Permanent magnet motor with shaft radial folding winding

A permanent magnet motor, axial and radial technology, applied in the shape/style/structure of winding conductors, magnetic circuits characterized by magnetic materials, static parts of magnetic circuits, etc., can solve the problem of not effectively improving torque density and Problems such as power density, uncompact motor structure, and small effective space utilization of permanent magnet motors can be achieved to improve the overall operating efficiency, compact motor structure, high motor power density and torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

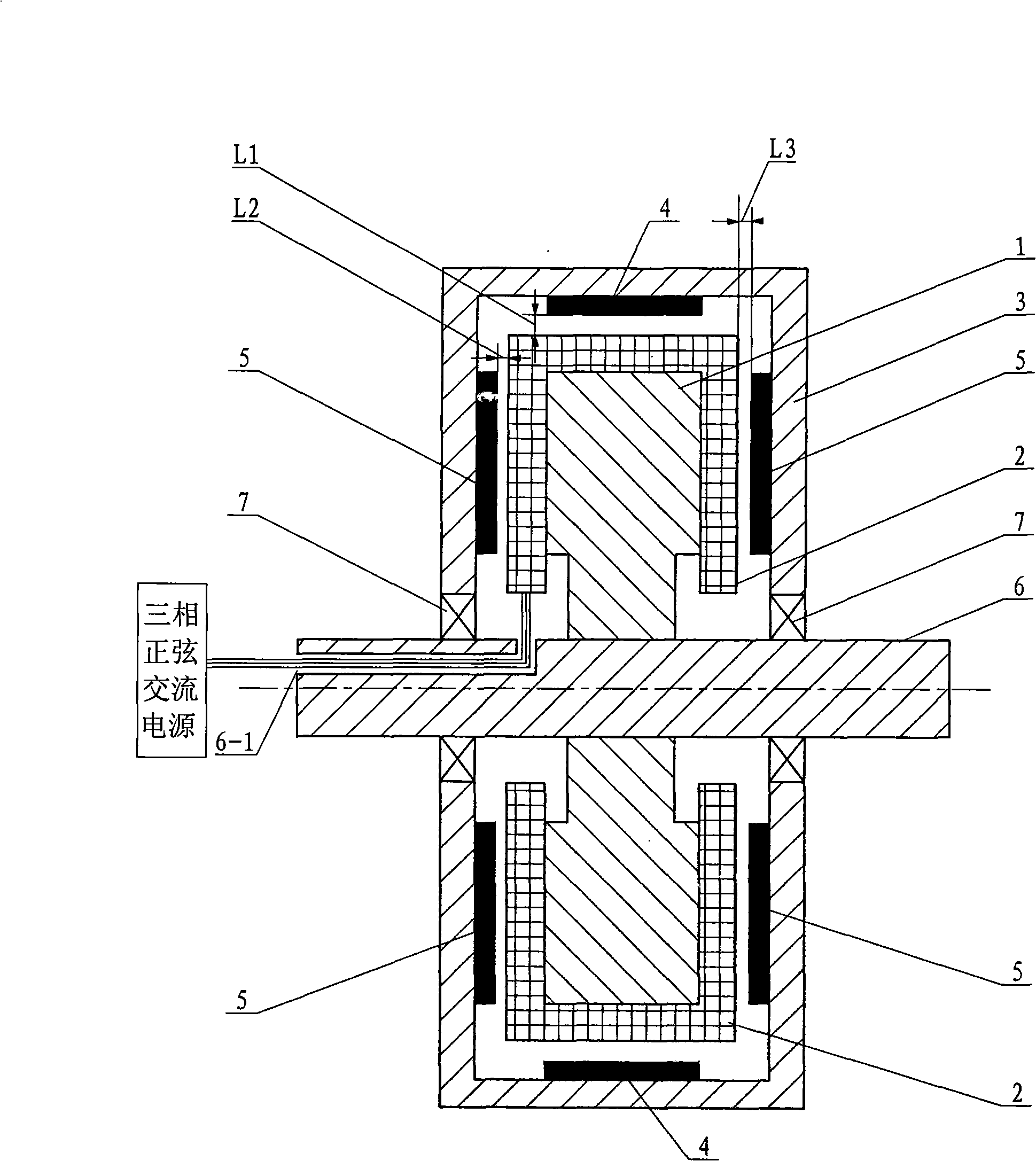

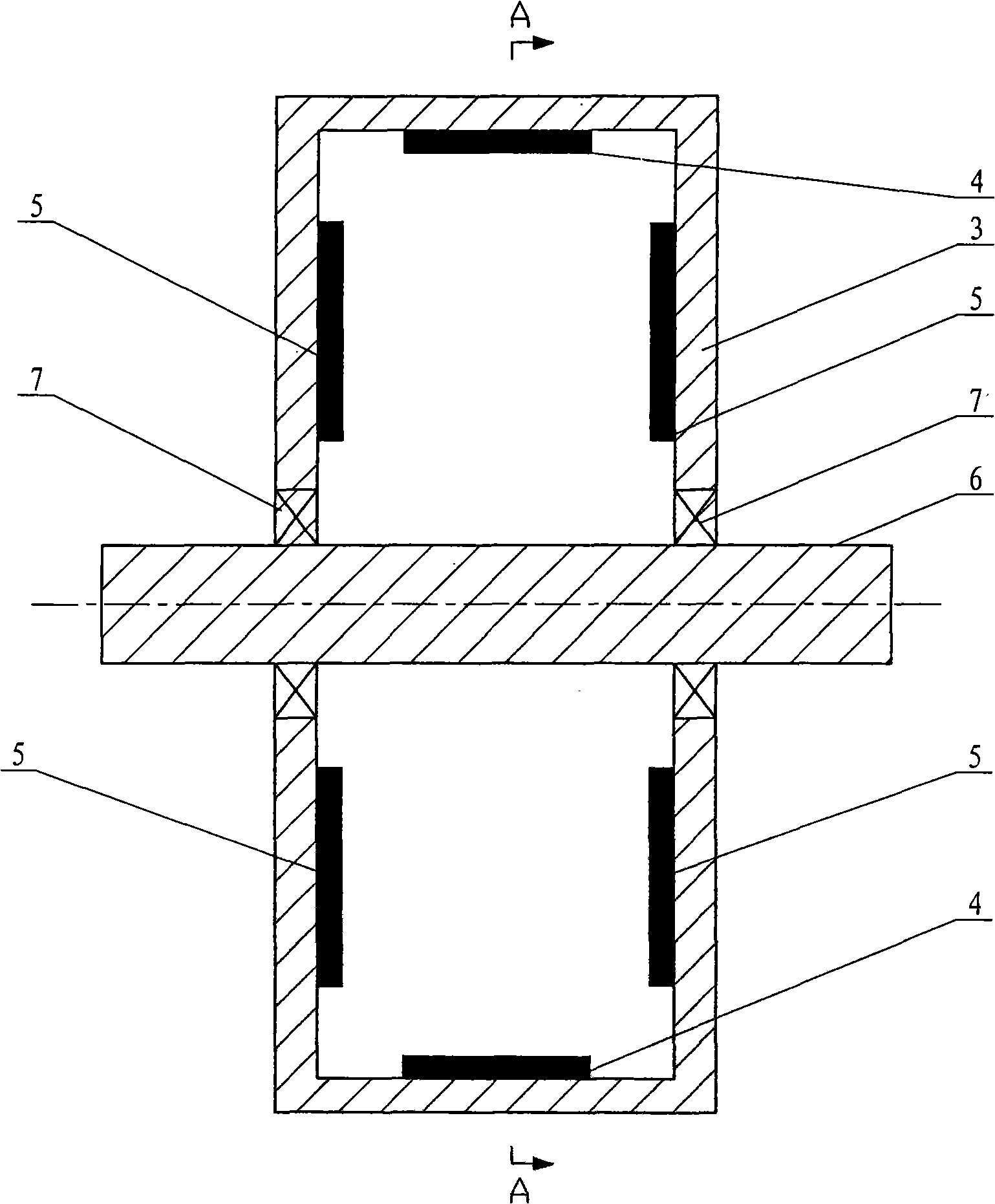

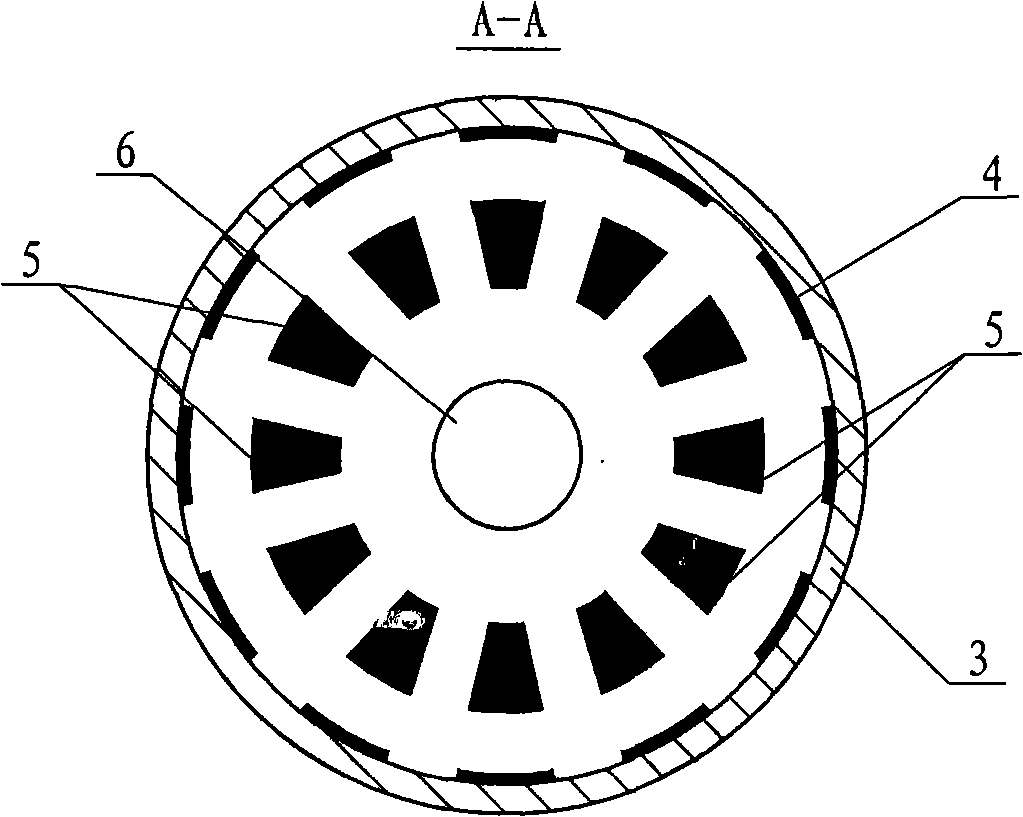

[0012] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, this embodiment is made up of stator, rotor and shaft 6, and stator is fixed on shaft 6, and rotor is arranged on the outside of stator, and described stator is made up of stator core 1 and stator winding 2, and stator core 1 is Ring, the outer surface of the stator core 1 is provided with a plurality of axial slots 1-1, the opening centerline of the axial slots 1-1 is axial, and the plurality of axial slots 1-1 surround the shaft 6 Evenly arranged, the two sides of the stator core 1 are respectively provided with a plurality of radial slots 1-2, and the opening centerlines of the plurality of radial slots 1-2 are evenly arranged radially around the shaft 6, and the axial slots 1 -1 corresponds to the radial slots 1-2 on both sides of the stator core 1 respectively, and communicates with each other respectively. The stator winding 2 is arranged in the -2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com