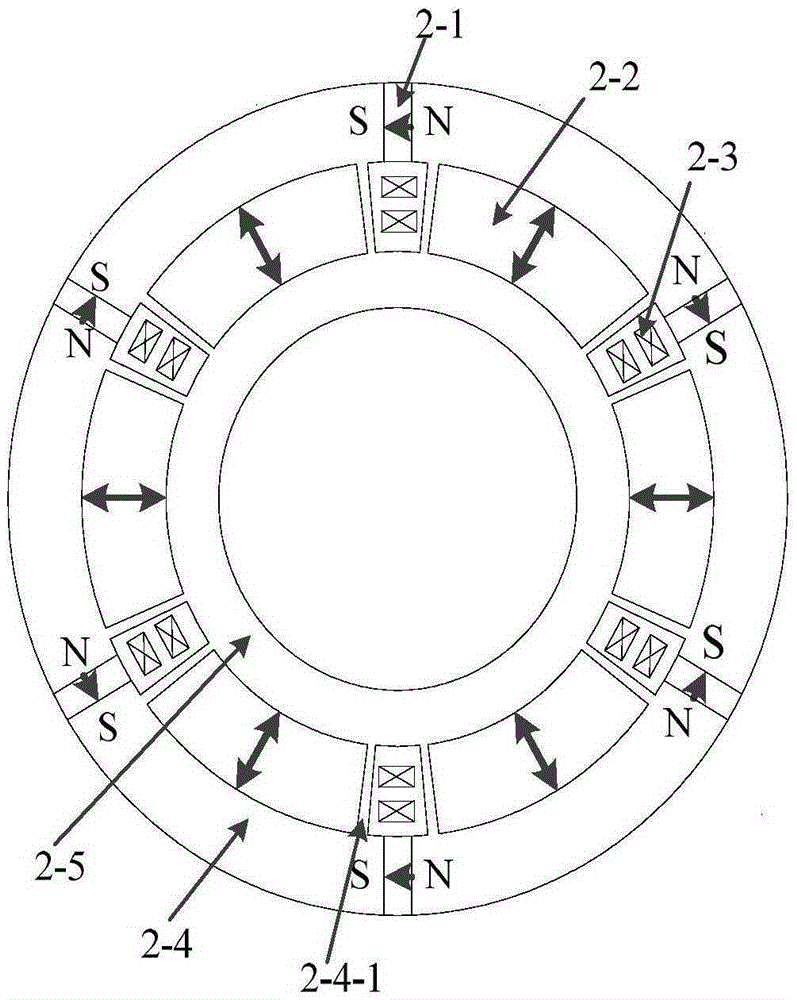

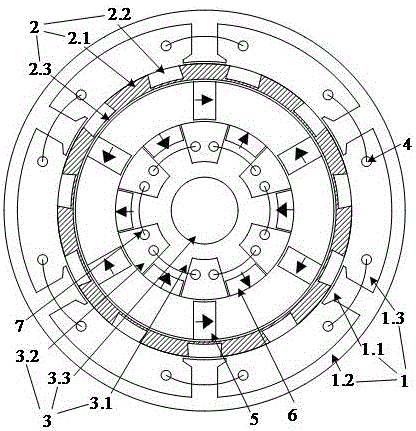

Magnetic gear composite motor

ActiveCN108011484AIncreased torque densityReduce Flux LeakageDynamo-electric machinesLow speedElectric machine

The invention discloses a magnetic gear composite motor. The magnetic gear composite motor comprises an outer stator, a modulation rotor and an inner rotor which are sequentially arranged in a concentrically nested manner from outside to inside, wherein air gaps are formed between the outer stator and the modulation rotor as well as between the modulation rotor and the inner rotor respectively; the outer stator is provided with a trapezoidal groove used for placing a fractional slot winding, and the groove opening is embedded with alternative-pole magnetic steel; the modulation rotor comprisesa plurality of magnet regulating yokes and a plurality of non-magnetic conductive materials embedded with punched holes respectively, and the adjacent magnet regulating yokes are embedded with the punched non-magnetic conductive materials therebetween; and the permanent magnet inner rotor comprises inner rotor permanent magnets and an inner rotor iron core which are concentrically nested to one another sequentially from outside to inside. According to the magnetic gear composite motor provided by the invention, a magnetic path of the magnetic gear motor on the stator is constructed through combining permanent magnets with different polarization directions, so that the magnetic path is enabled to be more efficient and reasonable, the flux leakage is reduced while low-speed and high-torquedirect drive output is realized, and the overall torque density and efficiency of the composite motor are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

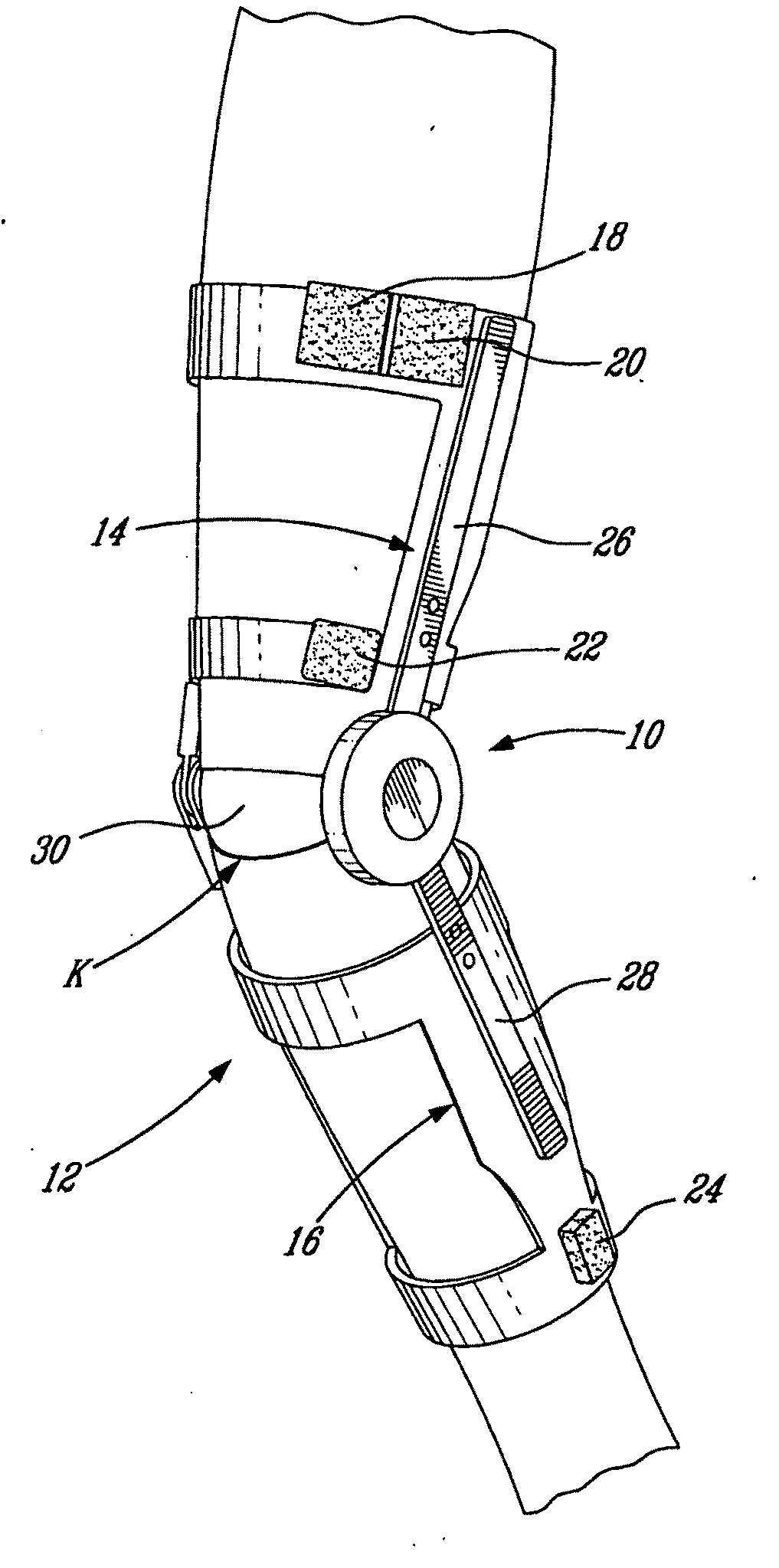

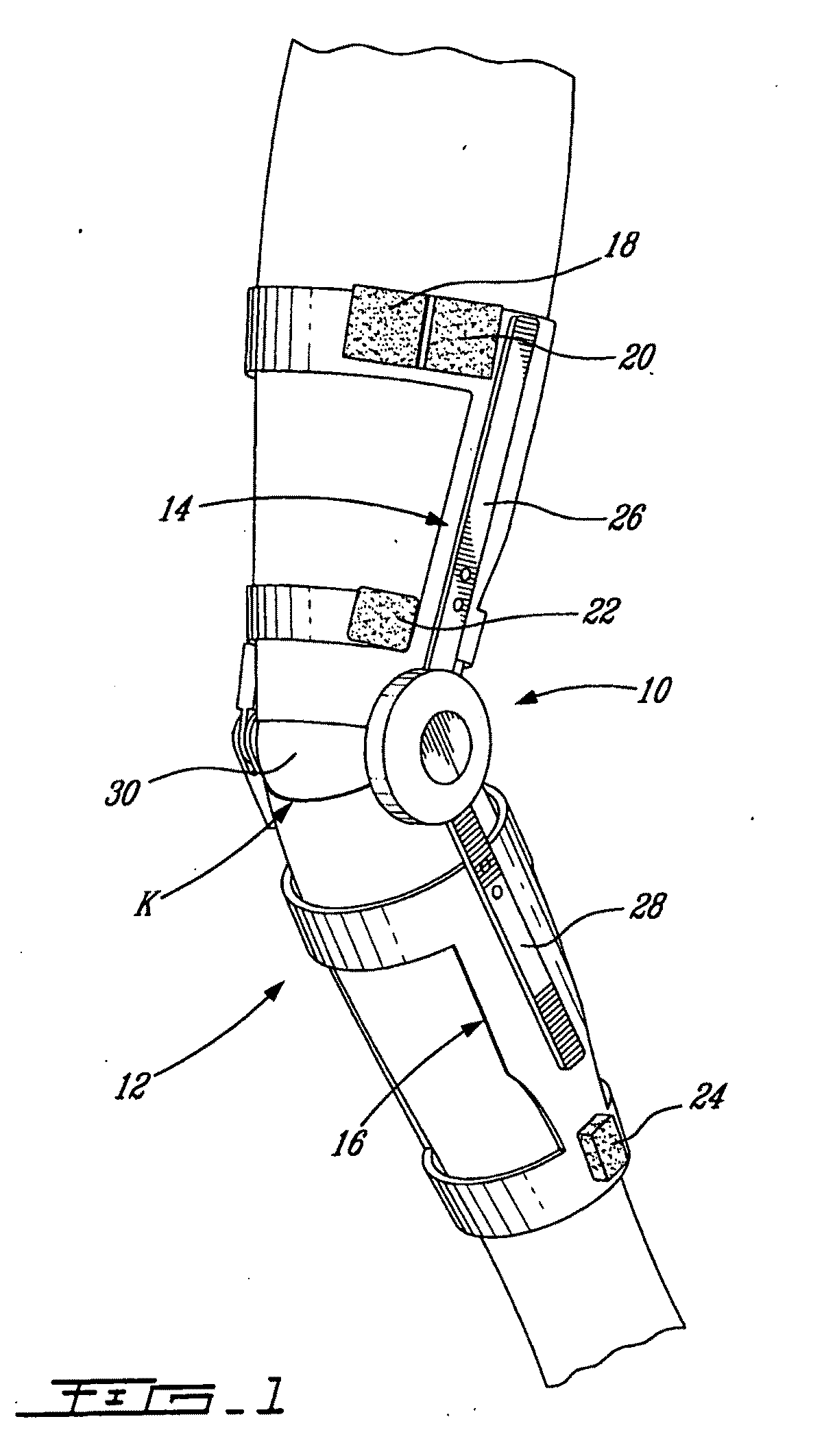

High Torque Active Mechanism for Orthotic and/or Prosthetic Devices

ActiveUS20100160844A1Increased torque densityWork measurementNon-surgical orthopedic devicesBrake torqueTorque density

A high torque active mechanism for an orthotic and / or prosthetic joint using a primary brake which can be provide by magnetorheological (MR) rotational damper incorporating and an additional friction brake mechanism driven by the braking force generated by the MR damper. This combination of MR damper and friction brake mechanism allows an increase in torque density while keeping the same level of motion control offered by the MR damper alone. The increased torque density achieved by this high torque active mechanism allows to minimize the size of the actuating system, i.e. its diameter and / or breath, while maximizing its braking torque capability. In this regard, the friction brake mechanism is advantageously positioned around the MR damper, such that the dimension of the package is minimized.

Owner:NATIONAL BANK OF CANADA

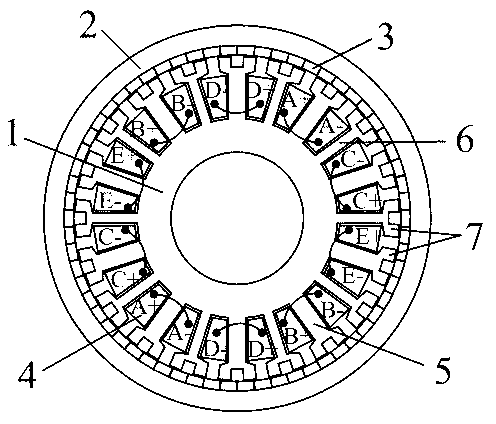

Mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and winding switching magnetism-weakening control method thereof

ActiveCN104578477ASimple structureImprove space utilizationAC motor controlMagnetic circuit stationary partsLow speedMagnetic poles

The invention discloses a mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and a winding switching magnetism-weakening control method thereof. The mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor comprises a salient rotor and a stator, wherein the stator contains stator cores, aluminium-nickel-cobalt permanent magnets, neodymium-iron-boron permanent magnets, centralized armature windings and pulsed magnetism-adjusting windings; iron core edges of two adjacent outer U-shaped units and tangentially-magnetized long-stripped neodymium-iron-boron permanent magnets form a first permanent magnetic pole, while the circumferentially-inward (outward) and parallel-magnetized V-shaped embedded aluminium-nickel-cobalt permanent magnets and inner U-shaped units form a second permanent magnetic pole; mixed magnetic poles are in alternating polarity distribution; when the motor runs at a low speed, the pulsed magnetism-adjusting windings are in direct-current pulsed working state, while in a high-speed weak-magnetism area, the pulsed magnetism-adjusting windings are converted into alternating-current armature windings. Requirements on performance in a low-speed area and in the high-speed area can be met at the same time; influence of an armature reaction field on the aluminium-nickel-cobalt permanent magnets with low coercivity is small; the utilization rate of permanent magnetism, the torque density, and the reliability of system operation are high.

