Curvilinear-tooth point-line meshing gear and processing method thereof

A technology of meshing gears and arc teeth, which is applied to belts/chains/gears, gear teeth, elements with teeth, etc. The problem of the cylindrical gear is raised late to achieve the effect of saving materials, improving transmission efficiency and saving materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

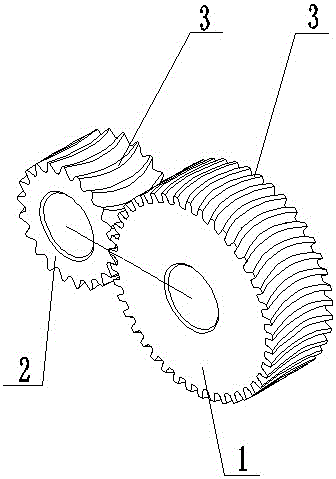

[0044] like Figure 1 to Figure 6 As shown, the arc tooth line point-line meshing gear of the present invention is an arc tooth line cylindrical gear, the tooth line of the gear tooth 3 is an arc tooth line, and the cross section of the gear tooth 3 at the midpoint of its tooth length direction is called the middle Section, the gear tooth is centered on its middle section, along the tooth length direction of the gear tooth 3 from the middle section to the left end is a left-handed line, along the tooth length direction of the gear tooth 3 from the middle section to the right end is a right-handed line, the left-handed line And the right-handed line is symmetrical with respect to the middle section; along the middle section of the gear tooth 3 extending to both ends, the tooth top gradually becomes narrower and the tooth root gradually thicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com