Crowned tooth gear, processing method and processing milling cutter

A crown-shaped tooth and gear technology, which is applied in the field of mechanical parts and gears, can solve the problems of affecting the service life of the coupling, increasing contact stress, and deterioration of the contact between the crown-shaped gear teeth and the ring gear, etc., and achieves simple structure, simple processing, The effect of improving performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

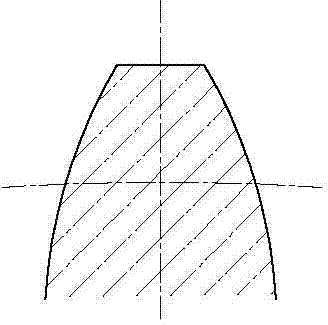

[0040] Depend on Figure 7 It can be seen that a drum-shaped gear is an involute gear, the outer circle of the tooth part is spherical, the tooth shape of the drum-shaped gear 14 is a gradual tooth shape, and the gear teeth have 14 teeth. The long direction is drum-shaped, the tooth profile of the radial section of the gear teeth 14 is consistent, the tooth root is a full arc, and the tooth profile angle is the normal tooth profile angle.

[0041] Depend on Figure 8 , Figure 9 , Figure 10 It can be seen that, since the tooth shape of the drum gear tooth 14 at the maximum drum shape is the same as that deviated from the drum gear tooth 14 maximum drum shape, that is, the tooth shape of the drum gear tooth 14 radial section is the same, the wheel The tooth 14 is in good contact with the tooth shape of the ring gear at any position.

[0042] A method for processing crown-shaped gears as described above, adopts a forming method to process the tooth shape, and it includes th...

Embodiment 2

[0056] Depend on Figure 13 It can be seen that the milling cutter described in this embodiment adopts a finger-shaped milling cutter, and the involute segment 10 of the cutting edge is determined by calculating its coordinate value using gear parameters, and the relational formula is:

[0057] x g =R x sin ω x

[0058] Y g =R x cos ω x

[0059] Where: R x is the radius of any circle of the gear, ω x is the center half angle between the teeth

[0060] ω x =(π-4ξtgα) / 2Z+Δ s / mZ+(invα x -invα)

[0061] Where: ξ is the gear variation coefficient, Δ s is the thinning amount α of the tooth thickness of the gear indexing circle x is the arbitrary circular pressure angle of the gear, α is the graduated circle pressure angle of the gear, Z is the number of teeth of the gear, and m is the modulus of the gear.

[0062] During processing, the milling cutter walks a circular trajectory in the direction of the tooth direction, and the remainder is the same as in embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com