Digital closed loop type optical fiber current sensor

A fiber-optic current and digital closed-loop technology, applied in voltage/current isolation, measuring current/voltage, instruments, etc., can solve problems such as long lag time, difficulty in improving response speed, slow response speed, etc., and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

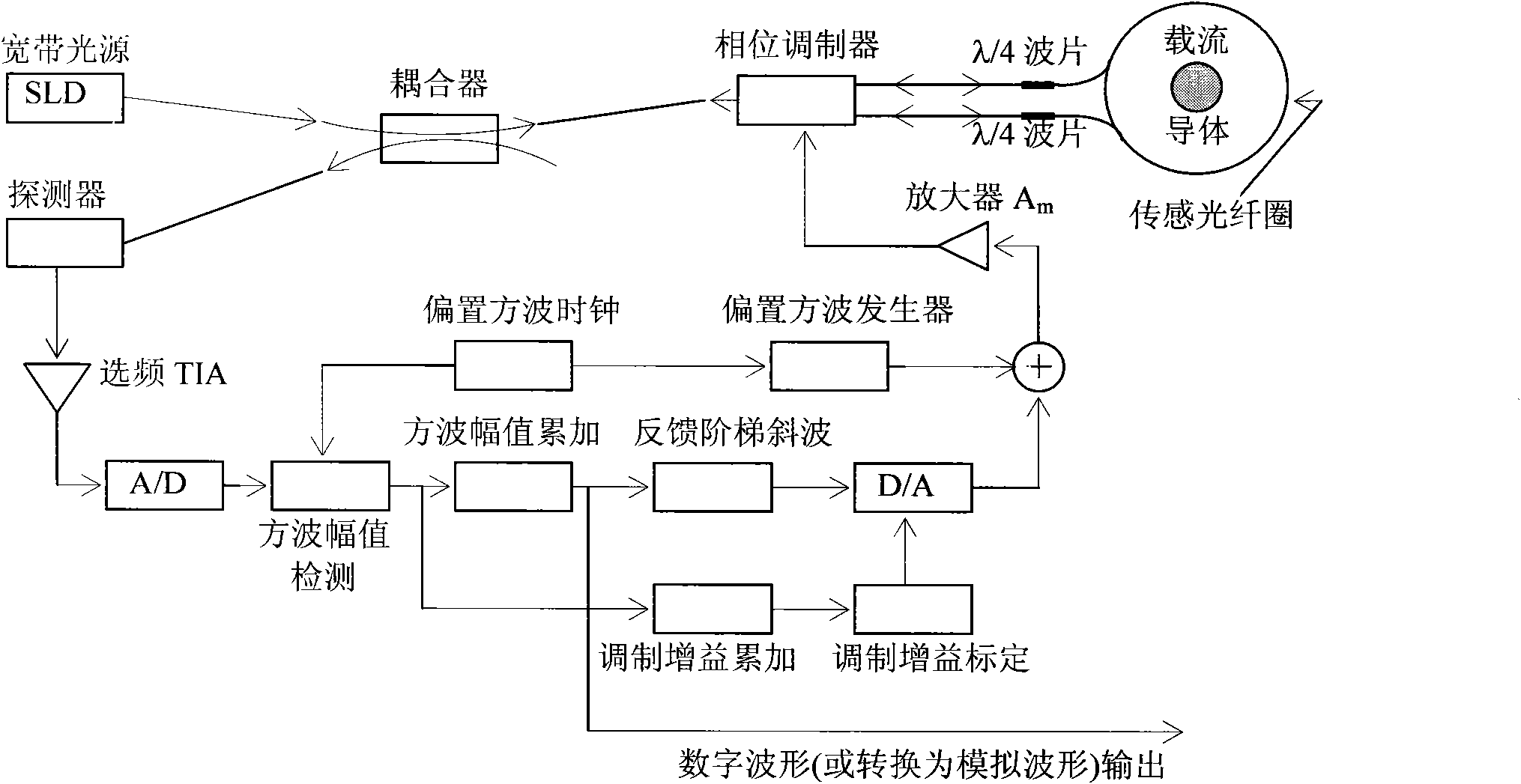

[0078] In order to improve the dynamic range and response speed of the digital closed-loop fiber optic current sensor, we can start by reducing the noise level of the output signal of the preamplifier of the signal processing system, because this can not only improve the measurement accuracy of the small signal end, but also reduce the lag of signal processing time. The solution proposed in this patent application is: the light wave phase modulation adopts a square wave, and the signal processing is no longer based on a square wave, but on a sine wave (hereinafter referred to as the square wave-sine wave solution). In order to explain why such a scheme can achieve this goal, we first analyze the signal characteristics that the digital closed-loop fiber optic current sensor needs to process.

