Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

560results about How to "Reduce copper consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing

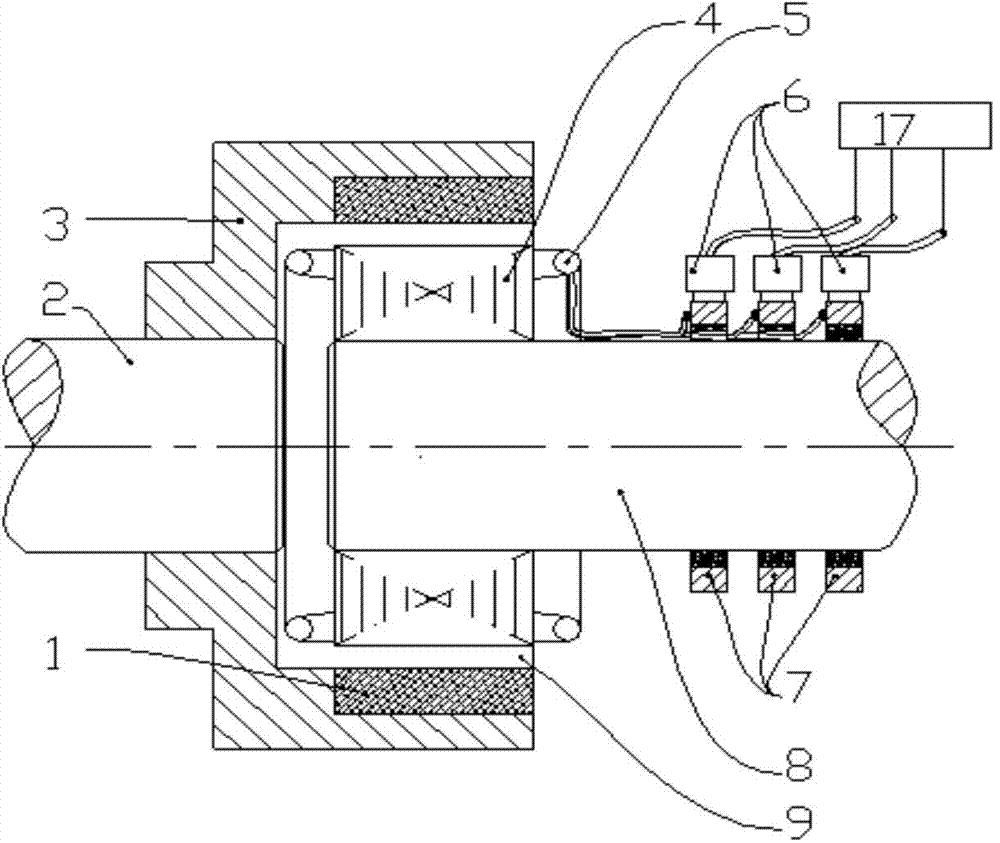

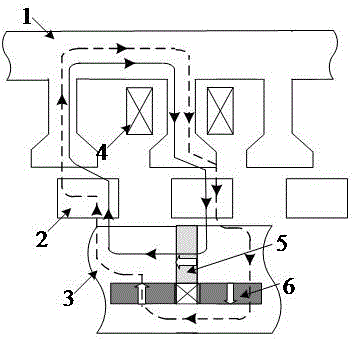

The invention discloses a radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing used for non-contact suspension bearing. An axial control coil is arranged between a radial stator core and an axial stator core; an axial air gap is formed between the axial stator core and the end face of a rotor in the axial direction; three same stator core magnetic poles uniformly distributed in the circumferential direction extend from the wall of an inner cavity of the radial stator core to the axle center; same radial control coils are wound on the three stator core magnetic poles, and radial air gaps are formed between the stator core magnetic poles and the outer wall of the rotor in the radial direction; same axially magnetized annular permanent magnets are arranged between two axial sides of the radial stator core and the axial stator core; and S poles of the permanent magnets face the radial stator core, and N poles of the permanent magnets face the axial stator core. The radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing integrates axial and radial functions, is only driven by a three-phase alternating current power inverter, is provided with two axially magnetized annular permanent magnets, controls the magnetic flux not to pass magnetic poles where the permanent magnets are positioned, and has the advantages of low power consumption, small volume, light weight and high bearing capacity.

Owner:JIANGSU UNIV

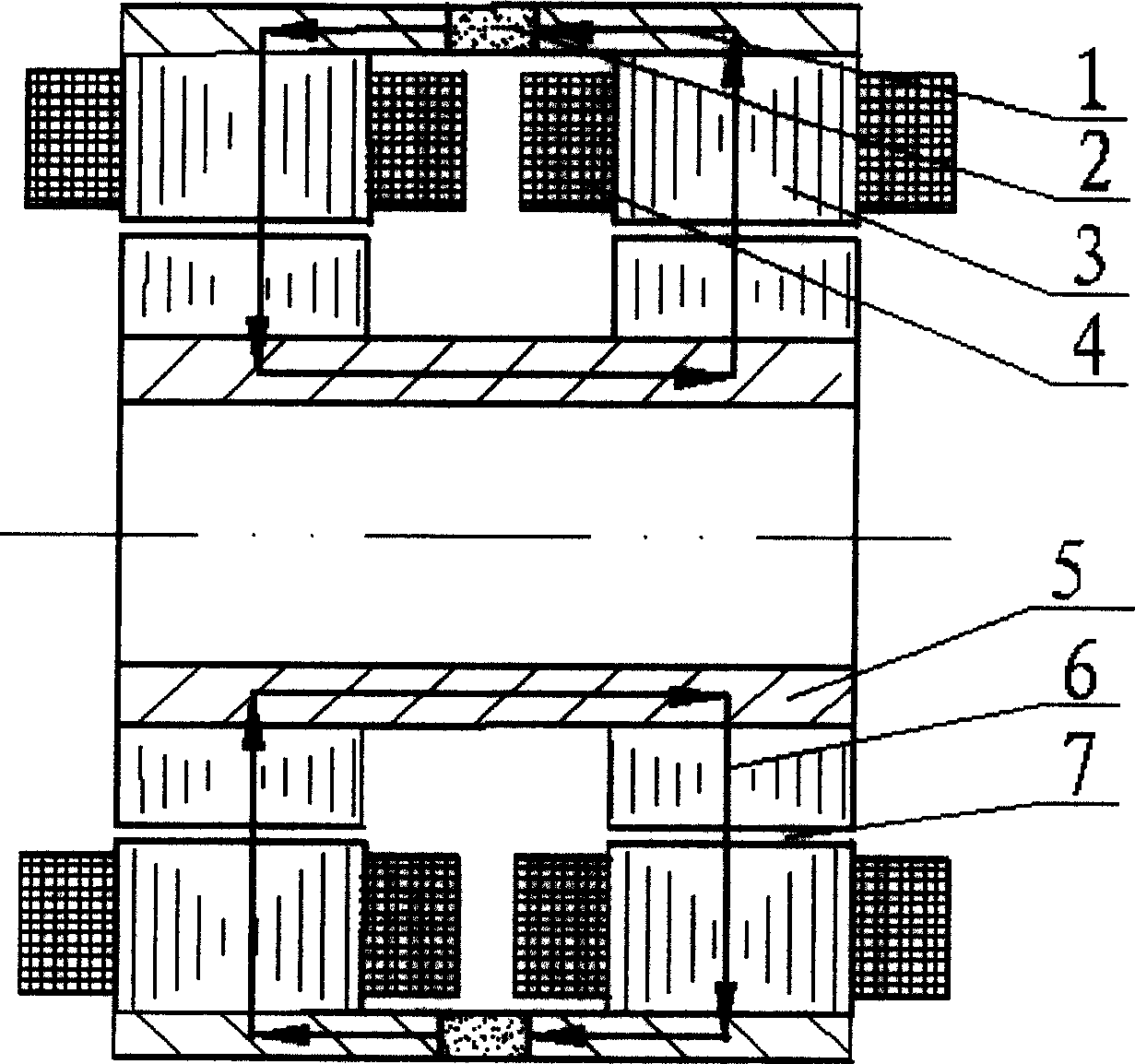

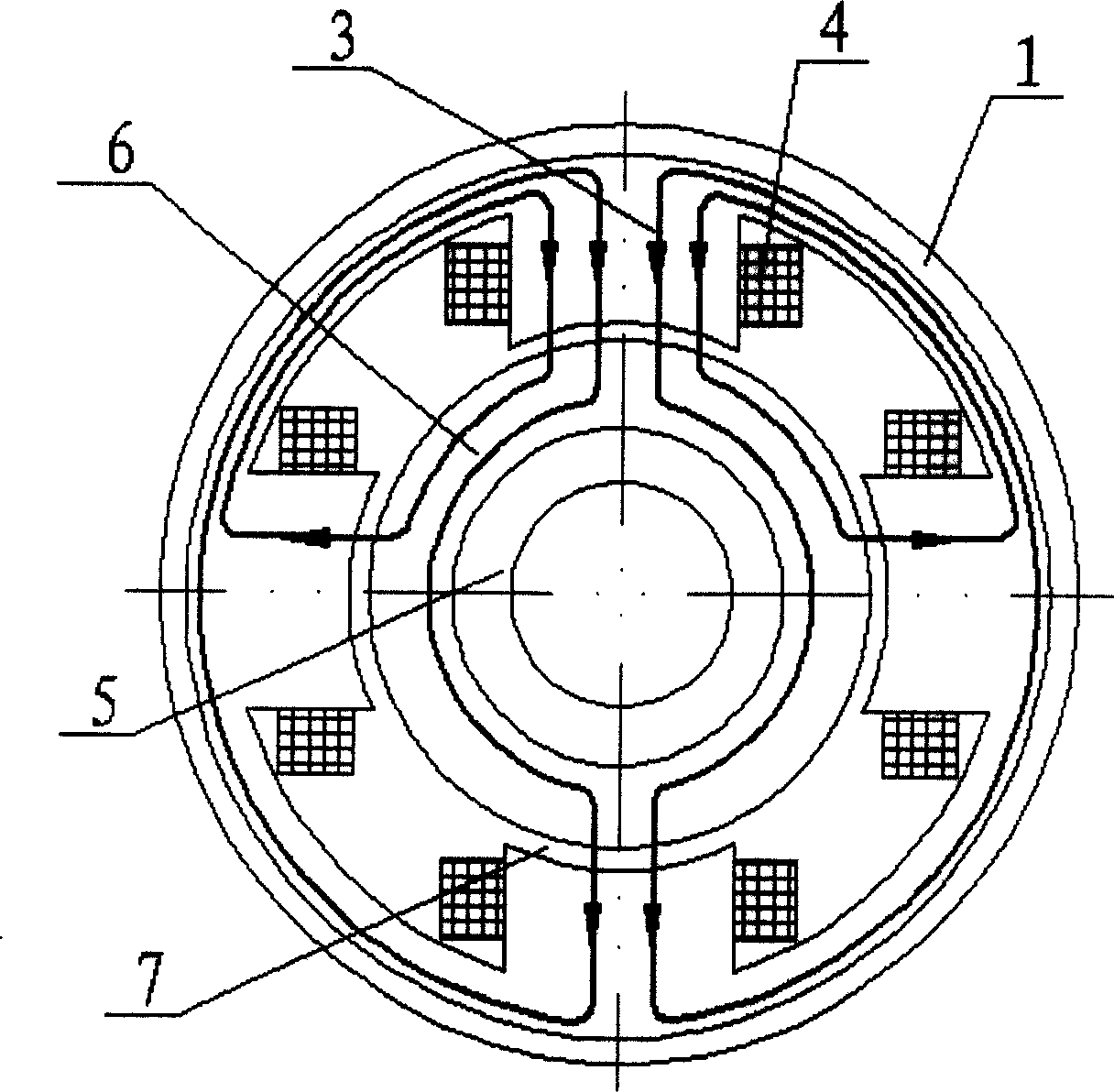

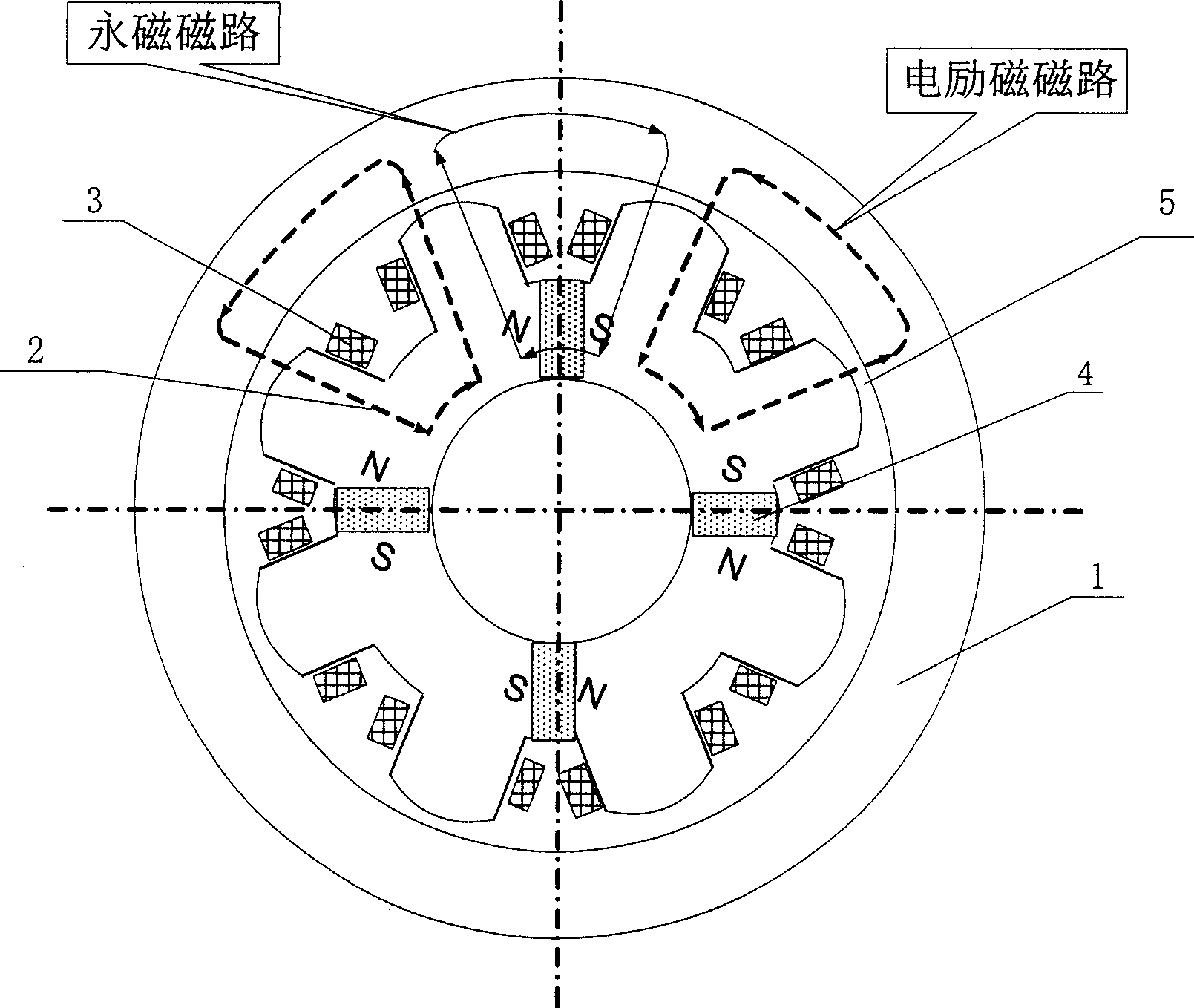

Permanent-magnetic biased axial magnetic bearing

InactiveCN101054997AReduce copper loss and control PA lossesReduce power consumptionEngine componentsBearingsPhysicsConductor Coil

A permanent magnet biased axial magnetic bearing is composed of a stator and a rotor, the stator is composed of four group of stator cores, a permanent magnet and windings, the four group of stator cores compose eight stator poles on circumference direction and are put along +X, -X, +Y, -Y direction, each stator core pole is winded with a winding. An axial magnetic gas gap is formed between the stator and the rotor, an arc permanent magnet is put between two stator core poles in each group of stator core, and a second gas gap is formed on the radial outside by the permanent magnet and two stator core poles of each group of stator core. The invention can realize the axial movement and radial twist control for the magnetic suspension rotor by the four group of stator cores distributed in +X, -X, +Y, -Y direction, and can greatly reduce the axial size of the system. The axial magnetic bearing also has the advantages of low power consume, reliable property and convenient control.

Owner:BEIHANG UNIV

Low power consumption permanent magnet biased internal rotor radial magnetic bearing

The radial magnetic bearing consists of outer magnetizer, permanent magnet, stator iron core, exciting coil, inner magnetizer ring and rotor iron core. Each stator iron core constitutes four stator magnetic poles, and two stator iron cores constitute eight stator magnetic poles on two, right and left, ends of the magnetic bearing and in four, X, Y, -X and -Y, directions. Each of the stator magnetic poles has corresponding wound exciting coil, and the stator iron core has connected outer magnetizer rings, permanent magnet between two outer magnetizer rings, inside rotor iron core with air gap between the inner surface of the stator iron core and the outer surface of the rotor iron core, and inner magnetizer ring to connect the right and left ends of the rotor iron core to form magnetic path. The present invention has the advantages of low power consumption, small size, light weight, easy manufacture, etc. and may be used as the no-contact support for rotating part in machine.

