CNC (computer numerical control) rotary clamp of machining center

A technology of rotating clamping device and machining center, which is applied in the direction of positioning device, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large quality of the main fixture, high labor intensity, low work efficiency, etc., to improve processing performance and The effect of machining accuracy, flexible adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

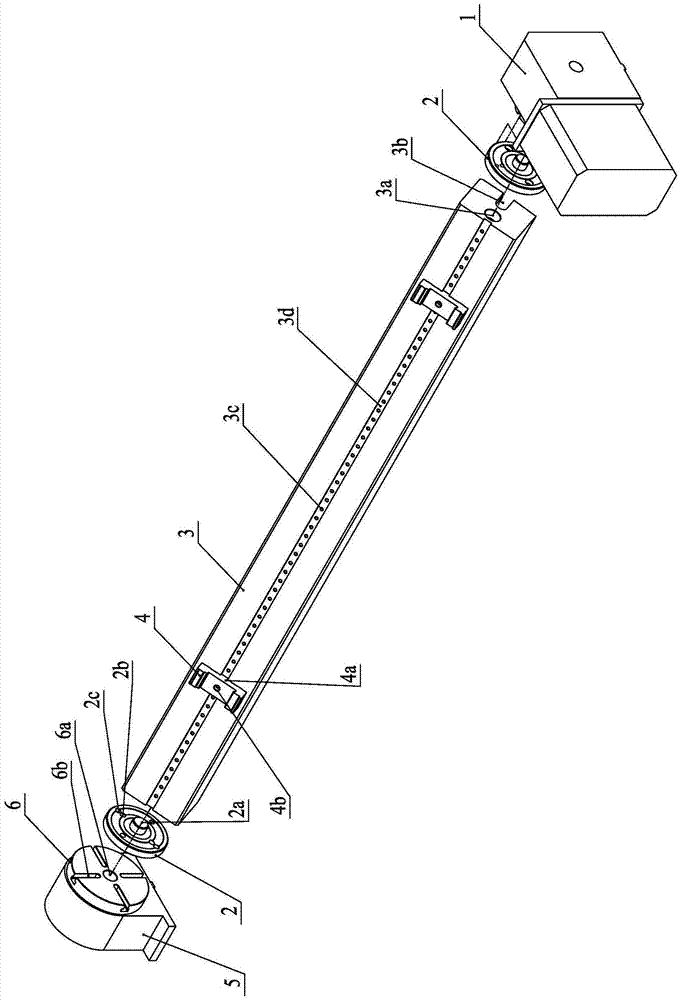

[0014] As shown in the figure: the CNC rotary clamping device of the machining center in the embodiment is mainly composed of a main clamp 3 , a CNC indexing head 1 , a tailstock 5 and a workpiece clamp 4 .

[0015] like figure 1 As shown, the main fixture 3 is elongated, the head end of the main fixture 3 is connected to the numerical control indexing head 1, and the tail end of the main fixture 3 is rotatably supported and installed on the tailstock 5; the front surface of the main fixture 3 is set There are several first installation holes 3c uniformly distributed along the length direction of the main fixture 3, the workpiece holder 4 is provided with a second installation hole 4a, and the workpiece holder 4 is installed in the first installation hole 3c and the second installation hole 4a The screws are fastened on the front surface of the main fixture 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com