Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2175 results about "Current transducer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

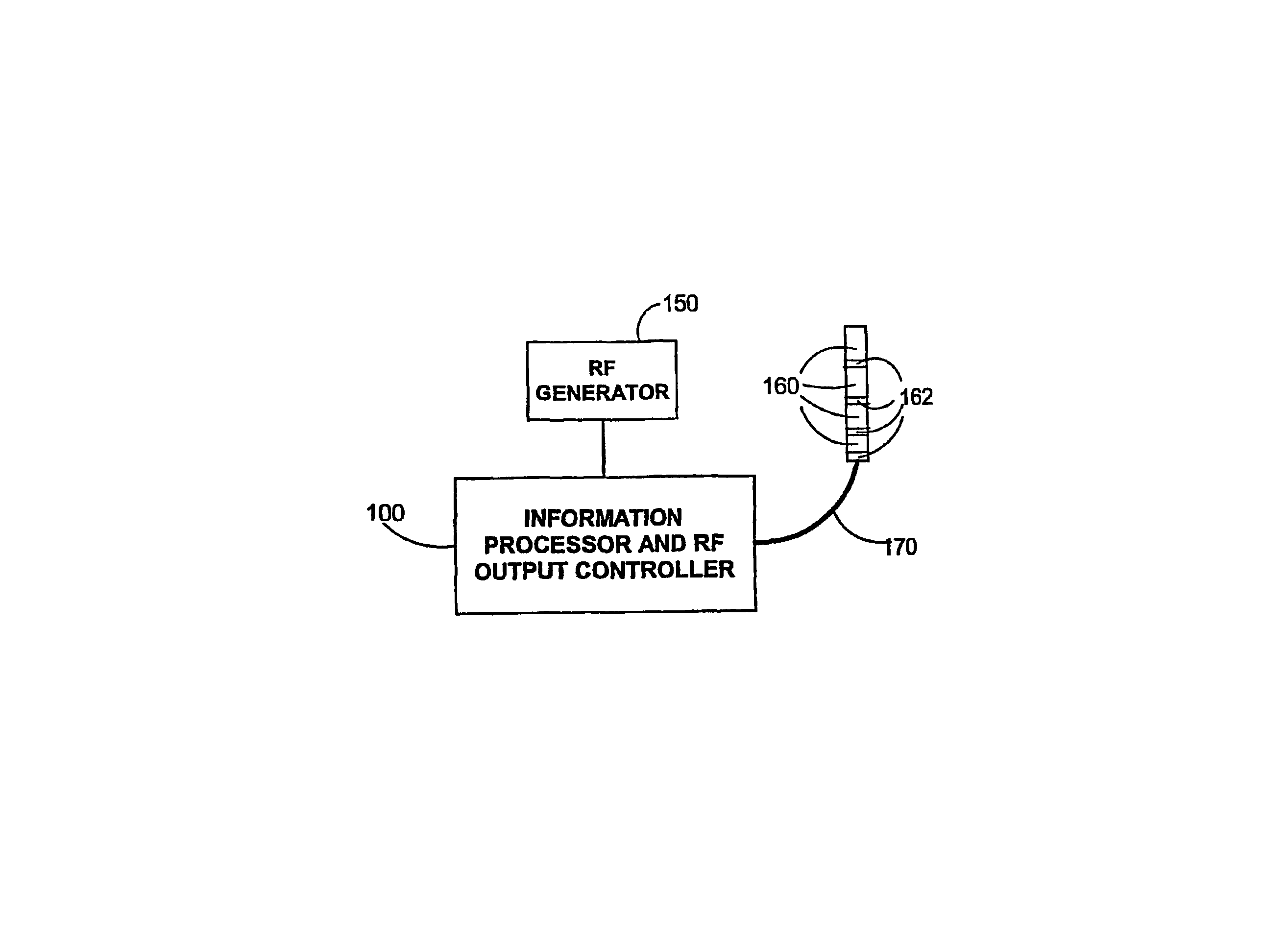

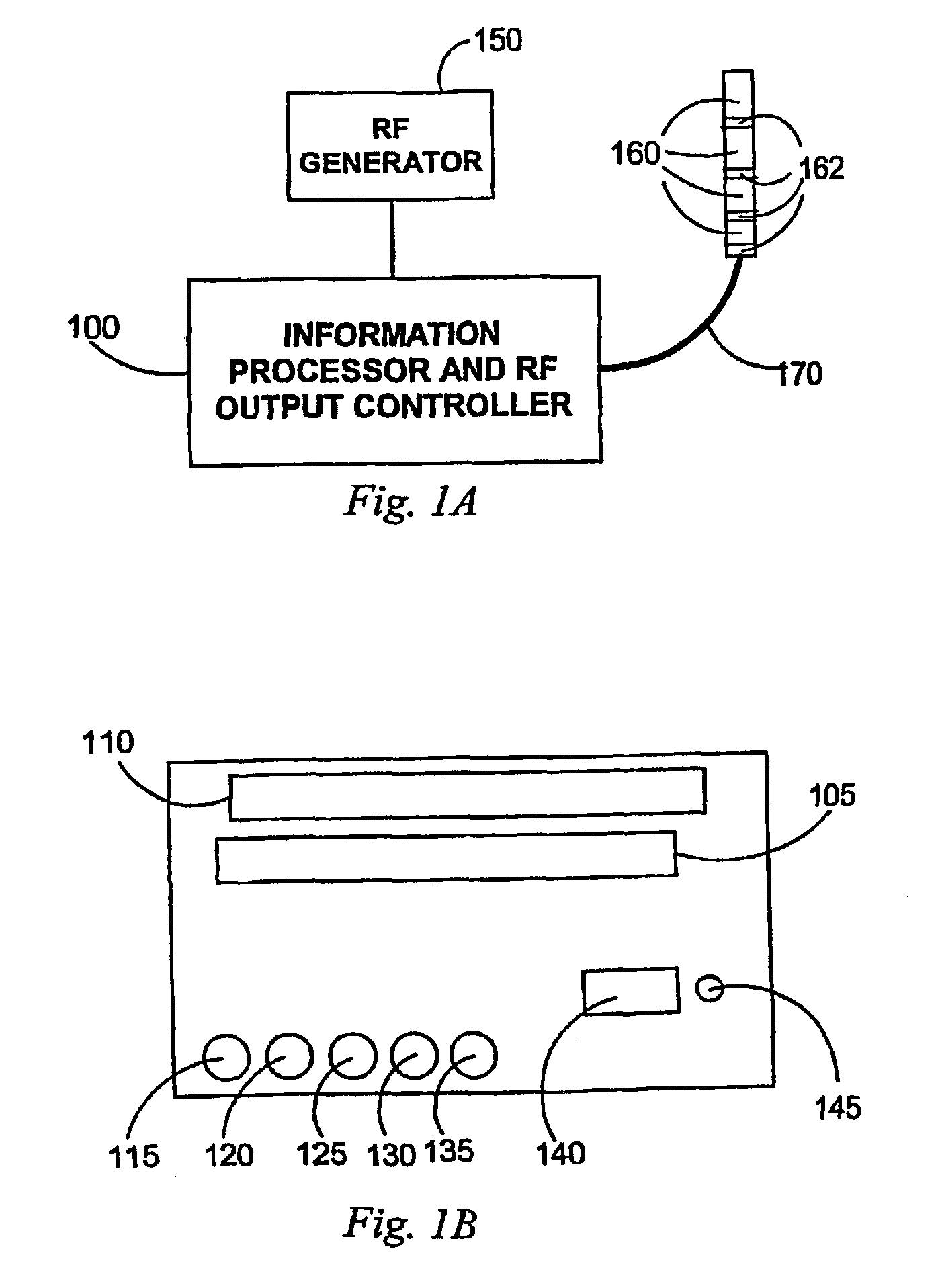

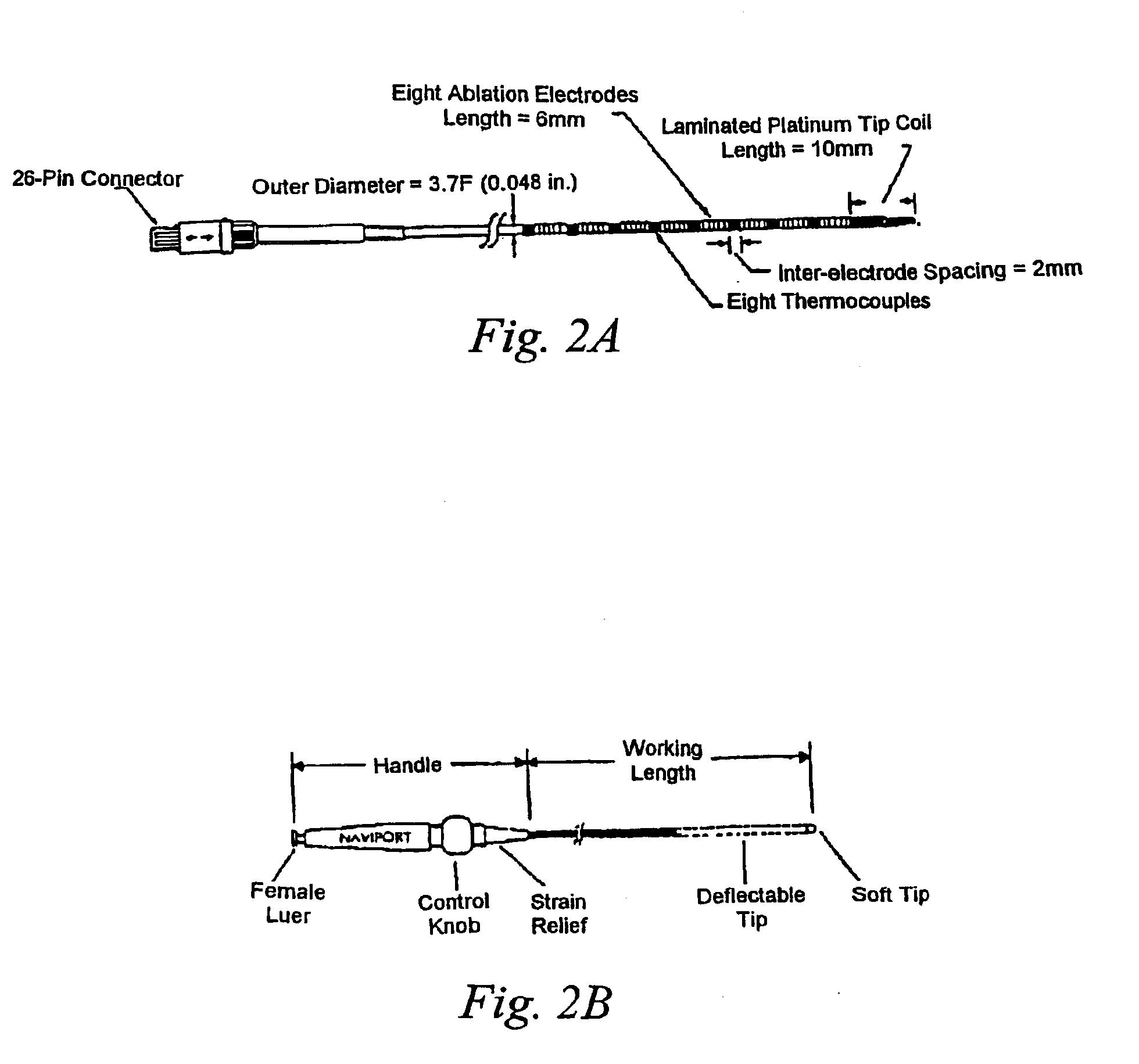

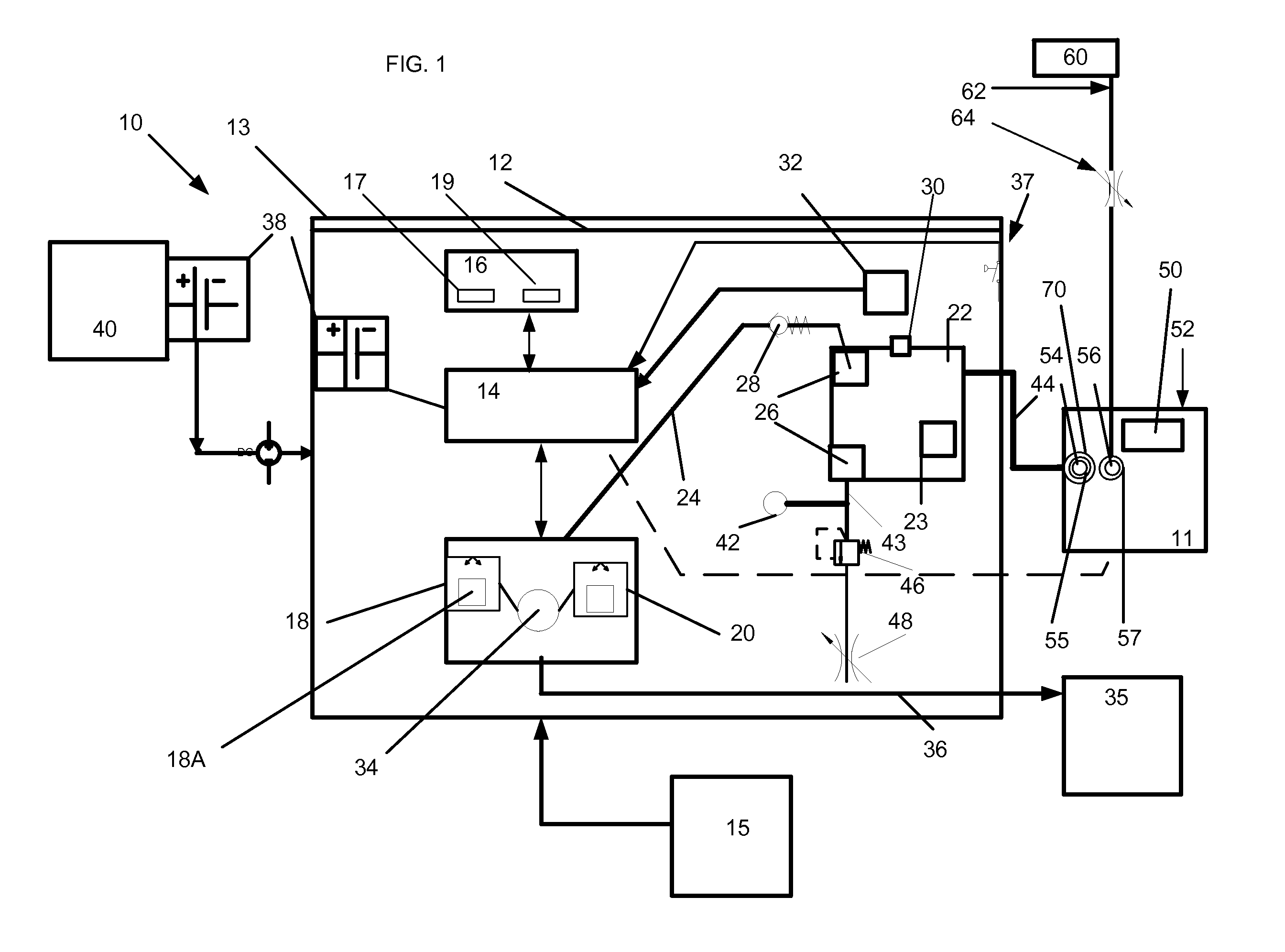

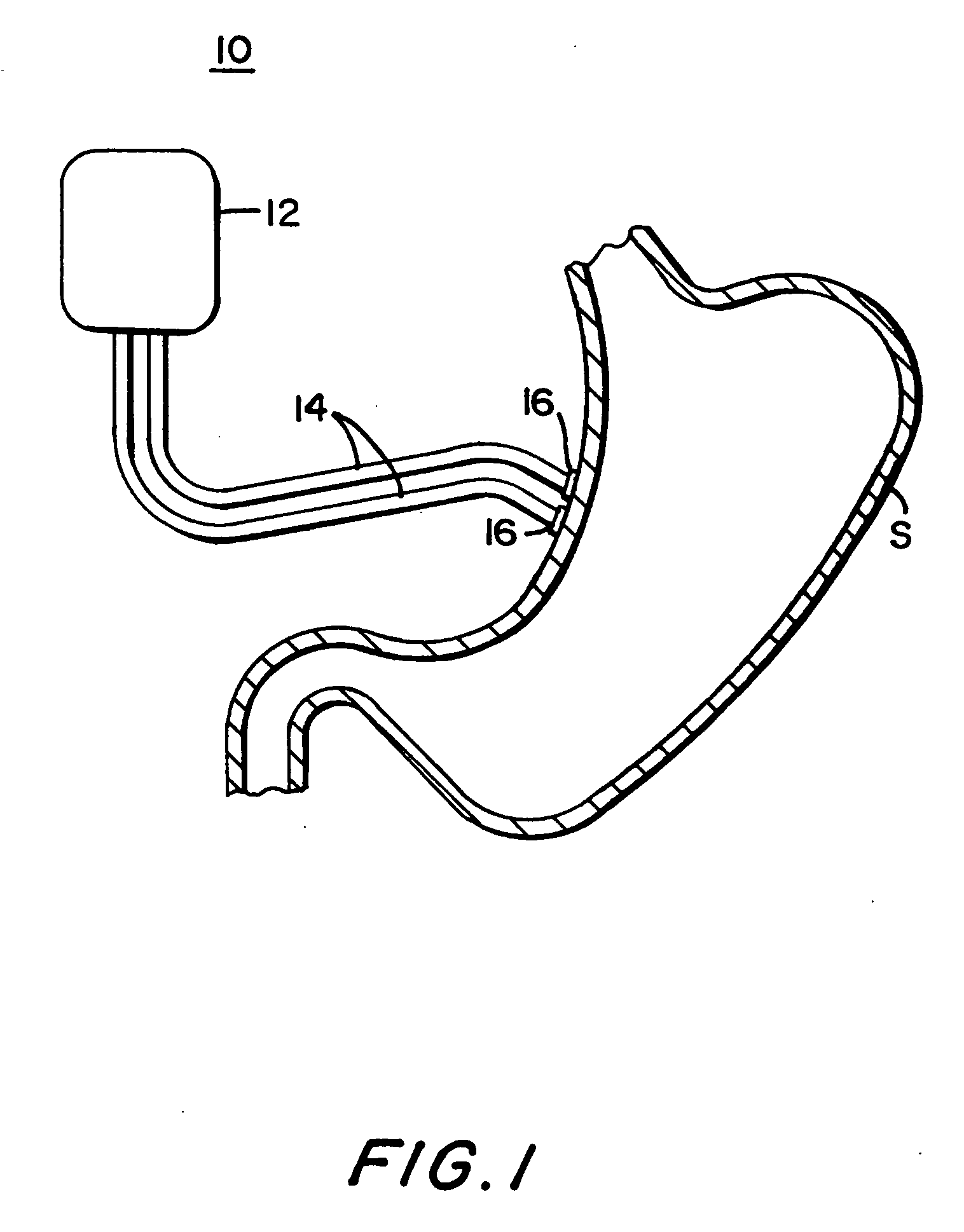

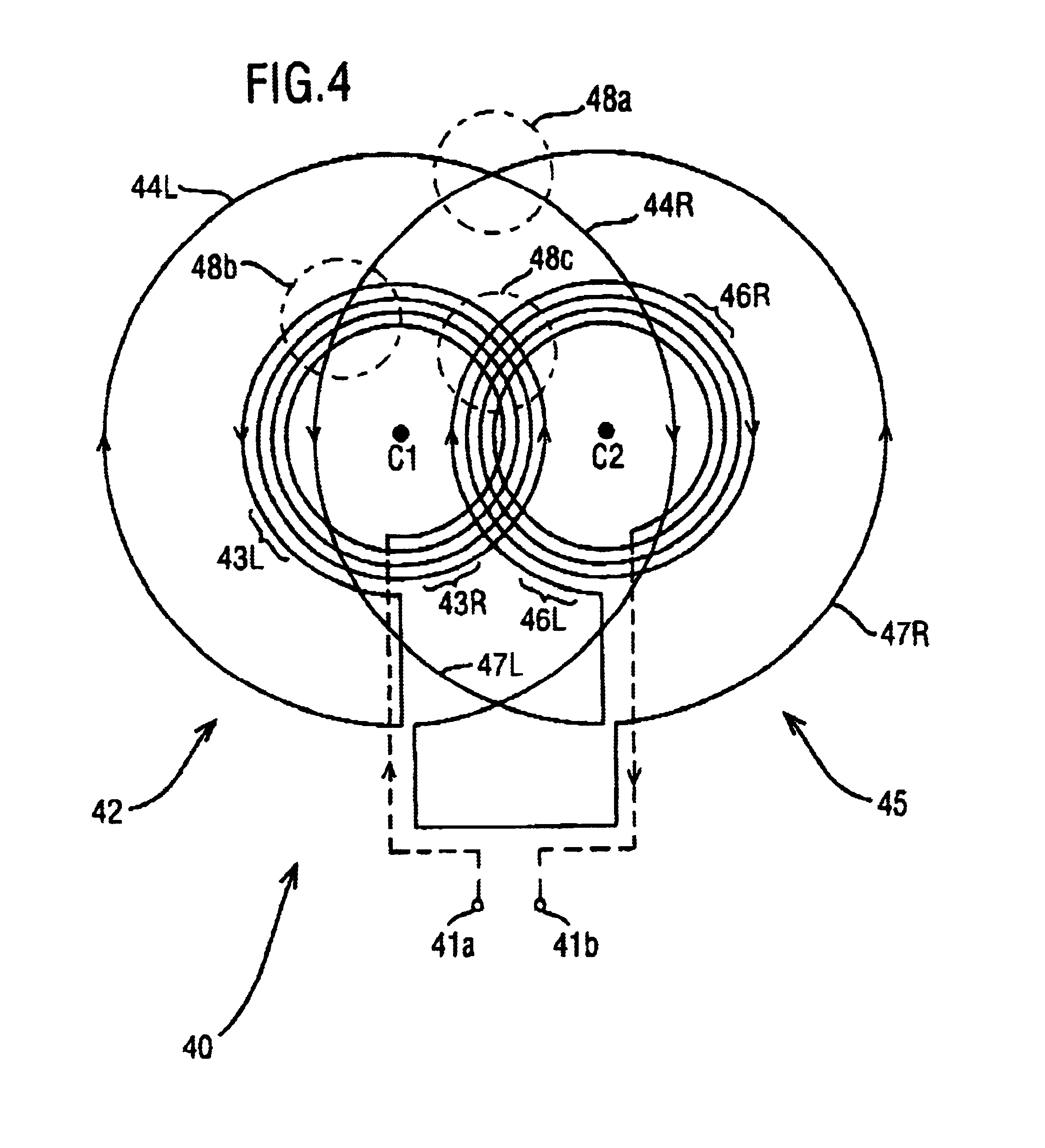

Multi-channel RF energy delivery with coagulum reduction

InactiveUS6936047B2Risk minimizationImprove efficiencySurgical instruments for heatingRf ablationCurrent sensor

A system for efficient delivery of radio frequency (RF) energy to cardiac tissue with an ablation catheter used in catheter ablation, with new concepts regarding the interaction between RF energy and biological tissue. In addition, new insights into methods for coagulum reduction during RF ablation will be presented, and a quantitative model for ascertaining the propensity for coagulum formation during RF ablation will be introduced. Effective practical techniques a represented for multichannel simultaneous RF energy delivery with real-time calculation of the Coagulum Index, which estimates the probability of coagulum formation. This information is used in a feedback and control algorithm which effectively reduces the probability of coagulum formation during ablation. For each ablation channel, electrical coupling delivers an RF electrical current through an ablation electrode of the ablation catheter and a temperature sensor is positioned relative to the ablation electrode for measuring the temperature of cardiac tissue in contact with the ablation electrode. A current sensor is provided within each channel circuitry for measuring the current delivered through said electrical coupling and an information processor and RF output controller coupled to said temperature sensor and said current sensor for estimating the likelihood of coagulum formation. When this functionality is propagated simultaneously through multiple ablation channels, the resulting linear or curvilinear lesion is deeper with less gaps. Hence, the clinical result is improved due to improved lesion integrity.

Owner:SICHUAN JINJIANG ELECTRONICS SCI & TECH CO LTD

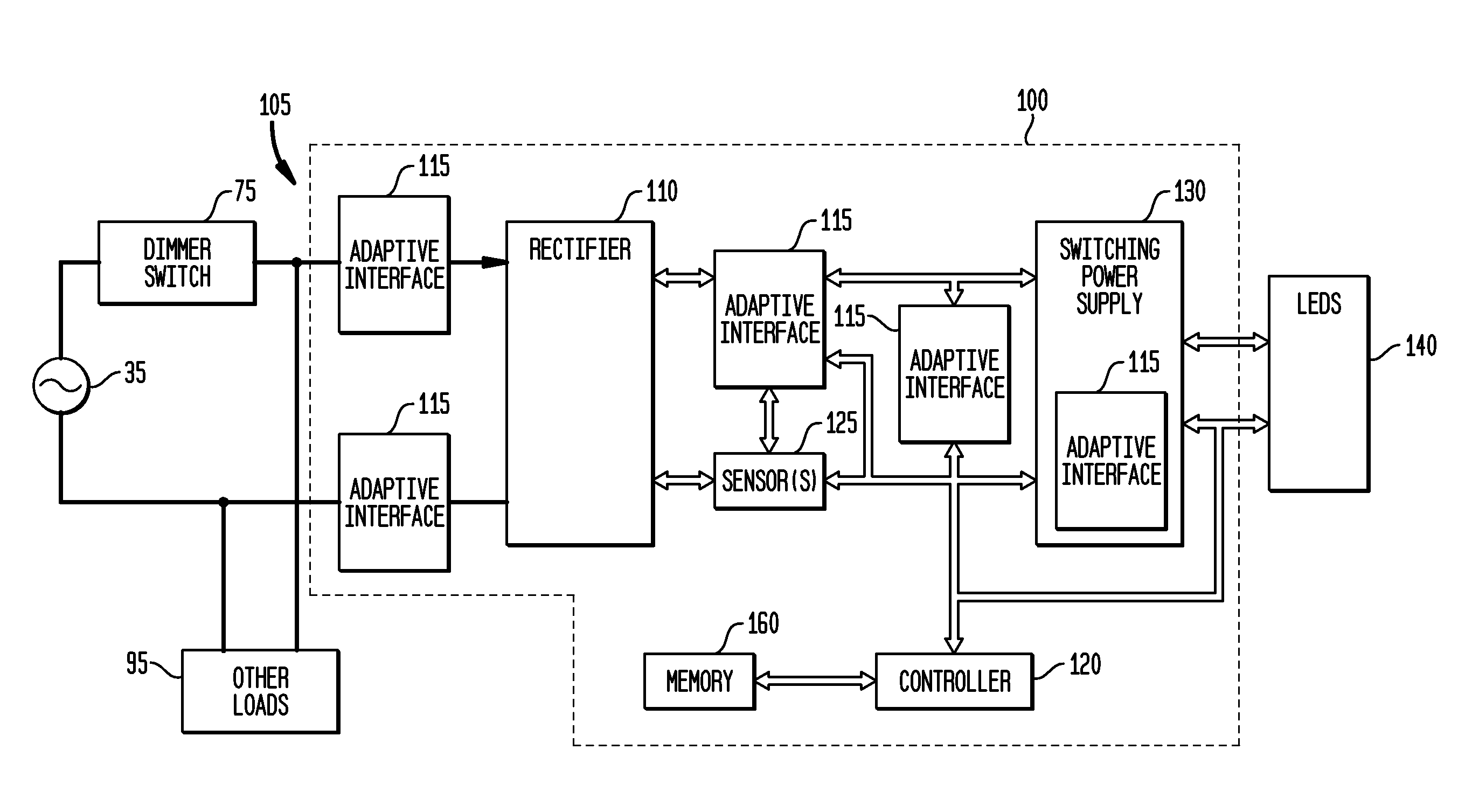

Adaptive Current Regulation for Solid State Lighting

ActiveUS20100213859A1Low component requirementsSeamless and stable operationElectrical apparatusElectroluminescent light sourcesDimmerEngineering

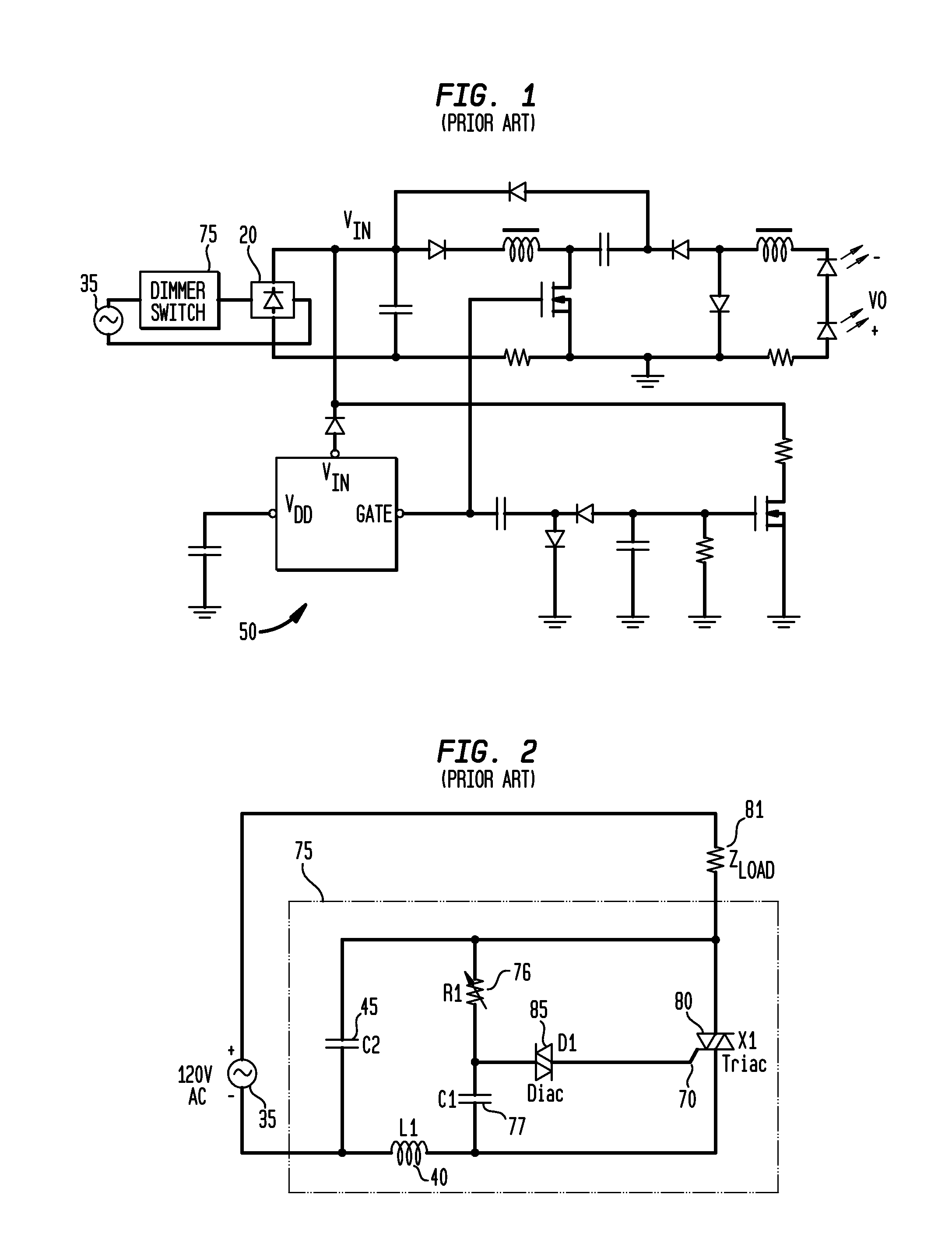

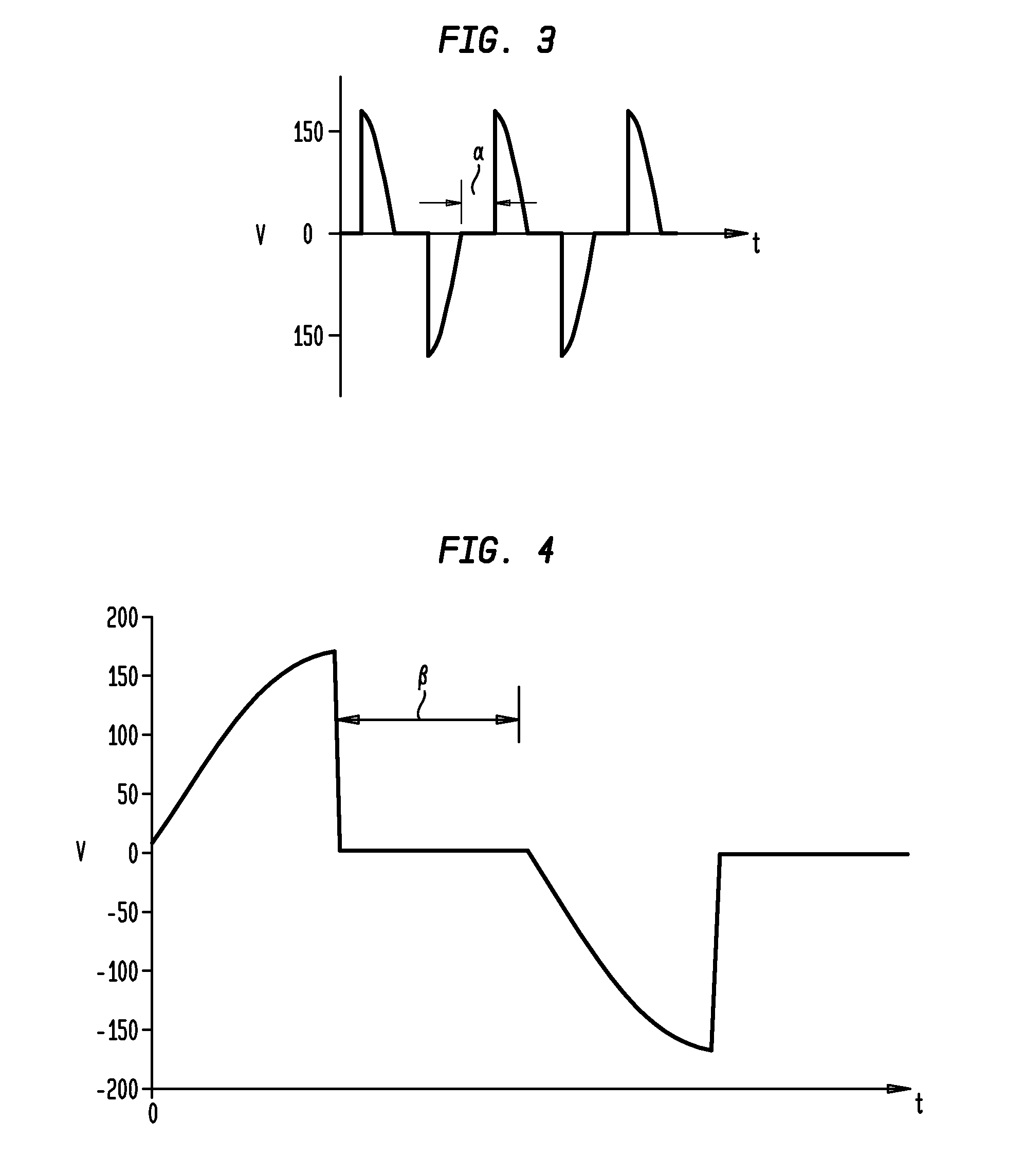

Exemplary embodiments provide an apparatus, system and method for power conversion to provide power to solid state lighting, and which may be coupled to a first switch, such as a dimmer switch. An exemplary system for power conversion comprises: a switching power supply comprising a second, power switch; solid state lighting coupled to the switching power supply; a voltage sensor; a current sensor; a memory; a first adaptive interface circuit to provide a resistive impedance to the first switch and conduct current from the first switch in a default mode; a second adaptive interface circuit to create a resonant process when the first switch turns on; and a controller to modulate the second adaptive interface circuit when the first switch turns on to provide a current path during the resonant process of the switching power supply.

Owner:CHEMTRON RES

DC feeder protection system

ActiveUS20120113554A1Emergency protective arrangement detailsEmergency protective arrangements for automatic disconnectionElectricityElectrical conductor

A direct current feeder protection system includes six conductors, four current sensors sensing four currents flowing in four of the conductors, four circuit interrupters interrupting currents flowing in the four conductors, and a processor cooperating with the current sensors to input four sensed currents, and to output a number of commands to the circuit interrupters. The processor includes a routine detecting a number of: a directional current fault of the sensed currents, a differential current fault of the sensed first and third currents or the sensed second and fourth currents, and a residual current fault of the sensed first and second currents or the sensed third and fourth currents, and to responsively output the commands. The first, fifth and third conductors are electrically connected in series with two of the circuit interrupters, and the second, sixth and fourth conductors are electrically connected in series with the other circuit interrupters.

