An electromagnetic tooth clutch

A clutch and cogging technology, which is applied in the field of electromagnetic cogging clutches, can solve problems affecting the meshing of movable end gears and fixed end gears, system noise, weak spring buffering effect, etc., so as to facilitate torque transmission, stable transmission structure, and easy The effect of surface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

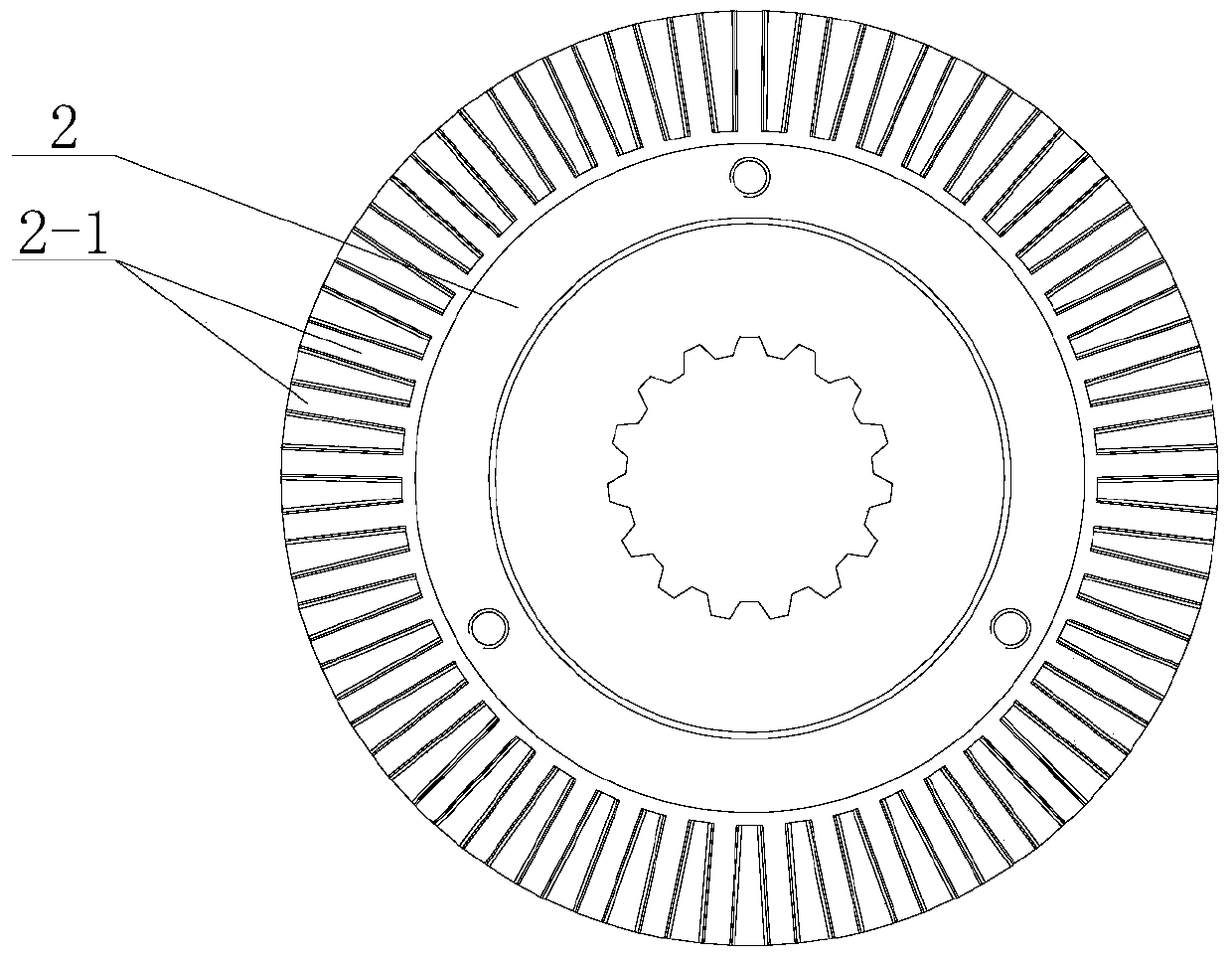

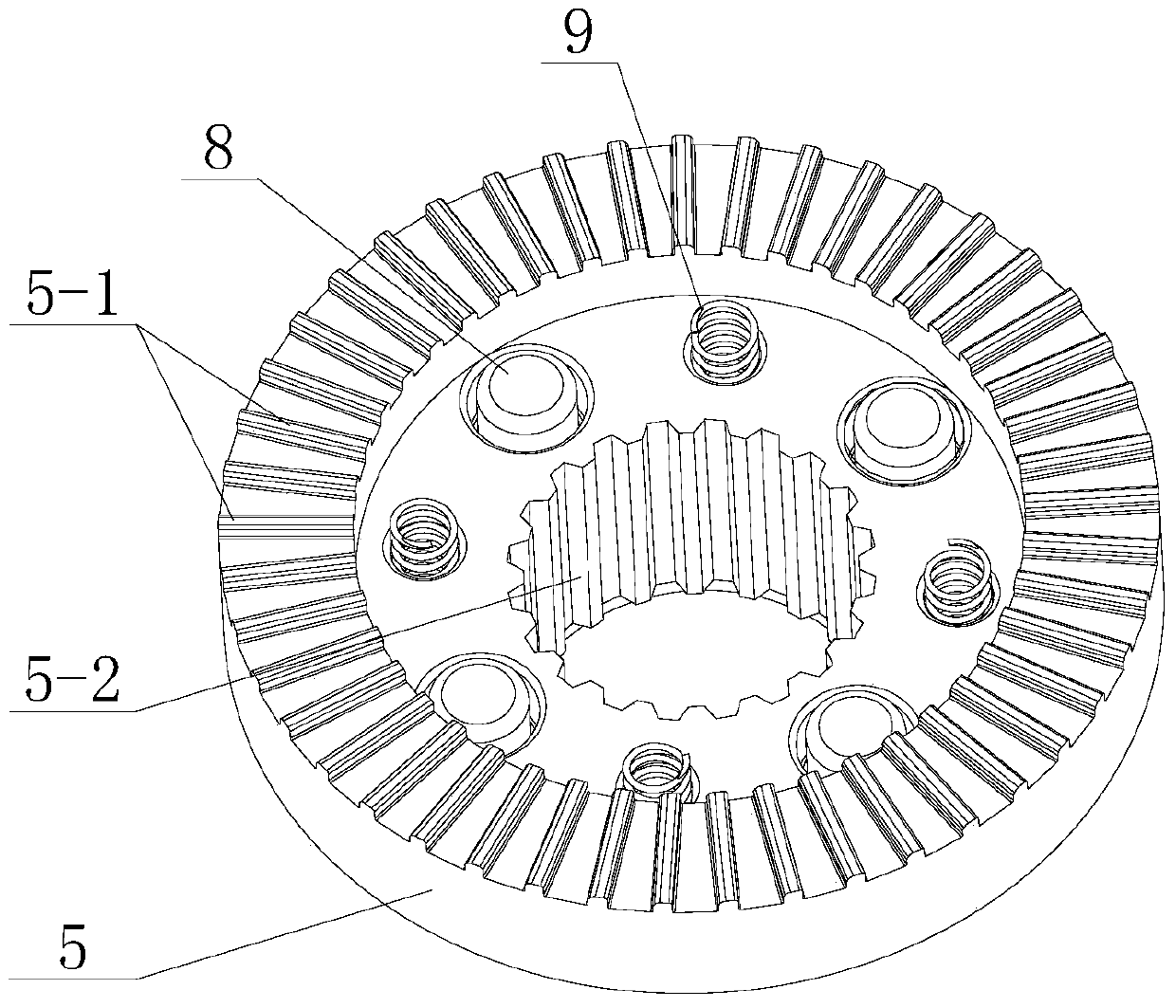

[0037] Such as figure 1 , figure 2 , image 3 Shown is one of the embodiments of the present invention. In this embodiment, the electromagnetic toothed clutch includes a movable toothed sleeve 5 and a fixed toothed sleeve 2 for meshing transmission. The movable toothed sleeve 5 is provided with end face transmission teeth 5-1. The fixed tooth sleeve 2 is correspondingly provided with an end face tooth groove 2-1, and the transmission tooth 5-1 is of equal thickness along the tooth length direction, and the tooth groove 2-1 meshing with the transmission tooth 5-1 is fan-shaped along the groove length direction, that is, the tooth groove The two sides of 2-1 have a predetermined included angle, and the width gradually increases along the radial direction of the fixed tooth sleeve 2 , and gradually decreases along the radial direction of the fixed tooth sleeve 2 .

[0038] Due to the combination of equal-thickness transmission teeth and sector-shaped tooth grooves, the transmi...

Embodiment 2

[0054] Such as Figure 8 As shown, it is the second embodiment of the present invention. In this embodiment, the armature 4 and the movable gear sleeve 5 are manufactured separately and combined together.

[0055] After the armature 4 and the movable gear sleeve 5 are made separately, they can be welded together, or bolted together, or bolts and welded can be used simultaneously. The armature 4 is made of No. 10 steel. Steel No. 10 is more sensitive to magnetic response.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com