Owner:BEIHANG UNIV

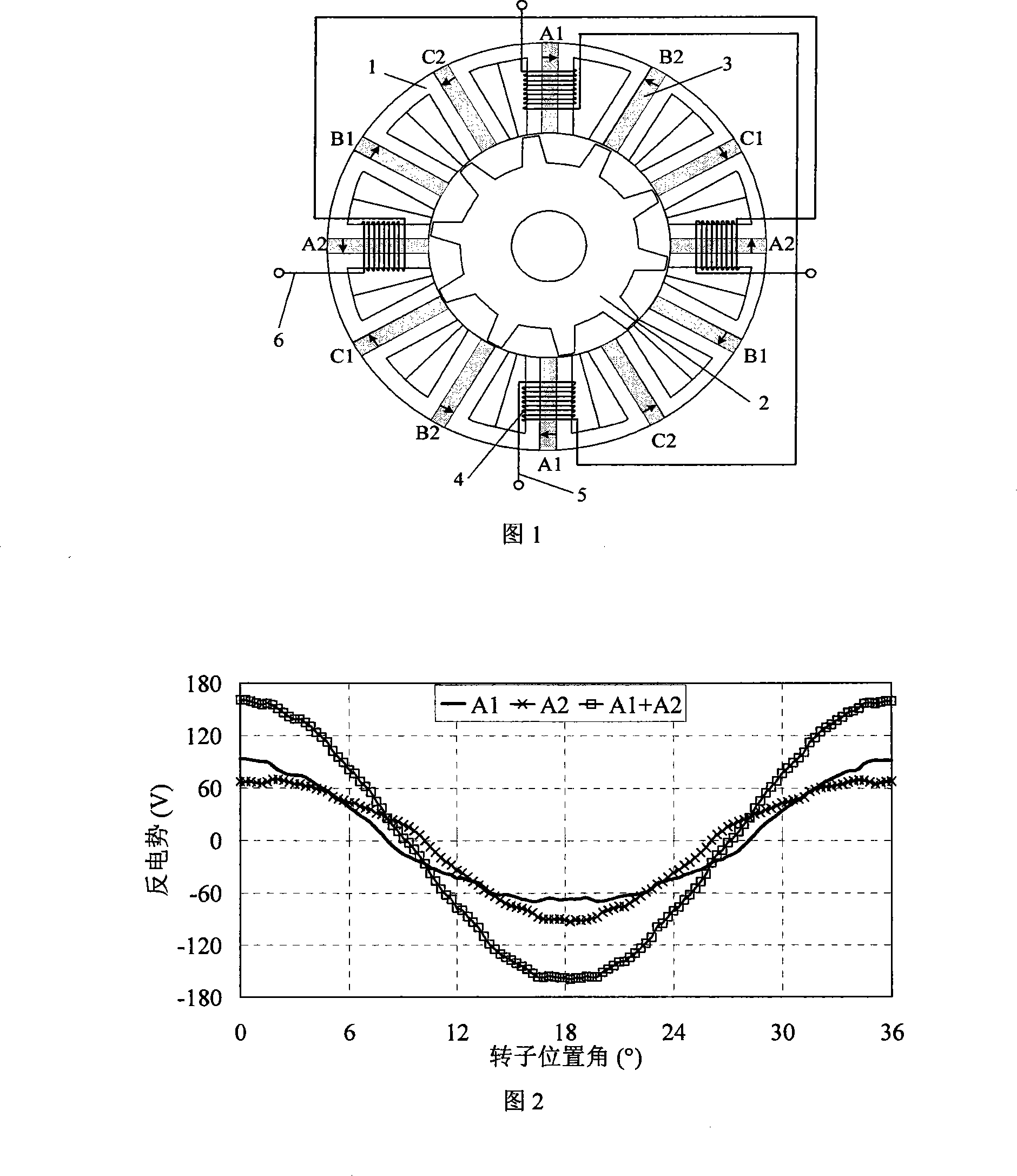

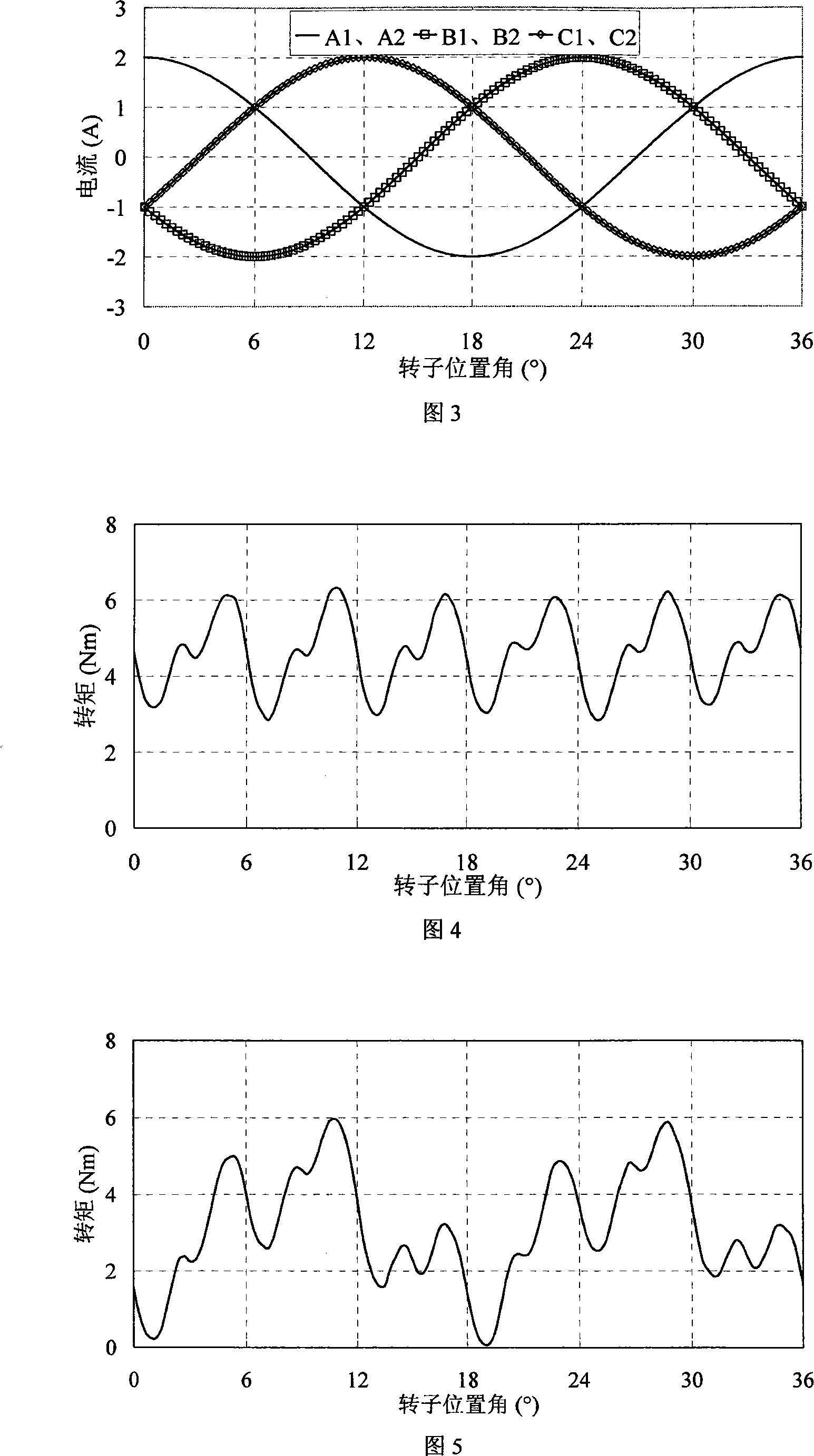

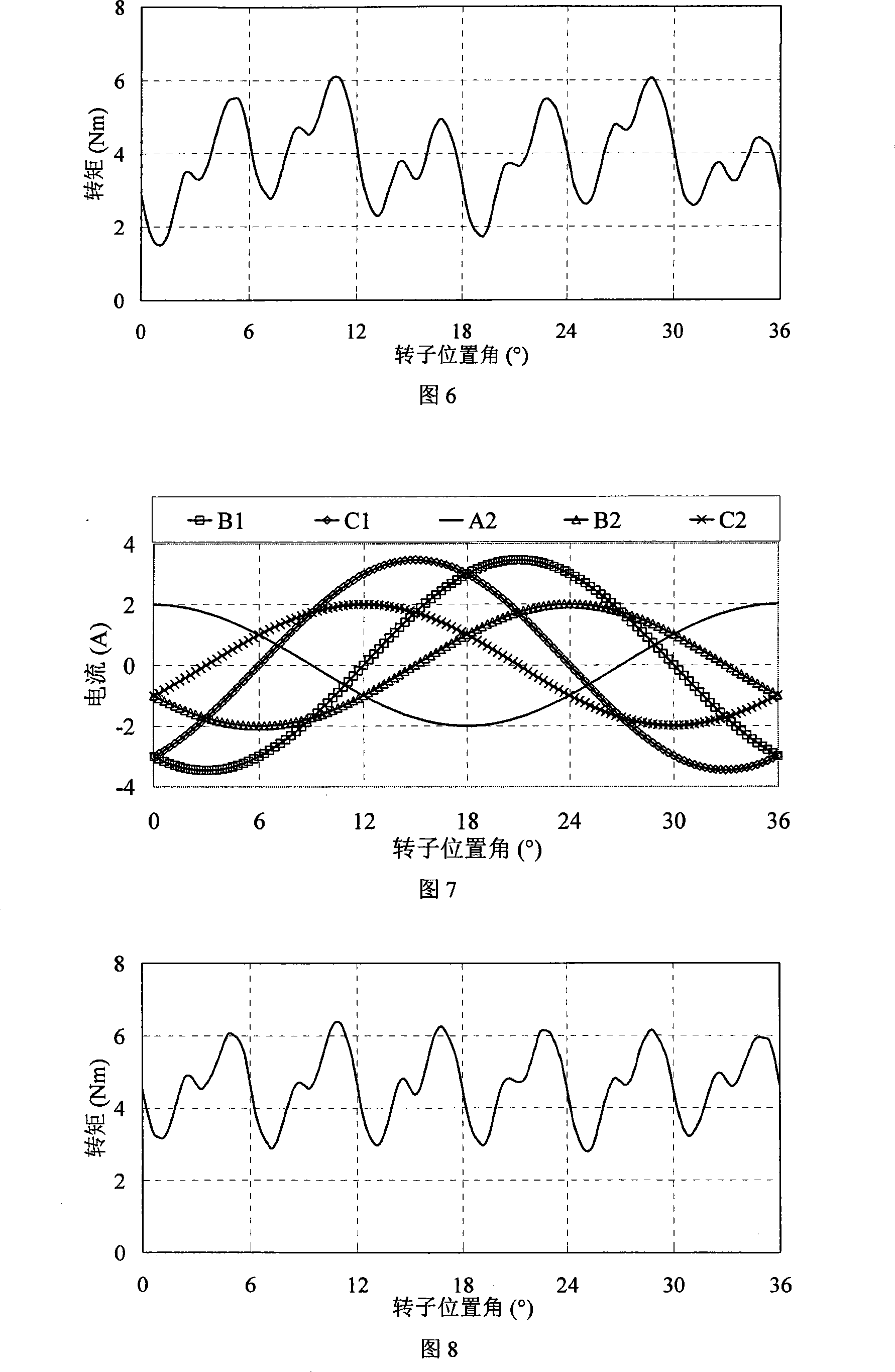

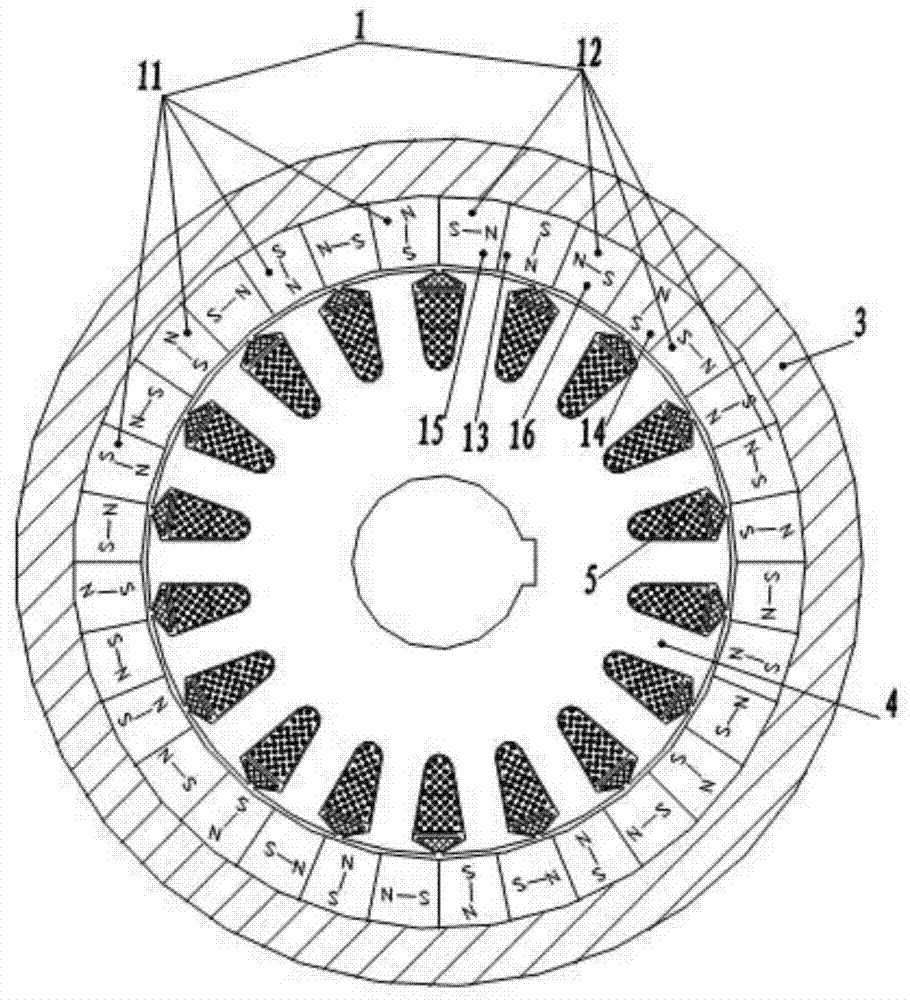

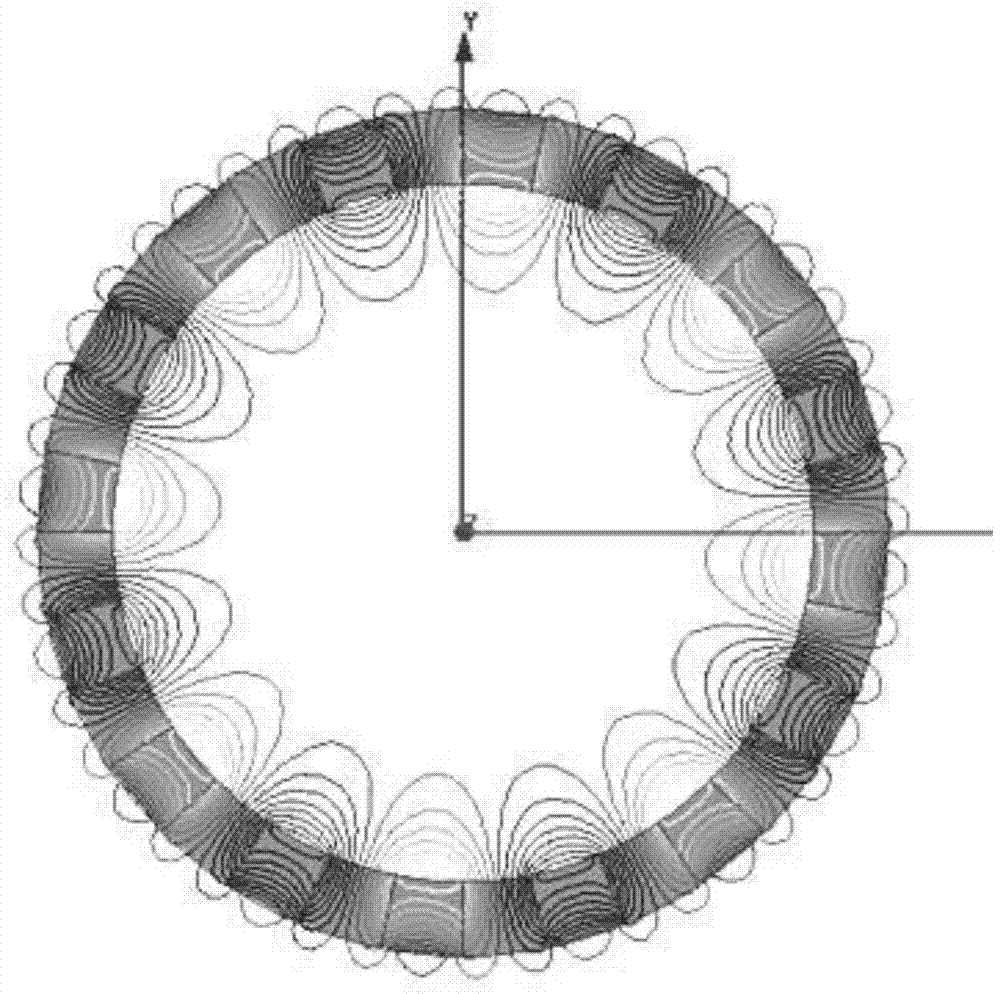

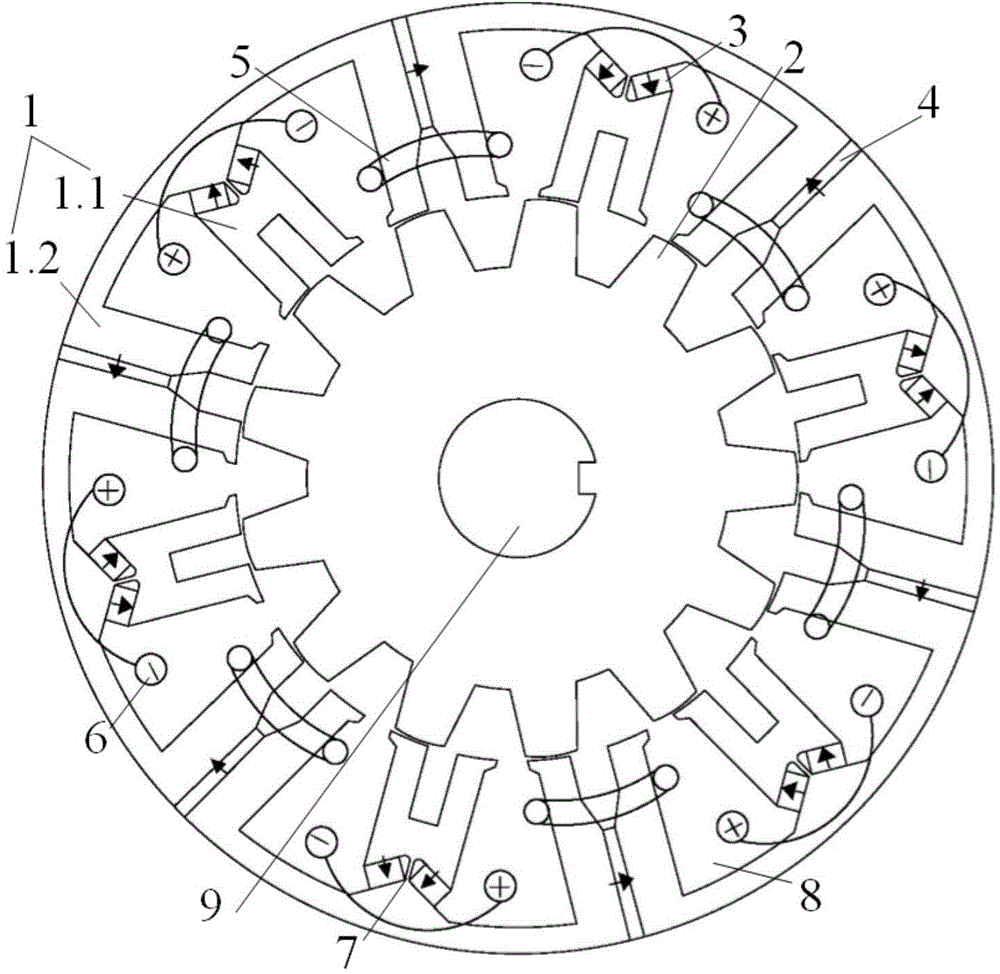

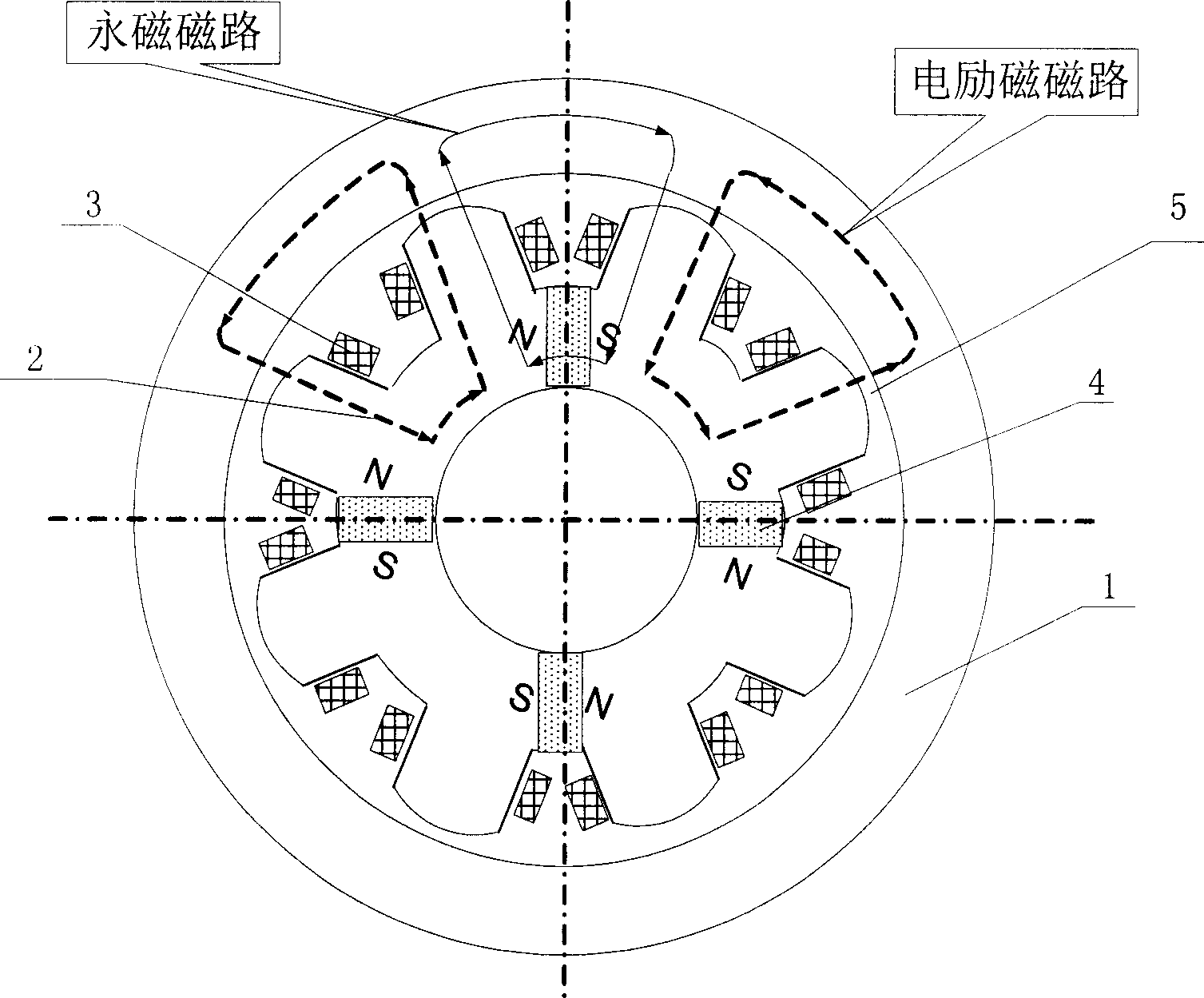

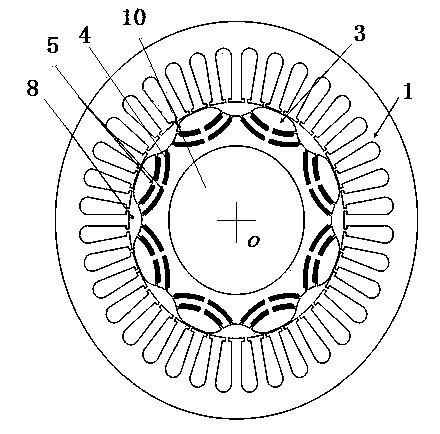

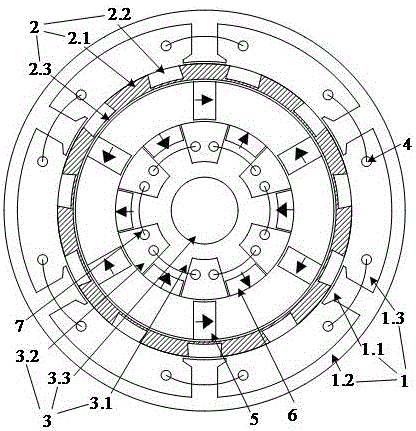

Double-channel fault tolerant type flux switch permanent magnet motor and control method thereof

InactiveCN101159391AImprove reliabilityImprove power densityTorque ripple controlMagnetic circuit rotating partsFault tolerancePhase currents

A dual-channel fault tolerant flux switch permanent magnet motor is a novel stator permanent magnet motor. The fault tolerant motor adopts a doubly salient structure, and the inner loop of the stator (1) is provided with salient poles evenly. Permanent magnets (3) are arranged onto the circle of the stator in pairs, which can be cooled easily; the rotor (2) adopts a simple salient structure, without windings nor permanent magnets. The fault tolerance motor integrates the advantages of a switch magnet resistance motor and a rotator permanent magnet fault tolerance motor, and has the advantages of high credibility, high power density, and preferable operating capacity when a failure occurs. The invention provides a fault tolerance strategy, and can improve the electromagnetic performance of the motor when a failure occurs by adjusting the phase and amplitude of non-fault phase current; the invention can accomplish the torque output in the approximately normal running status and have high theory and practical value.

Owner:SOUTHEAST UNIV

Winding type permanent magnet coupling transmission device

ActiveCN104767357ASimple structureEasy maintenanceMagnetic circuitDynamo-electric gearsPermanent magnet rotorPower flow

Owner:JIANGSU MAGNET VALLEY TECH

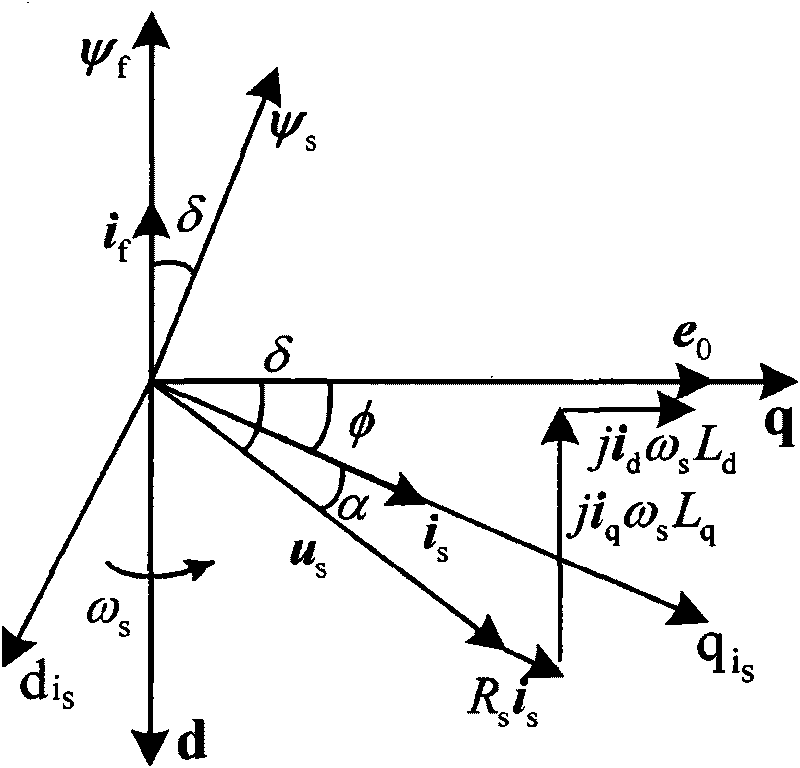

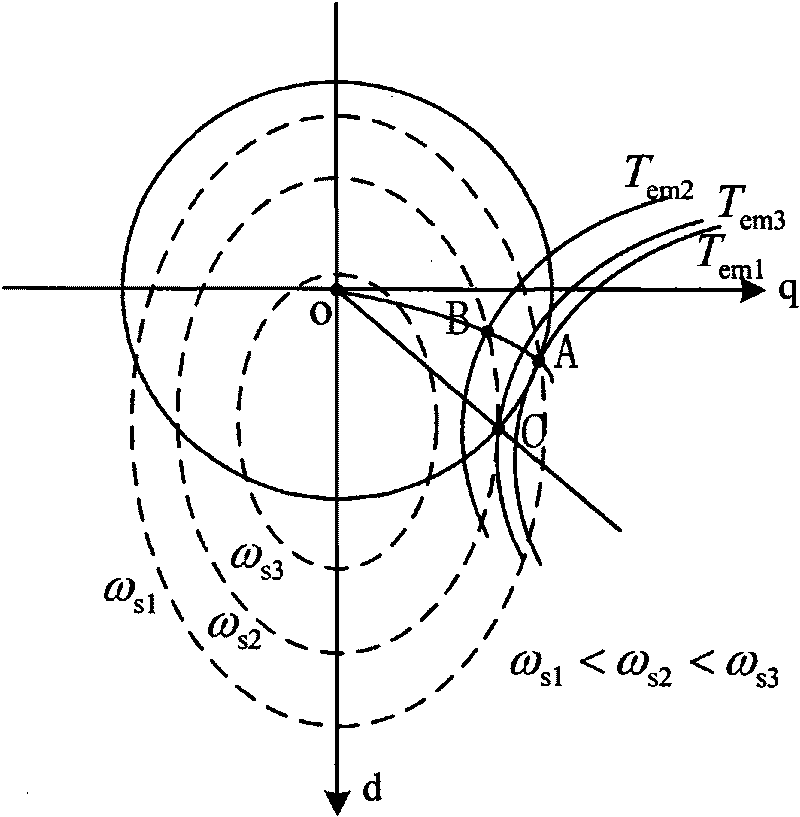

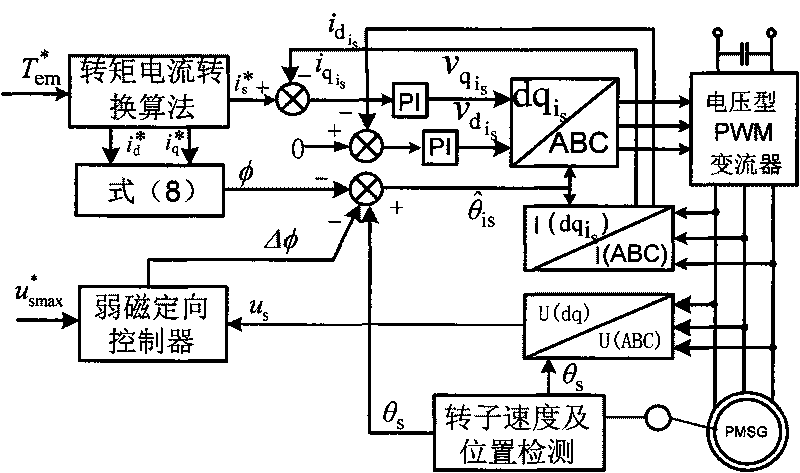

Composite vector control method for permanent magnet synchronous wind generator

ActiveCN101764567AConvenient and free switching controlReduce copper consumptionElectronic commutation motor controlVector control systemsControl mannerMathematical model

The invention relates to a composite vector control method for a permanent magnetic synchronous wind generator, comprising the following steps of: controlling the size and the direction of a stator current vector value according to a mathematical model of the permanent magnet synchronous wind generator by utilizing the vector control method, and establishing a composite vector control strategy of the permanent magnet synchronous wind generator based on stator current orientation. Through the stator current orientation, a maximum torque current ratio control mode is adopted between the cutting speed and the turning speed of the generator so as to improve the generated power of a system; and a weak magnetic control mode with maximum power output is adopted between the turning speed and the limiting speed, therefore, the system efficiency is improved, and the system stability is ensured.

