Direct-axis magnetic field enhanced type wide-range speed control permanent magnet brushless motor for electric automobile

A permanent magnet brushless motor, electric vehicle technology, applied in the direction of electric vehicles, motors, vehicle components, etc., can solve the problems of difficult adjustment of the air gap magnetic field, narrow speed regulation range, low output power, etc., and achieve increased direct-axis inductance , the effect of wide speed regulation range and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

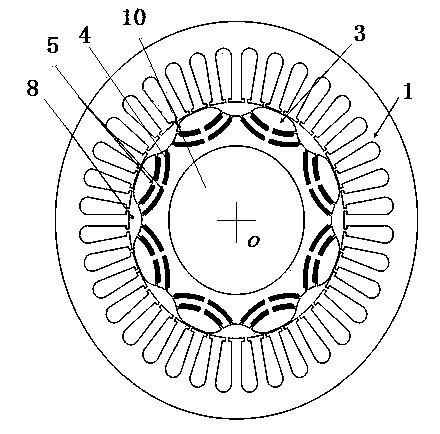

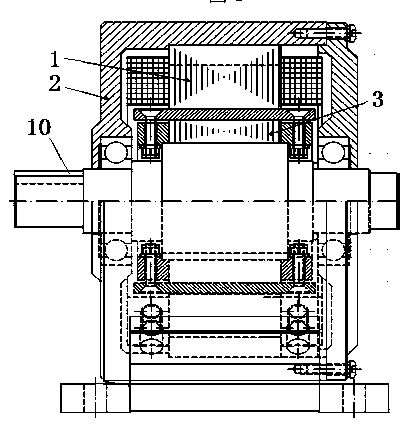

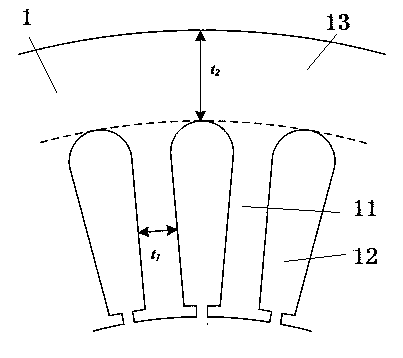

[0031] see figure 1 and figure 2 , the present invention includes a stator 1, a rotor 3, a rotating shaft 10 and an end cover 2, the stator 1 and the end cover 2 are fixedly connected together, the rotor 3 is coaxially located inside the stator 1, the center of the rotor 3 is coaxially connected to the rotating shaft 10, and the rotor 3 The central slot of the shaft is used to place the rotating shaft 10. There is an air gap between the inner wall of the stator 1 and the outer wall of the rotor 3, and the thickness of the air gap is related to the power level of the motor, the selected permanent magnet material, and the processing and assembly process of the stator 1 and rotor 3 . The rotor 2 has a salient pole structure, and the number of teeth of the rotor 2 is equal to the number of poles of the motor. Each tooth portion of the rotor 3 is fixedly inlaid with an arc-shaped permanent magnetic steel 4 . Both the stator 1 and the rotor 3 are formed by laminating silicon ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com