Owner:EATON INTELLIGENT POWER LTD

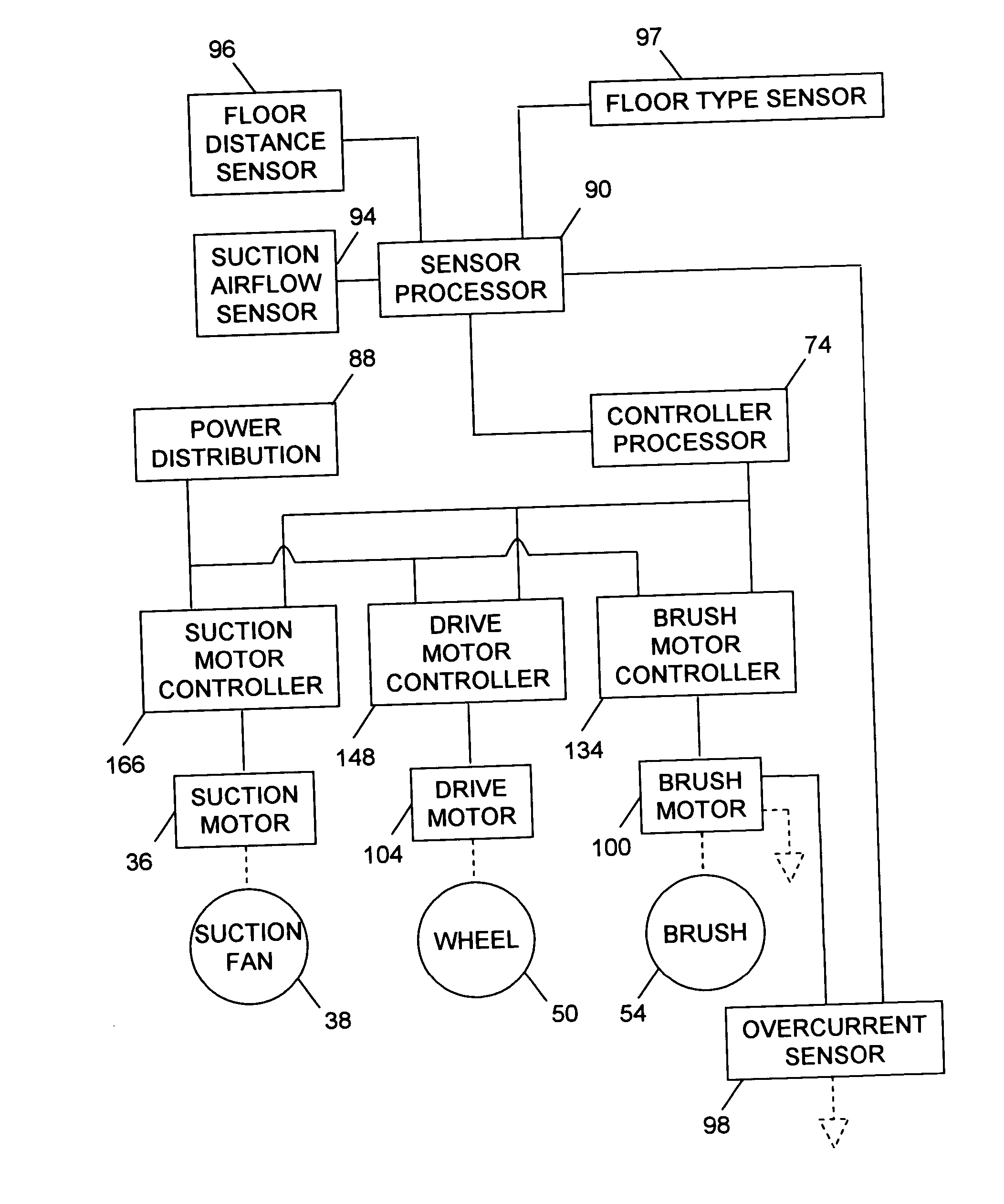

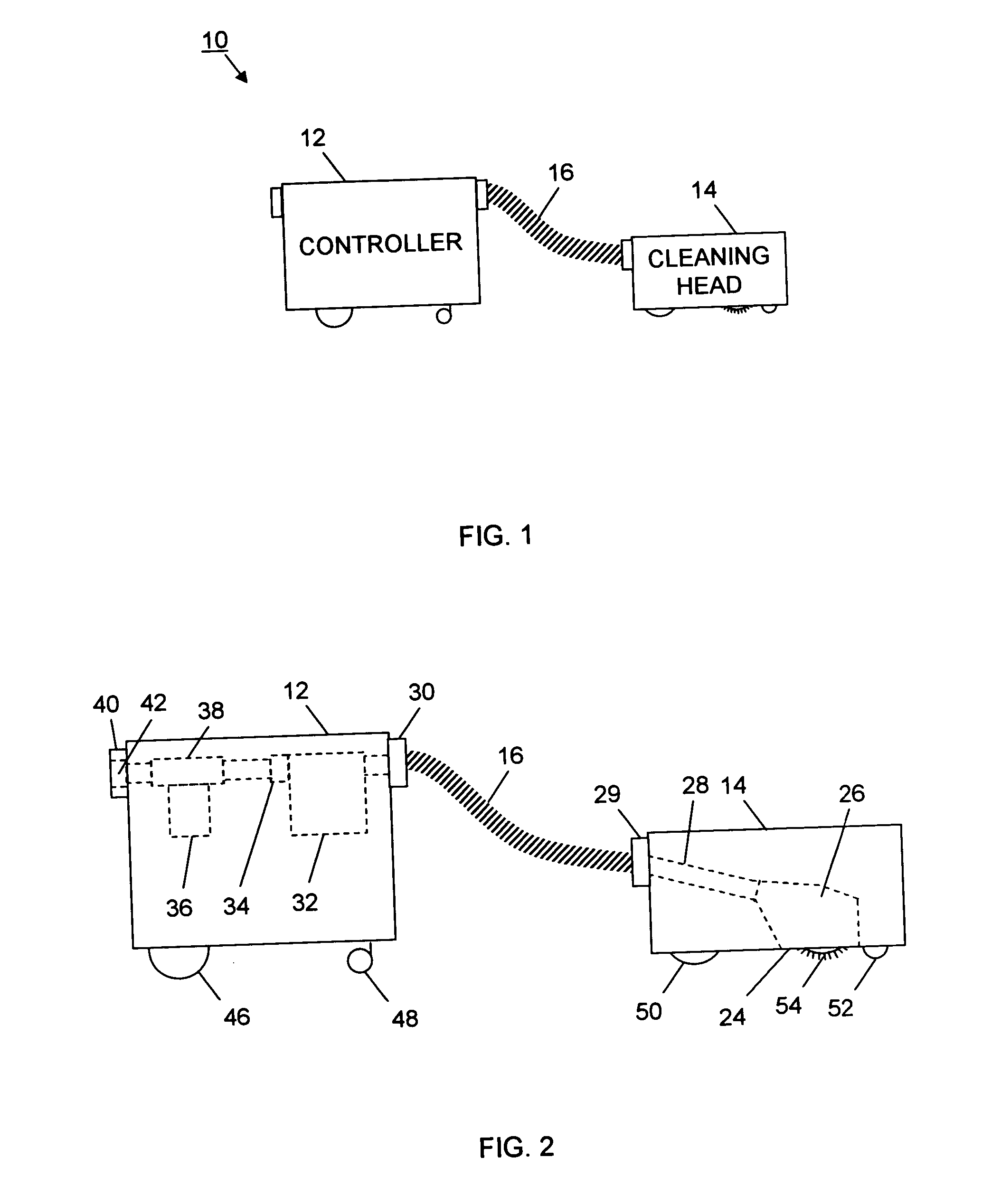

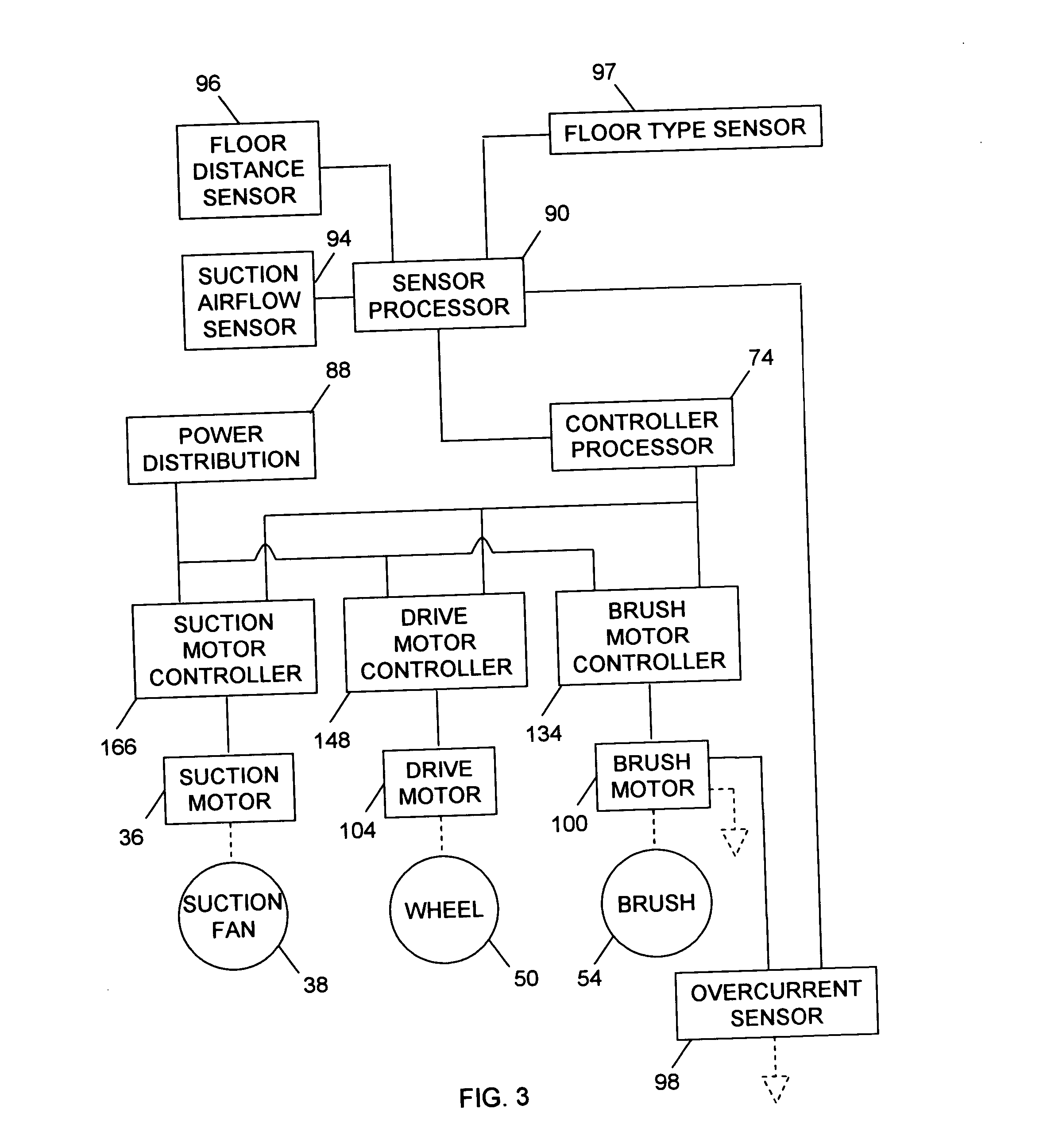

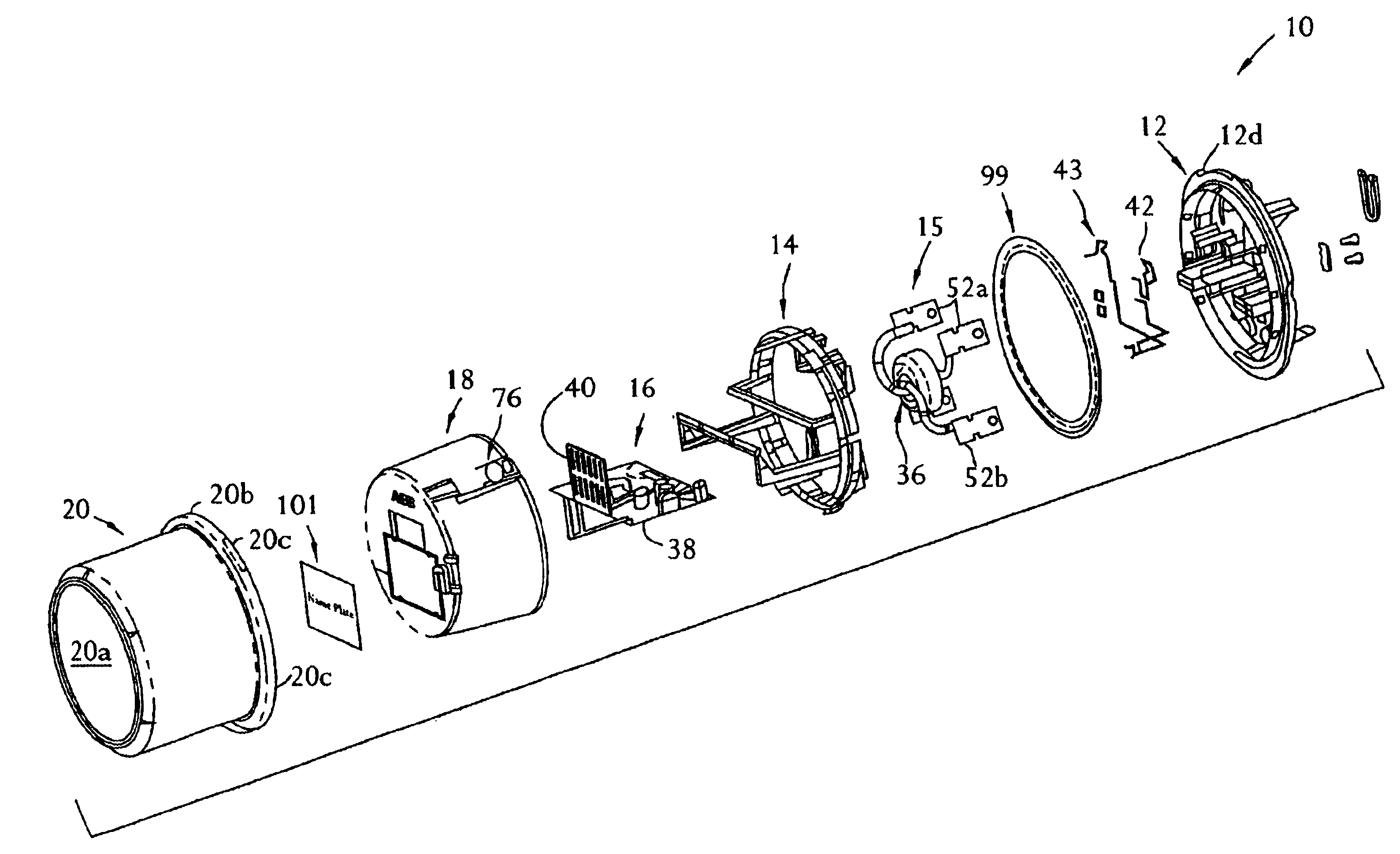

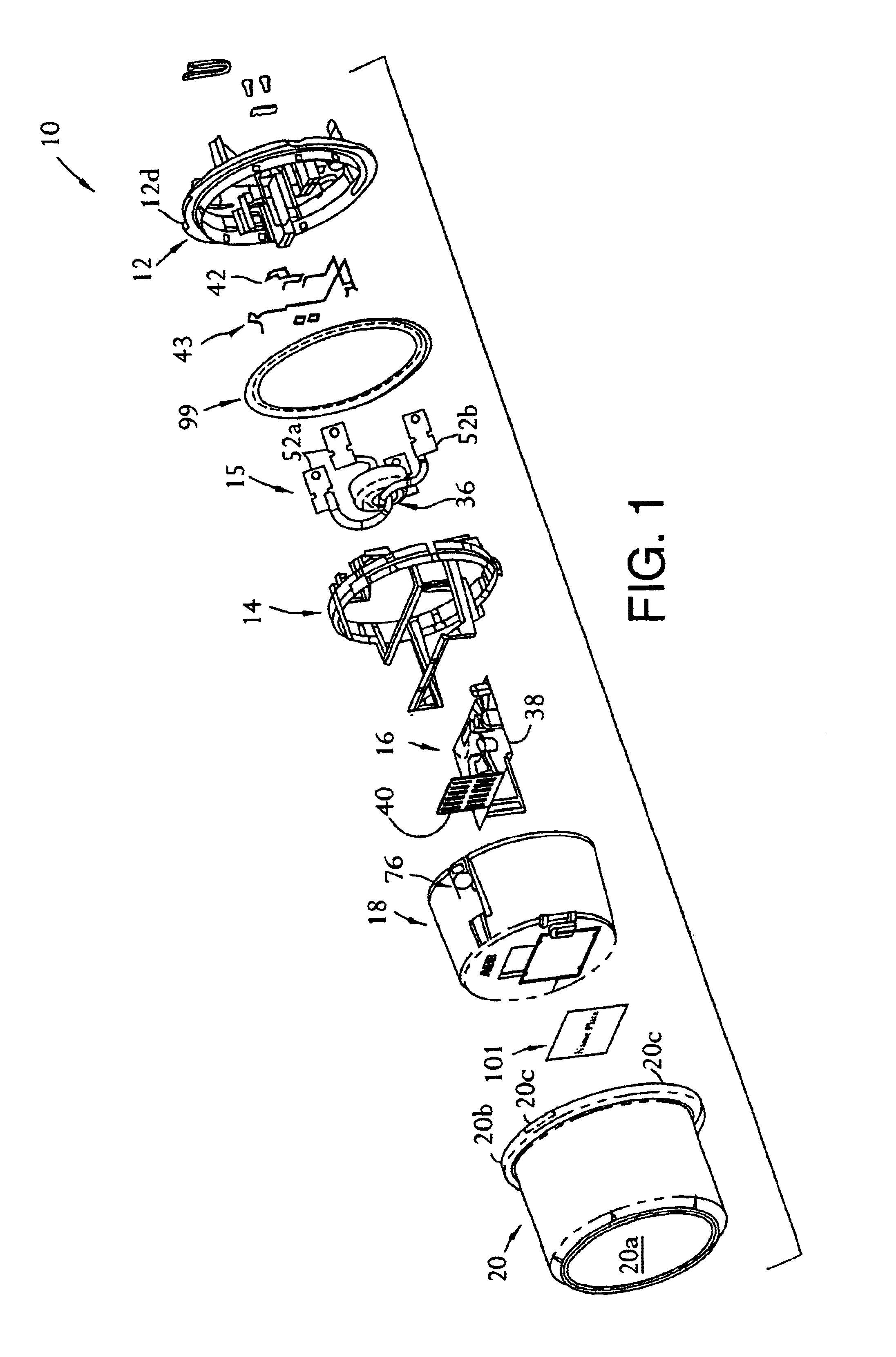

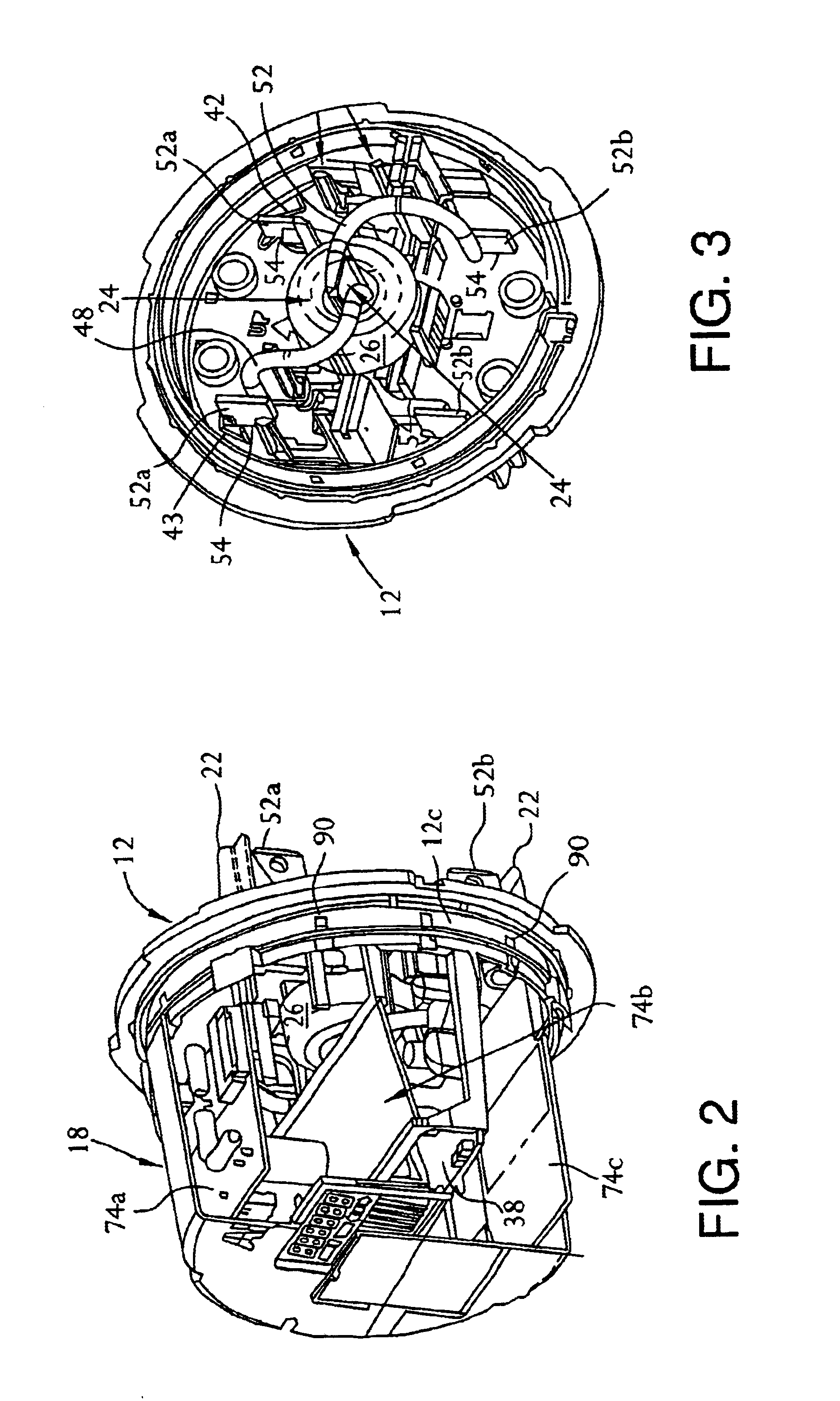

Sensors and associated methods for controlling a vacuum cleaner

Several methods of controlling a vacuum cleaner (10) using various types of sensors (94, 96, 97, 98) are provided. One method is based on a differential pressure between a suction airflow path and ambient air and includes: detecting the differential pressure, comparing the detected differential pressure to a predetermined threshold, and, when the detected differential pressure is less than the predetermined threshold, initiating a predetermined control procedure. A status indicator (164) is updated based on the detected differential pressure. Another method is based on a level of electrical current flowing through a brush motor (100). Still another method is based on a type or condition of the floor being traversed. Yet another method is based on a distance to a surface of a floor over which the vacuum cleaner is advancing. In another aspect of the invention, a vacuum cleaner is provided. In various combinations, the vacuum cleaner includes a vacuum source (36, 38), a brush motor (100), a drive motor (104), a controller processor (74), a sensor processor (90), an overcurrent sensor (98), a suction airflow sensor (94), a floor type sensor (97), and a floor distance sensor (96).

Owner:ROYAL APPLIANCE MFG

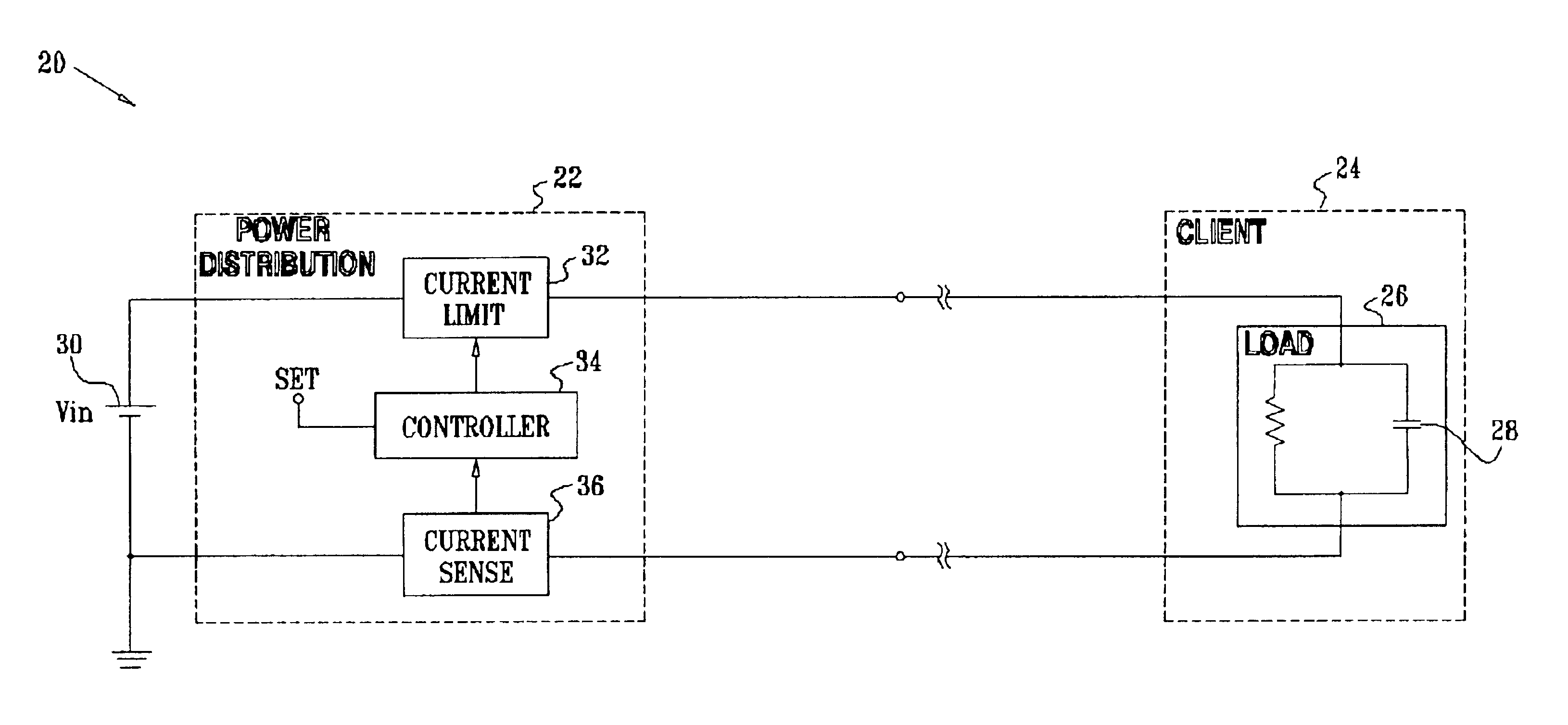

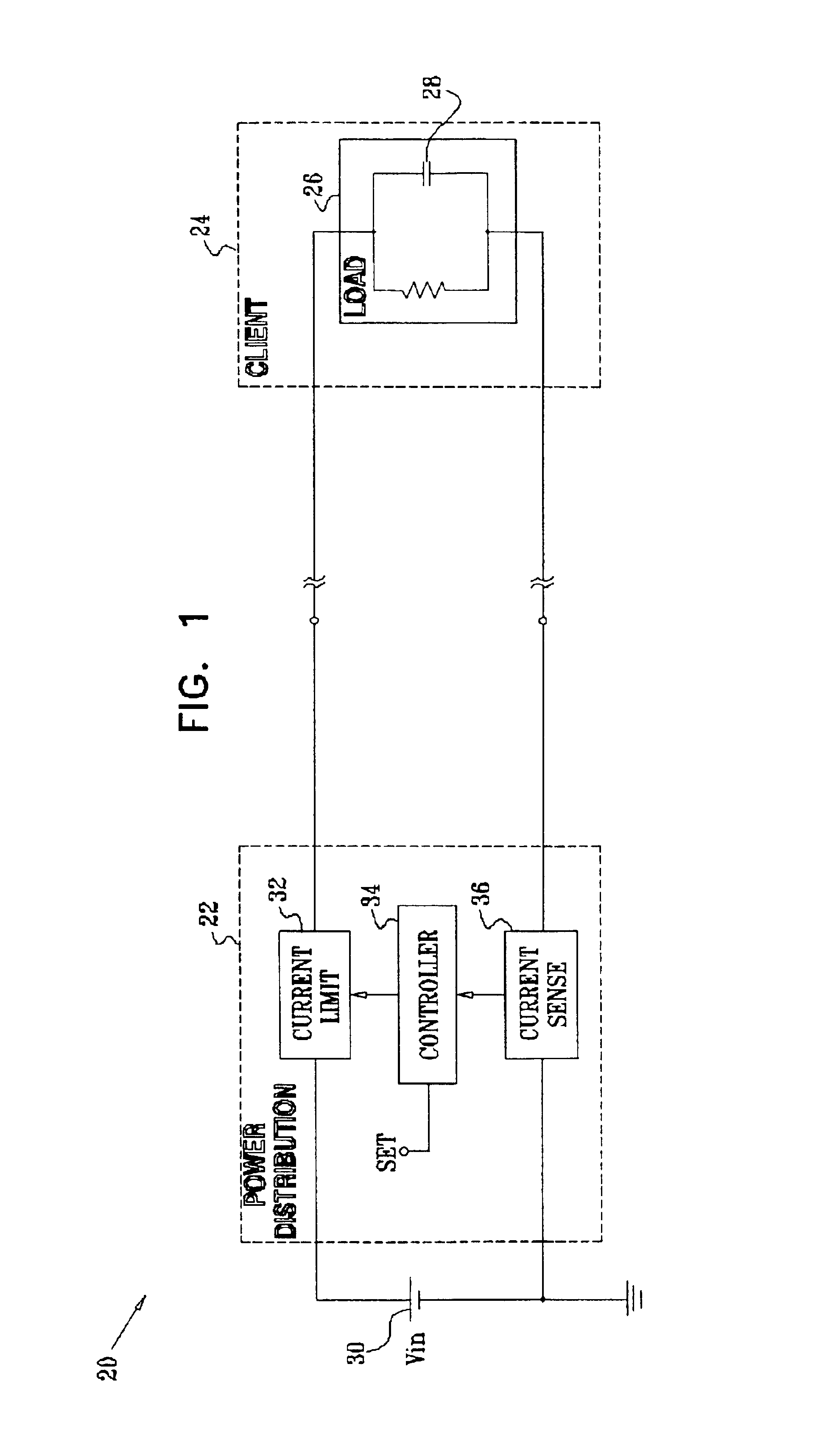

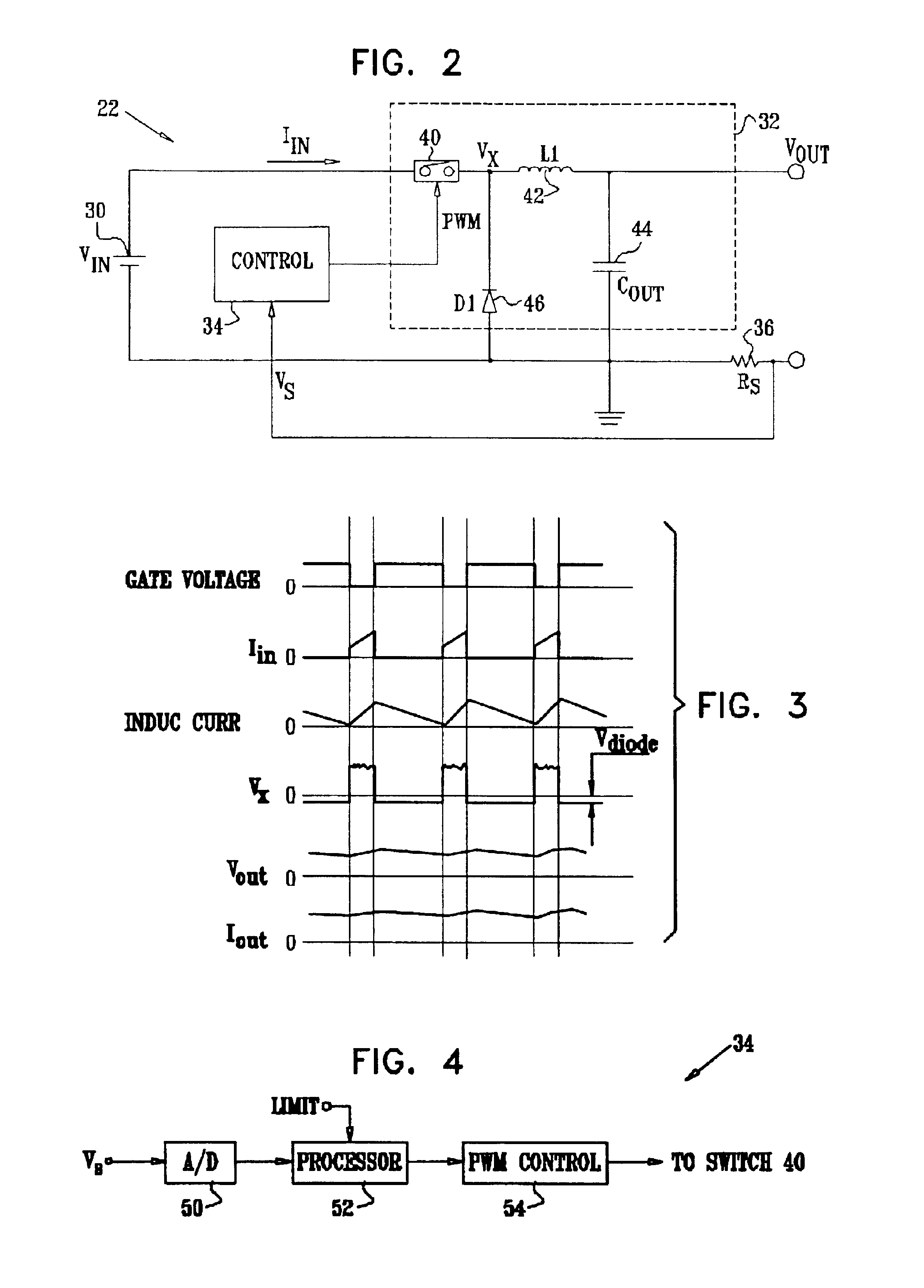

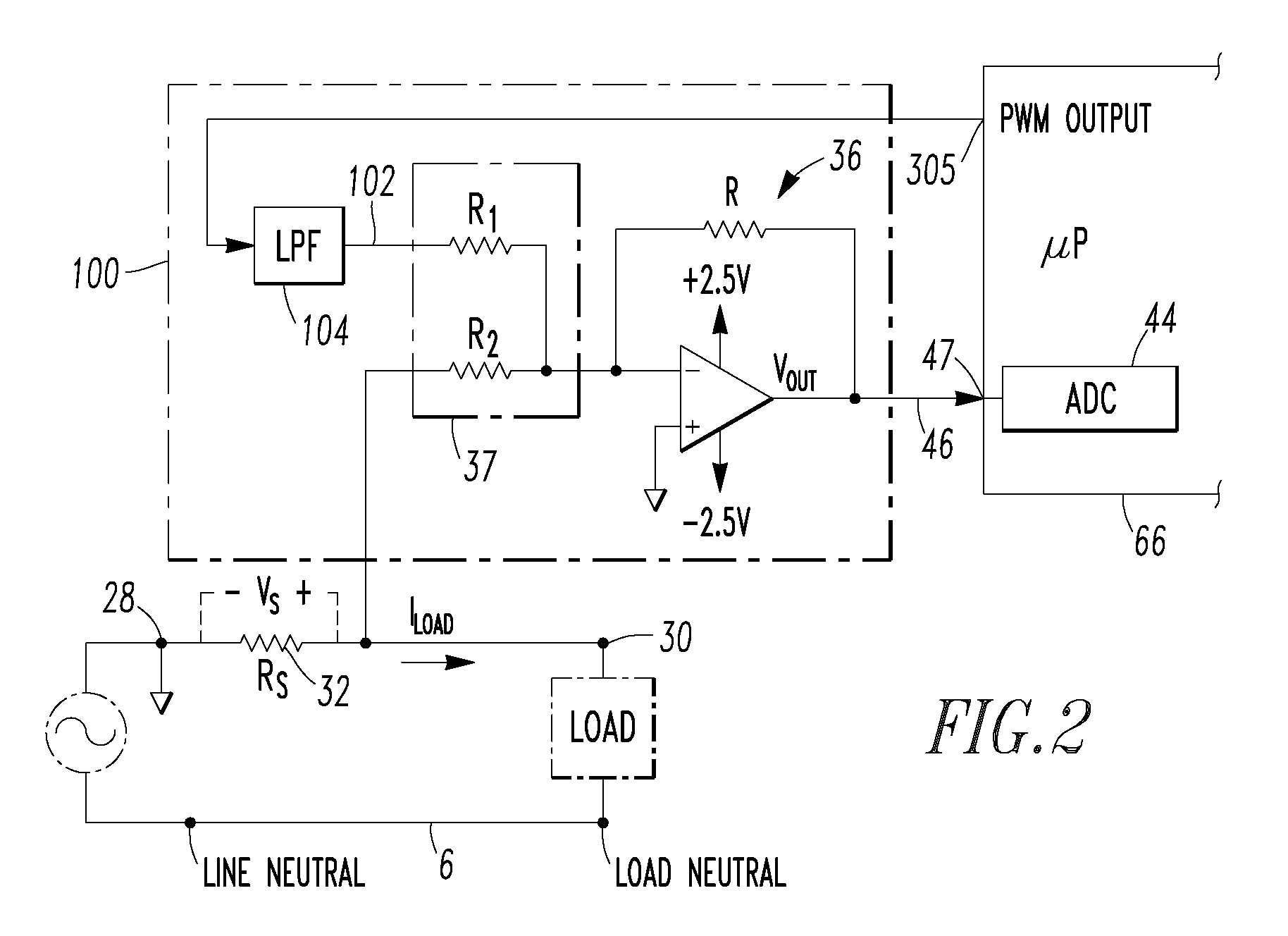

Power distribution with digital current control

InactiveUS6841979B2Minimum power consumptionEfficient power electronics conversionAc-dc conversionControl powerCurrent sensor

Power distribution apparatus, for controlling supply of a current from an electrical power source to at least one load, includes a current sensor, which is coupled to provide an indication of a magnitude of the current flowing to the at least one load. A current limiter is adapted, responsive to the indication, to apply a pulse width modulation to the current drawn from the source so as to maintain the magnitude of the current flowing to the at least one load within a predetermined limit.