Owner:SUNGROW POWER SUPPLY CO LTD

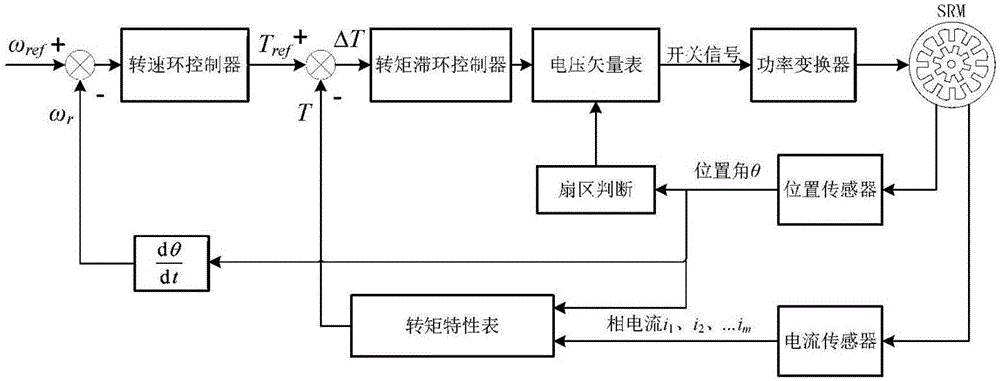

Switched reluctance motor direct instantaneous torque control method based on voltage vectors

ActiveCN105897076AAvoid frequent or sparse hysteresis state switchingReduce inductanceTorque ripple controlAC motor controlHysteresisVoltage vector

The invention discloses a switched reluctance motor direct instantaneous torque control method based on voltage vectors. The switched reluctance motor direct instantaneous torque control method is characterized in that sectors can be divided according to a torque characteristic curve of a switched reluctance motor, and a size of a hysteresis region can be determined in a self-adapted manner according to a torque pulsation coefficient and an expected torque; by considering a torque output capability of a conducted phase of a commutation region, real-time adjustment of a duty ratio of a voltage of every phase can be carried out according to an operation condition and a conduction rule, and the voltage vectors of the direct instantaneous torque control can be refined. The method provided by the invention is advantageous in that the realization costs are low, the sampling period can be expanded, the current pulsation and the torque pulsation can be reduced, the winding copper loss is low, and the practicability is strong.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

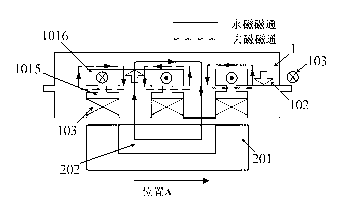

Mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and winding switching magnetism-weakening control method thereof

ActiveCN104578477ASimple structureImprove space utilizationAC motor controlMagnetic circuit stationary partsLow speedMagnetic poles

The invention discloses a mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and a winding switching magnetism-weakening control method thereof. The mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor comprises a salient rotor and a stator, wherein the stator contains stator cores, aluminium-nickel-cobalt permanent magnets, neodymium-iron-boron permanent magnets, centralized armature windings and pulsed magnetism-adjusting windings; iron core edges of two adjacent outer U-shaped units and tangentially-magnetized long-stripped neodymium-iron-boron permanent magnets form a first permanent magnetic pole, while the circumferentially-inward (outward) and parallel-magnetized V-shaped embedded aluminium-nickel-cobalt permanent magnets and inner U-shaped units form a second permanent magnetic pole; mixed magnetic poles are in alternating polarity distribution; when the motor runs at a low speed, the pulsed magnetism-adjusting windings are in direct-current pulsed working state, while in a high-speed weak-magnetism area, the pulsed magnetism-adjusting windings are converted into alternating-current armature windings. Requirements on performance in a low-speed area and in the high-speed area can be met at the same time; influence of an armature reaction field on the aluminium-nickel-cobalt permanent magnets with low coercivity is small; the utilization rate of permanent magnetism, the torque density, and the reliability of system operation are high.

Owner:SOUTHEAST UNIV

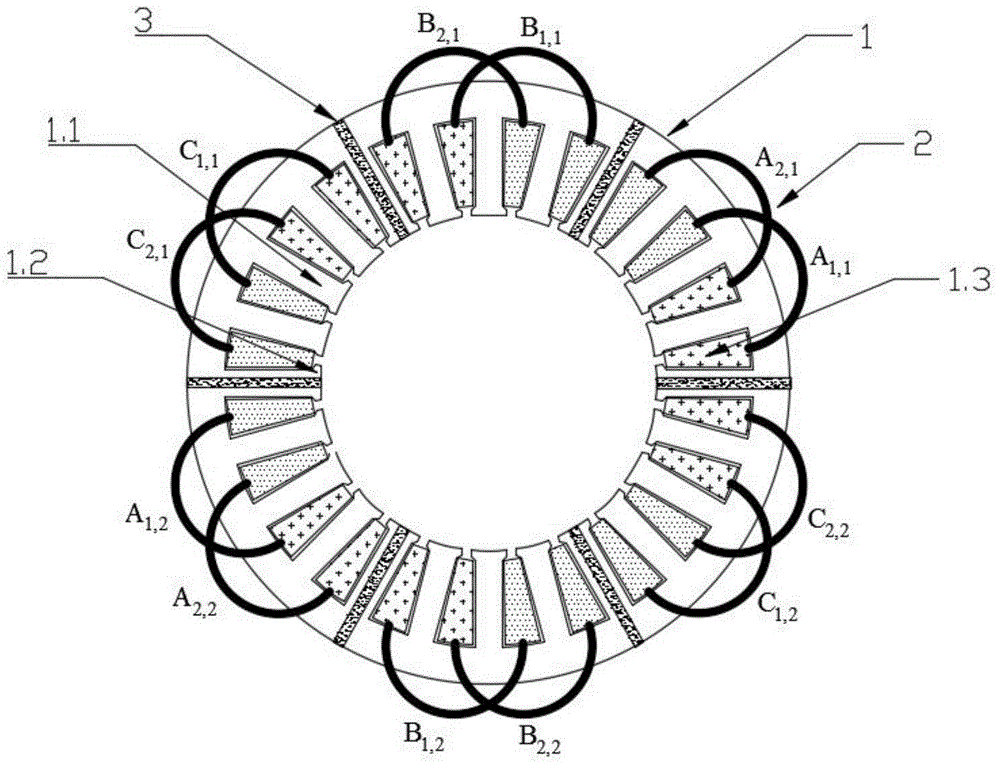

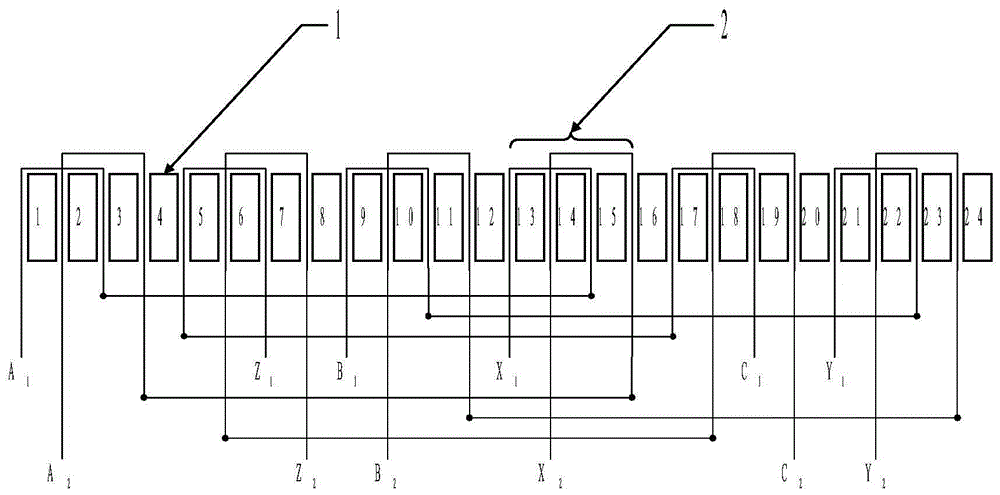

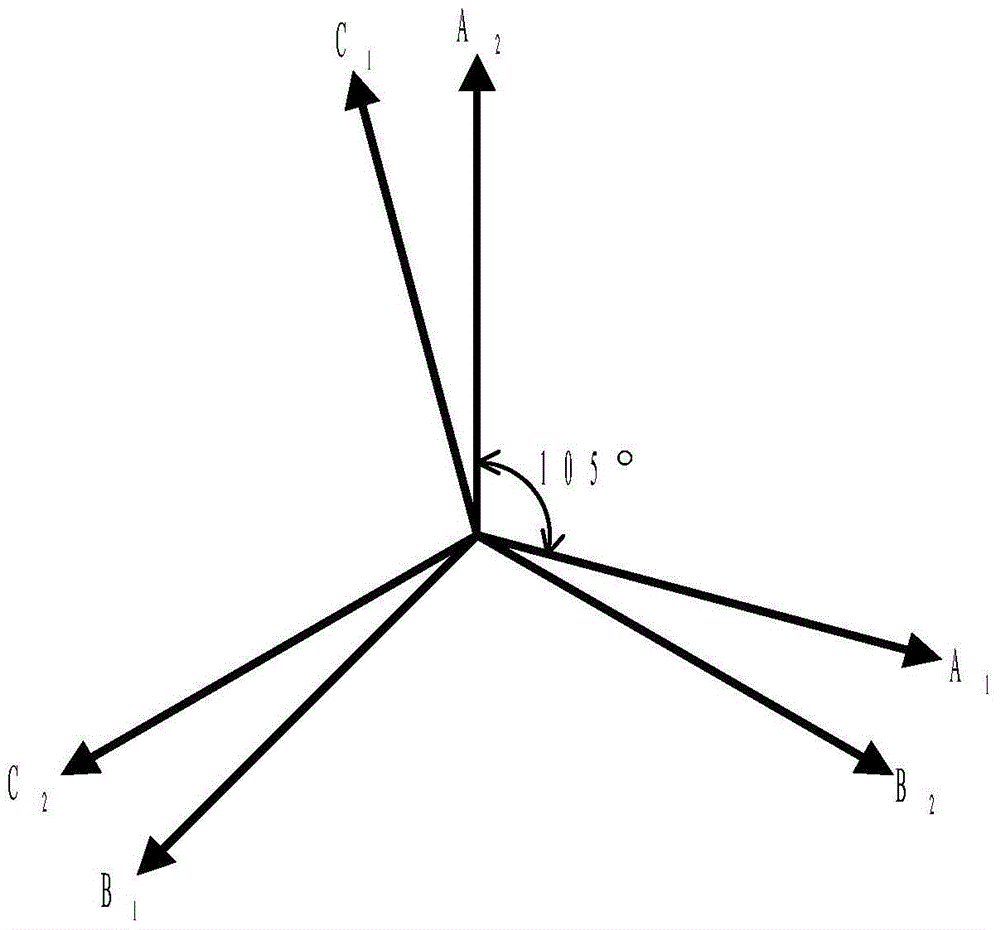

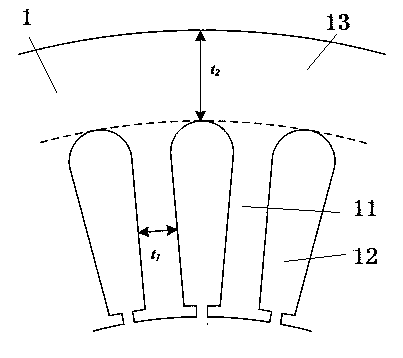

Structure for modular motor stator and end part overlapping fractional slot windings of modular motor stator

ActiveCN105680585ASmall torqueReduce torque rippleMagnetic circuit stationary partsWindings conductor shape/form/constructionMagnetomotive forceHarmonic

The invention provides a structure for a modular motor stator and end part overlapping fractional slot windings of the modular motor stator. The number of stator slots and the number of winding pole pairs are set to be 2Z and p respectively, wherein the stator slots are evenly distributed on the circumference; the stator comprises two sets of three-phase symmetric AC windings; the windings are evolved from traditional single-layer concentrated fractional slot windings; the arrangement of each set of windings is the same as that of the traditional single-layer concentrated fractional slot windings with Z slots and p pole pairs; the staggered angle of two sets of windings is one half of a coil span mechanically; overlapping regions at the end parts of the windings are distributed on the circumference of the stator at intervals; and modularization can be achieved by cutting the stator in the non-overlapping regions at the end parts of the windings. The structure can greatly reduce the non-working tooth harmonic content in magnetomotive force of the traditional concentrated fractional slot windings, so that the motor loss can be reduced; torque pulsation is stabilized; the noise is reduced; meanwhile, the structure has the advantage that the motor stator with the concentrated fractional slot windings can be modularized; manufacturing, transportation and assembly of a large motor are facilitated; the interphase mutual inductance is small; and improvement of the fault-tolerant capability of the motor is facilitated.

Owner:SOUTHEAST UNIV

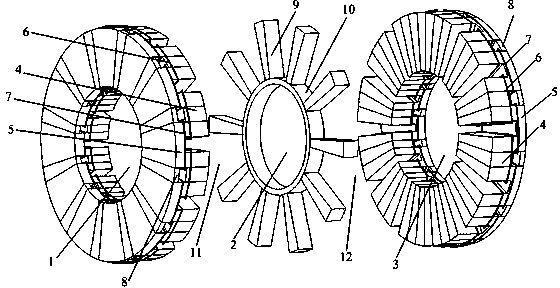

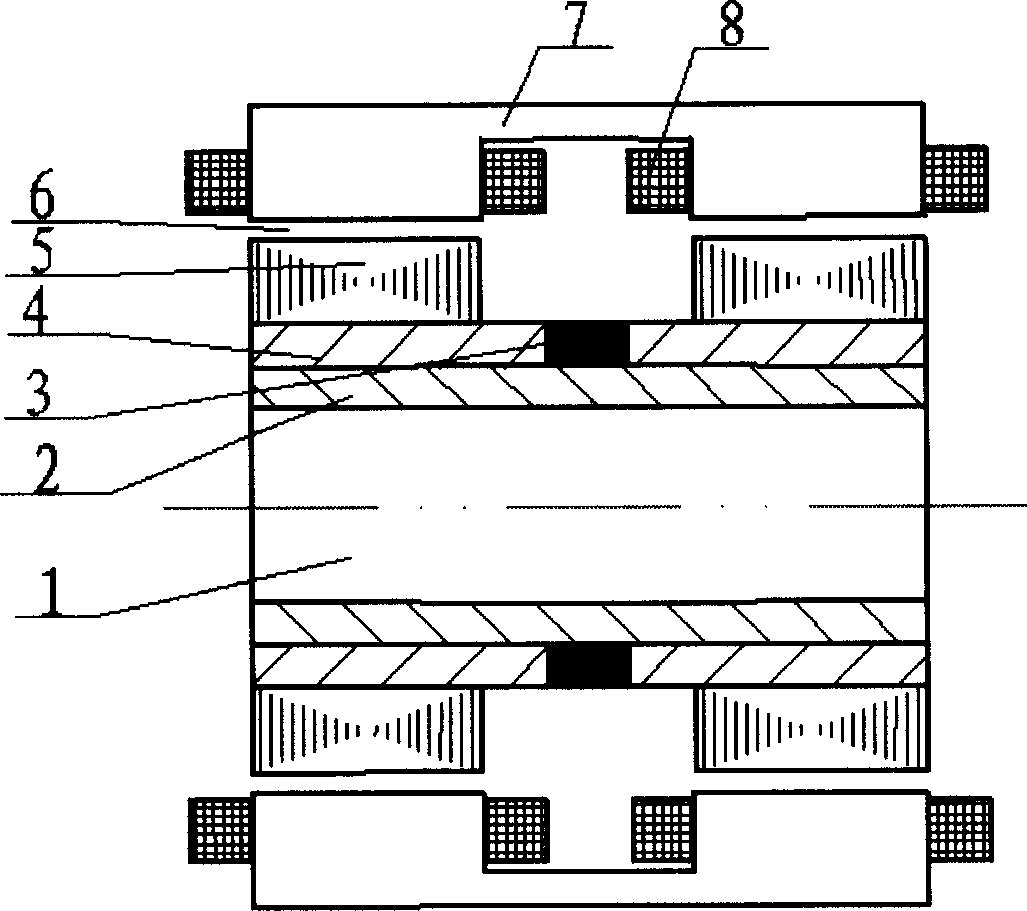

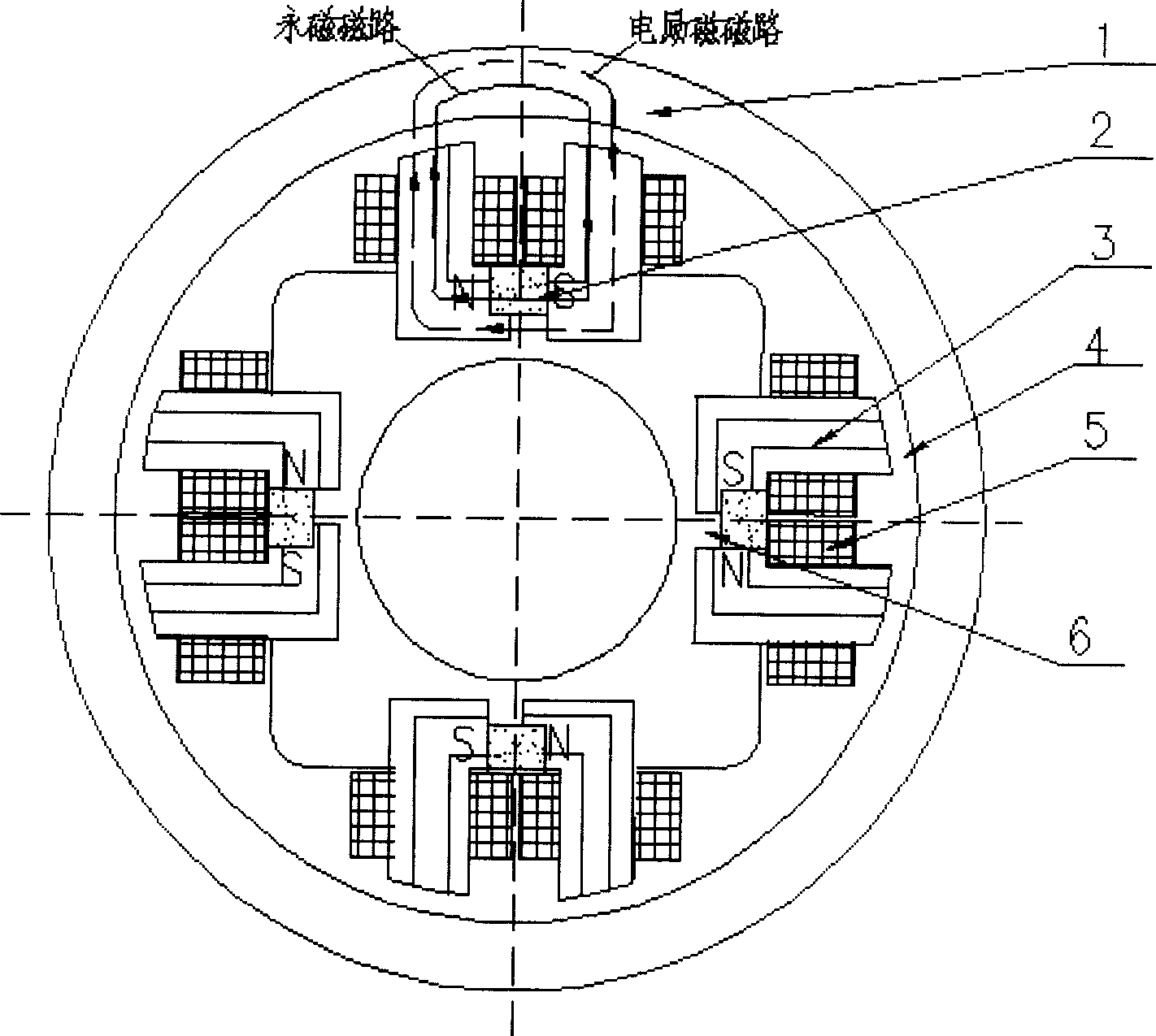

Double-stator disc type mixed excitation motor

InactiveCN103390978ASimple structureAdjusting the air gap magnetic fieldElectric machinesMagnetic circuit stationary partsElectric machineExcitation current

The invention discloses a double-stator disc type mixed excitation motor which comprises two stators, a permanent magnet, a three-phase concentrated armature winding, a single-phase concentrated excitation winding and a rotor. The stators and the rotor are arranged coaxially, and the rotor is arranged between the two stators. The permanent magnet, the armature winding and the electric excitation winding are all located on the stators. The rotor is free of the permanent magnet or the windings and simple in structure. An air-gap magnetic field is formed by an electric excitation magnetic field generated by the electric excitation winding and a permanent magnetic field generated by the permanent magnet, and adjusting of the air-gap magnetic field is achieved by changing electric excitation current. The motor structurally reserves the characteristics of a disc type magnetic flux switching permanent magnetic motor of being compact, simple and suitable for high-speed operation, can achieve a mixed excitation function without increasing the motor size additionally and guarantees good torque output capacity and high power density. The motor is small in axial size and suitable for strict and thin type installing in places of a hub driving motor for electromobile and the like.