Owner:SOUTHEAST UNIV

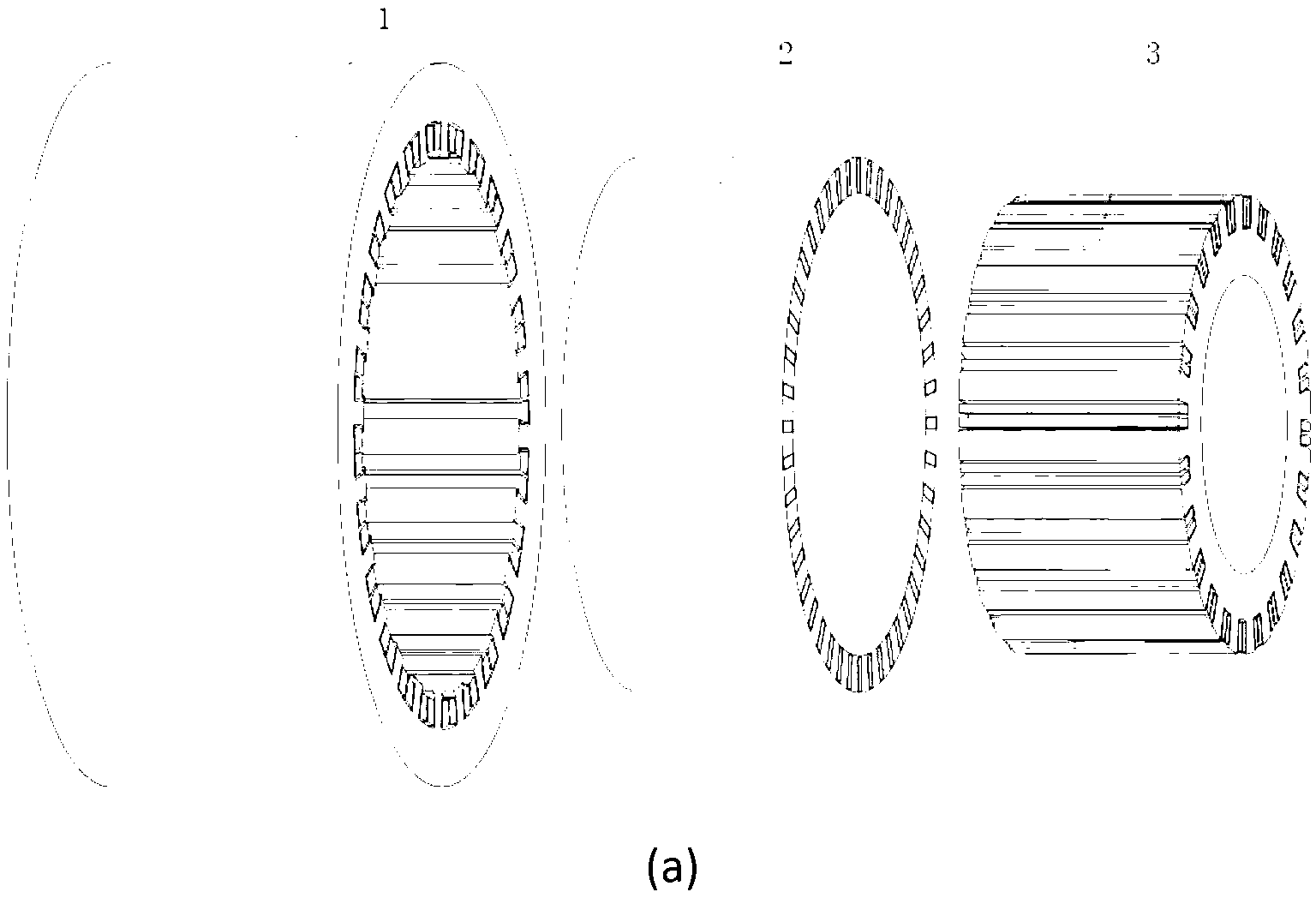

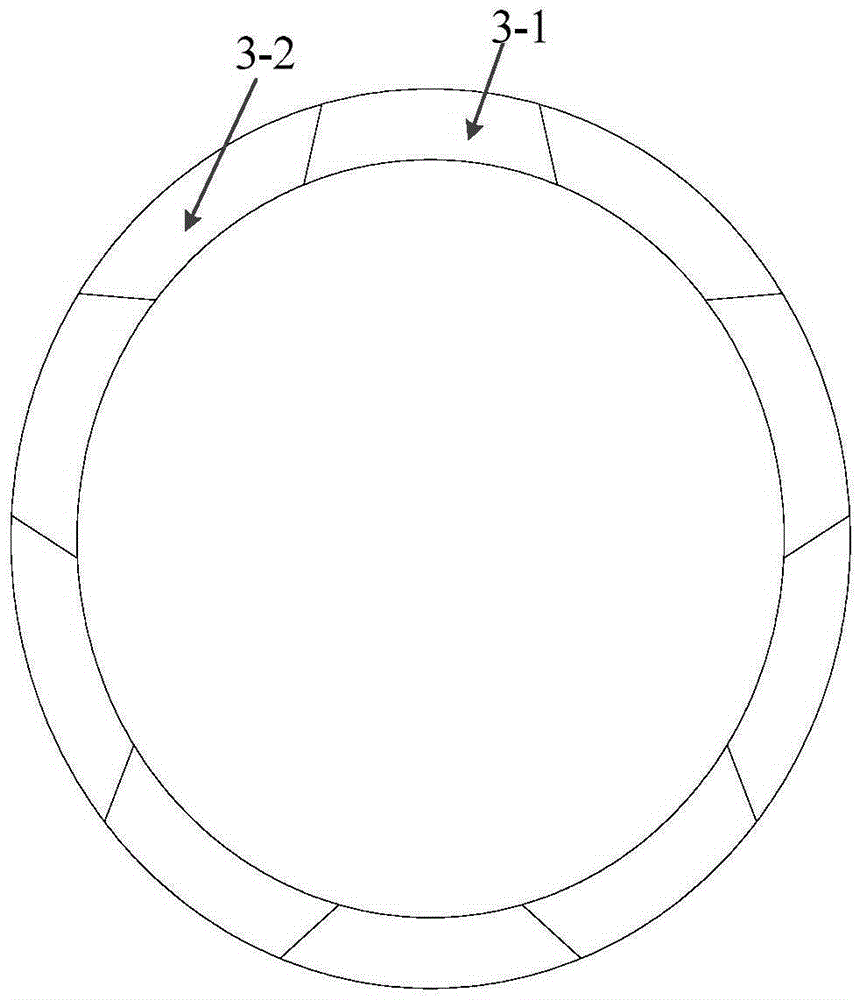

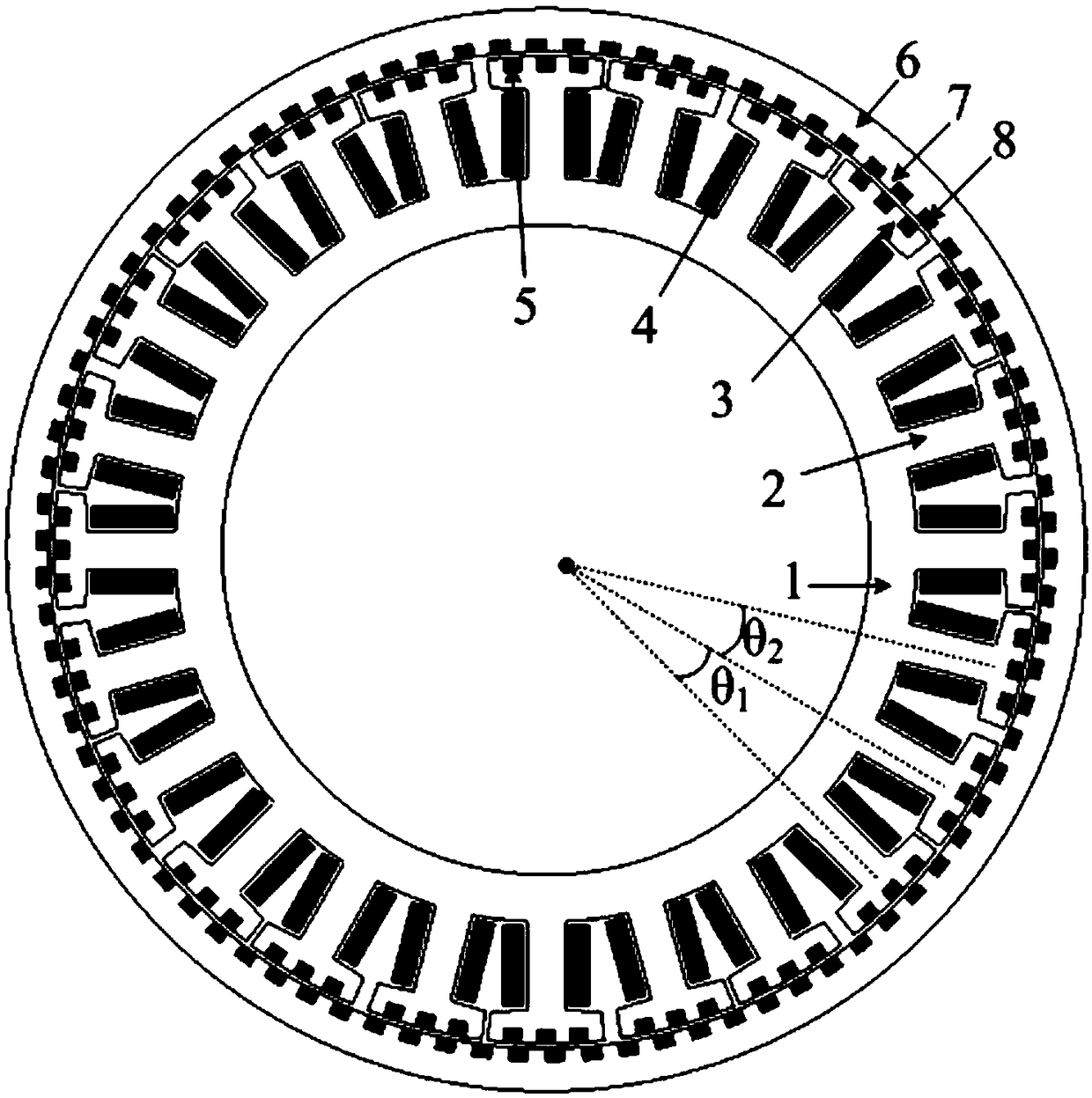

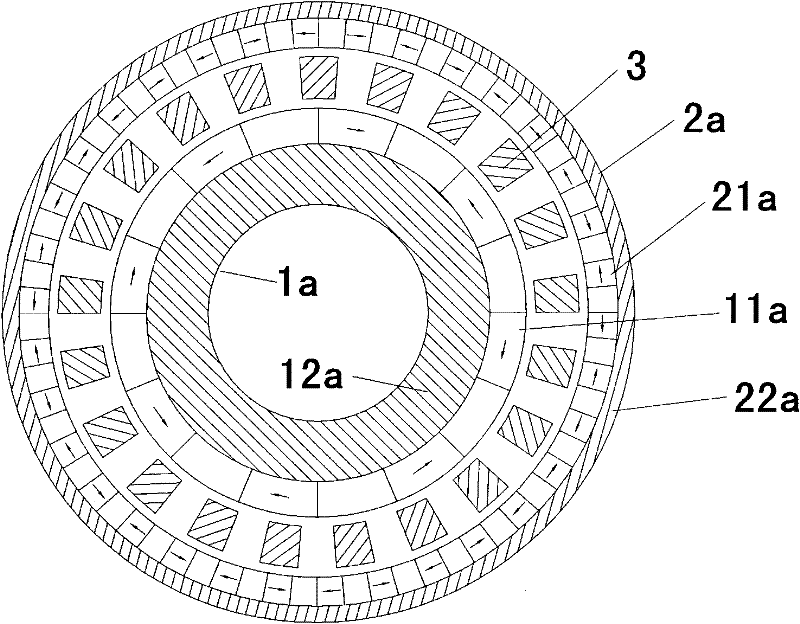

Radial magnetic field double-stator vernier motor

ActiveCN103178668ACompact structureImprove power factorMagnetic circuit rotating partsPower factorElectric machine

The invention discloses a radial magnetic field double-stator vernier motor which comprises a ring-shaped rotor (2) and two cylindrical stators (1 and 4). Multiple permanent magnets are arranged on the periphery of a ring body of the rotor at uniform intervals, multiple grooves are reserved on the peripheral wall of a cylinder body of each stator, each groove is used for accommodating a winding, and a projection between each two adjacent grooves forms a stator tooth. The radial magnetic field double-stator vernier motor is characterized in that the two stators (1 and 4) are different in diameter and are in coaxial inner-outer sleeving arrangement, the grooves on the two stators are identical in number, the rotor (2) is coaxially sleeved between the two stators (1 and 4), and distance between each stator tooth of the inner stator (4) and the corresponding stator tooth of the outer stator (1) is half of a groove spacing angle peripherally. Under the circumstance that the motor is similar to a traditional vernier motor in torque density, power factor is improved greatly and can reach above 0.8.

Owner:HUAZHONG UNIV OF SCI & TECH

Hybrid excitation-type stator partition-type hybrid permanent magnet flux switching memory motor

ActiveCN105337429ASolve the problem of mutual limitation of dosageIncrease dosageMagnetic circuit stationary partsWindings conductor shape/form/constructionTorque densityMemory motor

The invention discloses a hybrid excitation-type stator partition-type hybrid permanent magnet flux switching memory motor, which comprises an outer stator, an inner partition stator and a middle rotor, wherein the inner partition stator has a structure of an inner layer and an outer layer closely attached together, the outer layer is formed by an inner stator iron core and NdFeB permanent magnets, the NdFeB permanent magnets are uniformly embedded in the inner stator iron core along the circumferential direction, the NdFeB permanent magnets are magnetized tangentially, and the magnetizing directions of two adjacent NdFeB permanent magnets are opposite; and the inner layer is formed by pulse magnetizing windings and AlNiCo permanent magnets capable of being magnetized and demagnetized in an online mode, the AlNiCo permanent magnets are uniformly arranged along the circumferential direction, an inner stator groove is arranged between adjacent two AlNiCo permanent magnets, and the pulse magnetizing windings serially connected from beginning to end in sequence are placed in the inner stator grooves and are wound on the AlNiCo permanent magnets. Thus, under the same motor size, the amount of permanent magnets and the amount of armature windings can be increased to enhance torque density, the magnetic strength of the AlNiCo permanent magnets can be adjusted in an online mode, and a wide speed regulation range is provided.

Owner:JIANGSU UNIV

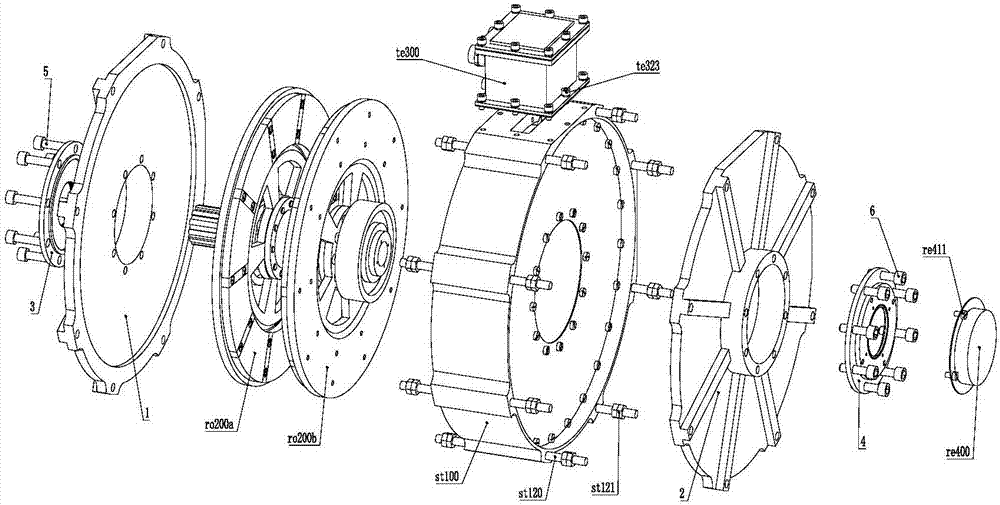

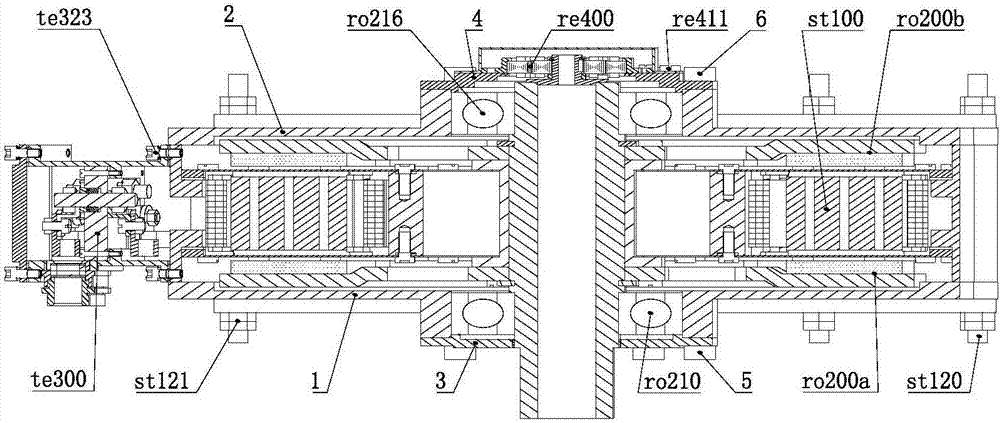

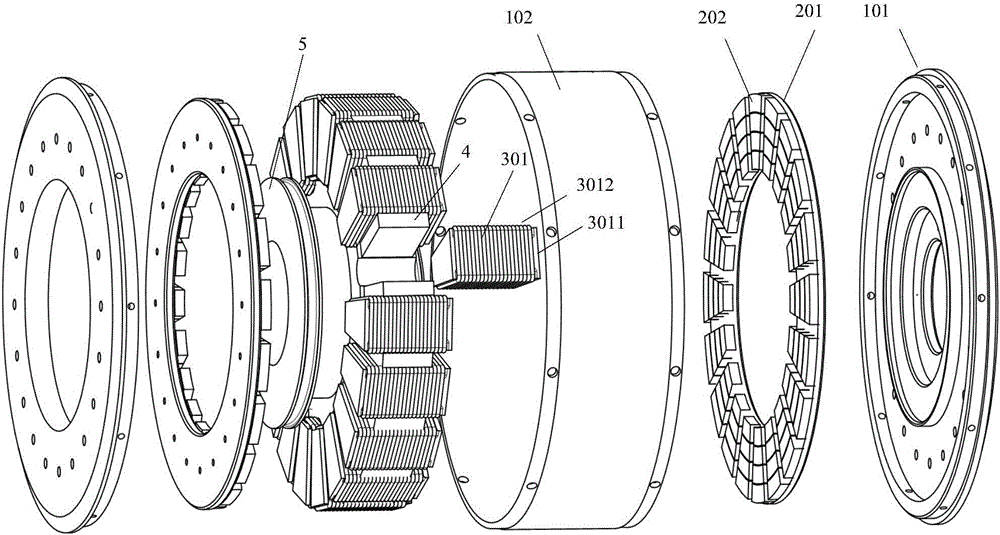

Disc type axial-flux motor with oil-immersed circularly cooled stator and segmented armatures

InactiveCN107196480AImprove power densityIncreased torque densityStructural associationCooling/ventillation arrangementSurface mountingTorque density

The invention discloses a disc type axial-flux motor with an oil-immersed circularly cooled stator and segmented armatures. A framework with double rotors and single stator is adopted; and a main shaft is designed. Each rotor adopts a magnetic steel surface-mounting type structure; and a whole stator oil-immersion circulation cooling and heat dissipation mode is adopted for temperature rise management. The disc type axial-flux motor with the oil-immersed circularly cooled stator and the segmented armatures comprises a stator assembly, a driving end rotor assembly, a non-driving end rotor assembly, a wire outlet box assembly and a rotary transformer assembly. An engine base is provided with an oil inlet joint and an oil outlet joint, both of which can carry out oil-immersion circulation cooling for the stator and have the advantages such as high convective heat transfer efficiency, big heat exchange area and fast heat transfer speed. The disc type motor adopting such a heat dissipation structure can achieve higher power density and higher torque density, is more compact in structure and is suitable for the occasions with strict requirements on the motor mounting space in future.

Owner:XI AN JIAOTONG UNIV

Stator permanent-magnetic doubly salient disc-type motor

ActiveCN105245073AAvoid damageEasy to installMagnetic circuit rotating partsElectric machinesTorque densityNon magnetic

The present invention discloses a stator permanent-magnetic doubly salient disc-type motor, which comprises stator mechanisms, a rotor mechanism and a motor shaft, wherein the rotor mechanism is arranged between the two stator mechanisms, the rotor mechanism and the stator mechanisms are arranged on the motor shaft, each stator mechanism comprises a stator core, two permanent magnets and 2N annular armature windings, 2N stator teeth are evenly distributed on the inner wall of each stator core, a groove between every two adjacent stator teeth is a stator groove, the permanent magnets magnetized in the peripheral direction are arranged in centers of any pair of stator grooves on the same diameter, and the 2N annular armature windings respectively sleeve the 2N stator teeth; and the rotor mechanism comprises a plurality of rotor cores and a non-magnetic-conductive rotor bracket, the plurality of rotor cores are evenly distributed on the outer circumference of the non-magnetic-conductive rotor bracket, and the rotor cores form rotor salient poles. The stator permanent-magnetic doubly salient disc-type motor can effectively improve the reliability of the motor, reduces size and weight of the motor, improves power density and torque density of the motor, and is suitable to be used in occasions with strict requirements on size of generators or motors.

