Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136results about How to "Guaranteed pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

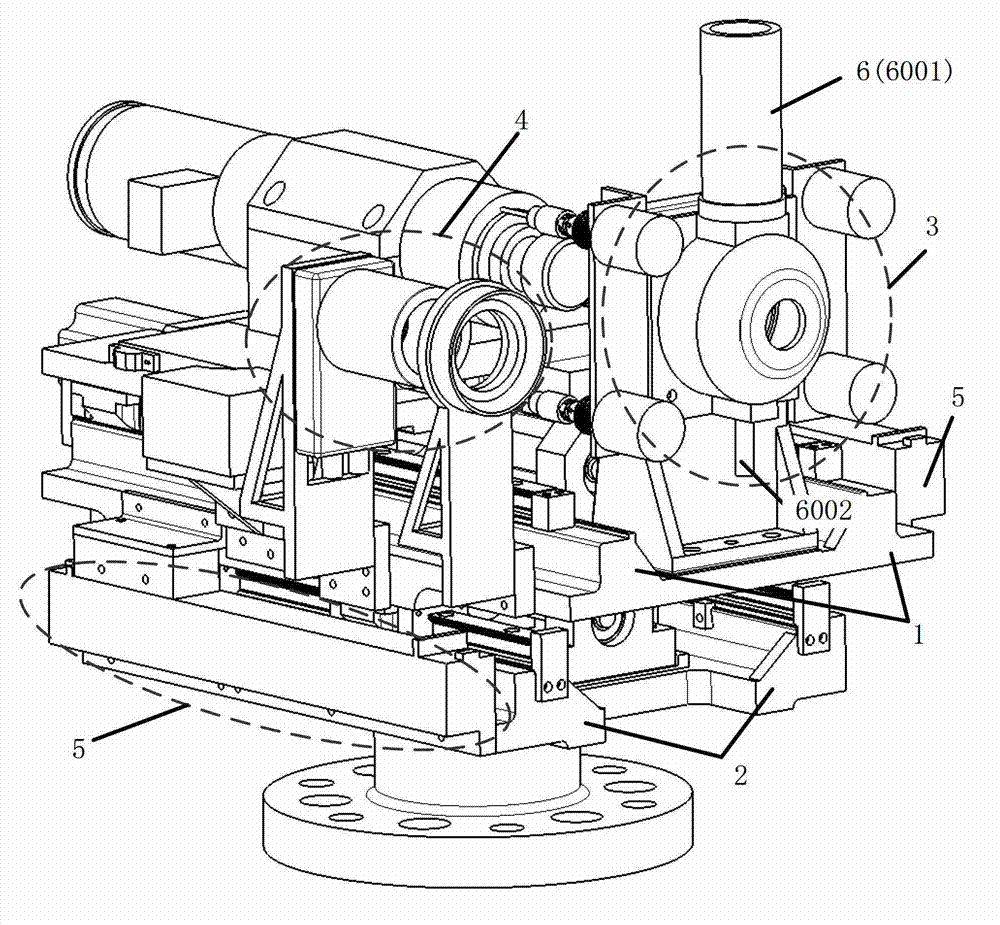

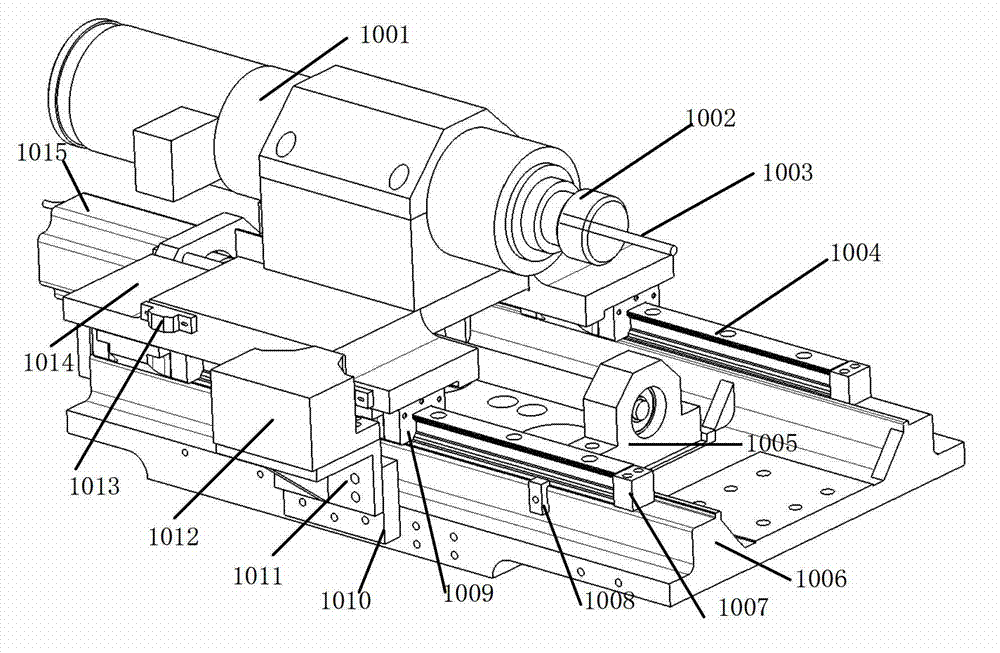

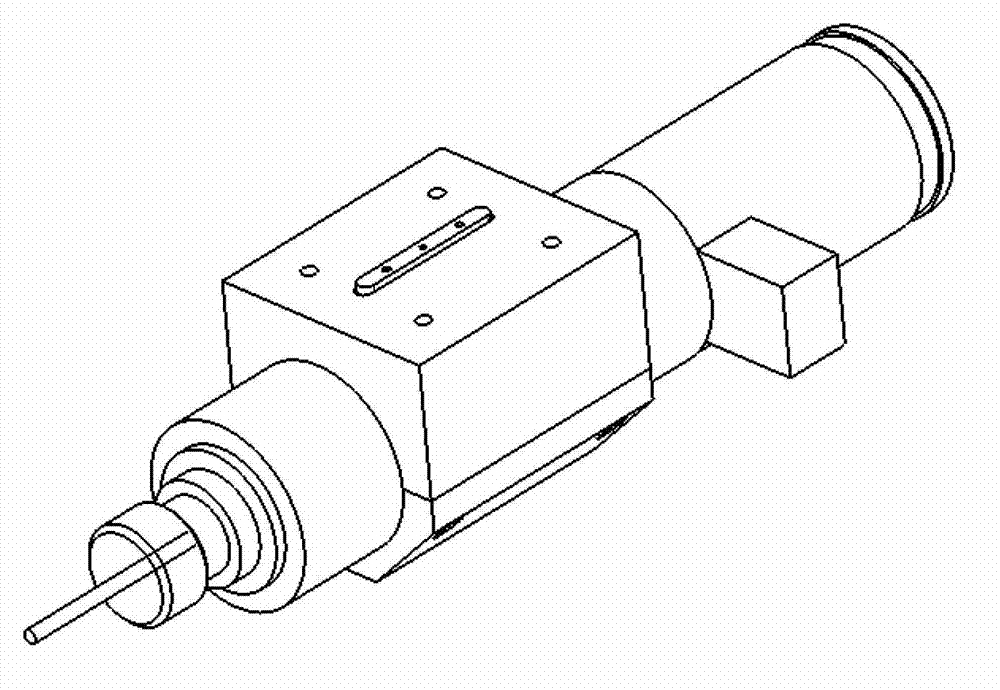

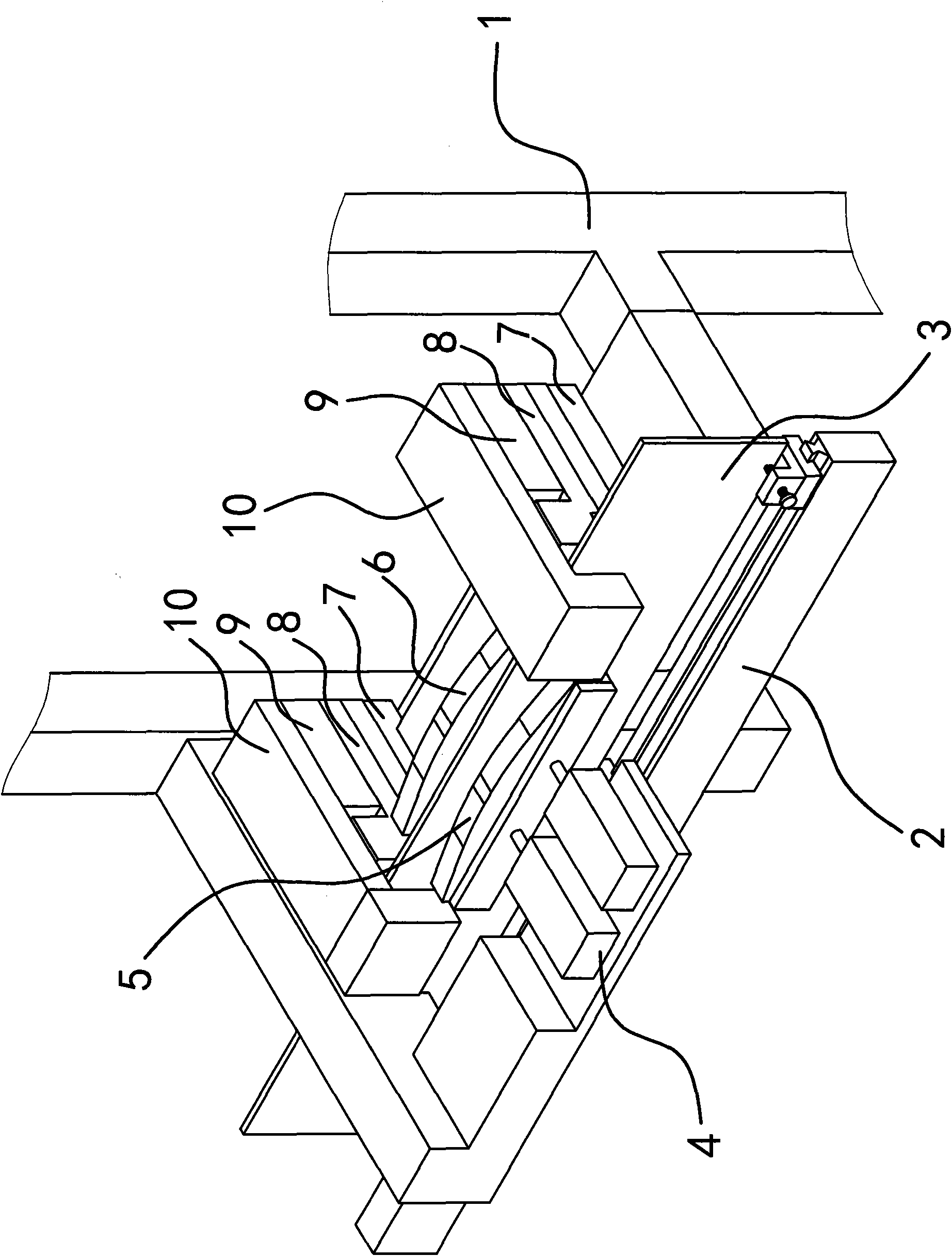

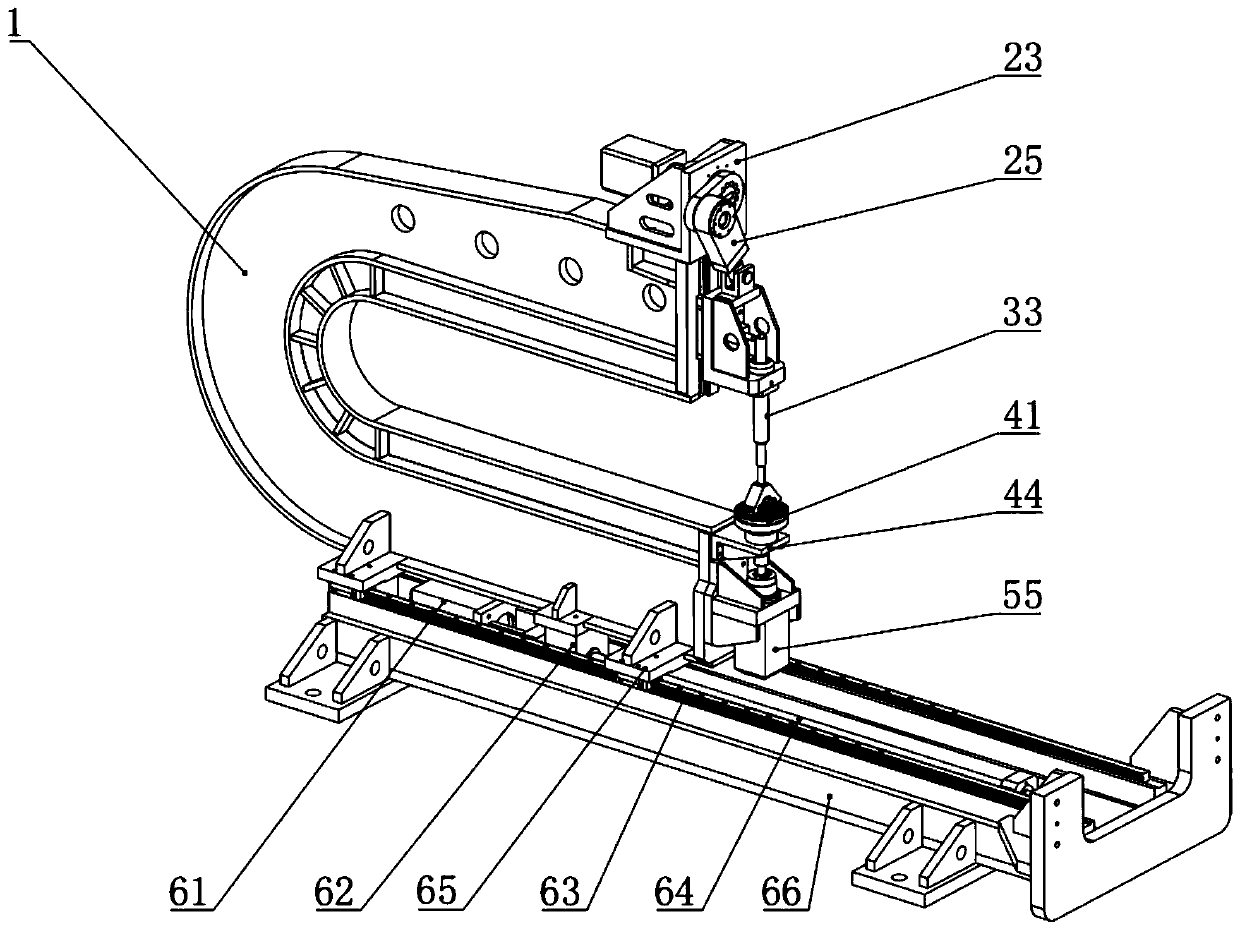

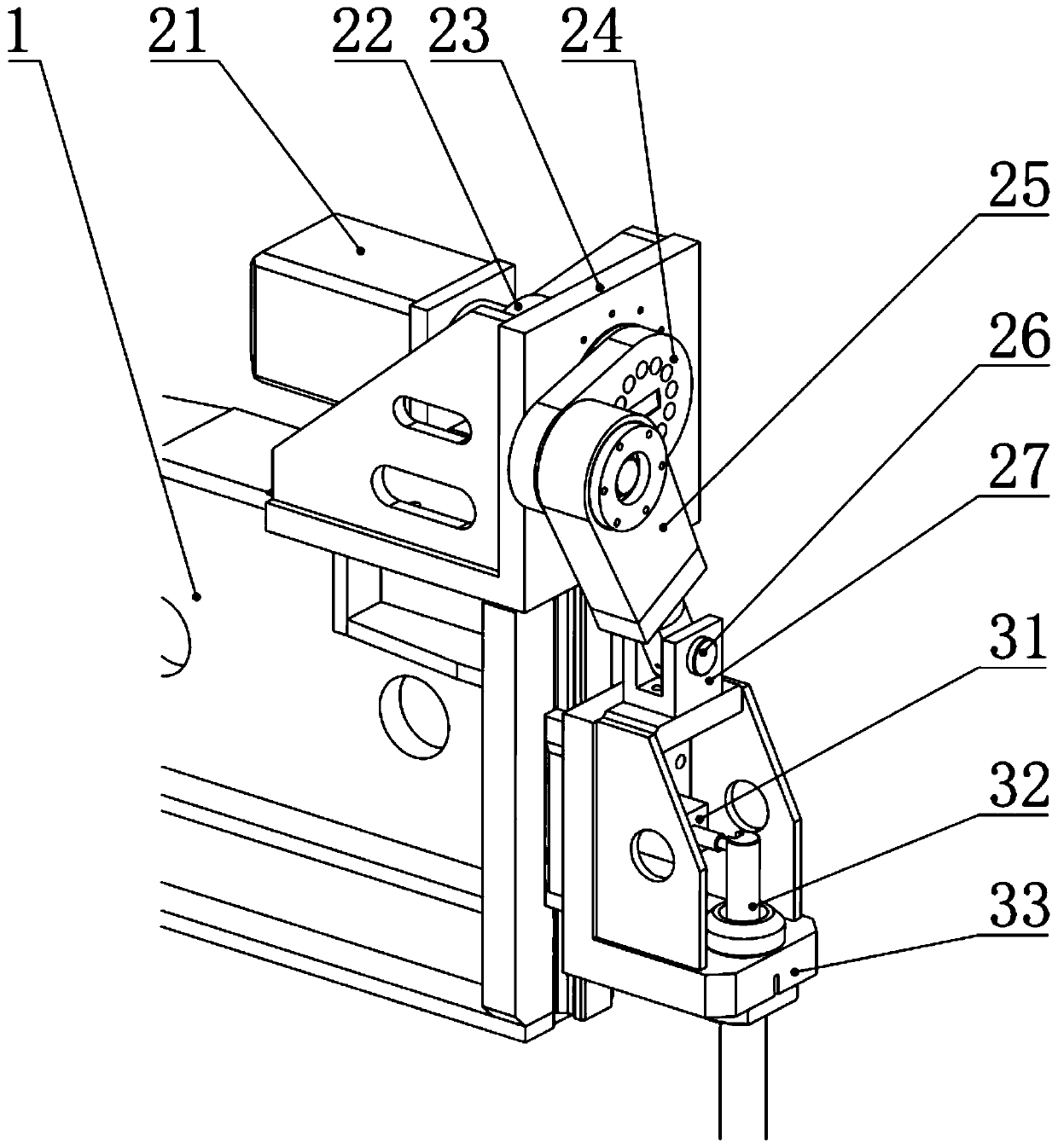

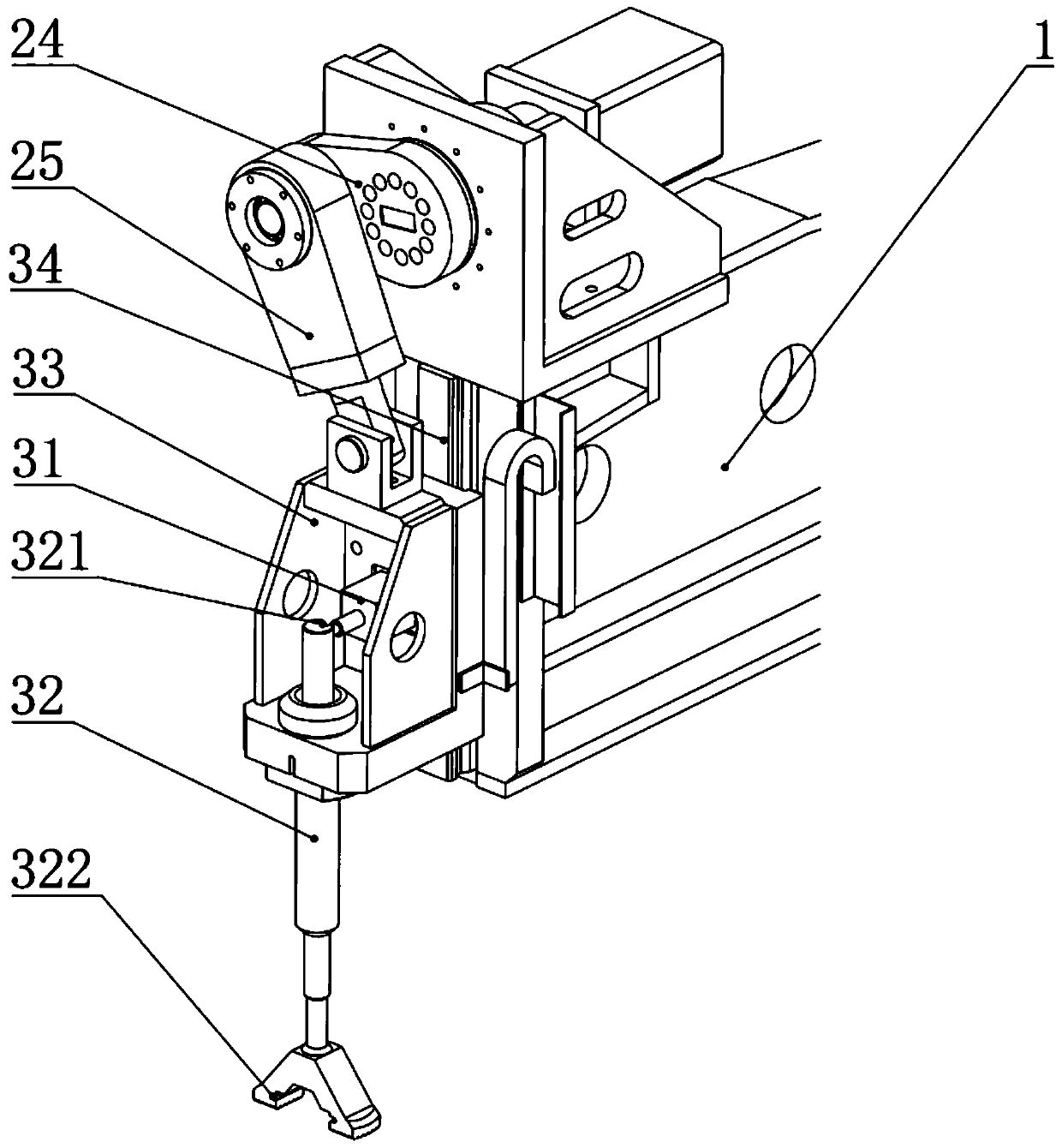

High-accuracy hole forming device for aircraft wall panel and a method of high-accuracy hole forming device

ActiveCN102756138AGuaranteed surface qualityOptimum working parametersAutomatic control devicesMeasurement/indication equipmentsControl systemClosed loop feedback

The invention provides a high-accuracy hole forming device for an aircraft wall panel and a method of the high-accuracy hole forming device. A main shaft module is used for feeding an electric main shaft along a hole forming axis; a feeding module is used for guaranteeing movement of the main shaft module and a pressure pin normal leveling module in the hole forming axis and providing pressure for a pressure pin to be abutted against the wall panel; the pressure pin normal leveling module is used for guaranteeing the stability of the wall panel in the hole forming process; the feeding module is matched with a grating scale module for work to realize accurate control over the hole forming feeding displacement; a visual alignment module and a control system form a closed loop feedback loop; positional deviation error of a projection point of a hole forming main shaft on the wall panel surface and an actual hole forming point can be measured and fed back in real time; and correction is performed through the closed loop system to guarantee that the positional accuracy of a formed hole is within a tolerance requirement range. According