Permanent magnet reluctance synchronous motor rotor structure having high torque density

A technology of reluctance synchronization and motor rotor, which is applied to synchronous machine components, magnetic circuit shape/style/structure, magnetic circuit, etc., can solve problems such as underutilization, improve utilization rate, increase torque density, reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

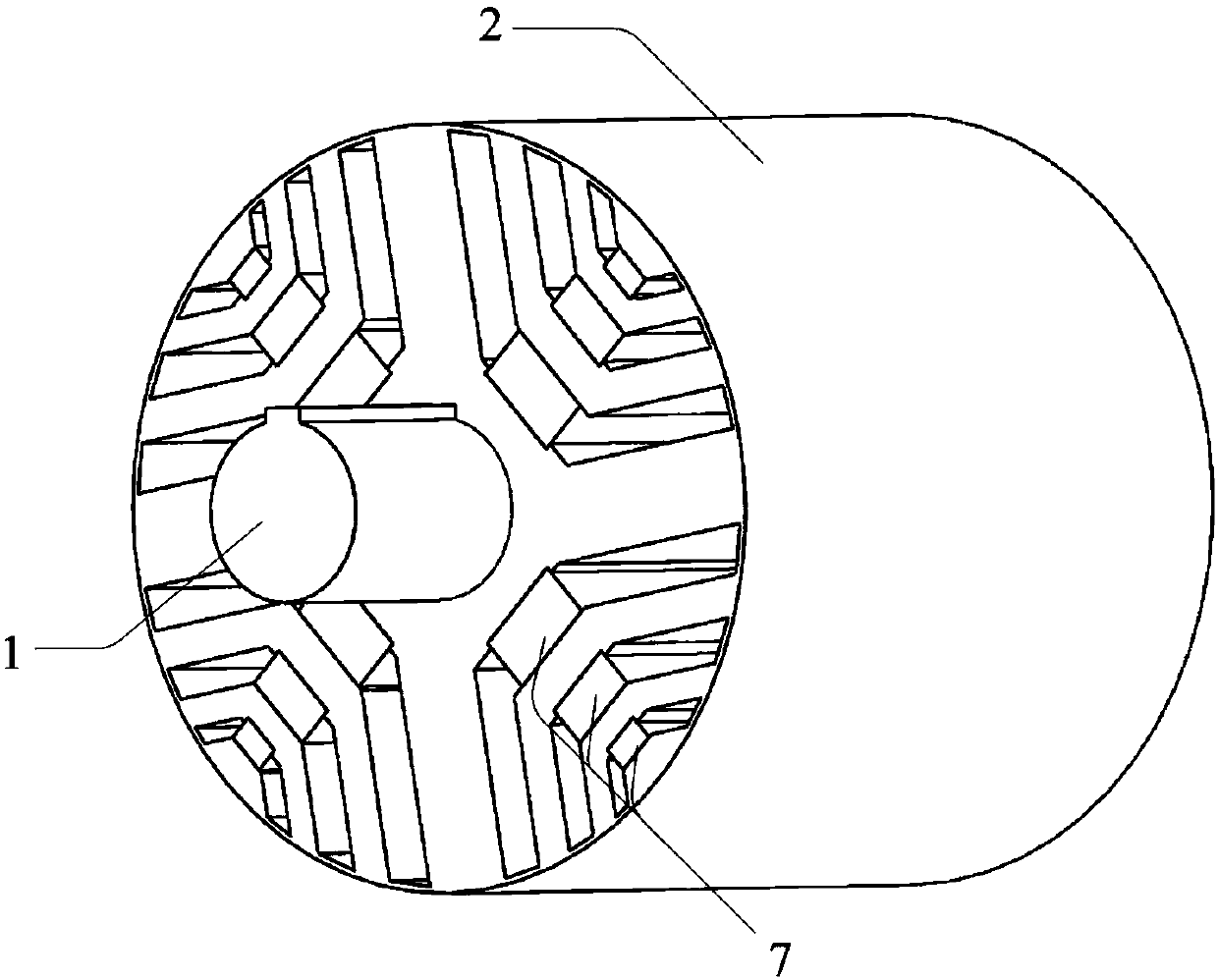

[0020] Such as figure 1 Shown is a high torque density permanent magnet reluctance synchronous motor rotor structure, including a central shaft 1 and a rotor core 2 (made of laminated rotor punches), the central shaft 1 and rotor core 2 are installed on the same central axis ;Around the central axis, P slot groups 3 with the same structural size are evenly arranged on the rotor core 2, and along the clockwise direction, the numbers of the slot groups 3 are sequentially recorded as 1, 2, . . . , i, . ··, P-1, P, where P is the number of magnetic poles of the motor;