Owner:SOUTHEAST UNIV

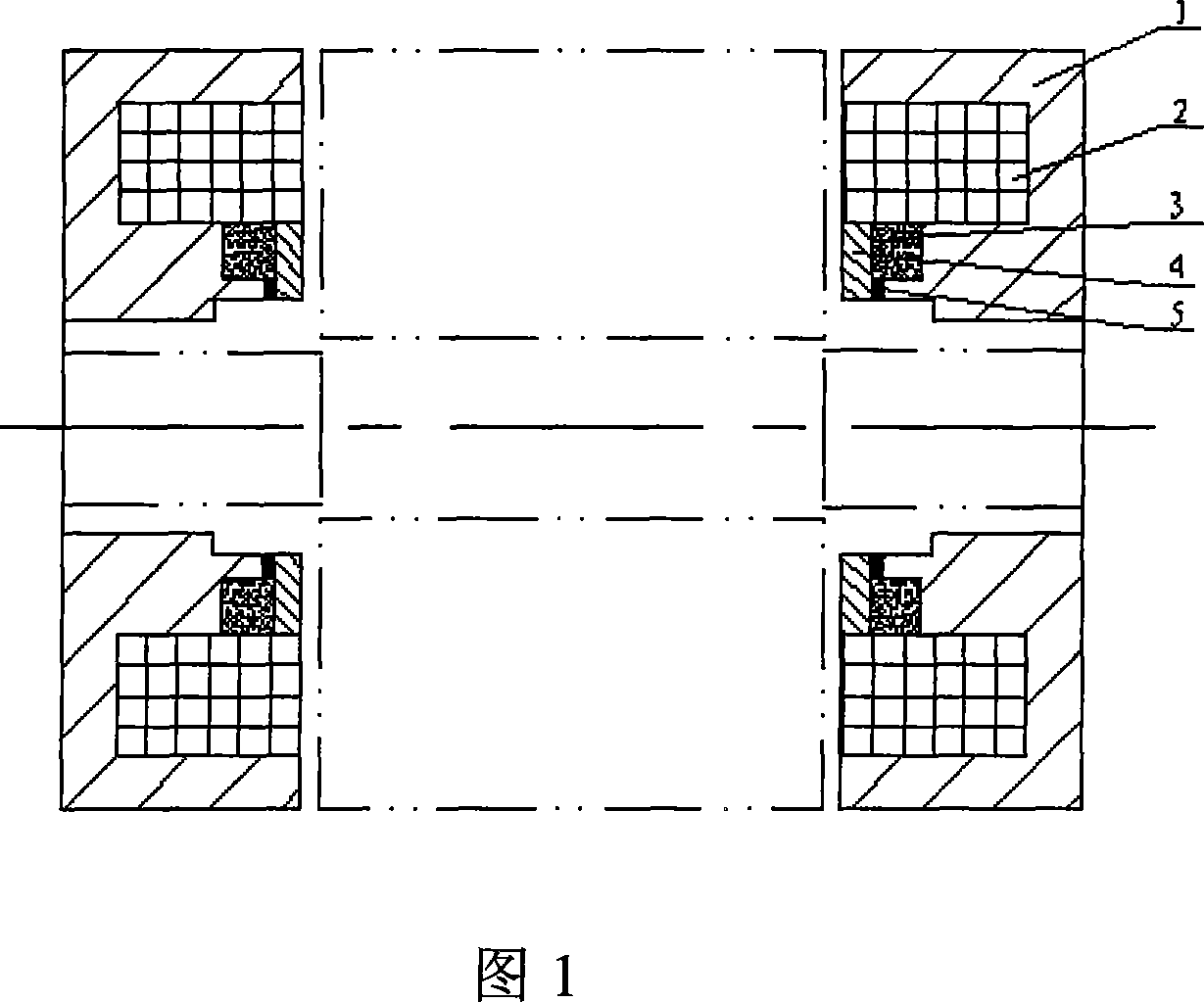

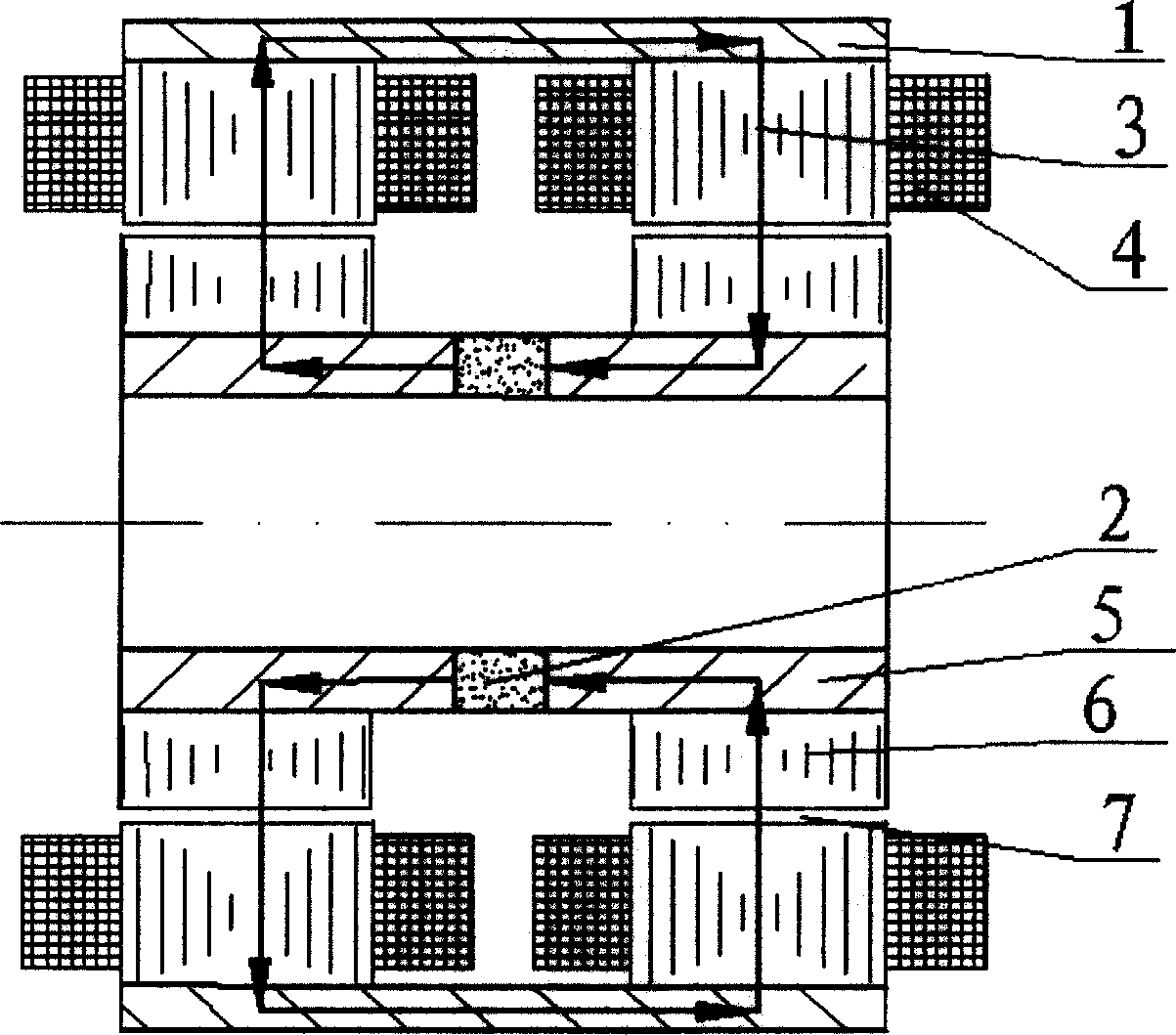

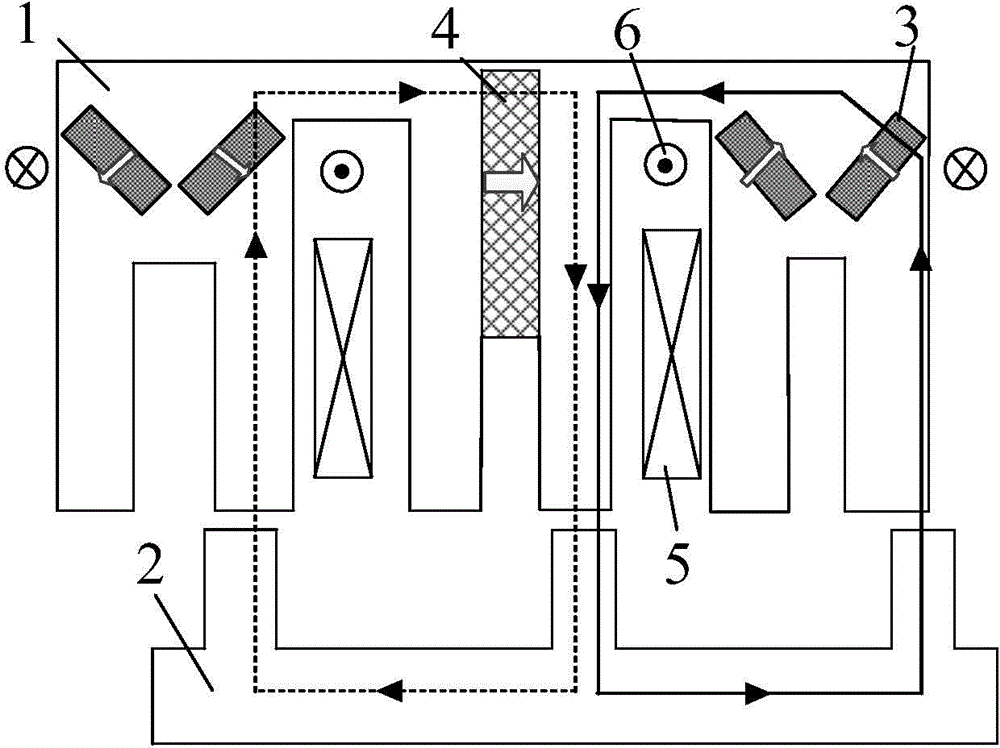

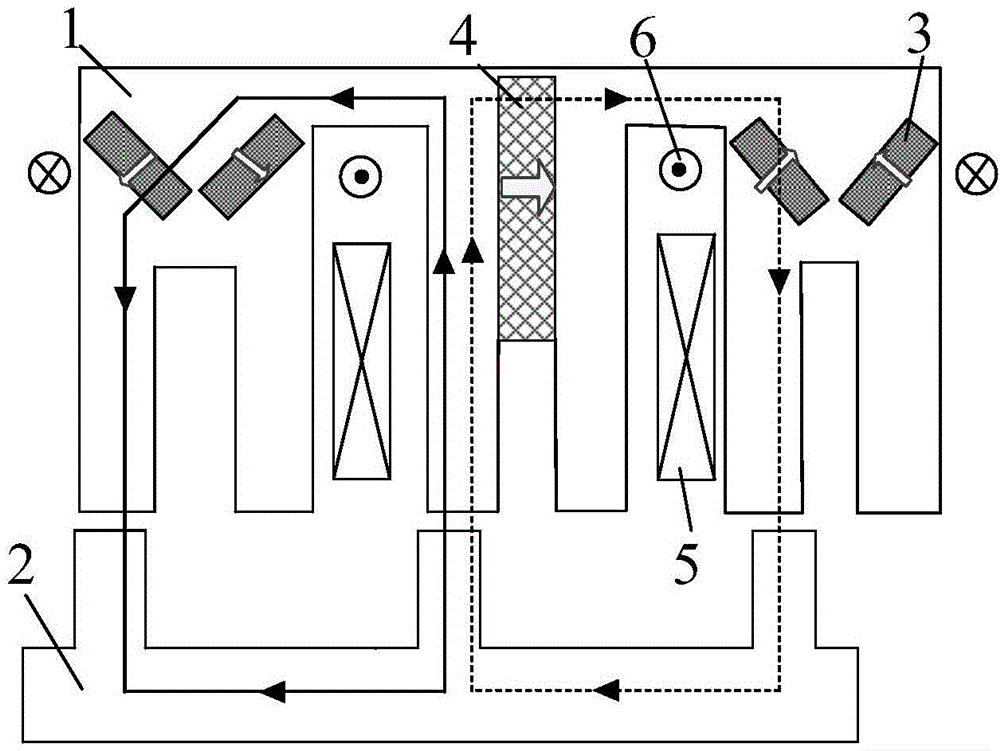

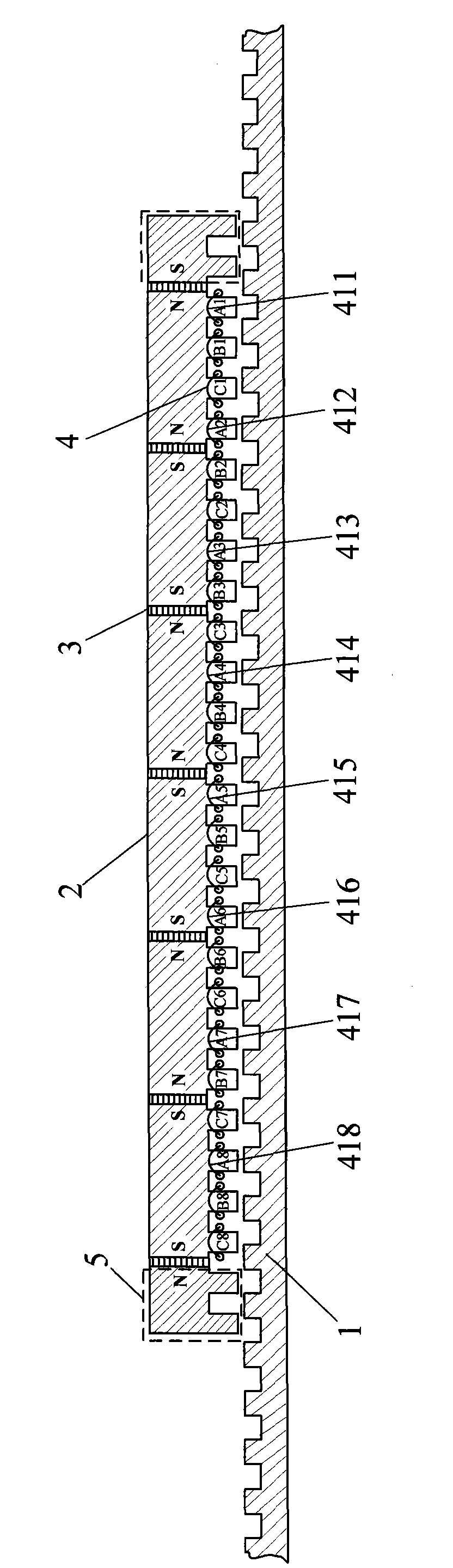

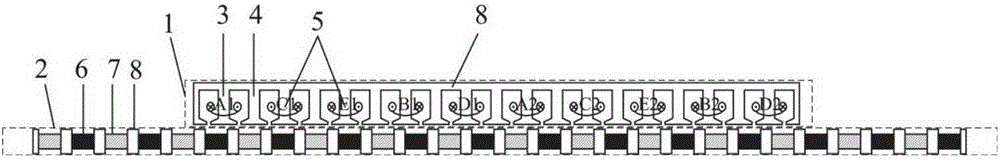

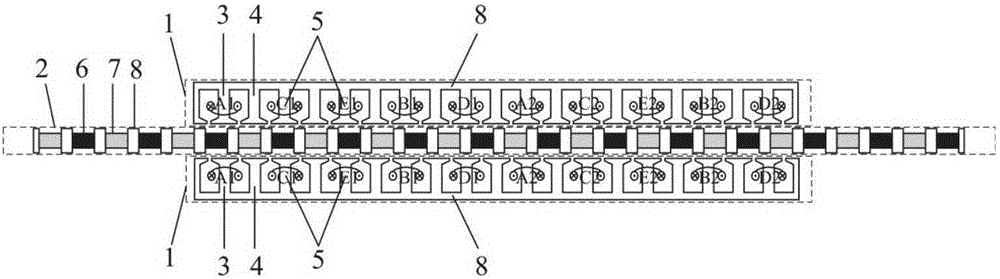

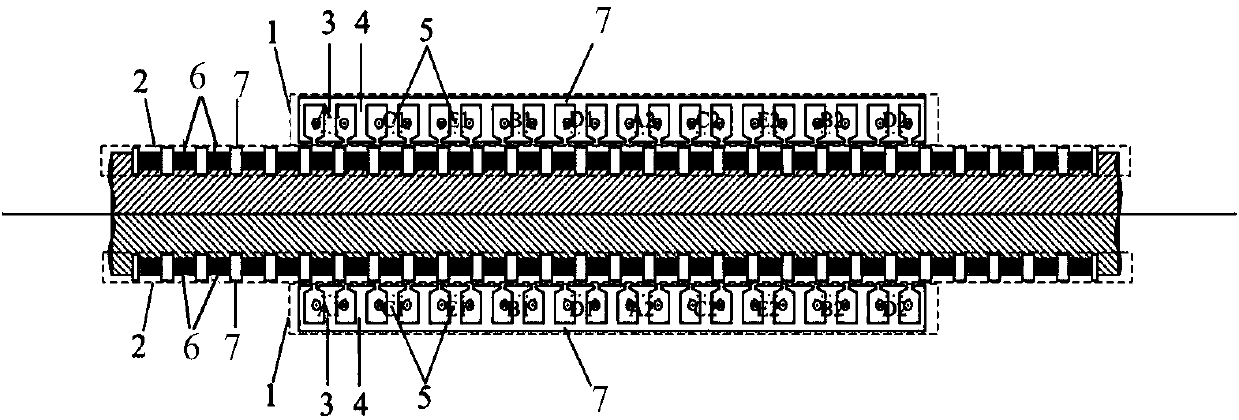

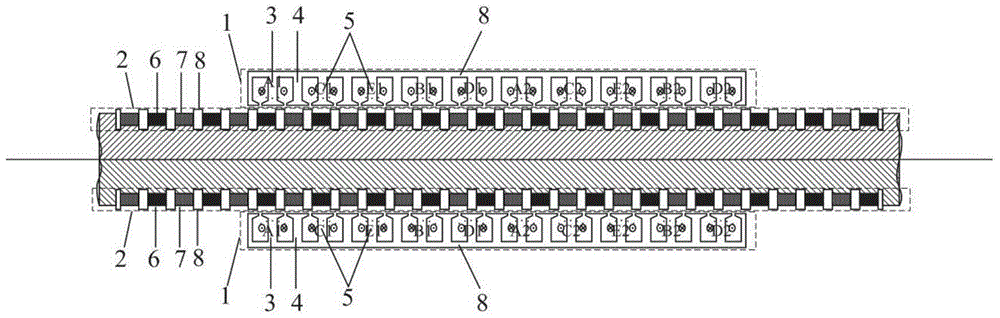

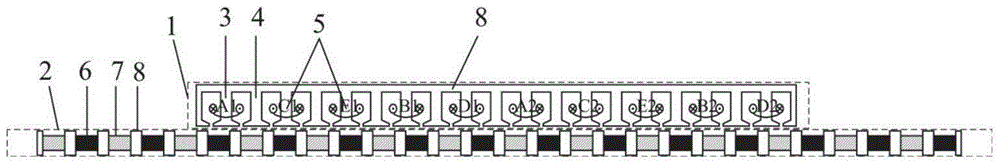

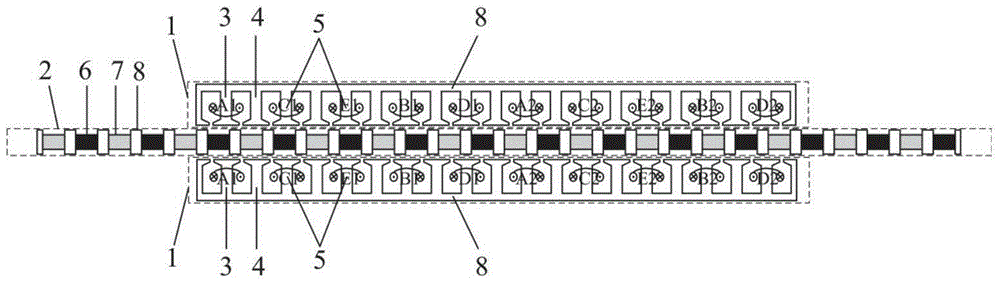

Multiphase long-stator primary permanent magnet linear motor

ActiveCN101783573AImprove cooling conditionsCompact structureMagnetic circuit rotating partsMagnetic circuit stationary partsPrimary permanentElectric machine

The invention relates to a multiphase long-stator primary permanent magnet linear motor which has the advantages of simple structure, firmness, stronger output thrust, higher power density and smaller thrust fluctuation. The motor comprises a stator (1), an air gap and rotors (2), wherein each rotor (2) comprises permanent magnets (3), a concentrated winding (4) and additional teeth (5); both the stator and the rotors are double-salient pole single-edges or double-edge flat-panel structures, and all concentrated winding coils of any phase are positioned in a rotor iron core slot; adjacent permanent magnets (3) form a serial magnetic circuit; the number of the permanent magnets (3) is NPM=2k*m+2, wherein k is a positive integer, and the number m of motor phases is not smaller than 3; both end parts of each rotor (2) are respectively provided with a permanent magnet which is an additional permanent magnet of each motor; the number of windings of the rotors is Nmt=(NPM-2)(m+1); and the central distance of adjacent teeth of the rotors is tau p.

Owner:SOUTHEAST UNIV

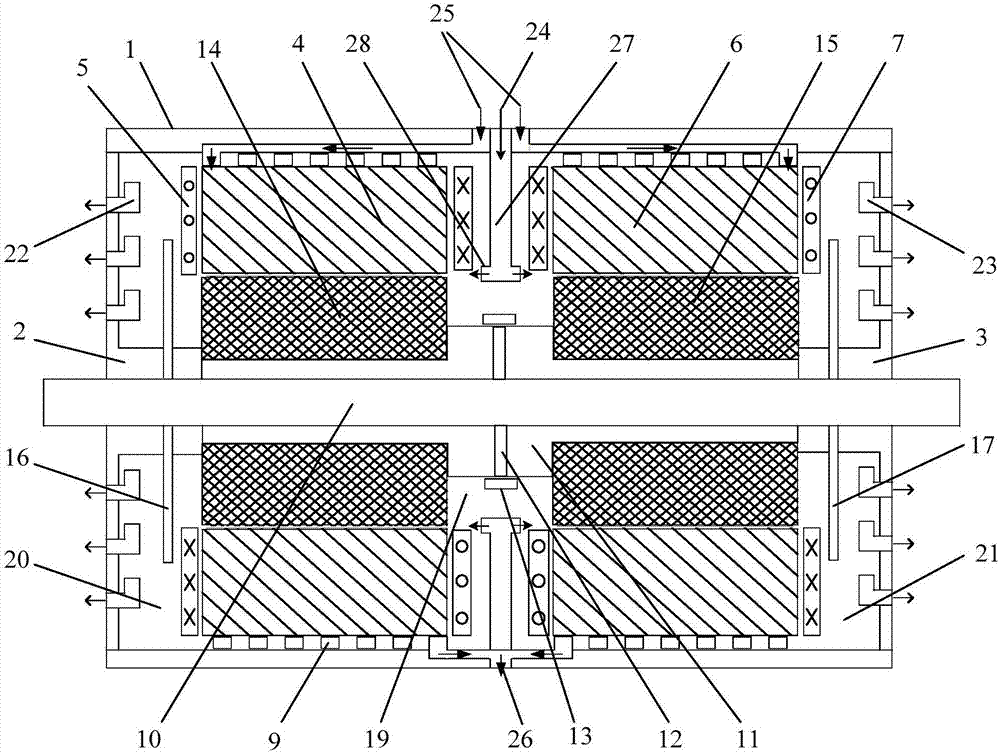

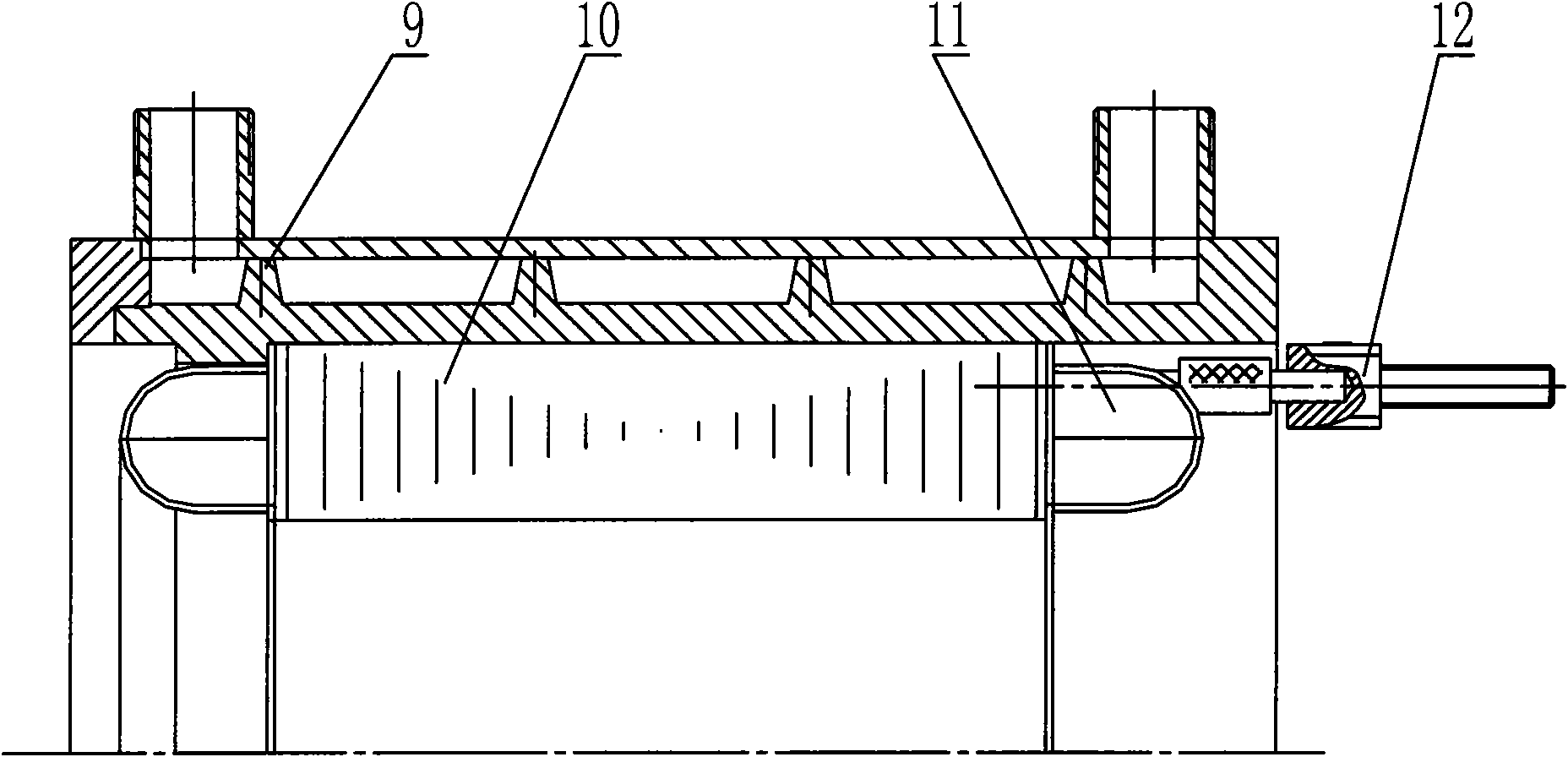

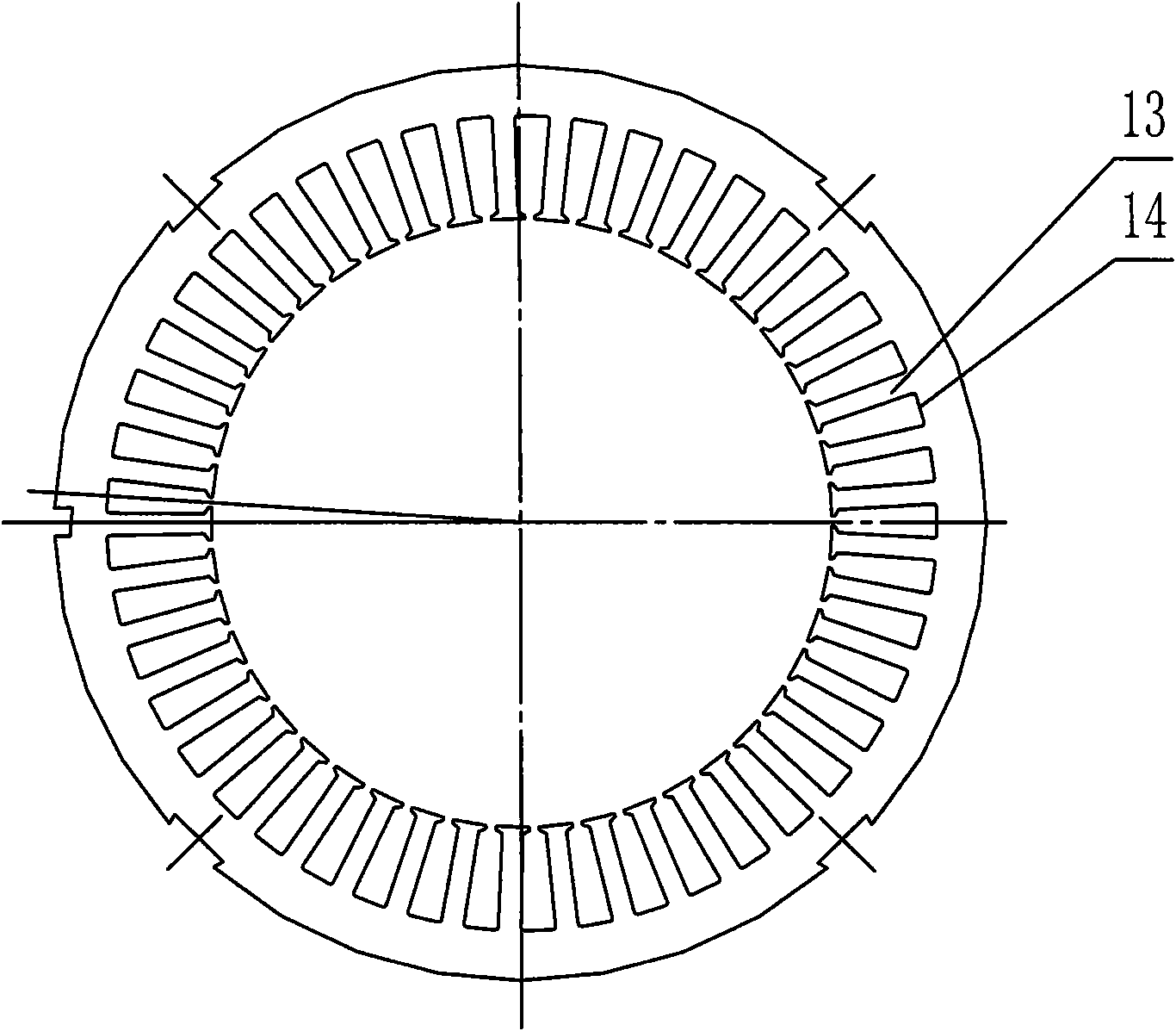

Axial permanent magnet assisted radial reluctance high-speed motor with hybrid cooling structure

PendingCN107147260AReduce consumptionReduce copper consumptionMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic reluctance

The invention provides an axial permanent magnet assisted radial reluctance high-speed motor with a hybrid cooling structure, and relates to the technical field of motors. The motor provided by the invention is provided with an air cooling and water cooling structure on the basis of a dual group 6 / 4-pole switched reluctance motor structure. The motor comprises a casing, a front end cover, a rear end cover, a rotor and a stator, and is characterized in that an inter-tooth slot of the stator and the rotor form a cooling air channel, each end cover is provided with air discharging holes, the casing is provided with a cooling air inlet, a cooling water inlet pipe opening, a cooling water outlet pipe opening and a circumferential ring-shaped air guiding channel, the back of a ring yoke of the stator is provided with a spiral water channel pipe, and two ends of the rotor are provided with self-cooling fans respectively. According to the invention, a cooling structure combining the air cooling stator and the water cooling stator is adopted, and a water cooling function and an air cooling function are opposite in direction and complementary in cooling region, so that the stator and the rotor of the motor are effectively enabled to be reduced in temperature, a problem of difficult heat dissipation of the motor under a high-speed operating condition is avoided, thus long-term safe and stable running of the motor is ensured, and the service life of the motor is effectively prolonged.