to the high-accuracy hole forming device, the positional accuracy, the surface roughness and the dimensional accuracy of the hole can meet the design requirements well; and meanwhile, slanting holes and oblique holes are not formed in the hole forming process, the temperature of a hole forming region is kept at a normal working temperature and the chip removal is normal.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

All-in-one machine for shell fabric washing and drying

ActiveCN103409960ASimple structureWash and rinse thoroughlyTextile treatment machine partsDrive motorWater washing

The invention provides an all-in-one machine for shell fabric washing and drying, and belongs to the technical field of machines. The all-in-one machine solves the technical problems that shell fabric is incapable of being washed, dried and collected at one time after being woven. The all-in-one machine for shell fabric washing and drying comprises a base, wherein the base is provided with a washing box; the box body of the washing box is partitioned into a washing tank and a bleaching tank through a partition board in the middle part of the washing box; two ends of the washing box are respectively provided with a shell fabric inlet I and a shell fabric outlet II; the inner wall of the washing box is provided with a washing roller I and a washing roller II which are parallel to each other; the washing roller I and the washing roller II are both positioned in the washing tank; the washing roller I is driven by a driving motor I; the base is further provided with a drying box; a shell fabric collecting device is arranged between the drying box and the base; the base is further provided with a shell fabric collecting box. The all-in-one machine has the advantages that the shell fabric can be washed, dried, collected and the like at one time.