Owner:CISCO TECH INC

Apparatus for employing low ohmic alloy conductors and method for simplifying current drain data retrieval

ActiveUS20130183043A1Decrease in Q-factorSmallAc-dc conversionTransformers/inductances coils/windings/connectionsElectrical conductorData retrieval

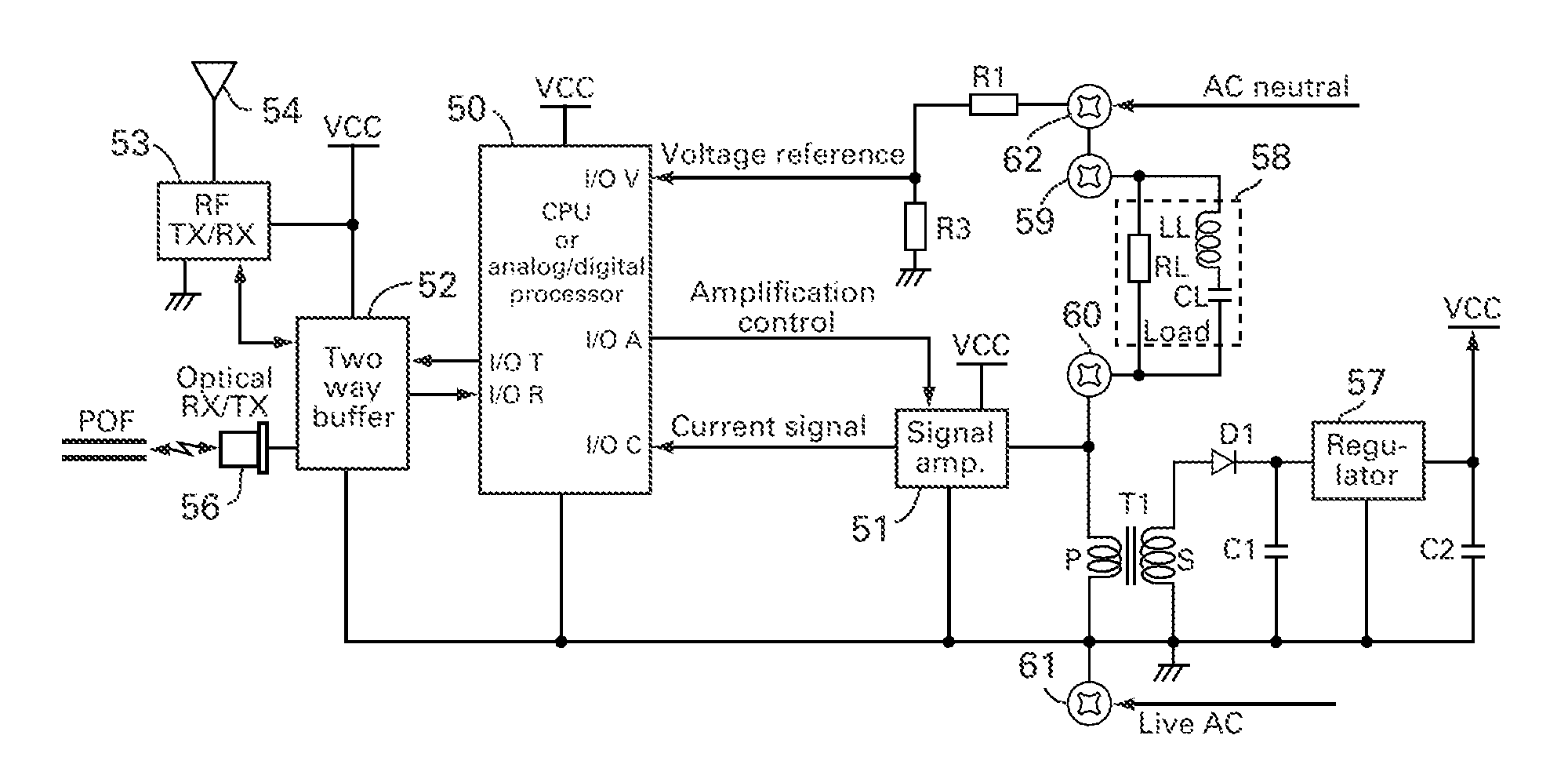

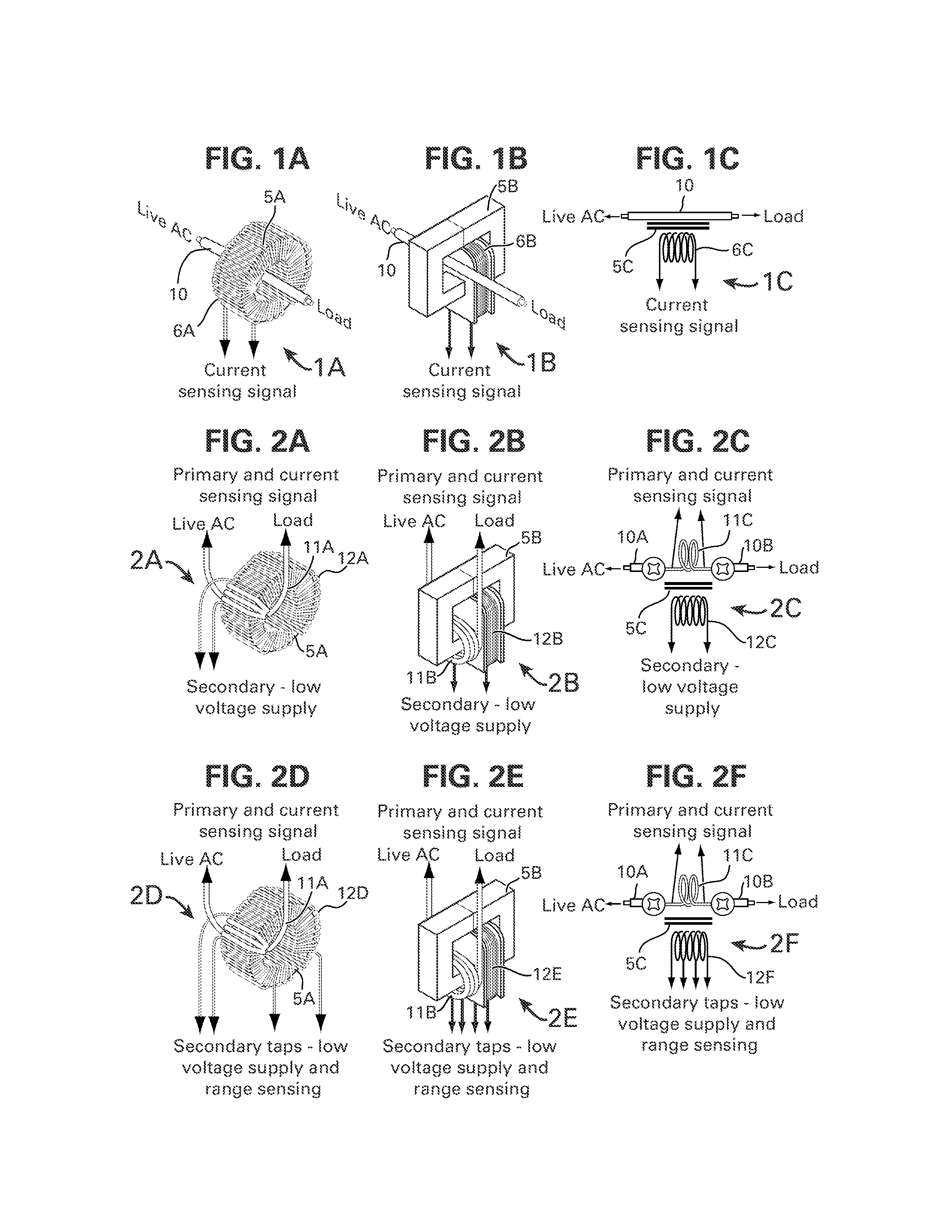

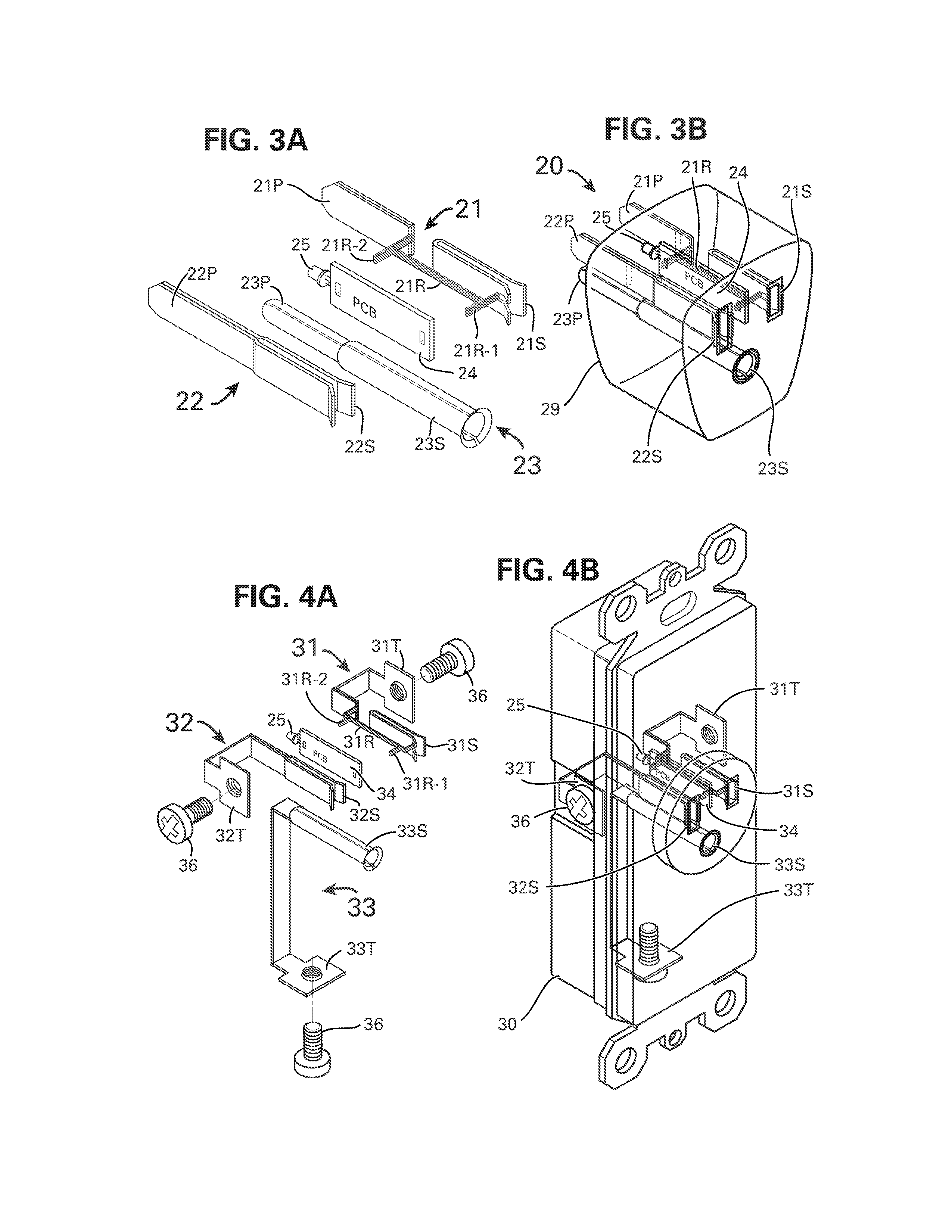

Apparatus and method for measuring current drain and reporting power consumption using current transformer with primary windings made of low ohmic alloy, enabling the use of the secondary coil to power the sensing and reporting circuits eliminating the power wasted by AC-DC power adaptors used for the current sensors. The saving is substantial as the current sensors will not drain a current when the AC outlets are disconnected from a load or when the load is switched off. The apparatus using low ohmic alloy is extended to the structuring of terminals, including power pins, power sockets and combinations to provide a low ohmic sensing elements in AC plugs, outlets, adaptors and extension cables with multi outlets, dissipating the heat from the sensing elements by the plugs and the larger metal heat dissipation.

Owner:ELBEX VIDEO LTD

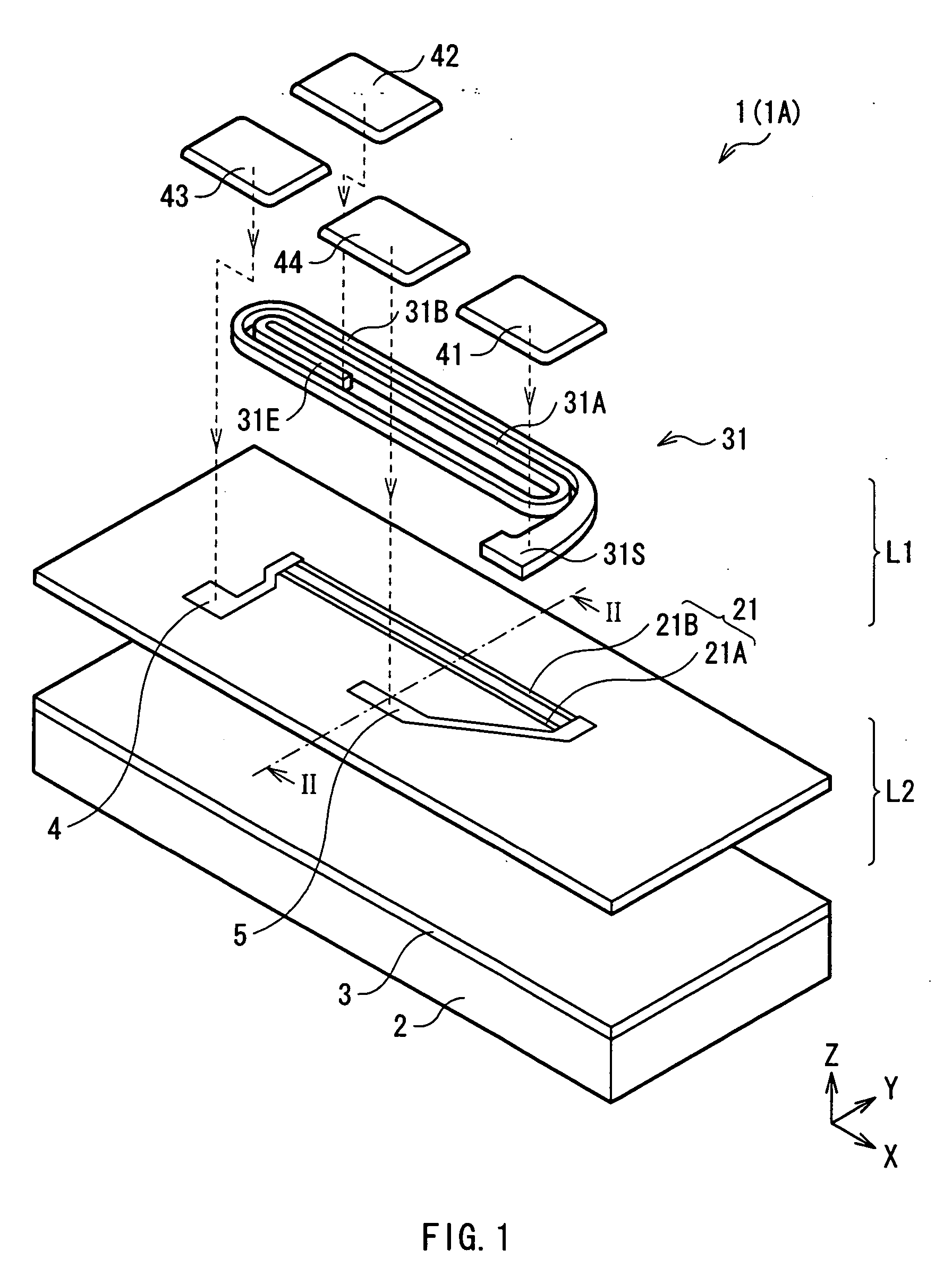

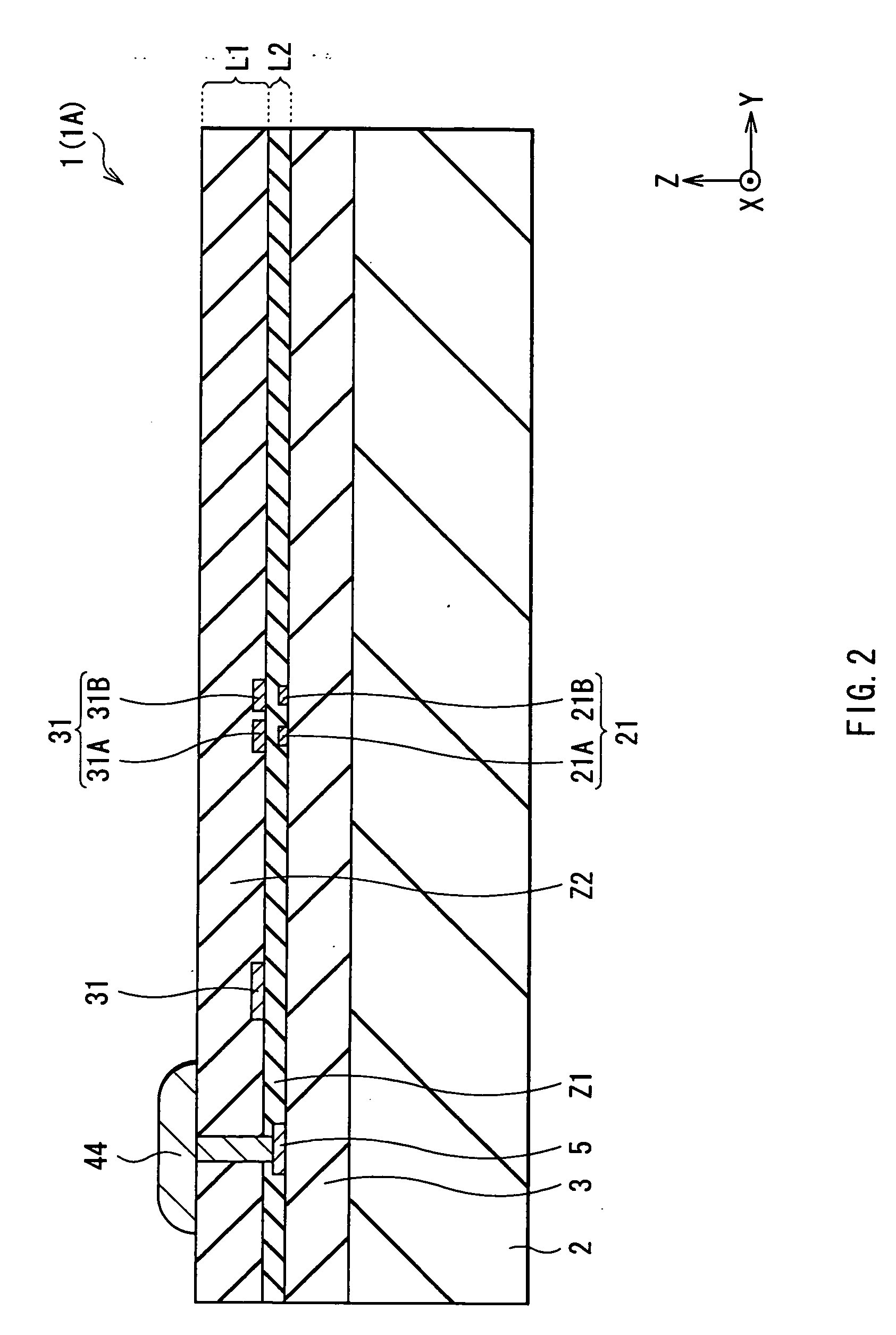

Current sensor

ActiveUS20060170529A1Reduced dimensionStrong applicationMagnetic-field-controlled resistorsSolid-state devicesElectrical resistance and conductanceMagnetic reluctance

A current sensor that is compact can detect with high sensitivity and high accuracy a magnetic field generated by a current. The current sensor has a thin film coil including turn portions extending in an X-axis direction at a second layer, and a first magnetoresistive element which includes element patterns disposed at a first layer in areas corresponding to the turn portions, the resistance value of which varies according to a magnetic field generated by a current detected of from 10 to 50 mA flowing through the turn portions. The distance between each turn portion and each element pattern is from 0.4 to 1.0 μm. Each cross-sectional area at the turn portions is from 0.4 to 3.0 μm2. This permits efficient detection of a magnetic field without the influence of heat generated from the thin film coil.

Owner:TDK CORPARATION

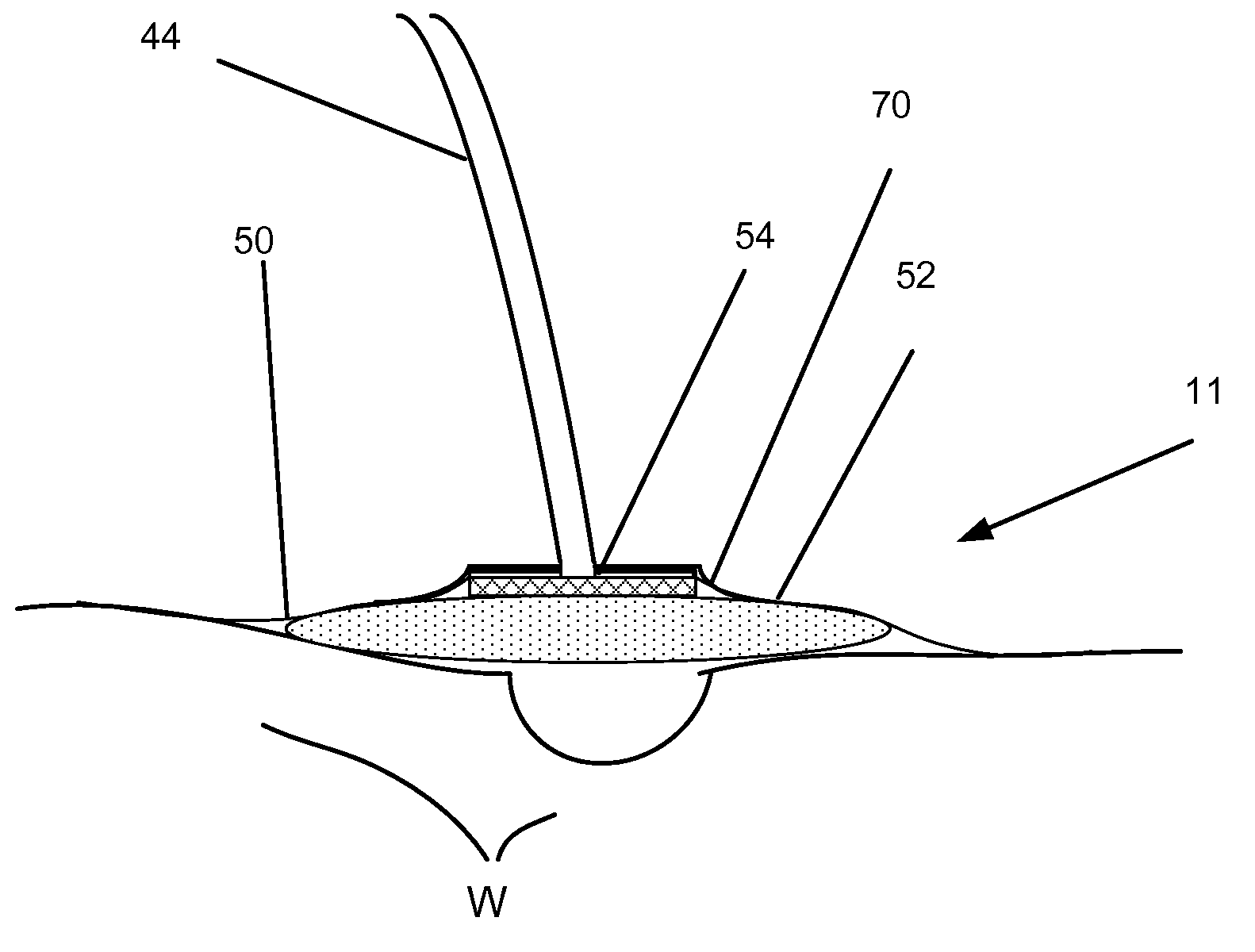

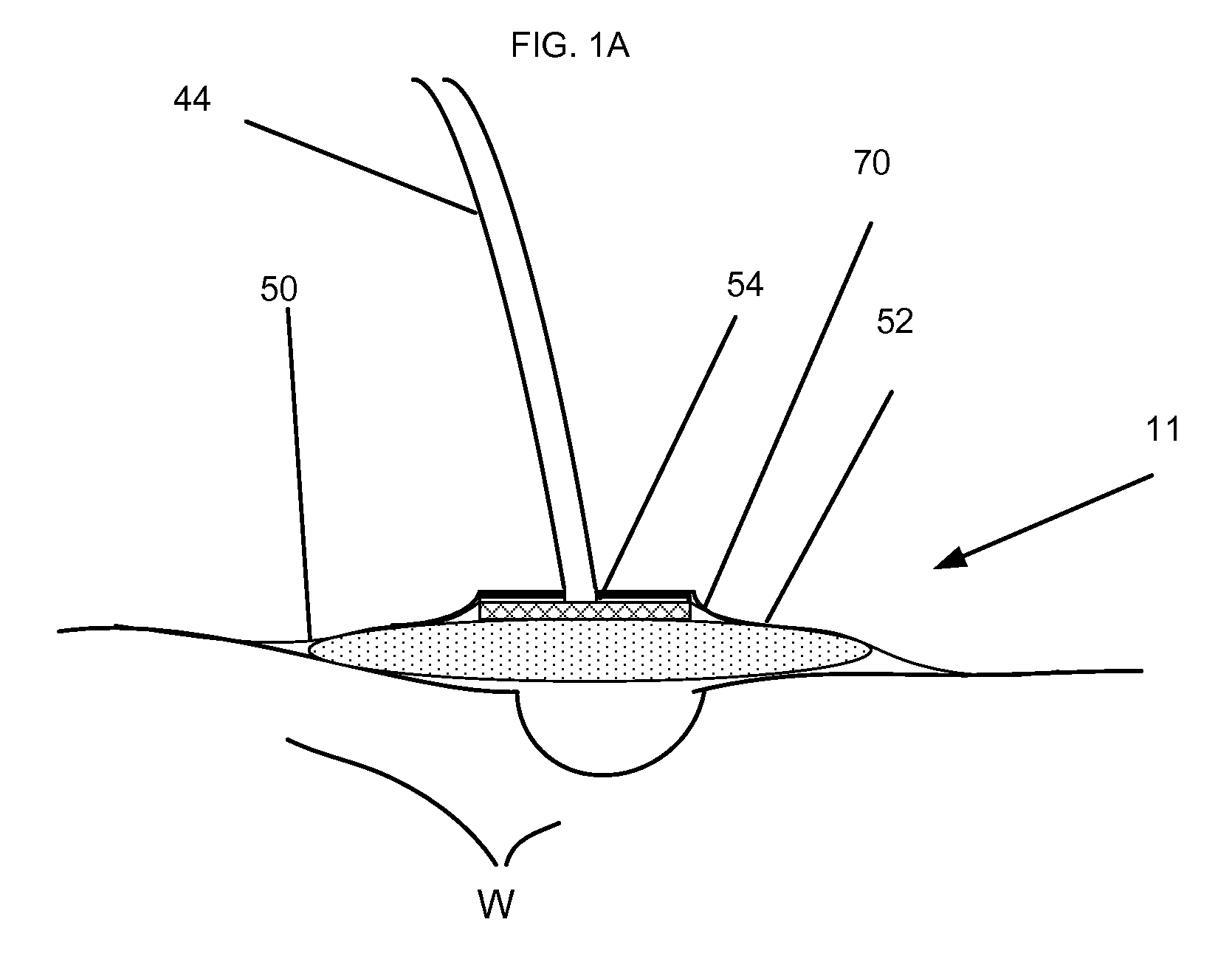

Pump leak monitor for negative pressure wound therapy

ActiveUS20110015593A1Promote wound healingImprove portabilityMedical devicesAdhesive dressingsPower flowTherapeutic Devices

A therapeutic device includes a fluid mover for one of raising, compressing, or transferring fluid, a therapeutic member operably connected to the fluid mover and actuated thereby, the therapeutic member operably disposably used on a patient in a manner to deliver therapy to the patient as function of actuation of the fluid mover, a controller operably associated with the fluid mover for controlling operation thereof, and a leak, blockage, temperature, voltage or current sensor operably connected to the fluid mover and the controller and to sense a leak, blockage, temperature, voltage or current in the device and send a signal to the controller whereby the controller controls the fluid mover as a function of the sensed signal.

Owner:INNOVATIVE THERAPIES LLC

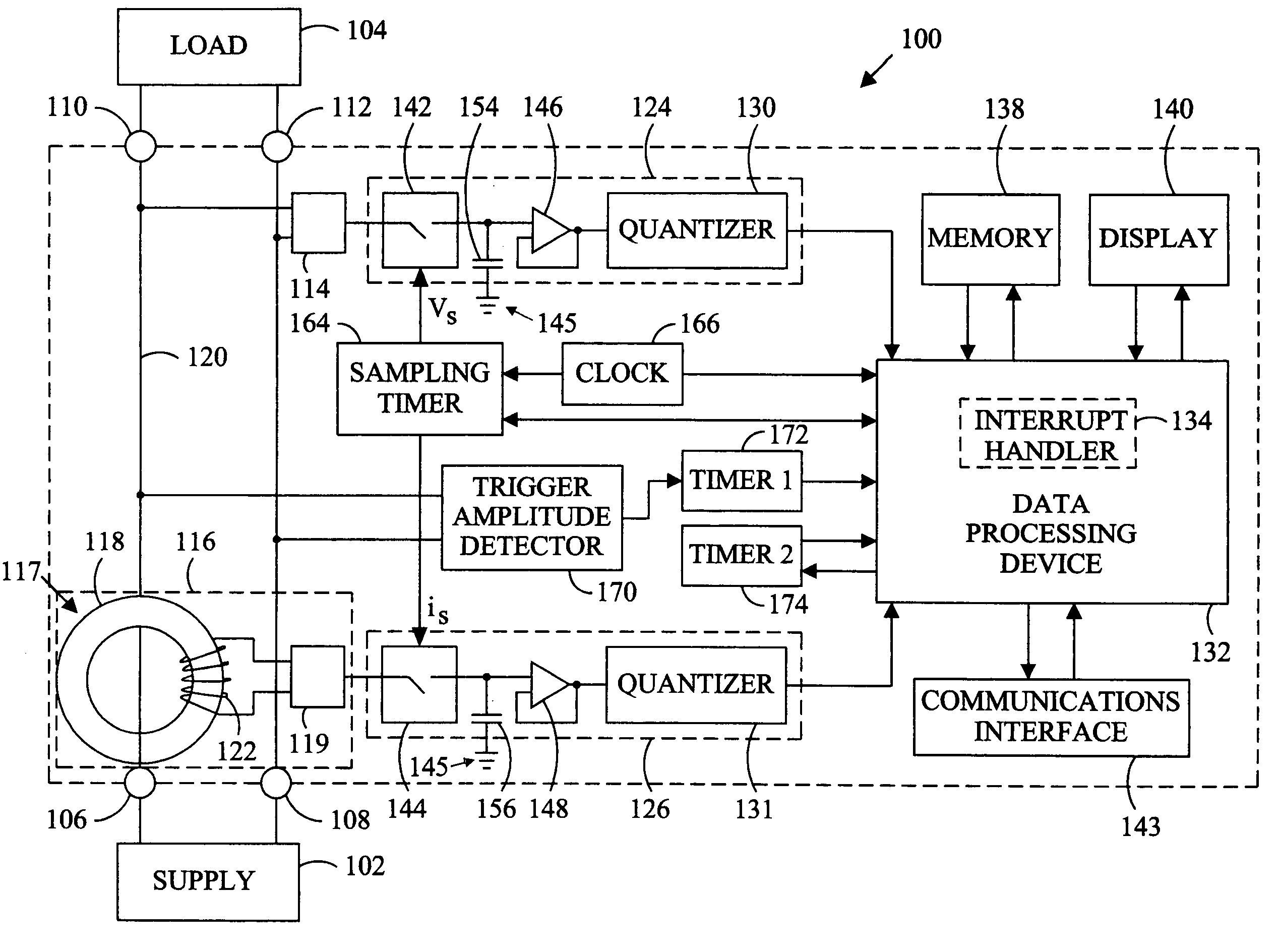

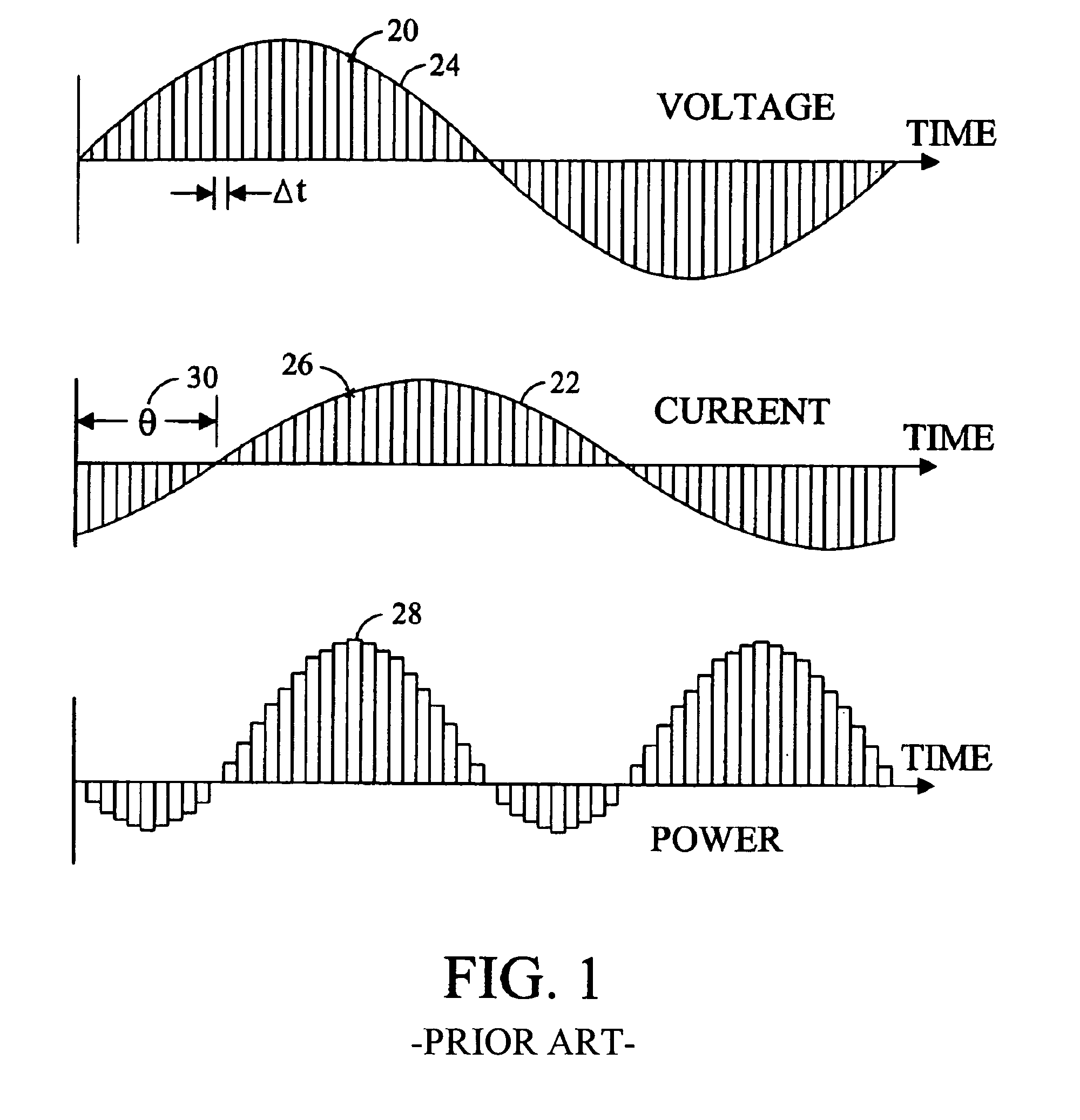

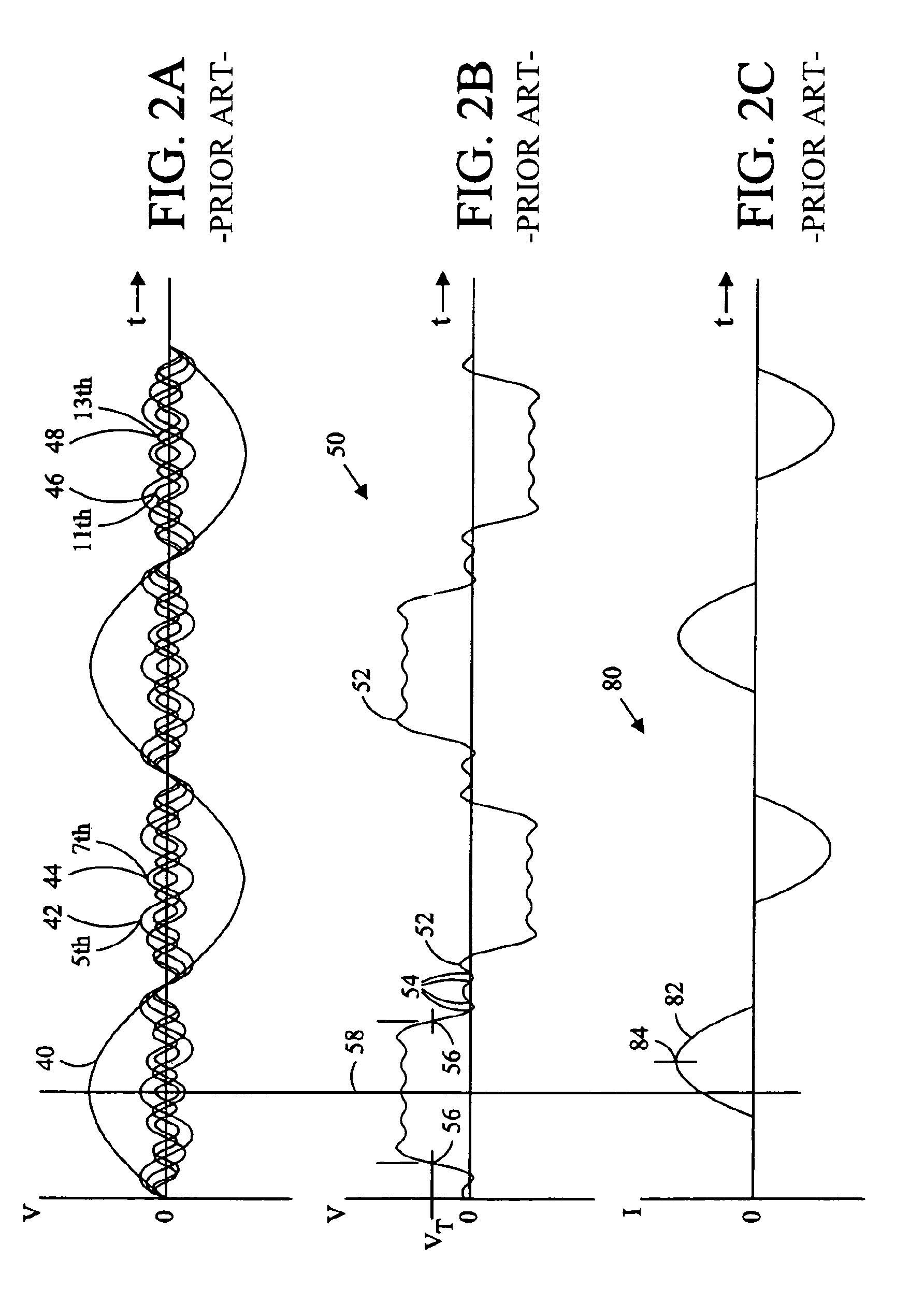

Power meter

The computational resources of a digital power meter can be reduced by utilizing an interrupt requested in anticipation of interrupt latency to perform real-time tasks, an approximation of a root mean square load current at an earlier time to compensate for a phase shift between the load current and the current transducer output, and an amplitude that is neither zero nor maximum to distinguish the cycles of a harmonically distorted waveform.

Owner:VERIS INDS

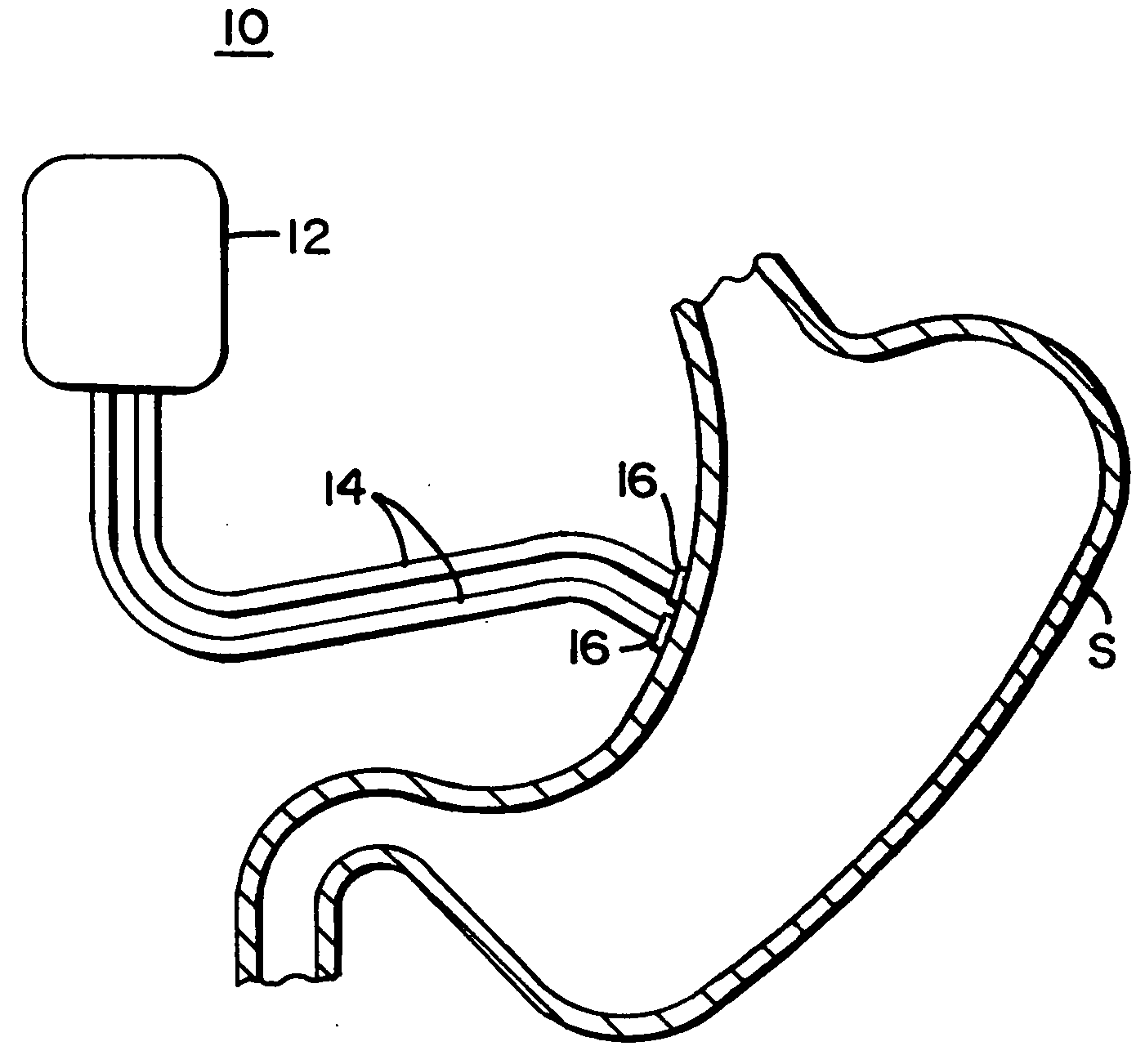

Gastric stimulator apparatus and method for use

InactiveUS20050113880A1Improve the level ofStimulating neuromuscular tissueInternal electrodesExternal electrodesReal-time clockCurrent threshold

Apparatus and method for stimulating neuromuscular tissue in the stomach. The neuromuscular stimulator stimulates the neuromuscular tissue by applying current-controlled electrical pulses. A voltage sensor detects the voltage across the neuromuscular tissue to determine if the voltage meets a predetermined voltage threshold. A control circuit adjusts the current-controlled pulse if the voltage is found to meet the voltage threshold, such that the voltage does not exceed the voltage threshold. A voltage-controlled pulse may also be applied to the tissue. A current sensor would then detect whether the current on the neuromuscular tissue meets a predetermined current threshold, and a control circuit adjusts the voltage-controlled pulse such that the current does not exceed the current threshold. A real time clock may be provided which supplies data corresponding to the time of day during the treatment period. A programmable calendar stores parameters of the stimulating pulse, wherein the parameters have a reference to the time of day.