Owner:NANJING UNIV OF SCI & TECH

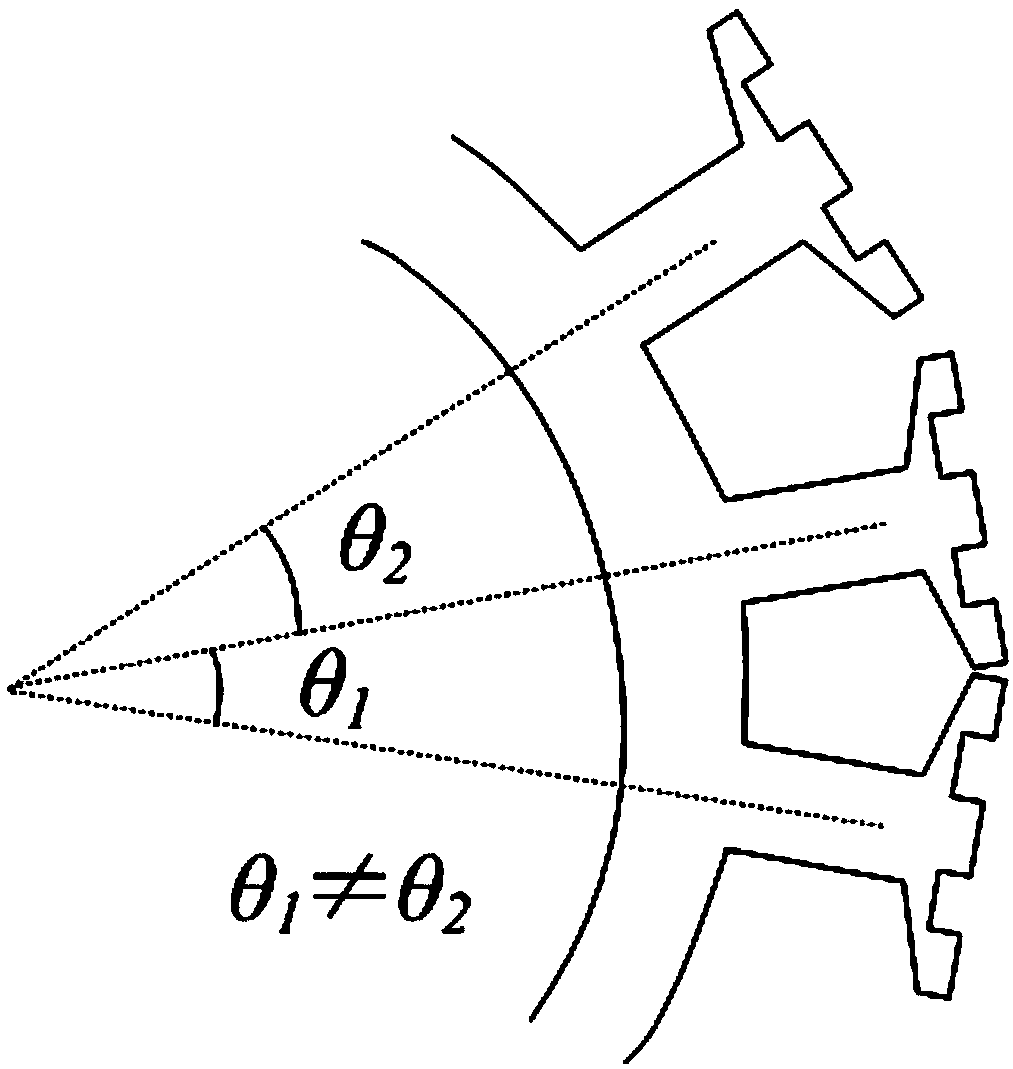

Non-uniform arrangement carnassial tooth fixed rotor permanent magnet vernier motor

InactiveCN108900055ASuppression of torque rippleSmooth output torqueMagnetic circuit rotating partsMagnetic circuit stationary partsLow speedElectric machine

Owner:无锡力必特自动化设备有限公司

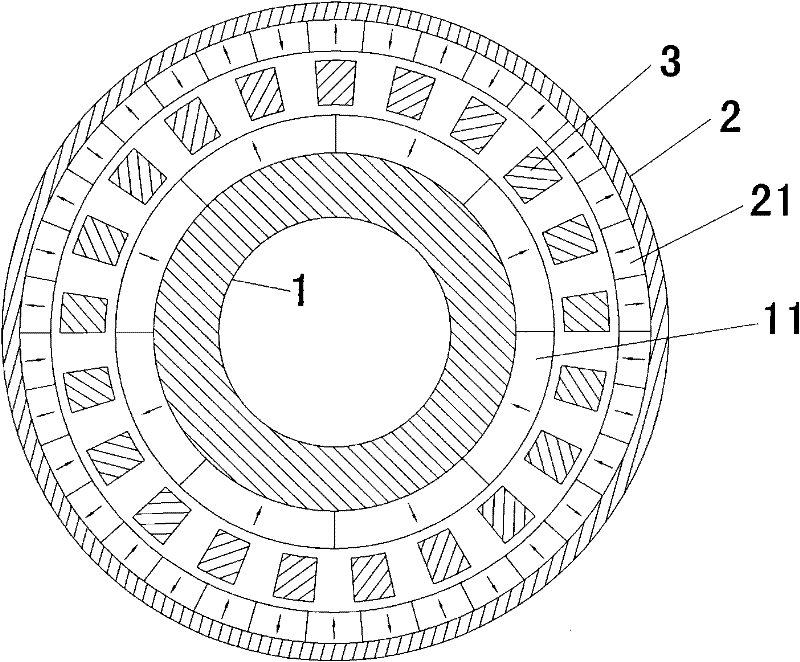

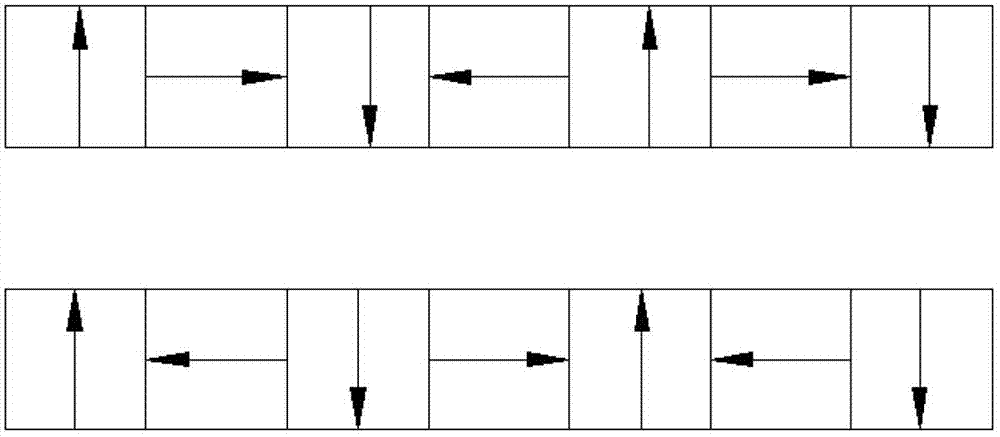

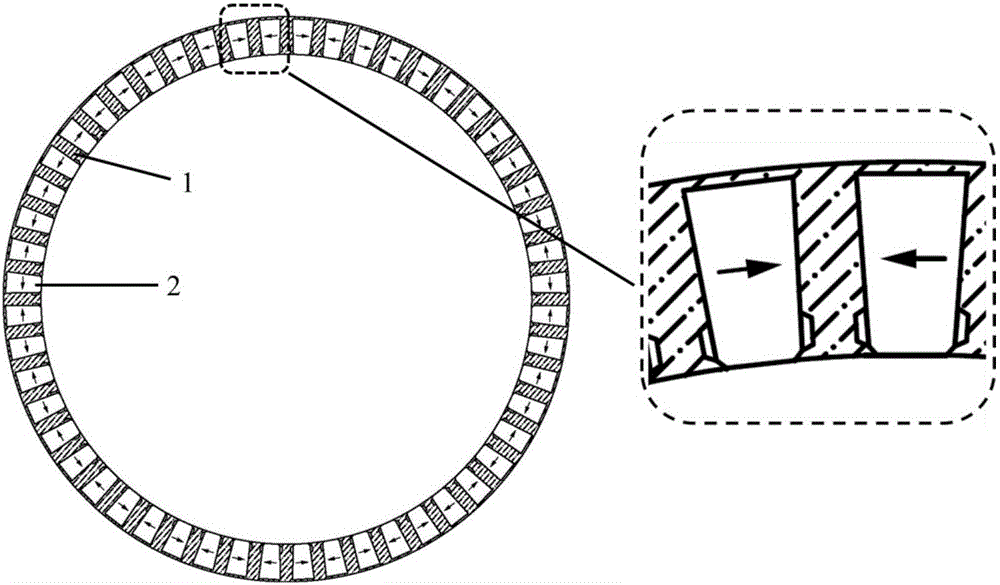

Stator-rotor double-permanent-magnet-type-vernier motor

ActiveCN103795159AIncrease profitIncreased torque densityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineryTorque density

The invention discloses a stator-rotor double-permanent-magnet-type-vernier motor which comprises a stator (1) and a rotor (2) coaxial with the stator (1). An air gap (9) is arranged between the stator (1) and the rotor (2). The stator (1) comprises a stator yoke and stator teeth (8) which extend in the radial direction from the outer surface of the stator yoke. A stator groove is formed by adjacent stator teeth (8) and the stator yoke. Stator permanent magnets (5) are arranged in each stator groove. The stator permanent magnets (5) in the same stator groove are arranged at certain spacing distance. An armature inner layer winding (3) is wound between adjacent stator teeth (8). According to the motor, rotor side permanent magnet flux leakage is obviously restrained, torque density is improved to the maximum degree, permanent magnets in a claw pole groove have a slot wedge effect, a claw pole winding is fixed in a groove, so that the structure is compact, the magnetizing directions of the permanent magnets are the same, and machining is easy.

Owner:SOUTHEAST UNIV

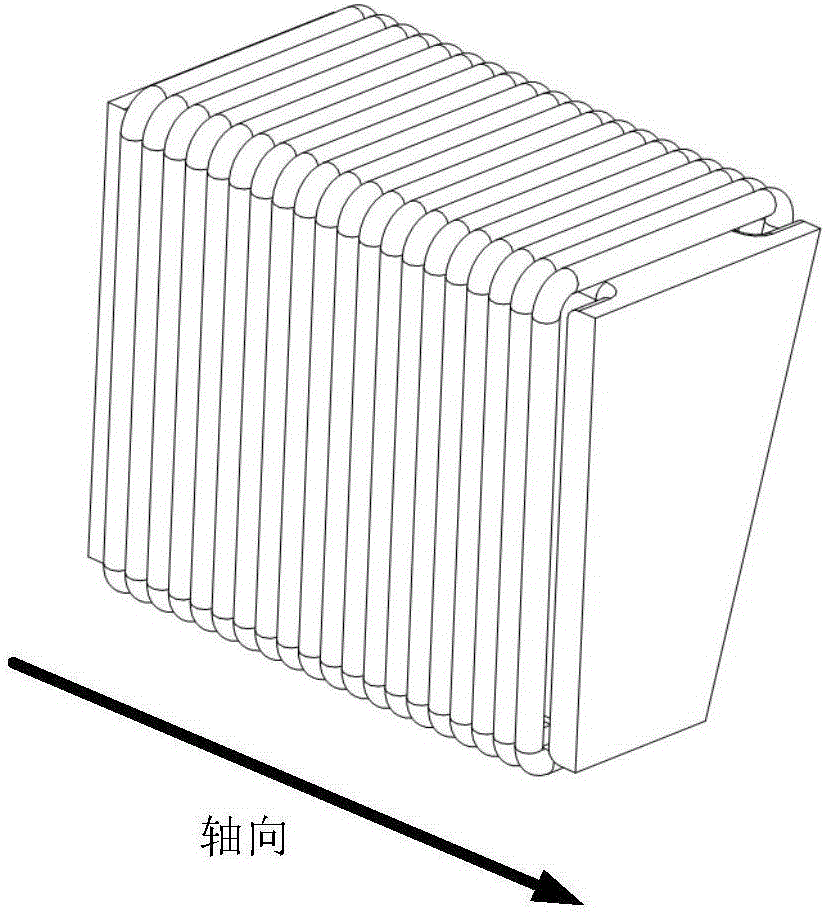

Permanent magnet motor with shaft radial folding winding

ActiveCN101345440AShorten the axial lengthSmall radiusMagnetic circuit rotating partsMagnetic circuit stationary partsTorque densityPermanent magnet motor

The invention discloses a permanent magnet motor with axial radial folding winding belonging to the motor field. The object of the invention is to solve the problems that the space effective utilization rate of the permanent magnet motor is low and the motor structure is not compact, thereby the torque density and power density are not effectively improved. The permanent magnet motor comprises a stator, a rotor and a shaft, wherein the stator is fixed on the shaft, the rotor arranged exterior of the stator rotationally connects with the shaft, a plurality of axial slots are uniformly distributed on the cylindrical surface of the round stator core, a plurality of radial slots are uniformly distributed in a radial form on the end faces of the two sides of the stator core, the axial slots and the radial slots are one-to-one correspondence and respectively communicate. A stator winding is arranged together on each axial slot and corresponding radial slot, a plurality of first permanent magnets are uniformly distributed on the inner circle wall of the rotor core and uniformly arranged around the shaft. A plurality of second permanent magnets are uniformly distributed in a radial form on the inner surface on each end face of the two sides of the rotor core, and the stator winding is a multiphase symmetric winding.

Owner:日照菁英传媒科技有限公司

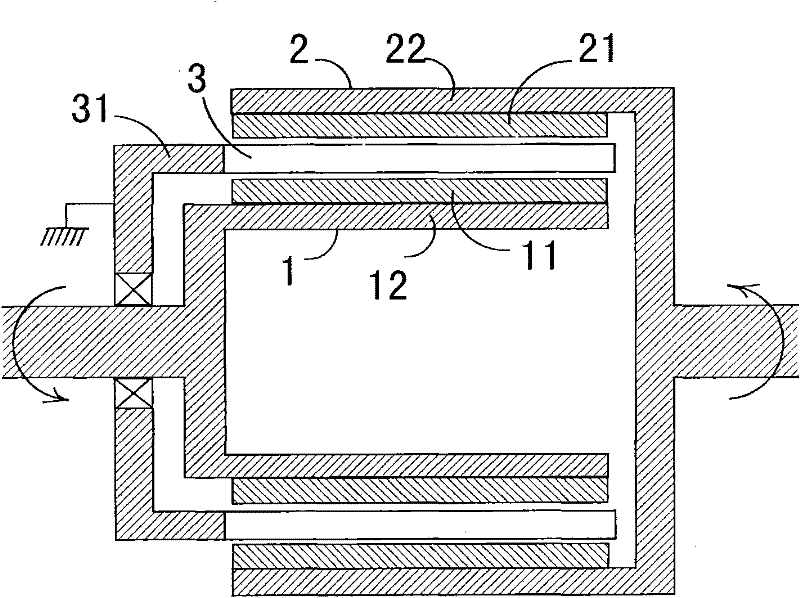

Axial-magnetic-field double-stator vernier motor

ActiveCN103178667ACompact structureImprove power factorDynamo-electric machinesPower factorTorque density

The invention discloses an axial-magnetic-field double-stator vernier motor which comprises a rotor and two stators. The rotor is shaped in a circular ring, multiple permanent magnets are uniformly arranged on the circumference of the ring at intervals, the stators are shaped in circular rings, multiple grooves are uniformly arranged on the circumference on the end faces of one ends of the rings and used for containing windings, and stator teeth are formed by protrusions among the grooves. The axial-magnetic-field double-stator vernier motor is characterized in that the two stators are coaxially arranged at an interval in an opposite groove manner, the rotor is coaxially arranged between the two stators, and half of a slot-pitch angle is distant between the stator teeth of the first stator and the stator teeth of the second stator. The vernier motor adopts an axial-magnetic-field double-stator structure, so that the torque density of the vernier motor is similar with that of conventional vernier motors and the power factor is evidently increased up to more than 0.8.

Owner:HUAZHONG UNIV OF SCI & TECH

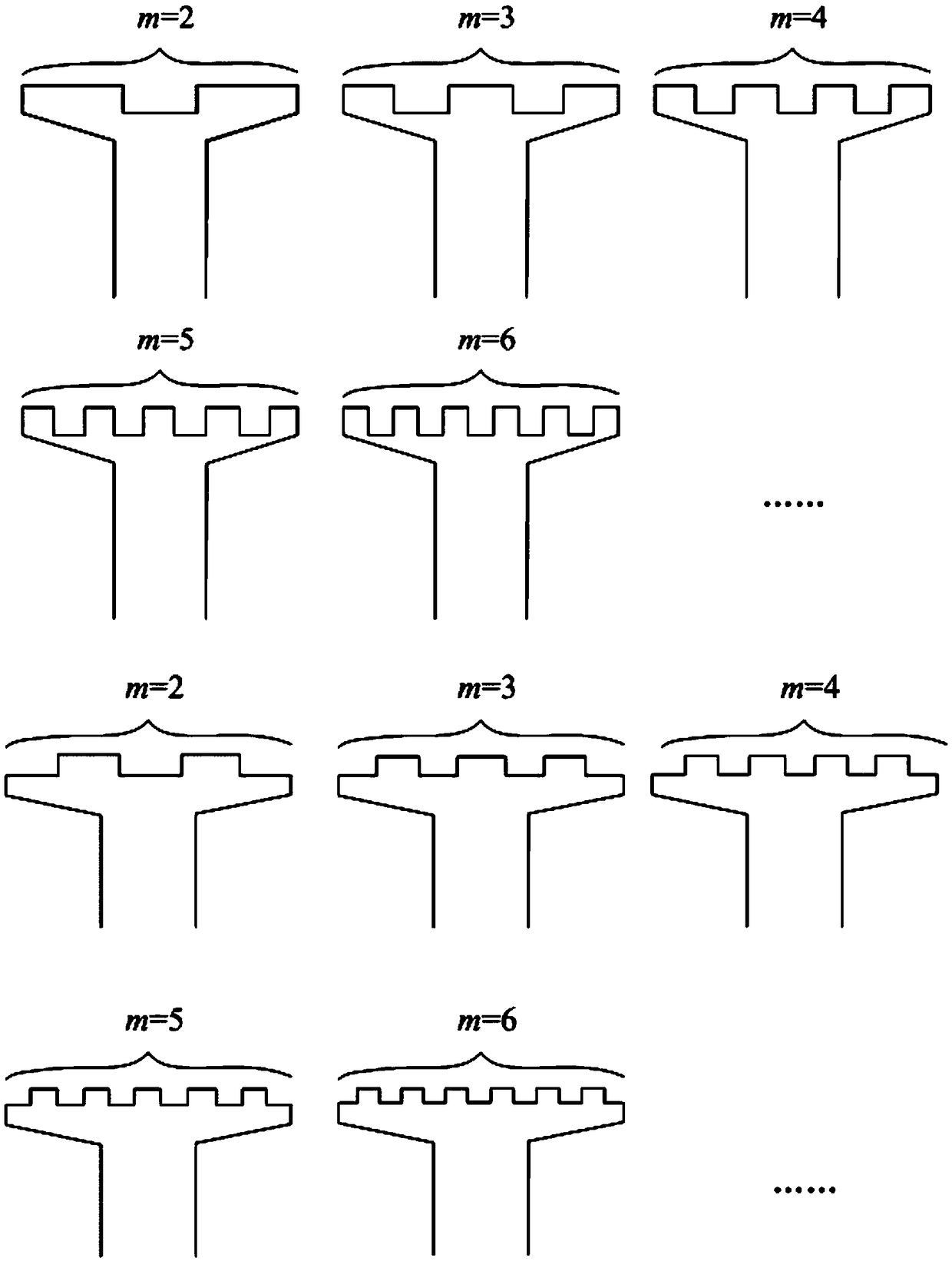

Fault tolerance type permanent magnetic vernier motor

InactiveCN102710078AReduce volumeImprove reliabilityMagnetic circuit rotating partsElectric machinesFault toleranceLow speed

The invention discloses a low-speed big-torque fault tolerance type permanent magnetic vernier motor for an electric automobile. The fault tolerance type permanent magnetic vernier motor comprises an inner stator and an outer rotor which are coaxial, wherein a permanent magnet is fixedly adhered to the inner surface of the outer rotor along the circumferential direction; the magnetizing direction of the permanent magnet is radial; the N pole and the S pole are arranged staggeredly; 10 armature teeth and 10 fault tolerance teeth are distributed on the circumference of the inner stator staggeredly; a single layer of concentrated armature winding is wound on the armature teeth; concentrated armature windings on the two armature teeth and radially opposite to each other are connected in series into one phase; the armature winding is a five-phase winding; the tooth width of the armature teeth is not equal to that of the fault tolerance teeth; and 40 modulation poles are distributed on the tooth tops of the armature teeth and the fault tolerance teeth uniformly along the circumferential direction. The torque density is greatly increased; the fault tolerance performance is remained; the volume of the motor is reduced; and the reliability and the operation ability with fault of the motor are improved.