Owner:ZHEJIANG HUAYUAN TEXTILE

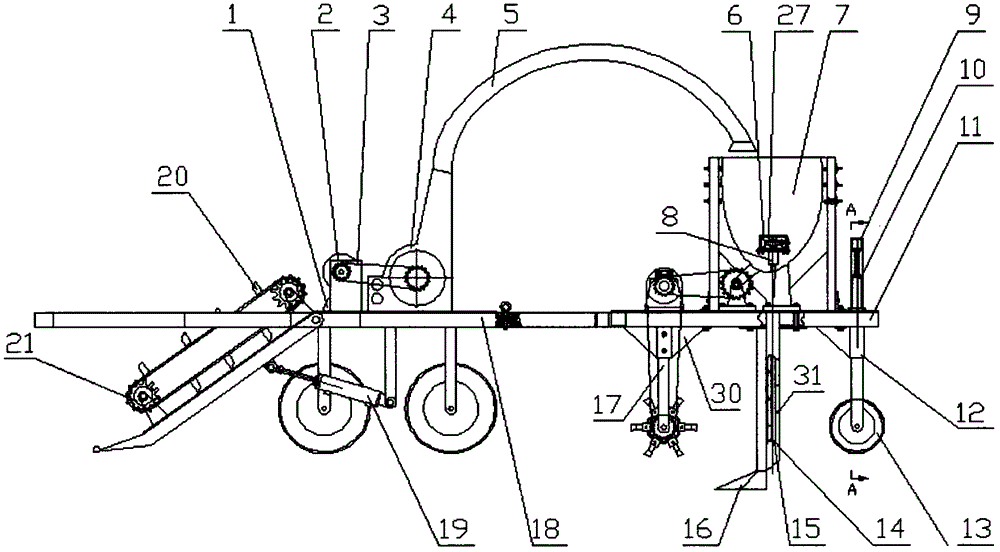

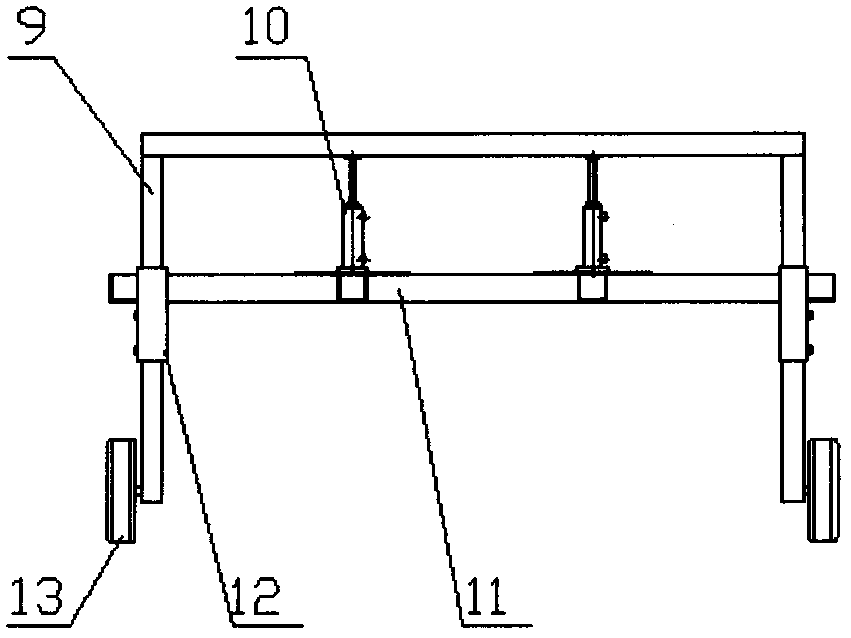

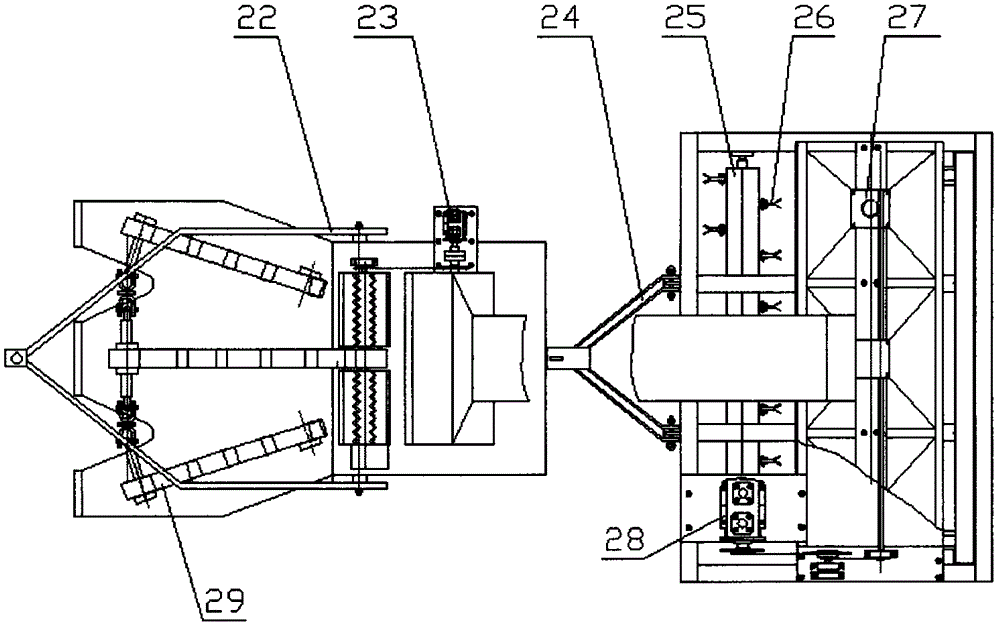

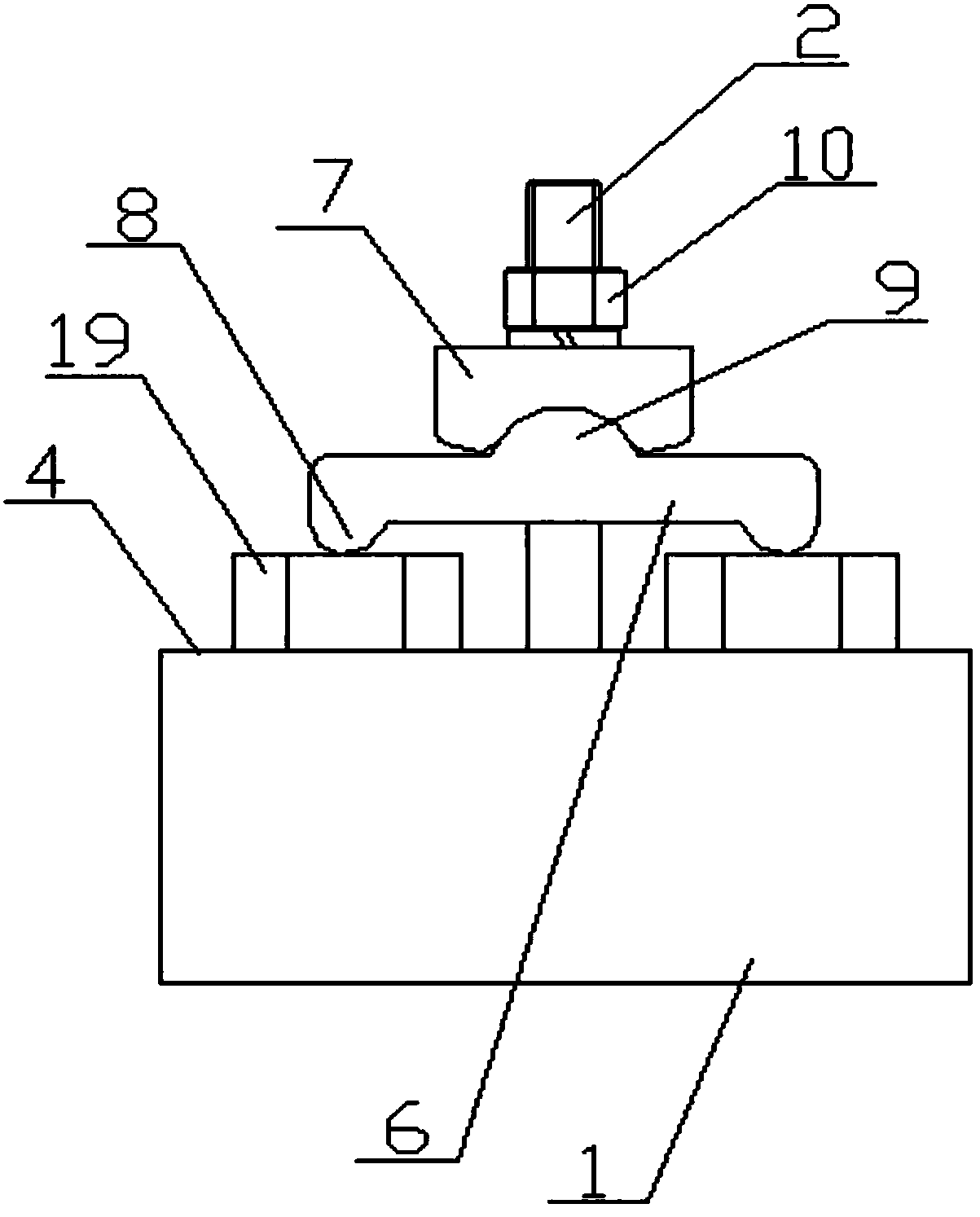

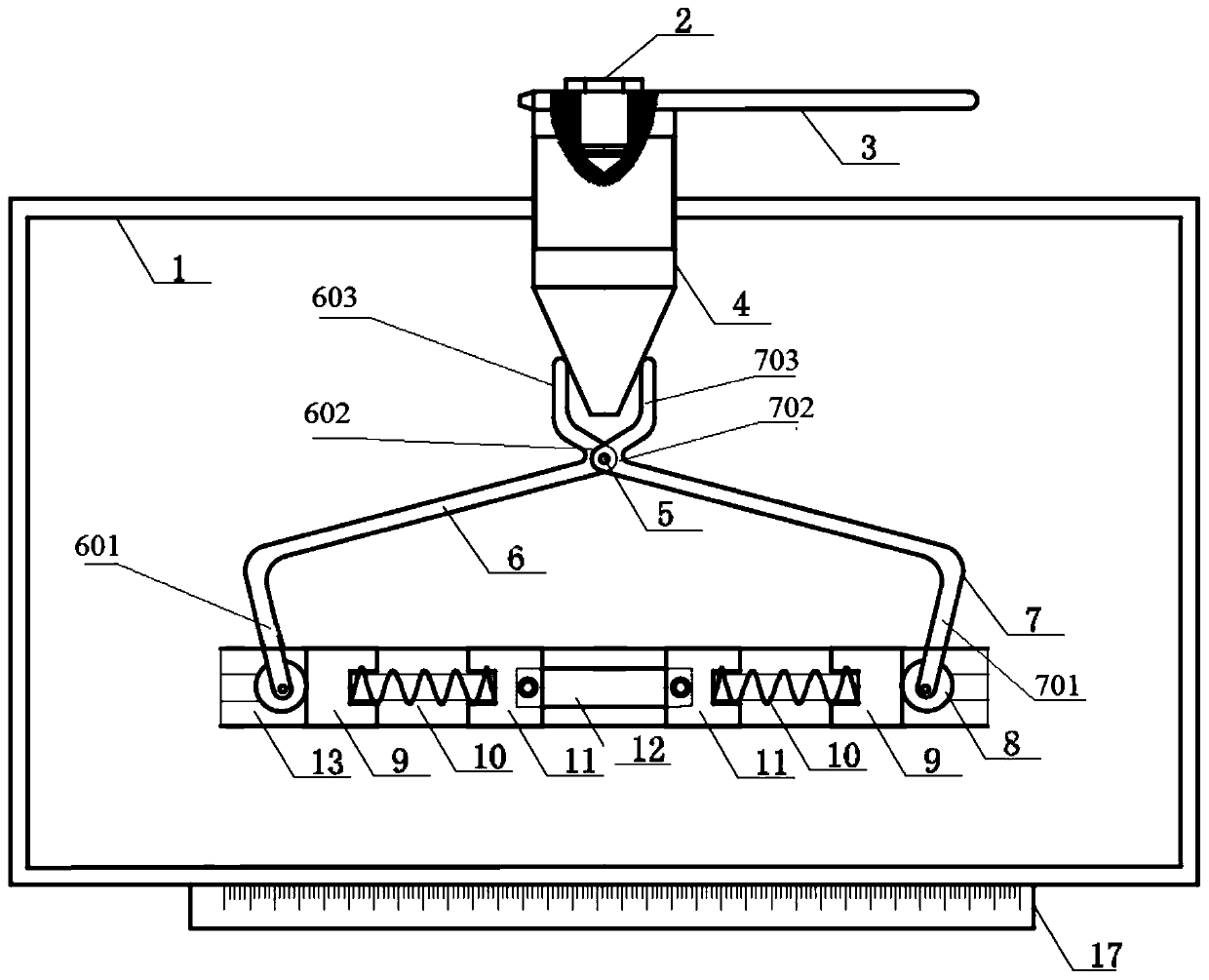

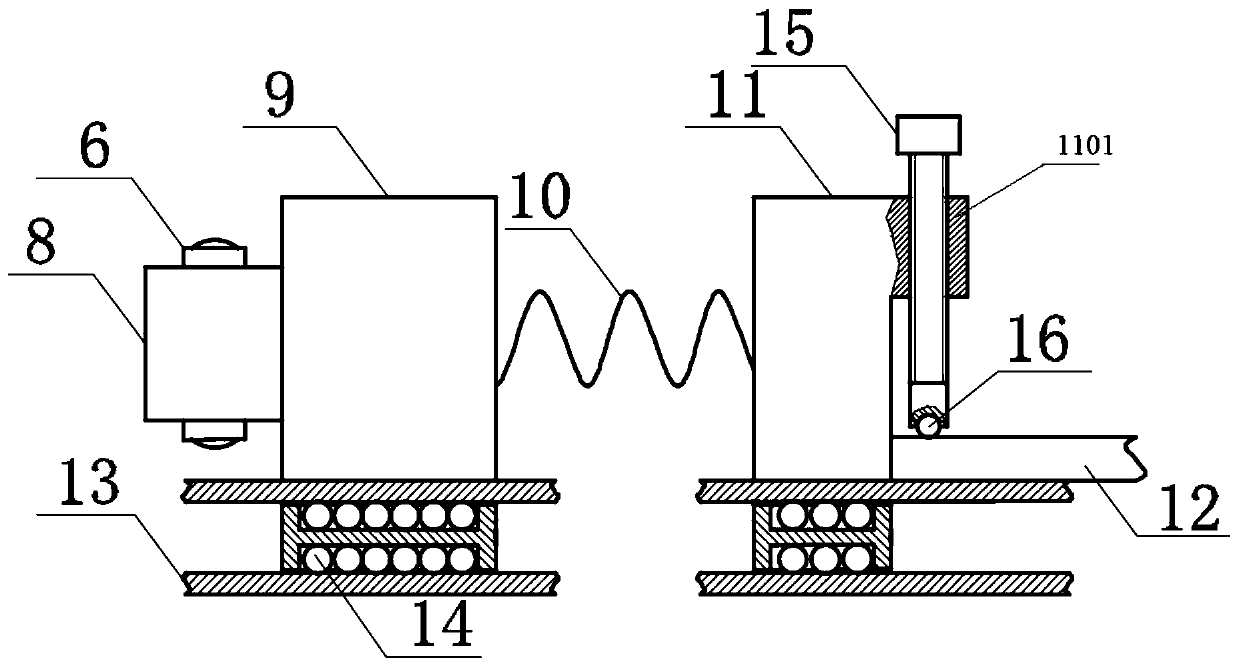

Maize straw three-dimensional returning machine

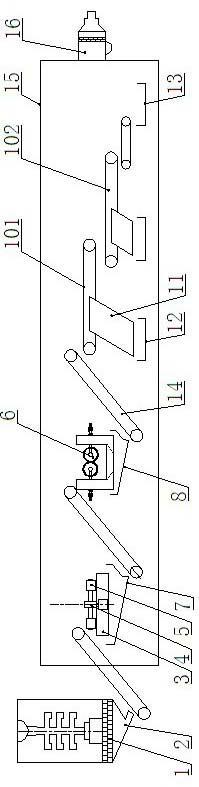

InactiveCN105210571AGood physical propertiesImprove fertilityLoadersCrop conditionersControl systemAgricultural engineering

The invention relates to a maize straw three-dimensional returning machine which mainly comprises a front frame, a rear frame, a straw picking device, a straw feeding device, a straw crusher, a stubble cleaning mechanism, a straw deep placement device, a hydraulic control depth-limiting mechanism, a front motor, a rear motor, a hydraulic control system assembly and the like. The straw picking device is assembled at the front end of the front frame, the straw feeding device is assembled on the front part of the front frame, the straw crusher is assembled in the rear part of the front frame, the stubble cleaning mechanism is assembled below the front part of the rear frame, the straw deep placement device is assembled in the middle part of the rear frame, the hydraulic control depth-limiting mechanism is assembled in the rear part of the rear frame, the front motor is arranged on the front frame, the rear motor is arranged on the rear frame, and power is provided to the pre-posed motor and the post-posed motor by a hydraulic output system of a tractor. The maize straw three-dimensional returning machine during work is pulled by the tractor, and picks, crushes and deeply places the maize straws in a field as the tractor moves and meanwhile cleans stubbles, so that operations of ground mulching return to field, reclaimed soil return to field and soil deep placement return to field on the maize straws are realized.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

