Amorphous, microcrystalline or nano-crystalline alloy stator iron core for axial magnetic flux motor and manufacture method for stator iron core

A technology of nanocrystalline alloy and axial magnetic flux, which is applied in the manufacture of stator/rotor body, magnetic circuit static parts, magnetic circuit shape/style/structure, etc. Alloy motor iron core process is complex, etc., to improve production efficiency and iron core yield, save resin thermosetting molding treatment, and avoid the effect of soft magnetic performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

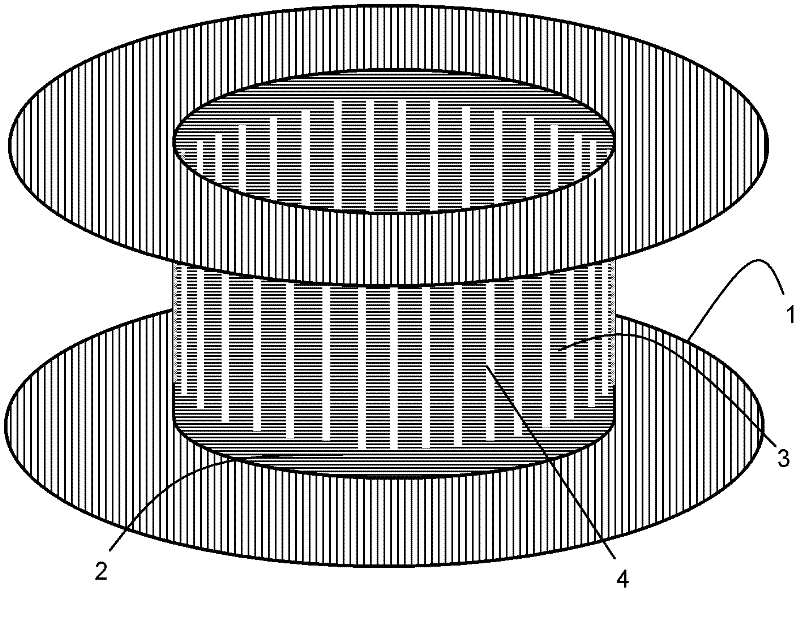

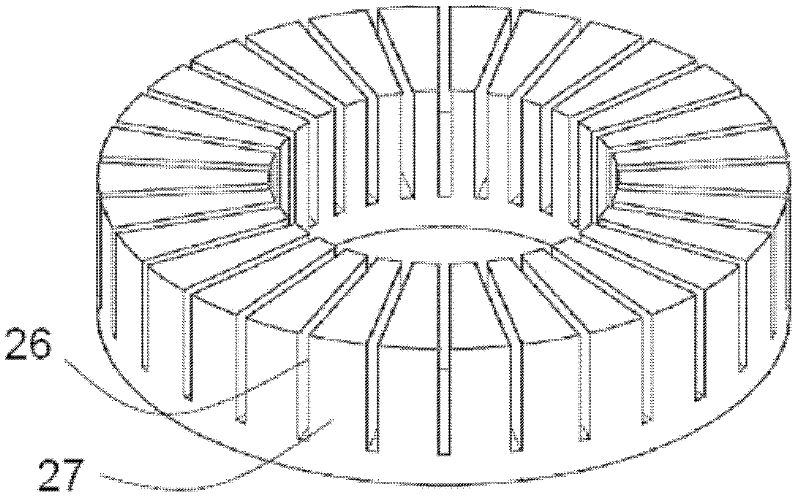

[0072] The nominal composition of the strip for making the axial flux amorphous alloy stator core is Fe 80 Si 9 B 11 (at.%), the thickness is 30±1μm, the width is 140mm, and the surface is smooth. The outer diameter of the amorphous alloy stator core to be produced is 180 mm, the inner diameter is 100 mm, the height is 40 mm, the slot depth is 30 mm, and the number of slots is 30. First, the amorphous alloy strip is rolled and cut into an amorphous alloy strip coil with a width of 80mm by rolling shearing equipment, and then the amorphous alloy strip with a width of 80mm is coiled twice to form a double amorphous alloy thin strip coil stand-by. Made of silicon steel sheets with a thickness of 0.5mm such as figure 1 The inner core of the iron core shown is composed of an annular bottom support 1 with an outer diameter of 180 mm and an inner diameter of 100 mm and a cylinder 2 with an inner diameter of 100 mm and a height of 80 mm. There are 30 inner core teeth 3 and 30 inn...

Embodiment 2

[0082] The rolling shearing, punching, coating, coiling and annealing treatment of the amorphous alloy strip are all the same as those in Example 1. That is, the amorphous alloy stator core made in embodiment 1 is subjected to a resin thermosetting treatment again. The specific process is as follows: the amorphous alloy stator core is immersed in the epoxy resin in the stainless steel tank, and put into the vacuum box together with the paint tank to evacuate to below 1Pa, and keep at this vacuum for 30 minutes. Then remove the vacuum environment, take out the amorphous alloy stator core and put it in an oven for thermal curing at 170°C. After 4 hours of heat preservation, turn off the power of the oven and let the amorphous alloy stator core cool down to room temperature naturally. So far, the axial magnetic flux amorphous alloy stator core processed by resin heat curing is completed.

[0083] The silicon steel core with the same specifications as the amorphous alloy stator c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com