Owner:JIANGSU UNIV

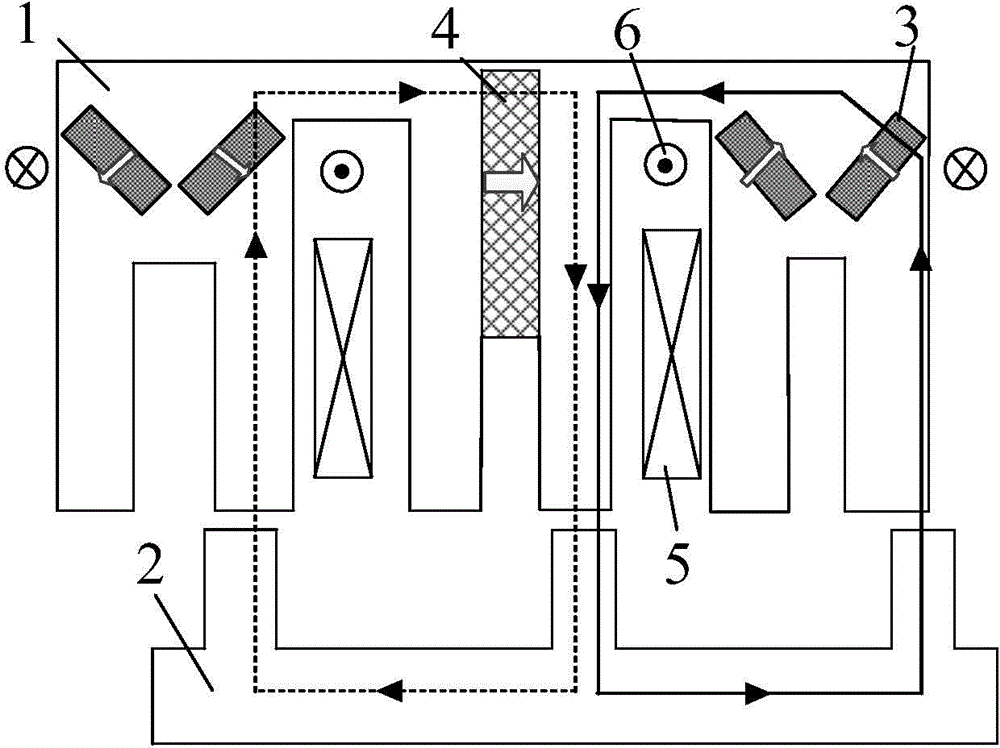

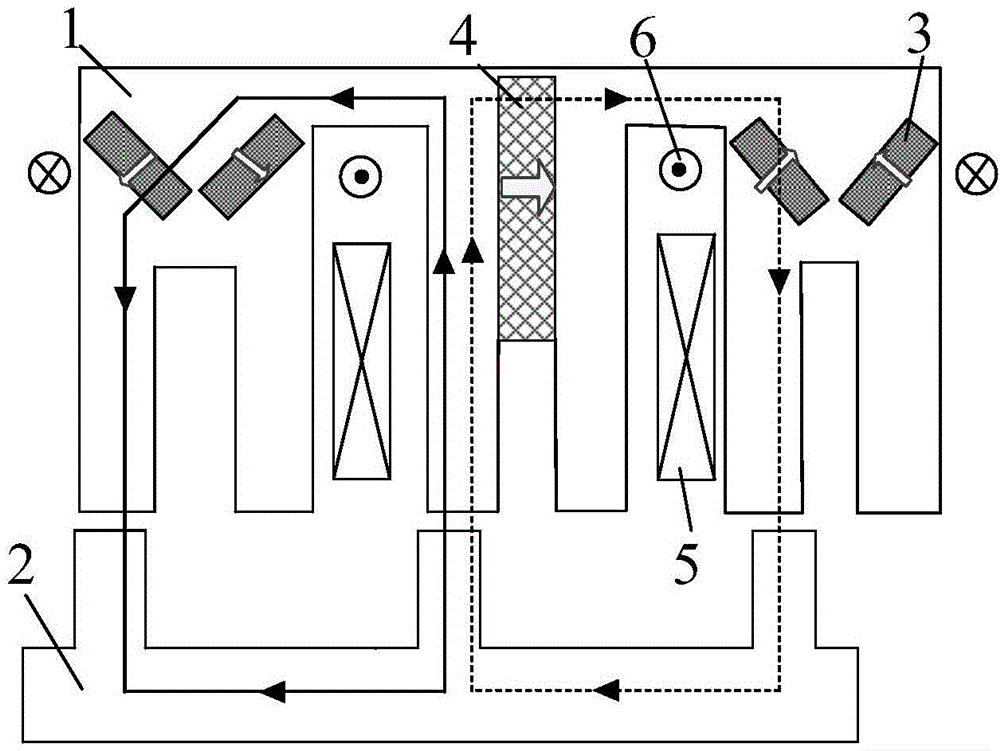

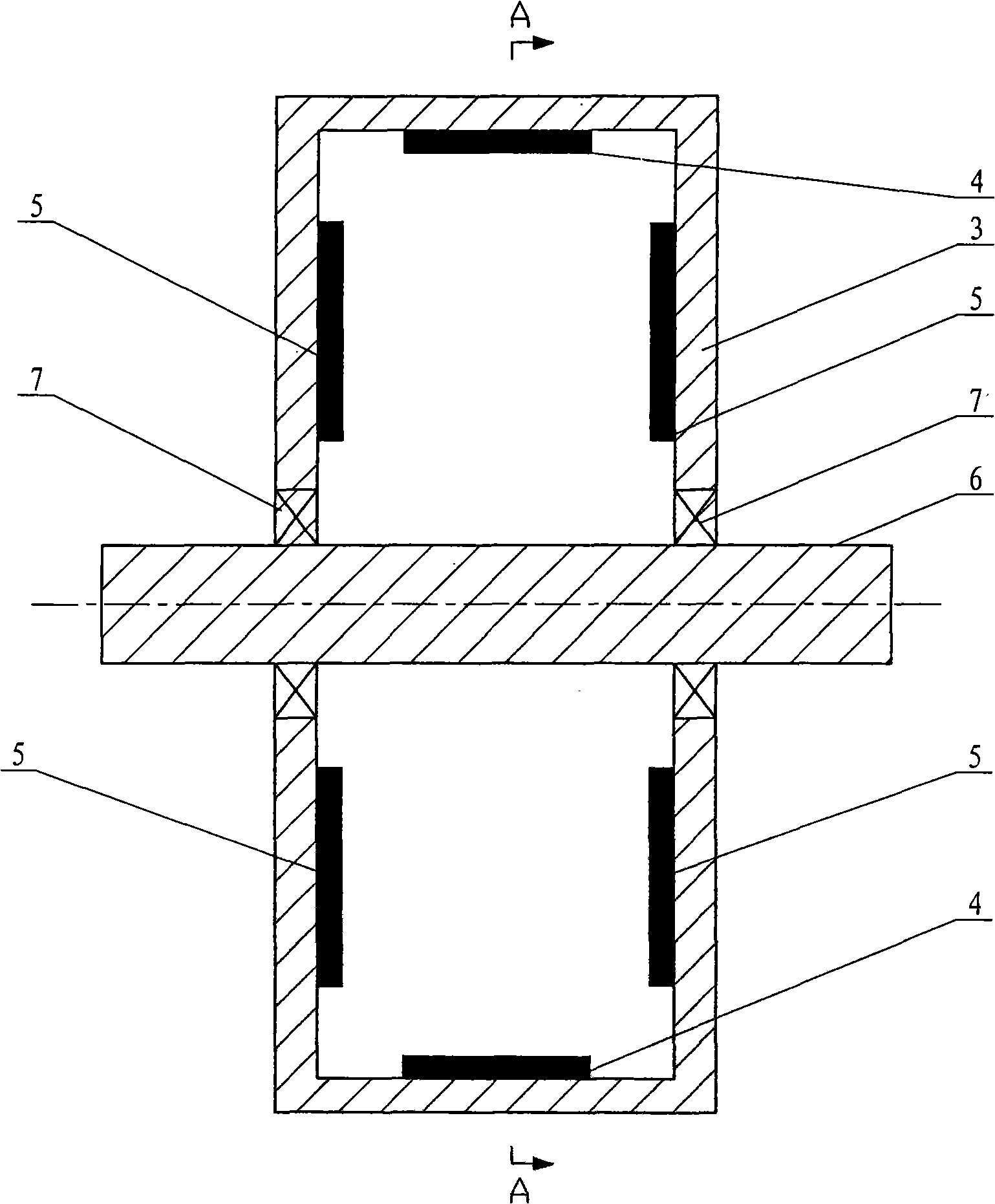

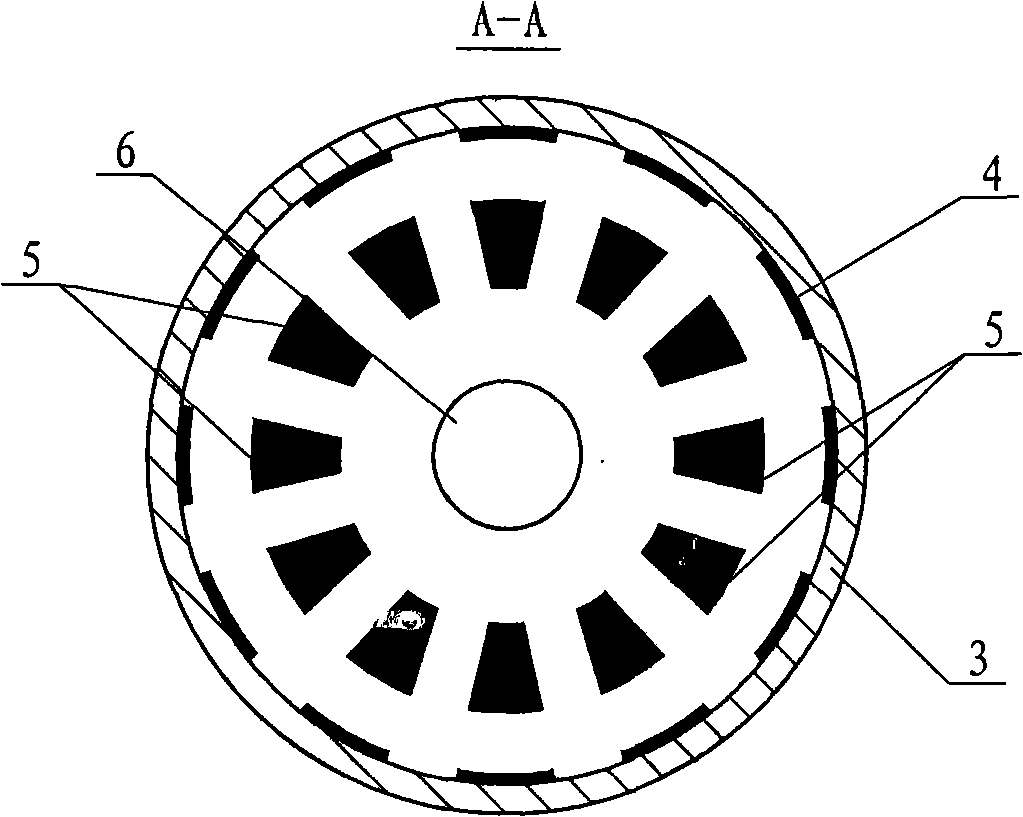

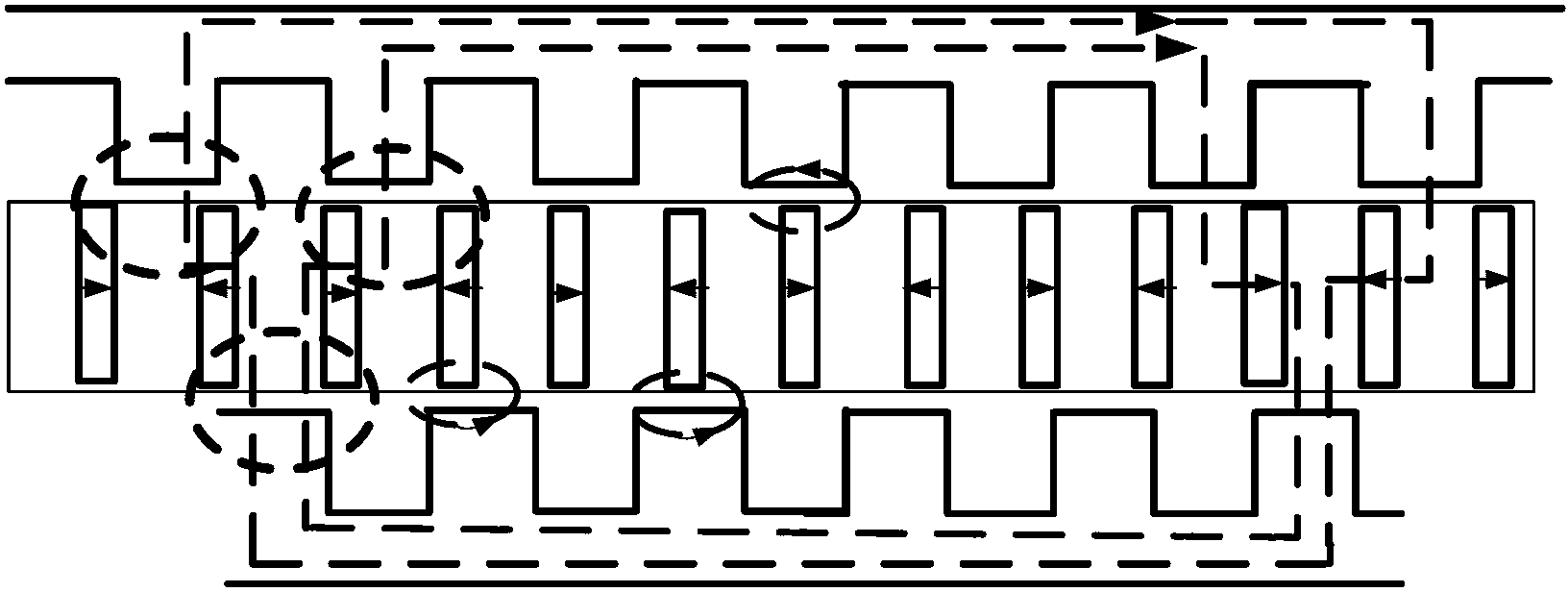

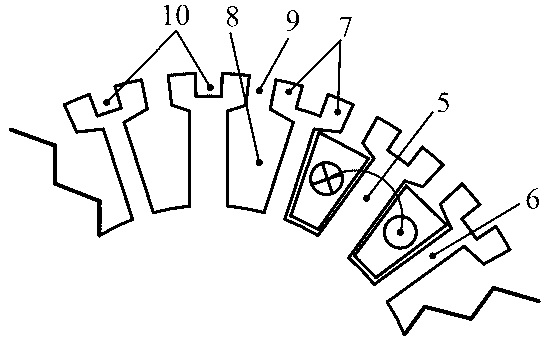

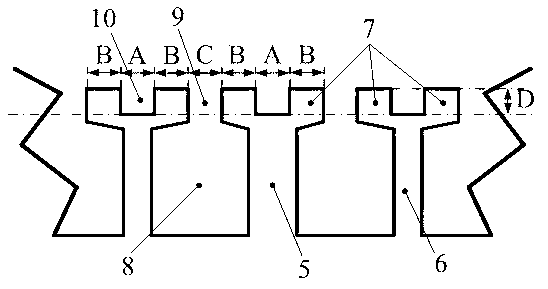

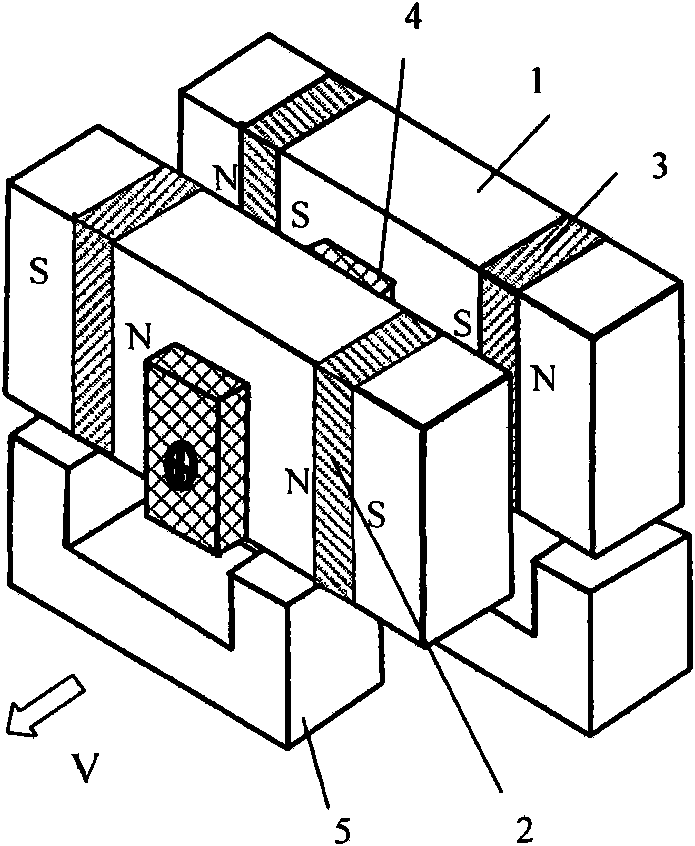

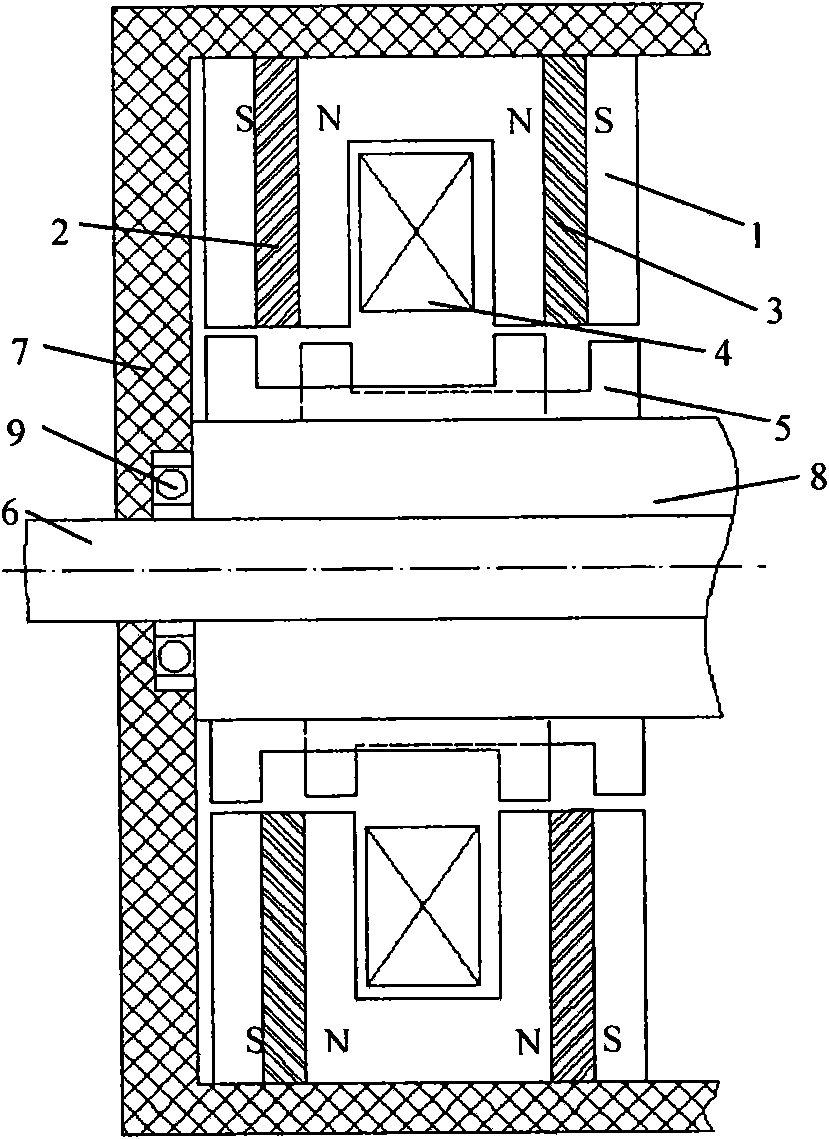

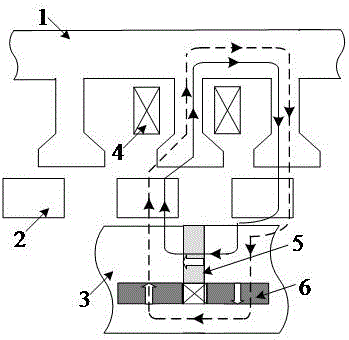

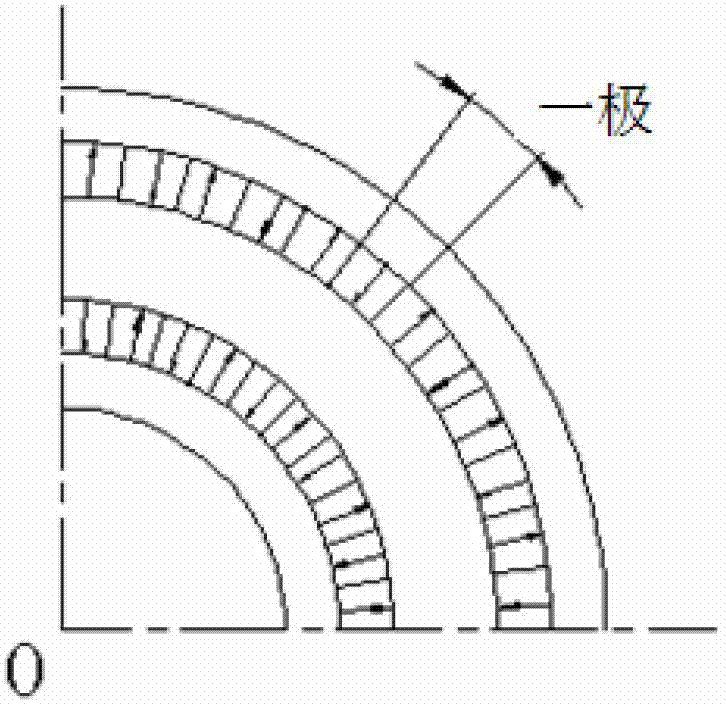

Magnetic flux switching type transverse magnetic flux permanent magnetism wind mill generator