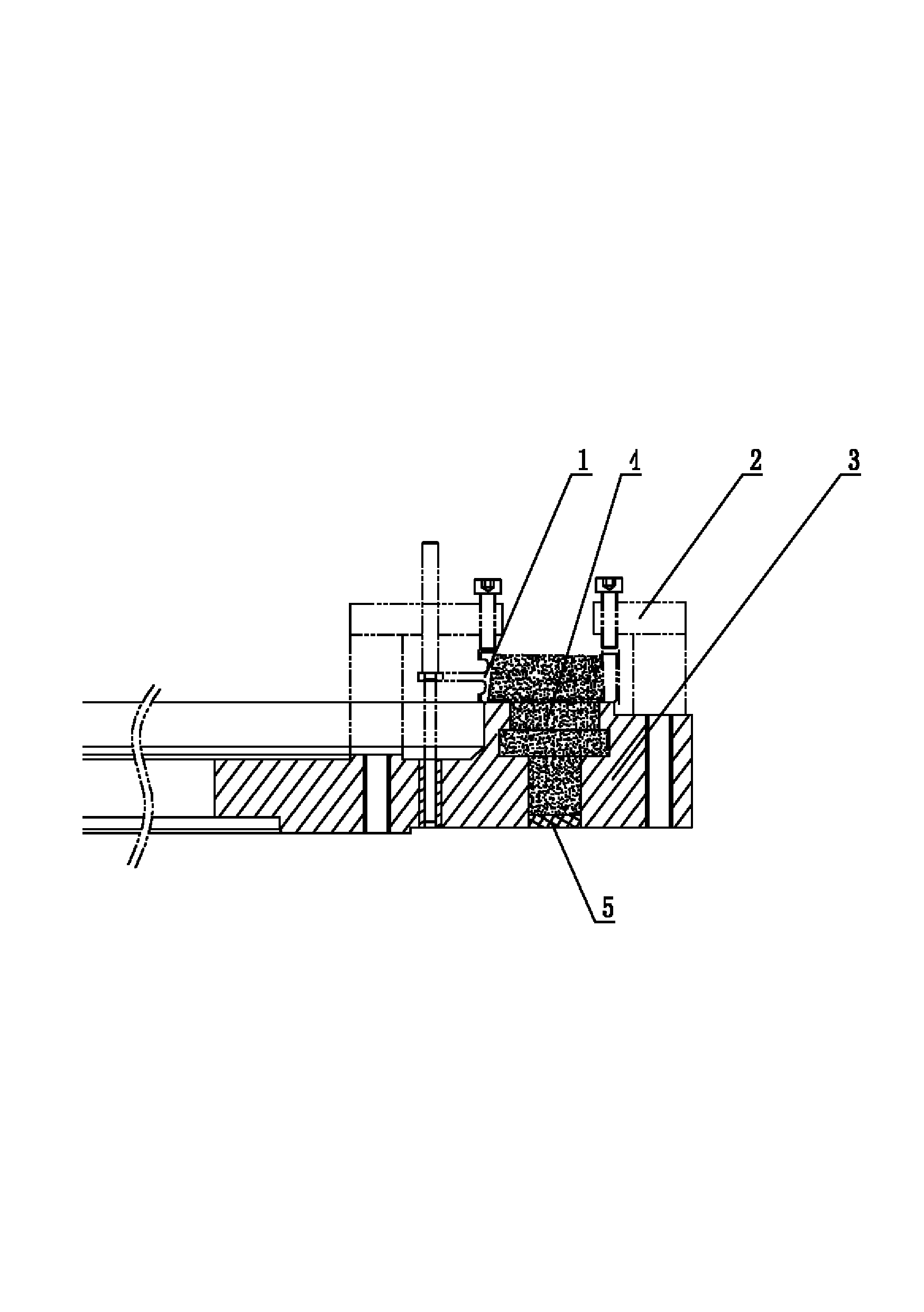

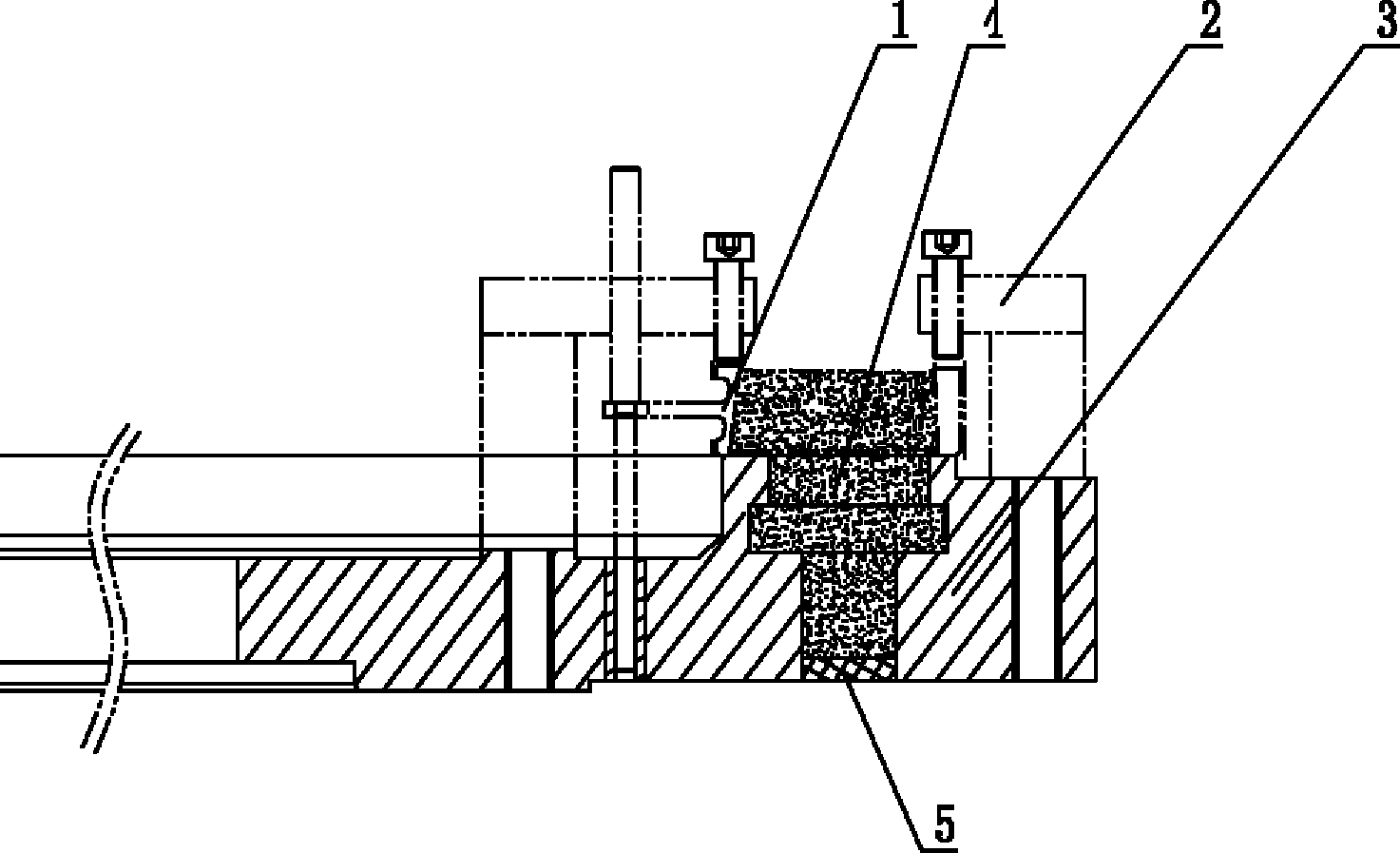

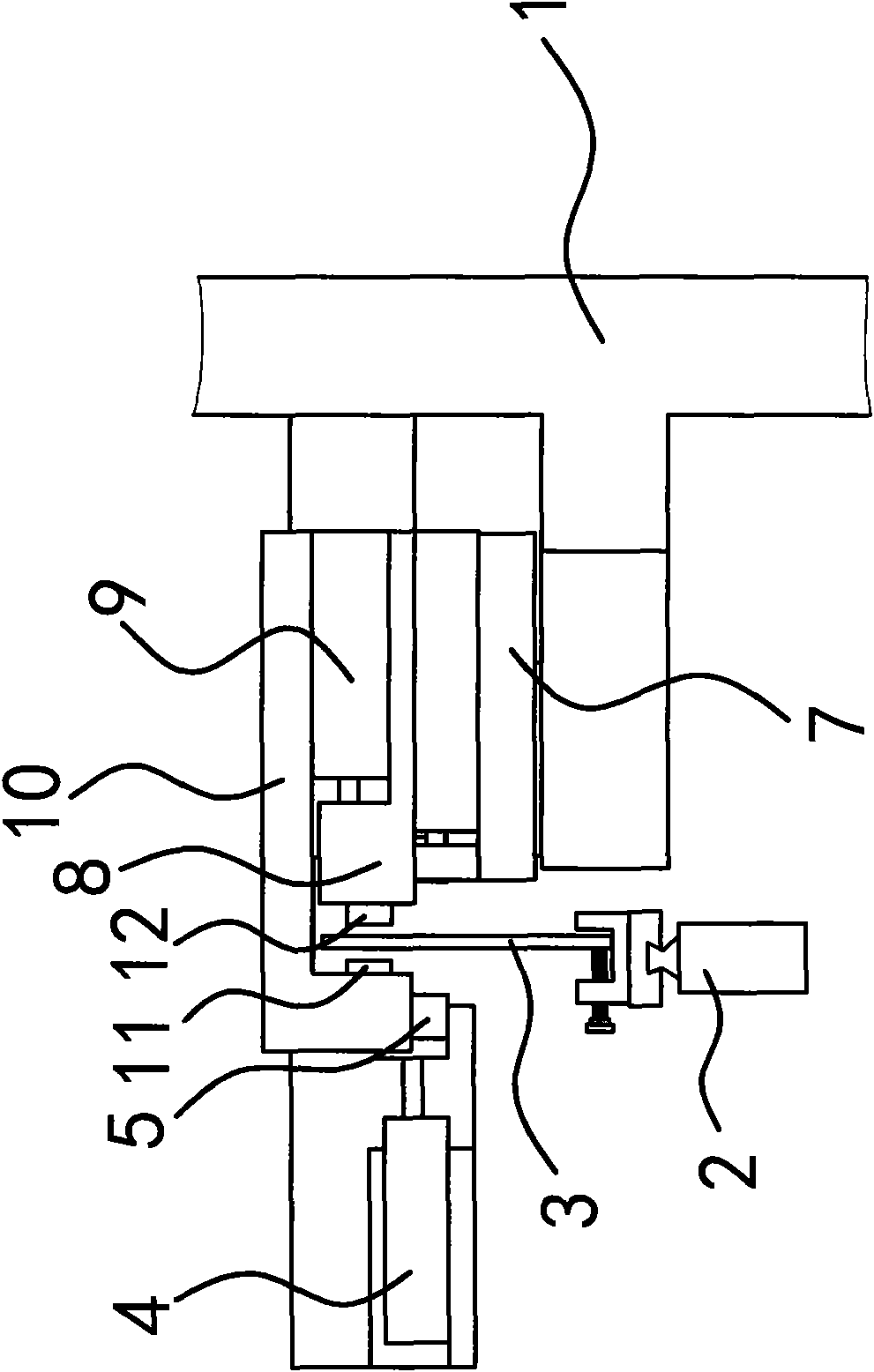

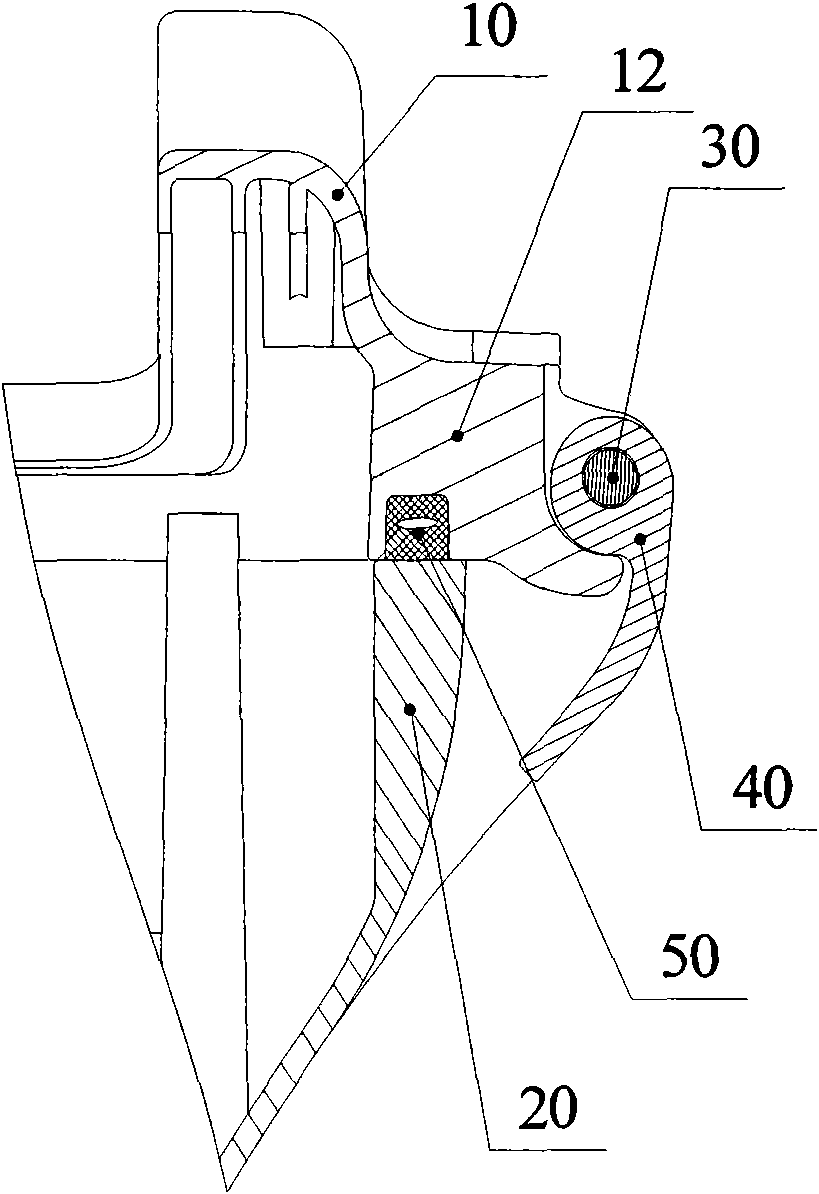

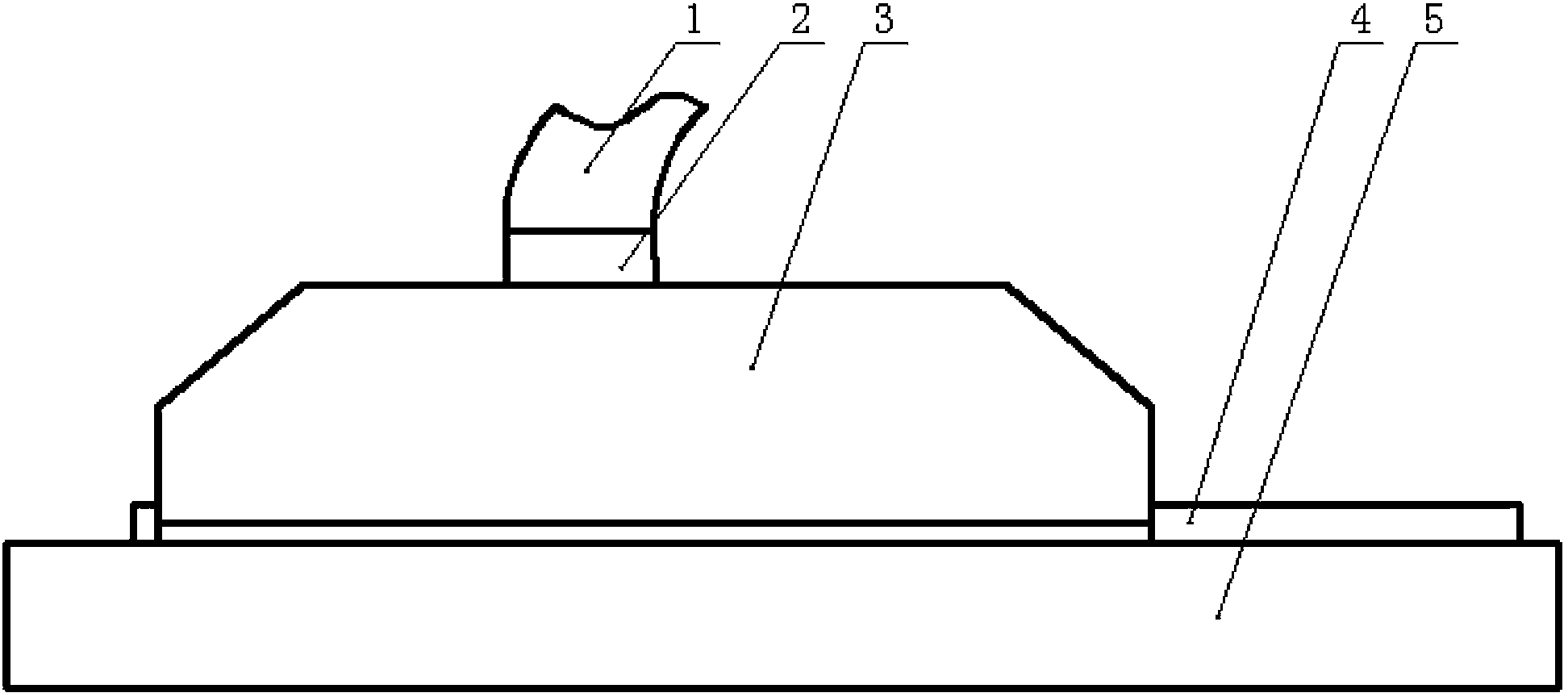

Novel integral turning method of blades

InactiveCN102145460AGuaranteed rigidityGuaranteed pressing forcePositioning apparatusMetal-working holdersAlloyMachining

The invention provides a novel integral turning method of blades, which can effectively solve the problem of insufficient pressing force of the blades during the assembly machining of the blades in the past and also overcome the defect of insufficient rigidity caused by interrupted cutting. The novel integral turning method of the blades is simple and can greatly enhance machining efficiency. The novel integral turning method of the blades is characterized by comprising the following steps of: positioning the blades by simulating an assembling state, and pressing the positioned blades on a turning jig by using a press plate; then pouring a low-melting-point alloy between the blades and the turning jig; disassembling the press plate after the low-melting-point alloy is cooled and solidified; firmly bonding the blades and the turning jig depending on the low-melting-point alloy so that an integral rigid part is formed by the blades and the turning jig, and then carrying out assembly machining on the blades; and after the blades are subjected to the assembly machining, placing the blades and the turning jig into hot water so that the blades and the turning jig are separated because the solid low-melting-point alloy is melted when heated, and therefore the assembly machining of the blades is completed.