Owner:SHENYANG POLYTECHNIC UNIV

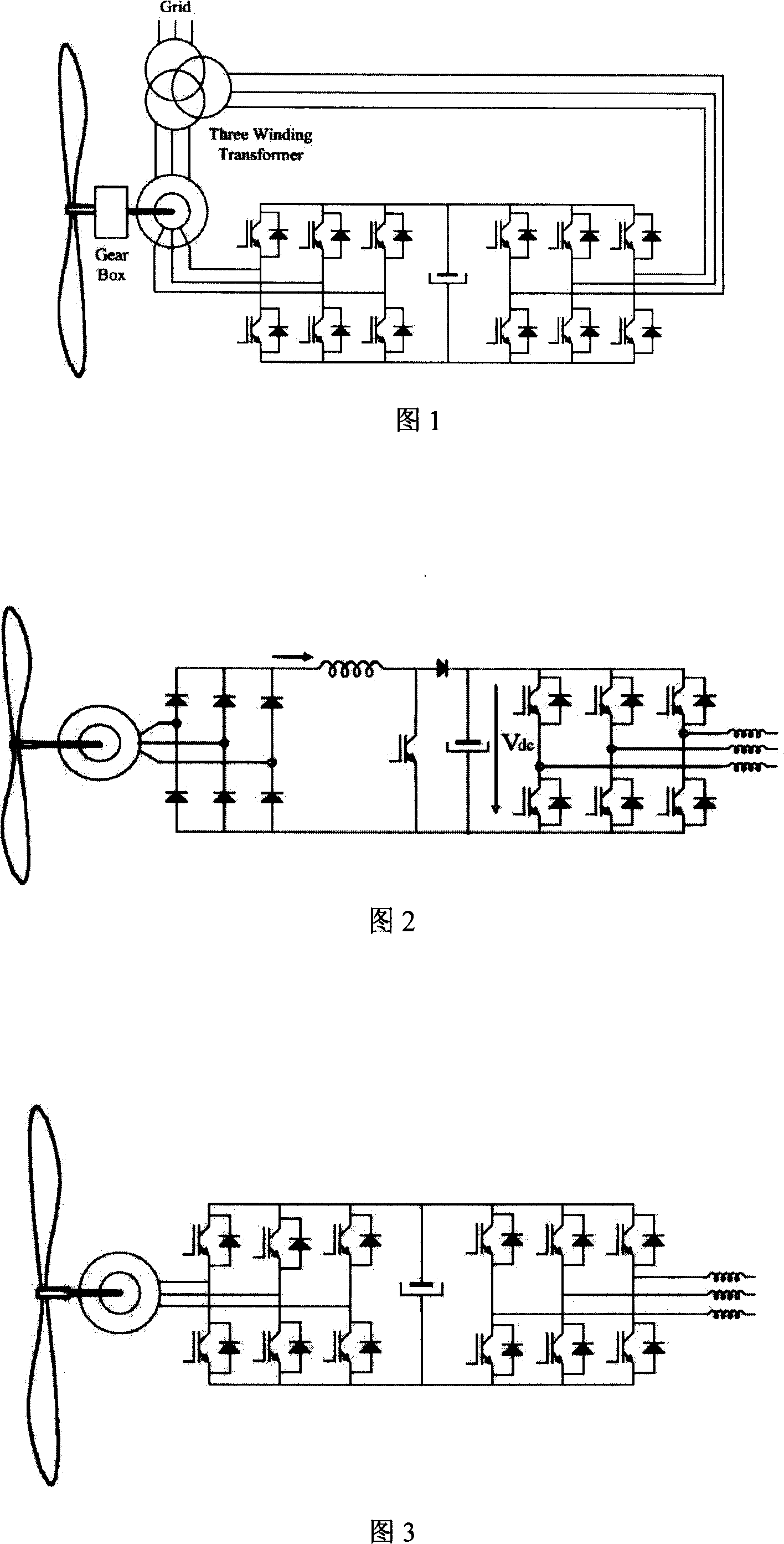

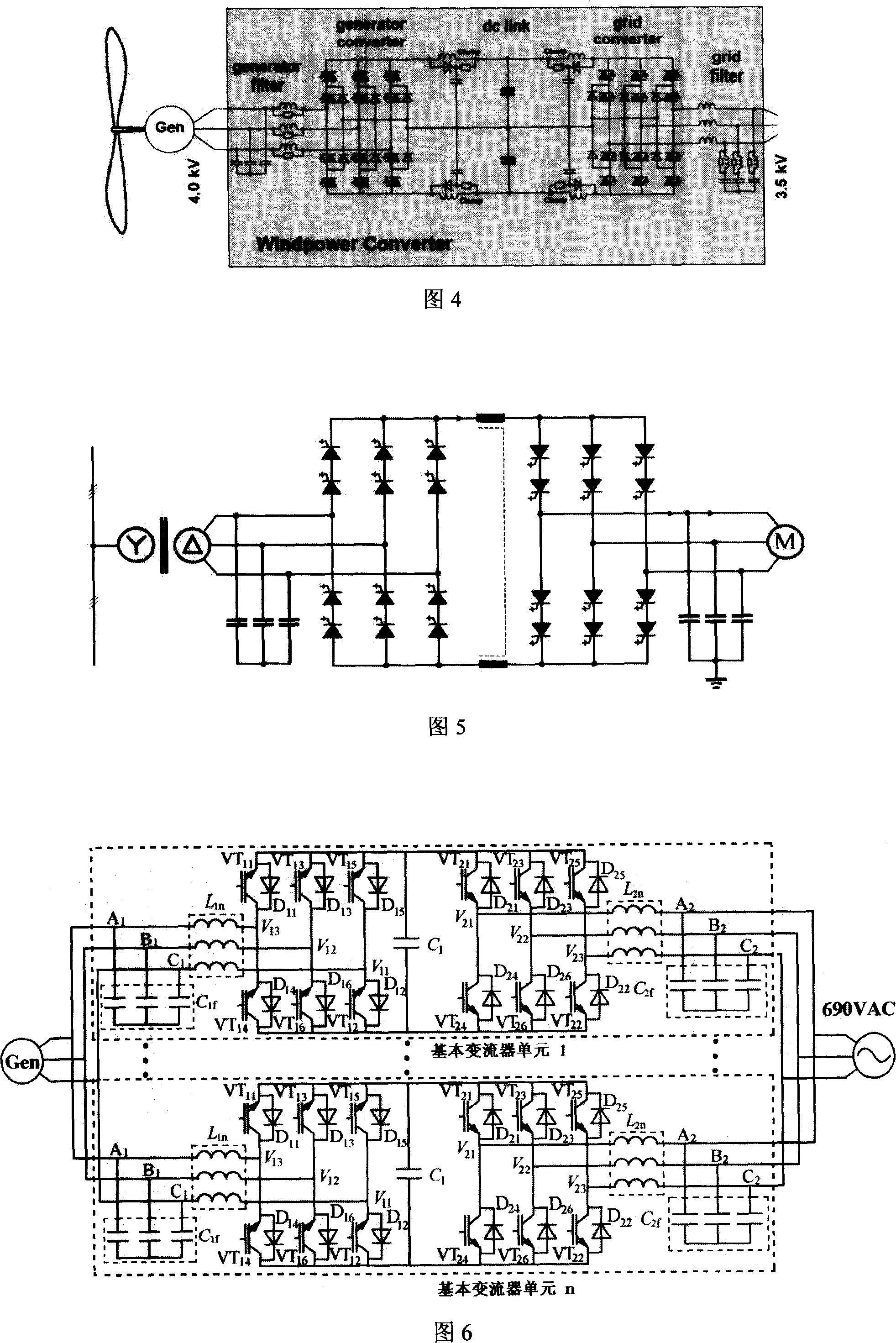

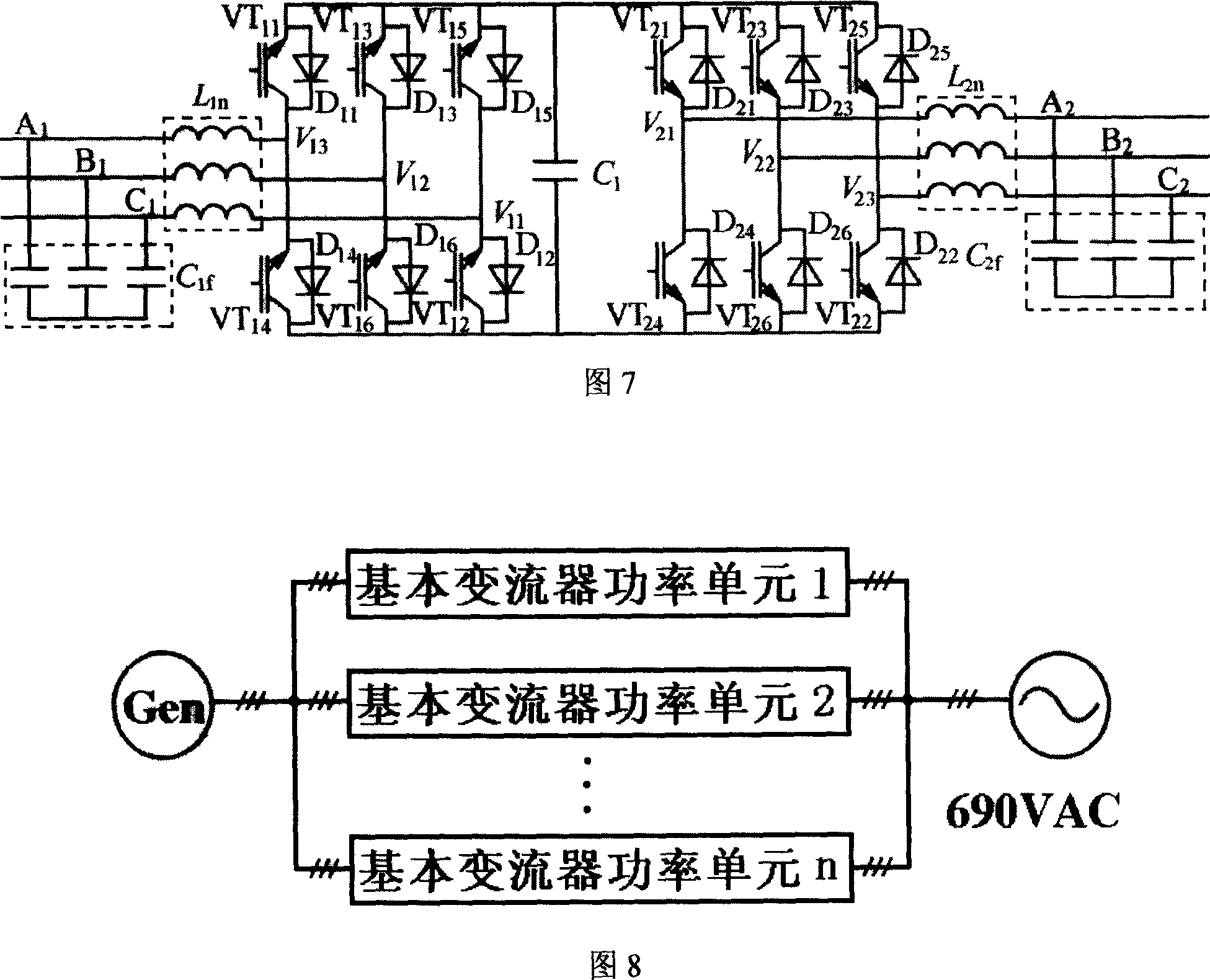

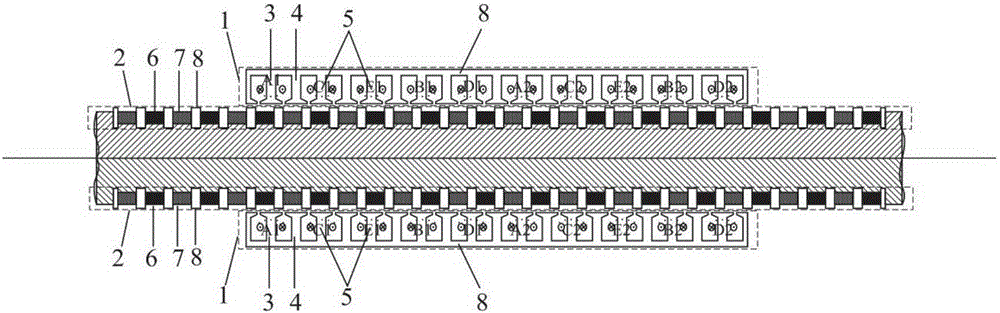

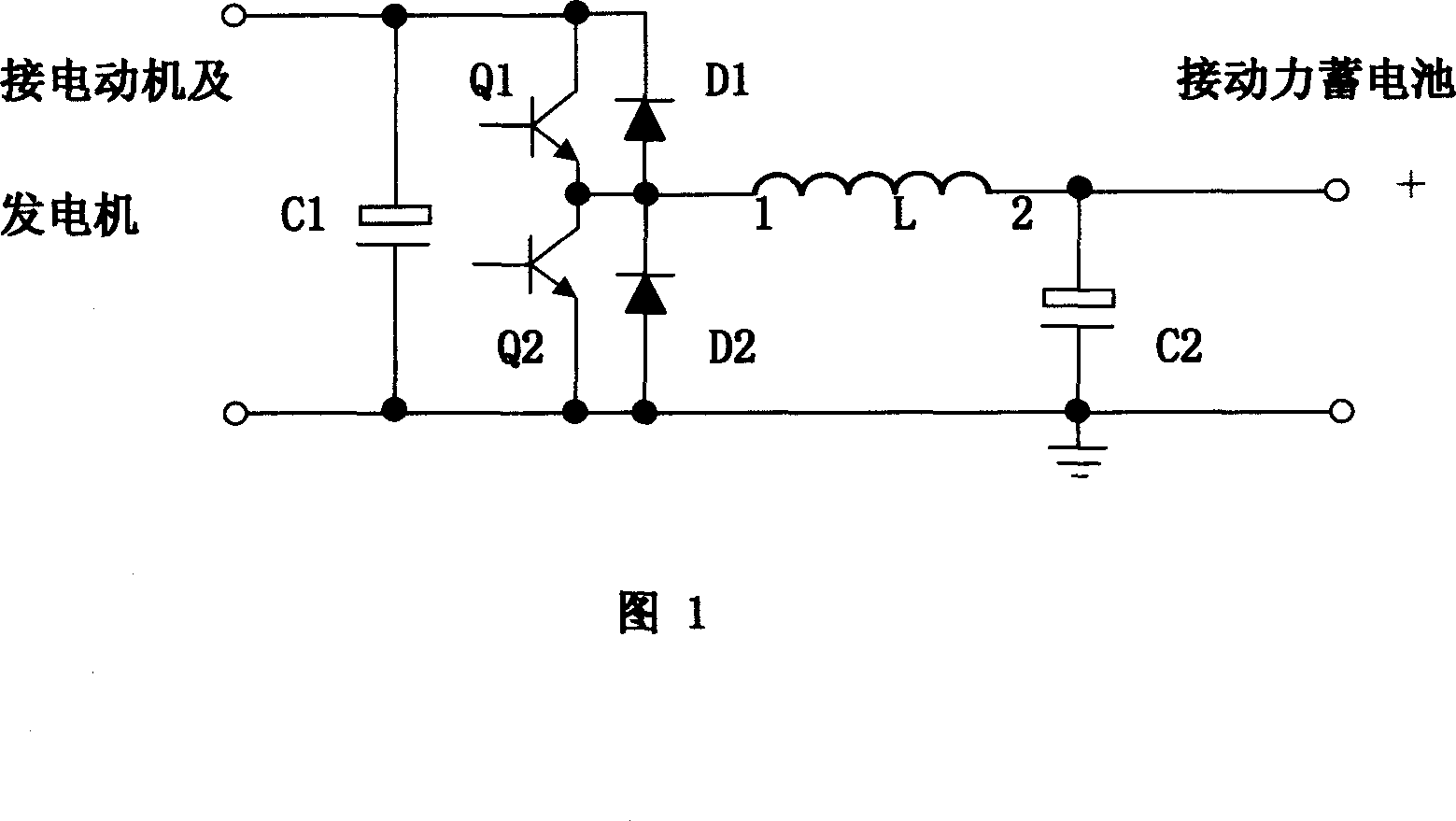

Full power combination converter for megawatt wind power generation

InactiveCN101013817AMeet grid connection conditionsReduce copper consumptionConversion with intermediate conversion to dcAc-dc conversionWind forcePower grid

The invention provides one megawatt wind motor power network integration alternator, which comprises wind motor and low voltage electrical net or lift transducer and at least two basic transducer power units with each one connected to form power main circuit, wherein, the basic transducer power unit comprises motor side three-phase PWM total transducer and PWM side integration transducer; power transducer main circuit output end connects low voltage network or lift transducer; the input end of transducer main circuit is connected to wind motor.

Owner:HARBIN JIUZHOU ELECTRICAL CO LTD

Short-circuit fault-tolerant vector control method for embedded hybrid magnetic material fault-tolerant cylindrical linear motor

InactiveCN105245156ASimple structureImprove reliabilityElectronic commutation motor controlAC motor controlVoltage source inverterCompensation strategy

The invention discloses a short-circuit fault-tolerant vector control method for an embedded hybrid magnetic material fault-tolerant cylindrical linear motor. The short-circuit fault-tolerant vector control method comprises the following steps: building a five-phase embedded hybrid magnetic material fault-tolerant cylindrical linear motor model; compensating normal thrust missing caused by a short-circuit fault phase and suppressing a thrust ripple caused by phase short-circuit current with non-fault phase current of the motor; and obtaining expected phase voltage by adopting a series of coordinate conversion and voltage feed-forward compensation strategies, and achieving a fault-tolerant vector control after the phase short-circuit fault of the motor by a zero-sequence voltage harmonic injection-based CPWM modulation mode. According to the short-circuit fault-tolerant vector control method, the motor can suppress the thrust ripple of the motor under the condition of a phase short-circuit fault-tolerant operation; more importantly, the dynamic property, the steady-state performance and the properties in a normal state are consistent; the switching frequency of a voltage source inverter is constant; a CPU is low in overhead; and a natural coordinate system only needs to counterclockwise rotate a certain angle in any phase short-circuit fault, so that the motor fault-tolerant operation can be achieved.

Owner:JIANGSU UNIV

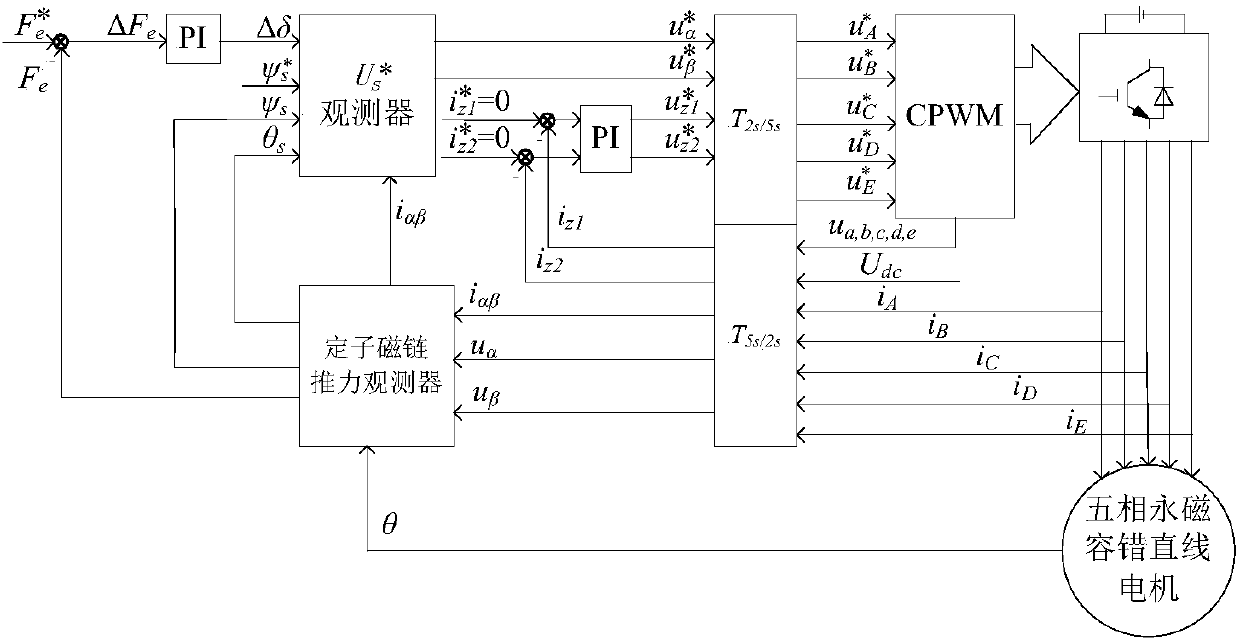

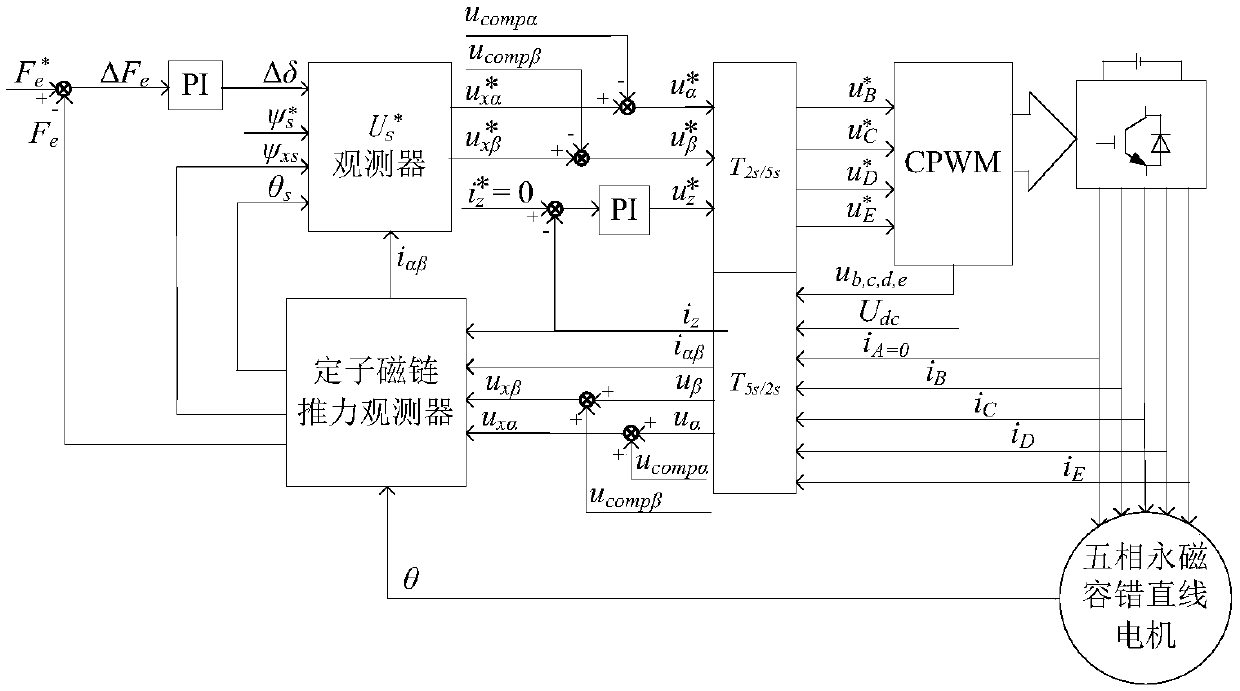

One-phase open-circuit fault-tolerant direct thrust control method for five-phase permanent magnet linear motor

InactiveCN108306571AIncreased complexitySave memory resourcesElectric motor controlVector control systemsPhase currentsModulation function

The invention discloses a one-phase open-circuit fault-tolerant direct thrust control method for a five-phase permanent magnet linear motor. Firstly, a Clark transform matrix and an inverse matrix thereof are derived based on fault-tolerant phase current. On the above basis, a stator flux linkage on alpha-beta is derived, a stator virtual flux linkage is defined according to the requirements of acircular stator flux linkage trajectory, and thus the voltage compensation on alpha-beta is derived. The stator actual voltage on the alpha-beta is derived by a modulation function of a voltage sourceinverter, and voltage is combined with voltage compensation and stator current, and a stator virtual flux linkage and thrust are observed by a stator flux observer and a thrust observer. Then statorvirtual target votlage is calculated according to given thrust, a given stator flux linkage amplitude and the observed stator virtual flux linkage and thrust. Finally, the stator actual voltage is calculated by the voltage and the voltage compensation, and the motor is controlled by the voltage by the voltage source inverter. According to the method, a thrust fluctuation caused by a motor failureis suppressed, and more importantly, the dynamic performance and steady state performance are consistent with that in a normal condition.