InactiveCN101577449AAvoid the situation that only corresponds to one stator coreIncreased torque densityMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesNon magnetic

The invention provides a magnetic flux switching type transverse magnetic flux permanent magnetism wind mill generator, which is a novel transverse magnetic flux permanent magnetism wind mill generator which is high in power density and torque density and is directly driven. A stator consists of a plurality of stator cores(1) distributed around a rotor and an armature winding(4); each stator core(1) is U-shaped, both sides of the stator core(1) are embedded with a first permanent magnet(2) and a second permanent magnet(3), and magnetic pole directions of the two permanent magnets are opposite; the ring-shaped winding(4) is arranged in the stator; the magnetic poles of the first permanent magnets(2) of the two adjacent stator cores(1) are opposite, and the magnetic poles of the second permanent magnets(3) of the two adjacent stator cores(1) are also opposite; all rotor cores(5) are the same in size; the two adjacent rotor cores(5) are aligned left and right respectively and arranged at intervals; the rotor cores(5) are made by overlapping silicon steel sheets and arranged on a cylinder(8) made of non-magnetic conduction materials to form the whole rotor; and the rotor is connected with a rotating shaft of a motor (6) and then connected with a shell(7) through a bearing(9).

Owner:SOUTHEAST UNIV

Little rare earth type wide speed regulation hybrid permanent magnetic flux switching double stator motor

ActiveCN105375715AEasy to increase power densityEasy to increase torque densityMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsTorque densityMagnetization

The invention discloses a little rare earth type wide speed regulation hybrid permanent magnetic flux switching double stator motor. According to the motor, X outer stator teeth are distributed uniformly and circumferentially on an inner surface of an outer stator, m phases of armature windings and magnetization windings are alternately wound on the X outer stator teeth; q magnetic conduction blocks and q insulation blocks are arranged on an outer circle surface of a rotor support of a middle rotor in a staggered mode; an inner stator comprises an inner stator core and a hybrid permanent magnetic unit, K hybrid permanent magnet units are uniformly embedded in the inner stator core along the circumference direction, each hybrid permanent magnet unit respectively comprises a middle non-rare-earth aluminum nickel cobalt permanent magnet and rare earth neodymium iron boron permanent magnets at two sides of the non-rare-earth aluminum nickel cobalt permanent magnet; a stator partitioning structure is employed, the armature windings and the permanent magnets are separated and are respectively arranged in the outer stator and the inner stator, a problem of mutual limit in quantity of traditional magnetic flux switching motor permanent magnets and armature windings is solved, and motor power density and torque density are easy to improve.

Owner:JIANGSU UNIV

Disc rotor motor

ActiveUS20150048696A1Increase the cross-sectional areaCompact designMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesTorque density

A disc rotor motor is demonstrated, having at least one stator that has at least one electrical stator winding and stator teeth, which have a tooth neck composed of a soft magnetic powder composite, and having at least one disc-shaped rotor, which has permanent magnetic poles composed exclusively of ferrite magnets at least for producing torque, with the rotor and stator oriented parallel to each other and spaced apart from each other by an axial gap. In order to find an optimum between costs, weight, and overall size as well as power and torque density, the invention proposes that the stator teeth each end in a tooth end that adjoins their tooth neck and is composed of a soft magnetic powdered composite, which tooth end widens out in its cross-sectional area in comparison to the tooth neck.

Owner:MIBA SINTER AUSTRIA

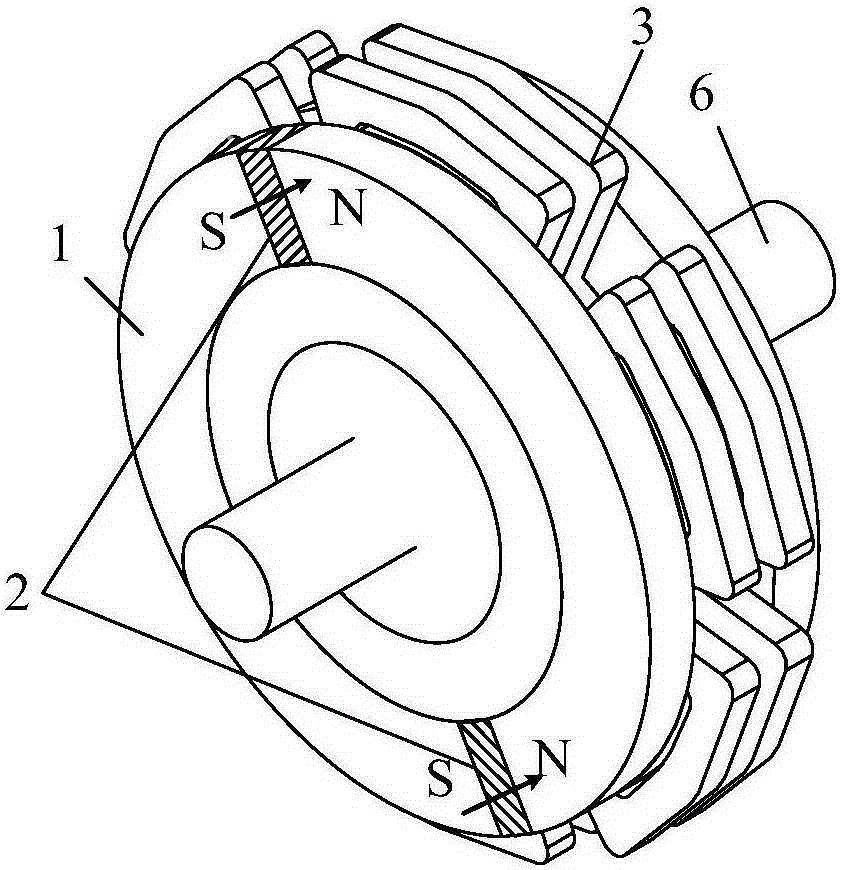

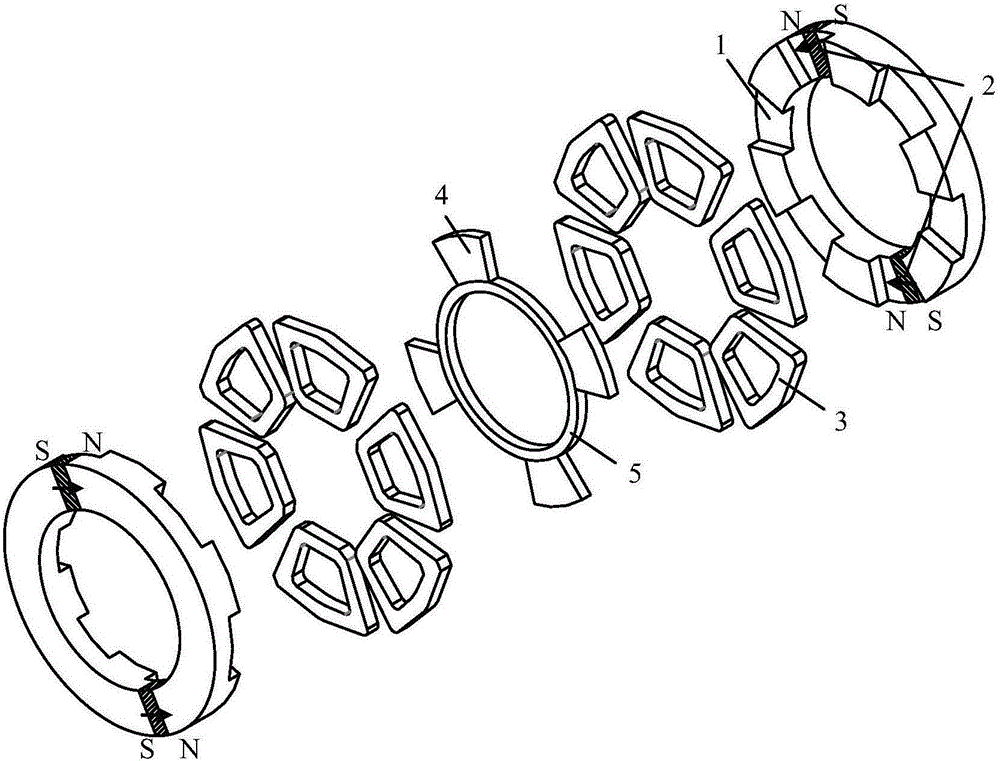

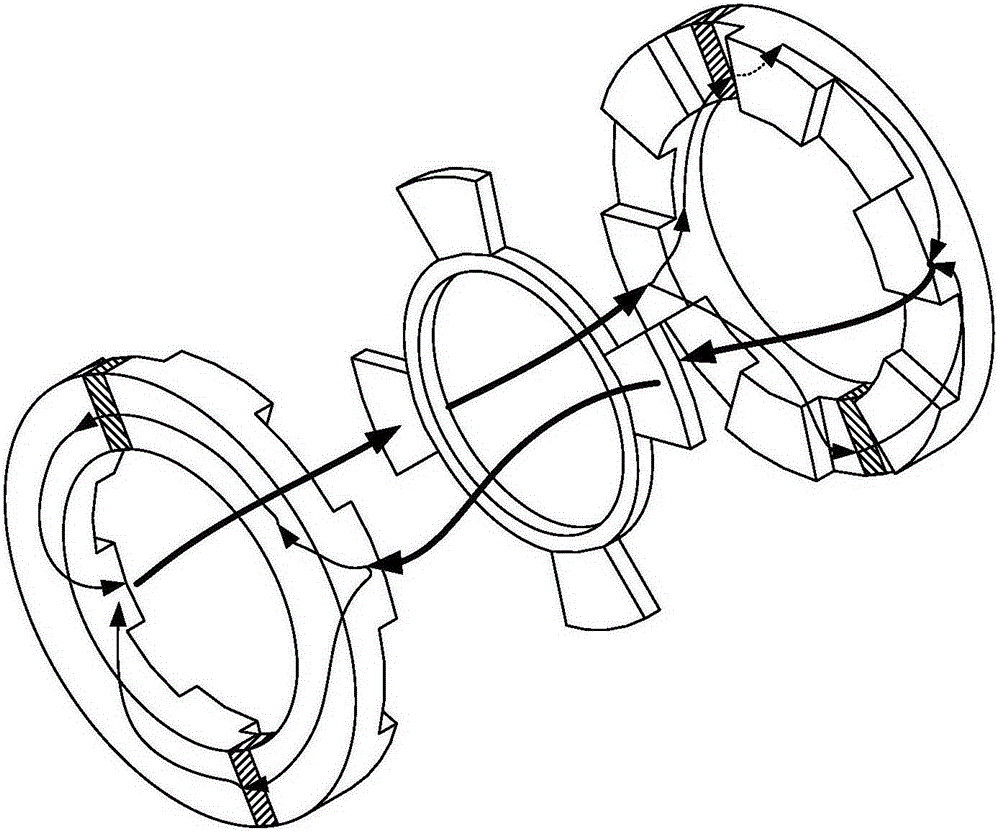

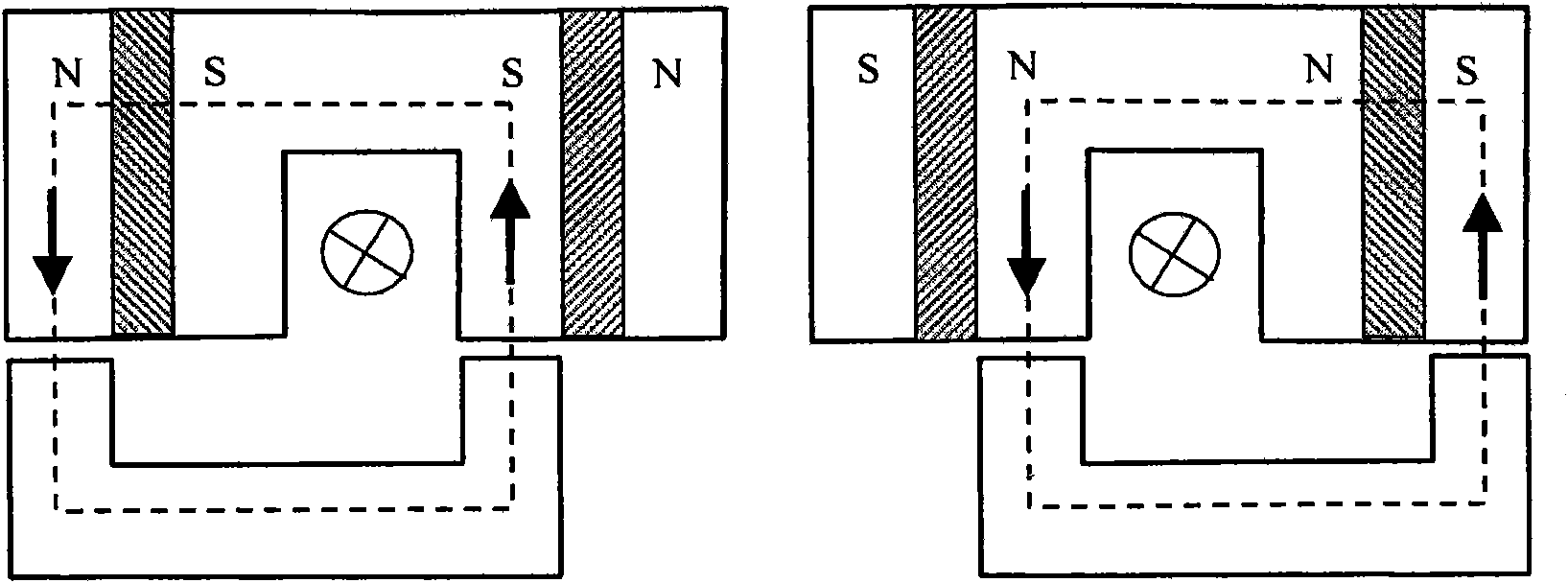

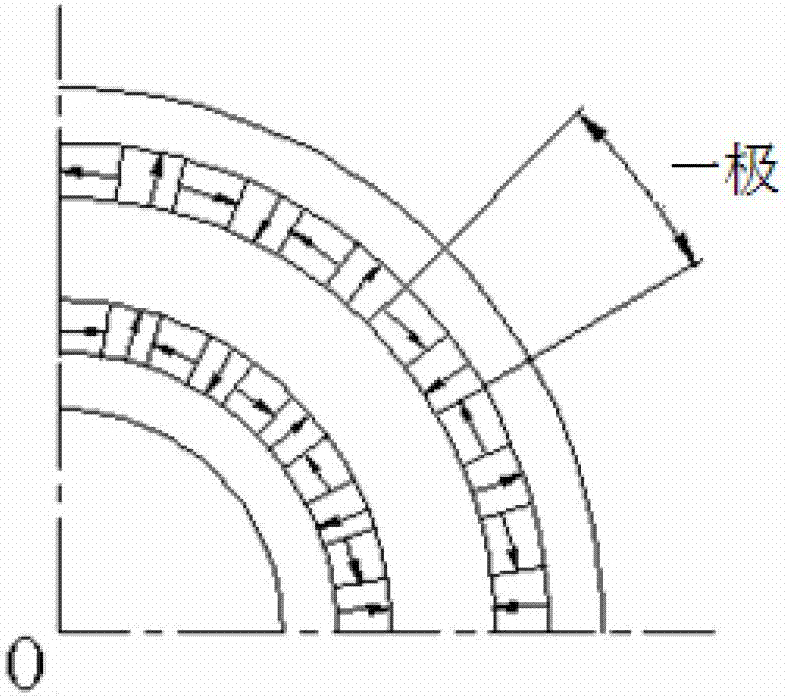

Magnetic gear and magnetic transmission device

The invention provides a new magnetic gear and a magnetic transmission device based on the magnetic gear, which are used for solving the problem of higher cost of the existing magnetic gear without lowering the torque density of the magnetic gear. For the magnetic gear, permanent magnets of the inner and outer rotors of the magnetic gear are separated by a magnetic material and are tangentially magnetized, and the supporting parts of the inner and outer rotors are made from a non-magnetic material. In the invention, as magnetic fields are converged to be enhanced at opposite sides of two groups of permanent magnets, the number of the permanent magnets is reduced by one half and the cost of the magnetic gear is lowered by one quarter in the case of equal torque density, and meanwhile the magnetic transmission device can obtain relatively higher torque density as well as a large transmission ratio by virtue of cycloidal motion between the first group of permanent magnets and the second group of permanent magnets.