Owner:MEDTRONIC TRANSNEURONIX

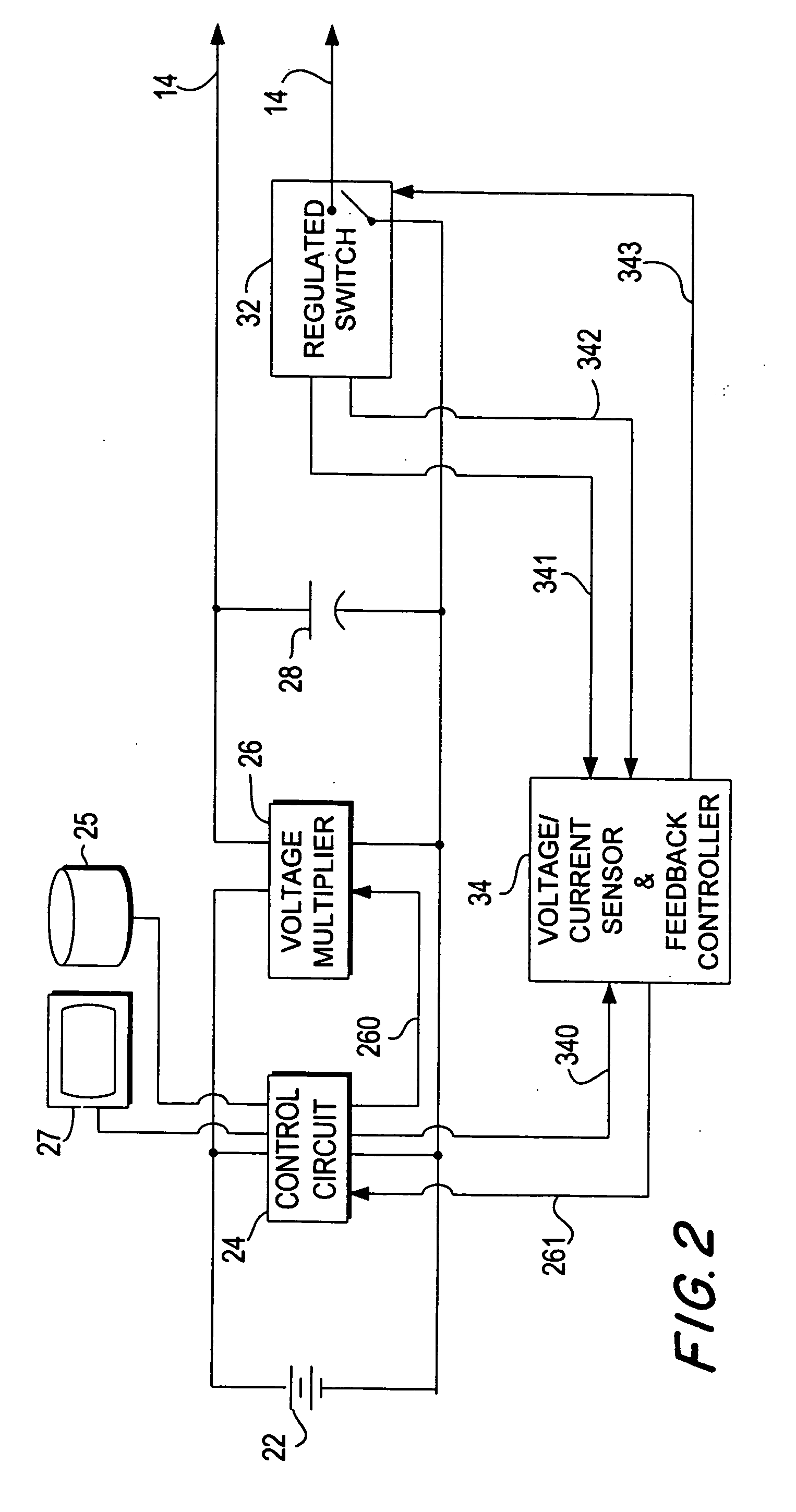

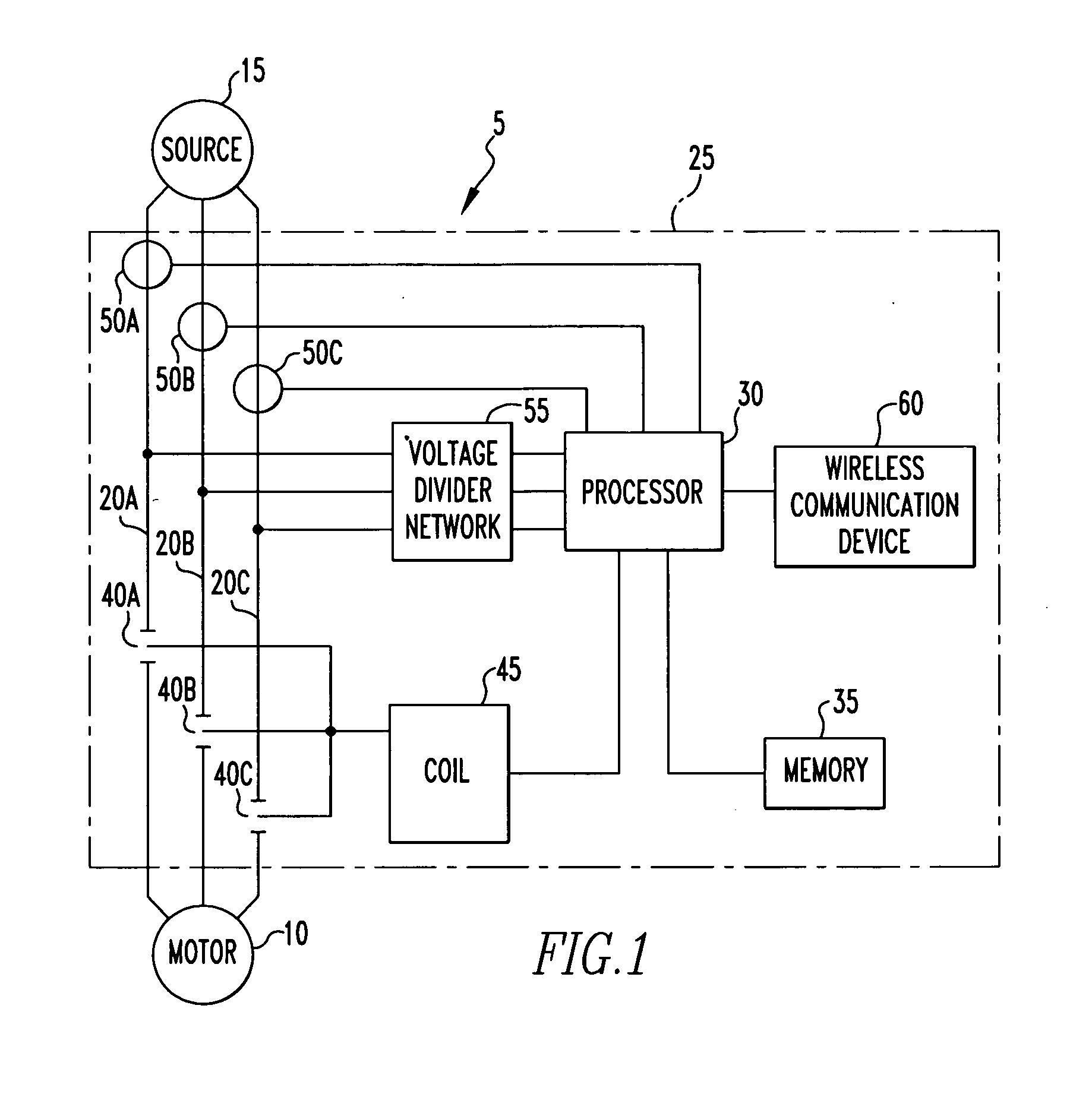

Medium voltage motor starter including a contactor having motor protection relay functionality

InactiveUS20060256488A1Protective functionEmergency protective arrangements for automatic disconnectionCurrent transducerElectricity

A contactor for connecting a medium voltage load, such as a medium voltage three-phase motor, to a medium voltage electrical source, such as a medium voltage three-phase electrical source, and for providing protection functionality for the load includes one or more electrical conductors each having separable contacts such that the load is selectively electrically connected to the source, and one or more current transducers each operatively coupled to a respective one of the electrical conductors for measuring a current thereon. A processor is in electronic communication with the one or more current transducers, and a memory is in electronic communication with the processor. The memory stores one or more routines executable by the processor that are adapted to perform one or more protection functions for the load based on the current measured by each of the one or more current transducers and to selectively open and close the separable contacts of each of said electrical conductors.

Owner:EATON CORP

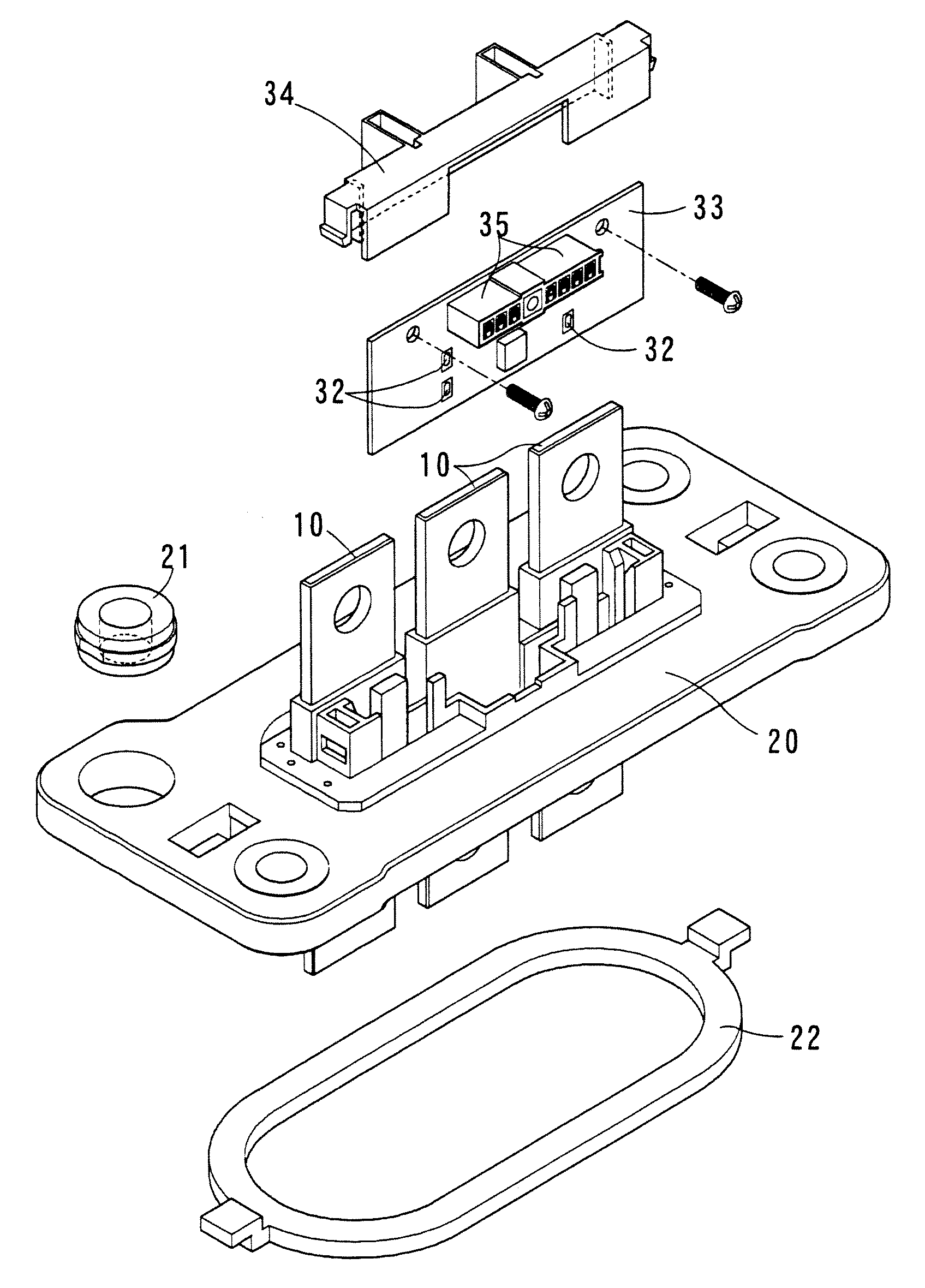

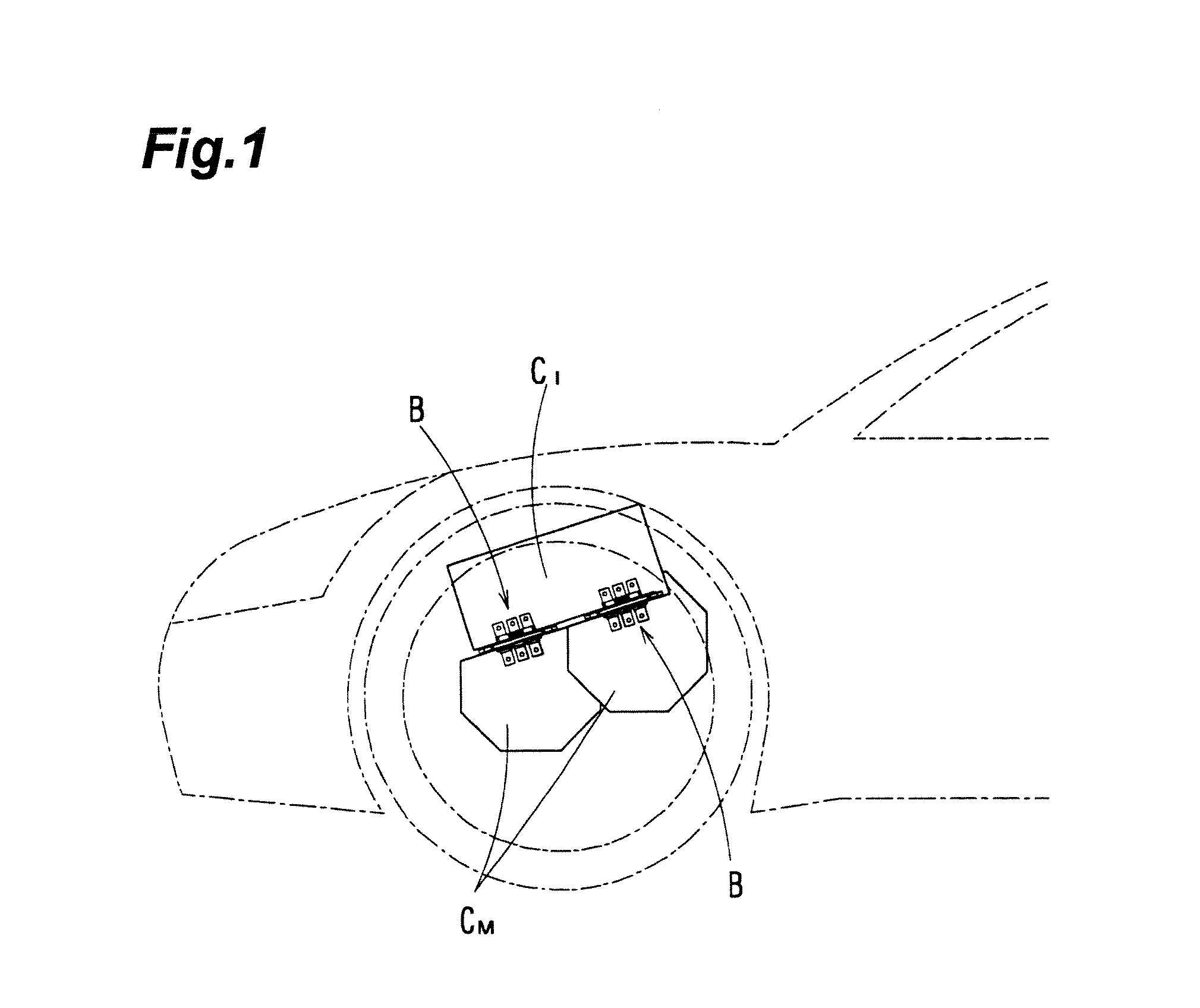

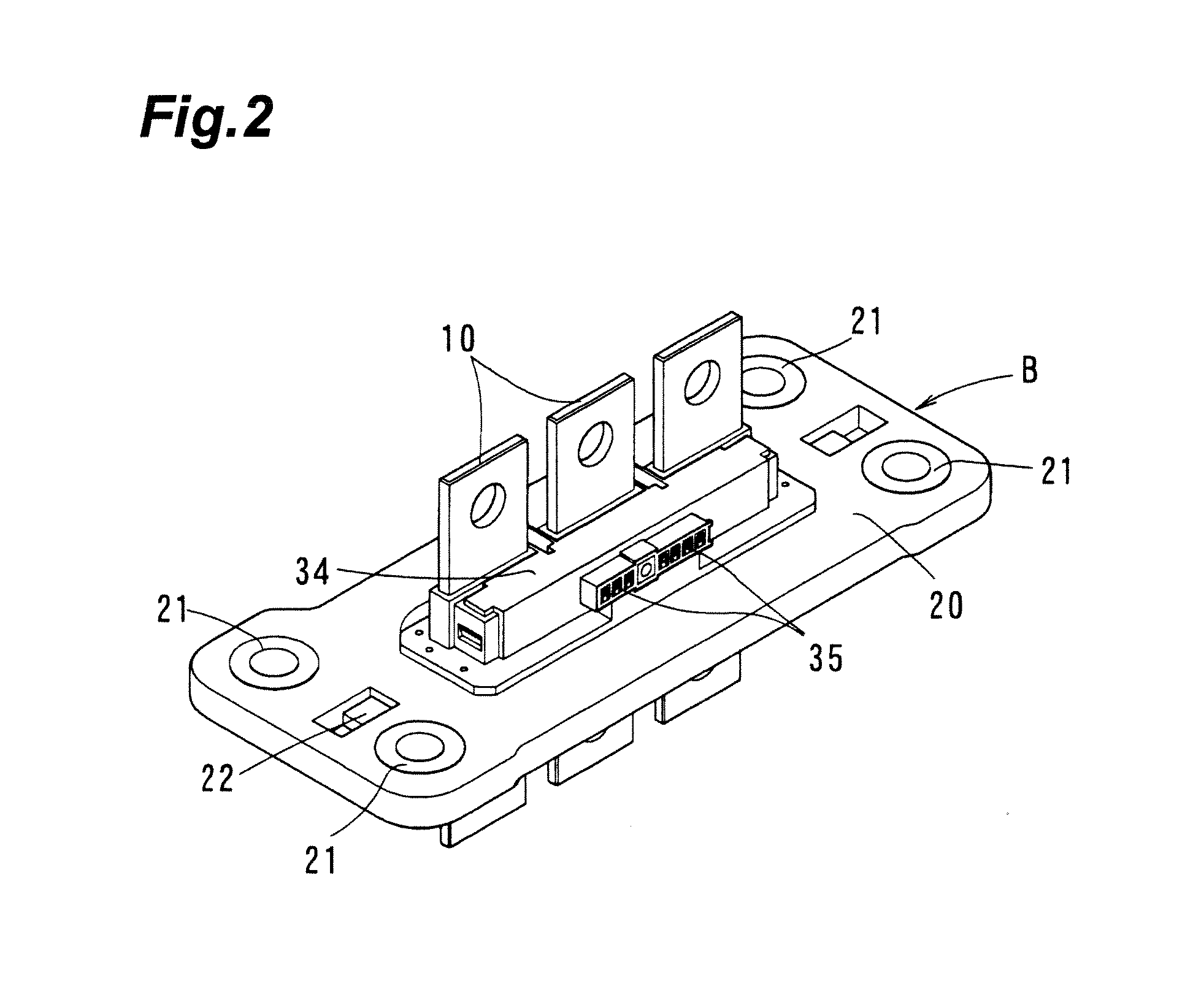

Relay busbar device with built-in current sensor for vehicle

ActiveUS20130214593A1Small sizeReduced space required for installationElectric devicesElectrical apparatusCurrent transducerBusbar

A relay busbar device of one embodiment is a relay busbar device with a built-in current sensor, which is interposed between a motor casing and an inverter casing, and includes a relay busbar both ends of which enter into both of the casings; a resin plate, through which the relay busbar penetrates, and which is interposed between the two casings; a magnetic core, positioned within the resin plate and surrounding the relay busbar; and a magnetic sensor provided in a removed portion of the magnetic core. The relay busbar is mold-formed integrally with the resin plate during resin molding thereof, and changes in magnetic field occurring in the removed portion due to the current flowing in the relay busbar are detected by the magnetic sensor, and the value of the current flowing in the relay busbar is measured.

Owner:SUMITOMO ELECTRIC IND LTD +2

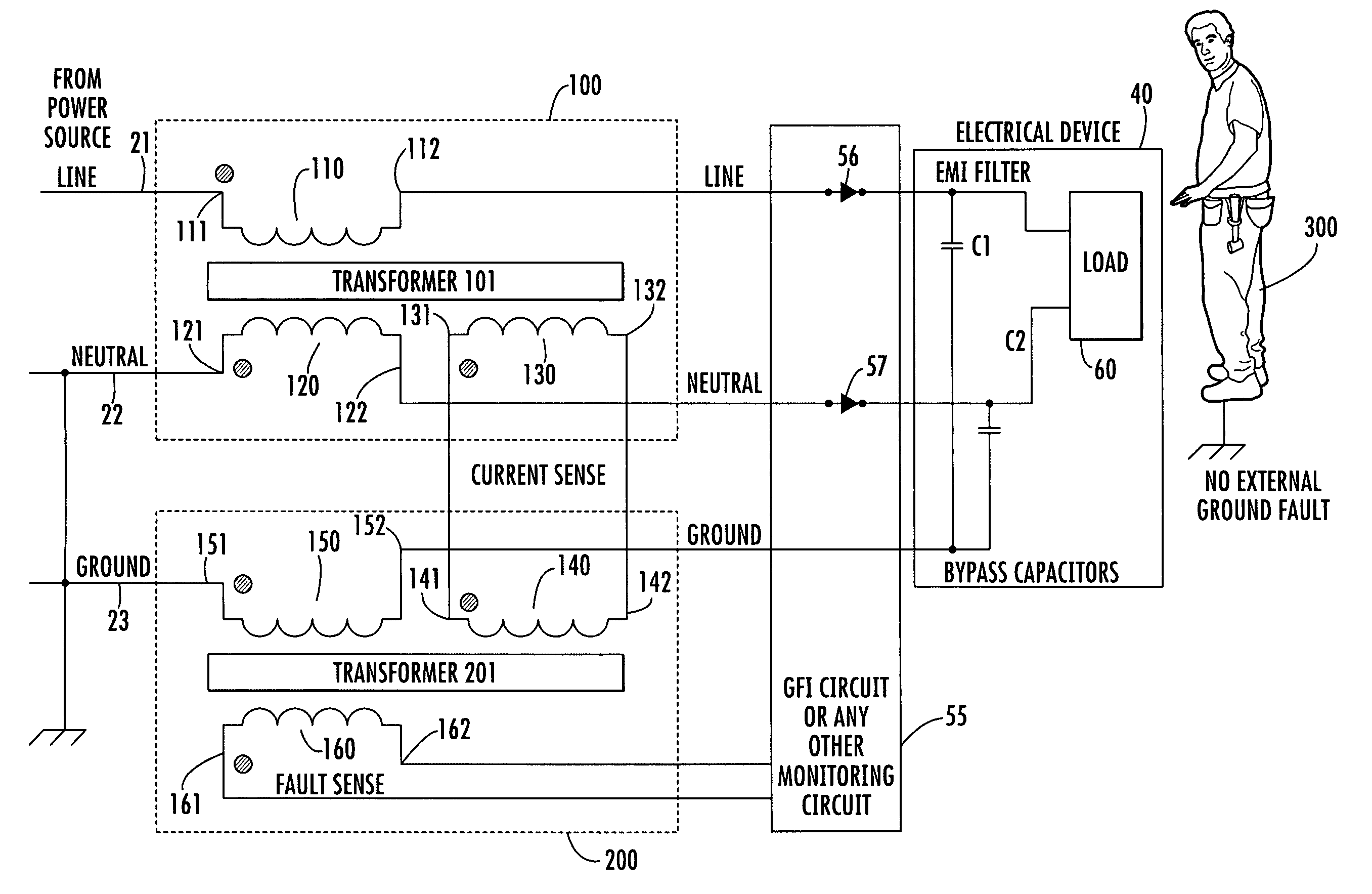

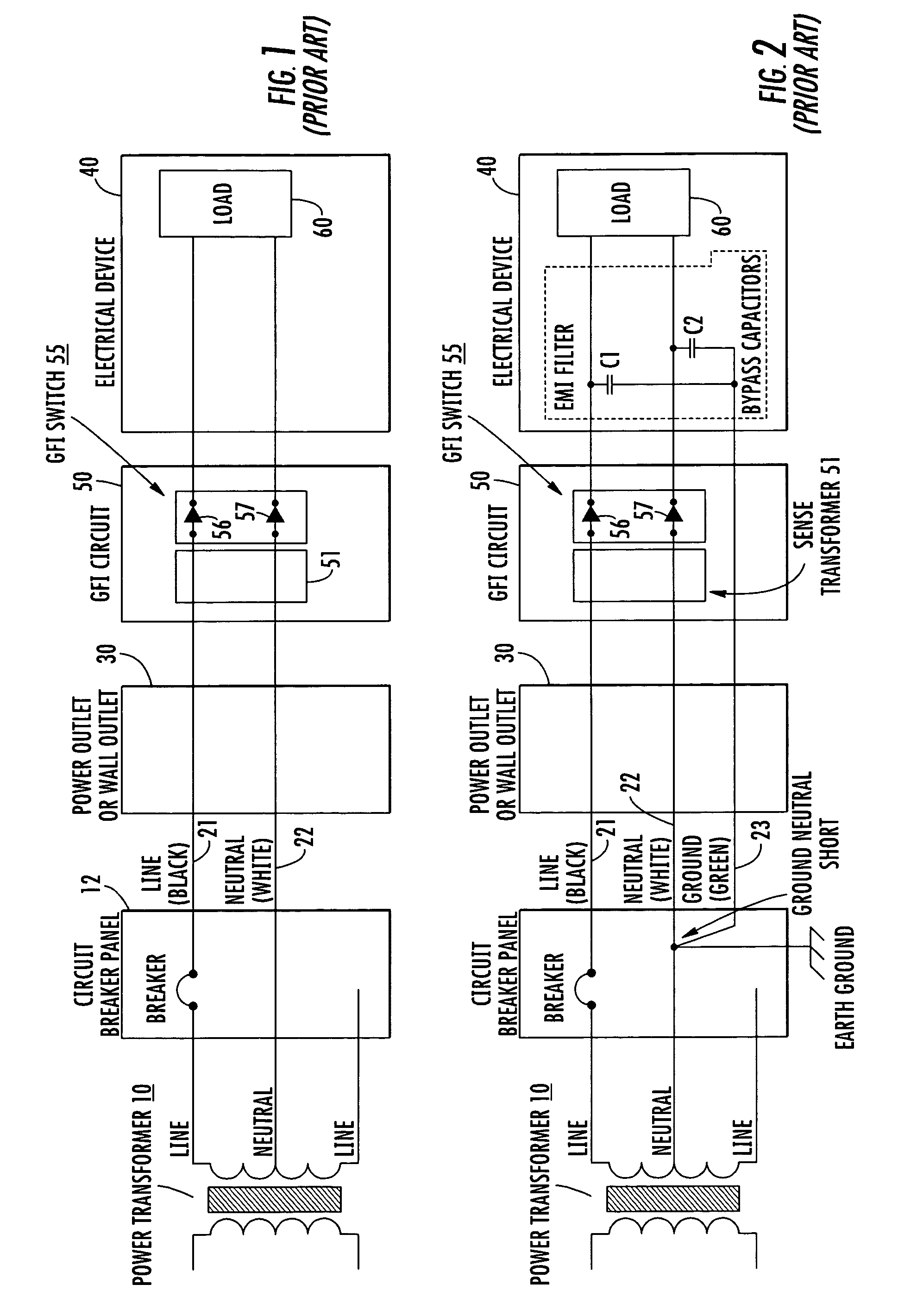

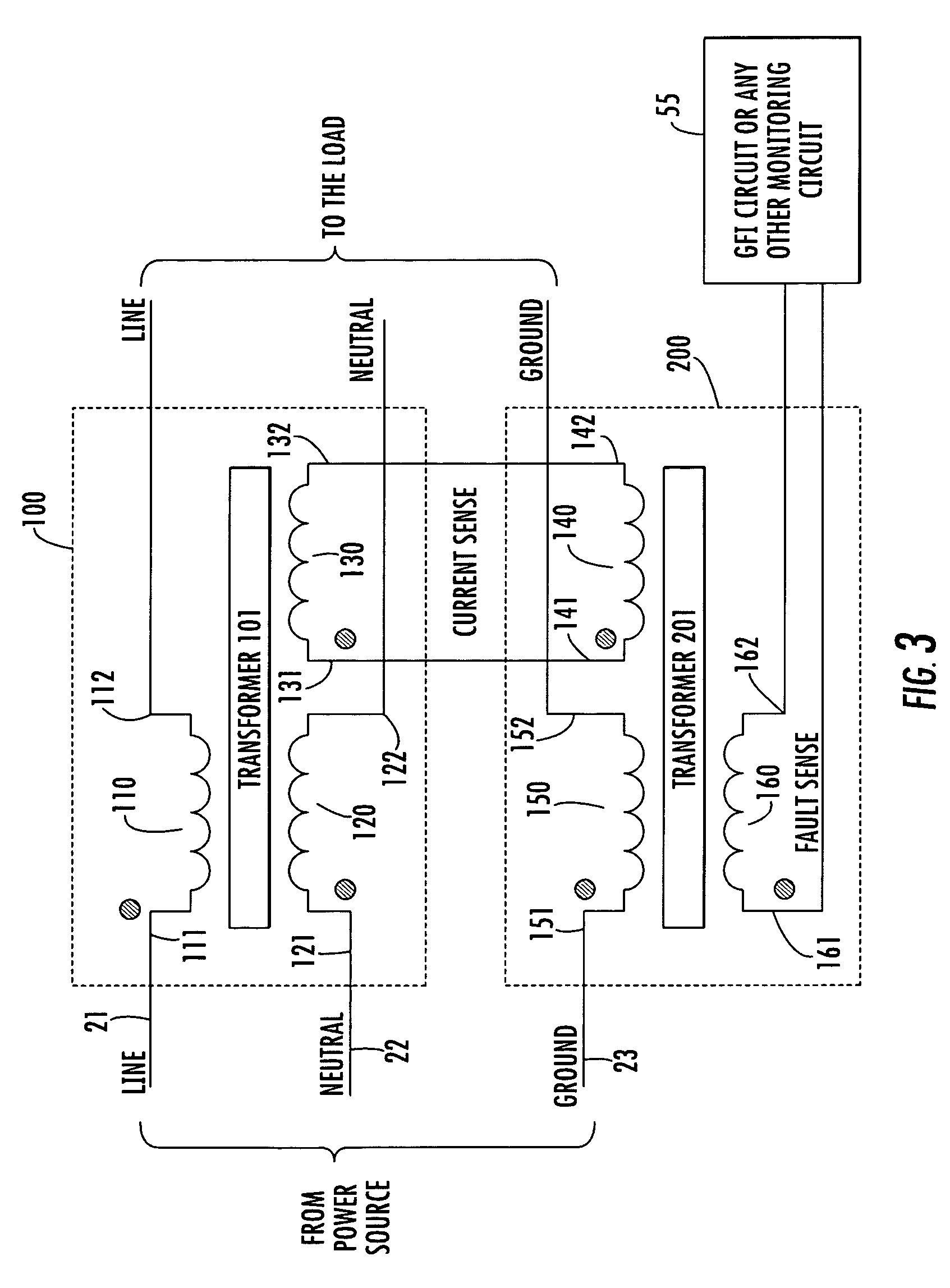

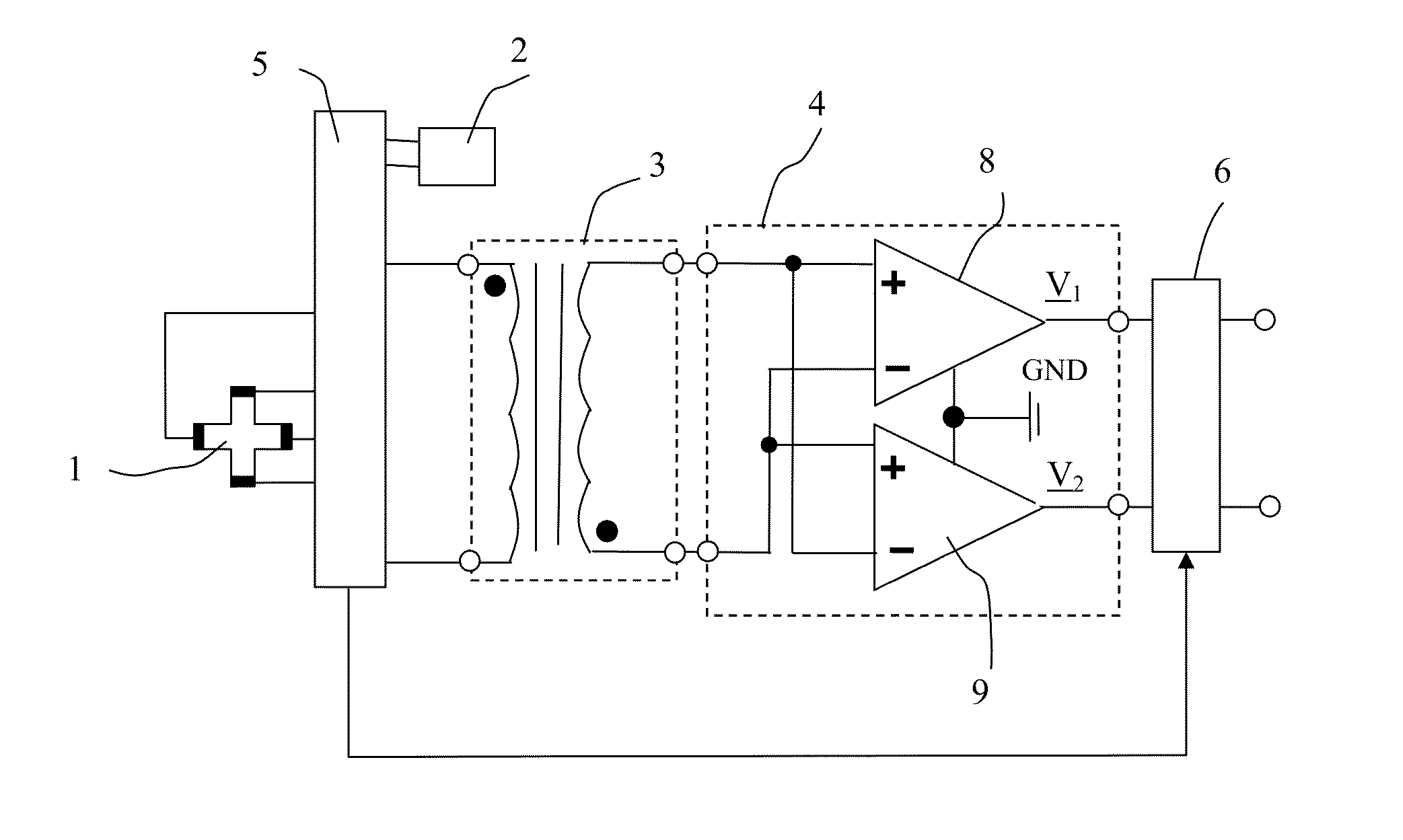

Transformer interface for preventing EMI-based current imbalances from falsely triggering ground fault interrupt

ActiveUS7375940B1Non-zero differential magnetic fieldTotal current dropArrangements resposive to fault currentCurrent sensorElectrical and Electronics engineering

A transformer interface prevents a false ground fault interrupt in a power supply arrangement. The power supply arrangement has a line wire and a neutral wire connected by way of a ground fault interrupt circuit to an electrically powered device, to which a ground wire is also coupled. The interface has current imbalance sensor transformer windings coupled to the line and neutral wires. A ground wire current sensor transformer winding is coupled to the ground wire. A detector transformer winding produces a signal that triggers operation of the ground fault interrupt circuit, in response to the difference between currents produced by the current imbalance sensor transformer windings exceeding detected ground wire current by a prescribed value.

Owner:ADTRAN

Circuit interrupter including test circuit

InactiveUS20090040666A1Emergency protective arrangement detailsArrangements responsive to excess currentElectricityCurrent sensor

A circuit interrupter includes separable contacts, a neutral conductor, an operating mechanism structured to open and close the separable contacts, and a plurality of current sensors structured to sense at least current flowing through the separable contacts. Each of the current sensors includes a primary winding and a secondary winding, the primary winding being electrically connected in series with the separable contacts. A trip mechanism is structured to cooperate with the secondary winding of the current sensors and the operating mechanism to trip open the separable contacts. A test circuit tests the current sensors and the trip mechanism. The test circuit is structured to apply a test signal directly to the secondary winding of each of the current sensors.

Owner:EATON CORP

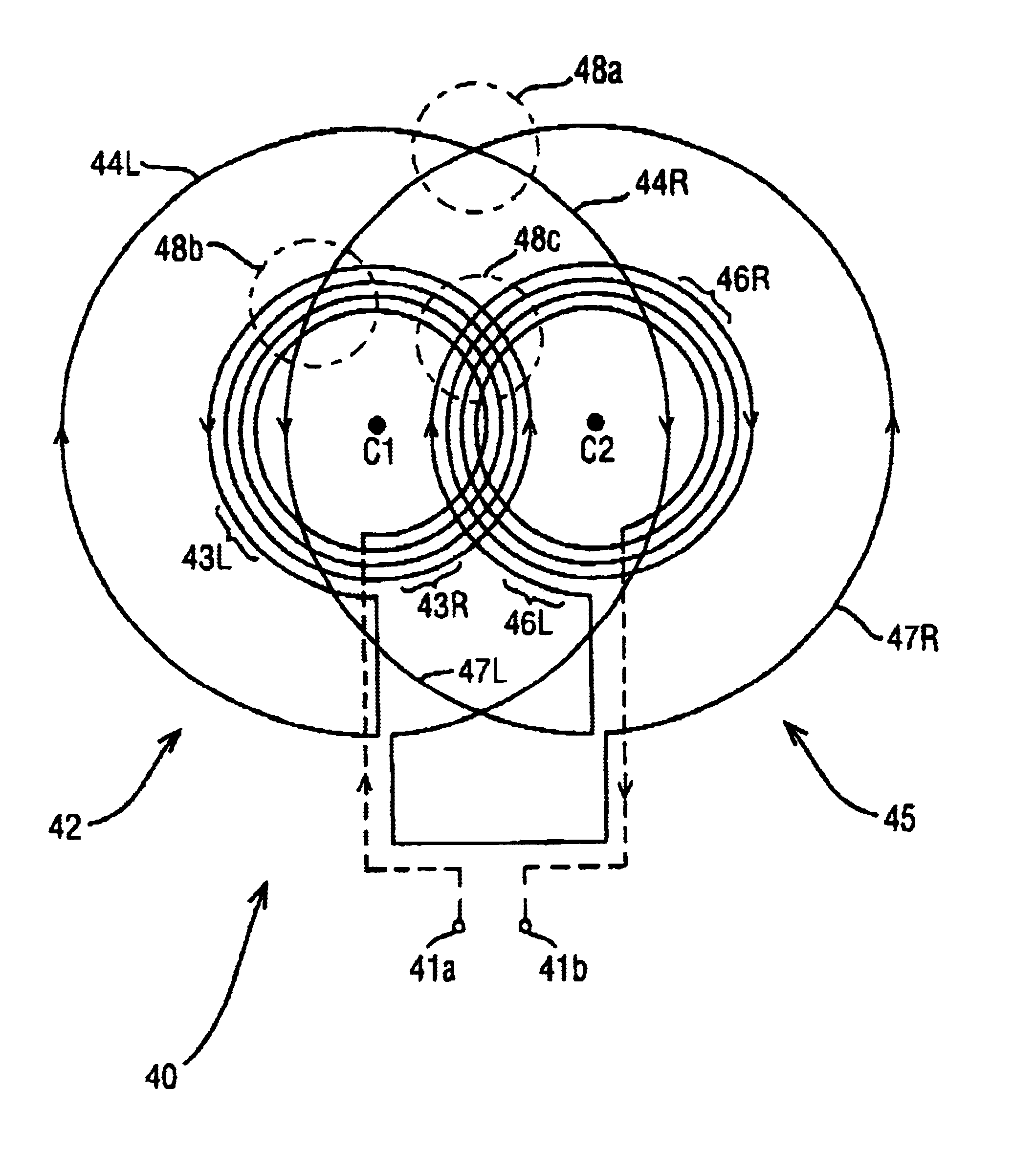

Current Sensor

InactiveUS6734661B2Reduce in quantityLess-expensive to manufactureMeasurement using dc-ac conversionDynamo-electric motor metersCurrent sensorWattmeter

A current sensor for measuring the load in a fiscal power meter has conductive paths connected between an inlet and an outlet for guiding the load currents through the sensor, and operates by sensing local magnetic fields generated around the conductive paths by the current flowing there through, thereby providing a current measure indicative of the magnitude of a given load. The sensor is distinguished by plural current coil elements arranged in a substantially common plane so as to be substantially insensitive to remotely generated magnetic fields but responsive to local magnetic fields for generating the current measure. The coil elements are disposed in zones having more than two effective centres and exhibiting mutually opposing responses to the remote field.