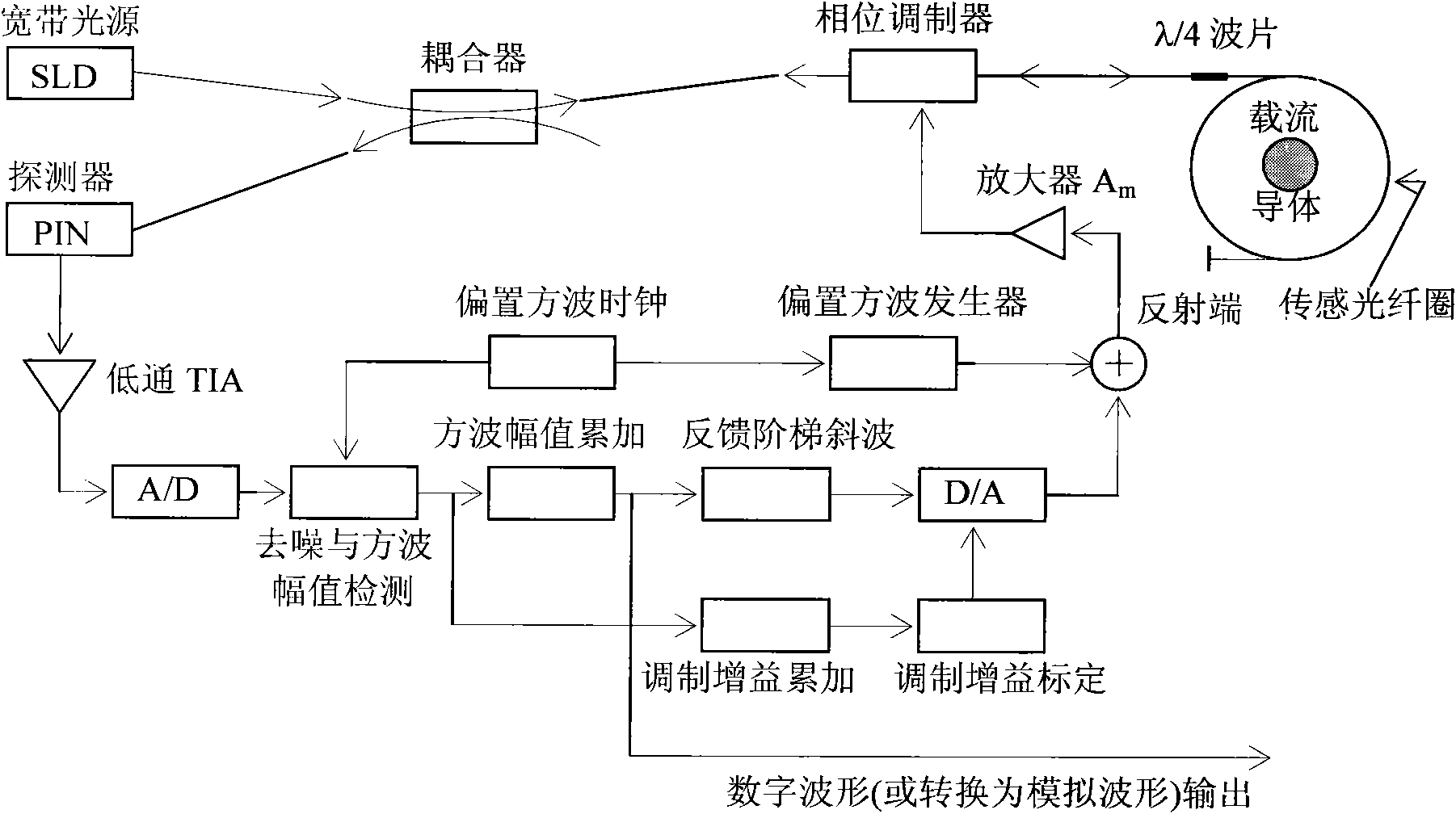

[0079] by figure 1 The optical path and circuit simplified diagram (referring to U.S. Patent No. 5,914,781, etc.) of the existing reflective square wave modulation-square wave detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com