Owner:东元总合科技(杭州)有限公司

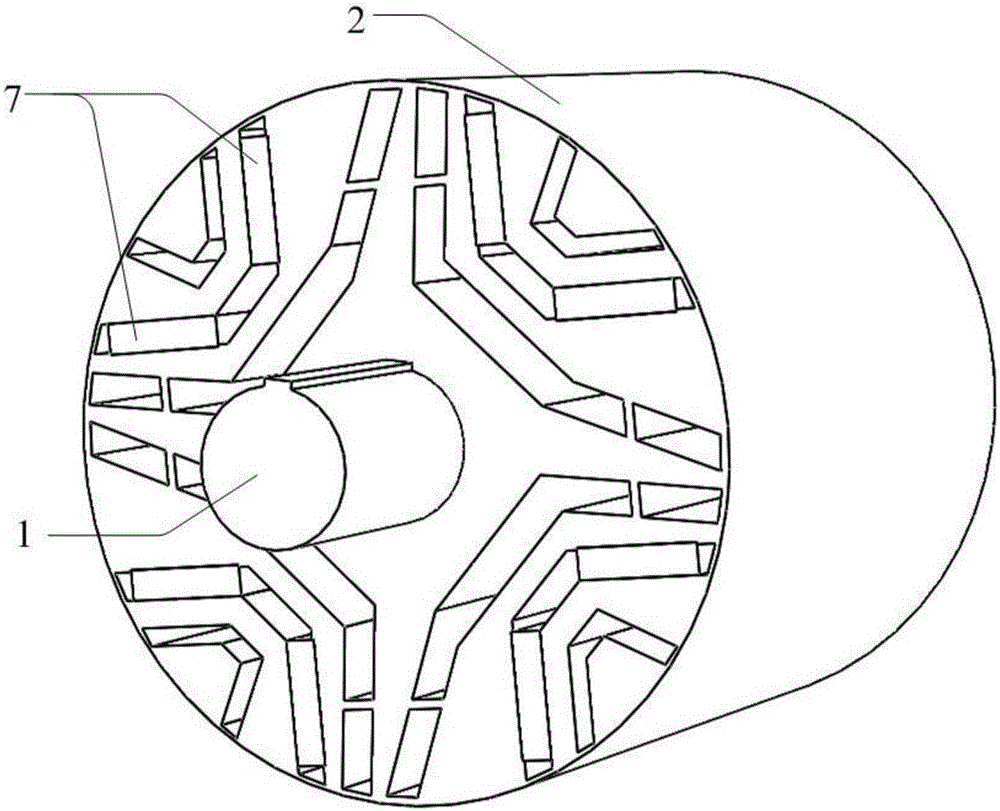

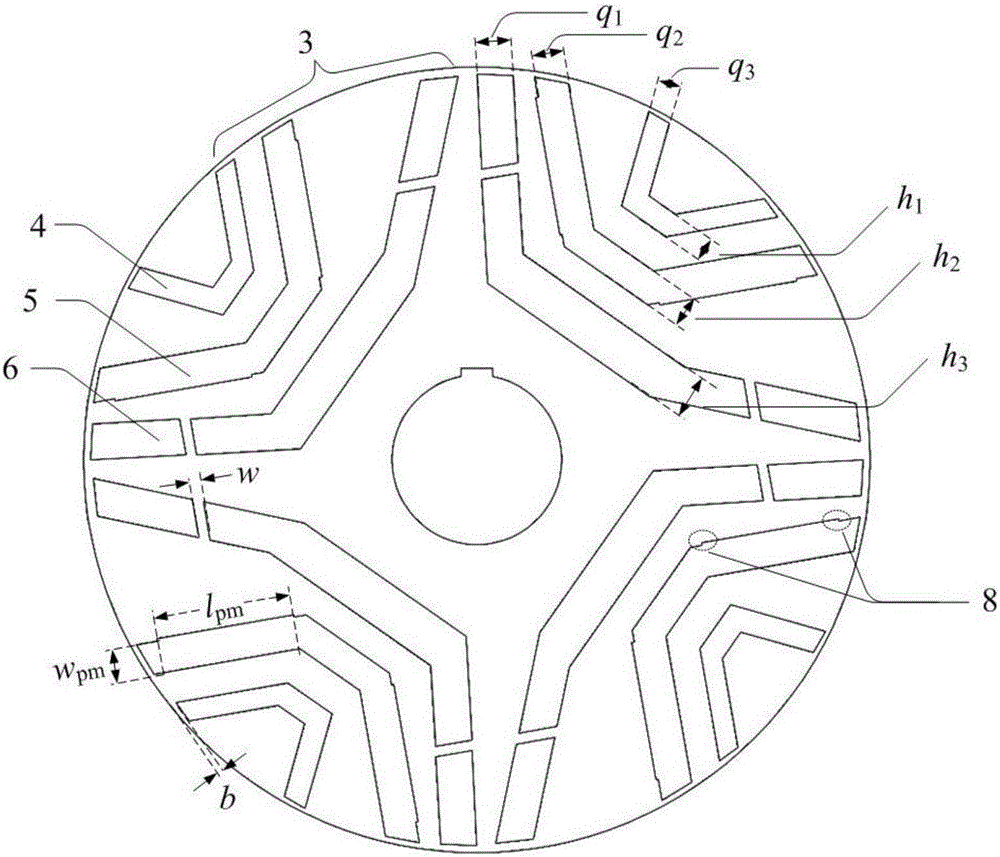

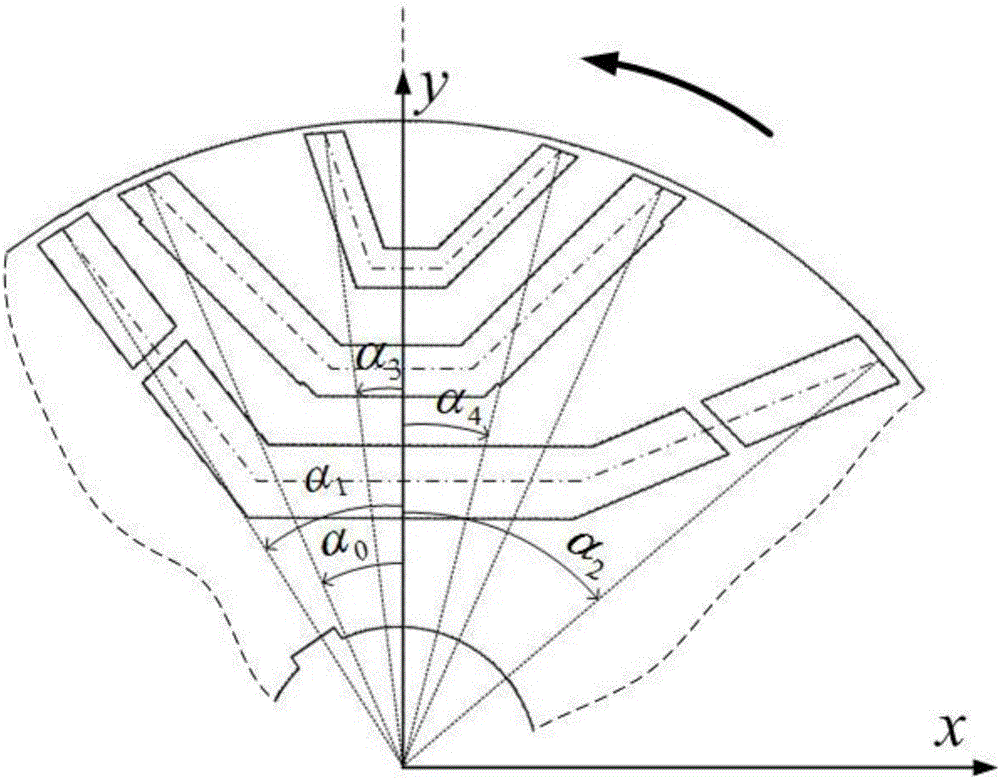

Permanent magnet reluctance synchronous motor rotor structure having high torque density

ActiveCN105958692AIncrease profitReduce manufacturing costMagnetic circuit rotating partsSynchronous machine detailsSynchronous motorElectric machine

The invention discloses a permanent magnet reluctance synchronous motor rotor structure having high torque density. The permanent magnet reluctance synchronous motor rotor structure comprises a central rotating shaft and a rotor iron core; the rotor iron core is uniformly provided with P groups of through grooves along the circumferential direction; each group of through grooves comprises three layers of U-shaped through grooves arranged in the radial direction of the rotor iron core at intervals; and a permanent magnet is embedded in the straight bottom side of each U-shaped through groove. By means of the permanent magnet reluctance synchronous motor rotor structure disclosed by the invention, the permanent magnet torque component and the reluctance torque component are sufficiently utilized in the synthesis torque of a motor; and thus, the torque density of the motor is increased.

Owner:SOUTHEAST UNIV

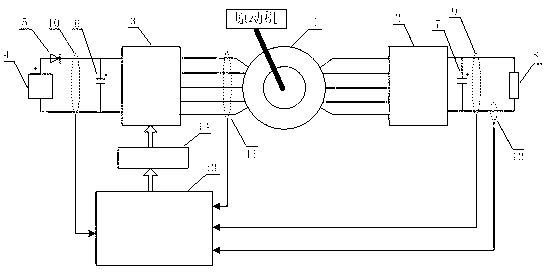

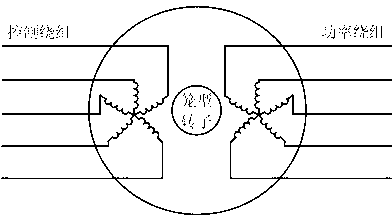

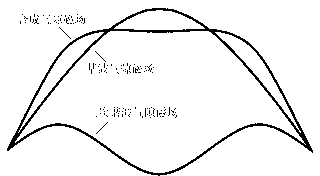

System and method for high-voltage direct-current starting and power generation of stator duplex winding asynchronous motor

ActiveCN103326649AImprove power densityIncreased torque densityWindings conductor shape/form/constructionGenerator control by field variationCapacitanceFault tolerance

The invention discloses a system and method for high-voltage direct-current starting and power generation of a stator duplex winding asynchronous motor. A main loop comprises the stator duplex winding asynchronous motor, a rectifier bridge, a power converter, a direct-current power source, a diode, a control side direct-current capacitor and a power side direct-current capacitor. A detecting loop comprises a first voltage transducer, a second voltage transducer, a first current transducer and a second current transducer. A control loop comprises a digital signal processor and a driving circuit. Five-phase centralized full-pitch star-shaped structures are adopted by both sets of stator windings which are a power winding and a control winding of the stator duplex winding asynchronous motor. In the starting and power generating process, the power converter implants three times of proper harmonic currents to the motor through the control winding under the control of the digital signal controller, an air-gap magnetic field is controlled to be a standard square wave, and therefore the torque density and the power density of the motor are improved. The system and method for the high-voltage direct-current starting and power generation of the stator duplex winding asynchronous motor is simple in structure and free of electric brush sliding rings, can achieve the integration of start and power generation, and has the advantages of being high in power density and torque density, easy to operate with fault-tolerance and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

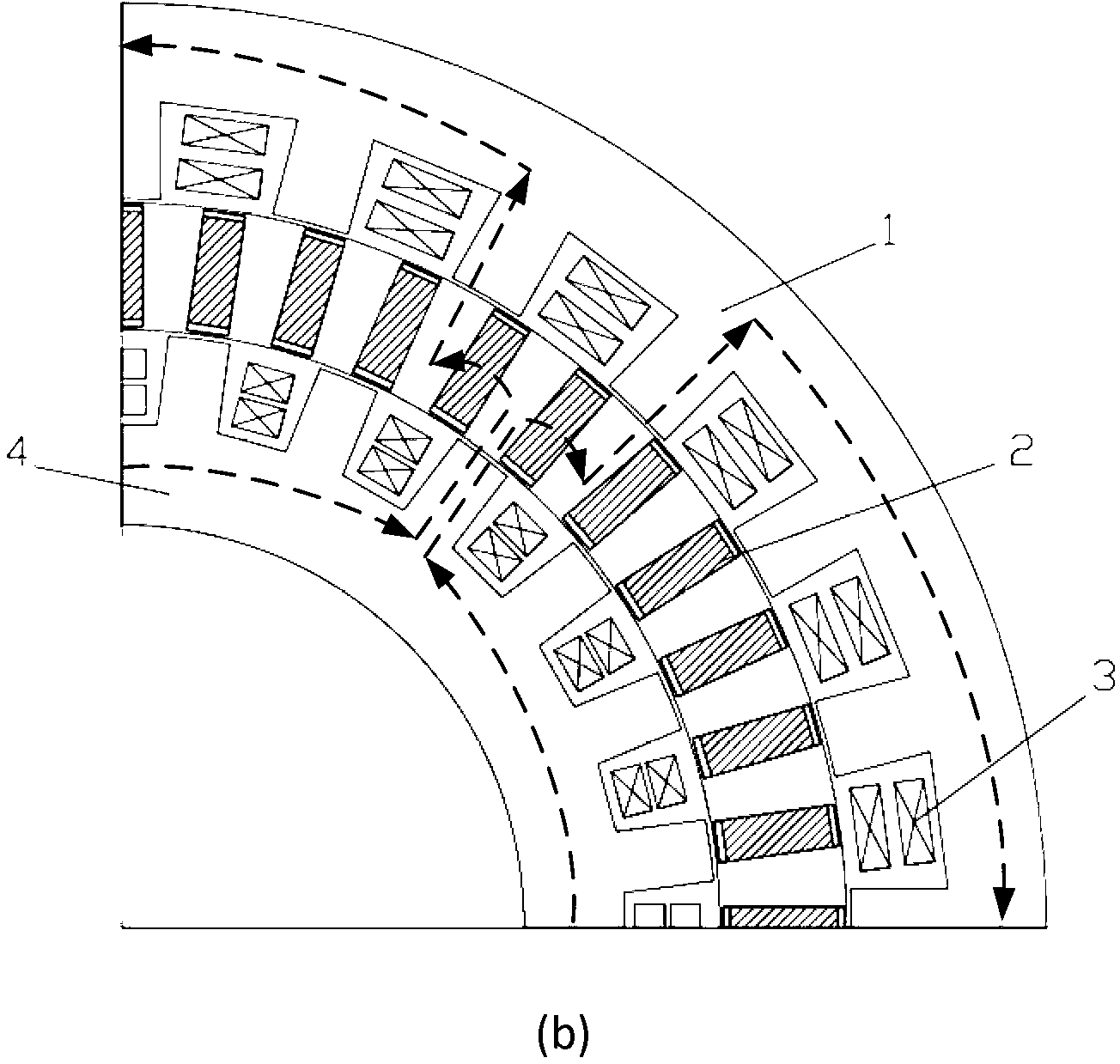

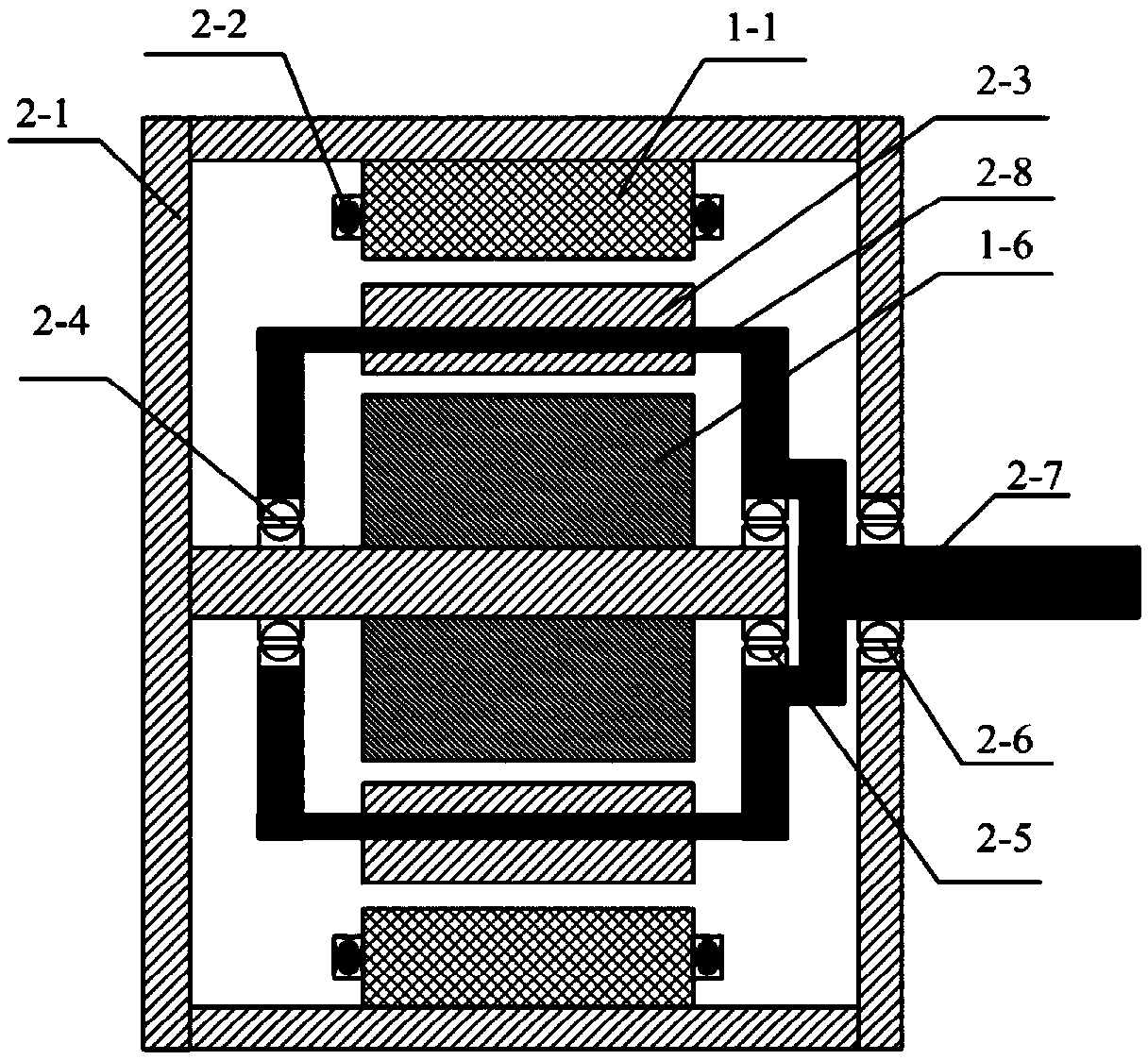

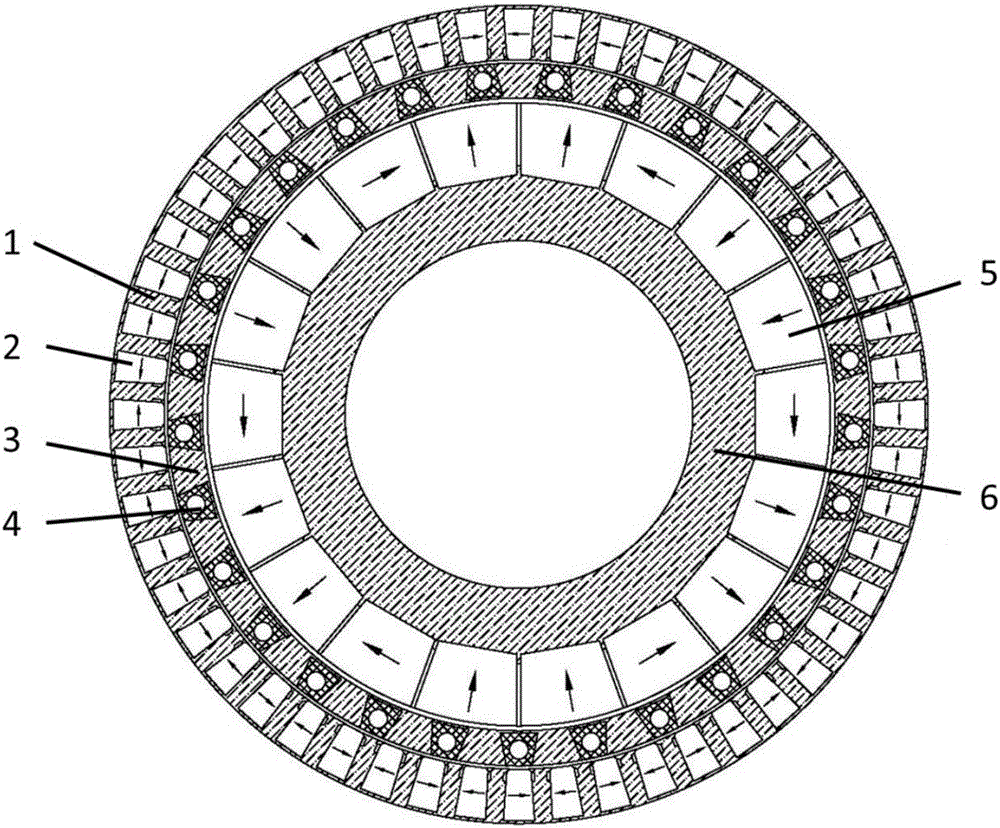

Magnetic gear type double-stator hybrid permanent magnet memory motor

InactiveCN105141092ASimple structureImprove space utilizationMagnetic circuit rotating partsMagnetic circuit stationary partsEpoxyElectric machine

The invention discloses a magnetic gear type double-stator hybrid permanent magnet memory motor. The motor comprises an external stator, a rotor and an internal stator which are coaxially arranged and sleeved from outside to inside in turn. The external stator comprises armature iron core teeth, stator yokes and armature windings which are arranged on the armature iron core teeth. The internal stator comprises an internal stator iron core provided with internal slots, neodymium iron boron permanent magnets, aluminum nickel cobalt permanent magnets and pulse magnetic regulating windings which are arranged in the internal slots of the internal stator. The two types of co-excitation permanent magnets are arranged in a "U" shape. The number of single permanent magnets on the internal stator is equal to that of external stator armature teeth. The whole rotor has an annular cup-shaped structure. Rotor iron blocks are fixed in a non-magnetic-conductive epoxy resin sleeve. The rotor iron blocks are connected via magnetic conductive bridges. Disadvantages that a conventional single stator has multiple internal excitation sources which are mutually hindered in space and torque density is relatively low can be solved. Besides, high power density is realized by arrangement of double-stator hybrid permanent magnets, and residual magnetization intensity and magnetization direction of the permanent magnets are regulated by applying pulse current so that motor magnetic field high-efficiency regulation is realized, and rotating speed operation range is enhanced.