Owner:JIANGSU UNIV

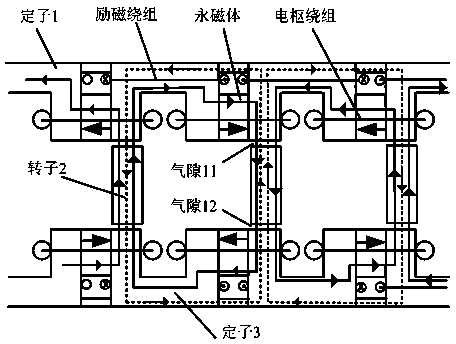

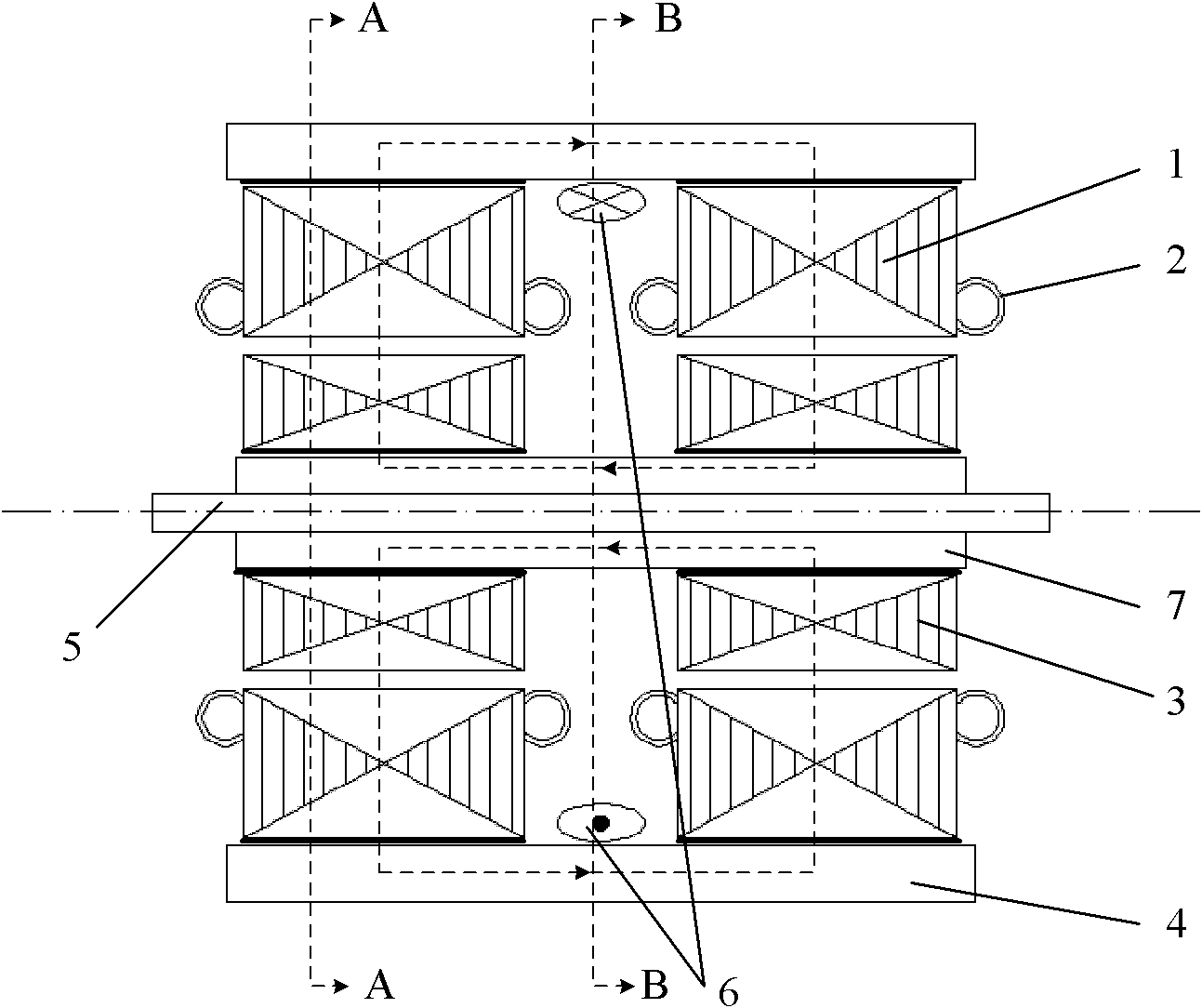

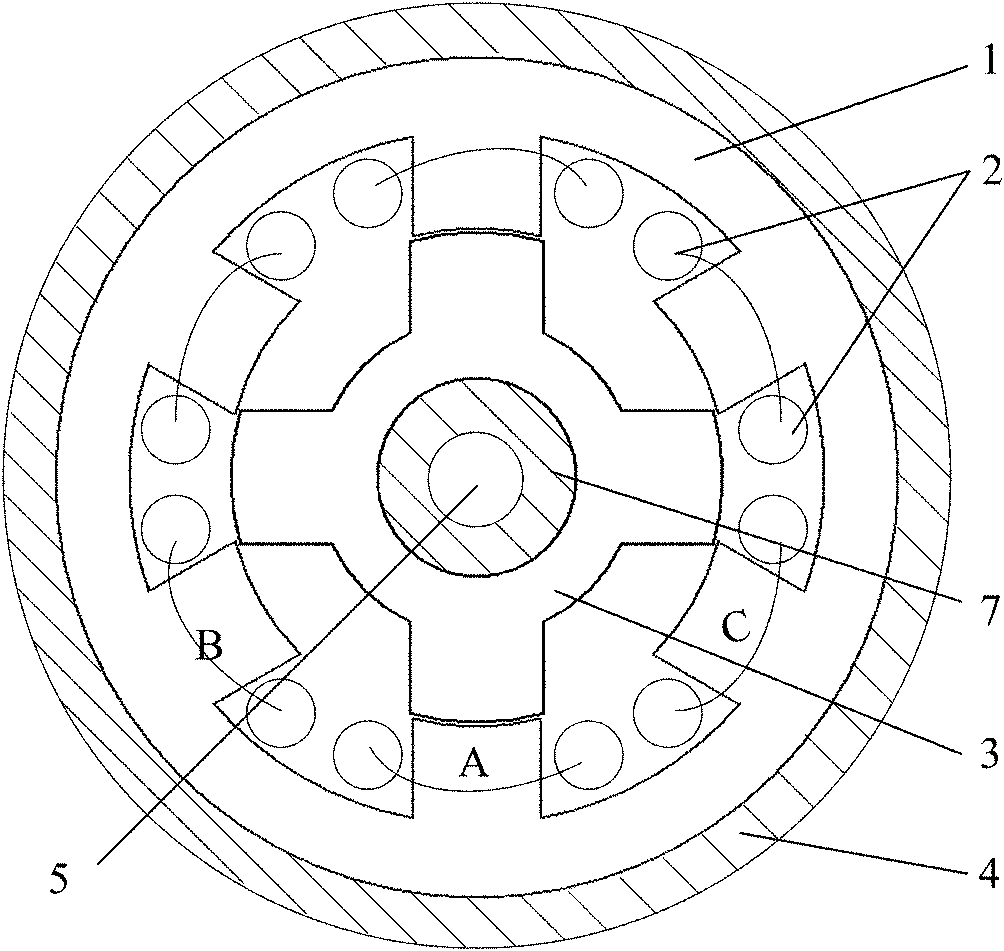

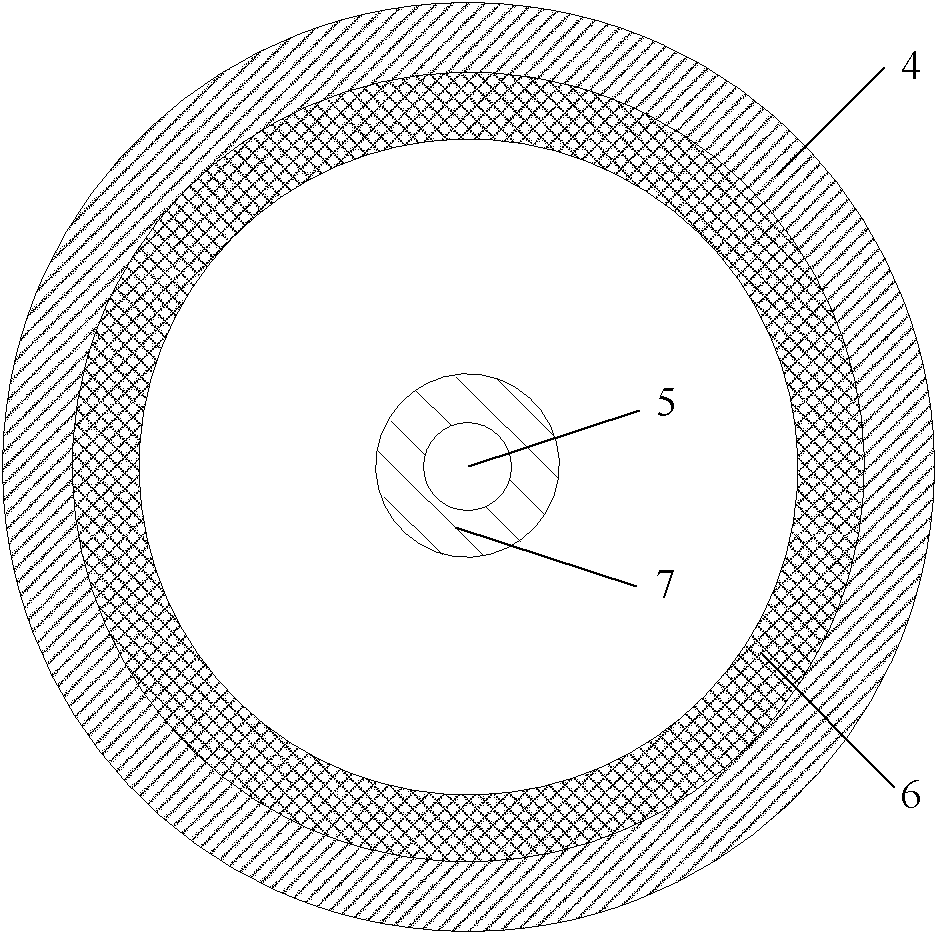

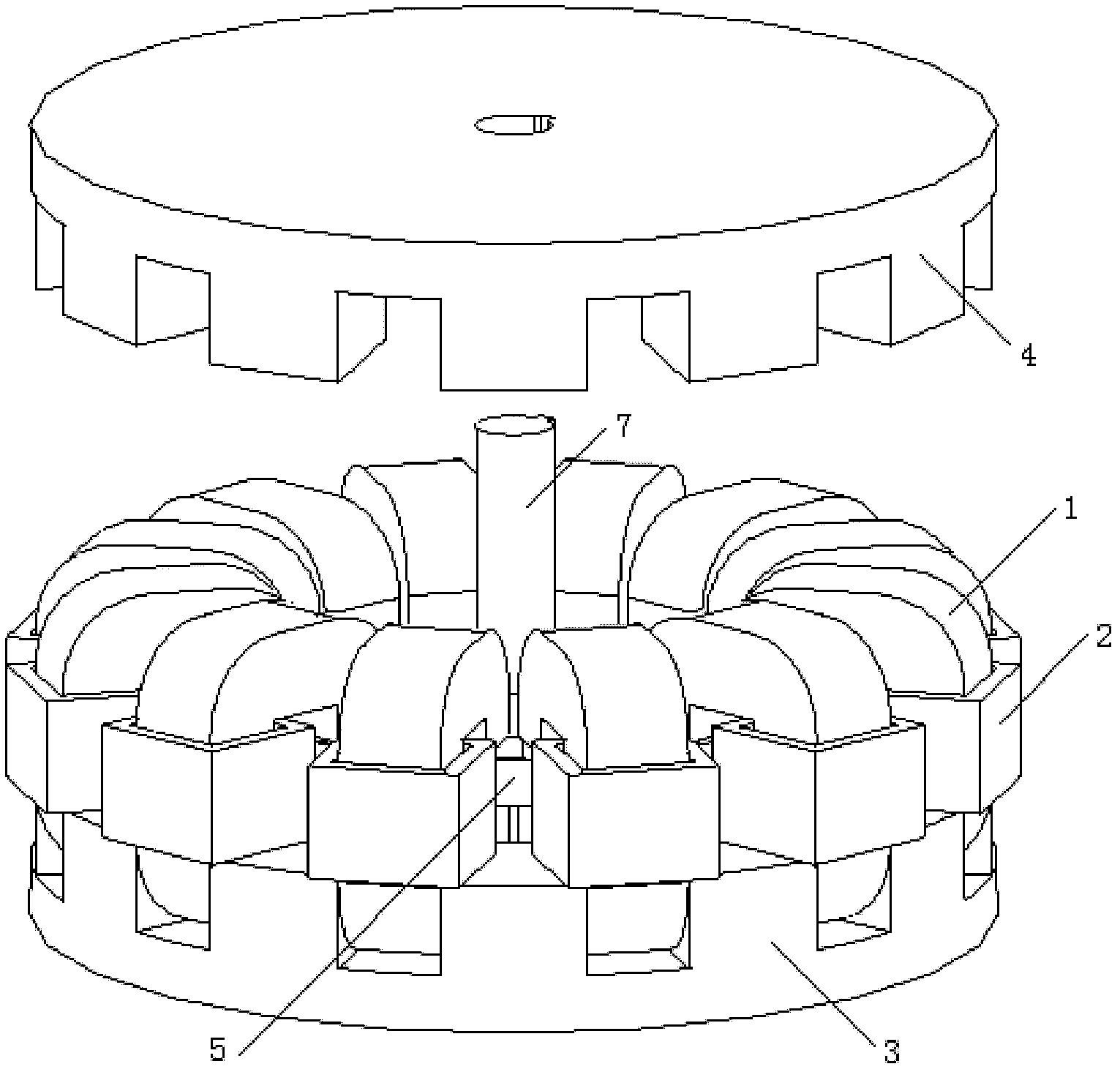

Axial excitation double salient pole motors

InactiveCN102035270AHigh utilization rate of axial cross-sectional areaImprove space utilizationMagnetic circuit rotating partsMagnetic circuit stationary partsConductor CoilUtilization rate

The invention discloses two axial excitation double salient pole motors and belongs to the field of motors with double salient pole structures. Each motor comprises at least two double salient pole monomer structures which are axially arranged, wherein each monomer structure consists of a salient pole stator core, an armature winding wound on the stator core and a salient pole rotor core; the stator core of each monomer structure forms a magnetic circuit through stator axial magnetic back iron; the rotor core forms a magnetic circuit through rotor axial magnetic back iron in a motor structure with an annular excitation winding or annular permanent magnet steel; the stator core, the stator axial magnetic back iron and the permanent magnet steel have arc structures which are equationally divided into 2n (n is a natural number) parts in the motor structure without the rotor axial magnetic back iron; and the rotor of each monomer structure is arranged on a rotating shaft. The motors have the advantages of high space utilization rate of the excitation winding, no additional air gap, high excitation efficiency and high utilization rate of axial sectional areas and can be used as electromotors or generators.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

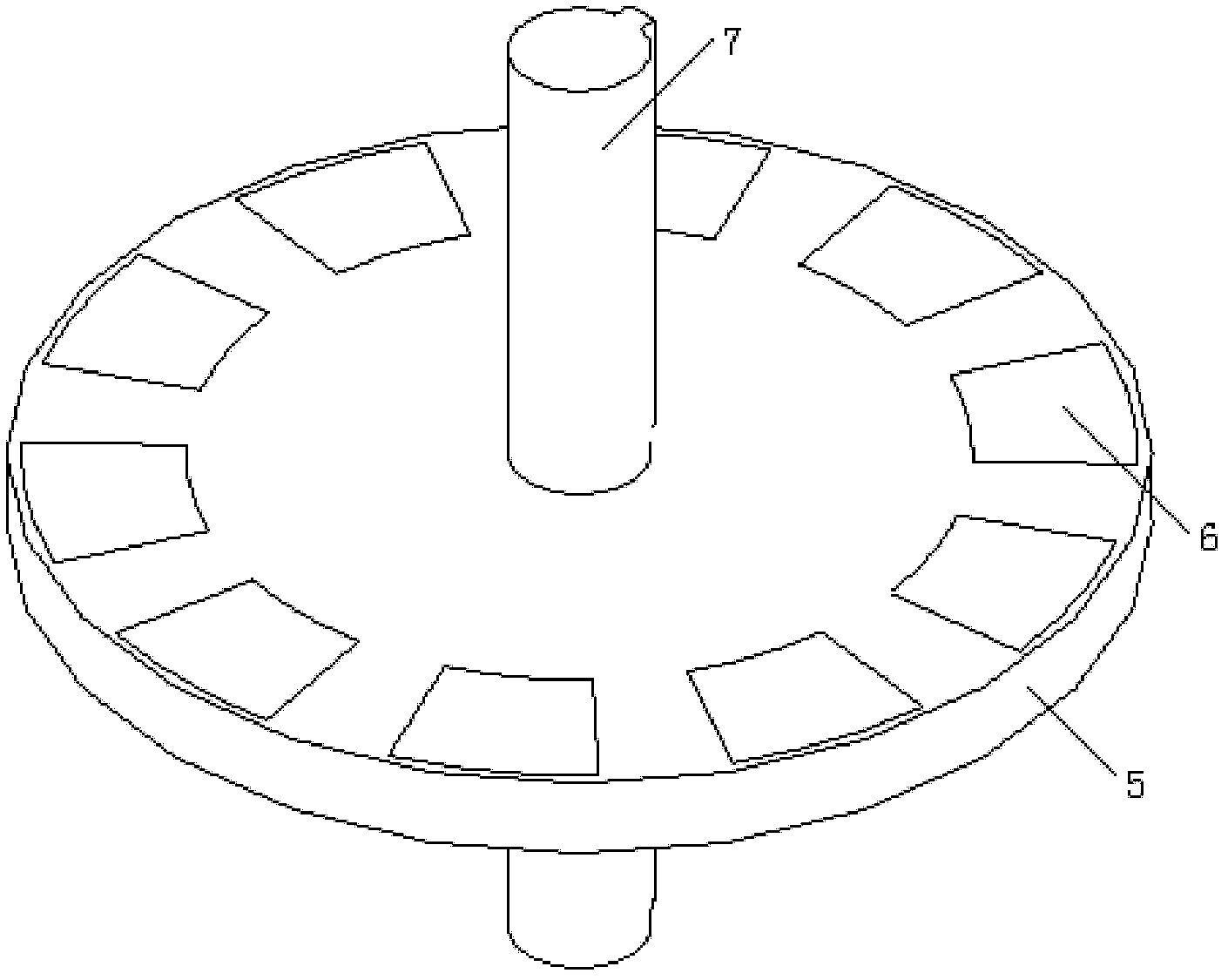

Permanent-magnet axial-magnetic-field brushless motor and assembling method thereof

InactiveCN102624183AIncrease the number of polesReduce cogging torque rippleMagnetic circuit rotating partsMagnetic circuit stationary partsBrushless motorsElectric machine

The invention discloses a permanent-magnet axial-magnetic-field brushless motor, which comprises a stator, a rotor, a lower end cap and an upper end cap, wherein the rotor is arranged at the center of the stator. The permanent-magnet axial-magnetic-field brushless motor is characterized in that the stator comprises a plurality of stator C-shaped iron cores and winding coils arranged on the iron cores; the rotor comprises a non-magnet-conductive rotor plate, a plurality of permanent magnets and a rotary shaft, the rotary shaft is arranged at the center of the non-magnet-conductive rotor plate, the permanent magnets are uniformly embedded on the circumference of the non-magnet-conductive rotor plate, the stator C-shaped iron cores are embedded in slots of the upper end cap and the lower end cap and circularly distributed on the circumference of the non-magnet-conductive rotor plate uniformly, and upper magnetic pole surfaces of the stator C-shaped iron cores correspond to the permanent magnets of the non-magnet-conductive rotor plate. The invention further discloses an assembling method of the motor. The permanent-magnet axial-magnetic-field brushless motor and the assembling method thereof have the advantages that electric load and magnetic load are set independently, the stator lamination iron cores are simple in manufacture, and coil magnetic loops formed by the stator windings are independent to each other. Besides, design difficulty of the motor is beneficially reduced, and manufacturing cost of the motor is reduced while performance of the motor is improved.

