Halbach-array-based magnetic coupling transmission device

A transmission device, magnetic coupling technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems of small torque density and transmission, low utilization rate of permanent magnets, magnetic leakage, etc., to achieve frictionless energy consumption, easy to use. The effect of low loading and unloading and starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

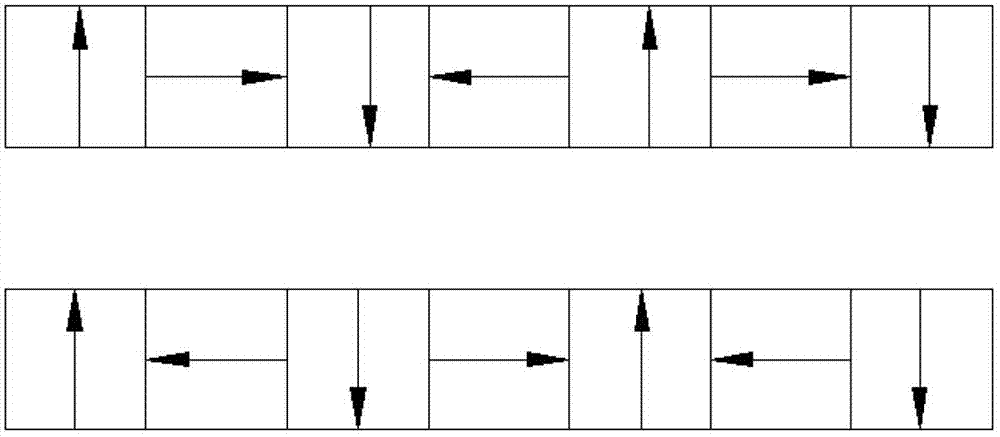

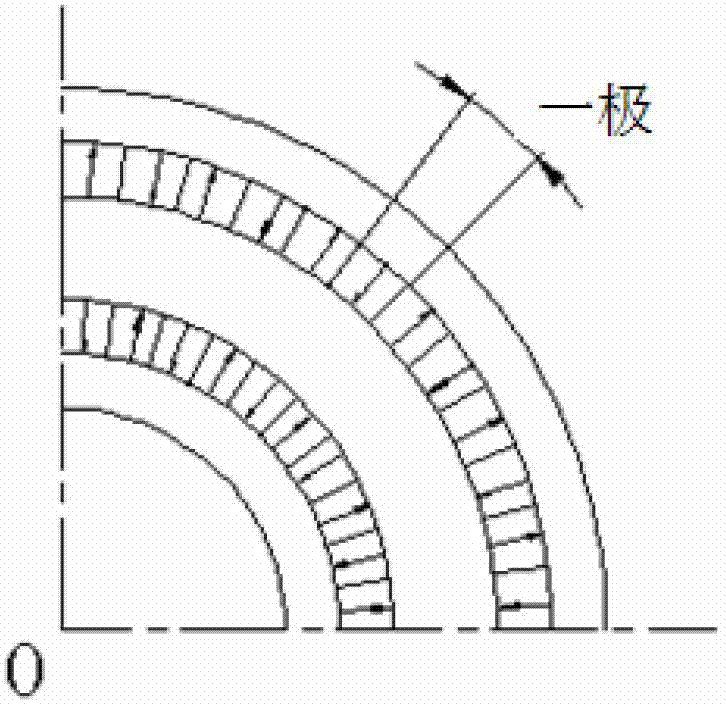

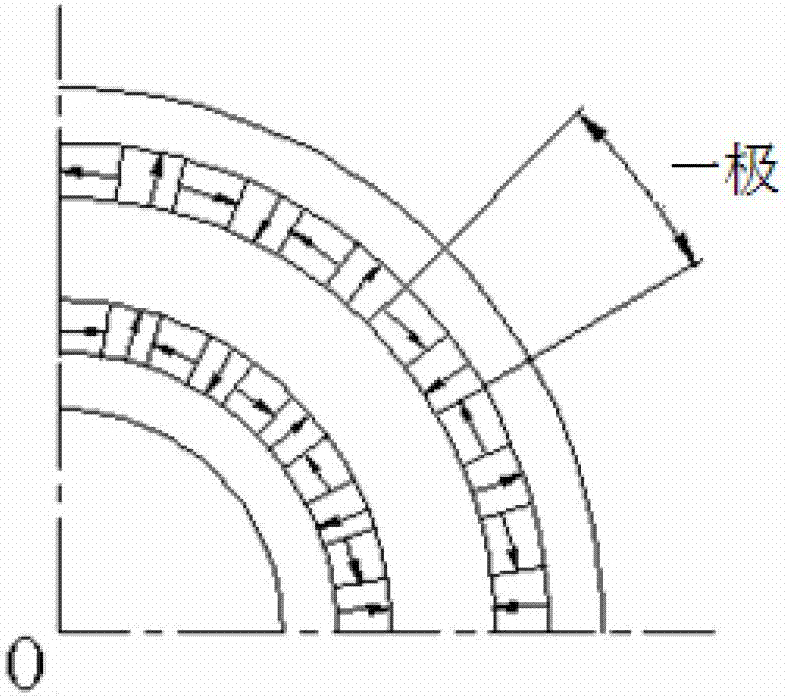

[0038] refer to Figure 3 to Figure 10 , a magnetically coupled transmission based on a Halbach array, including an input shaft 1, a bearing 3, a permanent magnet 6, a stator 9, a rotor 8, and an output shaft, and the output shaft and the input shaft 1 are respectively fixed to the bearing housing 2 through the bearing 3 On a support 4, the rotor 8 is connected to the input shaft 1 through the bearing 3 in the inner cavity of the rotor 8, and the two are in clearance fit, and the rotor 8 and the output shaft are eccentrically placed in the bearing. The connection method is connected; the stator 9 is nested outside the rotor 8 and forms an eccentric mechanism with the rotor 8, the stator 9 is fixed with a base 5, and the inner surface of the stator 9 and the rotor The outer surfaces of the rotors 8 are provided with the permanent magnets 6 capable of rotating the rotor 8, an air gap is provided between the two permanent magnets 6, and the magnetization directions of the permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com