Owner:COLBY EDWARD GRELLIER

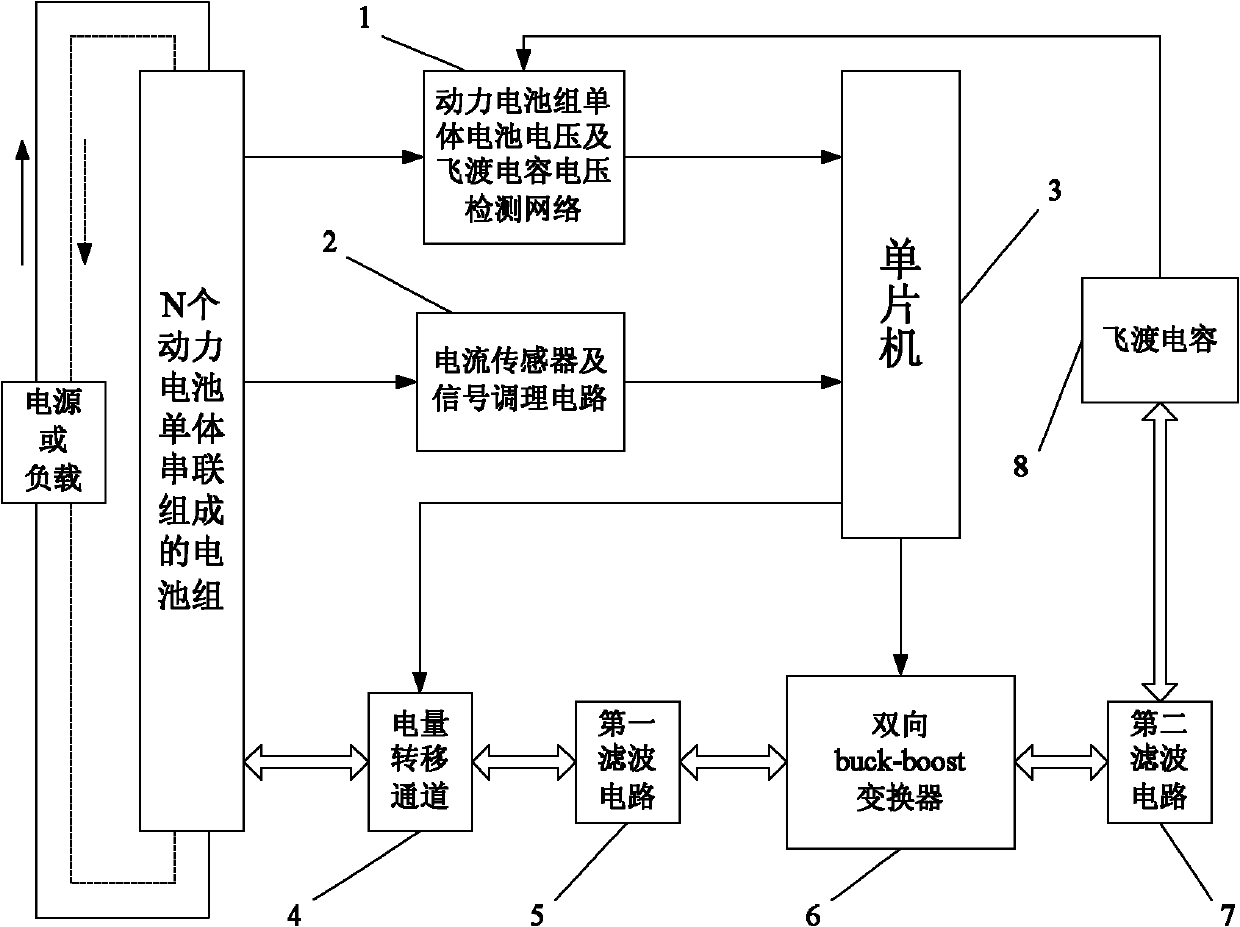

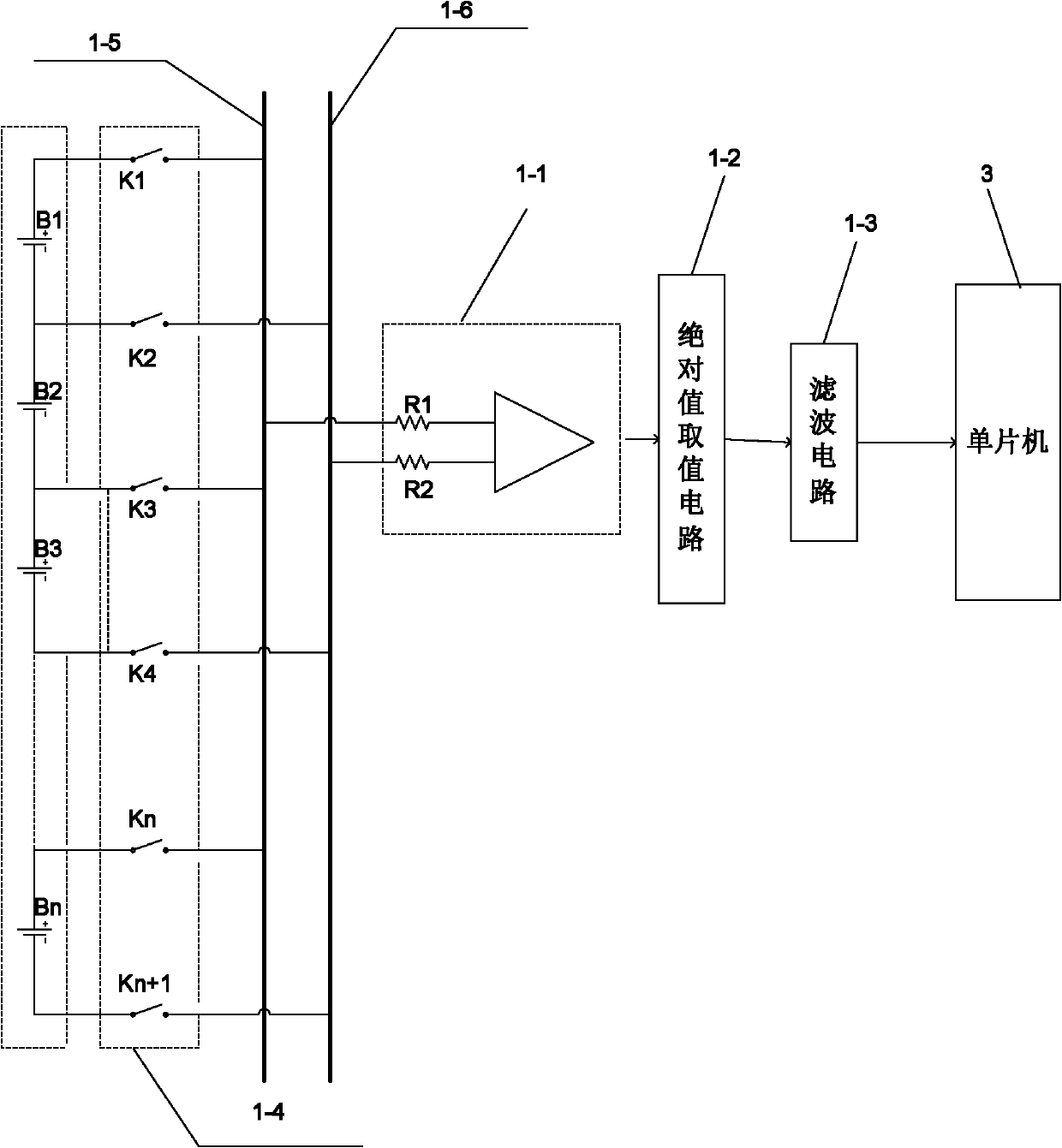

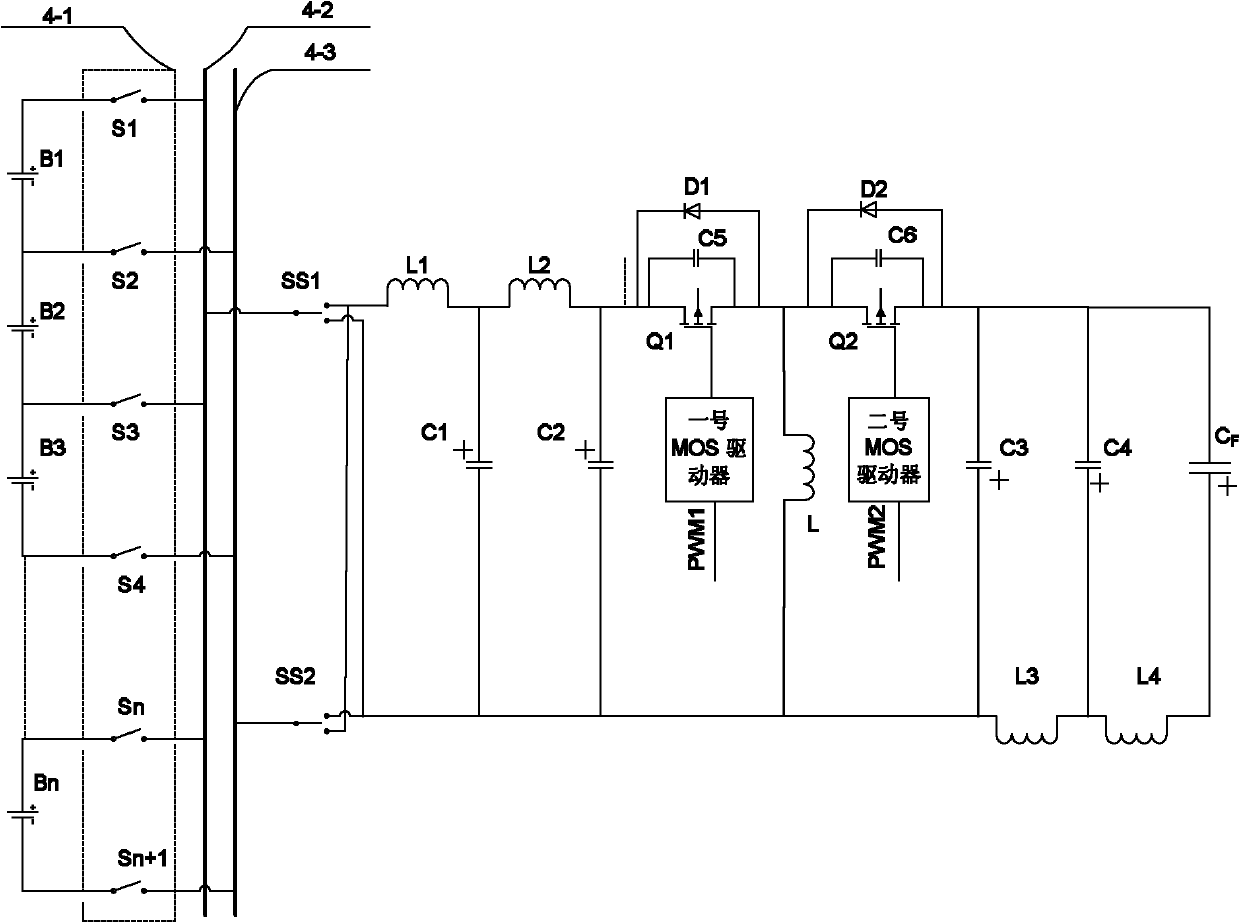

Energy transfer type power battery quick balancing system and control method

InactiveCN102170029AReduce consumptionReduce dependenceBatteries circuit arrangementsElectric powerElectrical batteryLow voltage

The invention relates to an energy transfer type power battery quick balancing system and a control method thereof. The invention relates to the battery voltage balancing system and further relates to the control method of battery pack quick balancing process, which solves the problem that a balanced battery single body and an energy storing element are impacted through pulse current by a currentbalancer in the prior art. The system comprises a power battery pack single body battery voltage and flying capacitor voltage detecting network, a current sensor and a signal modulating circuit, a single chip microcomputer, an electric power transfer channel, a first filter circuit, a two-way buck-boost converter, a second filter circuit and a flying capacitor. After starting to work, the system firstly detects the battery pack single body battery voltage, the flying capacitor voltage and the charging / discharging current; and if the dropout voltage between the highest voltage of the battery single body and the lowest voltage of the single body exceeds a set value, the balancing operation is started.

Owner:HARBIN INST OF TECH

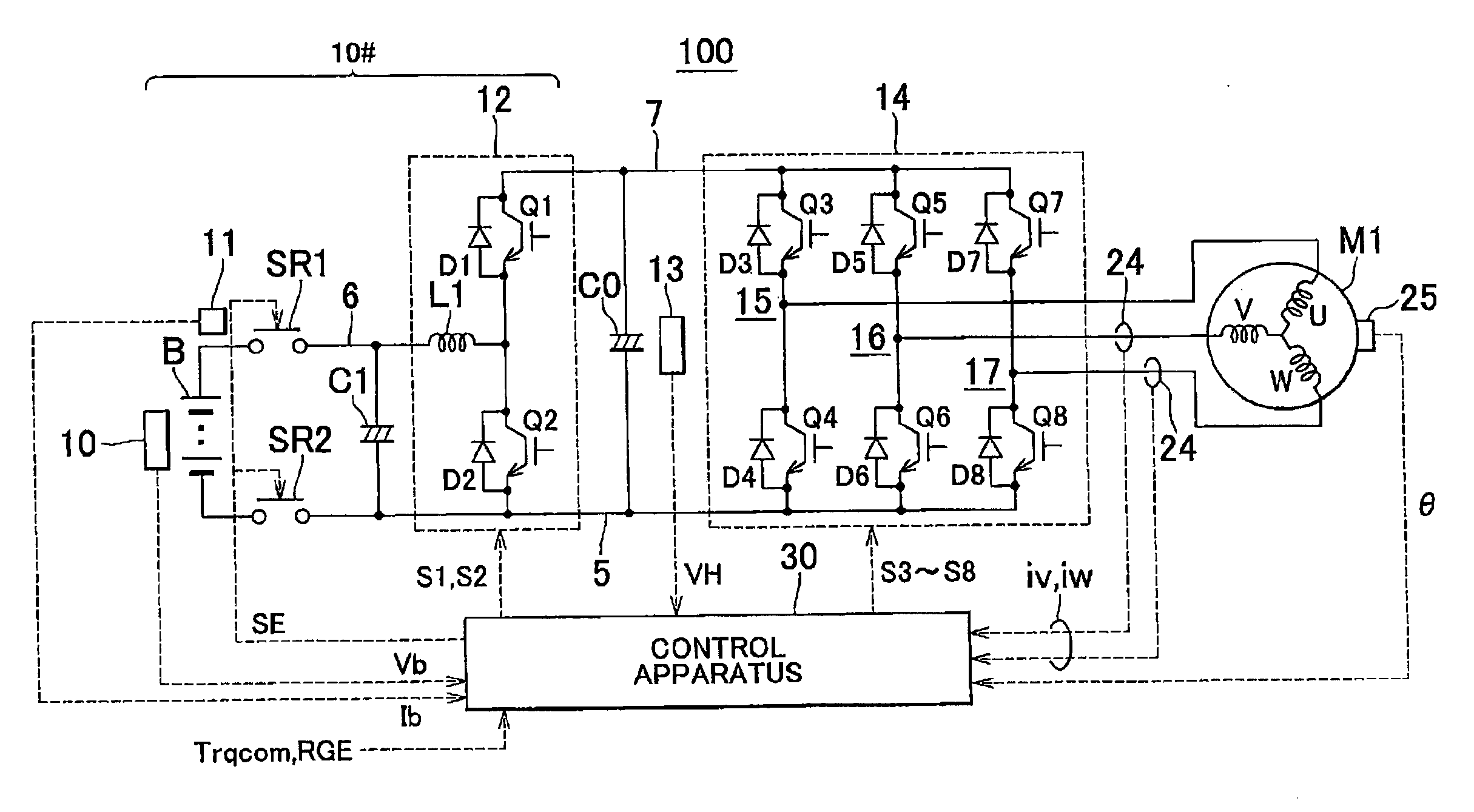

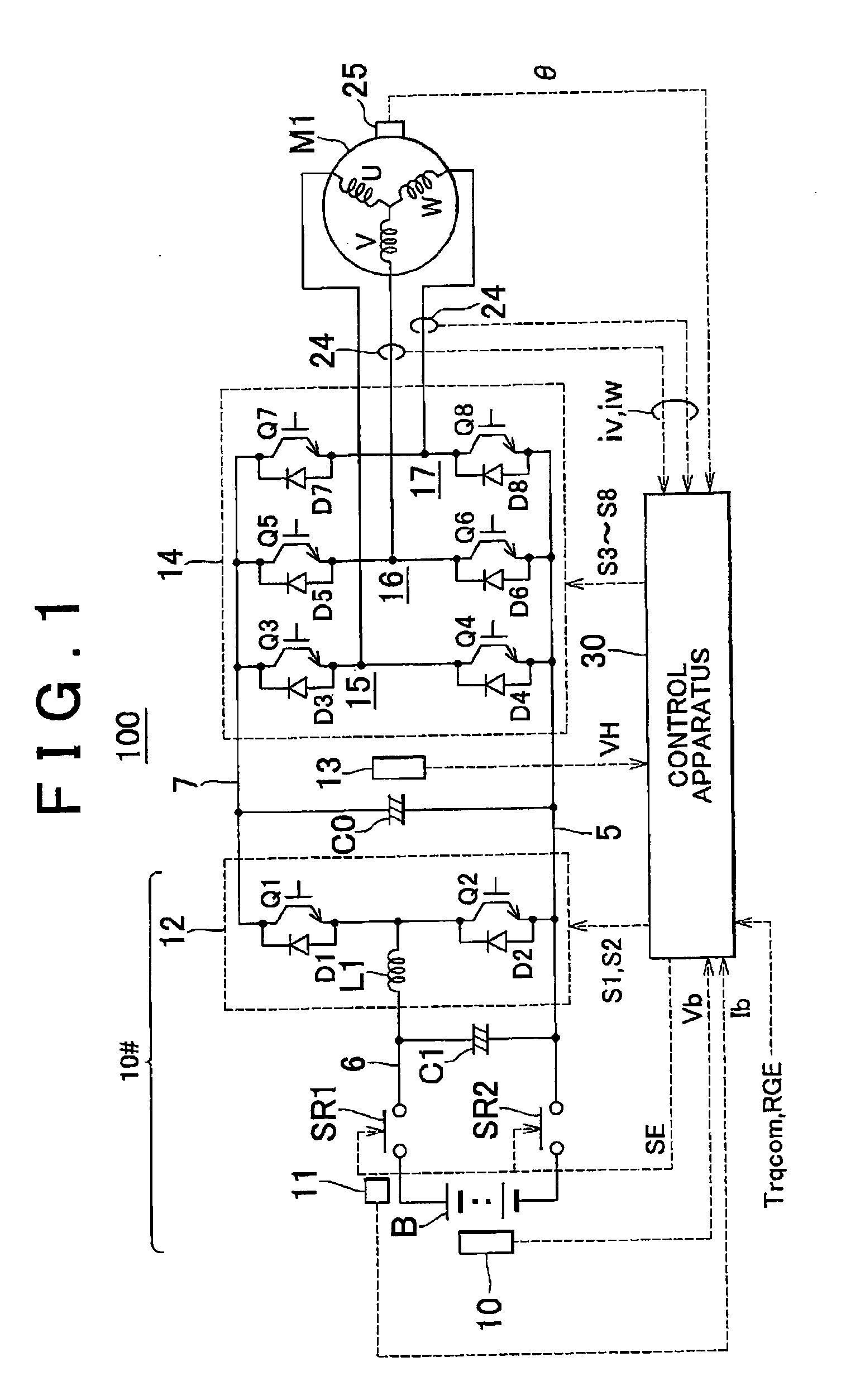

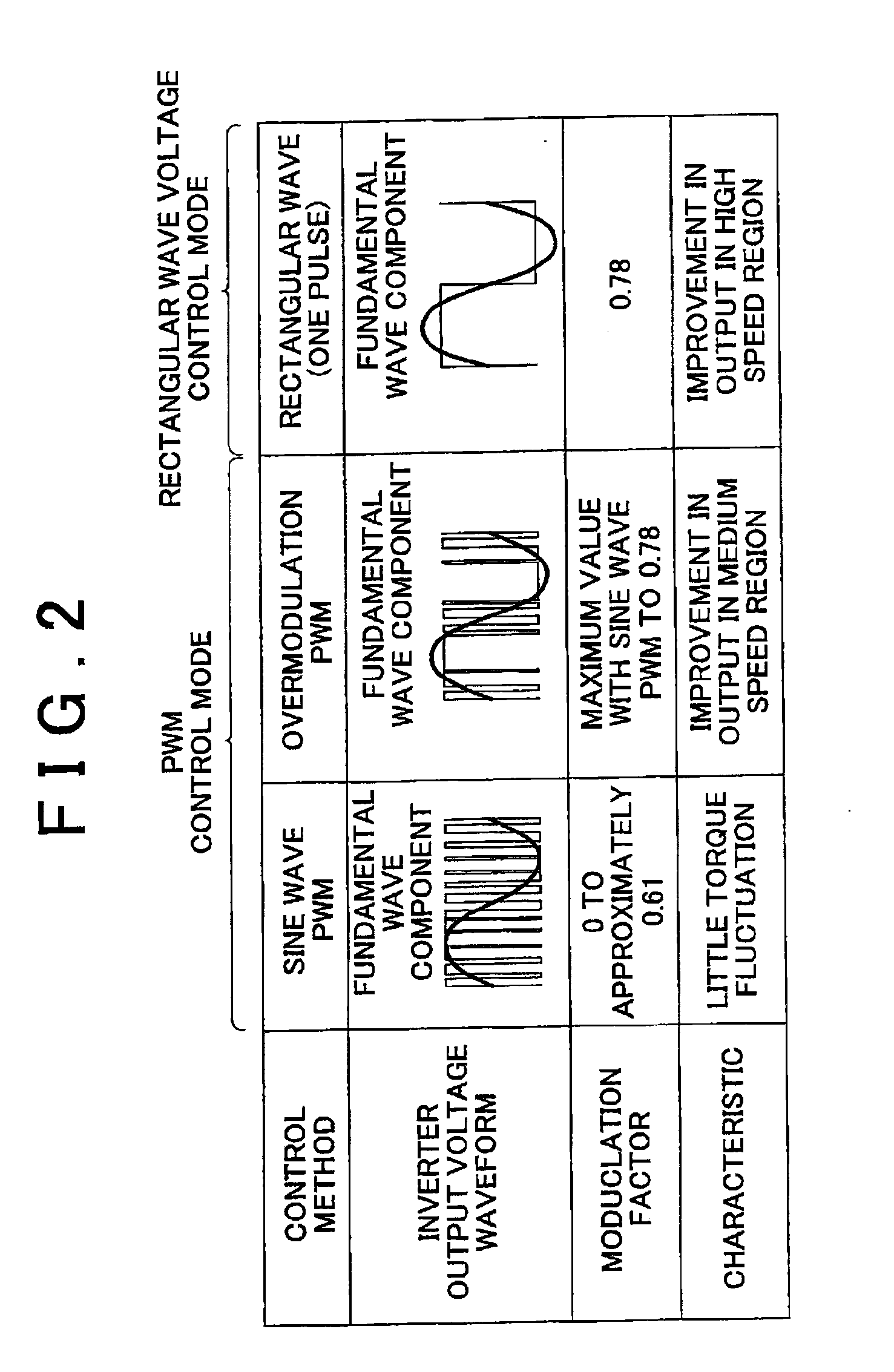

Alternating-current motor control apparatus

ActiveUS20100123418A1Simple structureImprove responsivenessVehicle testingTorque ripple controlPhase currentsCurrent meter

When a rectangular wave voltage control mode is selected, a control apparatus estimates the output torque of an alternating-current motor based on the outputs of a current sensor and a rotation angle sensor, and executes torque feedback control by adjusting the phase of rectangular wave voltage based on the difference between the torque estimated value and a torque command value. The control apparatus executes a switching interruption that outputs a control command to a switching element of an inverter every 60 degrees of electrical angle, and executes an angle interruption that samples the phase currents of the alternating-current motor based on the output of the current sensor and converts those phase currents into a d-axis current and a q-axis current every predetermined electrical angle that is set beforehand. The control apparatus for the alternating-current motor then sets the predetermined electrical angle such that the number of angle interruptions between switching interruptions varies according to the rotation speed of the alternating-current motor.

Owner:TOYOTA JIDOSHA KK +1

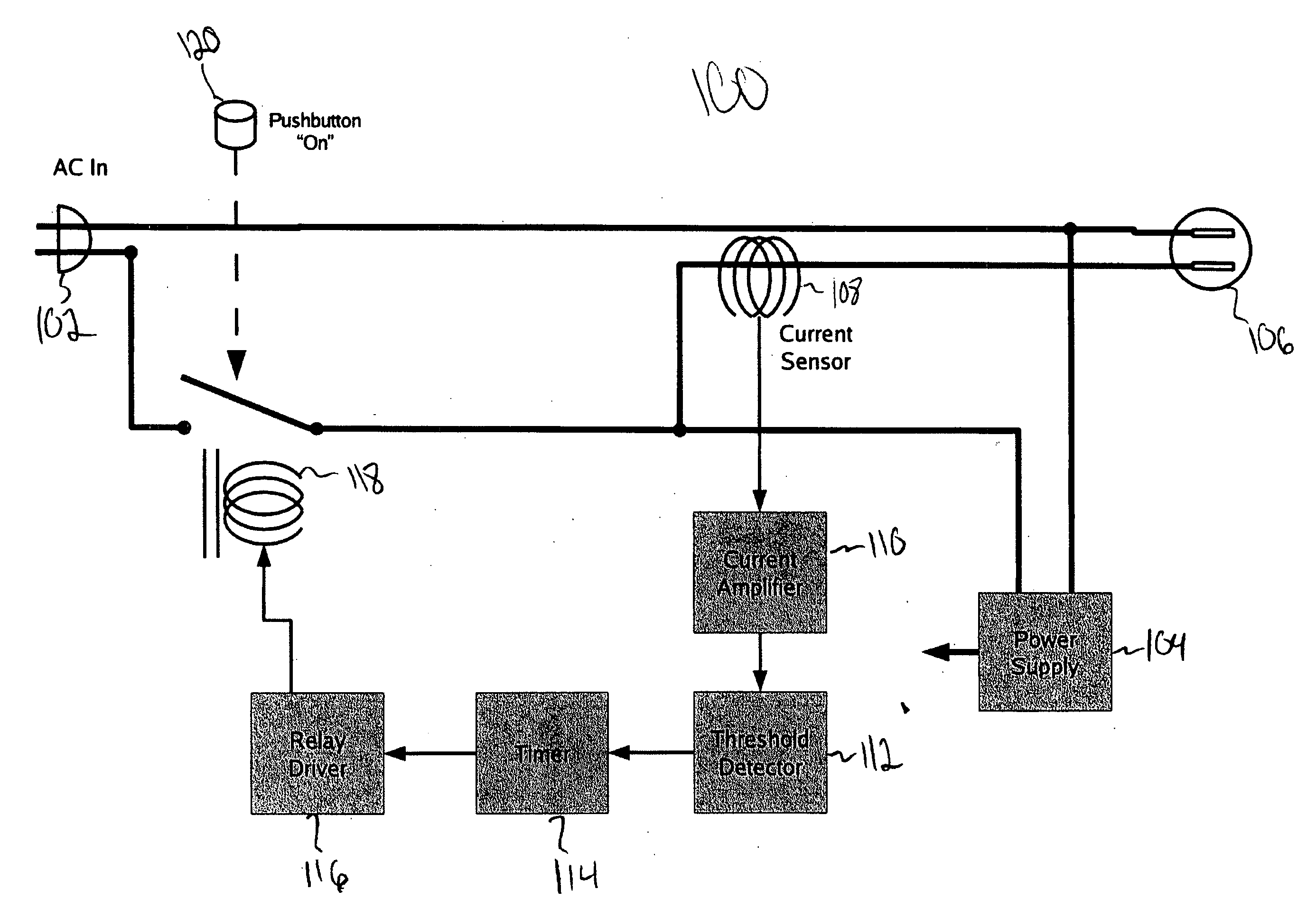

Energy-saving electrical adaptor

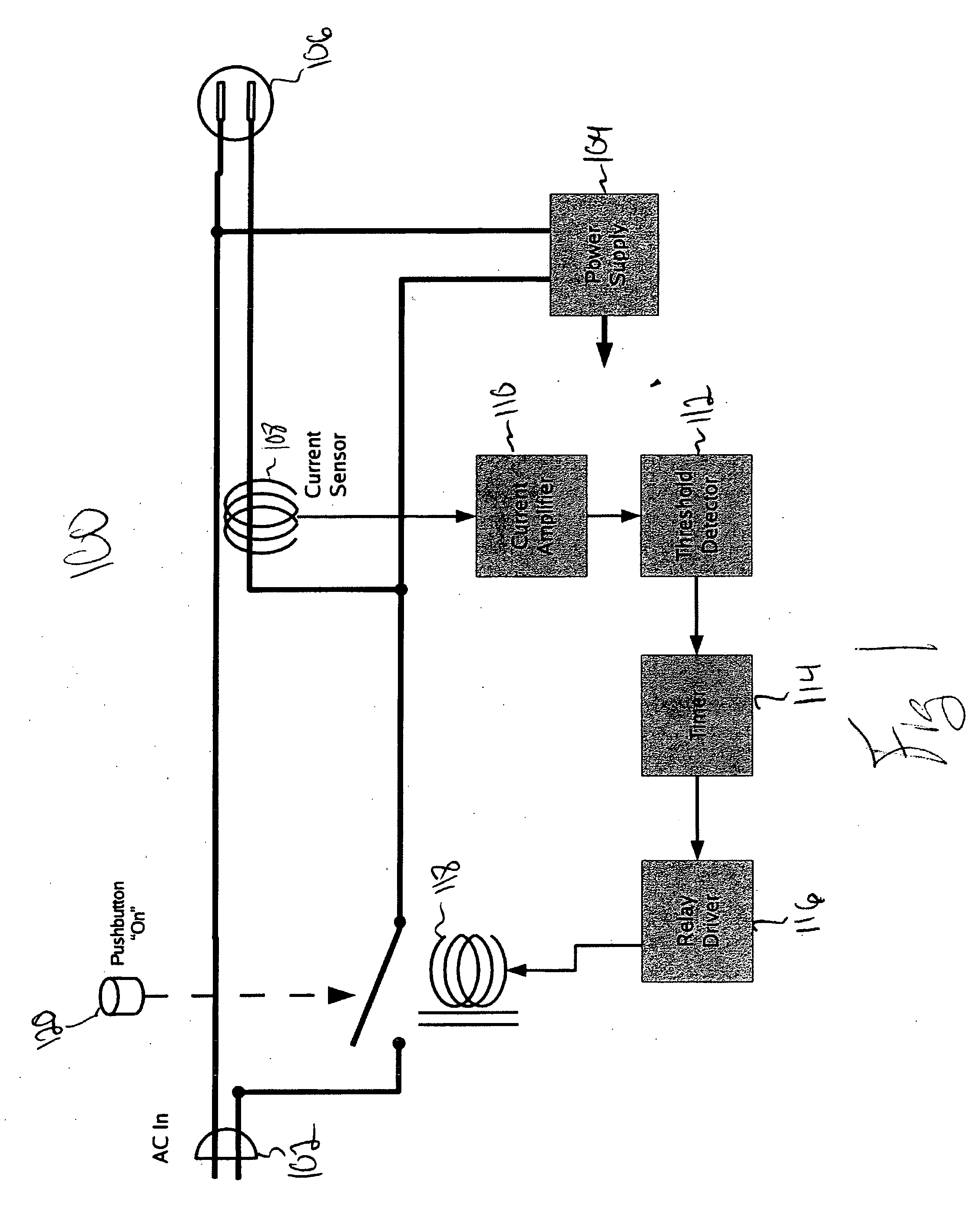

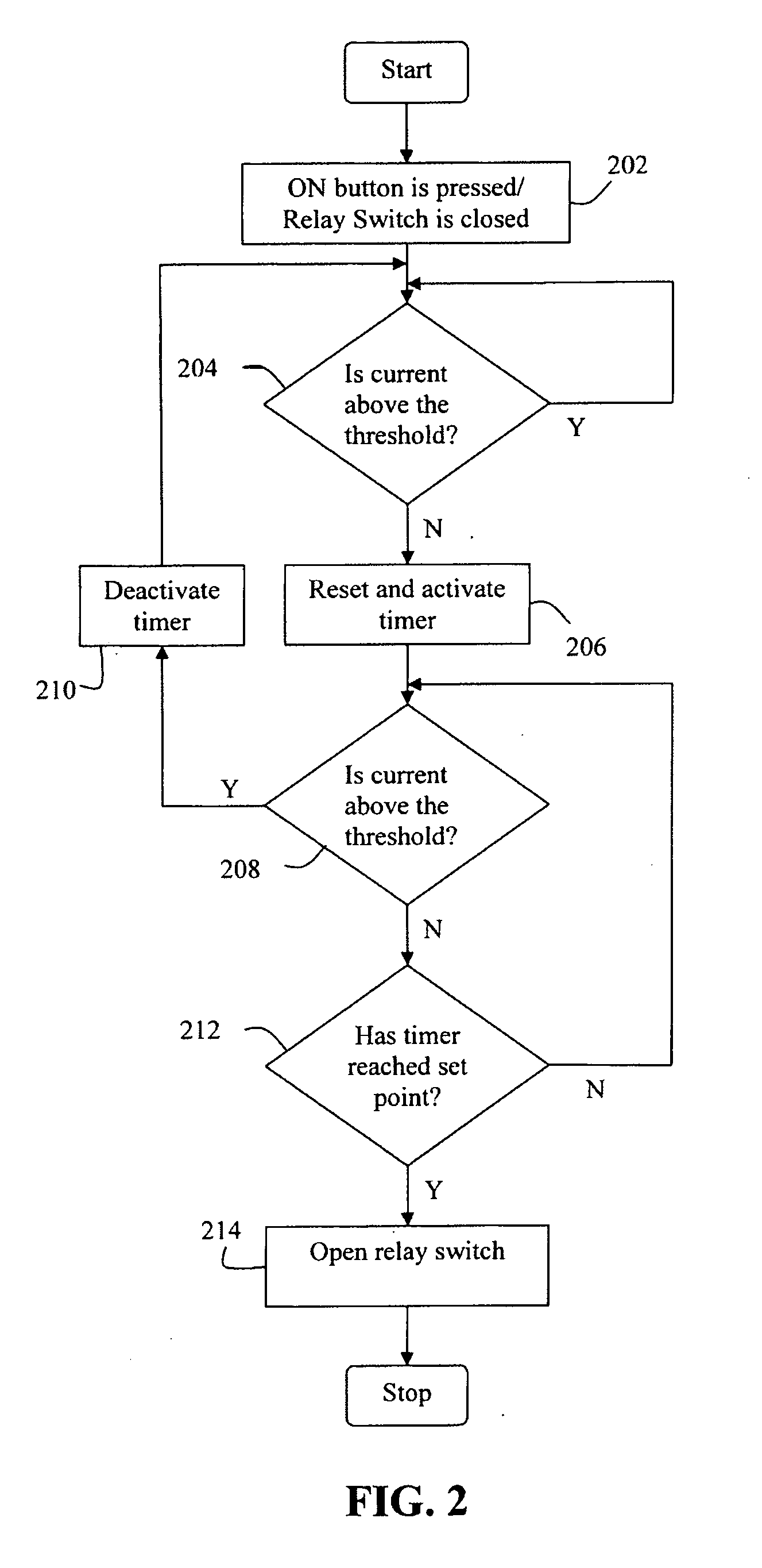

InactiveUS20080164768A1Boards/switchyards circuit arrangementsProtective switchesCurrent sensorEngineering

A power conservation apparatus having a power inlet for providing power to the power conservation apparatus and an external appliance, a power outlet operable to be connected to the appliance, a relay coupling the power inlet and the power outlet, a current sensor operable to measure a current flow from the power outlet to the appliance, a threshold detector operable to receive an input in accordance with the current flow and operable to determine if the appliance is in a state of non-use, and a timer having a set-point; wherein the timer is activated upon the appliance entering the state of non-use and wherein the relay is opened upon the timer reaching the set-point, so as to prevent the power conservation apparatus and the appliance from drawing power from the power inlet. When in the “off” state, the AC power consumed by the apparatus and coupled appliances is zero.

Owner:LITWACK MARK W

Electrical-energy meter

InactiveUS6838867B2Substation/switching arrangement detailsDynamo-electric motor metersElectricityCurrent sensor

A presently-preferred embodiment of an electrical-energy meter comprises a base adapted to be mounted on a supporting surface, a current sensor assembly comprising a plurality of contact blades extending through the base and adapted to electrically contact a conductor of electrical energy, and a current transformer mechanically coupled to the base and electrically coupled to the contact blades. The electrical-energy meter further comprises a circuit board assembly comprising a main circuit board electrically coupled to the current transformer and the contact blades. The electrical-energy meter also comprises a circuit-board support member comprising a rim portion fixedly coupled to the base, and a first bracket adjoining the rim portion. The first bracket has a first and a second leg each extending away from the rim portion and the base and each being adapted to securely engage the main circuit board.