Owner:SHANDONG UNIV

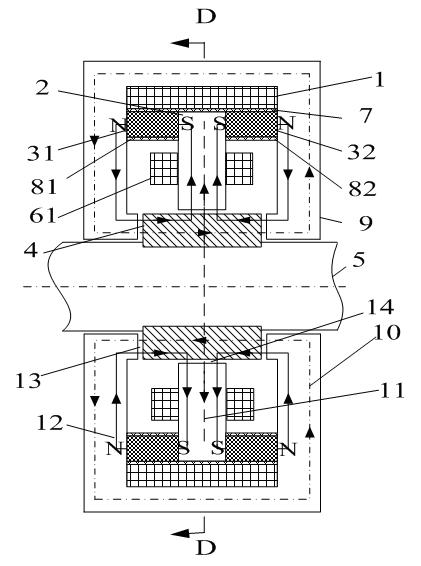

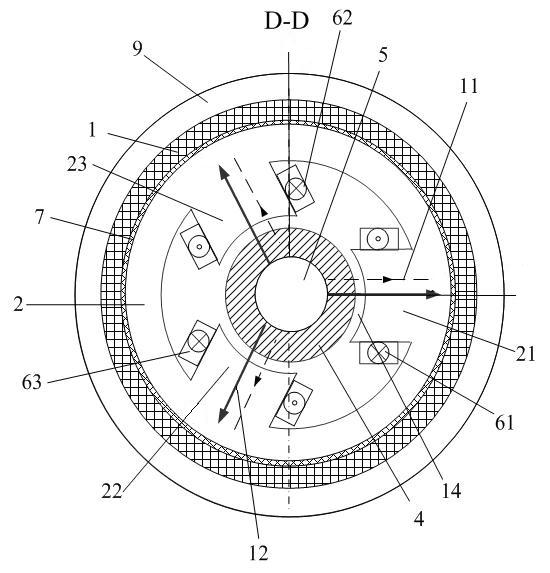

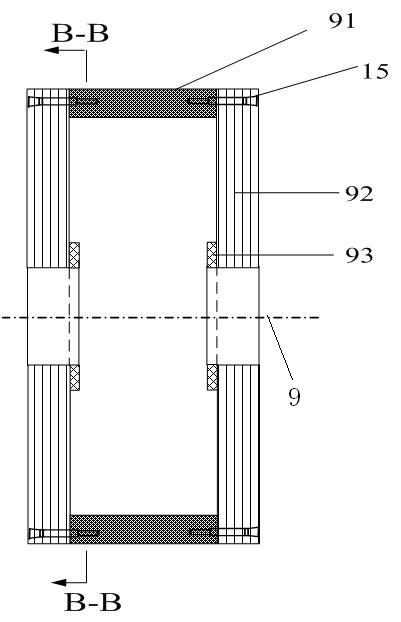

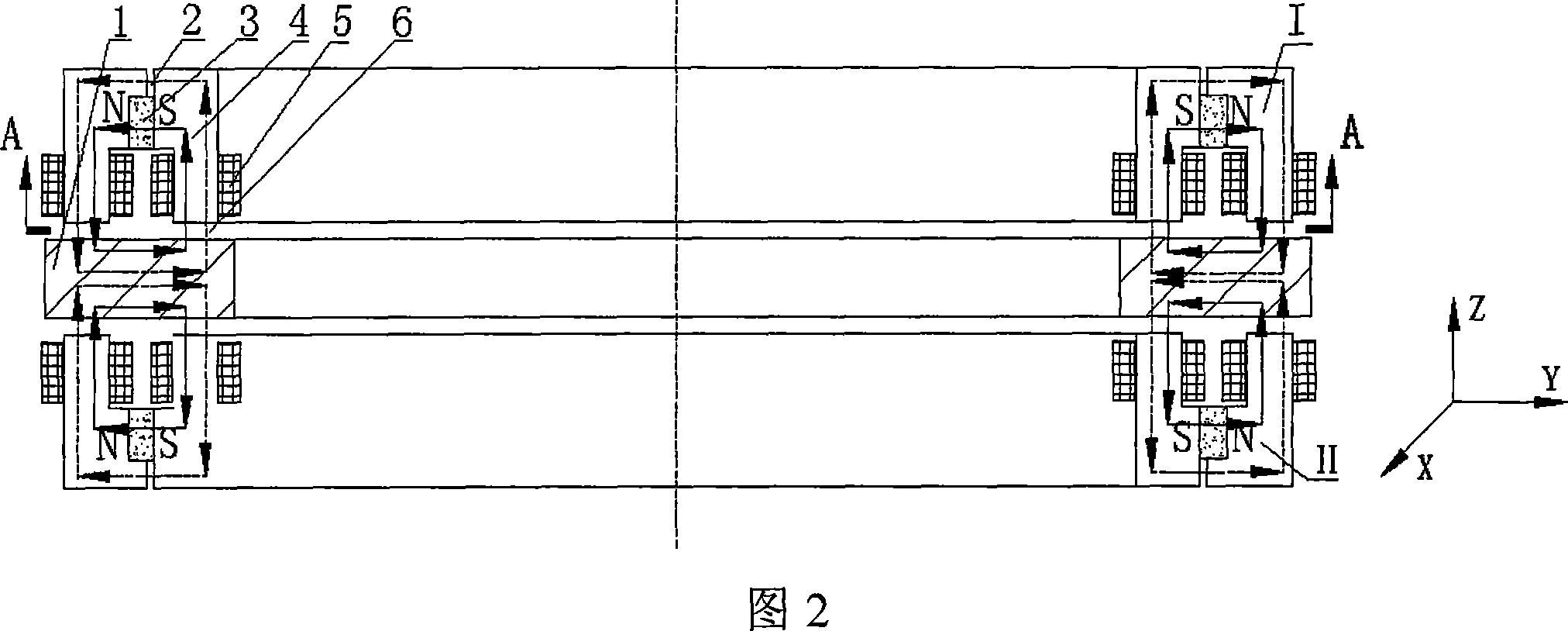

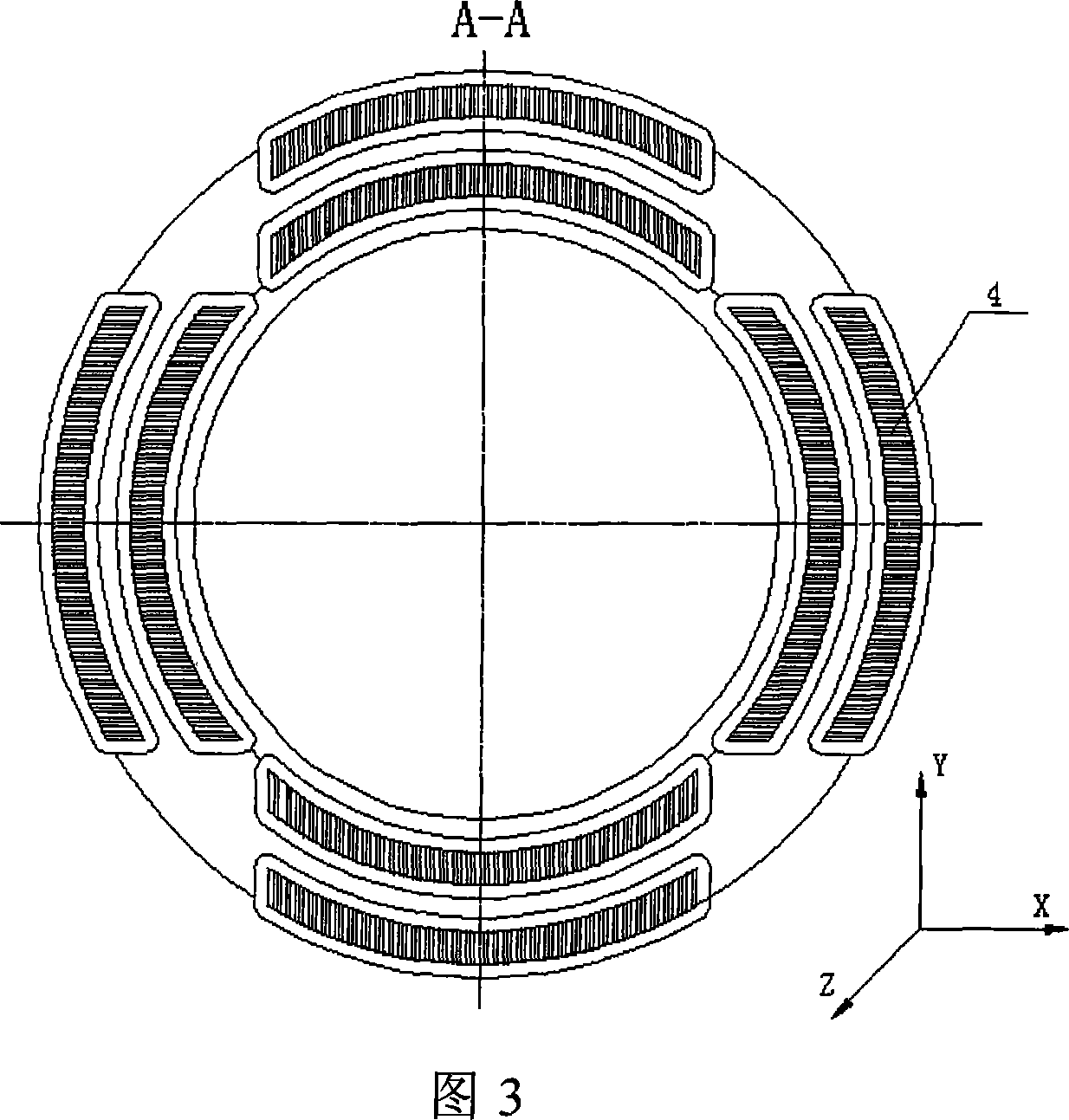

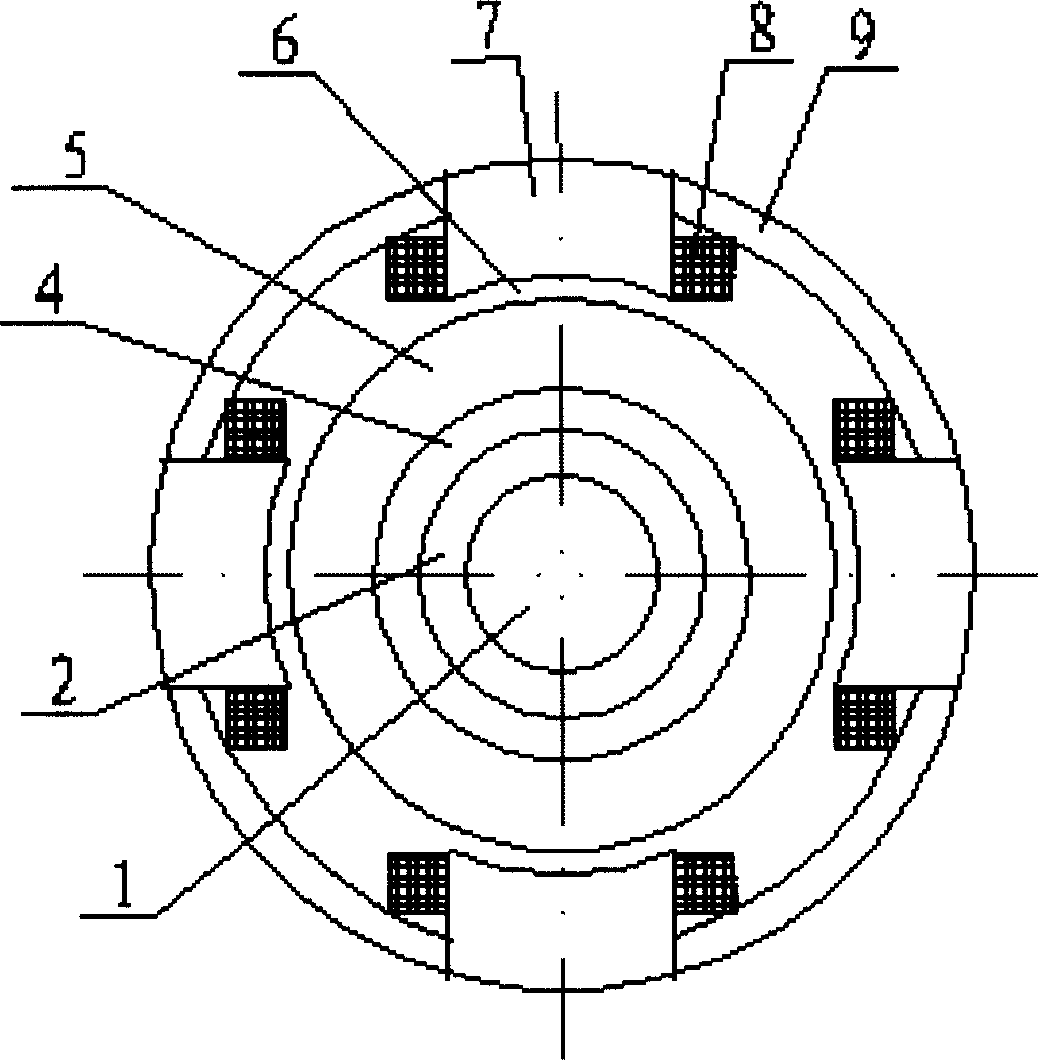

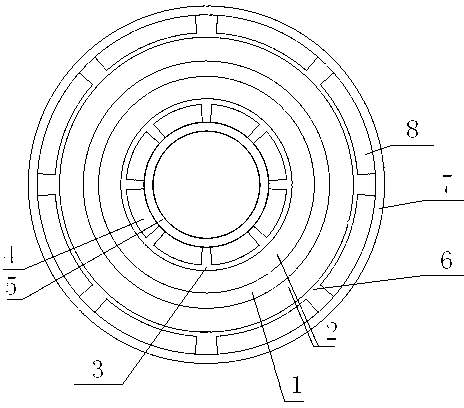

Low-power consumption permanent magnetic offset mixed radial magnetic bearing

InactiveCN1707127AReduce copper consumptionReduce power amplifier lossBearingsMagnetic bearingControl power

The permanent magnetic offset mixed radial magnetic bearing with low power consumption features that it consists of stator and rotor with air gap in between. The stator includes 8 stator magnetic poles and they forms 4 pairs in both right and left ends and separately for positive and negative directions in X and Y directions. Each stator magnetic pole consists of stator magnetic pole core and stator winding on the core, and 4 stator core yokes are connected across between two stator cores each to constitute the 8 stator magnetic poles, with magnetic isolators being set between the stator core yoke for X direction and that for Y direction. The rotor includes rotation shaft, permanent magnet, magnetizing sleeve and rotor core. The present invention has separated permanent magnetic path and electromagnetic part, lowered control current and control power consumption, small volume and light weight.

Owner:BEIHANG UNIV

Low watt consumption permanent magnet offset external rotor hybrid radial magnetic bearing

InactiveCN1752471AReduce volumeReduce eddy current lossShaftsRotary machine partsMagnetic bearingMagnetic poles

The permanent-magnet offset outer rotor mixed radial magnetic bearing with low power consumption is composed of rotor iron core. Permanent-magnets, stator iron cores and excitation coils. Said invention also provides ther arrangement mode, between outer surface of stator iron core and inner surface of rotor iron core a certain gap is remained to form air gap, between two stator iron cores and permanent magnet a second air gap is formed. The permanent magnet utilizes stator iron core magnet poles to form offset magnetic field on X and Y directions.

Owner:BEIHANG UNIV

Embedded type mixing magnetic material fault-tolerant cylindrical linear motor

The invention discloses an embedded type mixing magnetic material fault-tolerant cylindrical linear motor which comprises primary bodies and secondary bodies. The length of each primary body is smaller than that of each secondary body. An air gap is reserved between each primary body and the corresponding secondary body. Each primary body comprises armature teeth, fault-tolerant teeth and a coil winding. The 2*m armature teeth and the 2*m fault-tolerant teeth are uniformly distributed on each primary body, wherein m is the phase number of the motor and is larger than or equal to three; the armature teeth and the fault-tolerant teeth are arranged at intervals in a staggered mode. Only one set of disc-shaped coil windings are placed into an armature tooth groove of each primary body. No windings are arranged on the fault-tolerant teeth. The secondary bodies of the motor are made of mixing magnetic materials, a part of ferrite is used for replacing a part of rare earth permanent magnets to form four different mixing magnetic material structures, on one hand, the quantity of the adopted rare earth permanent magnets is greatly reduced, and the cost of the motor is reduced; on the other hand, as the magnetic energy product of the permanent magnets is reduced, the eddy-current loss of the motor is reduced greatly, and efficiency of the motor is improved.

Owner:JIANGSU UNIV

Direct-axis magnetic field enhanced type wide-range speed control permanent magnet brushless motor for electric automobile

ActiveCN104253499AMeet high torque performance requirementsImprove driving abilityMagnetic circuit rotating partsElectric machinesMagnetic barrierBrushless motors

The invention discloses a direct-axis magnetic field enhanced type wide-range speed control permanent magnet brushless motor for an electric automobile. A magnetic barrier fills each slot of a rotor, and the magnetic barriers are symmetrical relative to a centerline, i.e., a quadrature axis, of slot parts of the rotor; four sections of arc-shaped permanent magnet steel are fixedly embedded on each tooth part of the rotor, the four sections of arc-shaped permanent magnet steel are divided into an inner layer and an outer layer, two sections are arranged on each layer, the two sections of permanent magnet steel on each layer are the same in structure and are symmetrical relative to a centerline, i.e., a direct axis of the tooth parts of the rotor, the two sections of permanent magnet steel on the same layer do not run through each other and are not connected with each other, and an arc-shaped magnetic bridge is formed between the two sections of permanent magnet steel; a circle center of each section of permanent magnet steel is located on the diameter of the rotor; the direct-axis inductance of the motor is larger than the quadrature-axis inductance, so that the motor can adopt a control method with zero direct-axis current and can also adopt a direct-axis magnetic field enhanced control method during low-speed operation or startup, and can adopt a coordinated control method of direct-axis magnetic field enhancement and slight direct-axis magnetic field weakening during high-speed operation, and the speed control range is wider.

Owner:JIANGSU UNIV

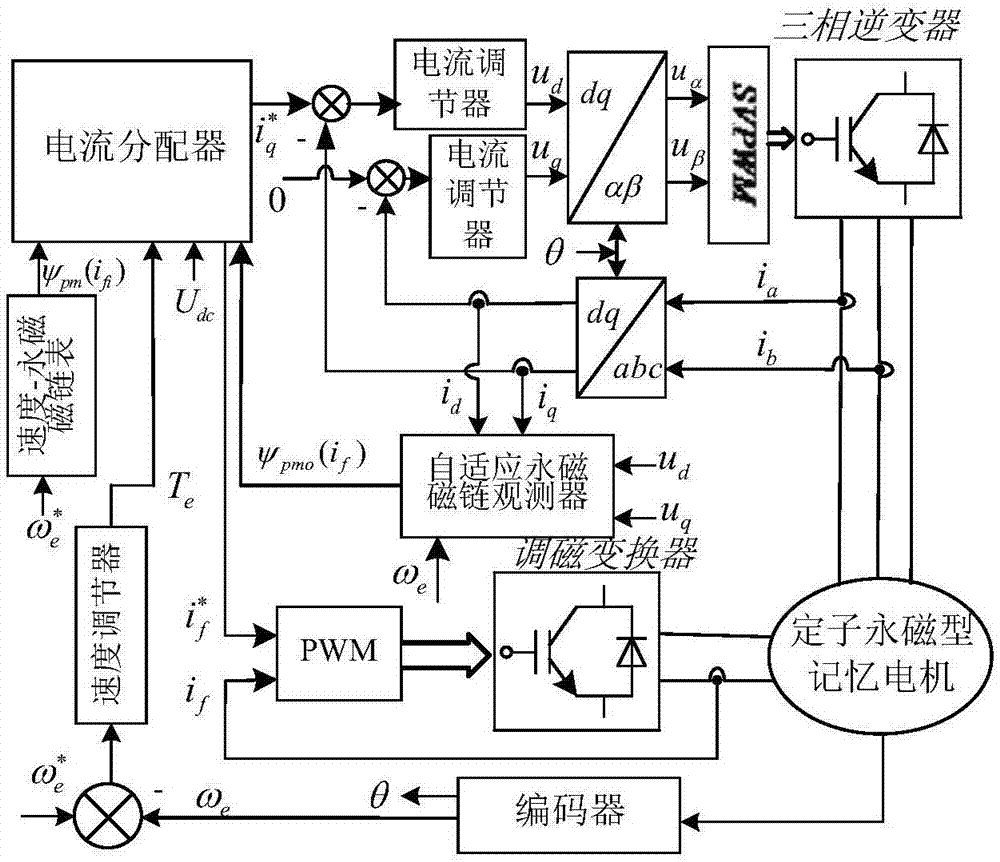

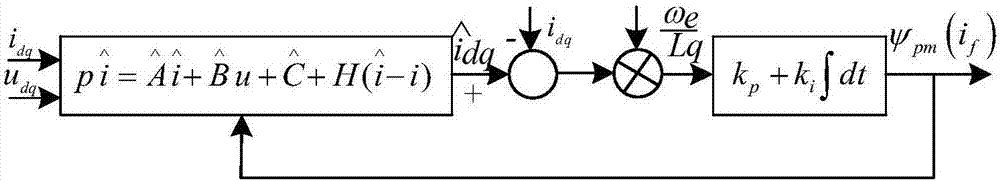

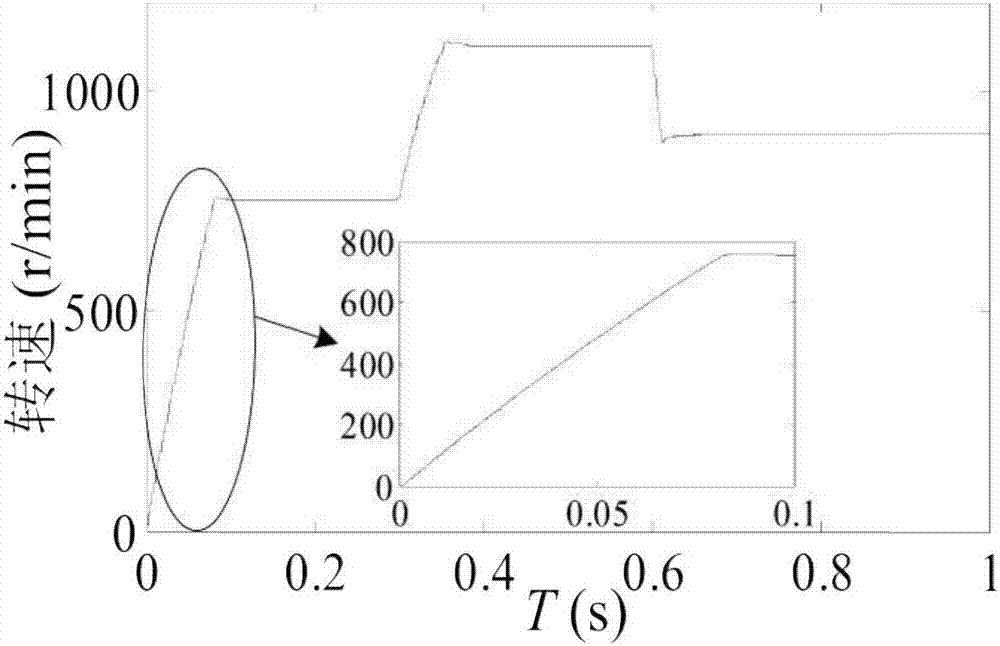

Segmented control method of permanent magnetic linkages of stator permanent magnetic type memory motor

ActiveCN106992729AAvoid repeated magnetizationThe effect of reducing calculation precisionElectronic commutation motor controlVector control systemsPhase currentsMemory motor

The invention discloses a segmented control method of permanent magnetic linkages of a stator permanent magnetic type memory motor. The method comprises following steps of S1, according to magnetization states of a permanent magnet, selecting k+1 permanent magnetic linkages including phipm (if0), phipm (if1), ..., phipm (if(k-1)), and phipm (ifk), wherein the phipm (if(k-1)) is larger than the phipm (ifj), and 1<=j<=k, calculating rotation speed omegaej according to direct current bus voltage Udc, the rated phase current In, and the quadrature axis inductance Lq(j) and the permanent magnetic linkage phipm (ifj) of the jth kind of magnetization state, and storing the permanent magnetic linkages of phipm (if0), phipm (if1) ..., phipm (if(k-1)), and phipm (ifk) and corresponding rotation speeds of omegae0, omegae1, ..., omegae(k-1), and omegaek into a speed-permanent magnetic linkage table, wherein the if is the magnetic field adjusting pulse; and S2, when the given rotation speed shown in the description meets the condition shown in the description, judging a magnetic field adjusting process of the permanent magnet by comparing the permanent magnetic linkage phipmo(if) and the permanent magnetic linkage phipm(ifj) corresponding to the rotation speed omegaej observed by the permanent magnetic linkage observer. According to the invention, speed adjusting range of the motor is enlarged, and effects on permanent magnetic linkage calculation accuracy imposed by motor parameters are reduced.

Owner:SOUTHEAST UNIV

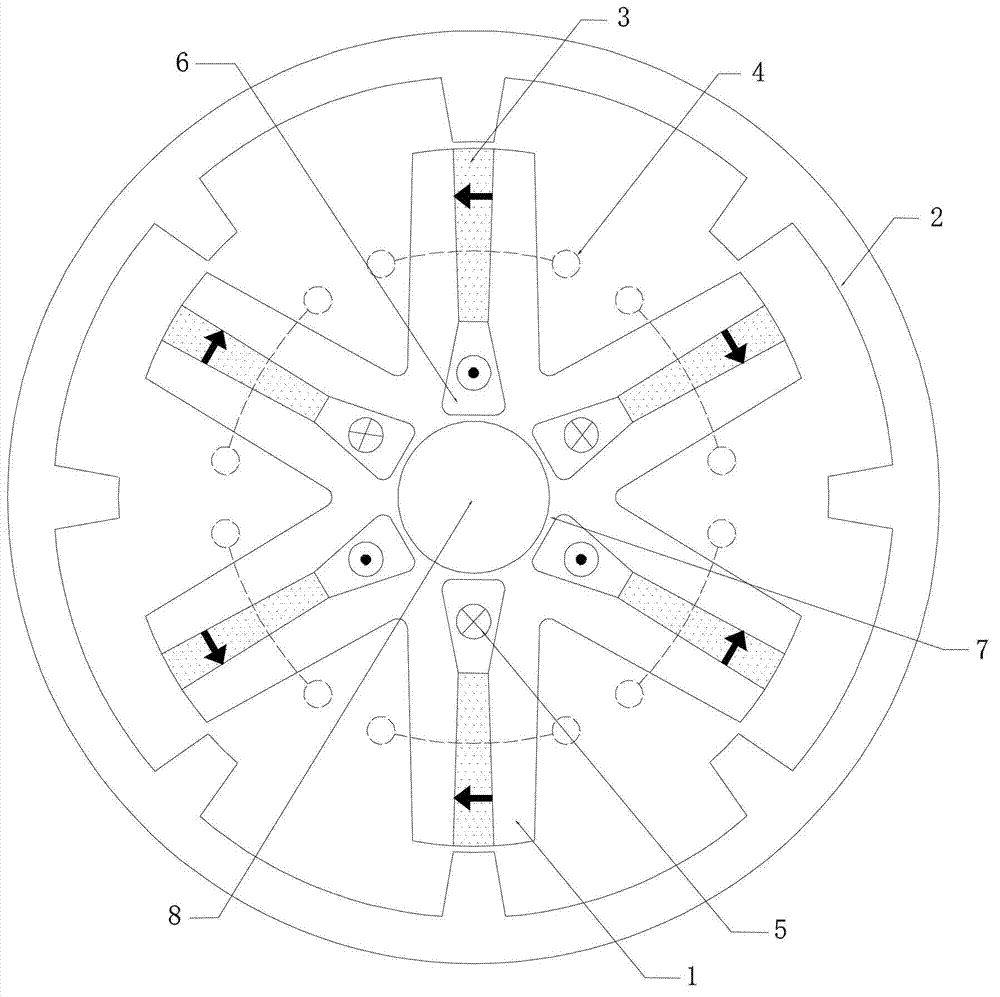

Built-in permanent magnet memory motor of magnetic flux switching type

InactiveCN103199661ASimple structureReduce wind resistanceMagnetic circuit rotating partsSynchronous machine detailsMechanical reliabilityElectric machine

The invention discloses a built-in permanent magnet memory motor of a magnetic flux switching type. The permanent magnet memory motor comprises a casing, a stator, a rotor and a rotating shaft, wherein the stator is a cylinder with a through hole and is formed by a star-shaped magnetic isolation block with a center through hole and partitioned rotor iron core discs; the rotating shaft is fixedly connected in the center through hole of the magnetic isolation block; and the partitioned rotor iron core discs are shaped like a fan and are uniformly distributed at the circumference of the rotor as well as fixedly connected to the outer surface of the magnetic isolation block. The stator comprises a stator iron core, permanent magnets, three-phase armature windings and pulse windings, wherein the stator iron core comprises a stator yoke and stator teeth formed by permanent teeth and armature teeth; the permanent magnets are shaped like a tile and radially magnetized, so that magnetic leakage factors are small; the magnetization directions of the two adjacent permanent magnets are opposite; the three-phase armature windings are wound on the armature teeth; and the pulse windings are wound on the permanent magnets. According to the permanent magnet memory motor, the weak magnetic ability and the rotation speed running range of the motor can be improved; and the no-load air gap magnetic field can be adjusted. In addition, the permanent magnet memory motor disclosed by the invention is strong in mechanical reliability, thereby being suitable for high-speed running.

Owner:SOUTHEAST UNIV

Permanent magnet biased external rotor radial magnetic bearing

InactiveCN1730960AReduce copper consumptionReduce volumeShaftsRotary machine partsMagnetic bearingCoupling

The permanent magnetic offset external rotor magnetic radial bearing features that it consists of rotor iron core, permanent magnet, stator iron core and exciting winding. Eight stator iron core magnetic poles distributed homogeneously in a circumference are wound with exciting winding; and four permanent magnets are embedded inside the stator iron core separately in the +X, -X, +Y and -Y directions to produce offset magnetic field in X direction and offset magnetic field in Y direction separately. Between the outer surface of the stator iron core and the inner surface of the rotor iron core, there is air gap. The permanent magnetic offset external rotor magnetic radial bearing of the present invention has the advantages of no coupling between the X direction permanent magnetic path and the Y direction permanent magnetic path, small size, low power consumption, reliable performance and easy control.