Owner:WUXI TURBINE BLADE

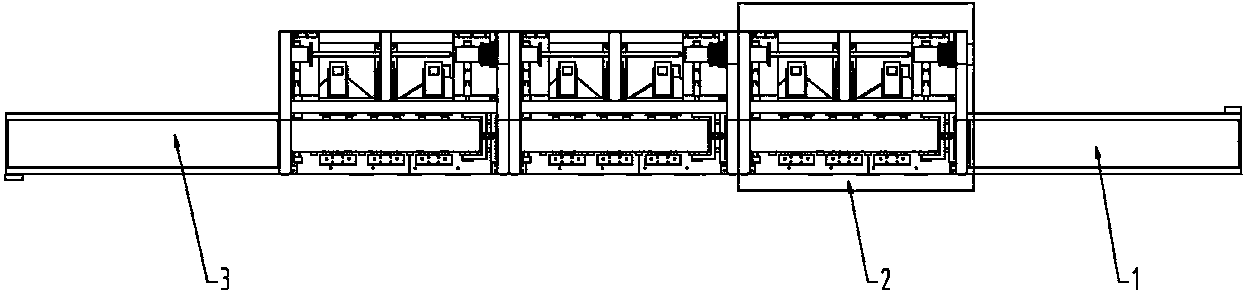

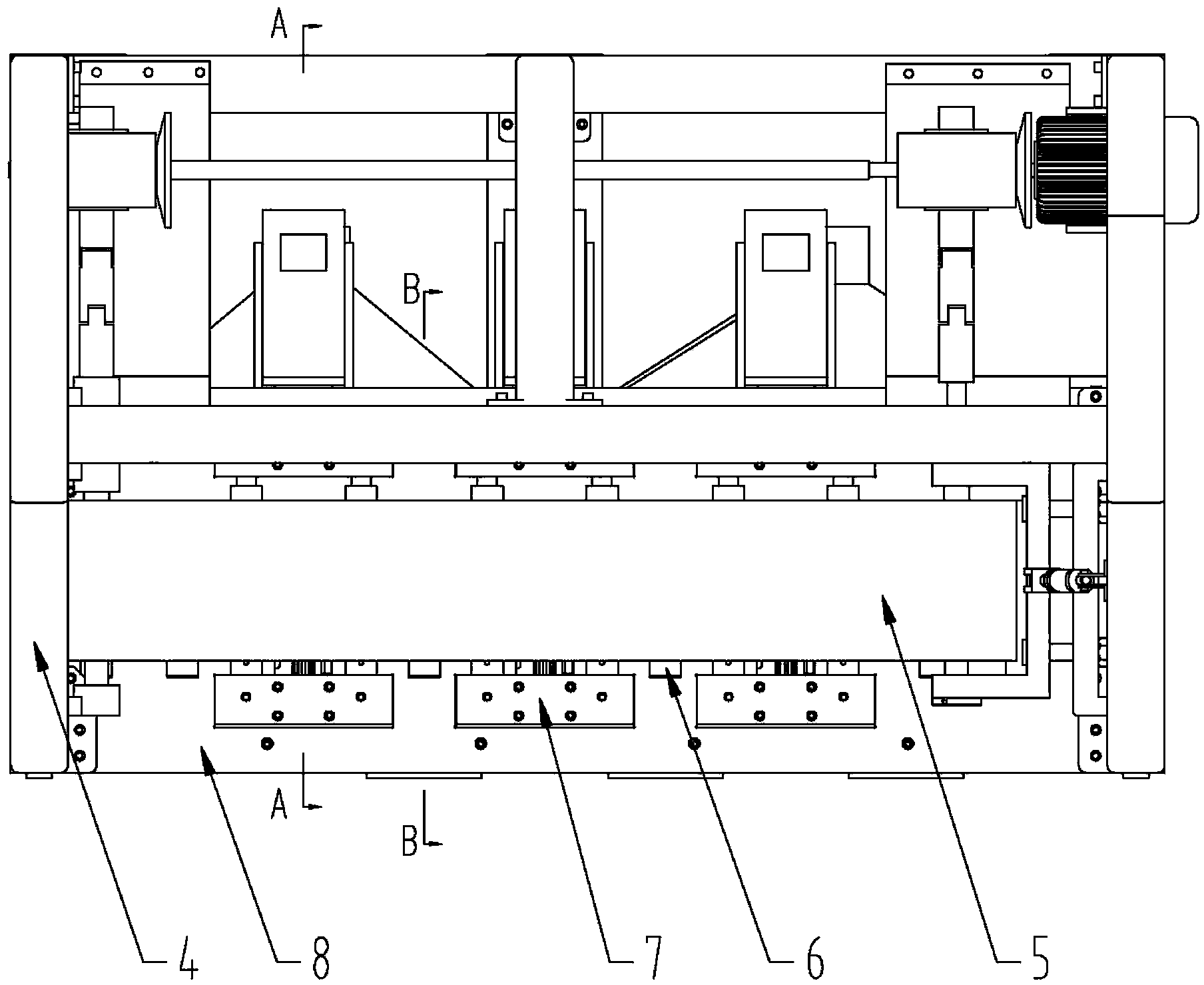

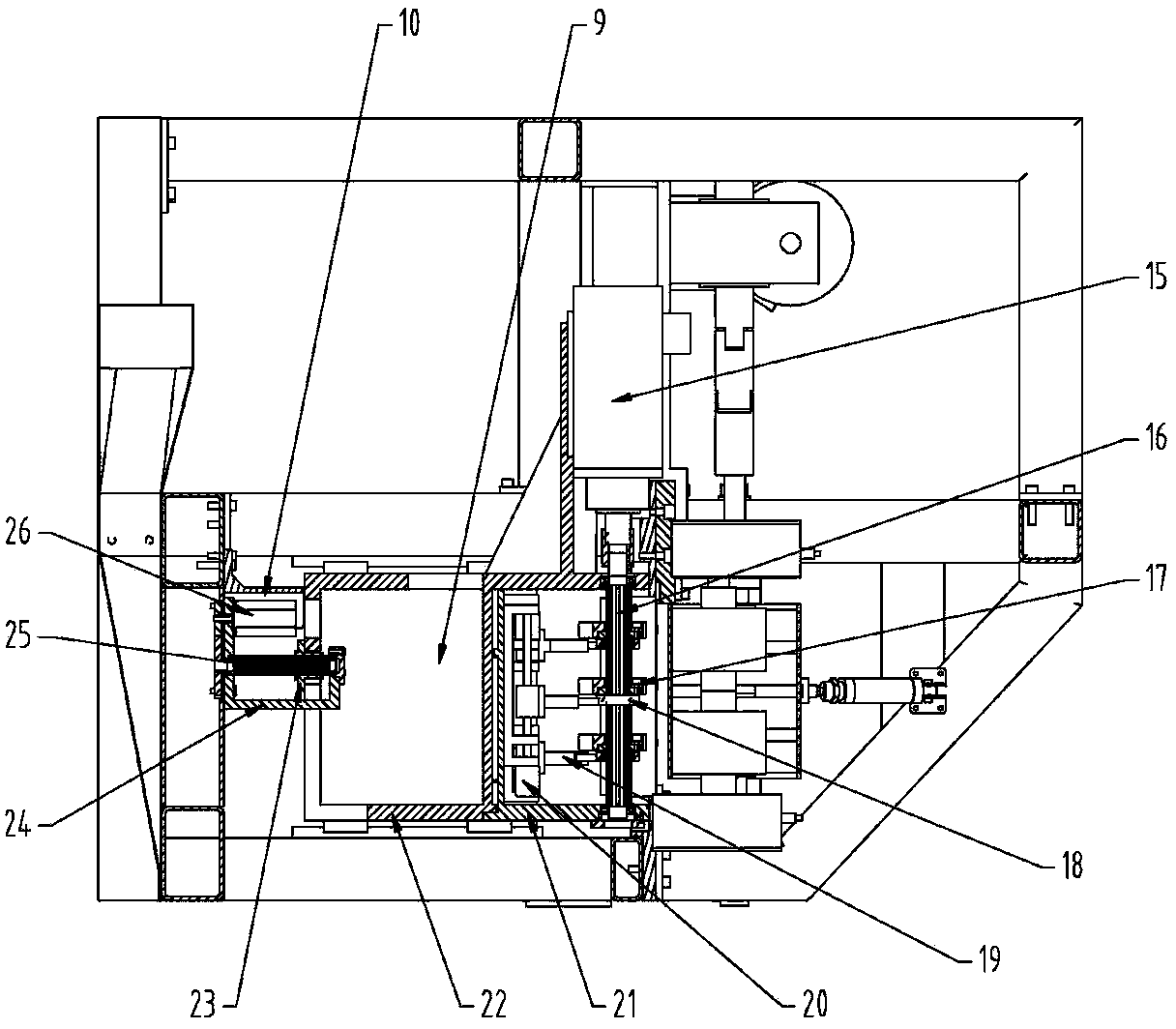

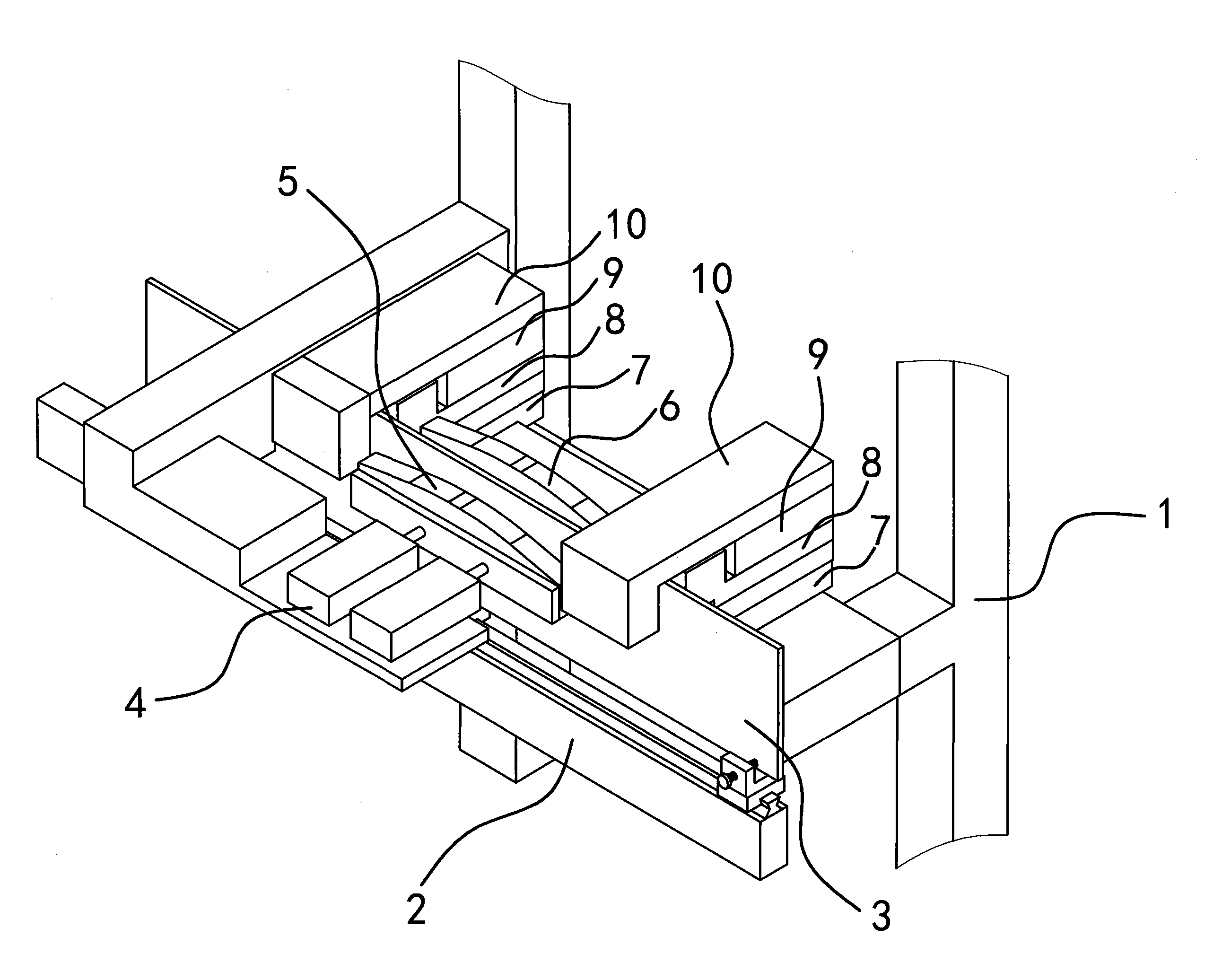

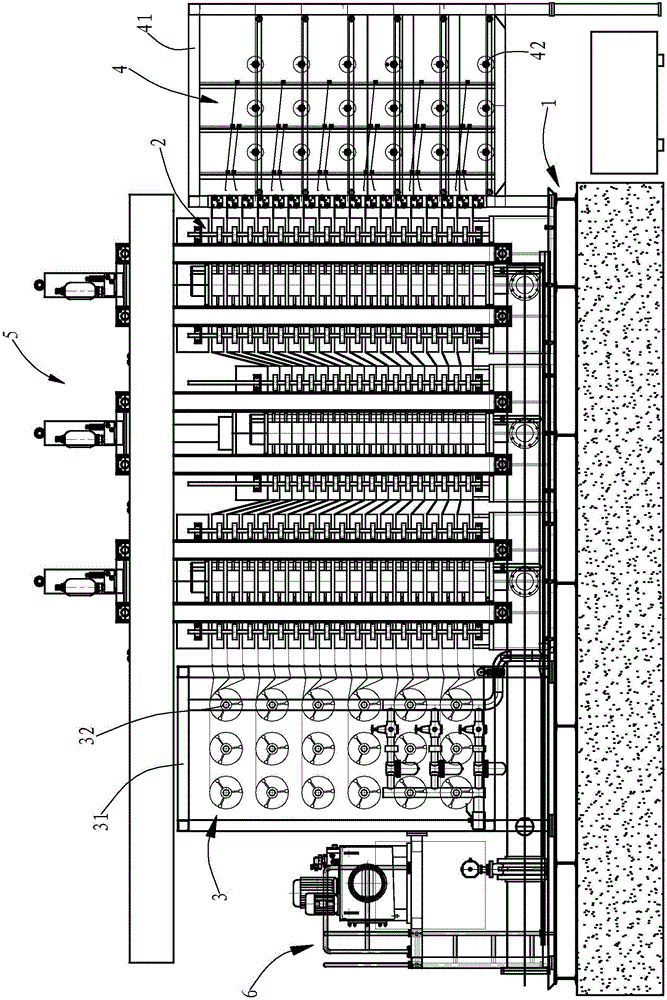

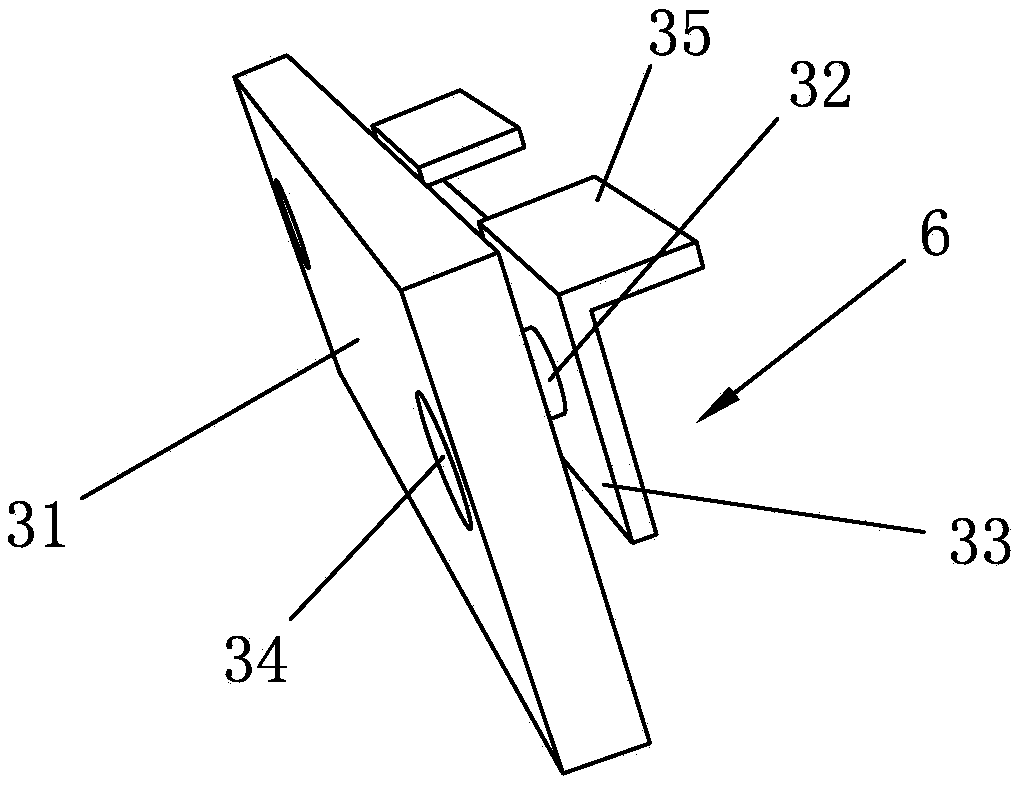

Full-automatic antique wood floor making machine

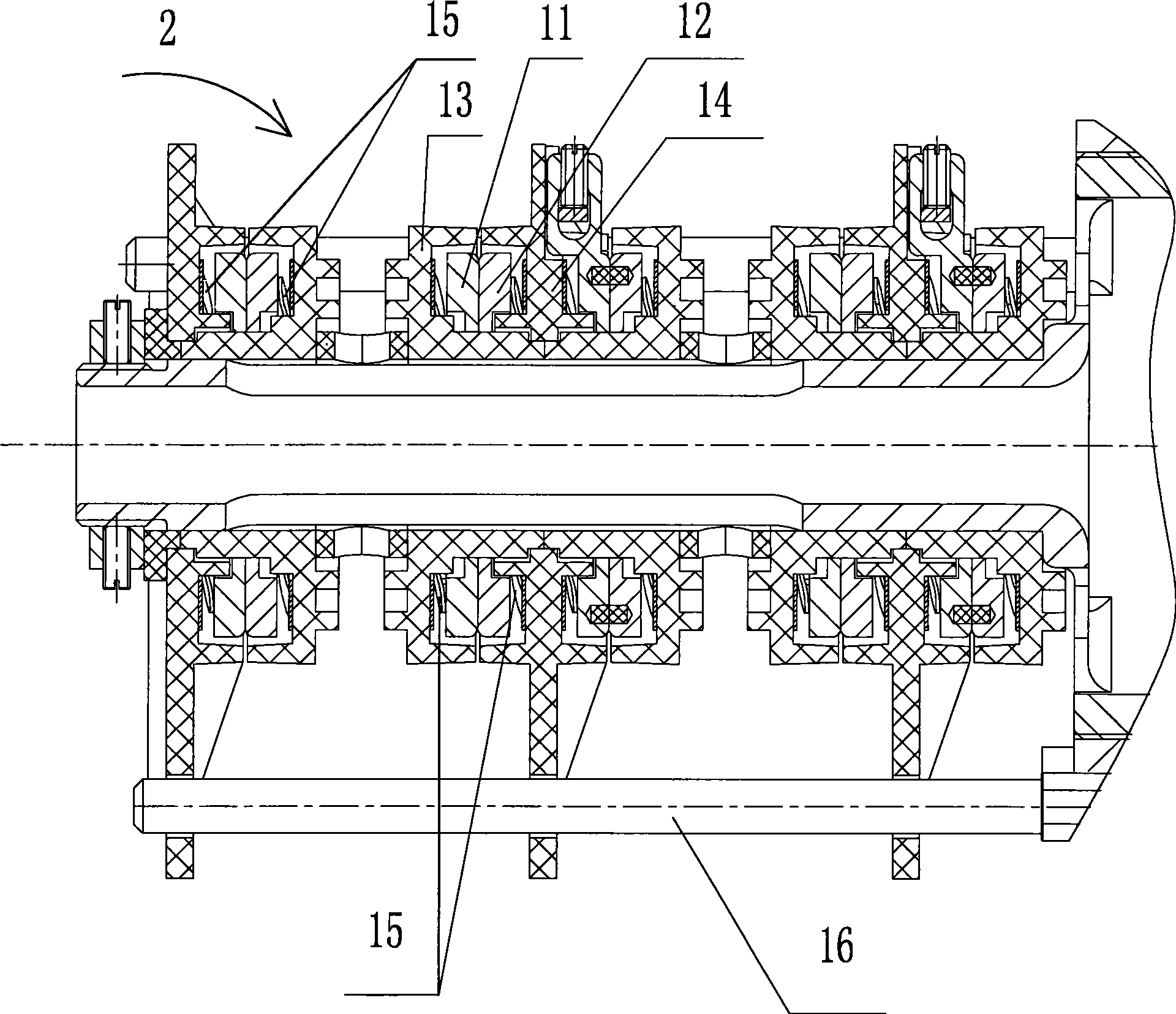

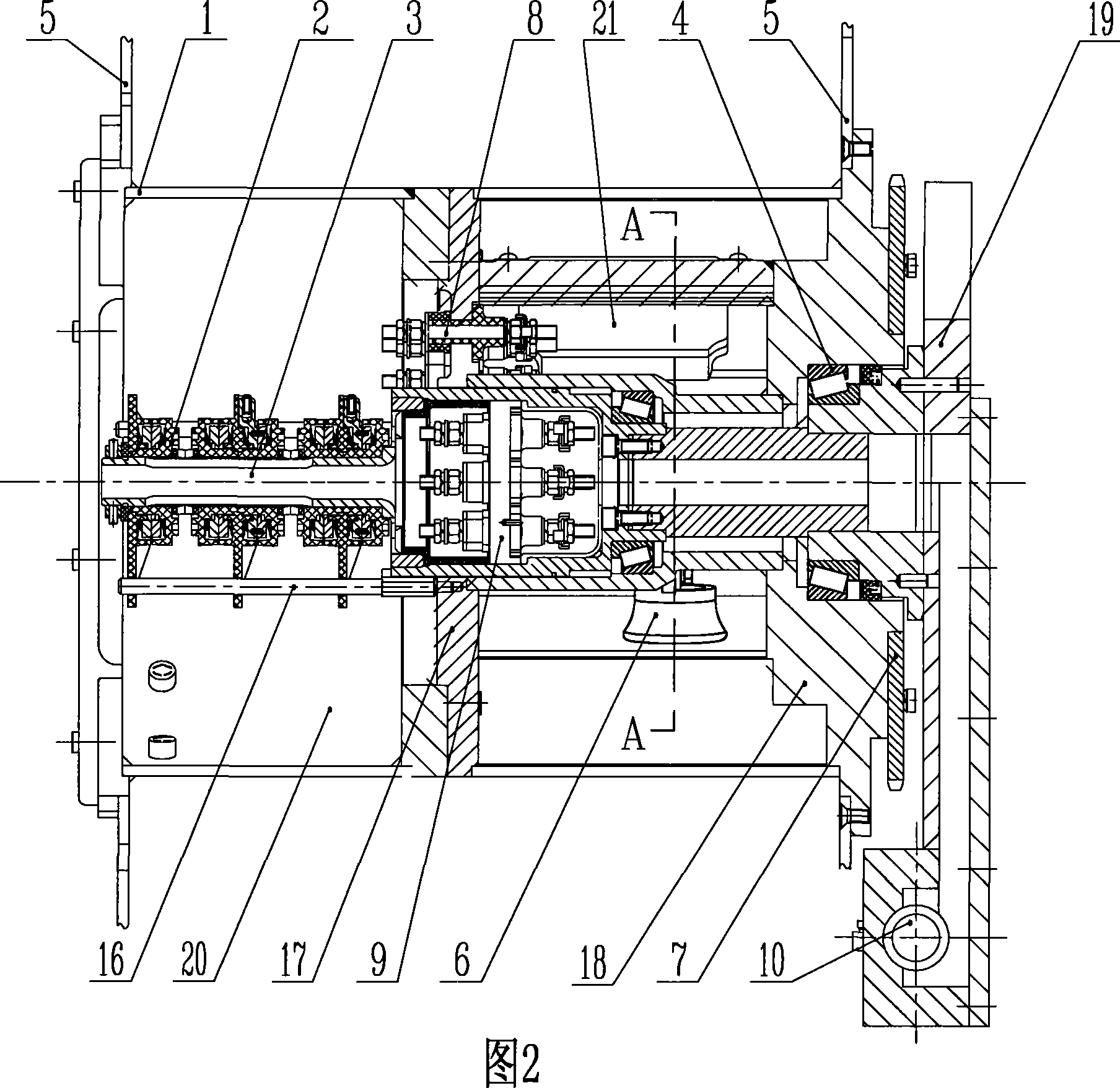

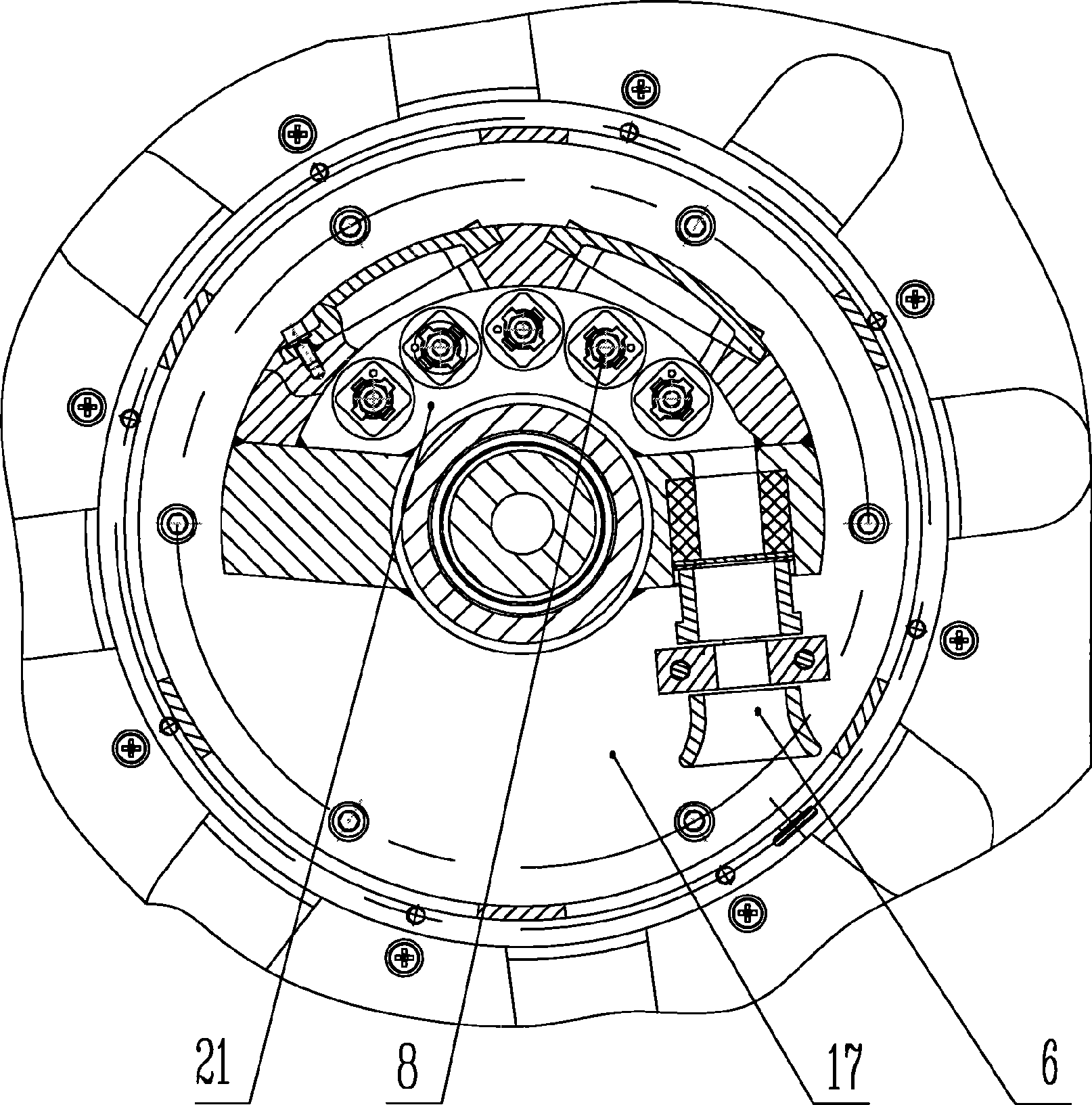

InactiveCN103507136ALow movement resistanceImprove transmission efficiencyWood working apparatusRolling resistanceEngineering

The invention discloses a full-automatic antique wood floor making machine. The full-automatic antique wood floor making machine comprises a feeding device (1), processing units (2) and a discharging device (3), wherein each processing unit (2) comprises a rack (4), a conveying device (5), pinch devices (7), a platen device (8) and a cutting system (9) are installed on each rack (4), each conveying device (5) is installed on the corresponding platen device (8), each pinch device (7) is arranged in a conveyor belt (36) of the corresponding conveying device (5), a pinch roller (34) of each pinch device (7) is arranged on the lower portion of the corresponding conveyor belt (36) in a pressing mode, and a cutting groove corresponding to each cutting system (9) is formed in the corresponding platen device (8) which is arranged below the corresponding pinch device (7). According to the full-automatic antique wood floor making machine, conveying efficiency and conveying stability are improved through rolling friction, variety of the cutting texture effect is improved through one spindle, a plurality of cutterheads and a lifting device, and the full-automatic antique wood floor making machine has the advantages that the structure is simplified, cost is reduced, processing efficiency is high, and the full-automatic antique wood floor making machine is applicable to popularization and use.