Owner:ELSTER ELECTRICTY LLC

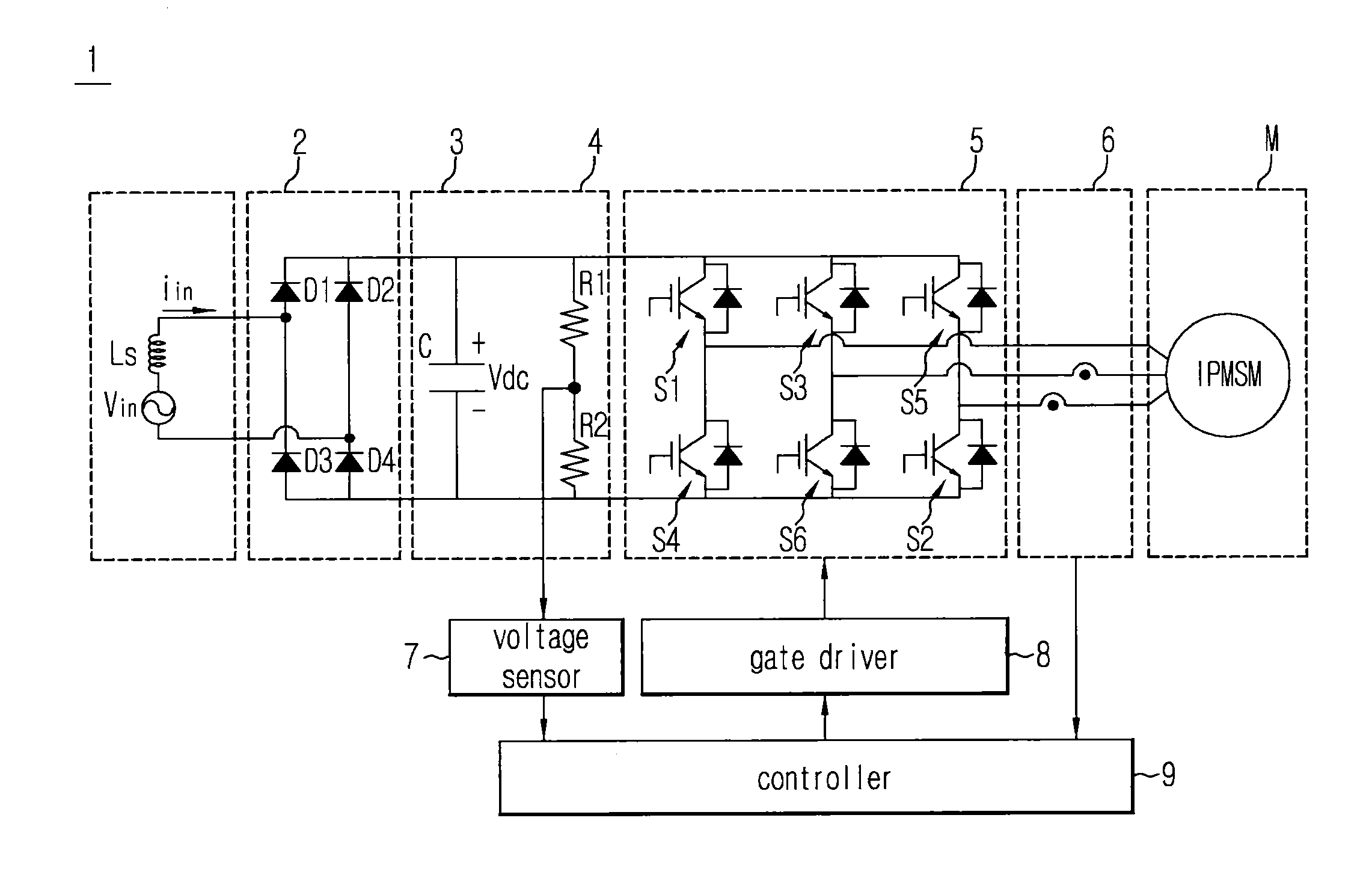

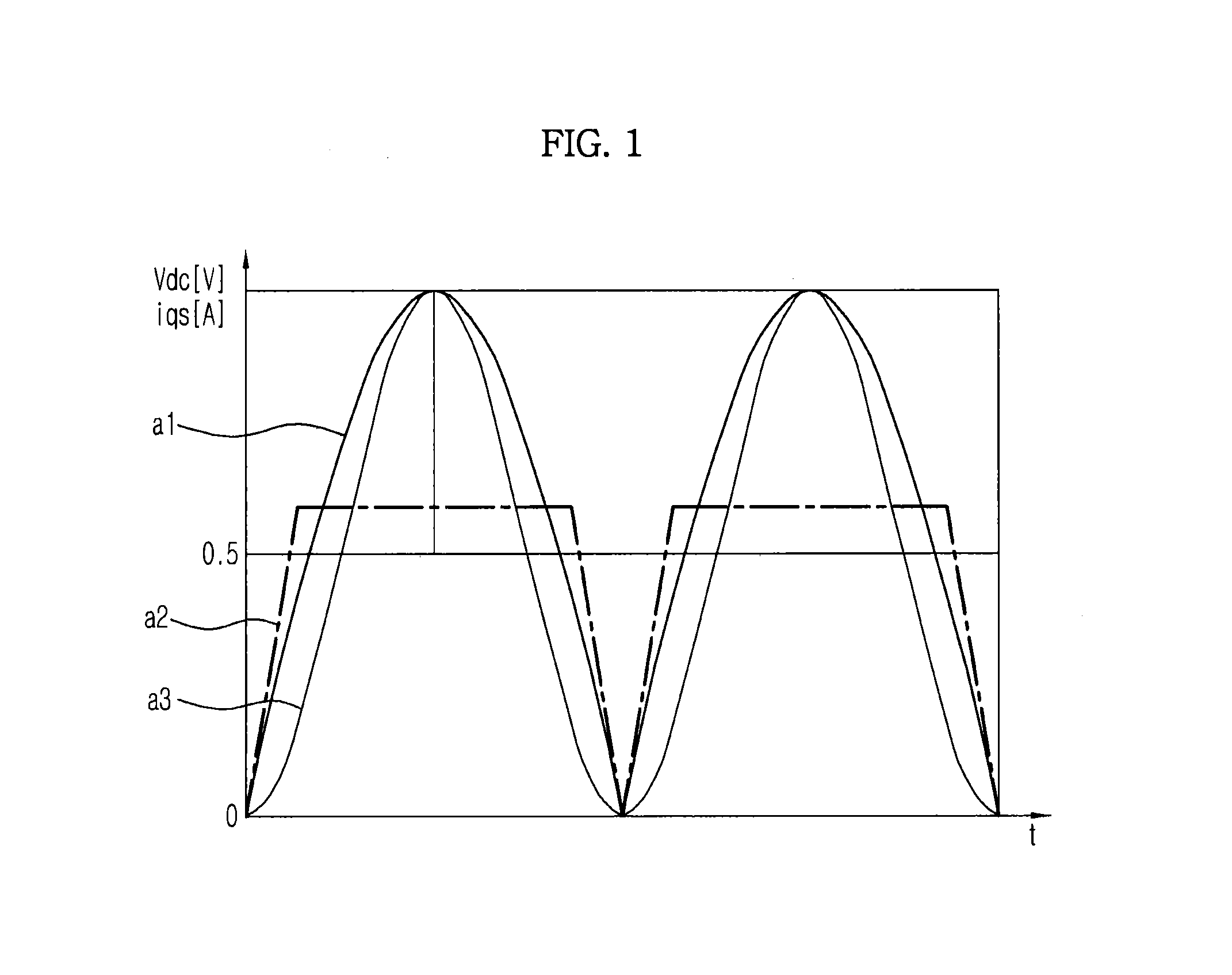

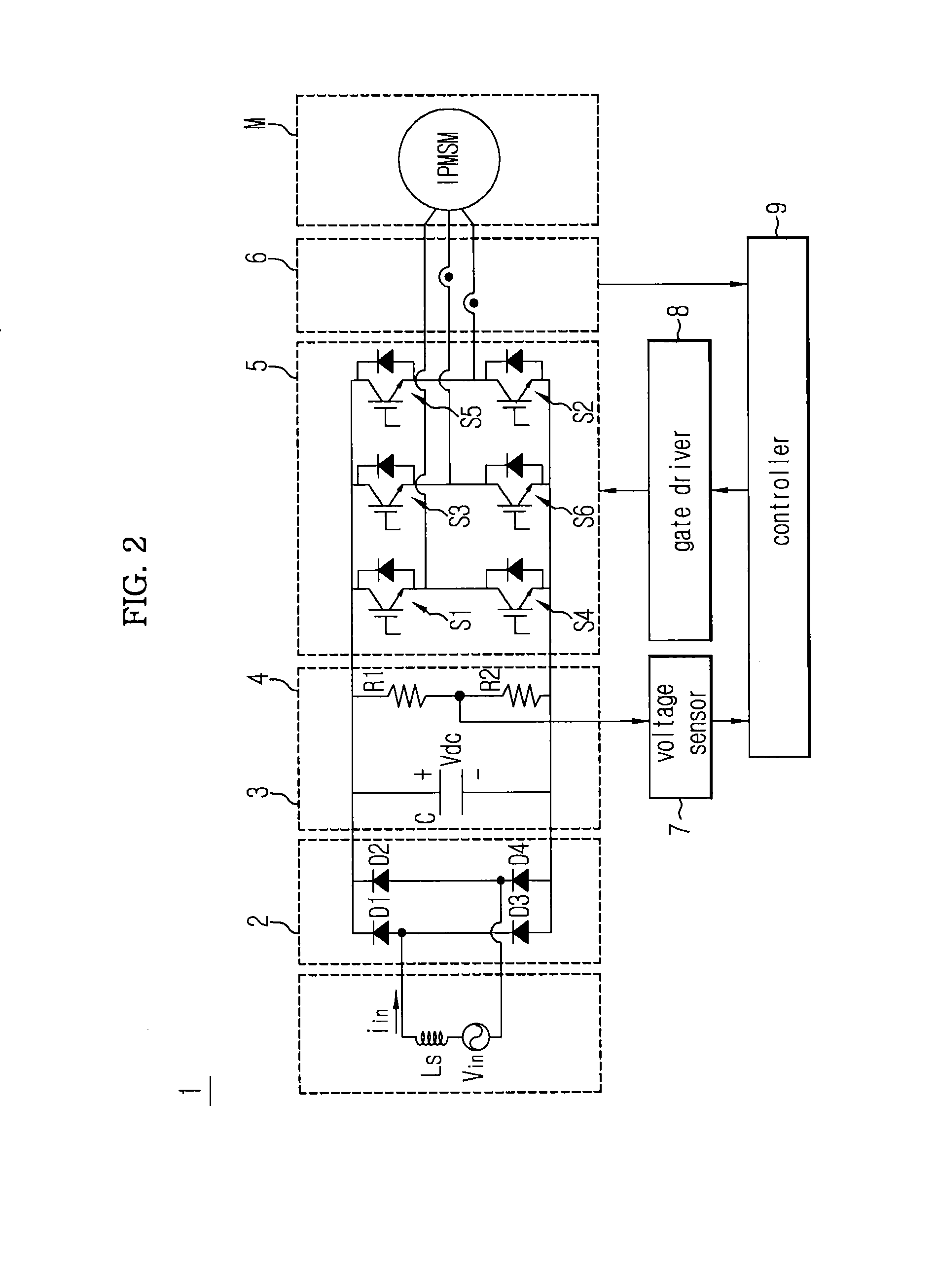

Inverter control apparatus and control method thereof

ActiveUS20140028237A1Low costImprove product reliabilityElectronic commutation motor controlMotor/generator/converter stoppersCapacitancePower inverter

An inverter control apparatus and a control method thereof are provided. The inverter control apparatus and a control method thereof stably operate a three-phase motor using a capacitor having a small capacitance for a DC link. The inverter control apparatus includes a current sensor to sense an output current of the inverter, a voltage sensor to sense a DC-link voltage of the inverter, and a controller to generate an average of a periodically varying rotor based q-axis current boundary value based on the output current and the DC-link voltage to generate a current reference on the basis of the average of the rotor based q-axis current boundary value, and to drive a three-phase motor based on the current reference. Stabilized variable speed control of a motor by using a small-capacitance capacitor for a DC link of an inverter is performed and reliability of an inverter circuit improved.

Owner:SAMSUNG ELECTRONICS CO LTD +1

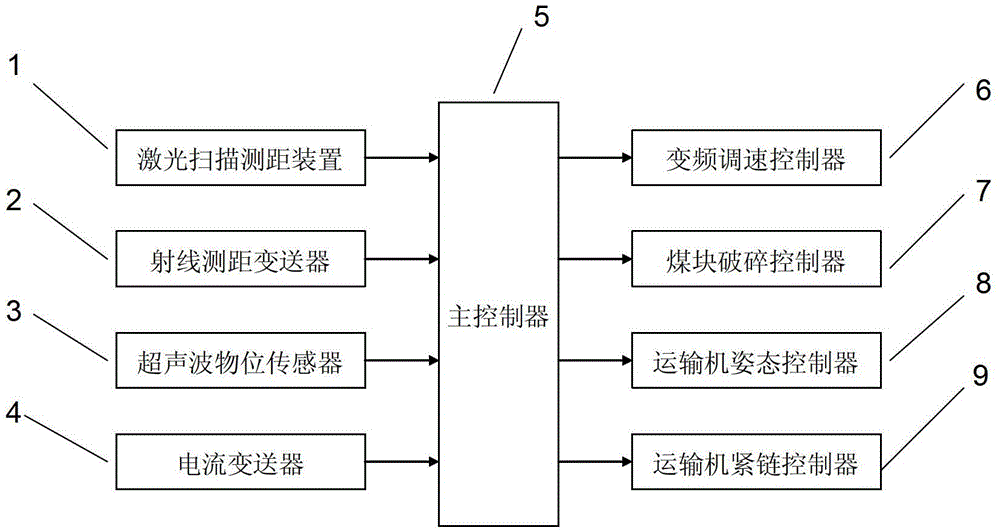

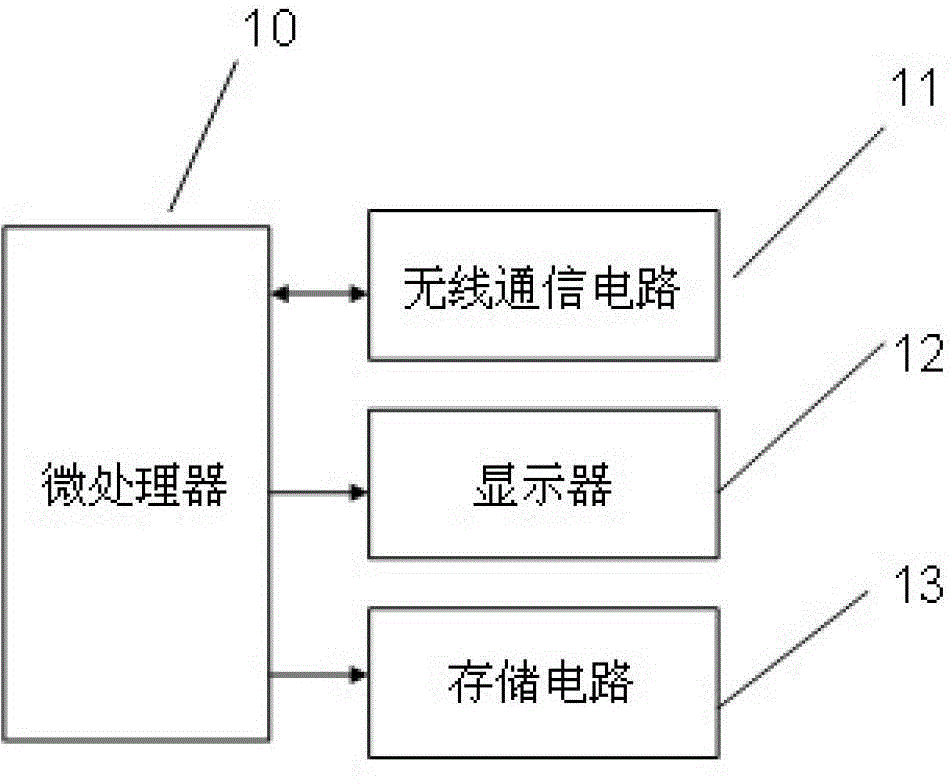

Intelligent control system and control method for scraper conveyer

InactiveCN103144936AAdjust posture in timeAvoid tooth skippingControl devices for conveyorsCurrent transducerAttitude control

The invention provides an intelligent control system and a control method for a scraper conveyer, which belong to the intelligent control systems for coal mine exploitation. The intelligent control system for the scraper conveyer comprises a laser scanning ranging device, a ray ranging transmitter, an ultrasonic level sensor, a current transducer, a master controller, a variable frequency and speed regulation controller, a coal crushing controller, a conveyor gesture controller and a conveyor chain stretching controller, wherein the laser scanning ranging device, the ray ranging transmitter, the ultrasonic level sensor and the current transducer transmit detection signals to the master controller in a wireless communication manner, and the master controller sends control instructions to the variable frequency and speed regulation controller, the coal crushing controller, the conveyor gesture controller and the conveyor chain stretching controller in the wireless communication manner. The running state of the scraper conveyer is mastered at any time and corresponding devices are controlled timely through monitoring of the laser scanning ranging device, the ray ranging transmitter, the ultrasonic level sensor and the current transducer, so that the scraper conveyer can be operated in an optimum running state.

Owner:CHINA UNIV OF MINING & TECH

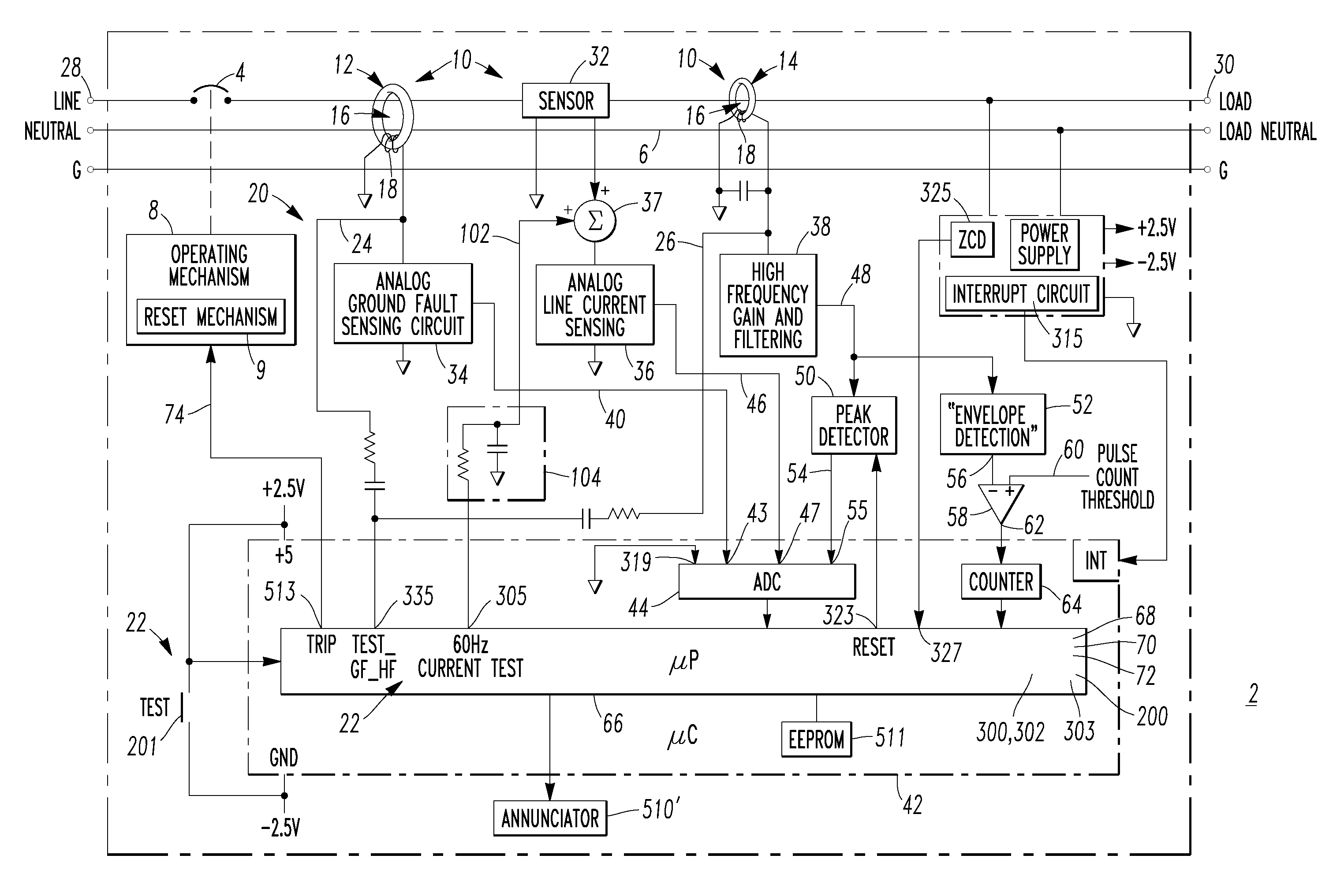

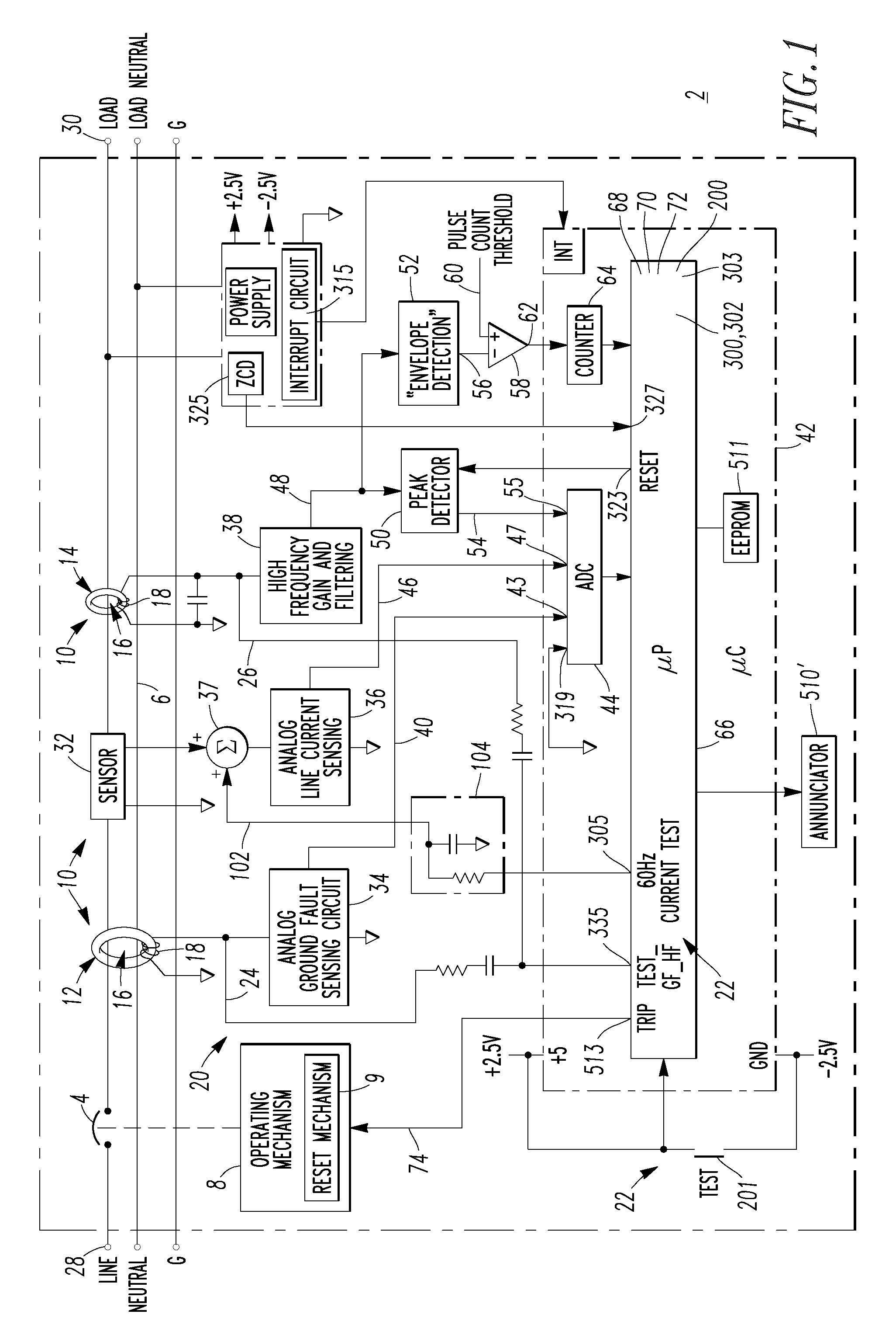

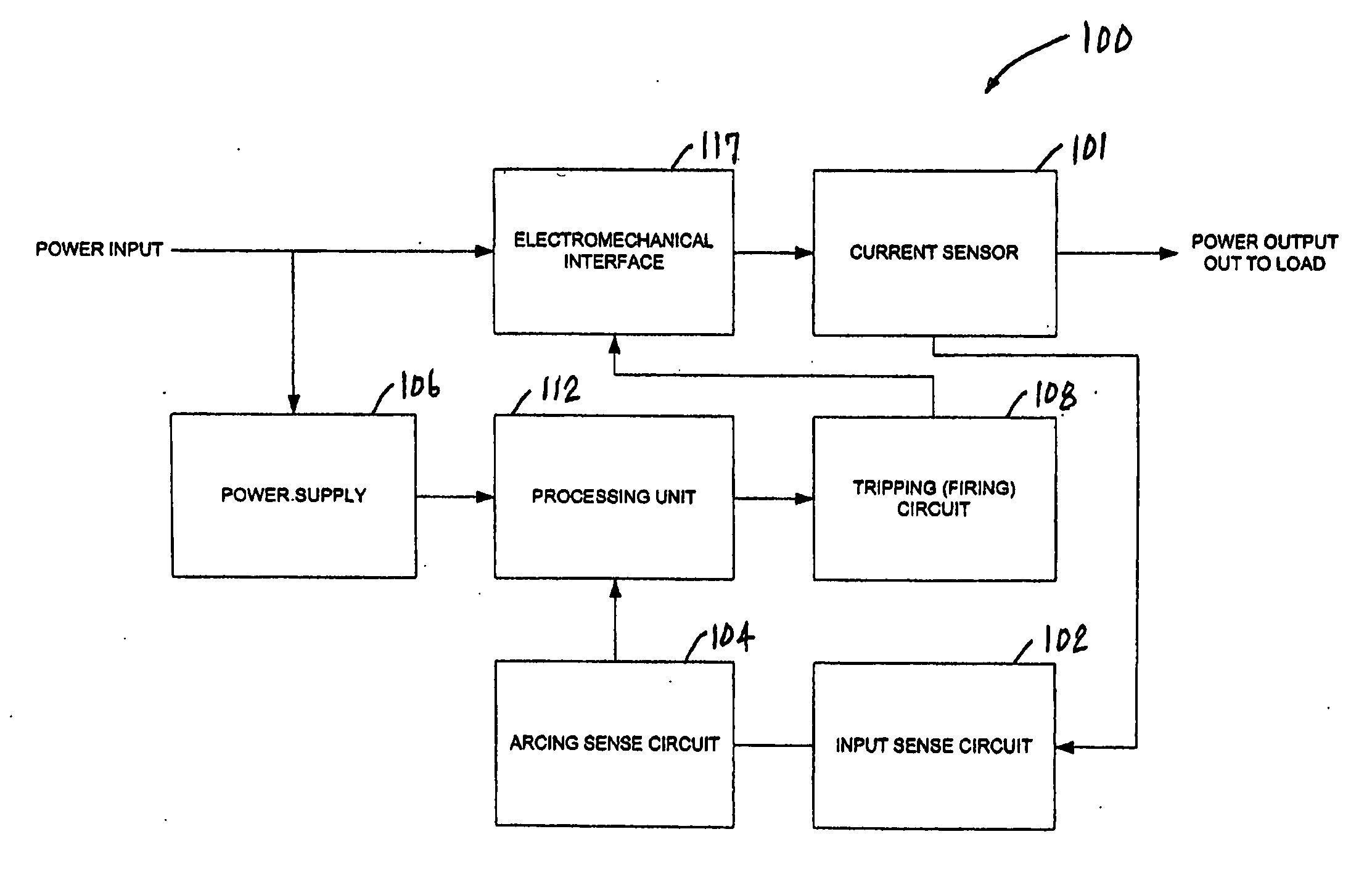

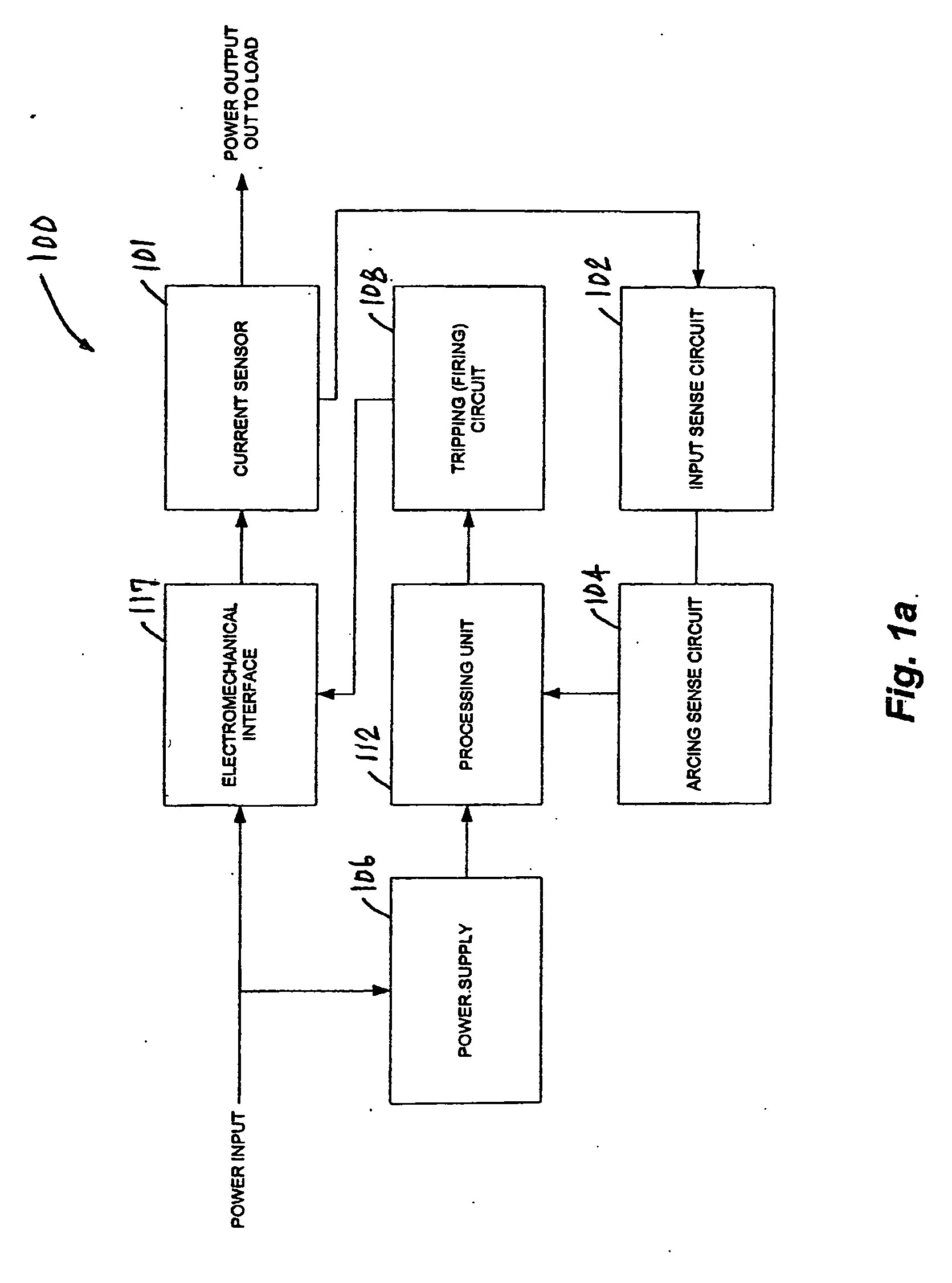

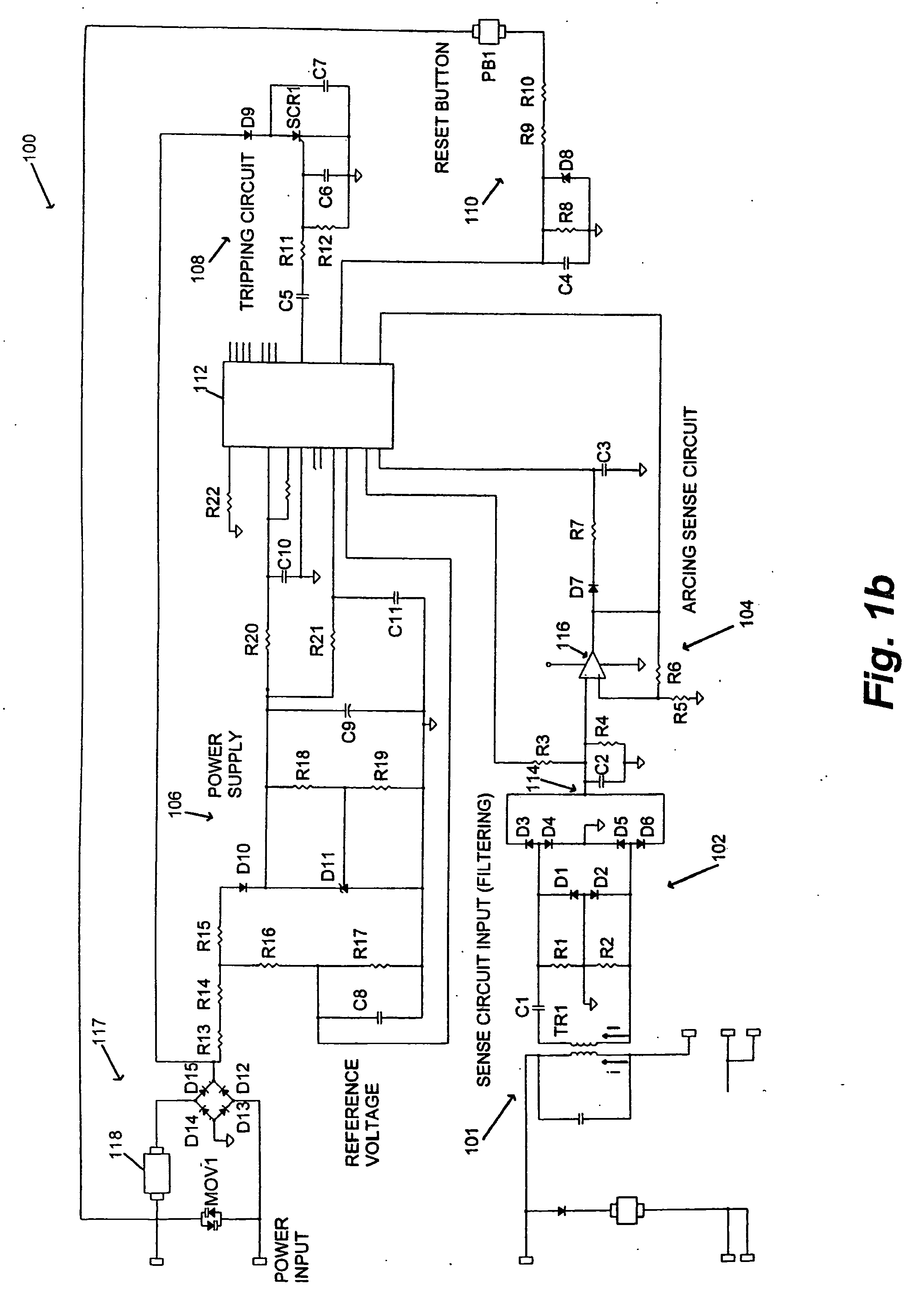

Methods of detecting arc faults characterized by consecutive periods of arcing

InactiveUS20060181816A1Improve reliabilityReduce generationTesting dielectric strengthShort-circuit testingNuisance trippingElectric arc

An apparatus and method for detecting electrical arc faults that has reduced susceptibility to nuisance tripping. The apparatus includes a current sensor, an input sense circuit, an arcing sense circuit, a power supply, a tripping circuit, a processing unit, and an electromechanical interface. The processing unit measures multiple voltage levels provided by the arcing sense circuit during a specified number of consecutive time periods. Next, the processing unit determines the number of consecutive time periods during which the voltage levels exceeded a specified minimum value, take on successively lower or higher values, or fall outside a predetermined normal range of values. Based upon the results of this determination, the processing unit either trips the electromechanical interface to interrupt power to a load, or inhibits tripping of the electromechanical interface, thereby reducing the occurrence of nuisance tripping.