Owner:SOUTHEAST UNIV

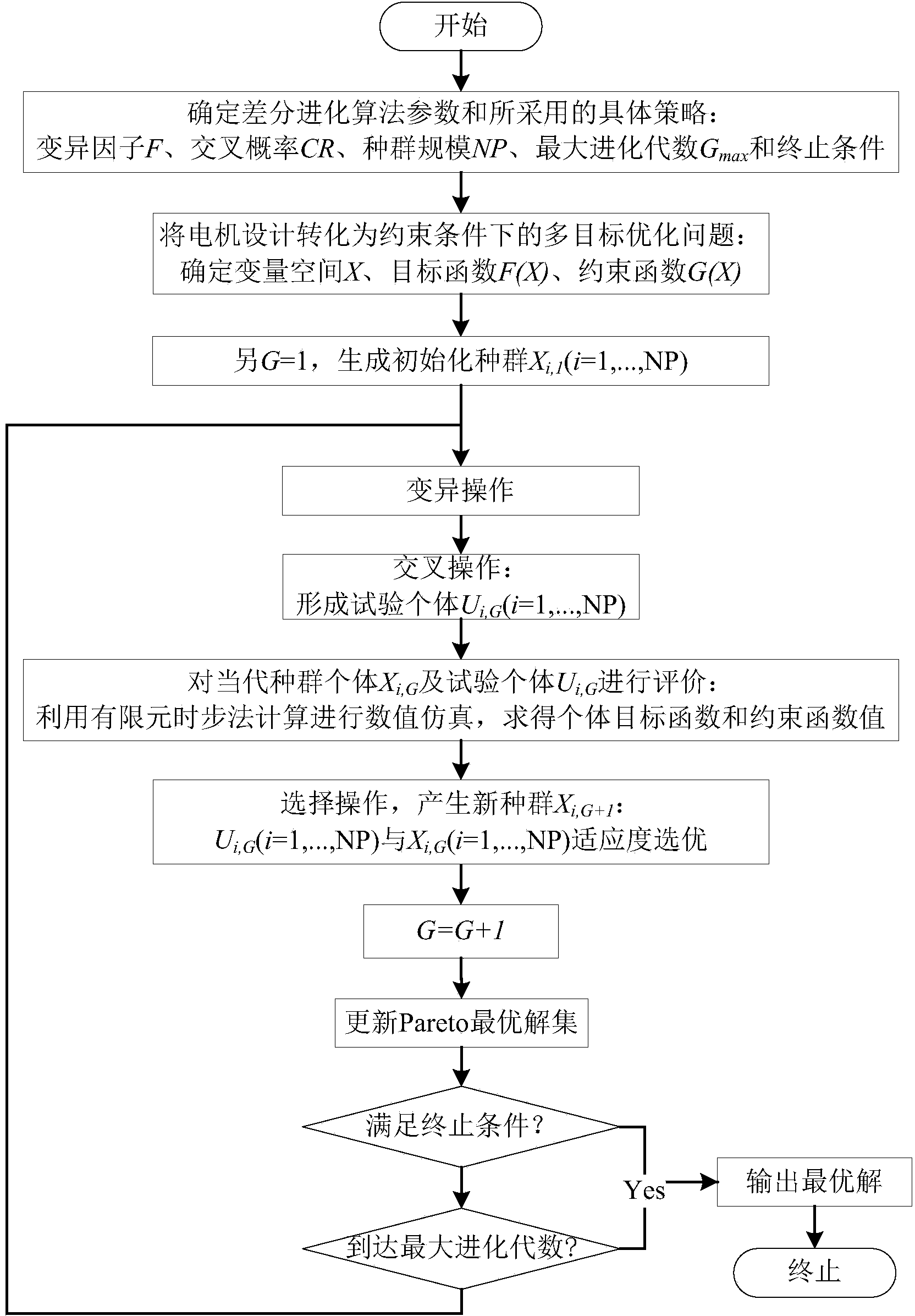

Method of optimallying designing closed-winding permanent magnet brushless DC motor

ActiveCN103678783AStrong differential evolution stabilityImprove search abilityGenetic modelsSpecial data processing applicationsPower factorTorque density

The invention relates to a method of optimallying designing a closed-winding permanent magnet brushless DC motor on the basis of differential evolution algorithm and finite element time-stepping method. The method includes: according to the particularity in the closed-winding permanent magnet brushless DC motor, by considering a body and a control part of the motor, using the cost in torque density and unit torque of a system as an optimization target; using constraint conditions such as parallel branch circulation, power factor, efficiency, torque output, fluctuation, heating, structural strength and the like. The method has the advantages that design schemes of each generation are varied, intersected and selected for differential evolution, and a Pareto optimal solution set is updated continuously; in order to ensure design accuracy, the finite element time-stepping method is applied to accurate dynamic simulation computation of the closed-winding permanent magnet brushless DC motor; the reliable and accurate method is provided for the design optimization of the closed-winding permanent magnet brushless DC motor, and the development of the novel motor is quickened.

Owner:南京华乘电气科技有限公司

Halbach-array-based magnetic coupling transmission device

The invention discloses a halbach-array-based magnetic coupling transmission device, which comprises an input shaft, a bearing, a permanent magnet, a stator, a rotor, and an output shaft, wherein the output shaft and the input shaft are fixed on a support through bearings and bearing seats; the rotor and the input shaft are in transmission connection through a bearing arranged in the molding cavity in the rotor and are in clearance fit; the rotor and the output shaft are connected in a manner that the bearing is arranged eccentrically; the stator is nested outside the rotor and forms an eccentric mechanism with the rotor; the stator is fixed with a base; permanent magnets which can make the rotor rotate are arranged on the inside surface of the stator and the outside surface of the rotor respectively; an air gap is formed between the permanent magnets; and the magnetization directions of the two permanent magnet are arranged in an Halbach manner. The device overcomes the drawback caused by contact of the conventional mechanical gears and the drawbacks of low transmission torque density and small transmission ratio of the common permanent magnet gears.

Owner:ZHEJIANG UNIV OF TECH

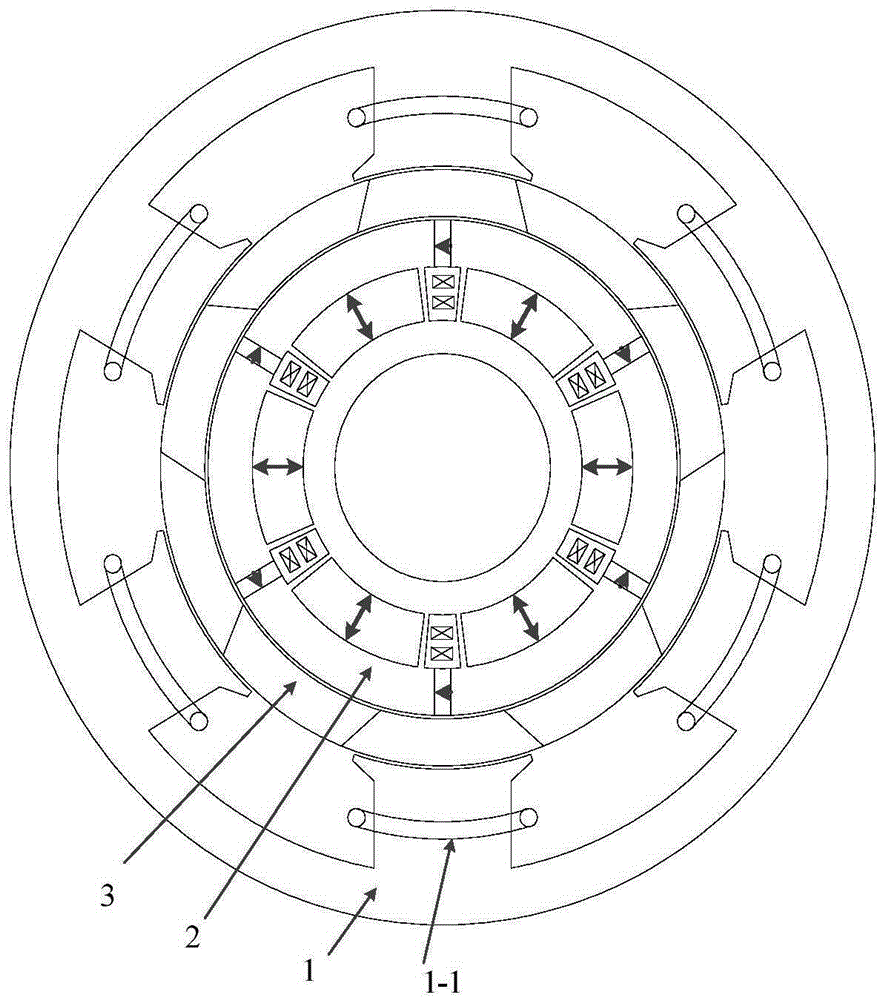

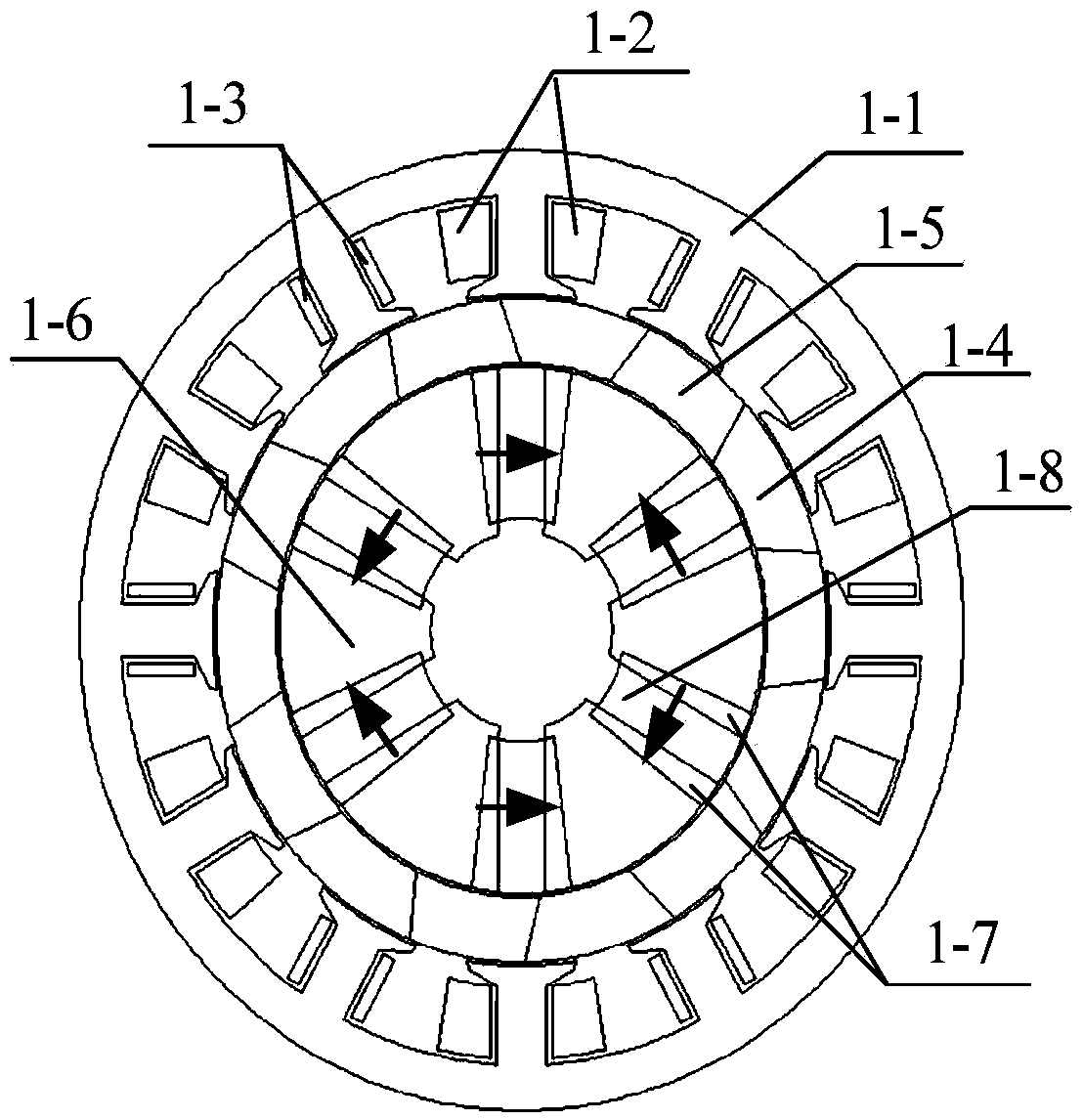

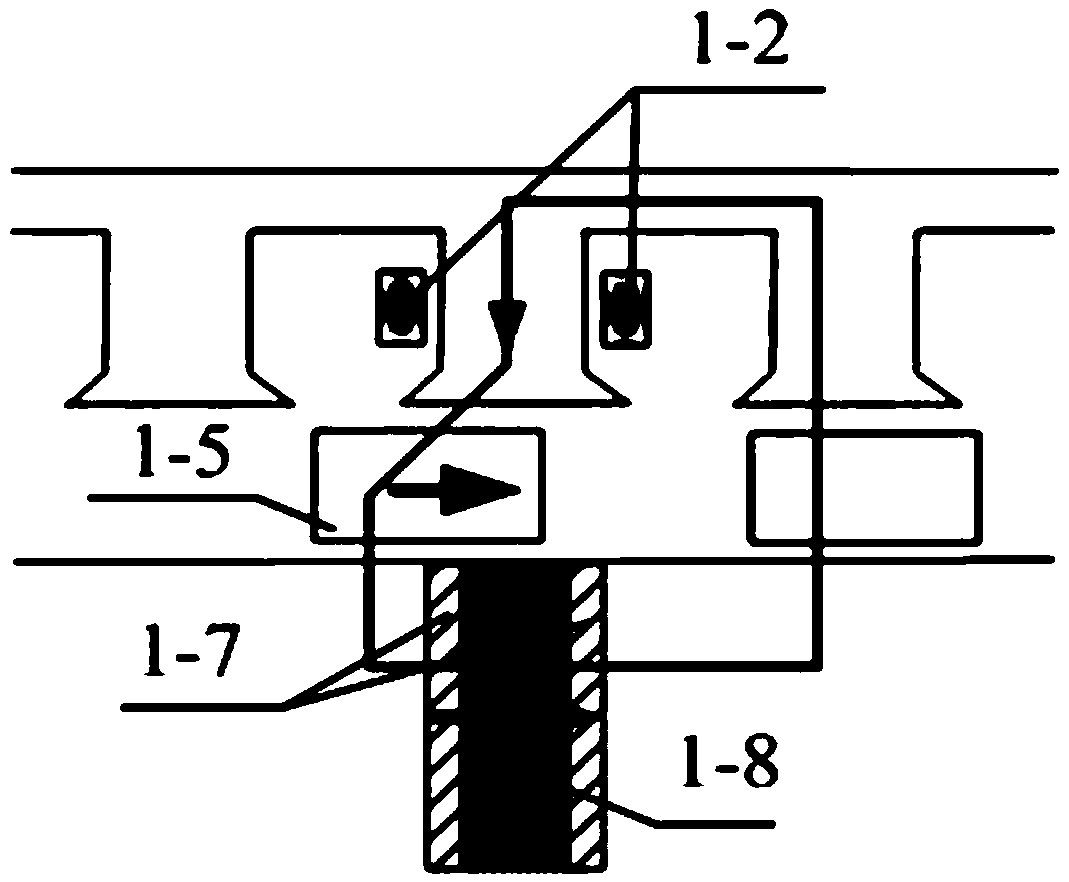

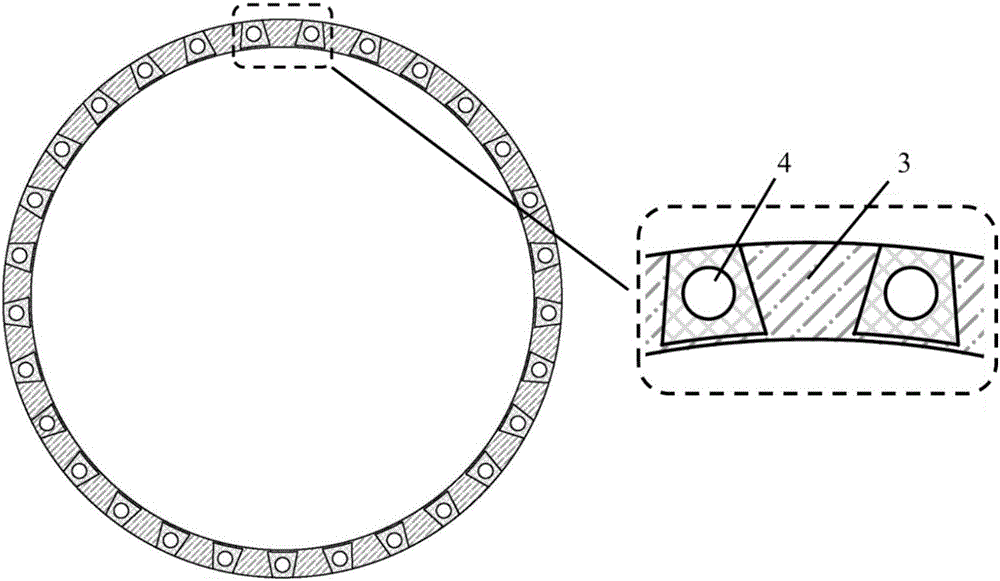

High torque density magnetic field modulation type magnetic gear

ActiveCN106787609AIncreased torque densityLow harmonic content of magnetic fieldPermanent-magnet clutches/brakesMagnetic tension forceTorque density

The invention discloses a high torque density magnetic field modulation type magnetic gear, which comprises a permanent magnetic outer stator, a modulation rotor and a permanent magnetic inner rotor which are concentrically nested to one another and arranged sequentially from outside to inside; air gaps are formed between the permanent magnetic outer stator and the modulation rotor as well as between the modulation rotor and the permanent magnetic inner rotor respectively; a trapezoidal groove is formed in the inner surface of an outer stator iron core of the permanent magnetic outer stator; demagnetization inhibition grooves are formed in the two sides of the inner end of the trapezoidal groove respectively; a tangentially polarized inverted trapezoidal outer stator permanent magnet is embedded in the trapezoidal groove; the demagnetization inhibition grooves have the action of inhibiting local demagnetization of the outer stator permanent magnet; the modulation rotor is composed of a plurality of magnet regulating yokes and a plurality of non-magnetic conductive materials embedded with punched holes respectively; the non-magnetic conductive materials embedded with the punched holes are embedded between two adjacent magnet regulating yokes respectively; the permanent magnetic inner rotor is composed of inner rotor permanent magnets and an inner rotor iron core which are concentrically nested to one another sequentially from outside to inside; and the inner rotor permanent magnets have a simplified Halbach structure. According to the magnetic field modulation type magnetic gear provided by the invention, higher torque density is realized under low torque ripples.