Owner:徐州领君自动化设备有限公司

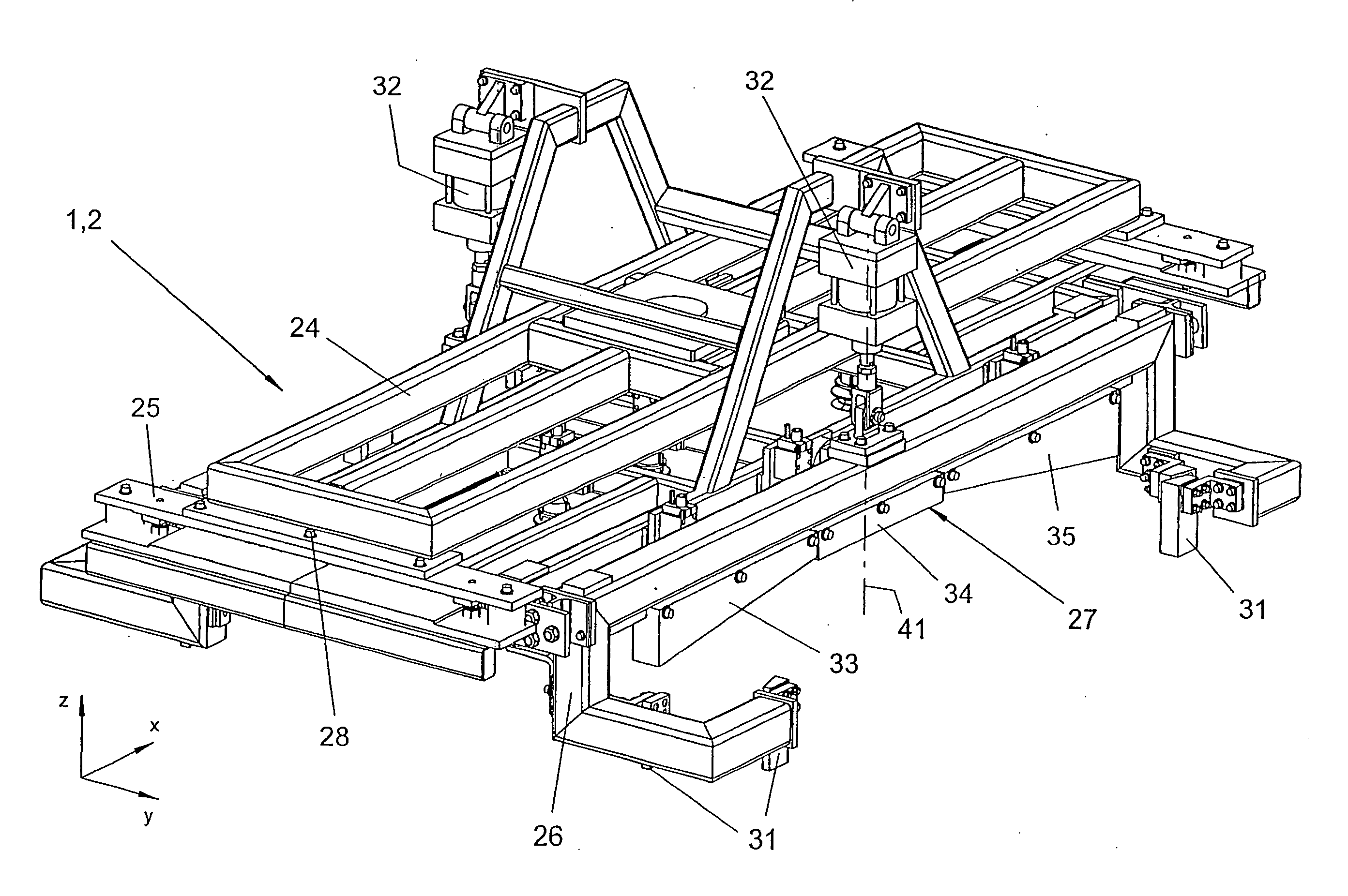

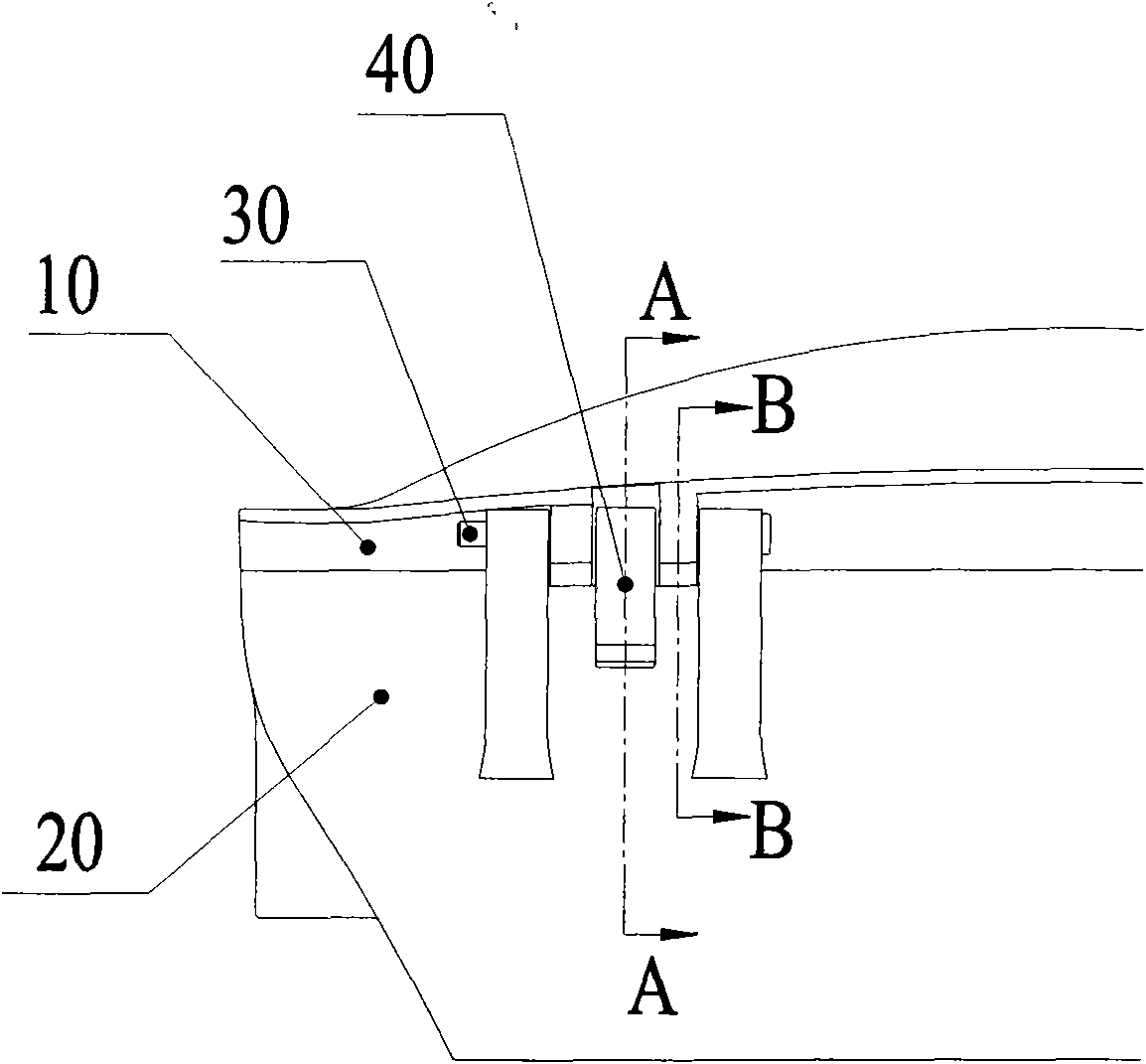

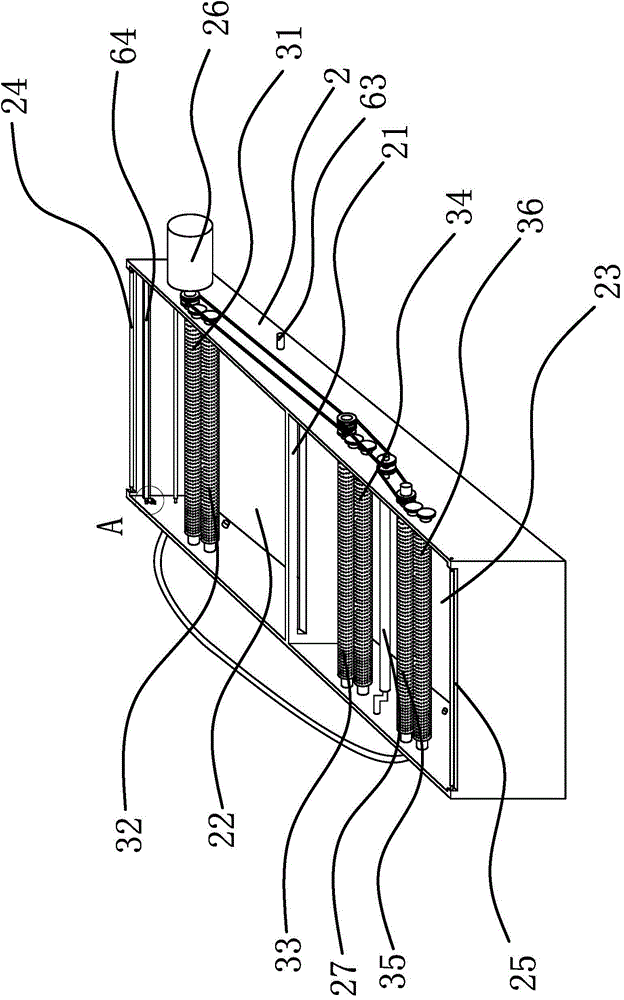

Joining device and joining process

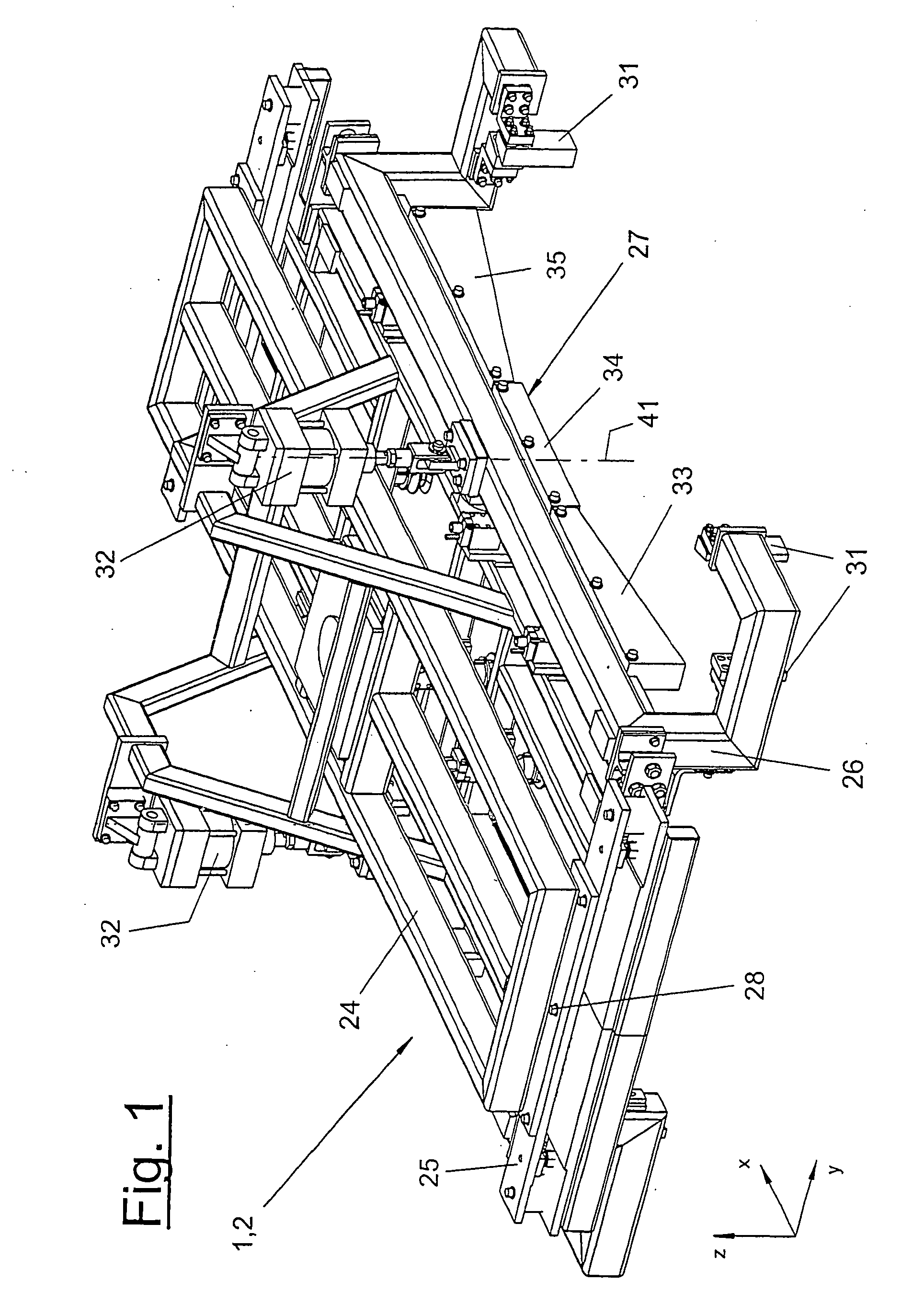

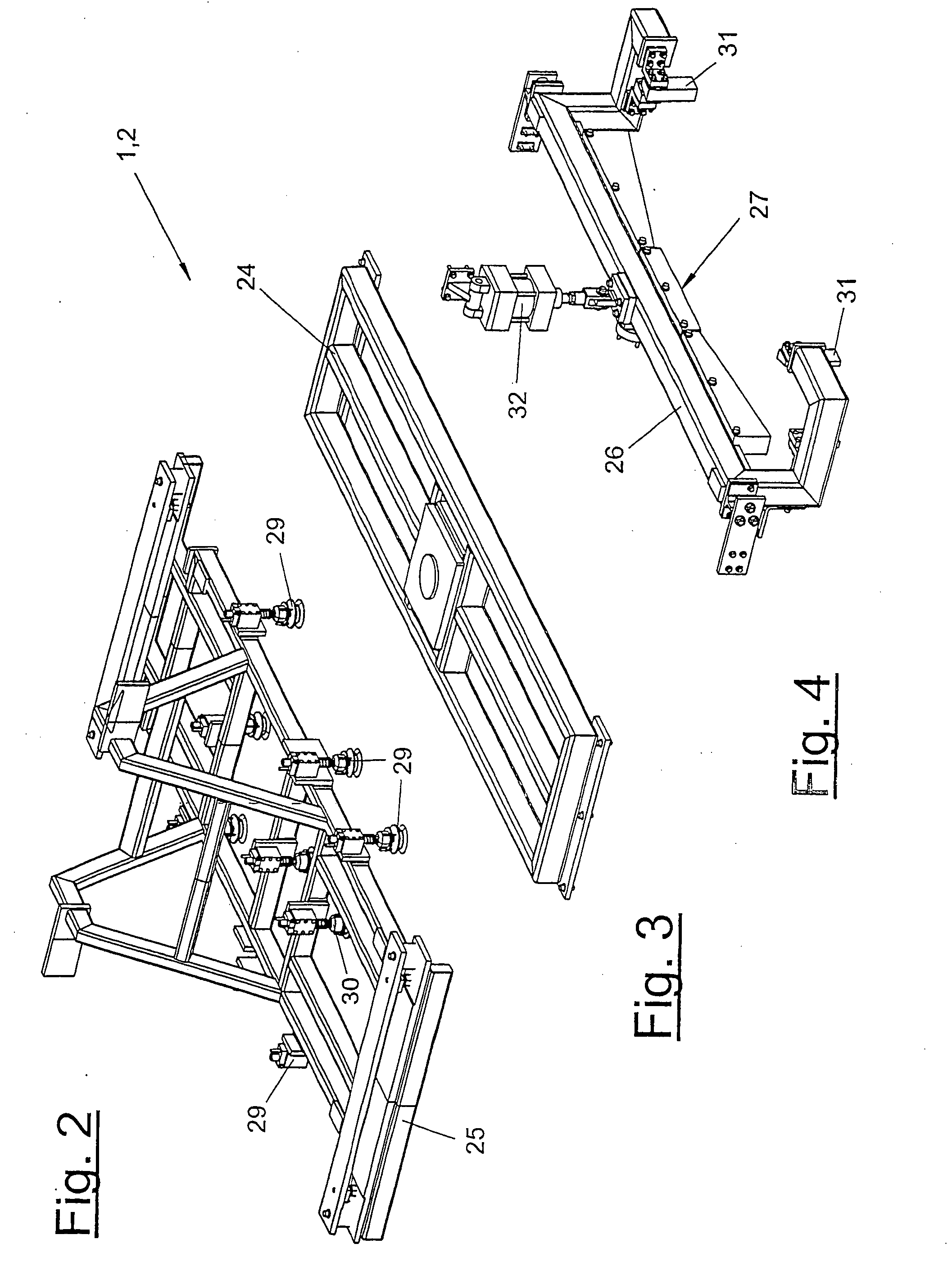

InactiveUS20060179628A1Improve techniqueJoining is strengthenedWelding/cutting auxillary devicesSuperstructure subunitsMarine engineering

A joining method and to a joining device (1) for joining roof skins (11) to parts (4) of vehicle bodies (3) is provided. The joining device (1) includes one or more joining grippers (2), which are comprised of at least one frame (24), of a number of gripping elements (29, 30), of at least one pressing strip (27), which acts upon the roof skin (11), and of an associated adjusting device (32). The pressing strip (27) is adapted to the joining contour (6) of the part (4) and has one or more dimensionally stable strip segments (33, 34, 35, 36, 37) that, independent of one another, are mounted on a strip support (26) with a limited flexibility in the direction of adjustment (41). The roof skin (11) with the joining part edge (13) thereof, is pressed against and fixed to the contact area (7) of the part (4) by means of the strip segments (33, 34, 35, 36, 37) and, optionally, is permanently deformed.

Owner:FORD GERMANY +1

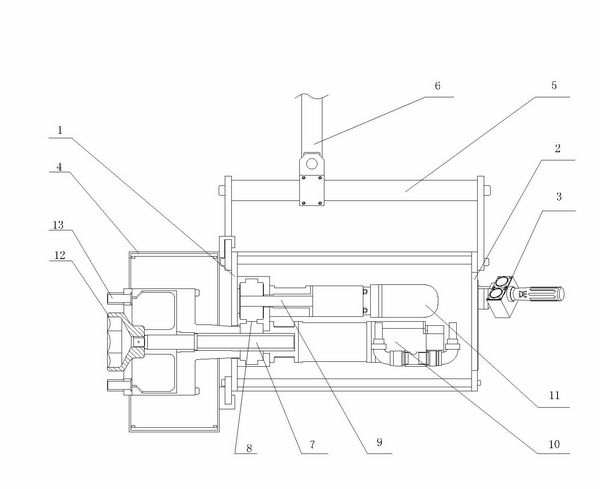

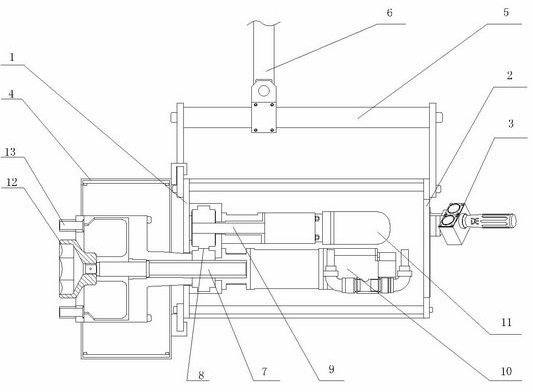

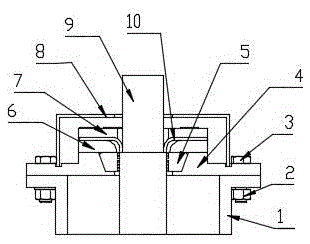

Hub main nut screwing and bearing pre-tightening force measuring machine and using method thereof

ActiveCN101979976AGuaranteed pressing forceSimple and fast operationMeasurement of torque/twisting force while tighteningWrench

The invention discloses a hub main nut screwing and bearing pre-tightening force measuring machine. The machine comprises a front sealing plate, a rear sealing plate, an operating handle, a protecting hood, a guide post, a suspension device, a nut screwing shaft, a gear, a revolution measurement rotating shaft, a first servo motor, a second servo motor, a special sleeve and a revolution measurement wrench; and the screwing of hub main nut and detection of bearing pre-tightening force can be simultaneously realized through one hub main nut screwing and bearing pre-tightening force measuring machine and various schemes for screwing and measurement are simultaneously provided for a user to select, so that the machine is easy and convenient to operate, has high assembly precision, uniform torque, and high measurement accuracy, is time-saving and labor-saving, achieves automatic unmanned operation and saves labor cost.

