Winding machine

A winder, mechanical technology, applied in thin material handling, conveying filamentous materials, transportation and packaging, etc., which can solve the problems of broken yarn winding and damage to the installation part of the contact roller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments of the present invention will be described.

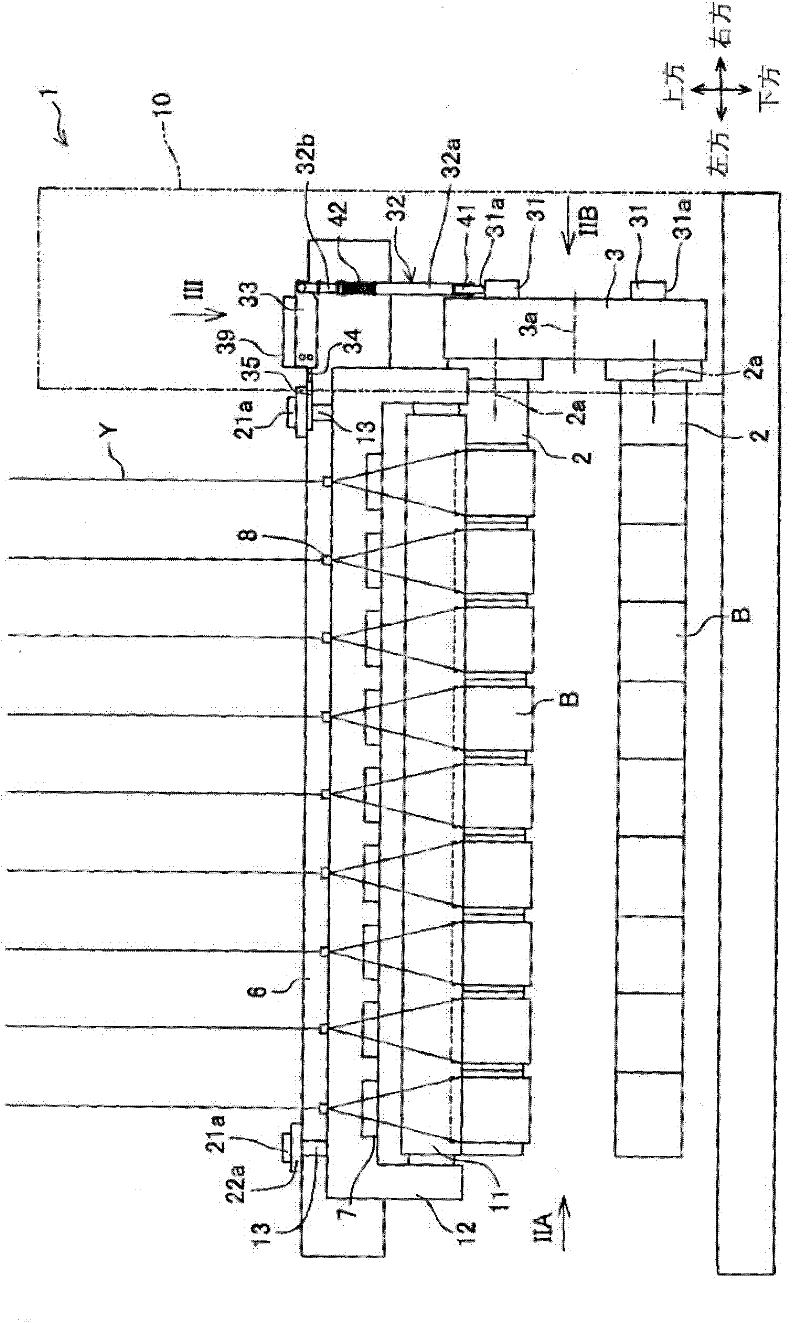

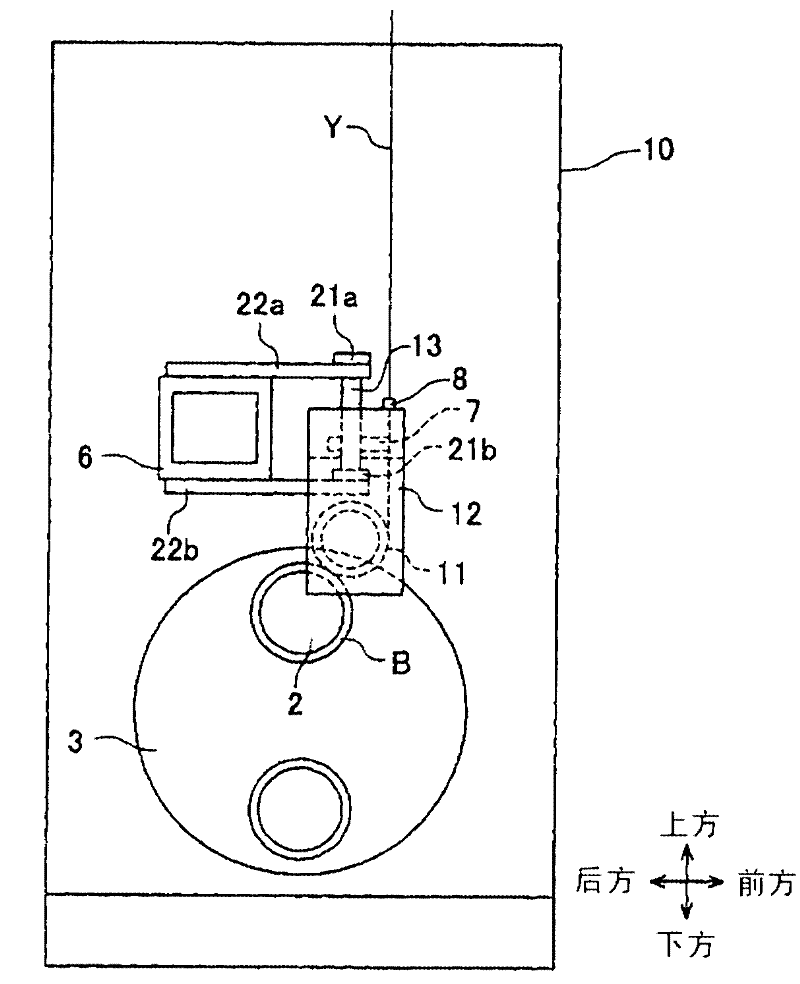

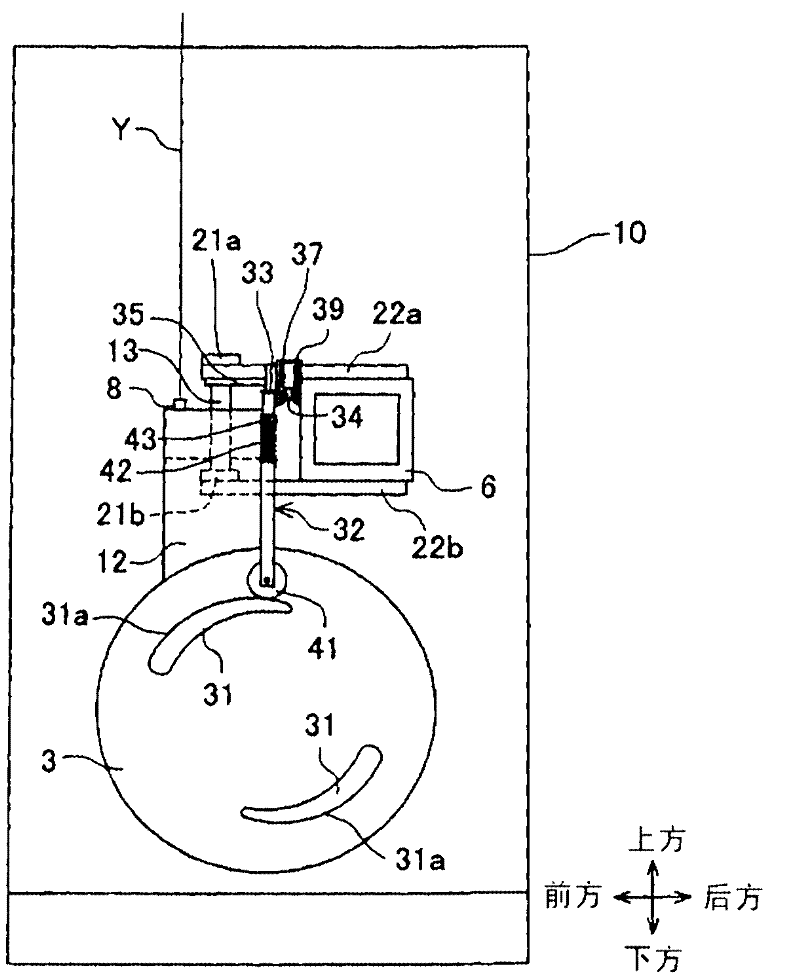

[0039] figure 1 It is the figure which looked at the winding machine concerning this embodiment from the front. Figure 2A It is viewed from the direction of arrow IIA figure 1 diagram. Figure 2B It is viewed from the direction of arrow IIB figure 1 diagram. Figure 3A It is viewed from the direction of arrow III figure 1 diagram. Figure 3B From Figure 3A The figure which removed the attachment member 22a and the swing shaft 36 mentioned later. Figure 4 yes Figure 3A Sectional view of line IV-IV. Among them, in figure 1 In , a part of the body 10 of the winding machine 1 is shown with a two-dot chain line, and the inside of the part indicated with a two-dot chain line is shown. Figure 3B In the figure, the position of the mounting member 22a is indicated by a two-dot chain line in order to make the positional relationship of each member easy to understand. In addition, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com