Radial magnetic field double-stator vernier motor

A radial magnetic field, vernier motor technology, applied in the direction of electromechanical devices, electrical components, magnetic circuit rotating parts, etc., can solve the problems of low power factor, low operation reliability, etc., and achieve the effect of improving power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and effect of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples. The following examples are only used to explain the present invention and do not constitute a limitation to the present invention.

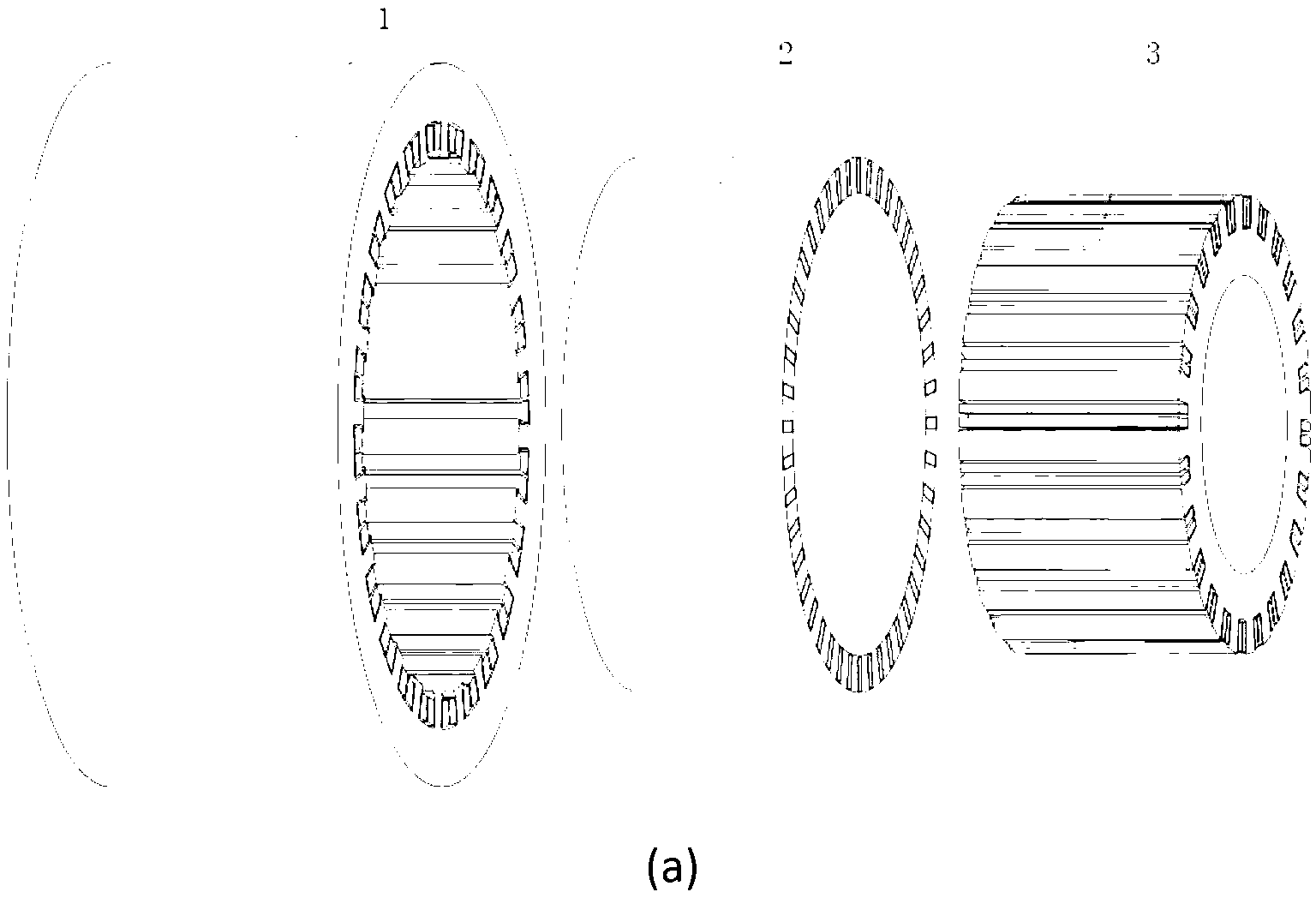

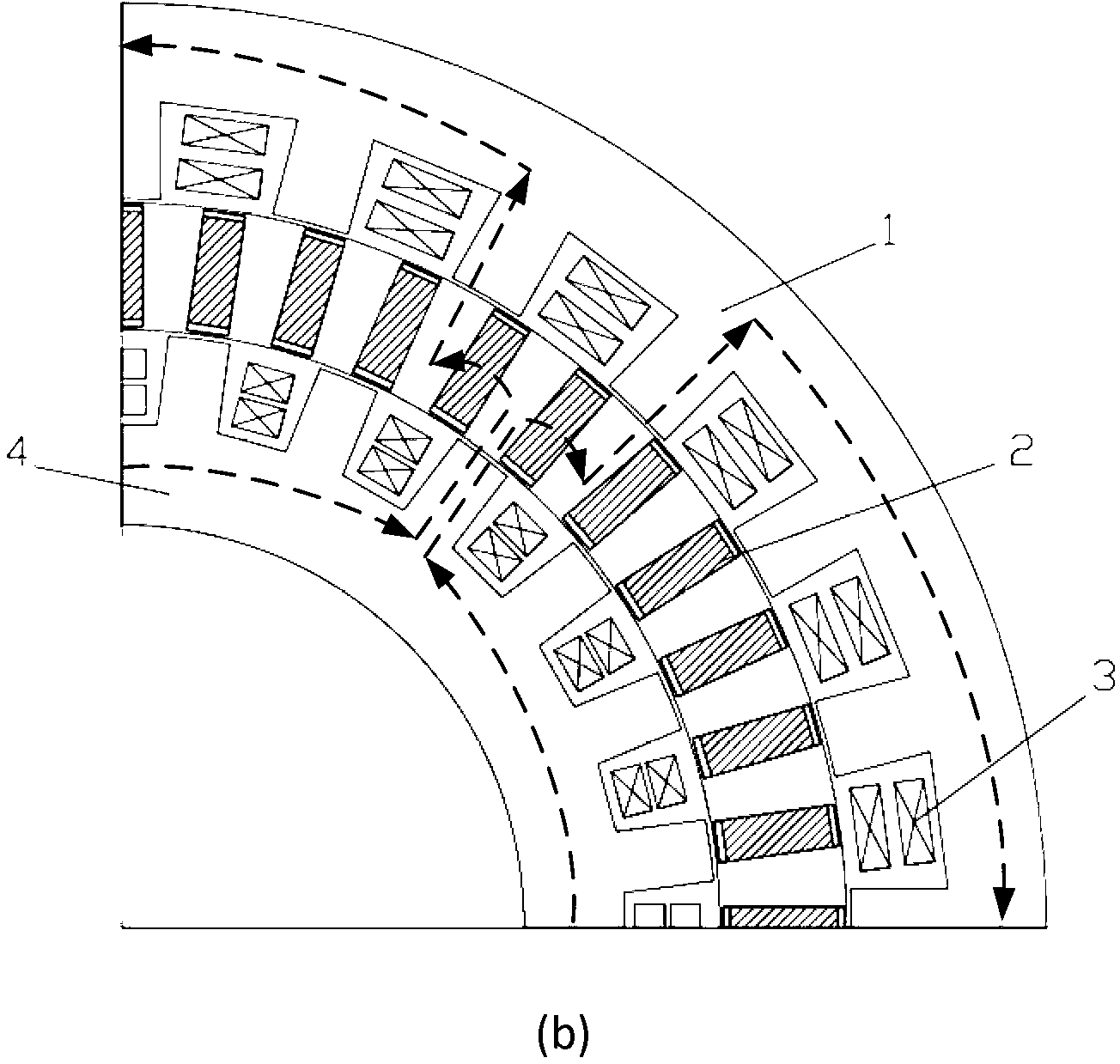

[0028] Such as figure 2 As shown, the vernier motor of this embodiment includes two stators and a rotor, the two stators are the inner stator 4 and the outer stator 1 respectively, the rotor 2 is in the middle of the outer stator 1 and the inner stator 4, and the three are concentric.

[0029] The motor topology of this embodiment contains double air gaps; the two stator windings 3 adopt single-phase or multi-phase windings ( figure 2 Only the effective part of the winding is drawn, the ends are not drawn).

[0030] The permanent magnets of the rotor 2 are preferably built-in and tangentially magnetized, and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com