Owner:SENSATA TECH MASSACHUSETTS INC

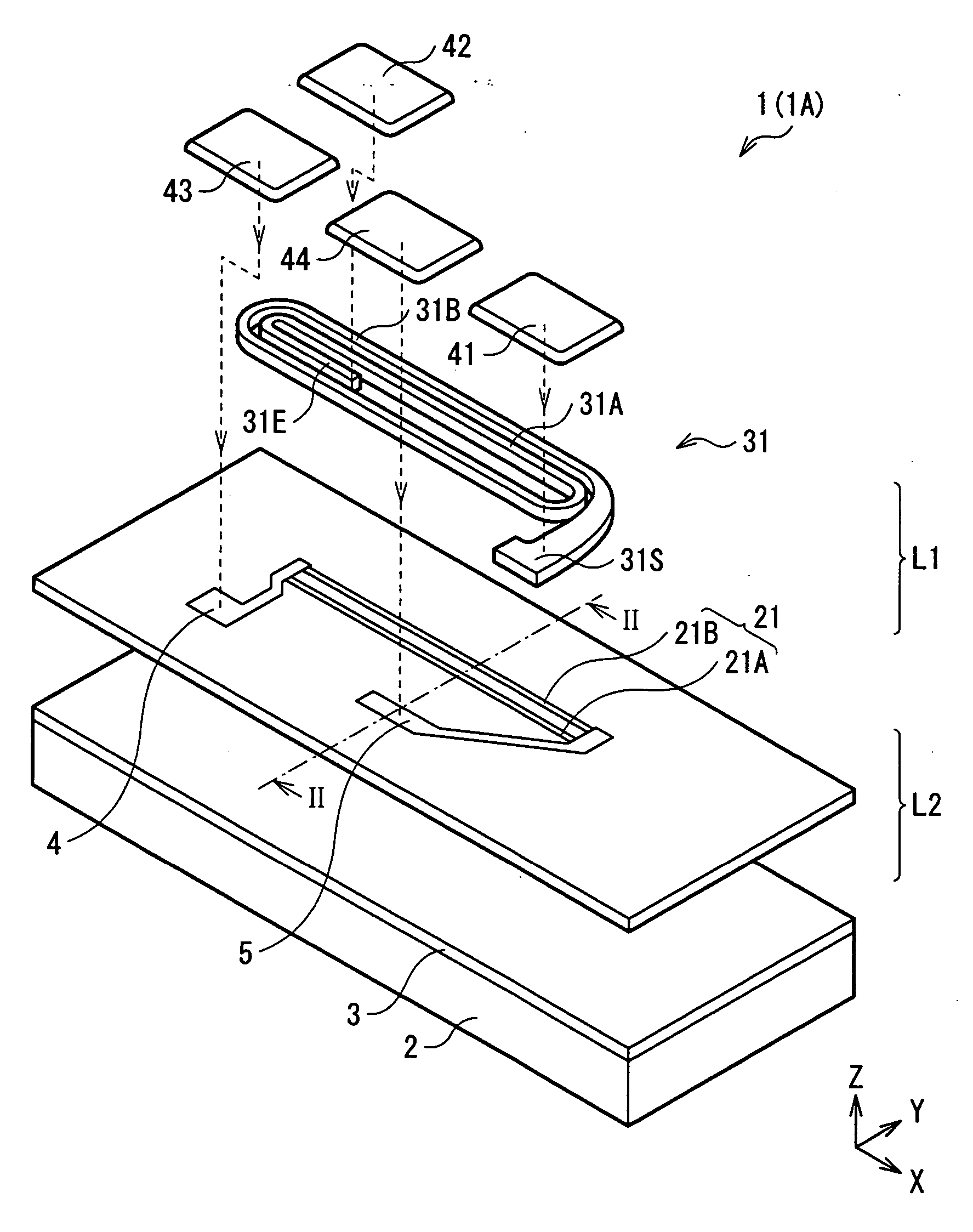

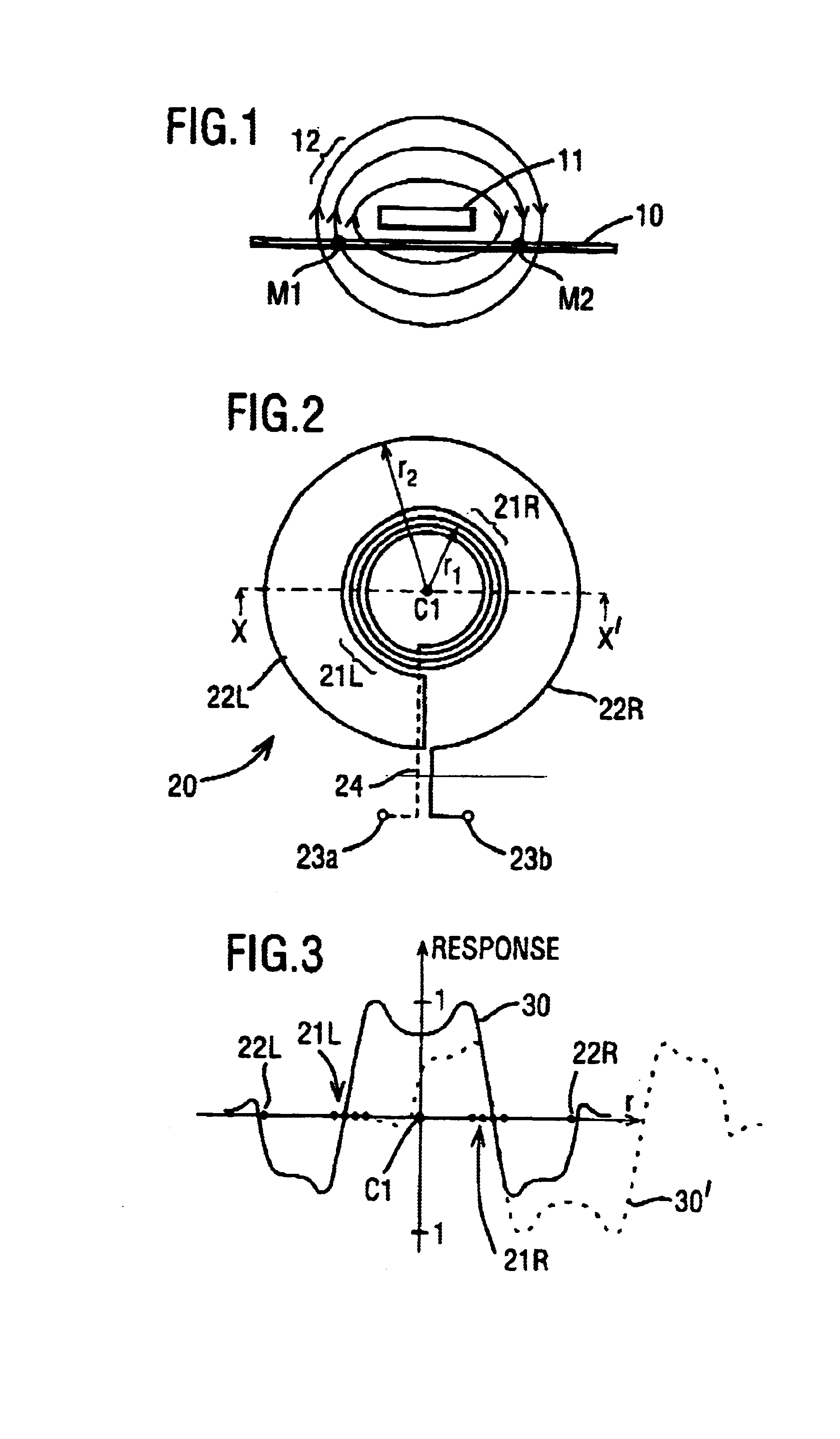

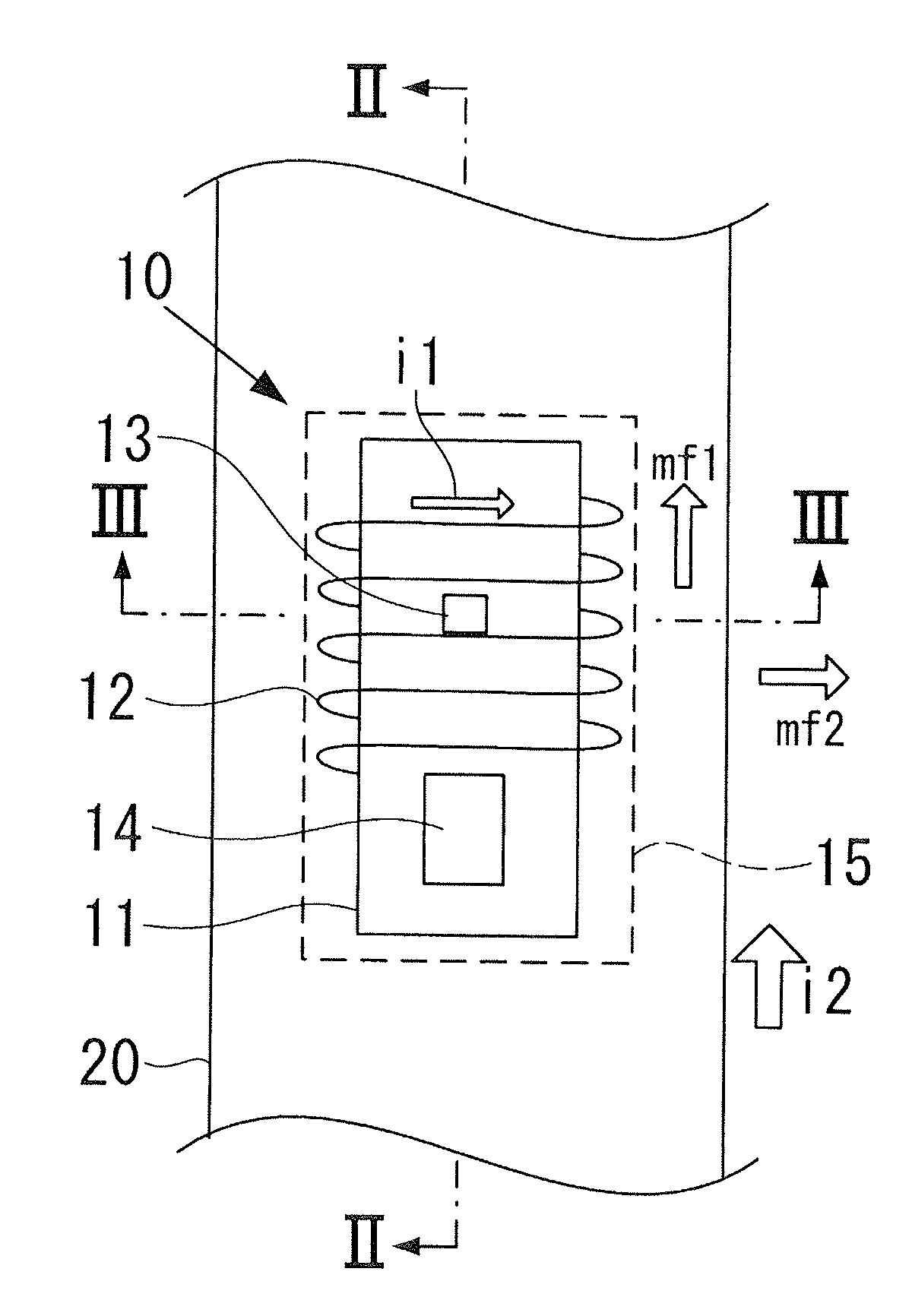

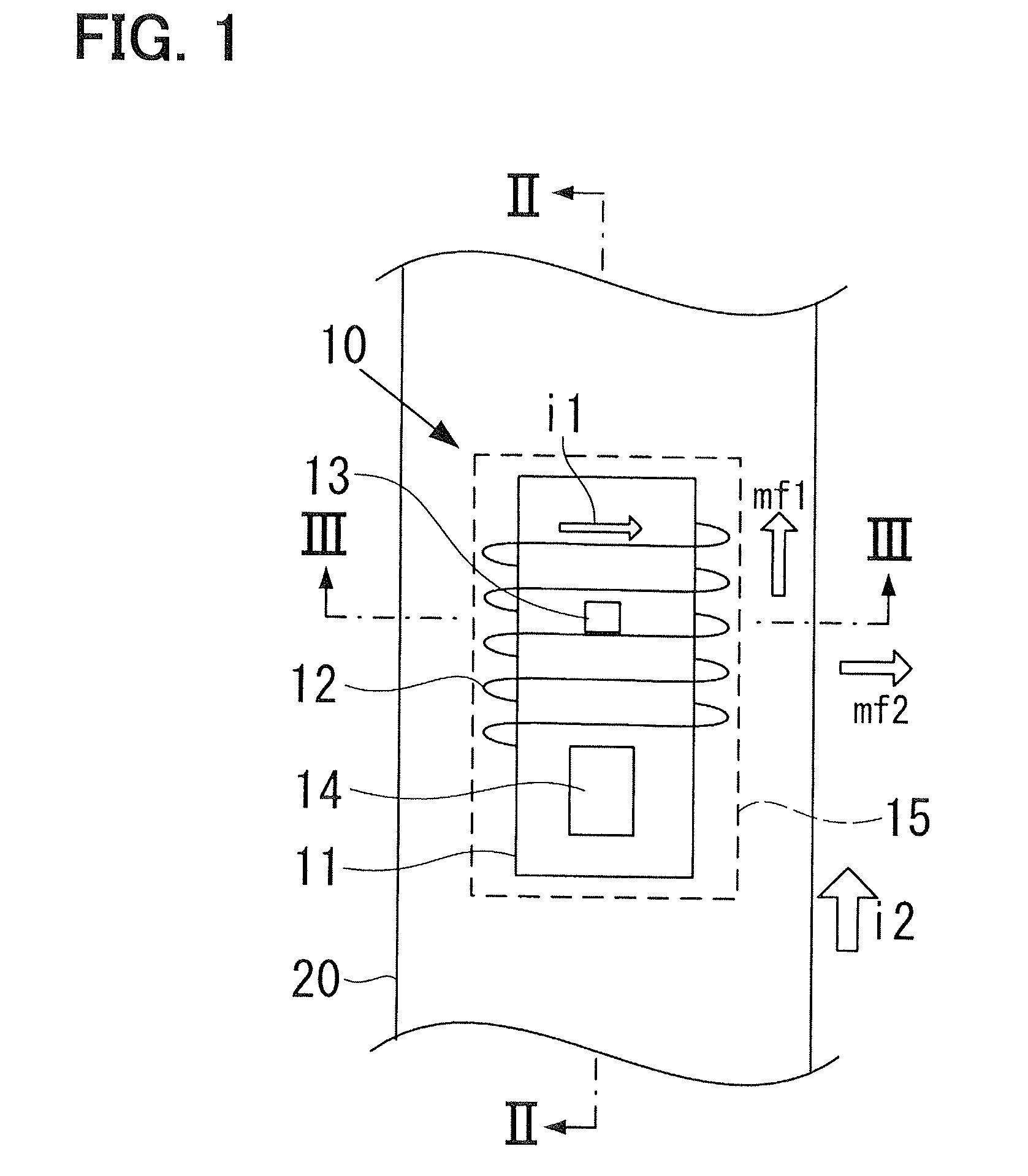

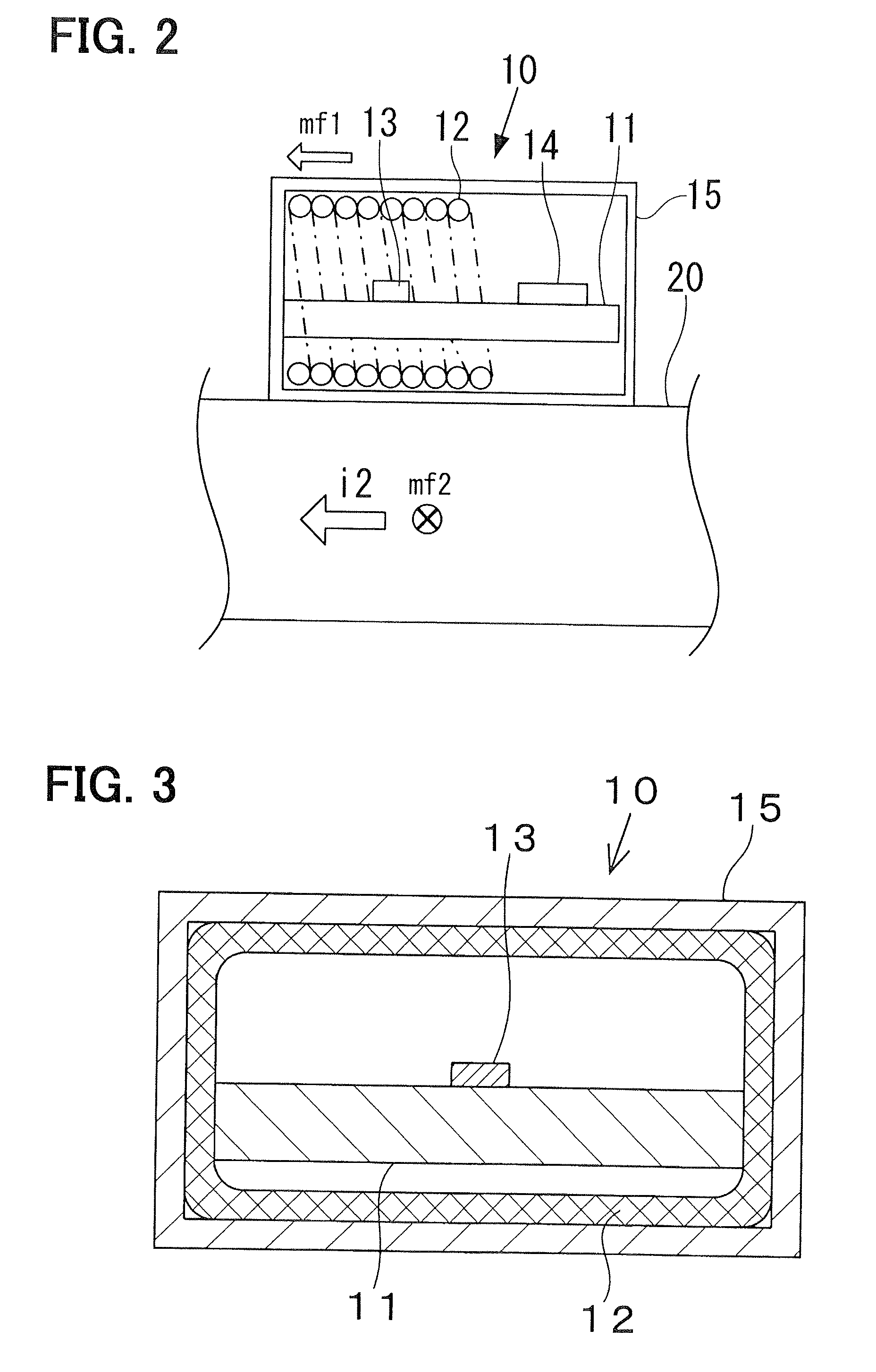

Current sensor

InactiveUS20110285384A1Total current dropMeasurement using dc-ac conversionVoltage/current isolationPower flowCurrent sensor

A current sensor for detecting a first electric current flowing through a current path includes a sensor chip, a coil, a current control circuit, and an output circuit. The sensor chip includes a magnetoresistive element and is adopted to be located near the current path. The coil applies a bias magnetic field to the magnetoresistive element. The current control circuit supplies a second electric current to the coil. The second electric current periodically changes in polarity. The output circuit outputs a difference between a first voltage and a second voltage. The first voltage is generated by the magnetoresistive element, when the second electric current flowing through the coil has a positive polarity. The second voltage is generated by the magnetoresistive element, when the second electric current flowing through the coil has a negative polarity.

Owner:DENSO CORP

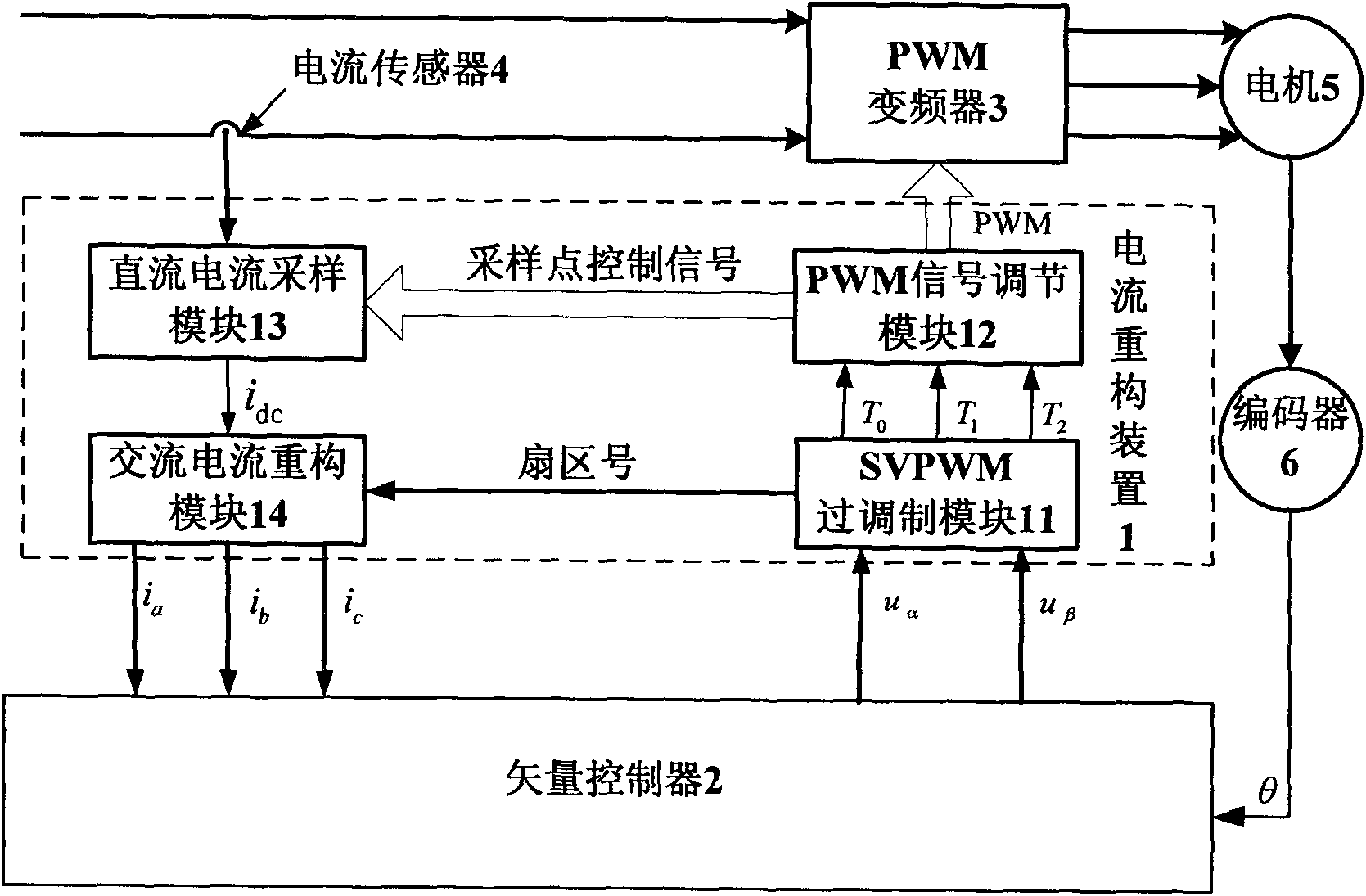

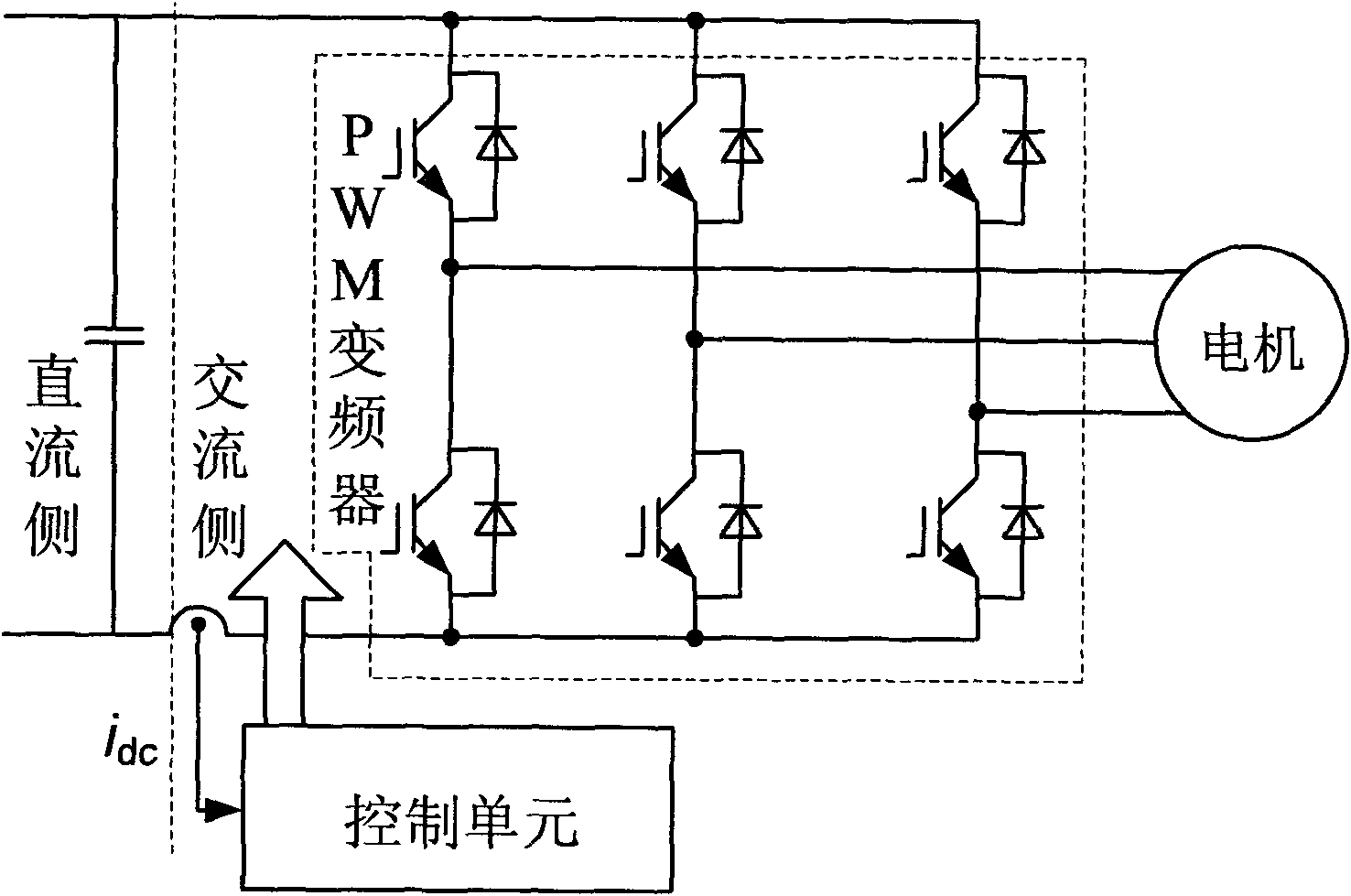

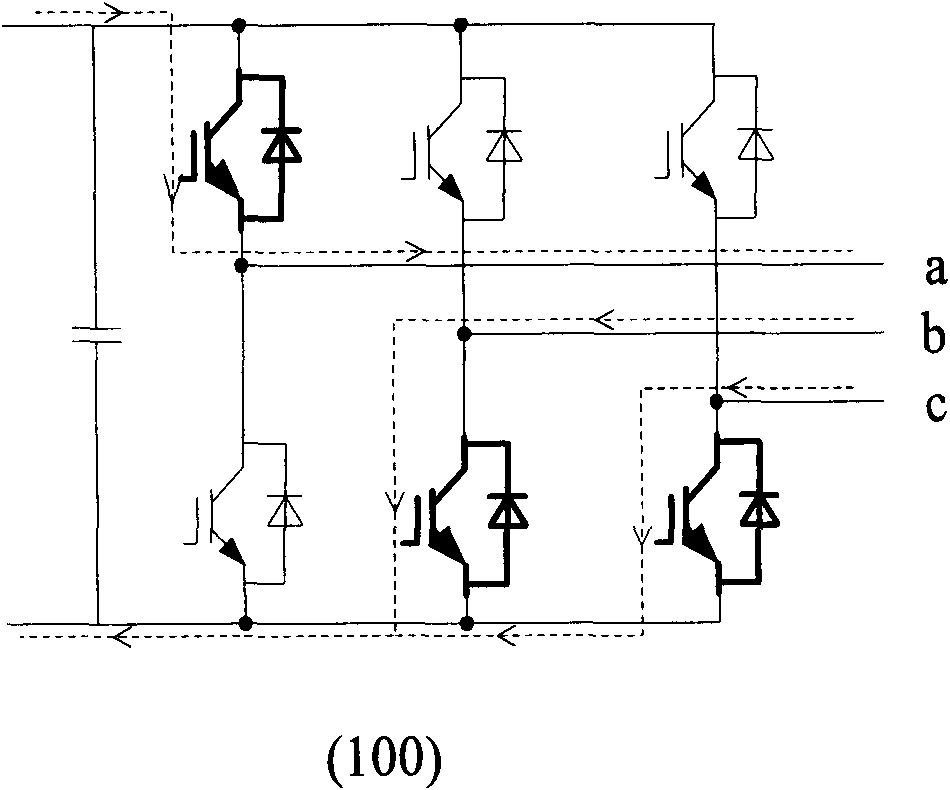

Electric current reconstructing and over-modulating device of air conditioning frequency converter and method thereof

InactiveCN101674046AImprove voltage utilizationReduce capacityAC motor controlVector control systemsFrequency changerDc current

The invention relates to an electric current reconstructing and over-modulating device of an air conditioning frequency converter, which is characterized by comprising an electric current reconstructing device, a vector controller, a pulse width modulation (PWM) frequency converter, a direct current side electric current sensor, an electric motor and a coder. The electric current reconstructing device comprises an SVPWM over-modulating module, a pulse width modulation (PWM) signal adjusting module, a direct current sampling module and an alternating current reconstructing module. An electric current reconstructing and over modulating method of the air conditioning frequency converter comprises the steps: sampling the direct current side electric current of the pulse width modulation (PWM)frequency converter at twice by the electric current reconstructing device; counting an approach vector switch action time which meets a minimum sampling time request according to the two sampling values; sampling the direct current side electric current at twice again in the approach vector switch action time; and reconstructing three phase alternating current according to the sampling values ofthe direct current at twice, thereby realizing the closed loop control of the pulse width modulation (PWM) frequency converter. The modulating method can be widely used for the field in reconstructingand over-modulating the electric current of the frequency converter in air conditionings and electric vehicles.

Owner:TSINGHUA UNIV

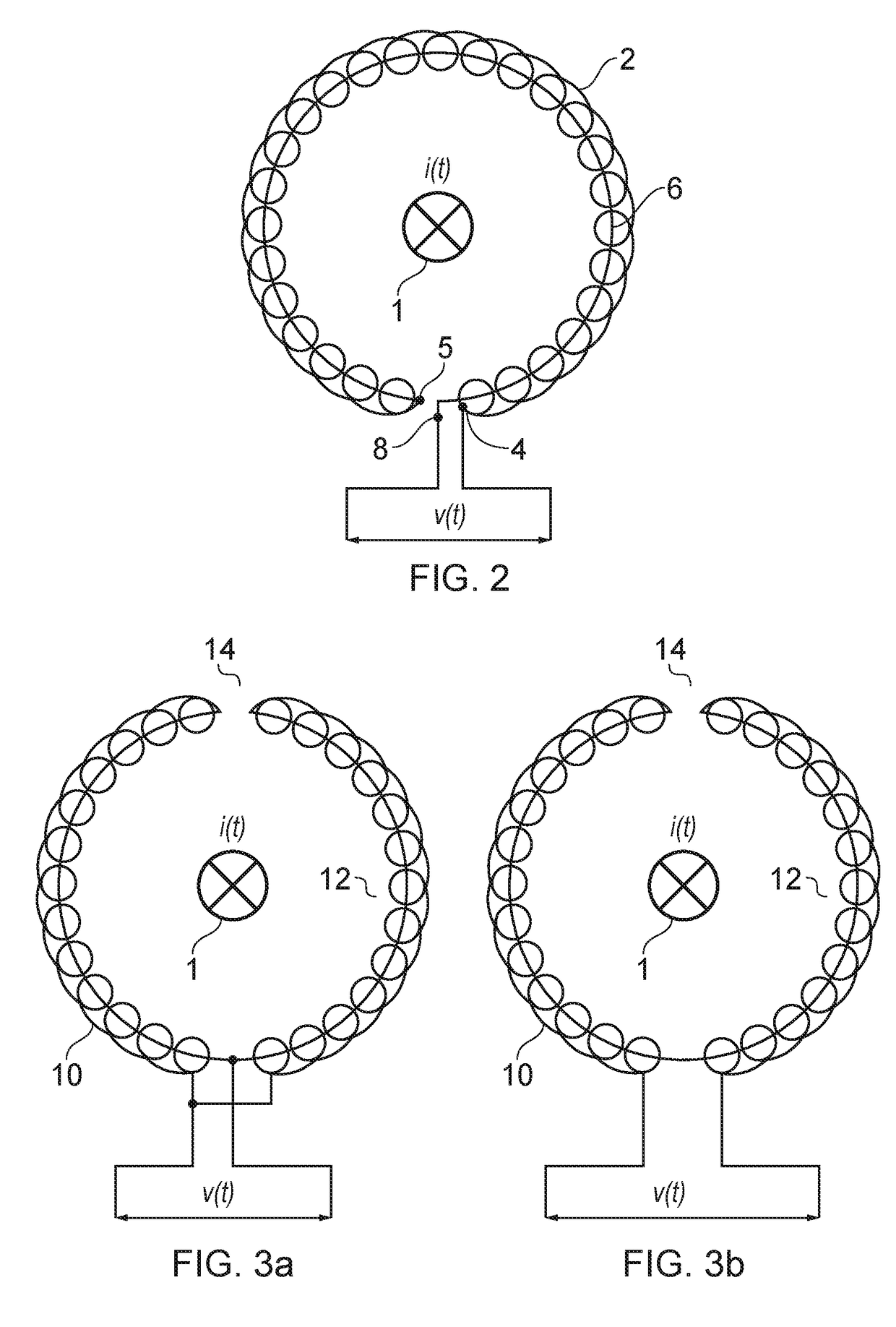

Current sensor and a method of manufacturing a current sensor

ActiveUS20170356935A1Accurate currentLow costRate of change measurementManufacture of electrical instrumentsCurrent sensorElectrical current

The present disclosure provides an improved Rogowski-type current sensor. The current measurement coil, and the compensation coil are provided on the same board. The measurement coil and the compensation coil are arranged such that they at least partially overlap by virtue of each repeatedly changing side of the board. This arrangement makes the current sensor far better at rejecting interference than certain other PCB Rogowski type coil arrangements.

Owner:ANALOG DEVICES INT UNLTD

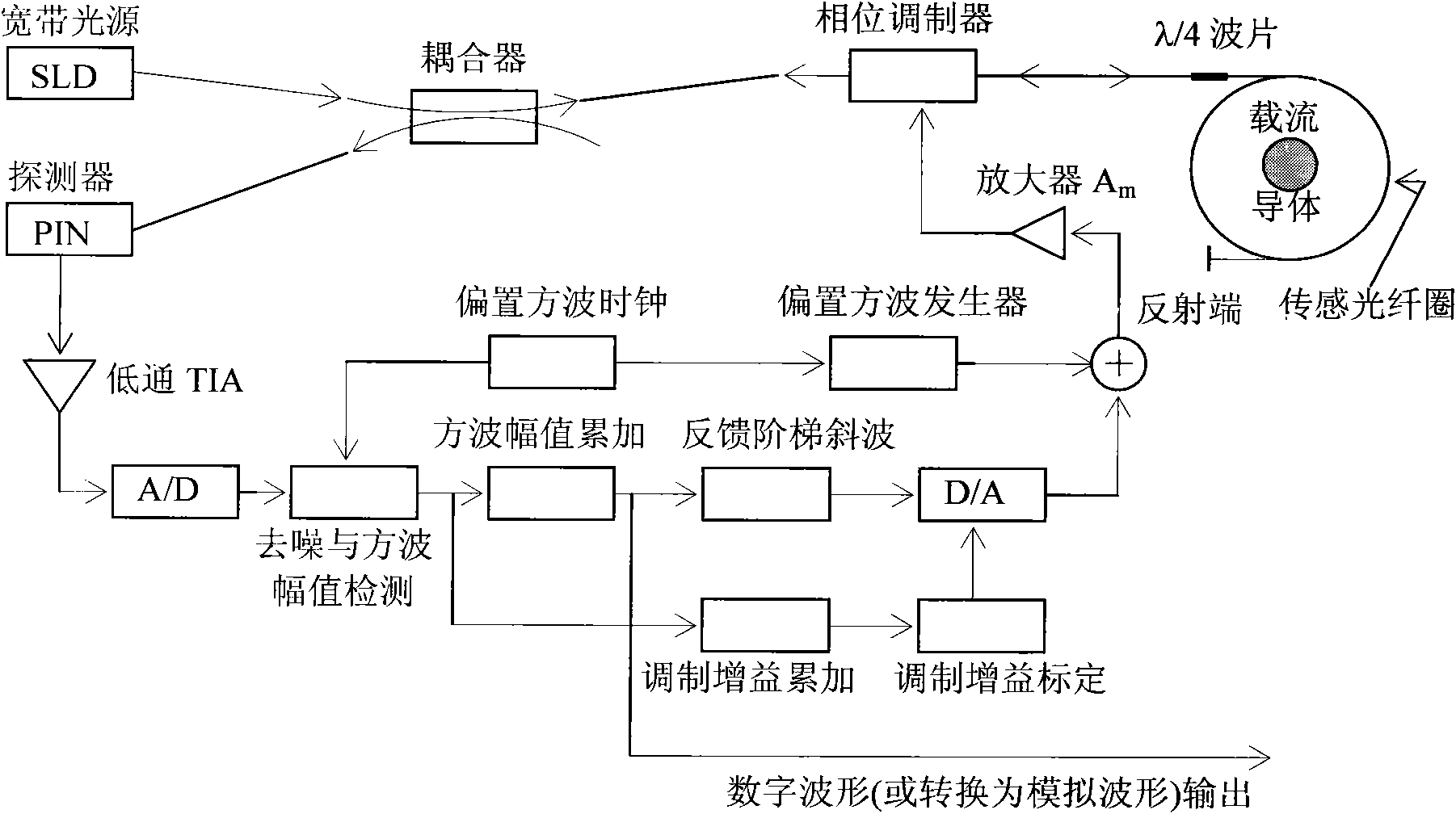

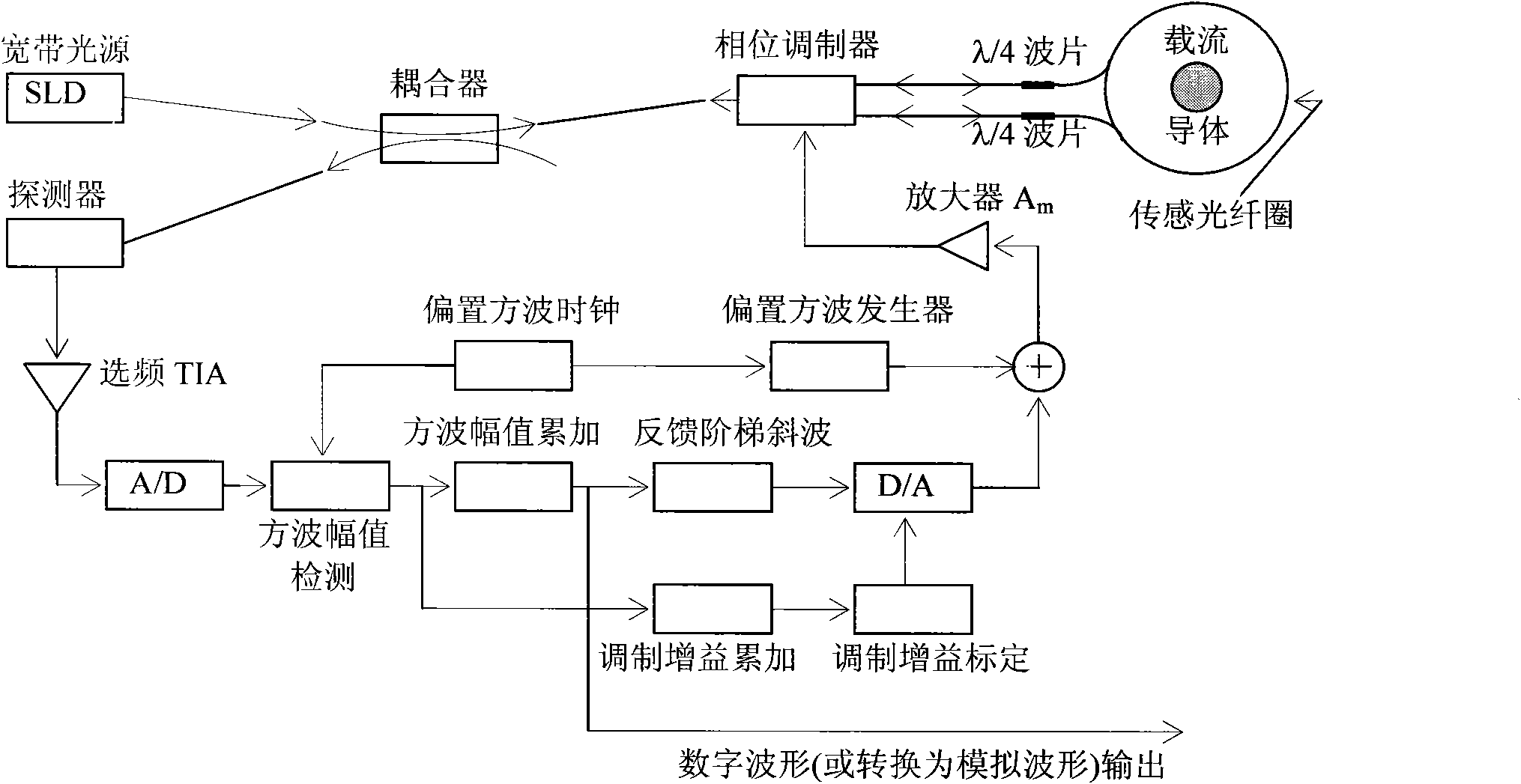

Digital closed loop type optical fiber current sensor

ActiveCN101957399AHigh sensitivityImprove dynamic rangeCurrent/voltage measurementVoltage/current isolationCurrent transducerNoise level

The invention provides a digital closed loop type optical fiber current sensor. A modulation signal of a light wave phase modulator of a sensor optical path system is an amplitude modulation square wave; a signal processing system extracts any harmonic wave of amplitude modulation square wave current output by a photoelectric transducer and extracts tested current information from the current; a pre-amplifier of the signal processing system is a transimpedance amplifier TIA, and the bandwidth is below 1 / 650 when the square wave transient amplitude value (prior art) is directly extracted from the amplitude modulation square wave, so that thermal noise output by the pre-amplifier and the shot noise level are also reduced to be below 1 / 650 of the prior art; and current-voltage conversion gain of the transimpedance amplifier TIA is not determined by the resistance of a feedback network of the TIA, so that a low-resistance resistor is adopted in the feedback network of the TIA while the high current-voltage conversion gain is ensured, and the thermal noise of the resistor which accounts for a significant proportion in the level of the noise output by the TIA is reduced to be negligible.