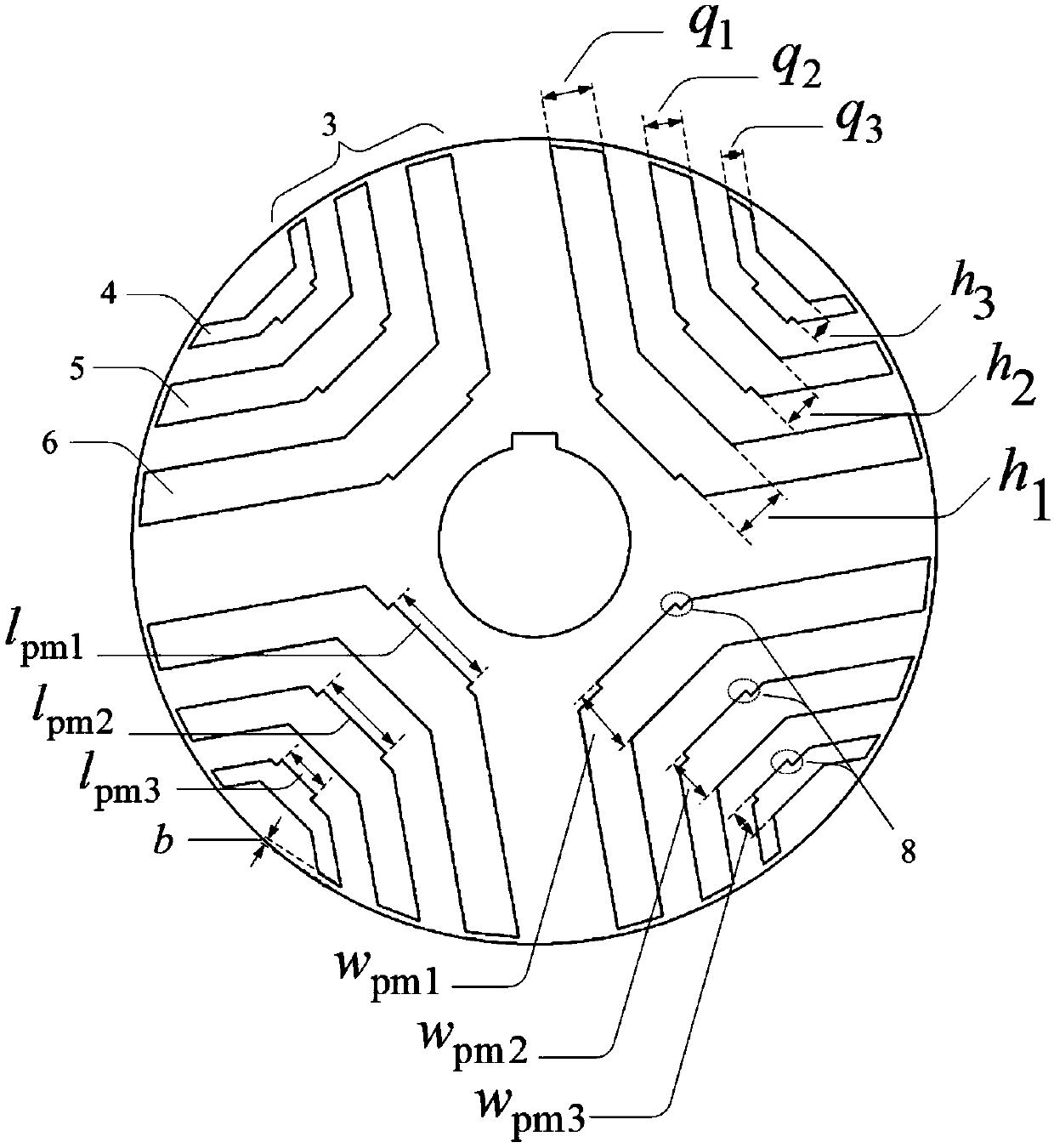

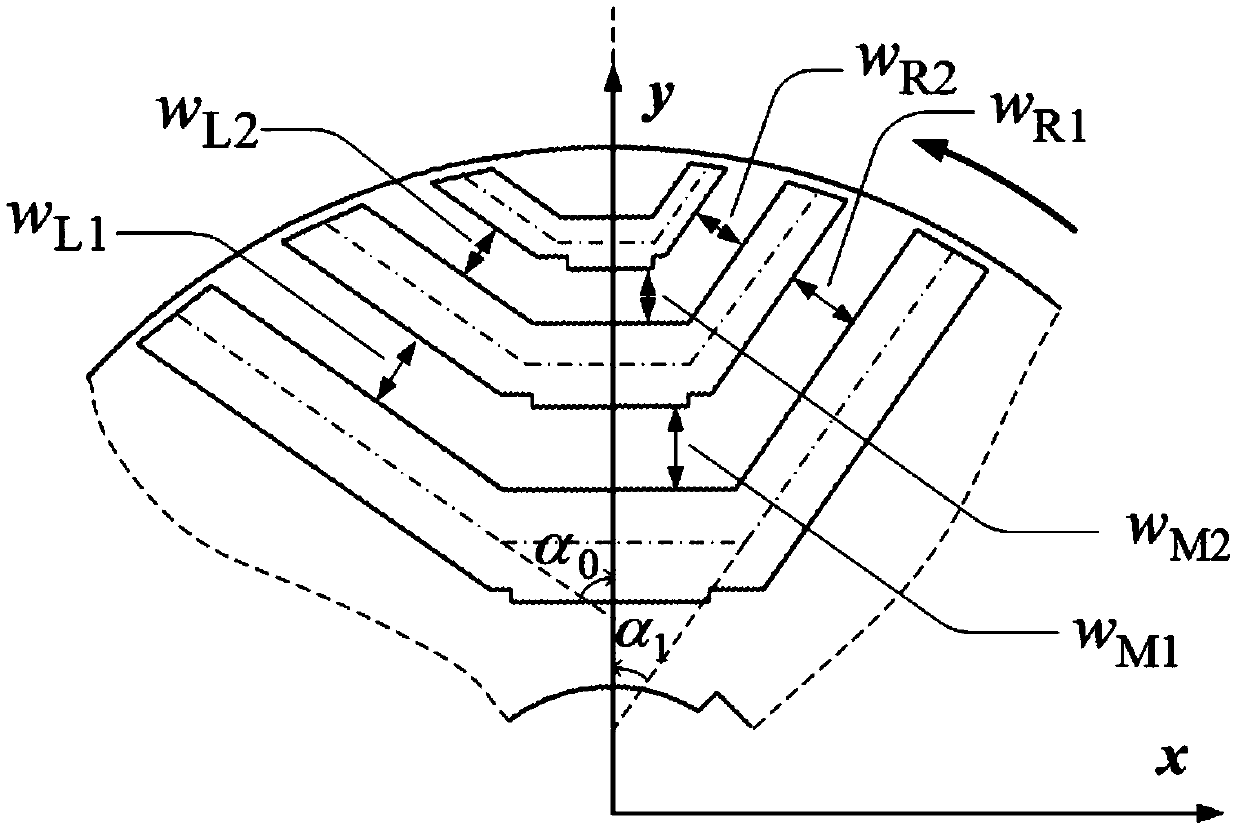

[0021] Such as figure 2 As shown, each slot group 3 includes three U-shaped slots, each U-shaped slot includes a straight base and two straight flanks, and the three straight bases are parallel to each other; according to the distance between the straight base and the central axis The three U-shaped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com