Owner:HUAZHONG UNIV OF SCI & TECH

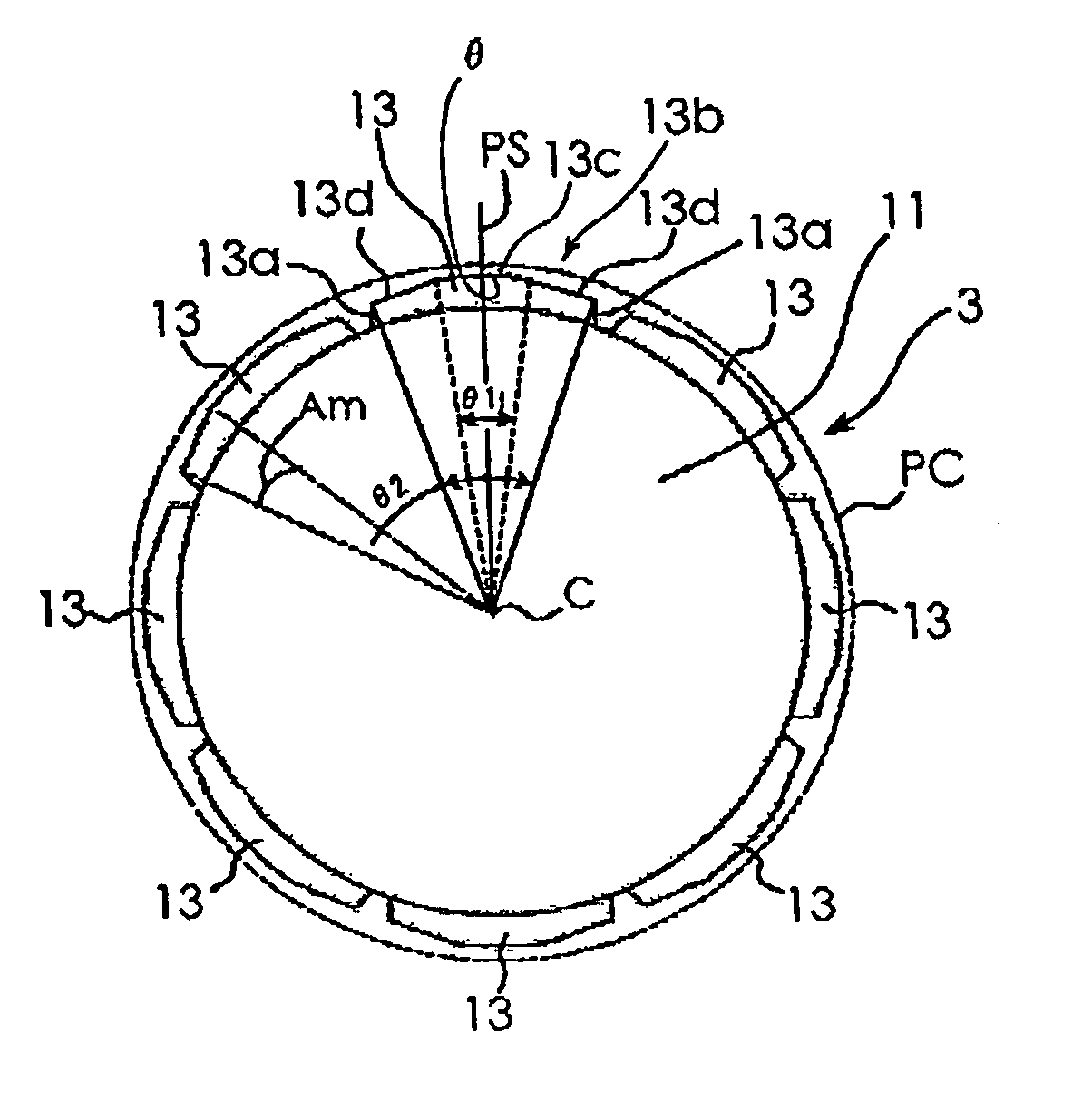

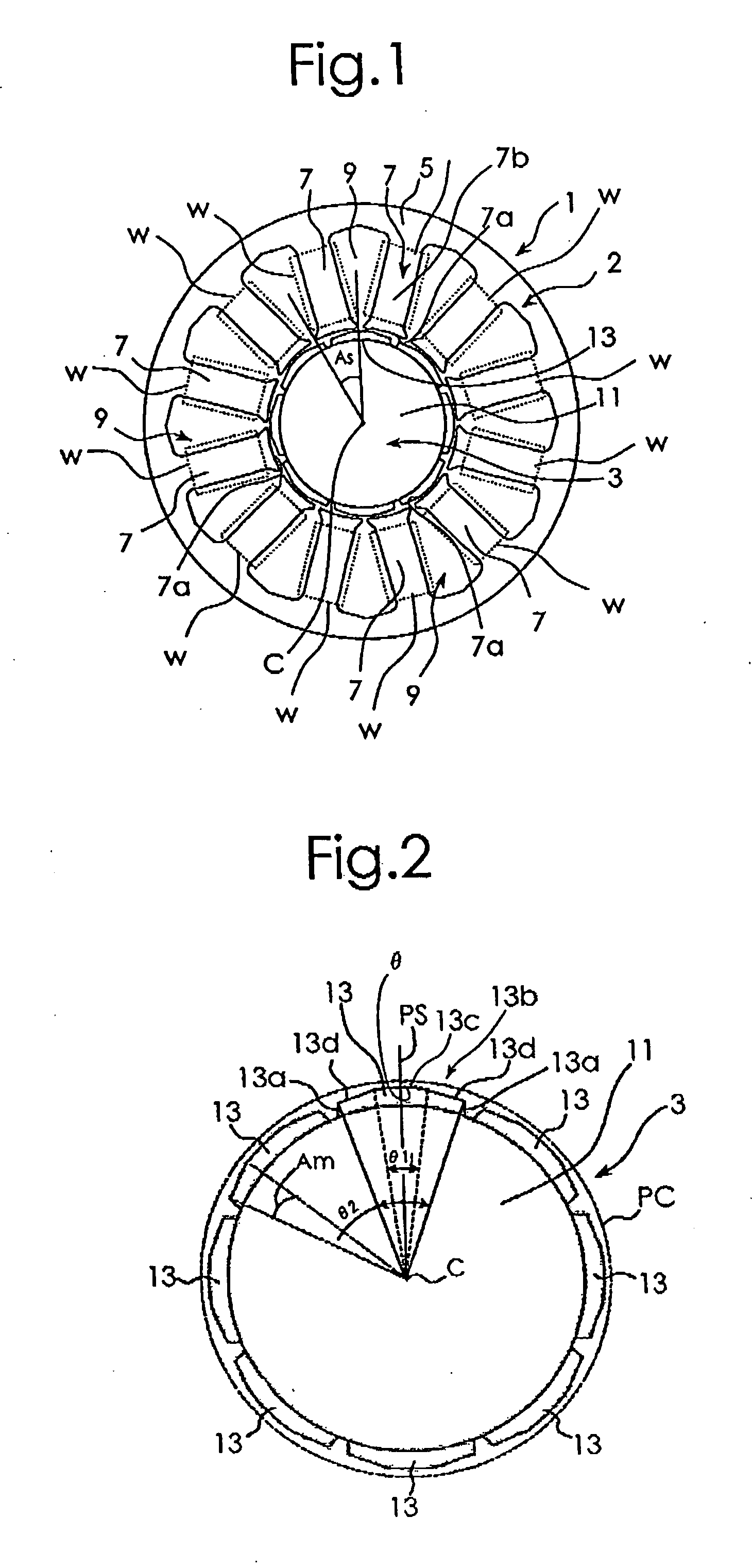

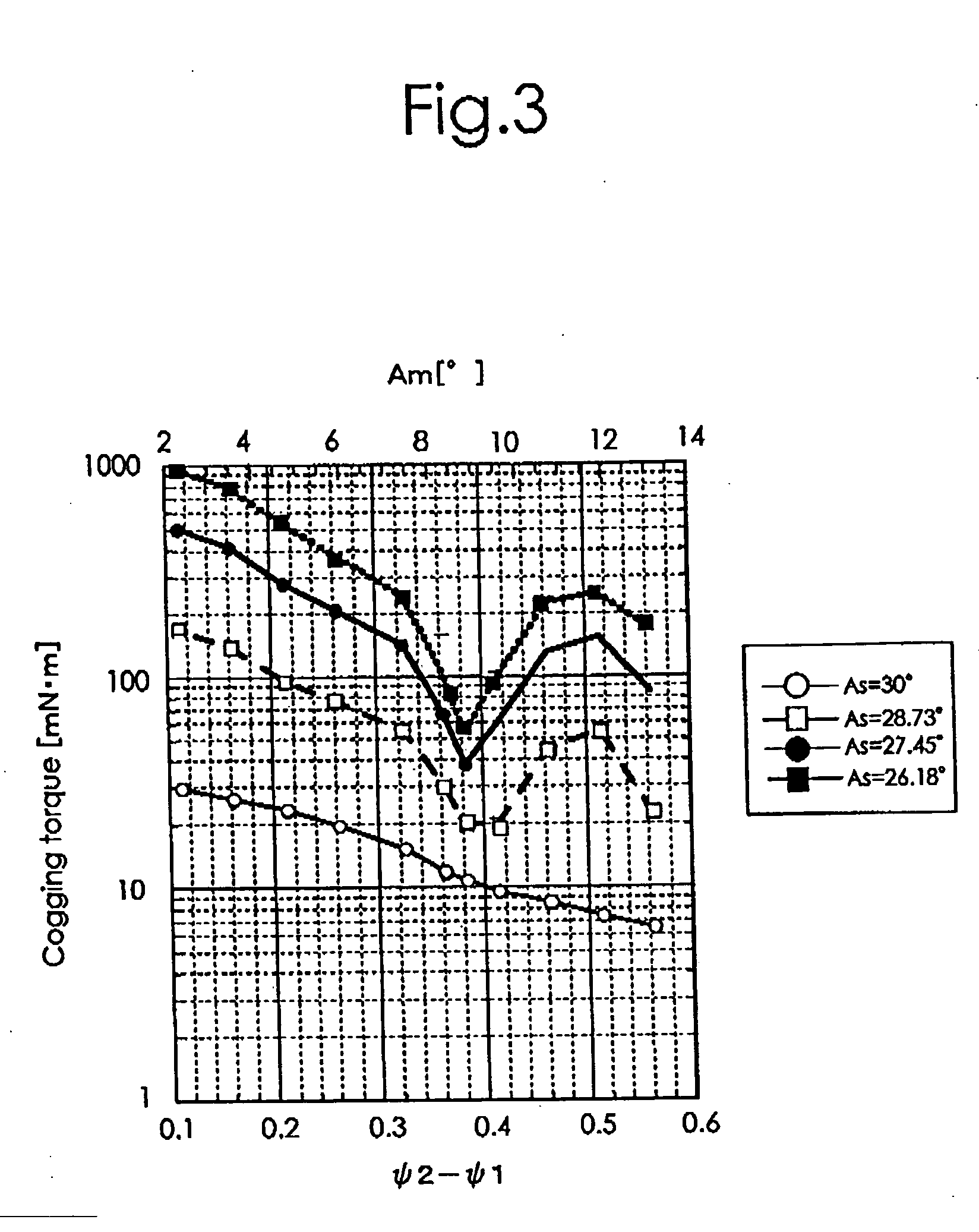

Permanent magnet rotary motor

InactiveUS20050258698A1Reduce torqueIncreased torque densityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesTorque density

There is provided a permanent magnet rotary motor that can maintain higher torque density and can also reduce cogging torque more greatly than a conventional permanent magnet rotary motor. A pair of end surfaces of each of permanent magnets used for a rotor are substantially parallel to a virtual plane that extends in the radial direction of a rotor core while passing through the centers of a stator core and an arc surface. Then, the length of the arc surface in the peripheral direction of a rotor core and inclinations of inclined surfaces are so determined that a pole arc ratio Ψ1 of the arc surface and a pole arc ratio ψ2 of a magnetic pole surface in each permanent magnet satisfy the relation of P / 2N≦Ψ2−Ψ1≦1.38×P / 2N.

Owner:SANYO DENKI CO LTD

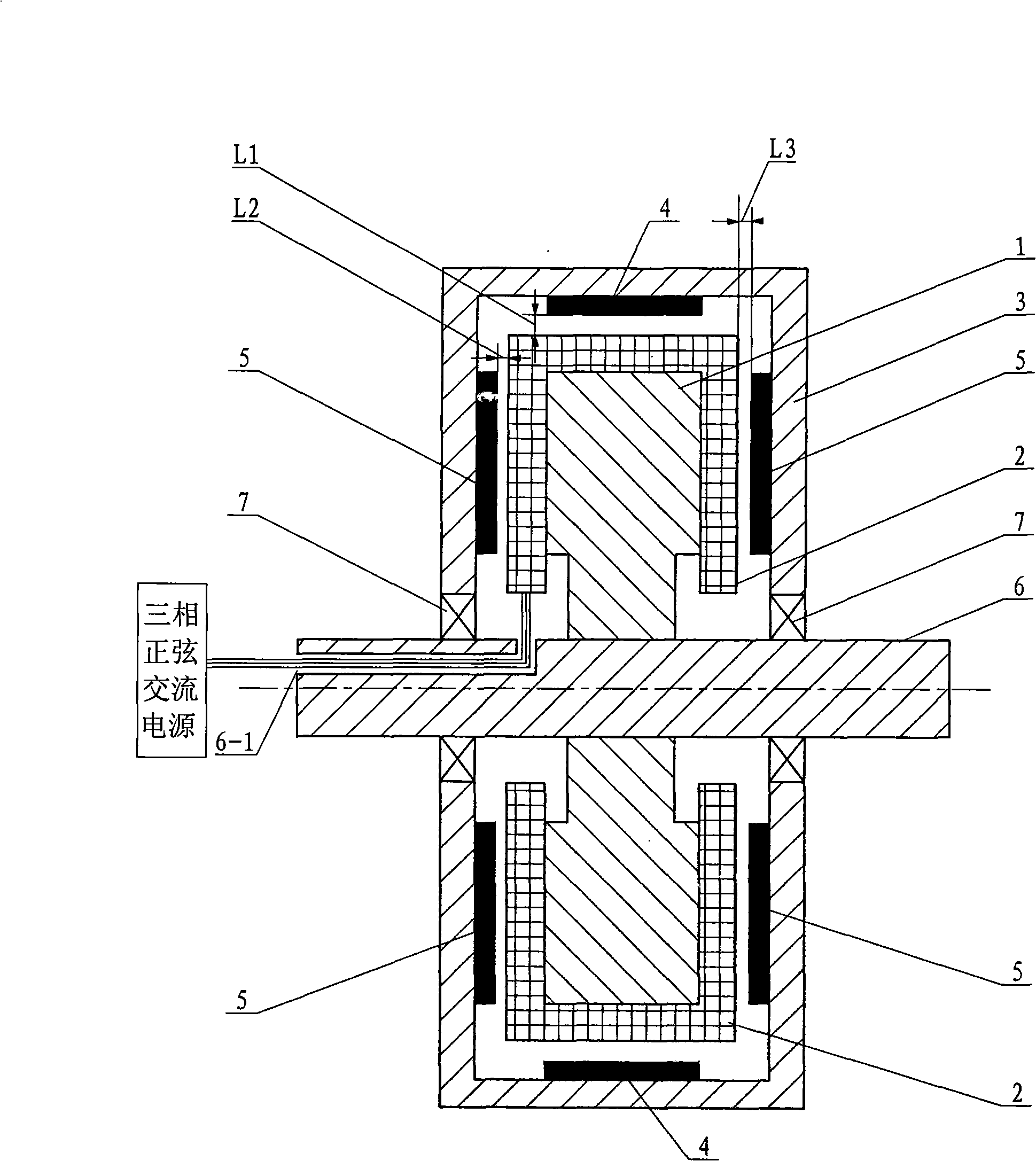

Axial magnetic flux hub motor for enhanced heat emission of windings

ActiveCN106452013AImprove cooling conditionsAvoid increasing the axial equivalent air gap lengthCooling/ventillation arrangementHeat transmissionTorque density

The invention provides an axial magnetic flux hub motor for enhanced heat emission of windings. The motor adopts a sandwich structure with a stator in the middle and rotors on the two sides in the axial direction. The stator of the motor consists of Q stator tooth units, and Q represents the number of slots of the motor and is the time of positive integer of the number m of phases of the motor. Each stator tooth unit comprises a stator tooth iron core and a coil wound around the stator tooth iron core, and a super-conduction flat heat pipe is arranged between the two adjacent stator tooth units. One end of each super-conduction flat heat pipe is in close contact with windings of the two stator tooth units for clamping each super-conduction flat heat pipes therebetween, and the other end of each super-conduction flat heat pipe is inserted into a cooling runner of a stator support. The heat of the windings is quickly transmitted to the cooling runner of the stator support by the super-conduction flat heat pipes by utilizing the features of enhanced heat transmission and enhanced heat exchange of the super-conduction flat heat pipes, thereby realizing enhanced heat emission of the windings and enhancing the torque density of the hub motor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com