Owner:CHINA ELECTRIC POWER RES INST +1

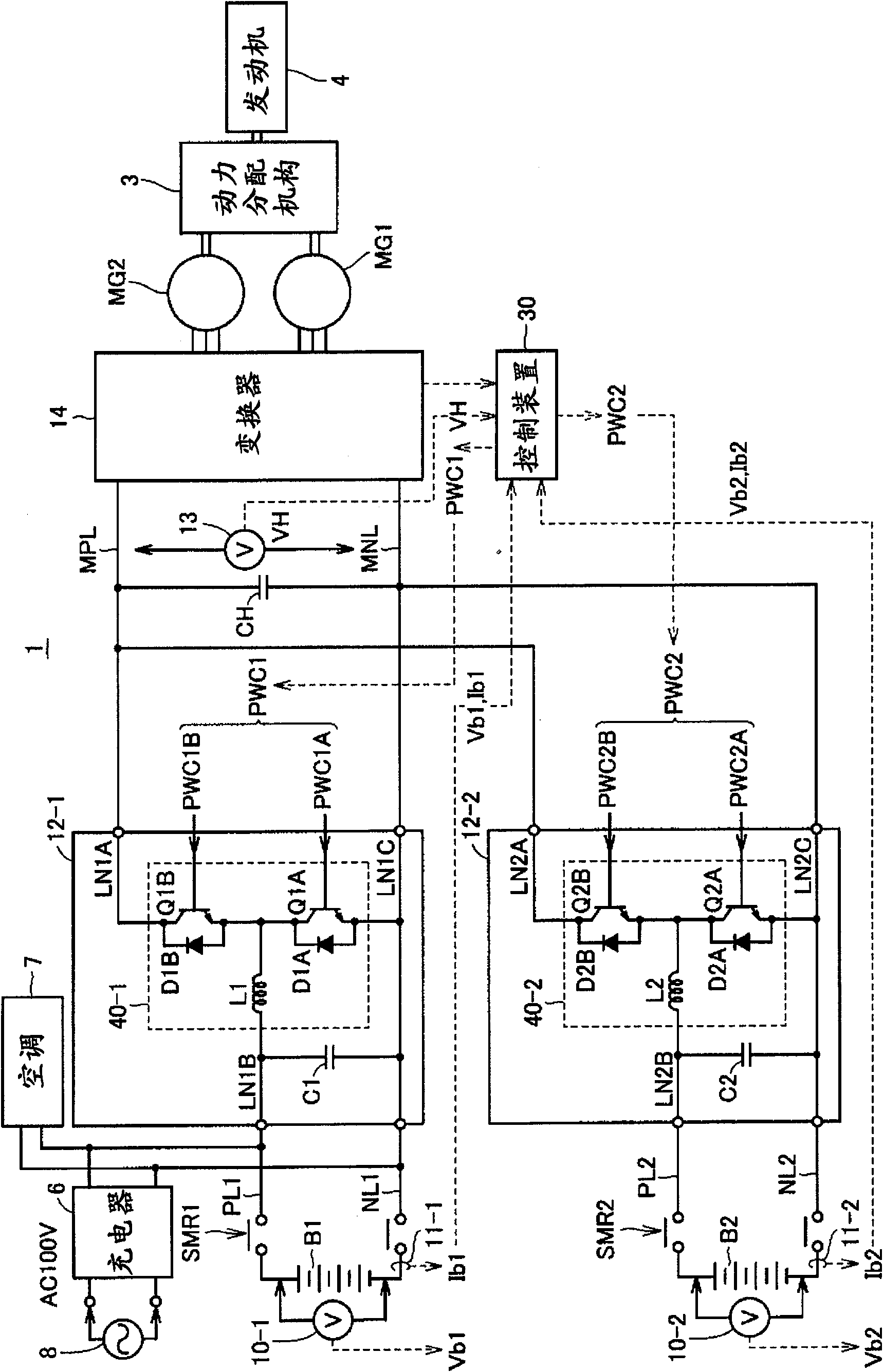

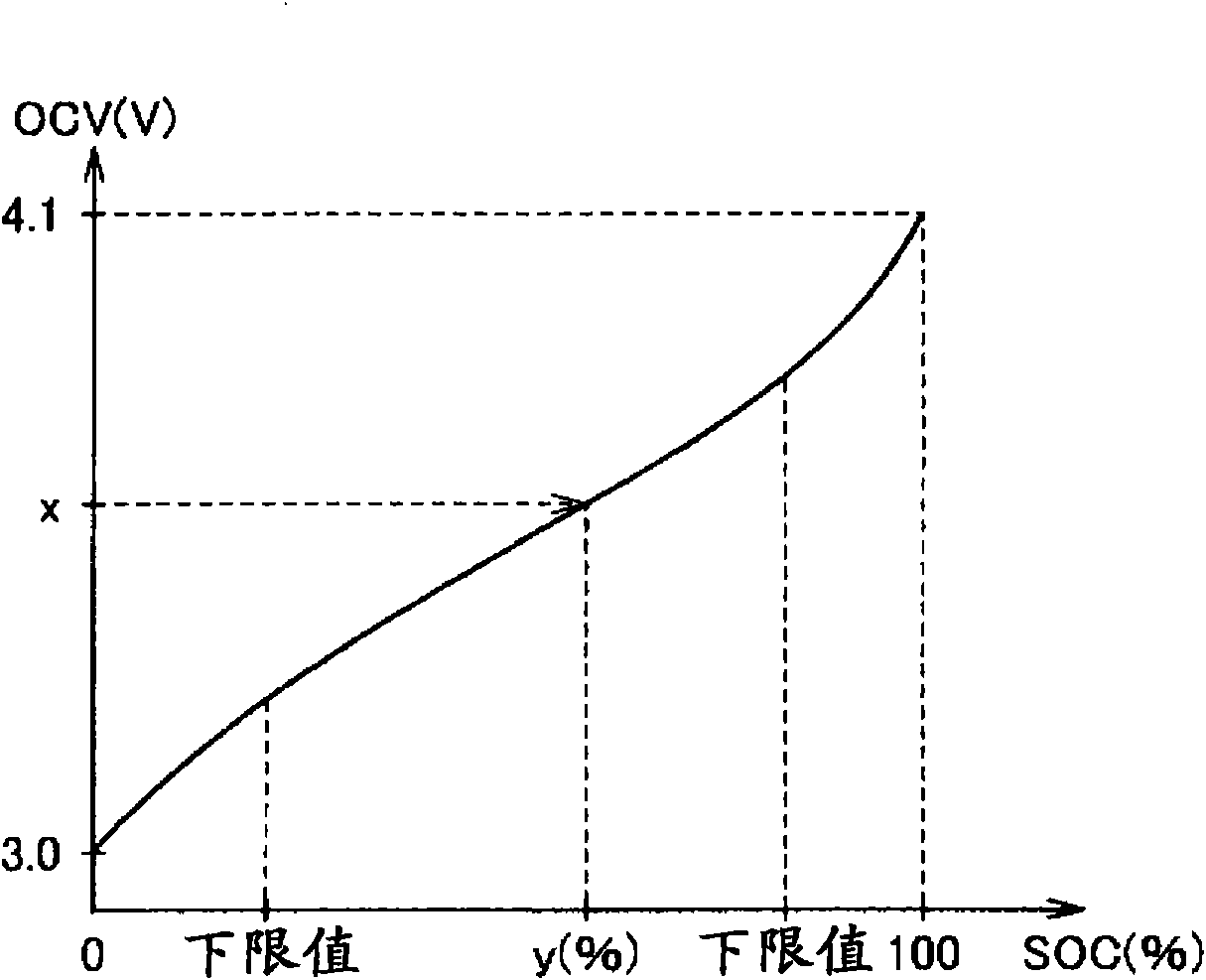

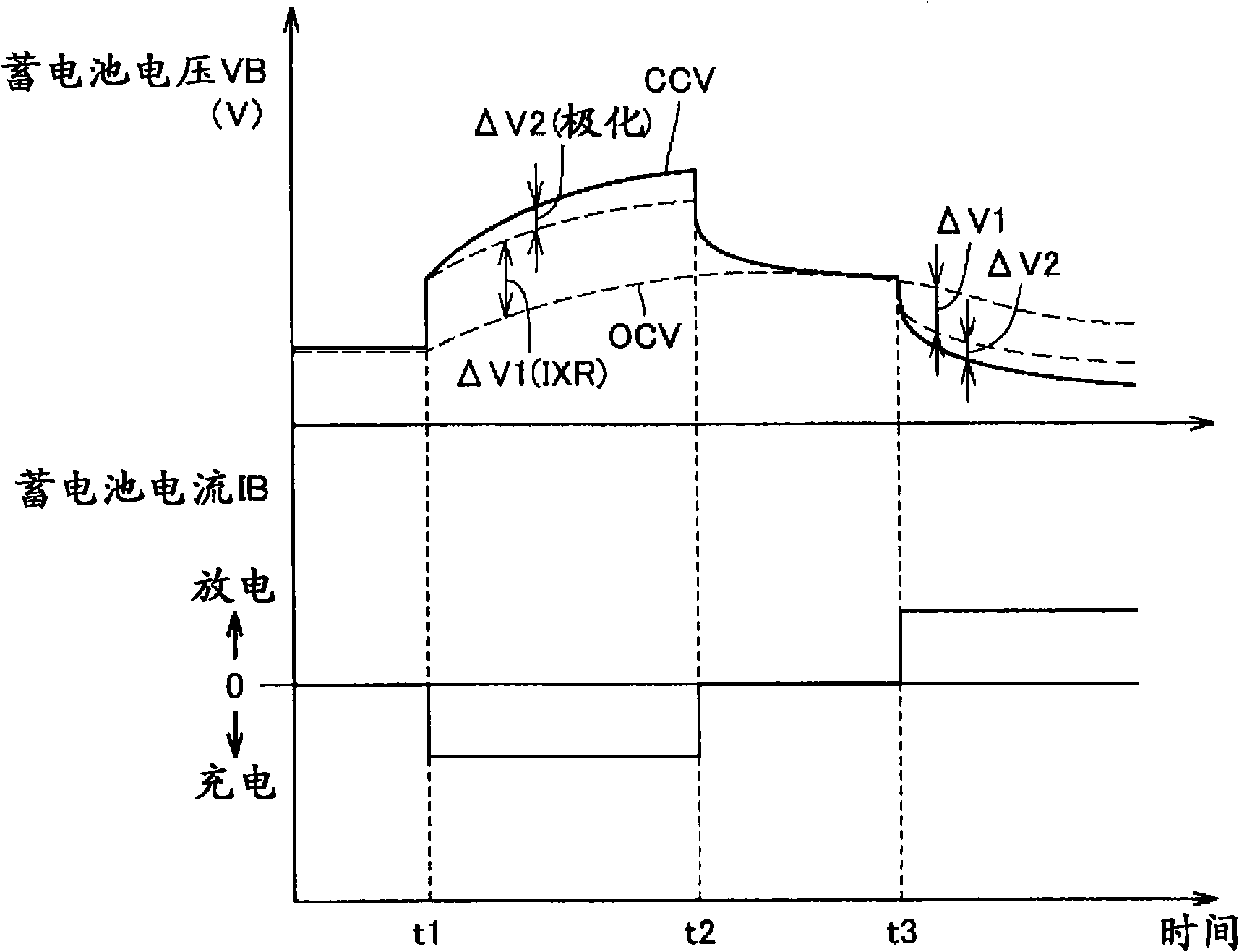

Vehicle and method for estimating charged state of secondary battery

ActiveCN101939892AImprove charging capacityImprove discharge capacityBatteries circuit arrangementsInternal combustion piston enginesPower flowElectrical battery

A vehicle (1) comprising a chargeable / dischargeable battery (B1), a current sensor (11-1) for detecting the current from the battery, and a control unit (30) for estimating the charged state of the battery and controlling the charging / discharging of the battery according to the charged state. In a first operation mode in which charging and discharging cycles are repeated, the control unit (30) estimates the open-circuit voltage of the battery, and determines the charged state on the basis of the value which is obtained by correcting the open-circuit voltage according to the polarization. In asecond operation mode in which either one of charging and discharging is continued, the control unit (30) determines the charged state on the basis of the result of integration of the current detected by the current sensor. Hence, the charged and discharged amperehours are large, thereby providing a vehicle which can effectively utilize the secondary battery.

Owner:TOYOTA JIDOSHA KK

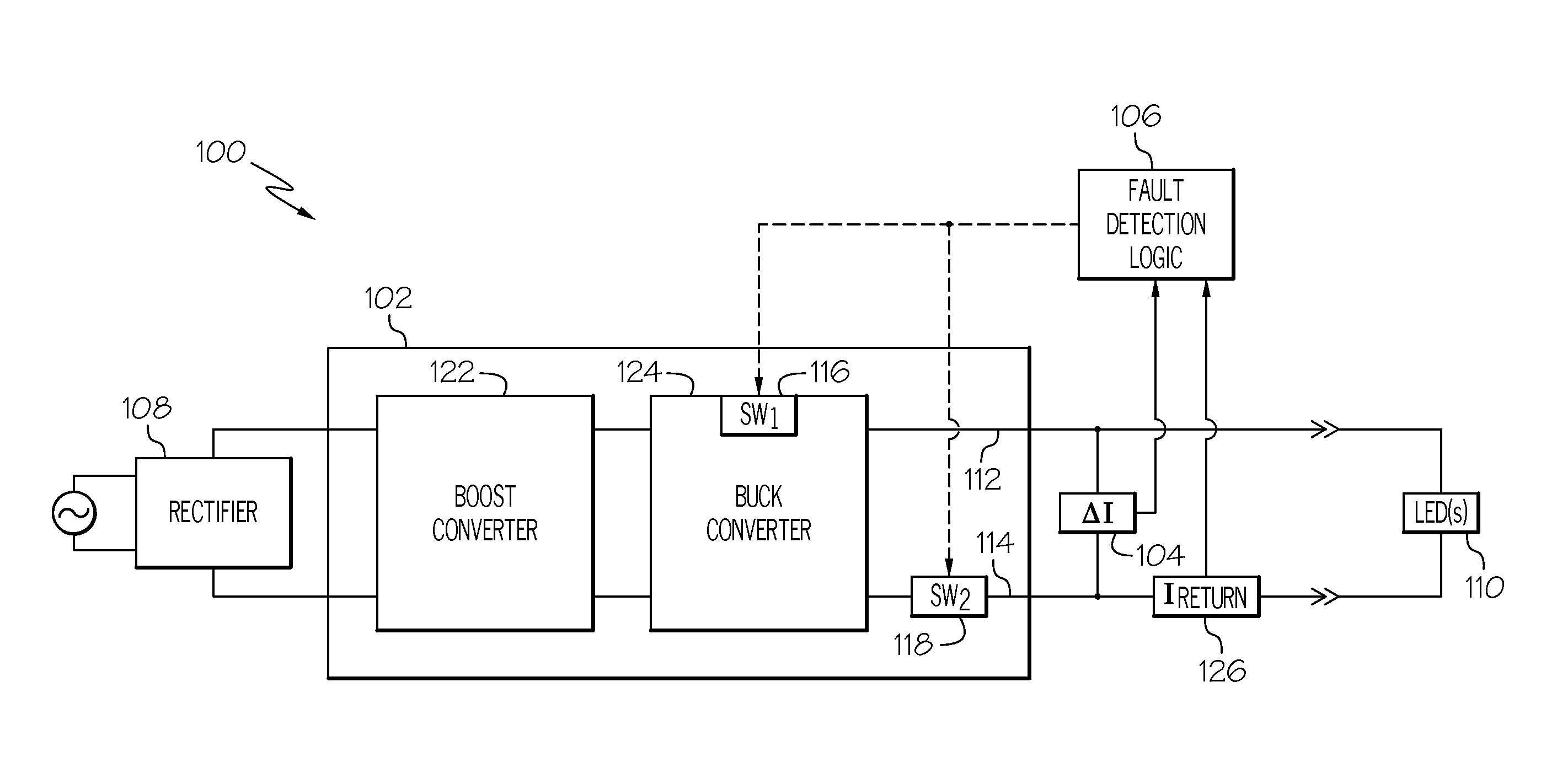

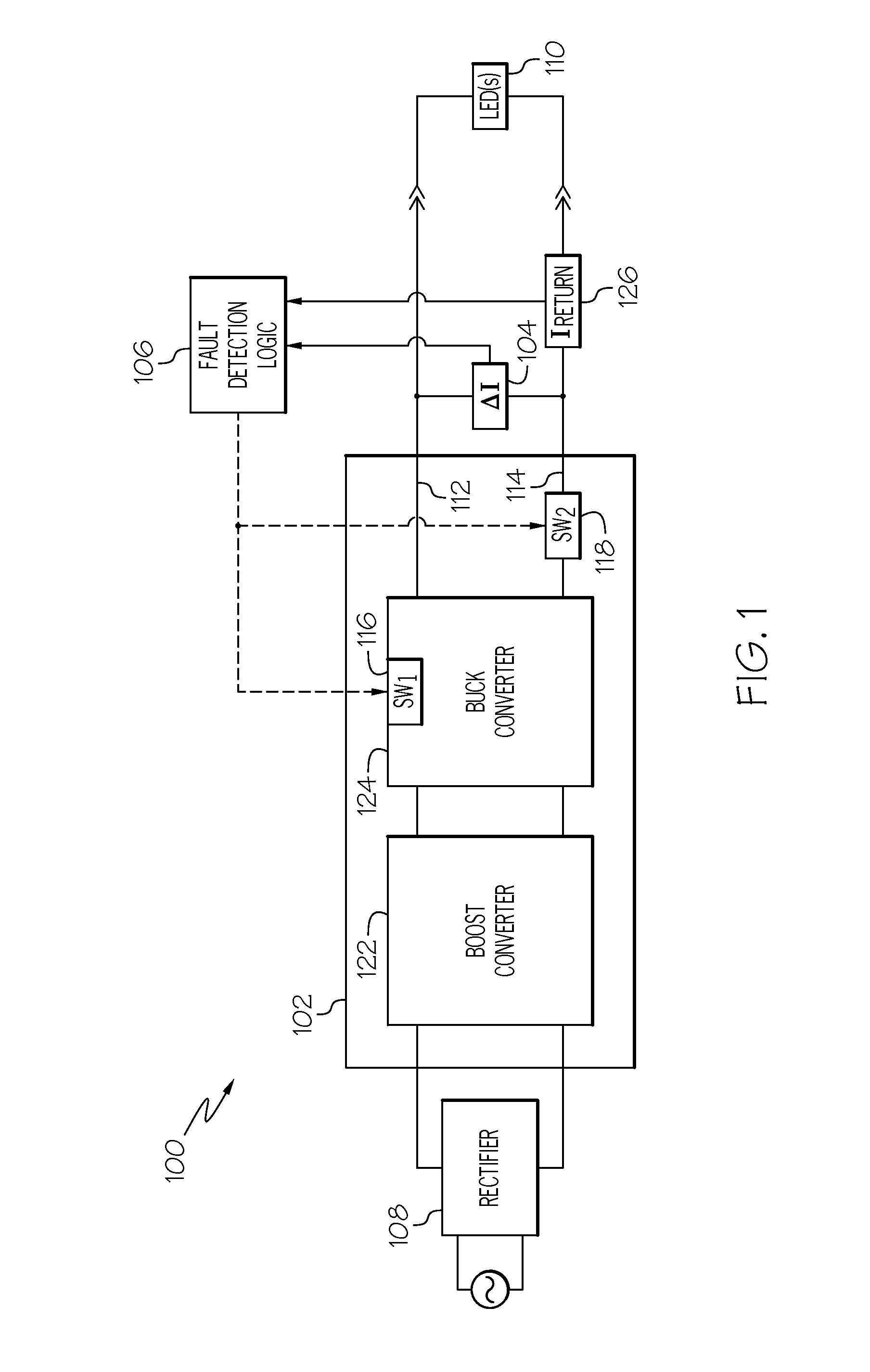

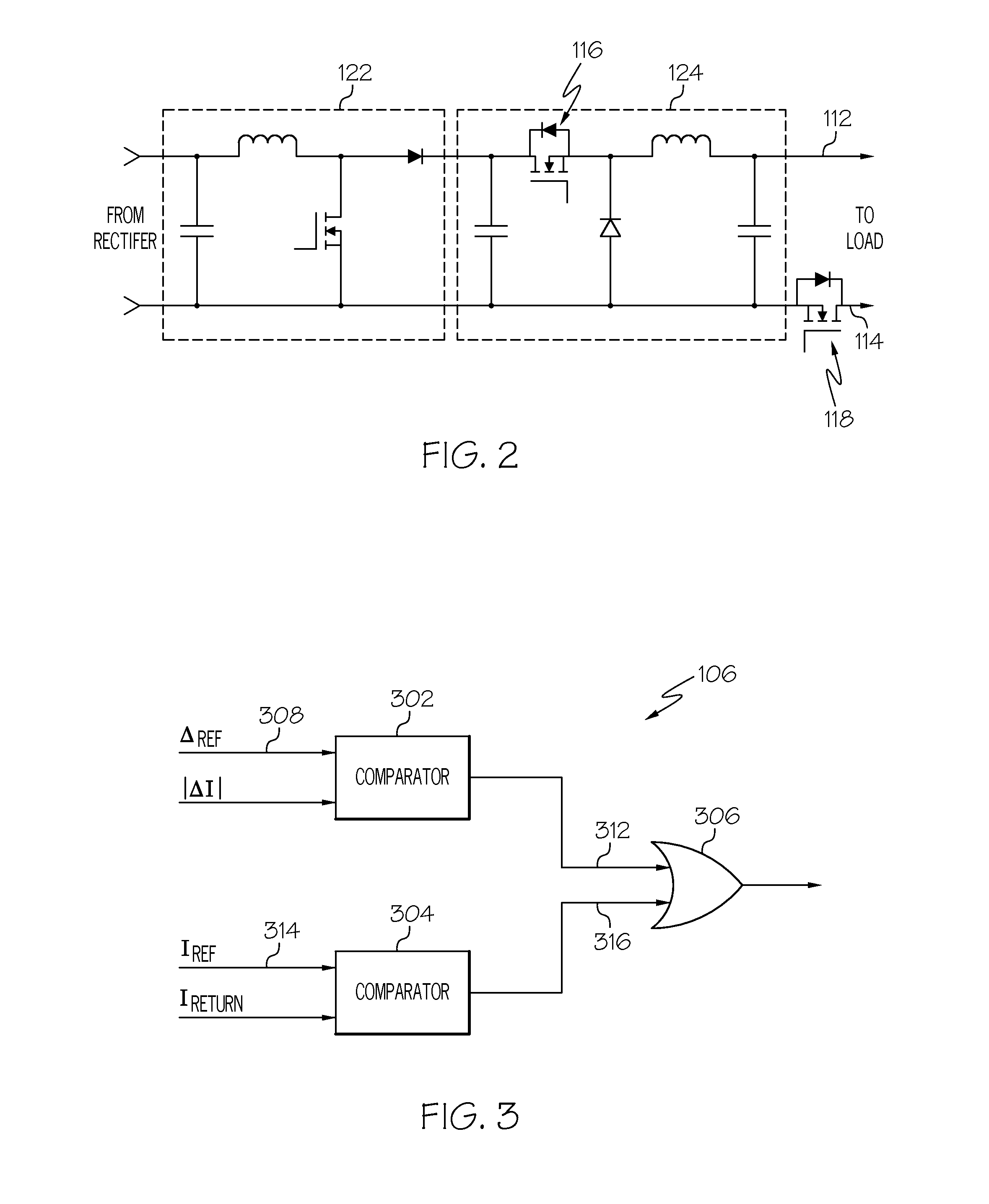

Non-isolated power supply output chassis ground fault detection and protection system

ActiveUS20160118784A1Apparatus without intermediate ac conversionArrangements responsive to excess currentPower flowCurrent sensor

A non-isolated power supply is configured to receive an input voltage and supply an output voltage, and includes a supply line, a return line, a first semiconductor switch coupled in series in the supply line, and a second semiconductor switch coupled in series in the return line. The first and second semiconductor switches are each configured to operate in an ON state and an OFF state. The differential current sensor is configured to sense differential current between the supply line and the return line. The fault detection logic is coupled to the differential current sensor, the first semiconductor switch, and the second semiconductor switch, and is configured to detect when the differential current exceeds a predetermined current magnitude, and command the first and second semiconductor switches to operate in the OFF state upon detecting that the differential current exceeds the predetermined current magnitude.

Owner:HONEYWELL INT INC

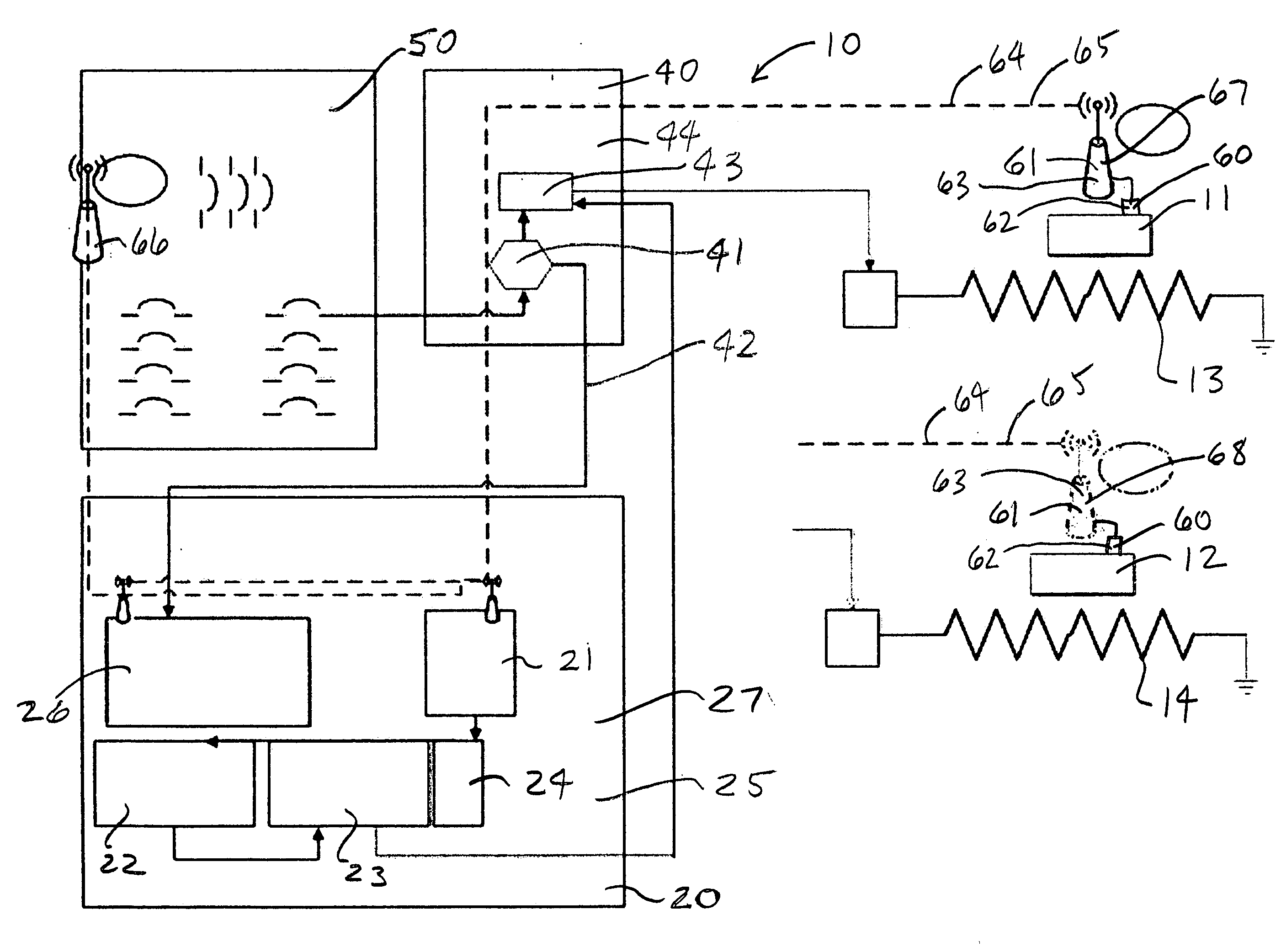

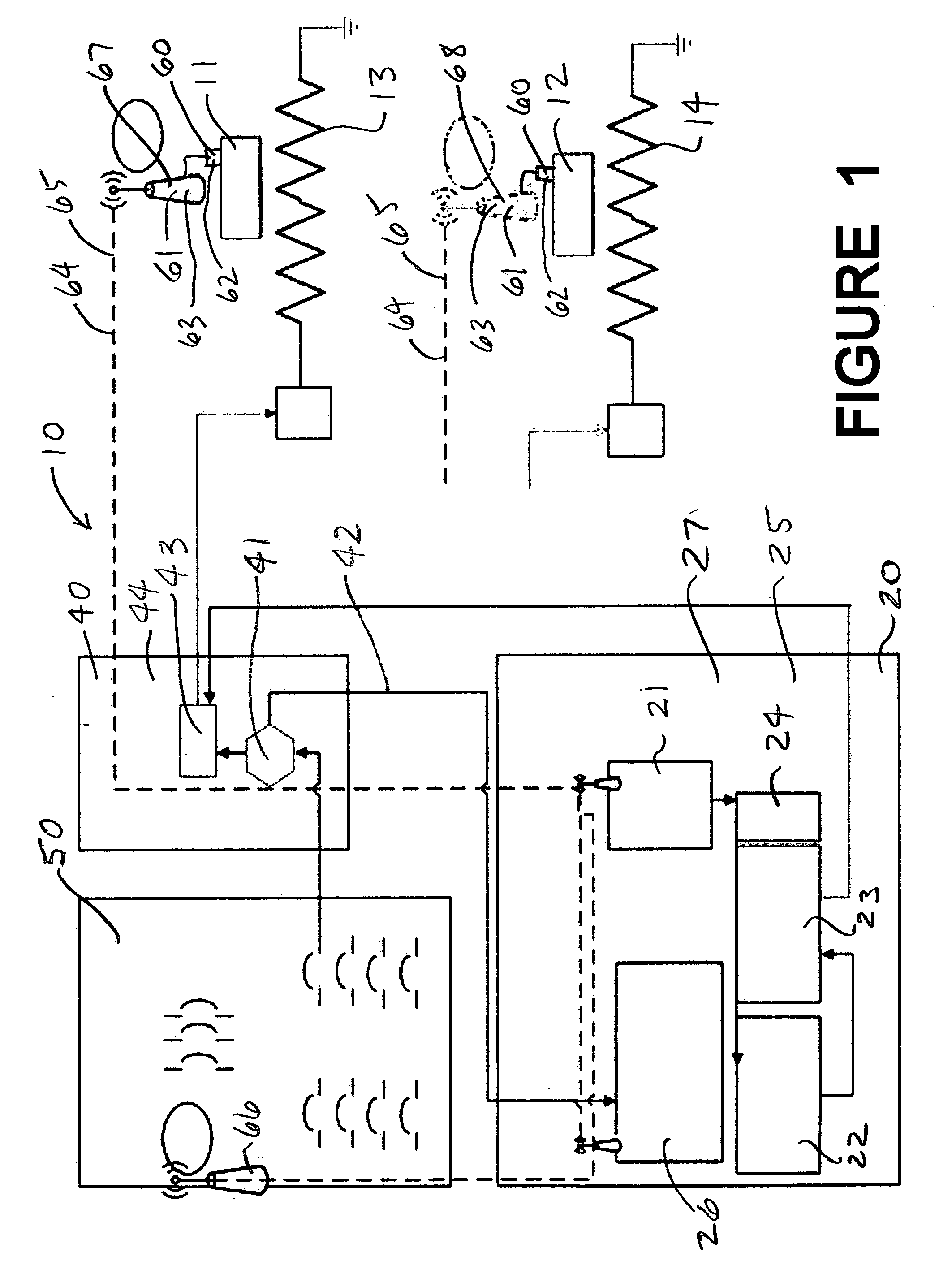

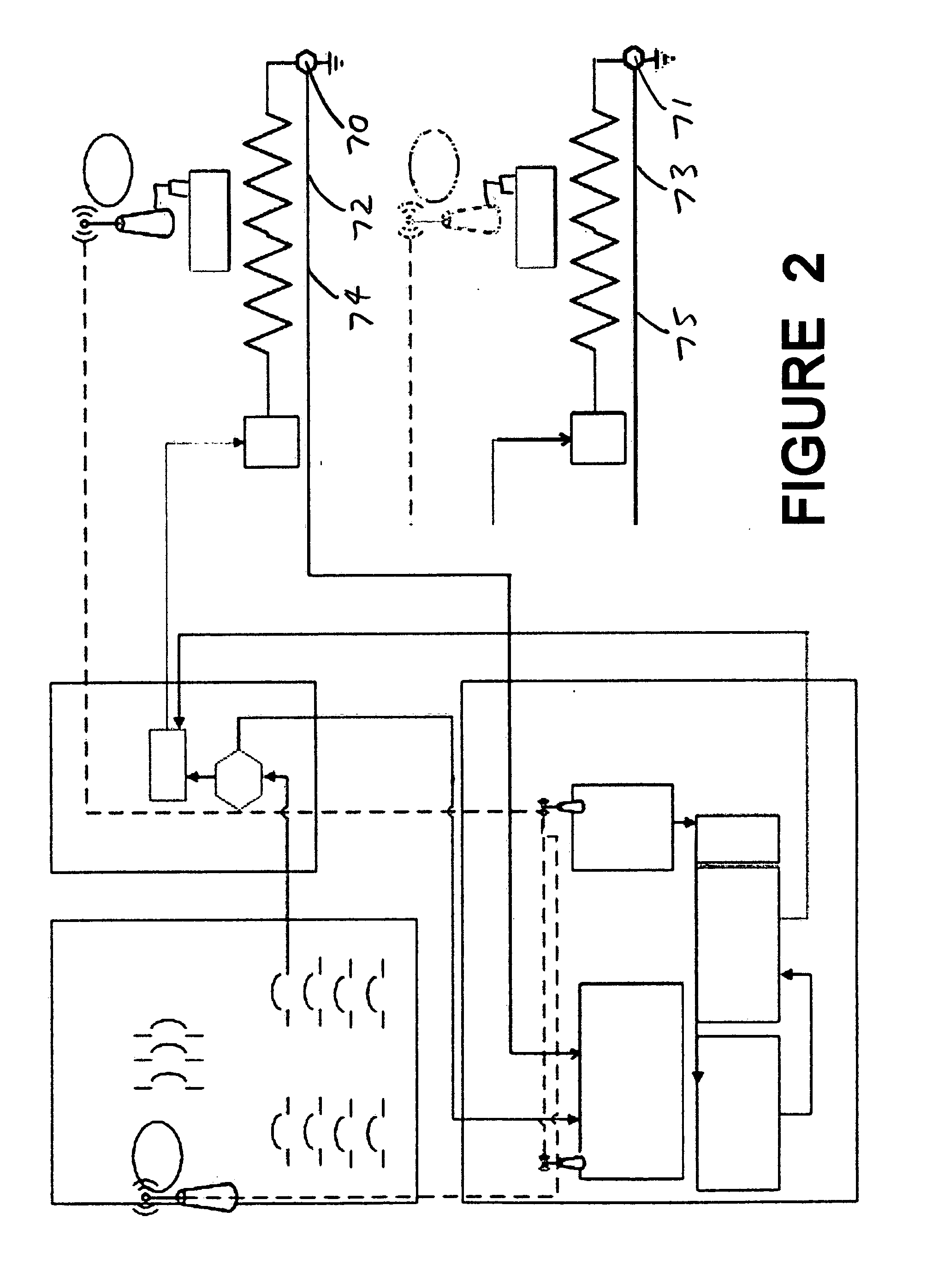

Wireless electric heat trace and vibration control and monitoring system

InactiveUS20110163082A1Quick fixReduce distanceTemperature control using digital meansMechanical oscillations controlCurrent transducerVibration control

A monitoring system for monitoring the temperature and vibration of equipment, comprising a central digital computer, a MESH communication network, wherein the network feeds signals to the central digital computer, a plurality of heating elements for heating the equipment, temperature / vibration sensors adapted to measure the temperature of the equipment, wherein each sensor is adapted to provide a signal representing the temperature / vibration of the piece of equipment to which the sensor is associated, to the network, wherein each temperature / vibration sensor can also be used to control the electric heaters, a temperature sensor that monitors the ambient temperature of the facility, and current transducers associated with the heaters, to monitor the energy use and current loss of the heaters, wherein the central computer uses the data it receives from the other elements of the monitoring system to determine when the equipment is not at the correct temperature / vibration and diagnoses the reason why.

Owner:BRACE INTEGRATED SERVICES INC

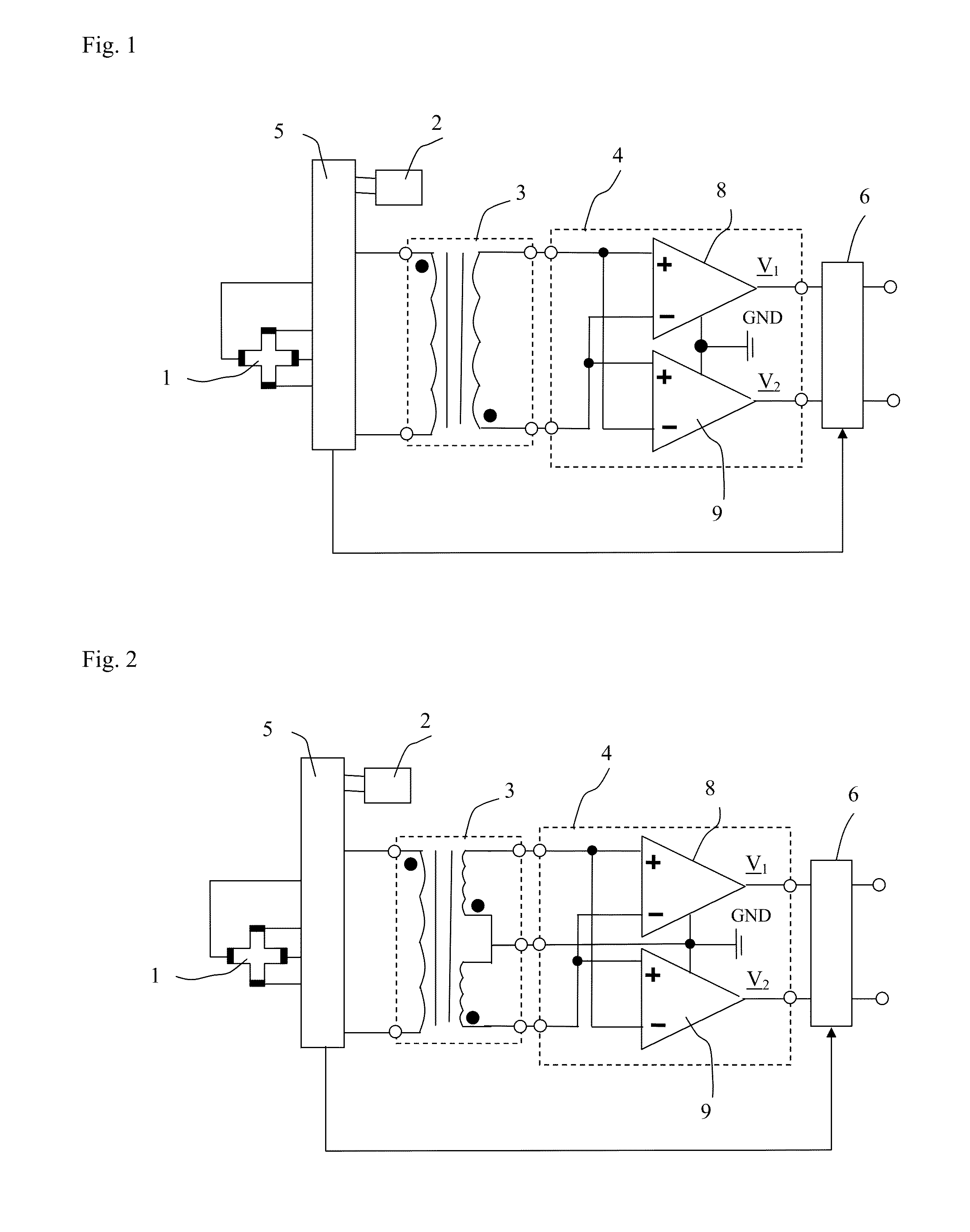

Current Transducer For Measuring An Electrical Current

InactiveUS20140009146A1Improve immunityMagnetic field measurement using flux-gate principleShort-circuit testingCurrent transducerMagnetic transducers

The invention concerns a current transducer for measuring a current flowing through a cable, comprising at least one magnetic field sensor and an electronic circuit. The current transducer comprises a head with a ferromagnetic core optimized to reduce the effects of external magnetic fields. The invention further concerns a magnetic transducer comprising a magnetic field sensor and an electronic circuit. The electronic circuit comprises at least one current source, a transformer, a fully differential preamplifier coupled to the transformer, a phase sensitive detector coupled to the preamplifier and a logic block configured to operate the magnetic field sensor(s) to provide an AC output voltage. The magnetic field sensor(s) is preferably either a Hall element or an AMR sensor or a flux-gate sensor.

Owner:SENIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com