Owner:BEIHANG UNIV

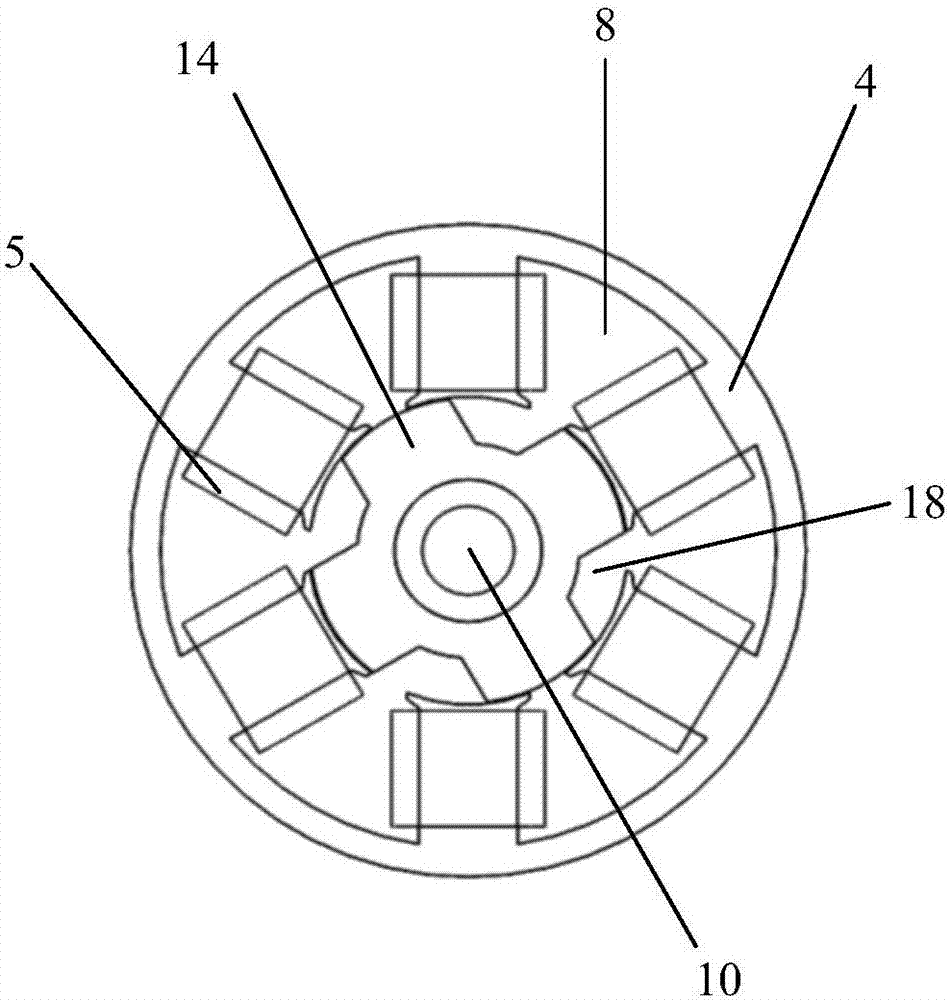

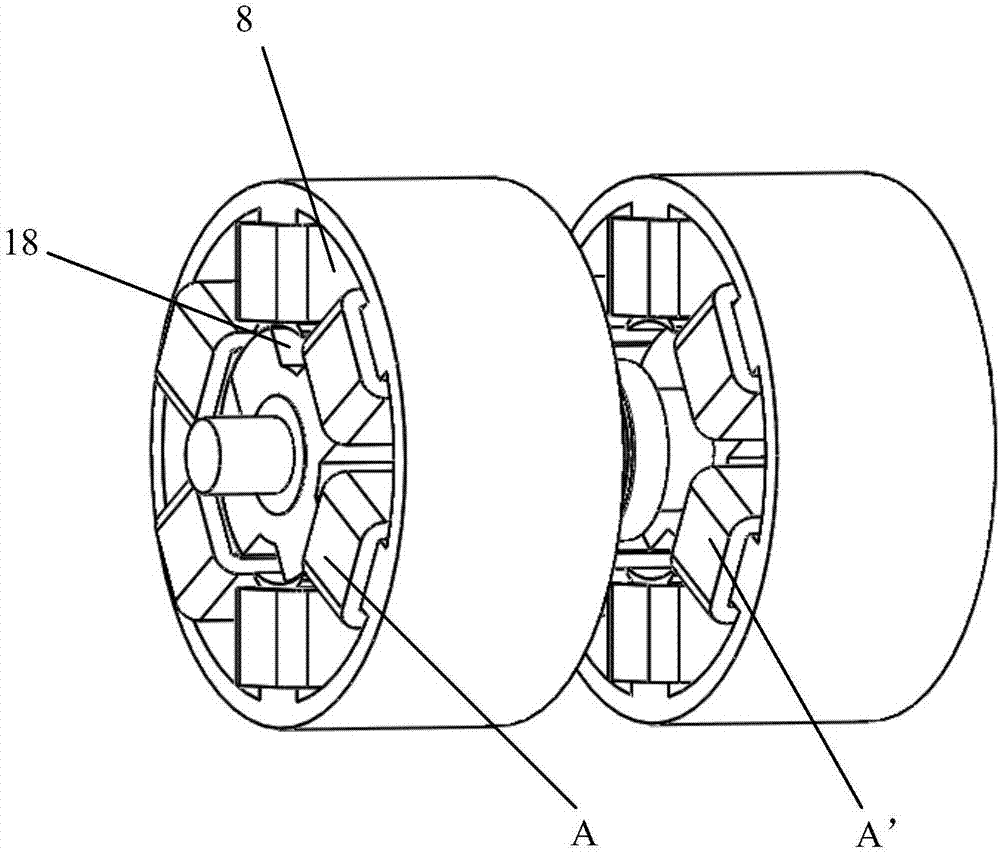

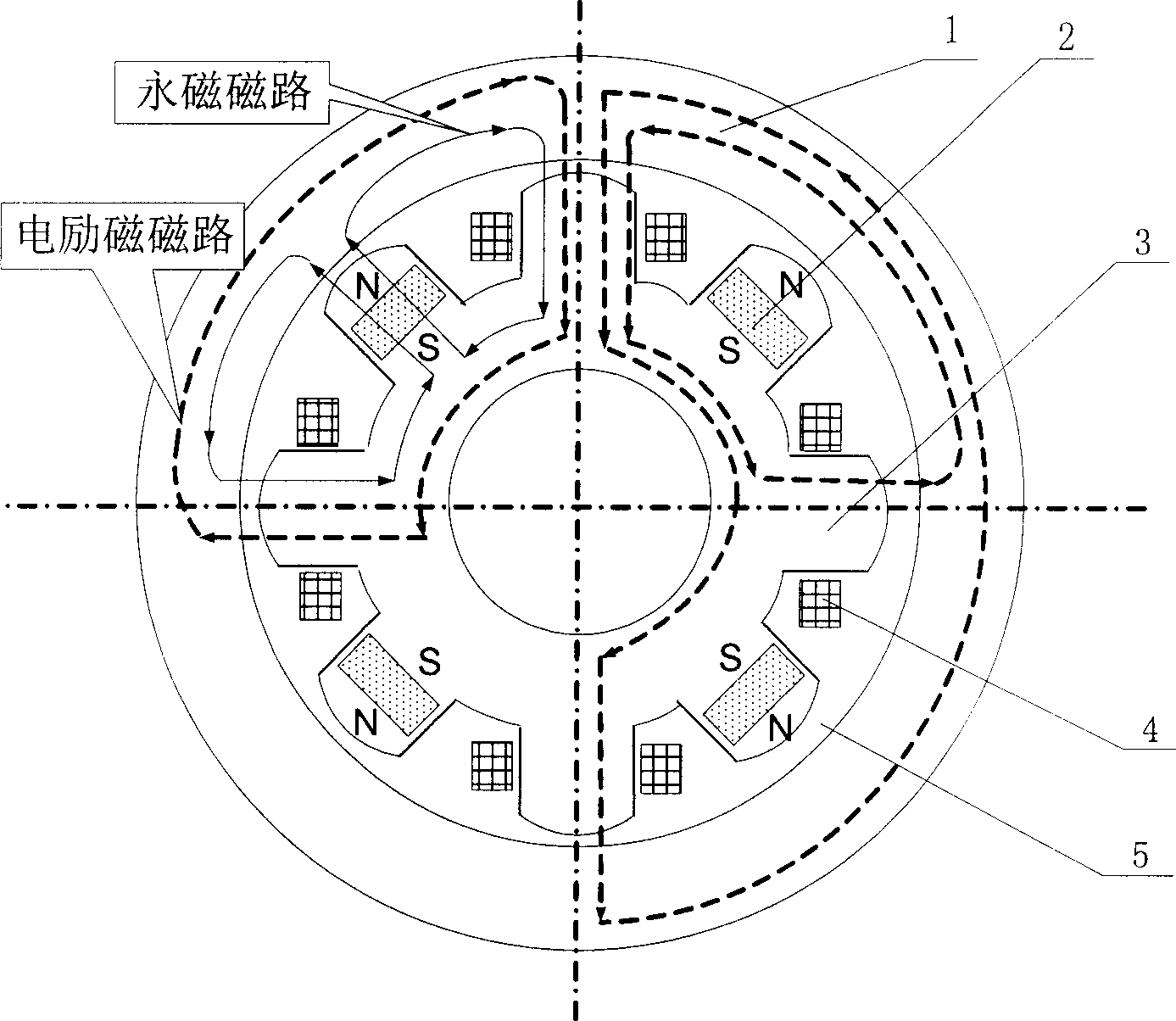

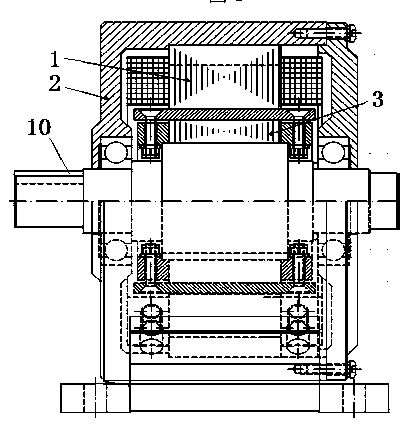

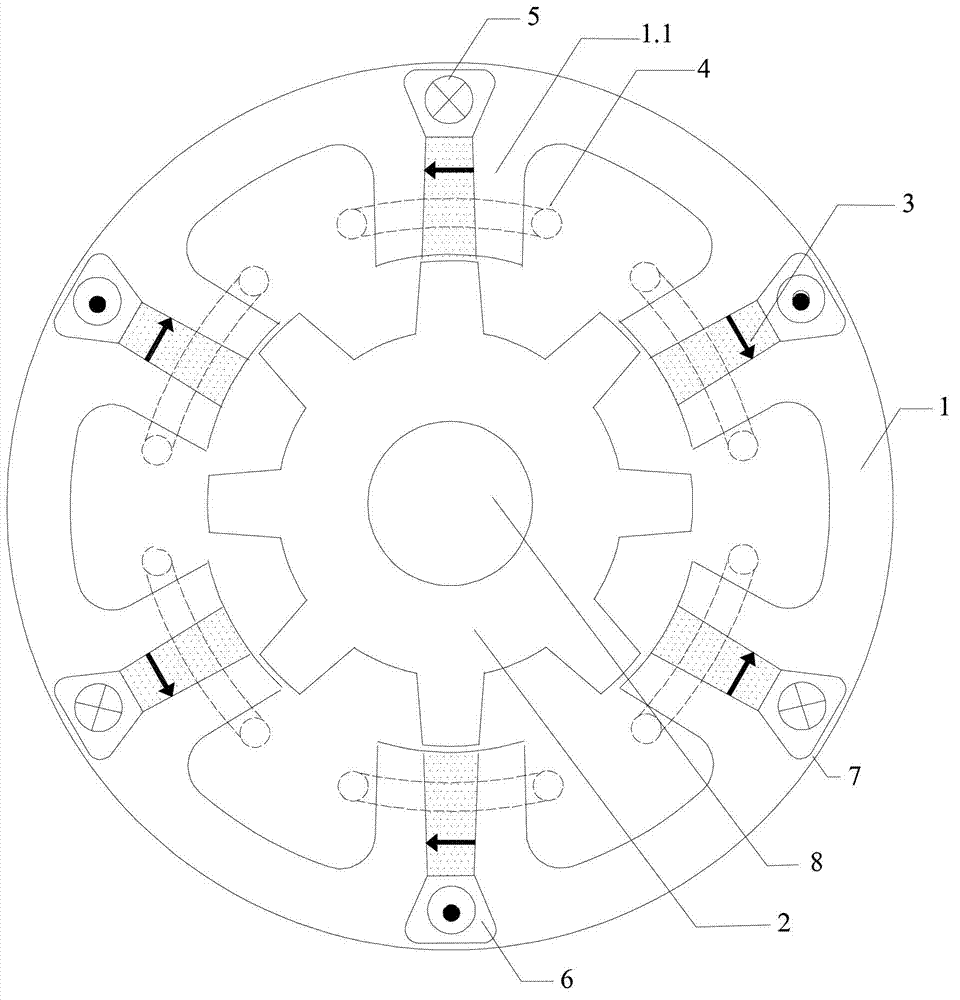

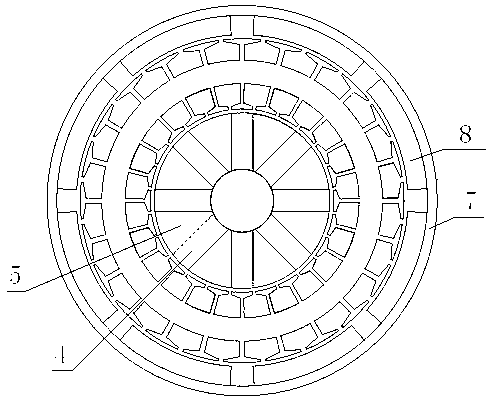

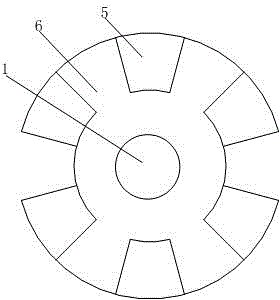

Magnetic flux switching type permanent magnet memory motor

ActiveCN103051139ASimple structureStable structureSynchronous machinesMagnetic circuit stationary partsElectric machineMemory motor

The invention discloses a magnetic flux switching type permanent magnet memory motor comprising an enclosure, a stator contained in the enclosure, a rotor (2) and a non-magnetic rotary shaft (8). The magnetic flux switching type permanent magnet memory motor is characterized in that the stator (1) is arranged at the outer part of the rotor (2); the rotor (2) is fixedly arranged on the non-magnetic rotary shaft (8) and is in a convex pole type; the rotor (2) comprises a rotor main body part and rotor teeth which protrude from the main body part to a direction which is far away from the center of the rotor; the stator comprises a stator iron core (1), a permanent magnet (3), a three-phase armature winding (4) and a pulse winding (5); the stator iron core (1) comprises a plurality of stator yokes and stator teeth (1.1) which protrude from the stator yokes to the direction of the center of the stator iron core; and the three-phase armature winding (4) is wound on the stator teeth (1.1). According to the magnetic flux switching type permanent magnet memory motor disclosed by the invention, a motor no-load gap magnetic field is adjustable, and the weak magnetism capability and the rotary speed operation speed of the motor are improved; and meanwhile, the torque and the power density of the motor are improved and the copper consumption of the motor is reduced.

Owner:SOUTHEAST UNIV

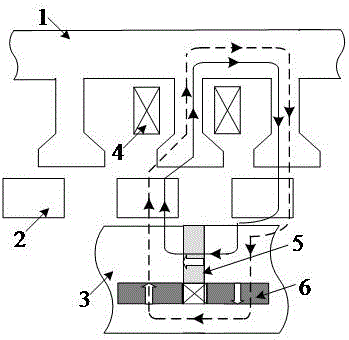

Birotor permanent magnet motor applied to wind power generation

InactiveCN103269140AIncrease the number of winding coilsImprove power densityDynamo-electric machinesWind drivenThermodynamics

The invention discloses a birotor permanent magnet motor applied to wind power generation. Rotors of the birotor permanent magnet motor comprise an inner rotor and an outer rotor. A stator comprises a stator core and a stator winding, wherein the inner rotor and the outer rotor share the stator, and the stator winding is wound on the stator core. The inner rotor is arranged inside the stator, an inner air gap is formed between the inner rotor and the stator, and the inner rotor comprises an inner rotor permanent magnet and an inner rotor core. The outer rotor is arranged outside the stator, an outer air gap is formed between the outer rotor and the stator, and the outer rotor comprises an outer rotor core and an outer rotor permanent magnet of which the surface is attached to the inner surface of the outer rotor core. The inner rotor and the outer rotor are fixedly connected and rotate synchronously. The magnetizing direction of the inner rotor permanent magnet and the magnetizing direction of the outer rotor permanent magnet are opposite. An inner magnetic circuit and an outer magnetic circuit are parallel and are closed through the stator core shared by the inner magnetic circuit and the outer magnetic circuit. The back-to-back annular winding can effectively reduce copper loss of the motor, enlarge an effective air gap area of the motor, and strengthen power generation capacity of a wind driven generator at a low wind speed.

Owner:JIANGSU UNIV

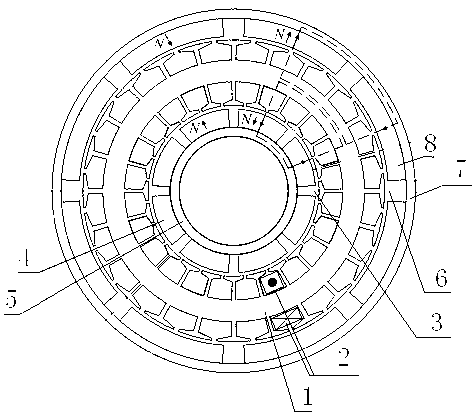

Magnetic gear type double-stator hybrid permanent magnet memory motor

InactiveCN105141092ASimple structureImprove space utilizationMagnetic circuit rotating partsMagnetic circuit stationary partsEpoxyElectric machine

The invention discloses a magnetic gear type double-stator hybrid permanent magnet memory motor. The motor comprises an external stator, a rotor and an internal stator which are coaxially arranged and sleeved from outside to inside in turn. The external stator comprises armature iron core teeth, stator yokes and armature windings which are arranged on the armature iron core teeth. The internal stator comprises an internal stator iron core provided with internal slots, neodymium iron boron permanent magnets, aluminum nickel cobalt permanent magnets and pulse magnetic regulating windings which are arranged in the internal slots of the internal stator. The two types of co-excitation permanent magnets are arranged in a "U" shape. The number of single permanent magnets on the internal stator is equal to that of external stator armature teeth. The whole rotor has an annular cup-shaped structure. Rotor iron blocks are fixed in a non-magnetic-conductive epoxy resin sleeve. The rotor iron blocks are connected via magnetic conductive bridges. Disadvantages that a conventional single stator has multiple internal excitation sources which are mutually hindered in space and torque density is relatively low can be solved. Besides, high power density is realized by arrangement of double-stator hybrid permanent magnets, and residual magnetization intensity and magnetization direction of the permanent magnets are regulated by applying pulse current so that motor magnetic field high-efficiency regulation is realized, and rotating speed operation range is enhanced.

Owner:SOUTHEAST UNIV

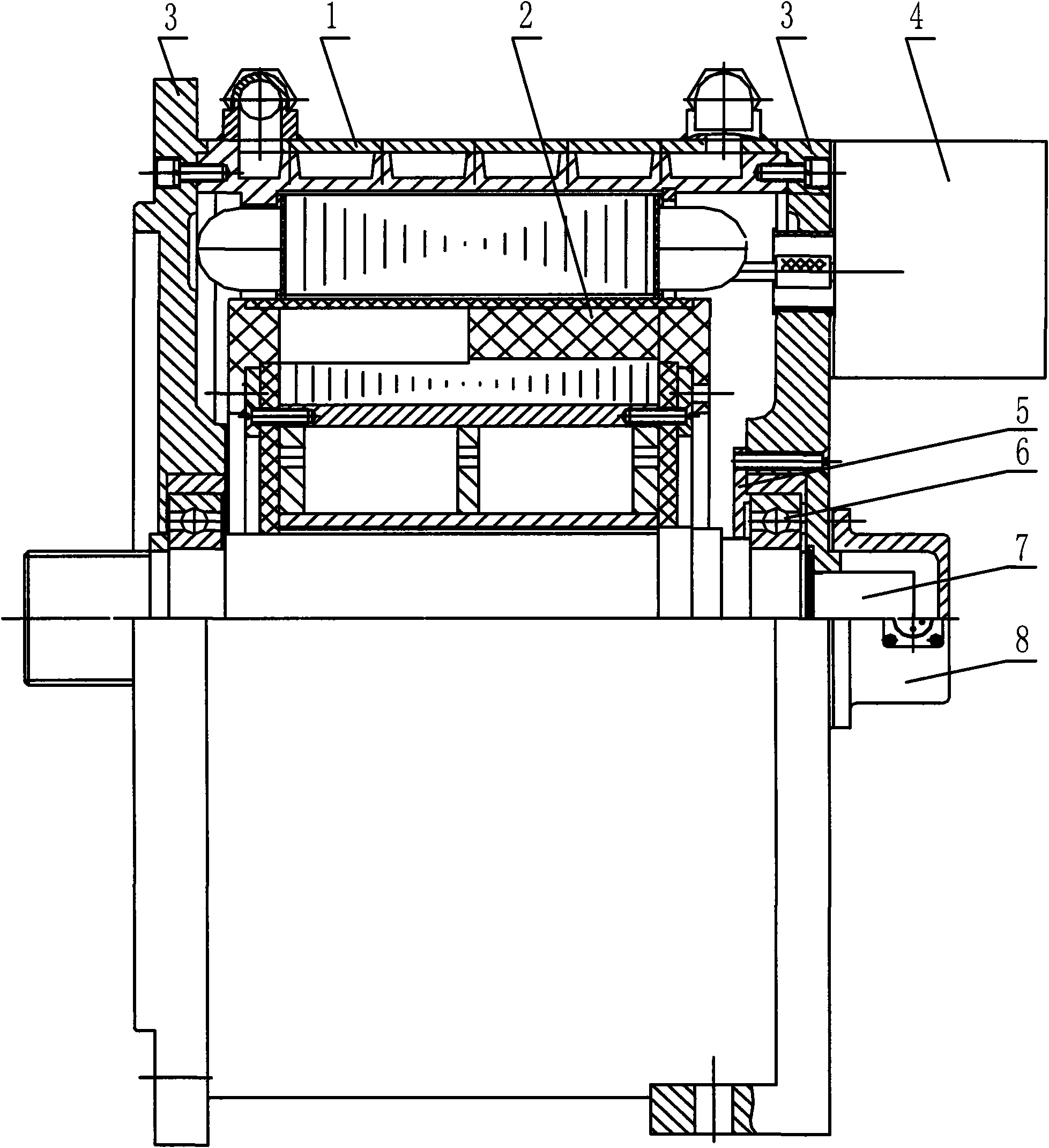

DC voltage control system for hybrid power automobile and working method thereof

The invention discloses a DC voltage control system of hybrid electric vehicle, comprising generator, electromotor, storage battery and control unit. The control unit controls the generator and electromotor and is connected with them. Generator and electromotor are connected with the storage battery in current. A voltage-increasing power supply circuit for increasing outputting voltage of storage battery to electromotor and a voltage-decreasing charging circuit for decreasing outputting voltage of generator or obtaining outputting voltage from vehicle kinetic energy to the storage battery when electromotor is used as regenerative braking are set between the electromotor and the storage battery. The control unit is used to control on-off and switch of the voltage-increasing power supply circuit and the voltage-decreasing charging circuit. Because voltage-increasing circuit is adopted storage battery can adopt low-voltage battery group so as to decrease battery system cost and cubage and achieve demands of low cost and mass production. Because power supply increasing voltage of electromotor is improved copper quantity for motor winding can be decreased greatly; motor size is decreased; consumption is decreased and efficiency is improved under the status of the same power.

Owner:BYD CO LTD

Electric vehicle hybrid excitation hub motor

ActiveCN105914981AAchieve integrationReduce volumeSynchronous machine detailsLow speedElectric machine

The invention provides an electric vehicle hybrid excitation hub motor which is composed of a shaft, a hub, rotor poles, stator poles, two sets of armature windings, stator iron cores, excitation windings, permanent magnets and a hub cap. The fan-shaped stator iron cores are fixed in the middle of the shaft in a back-to-back way. The two sides of the stator iron cores are provided with the protruding stator poles. The rotor poles are fixed on the internal walls of the two end surfaces of the hub. One permanent magnet is clamped between every two stator iron cores which are aligned in a circumferential direction. A groove is arranged between the two opposite stator iron cores and used for embedded arrangement of the excitation windings. Each stator pole is provided with the armature windings in a winding way. Integration of the hub and a driving motor is effectively realized by the technology so that the size and the weight of a driving system can be reduced; the rotor has no permanent magnet or excitation winding so that the possibility of demagnetization of the permanent magnets caused by impact can be reduced; a permanent magnetic field can be enhanced by an electric excitation magnetic field at low speed so that high-torque output can be realized; and the permanent magnetic field can also be weakened at high speed so that high-speed weak magnetic control can be realized.

Owner:SHANDONG UNIV OF TECH

Three-phase water-cooling permanent magnet synchronous motor

InactiveCN101577454AEven heat dissipationHigh mechanical strengthMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorPermanent magnet synchronous motor

The invention relates to a three-phase water-cooling permanent magnet synchronous motor which comprises a base, a permanent magnet rotor, an end cover, an outlet box, a bearing inner cover and a bearing, wherein the base comprises a water-cooling casing and a stator winding, and the water-cooling casing comprises a casing outer wall and a casing inner wall. The invention is characterized in that a helical groove is made on the surface of the casing inner wall, and helical convex ribs are formed in the groove and form a helical water groove with the casing outer wall. The permanent magnets of the permanent magnet rotor are arc permanent magnets with sections being crown faces, the arc permanent magnets are fixedly pasted on the surface of a rotor iron core in an equidistant manner according to the polarity along the circumference of the permanent magnet rotor and are mutually separated by insulation partition boards, both ends of each arc permanent magnet are fixed by insulation baffles, and an insulation sheath wraps the permanent magnet rotor outside. The invention has the advantages of uniform heat dissipation of the casing, high mechanical strength of the casing and low leakage coefficient of the permanent magnets, thereby improving the utilization rate of the permanent magnets, increasing the accumulation energy of air gaps, reducing copper loss and facilitating wire connection.

Owner:BAOTOU TIANSHAN MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com