Owner:DALIAN DEXIN M&E TECH ENG

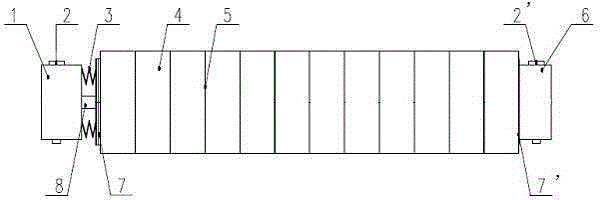

Resistor

ActiveCN102723154ANot easy to damageSolve the fragileResistor mounting/supportingElectrical resistance and conductanceDamping function

The invention relates to a resistor, comprising an insulating bar, a group of resistance pellets, and connection seats, wherein the resistance pellets are connected on the insulating bar in series; the connection seats are arranged at the two ends of the insulating bar respectively; a conductive damping piece is arranged between two adjacent resistant pellets and is sleeved on the insulating bar; and a pressure spring which is used for compressing the resistance pellets is arranged between one of the connection seat and the resistant pellet adjacent to the connection seat. According to the resistor, the conductive damping piece is arranged between two adjacent resistant pellets and is sleeved on the insulating bar, and the pressure spring which is used for compressing the resistance pellets is arranged between the connection seat at one end of the insulating bar and the resistant pellet adjacent to the connection seat, accordingly, each element of the resistor can be ensured to be electrically contacted well, and the conductive damping pieces between the resistance pellets have a damping function in a vibration environment, so that the resistance pellets are not easy to damage, and the problem that the resistance pellets are easy to damage in the vibration environment in the prior art is solved.

Owner:HENAN PINGGAO ELECTRIC +1

Saw plate positioning device for gang saw welder

ActiveCN101829874AImprove performanceExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesHardnessEngineering

The invention provides a saw plate positioning device for a gang saw welder, which belongs to the technical field of machinery and solves the problem that two sides of a clamping block in the conventional gang saw welder have no positioning devices, so a saw plate is easy to deform when the heated hardness is reduced, the motion is instable during moving the saw plate and the precision of a next welding point is reduced. The saw plate positioning device for the gang saw welder comprises a first clamping block and a second clamping block; the first clamping block is fixed on a rack; the second clamping block is arranged on the rack through an air cylinder, and the propped faces of the second clamping block and the rack are arranged opposite; the positioning device also comprises a first guide piece; and an elastic mechanism, which enables the first guide piece to move in the direction of the guide face of the first guide piece close to the propped face of the second clamping block when the first clamping block and the second clamping block are loosened from the saw plate, is arranged on the rack. The saw plate positioning device for the gang saw welder can ensure the accuracy of welding saw teeth, avoid deformation and improve the production efficiency, and has the advantage of stable performance.

Owner:项大清

Flame proof cable winding drum

InactiveCN101442172AGuaranteed contact areaGood current transferRotary current collectorBurning outElectricity

The invention relates to a cable winding device, in particular to an explosion-proof cable drum, which solves the problem of burning out of slip rings due to arcing caused by the fact that a brush is easy to wear and generate gaps or a brush clamping device is aged and loosened along with time in a collecting slip ring of the prior cable drum. The explosion-proof cable drum is provided with a drum shell and the collecting slip ring, wherein the collecting slip ring is provided with two relatively rotational slip rings, and one is a static slip ring and the other is a movable slip ring; and the static slip ring is in end face contact with the movable slip ring. The explosion-proof cable drum can safely convert rotary current into static current. The explosion-proof cable drum is taken as a changeover gear of main voltage source input, safely converts the rotary current which is inputted by the exterior of the drum into the relatively static current through relative rotation of the movable slip ring and the static slip ring, and leads the static current into an electric cabinet to supply power to the whole machine. The explosion-proof cable drum adopts a novel slip ring group, guarantees enough contact area and compression strength, and better transfers current.

Owner:SANY HEAVY EQUIP

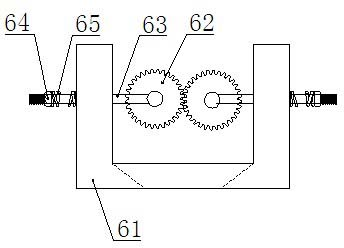

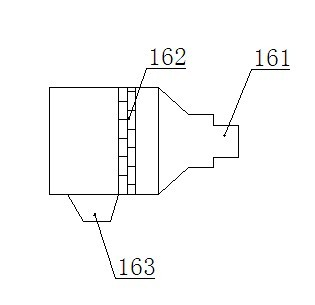

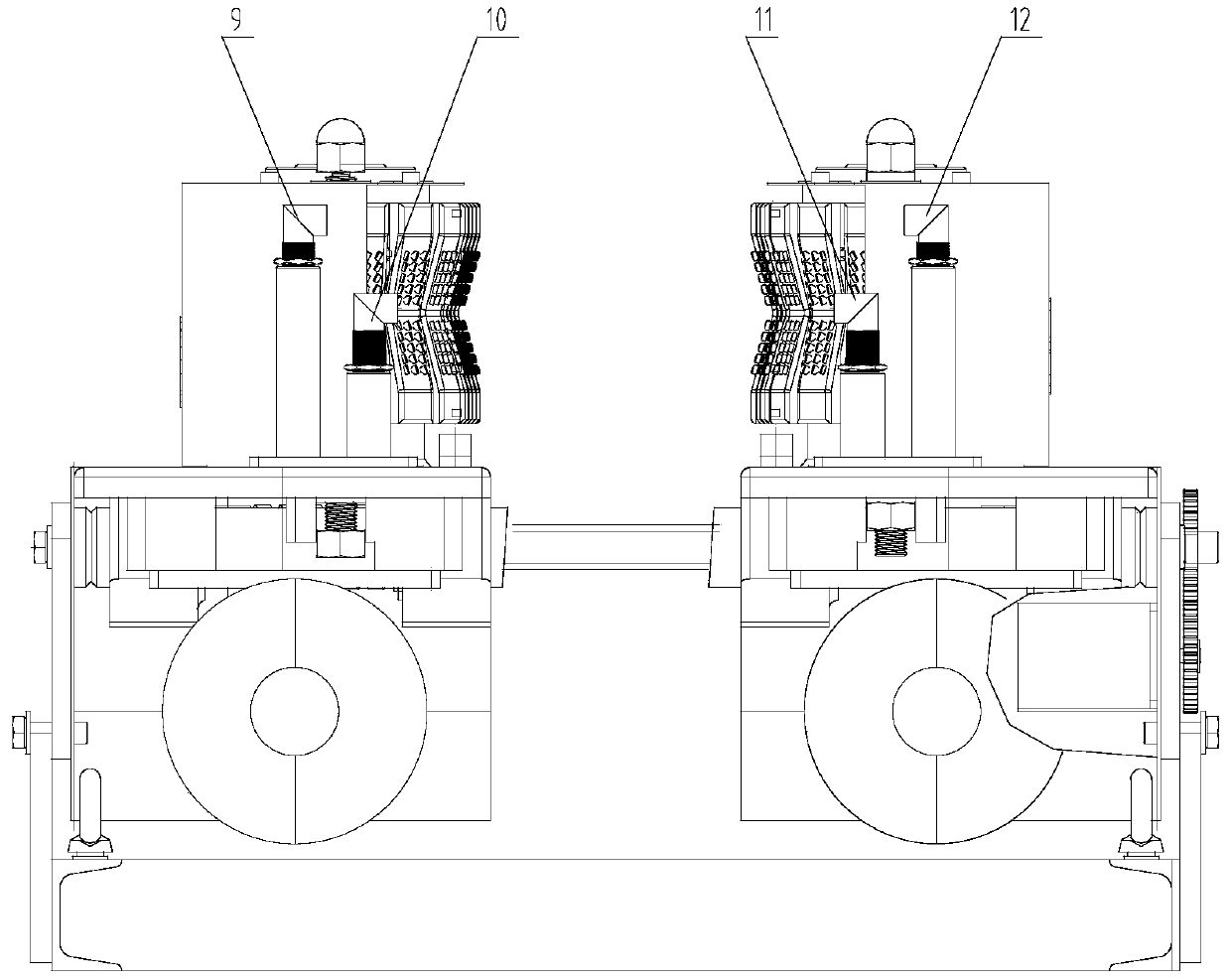

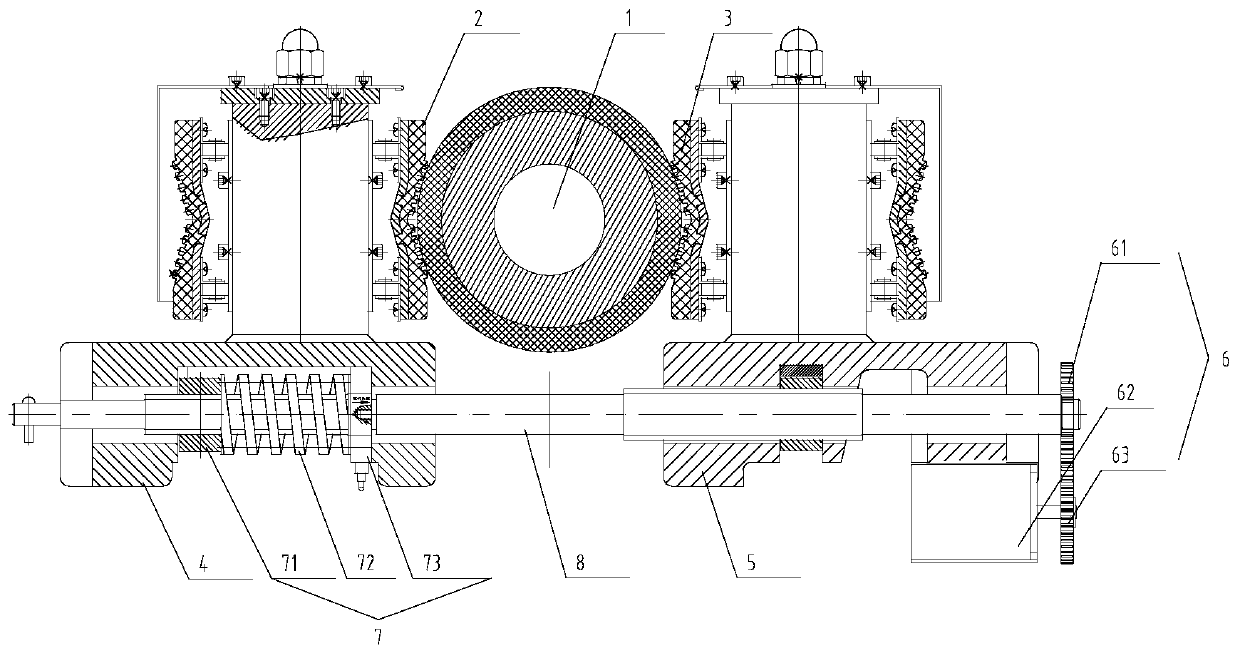

Investment cast shell crushing, grading and screening system

The invention relates to an investment cast shell crushing, grading and screening system comprising a vibration cleaning and shakeout mechanism, a grinding and crushing mechanism, a gear pair rolling mechanism and a grading and screening mechanism which are connected through a conveyer belt. When mould sand is cleared, an investment cast is arranged on the vibration cleaning and shakeout mechanism; the mould sand outside the cast is vibrated to a shakeout collection hopper, conveyed into the grinding and crushing mechanism and the gear pair rolling mechanism, so that large caked mould sand can be crushed; and the mould sand is conveyed to the grading and screening mechanism to be graded and collected according to the sizes of the mould sand particles after being crushed. According to the mould sand grading and screening system in the structure, an assembly line which carries out sand cleaning, shakeout, crushing and screening processes on the investment cast automatically, no manual operation is needed, so that the mechanical automation degree is high, the working efficiency and the reuse rate are greatly improved, the labor intensity of a worker is reduced, dust is not scattered, and green manufacturing, environmental protection and sustainable development are realized.

Owner:RUGAO DASHENG LINE EQUIP

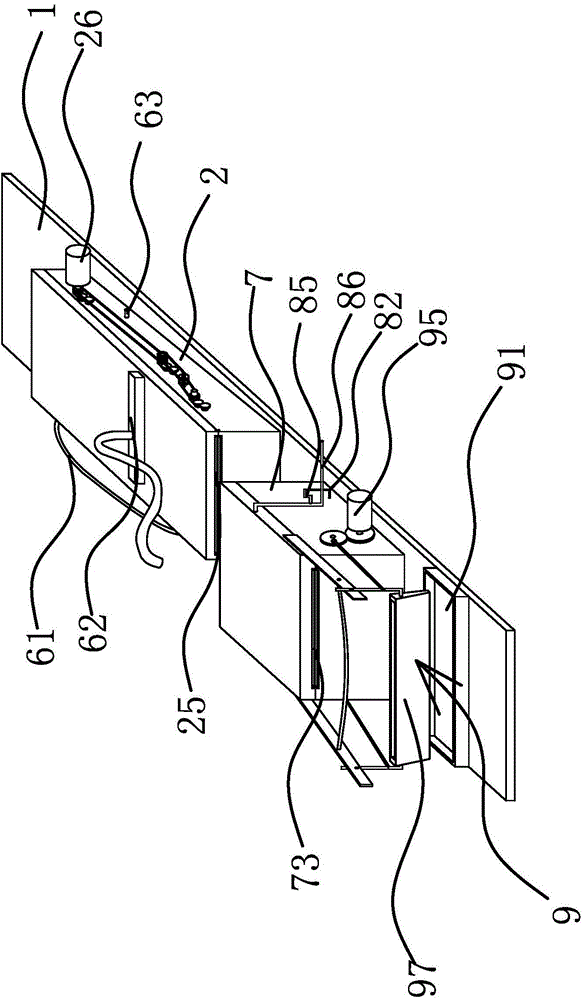

Intelligent automatic cable conveyor

PendingCN109879111AReduce manual operation efficiencyReduce labor intensityFilament handlingLoop controlClosed loop

The invention relates to an intelligent automatic cable conveyor. A position sensor group for detecting a position of a cable is arranged at the inlet of a cable conveying channel, so that a caterpillar band is driven automatically to move through a conveying motor when the position sensor group senses the cable. A left bracket and a right bracket are driven by a lead screw electric driving mechanism to move synchronously oppositely or reversely, so as to clamp the cable placed in the cable conveying channel automatically. A pressing force detecting device for detecting a pressing force of thecable is arranged in the right bracket. The intelligent automatic cable conveyor can achieve automatic clamping of the cable, adjustable speed and automatic conveying and form closed-loop control, sothat the pressing force of the cable is adjusted automatically according to a set threshold value. Meanwhile, the conveyor can be adjusted in speed according to the field construction situation, so that the labor intensity and the cost of constructors are reduced greatly, and the intelligent automatic cable conveyor has the advantages of high cable paving quality and high efficiency.

Owner:CHANGLAN CABLE ACCESSORIES

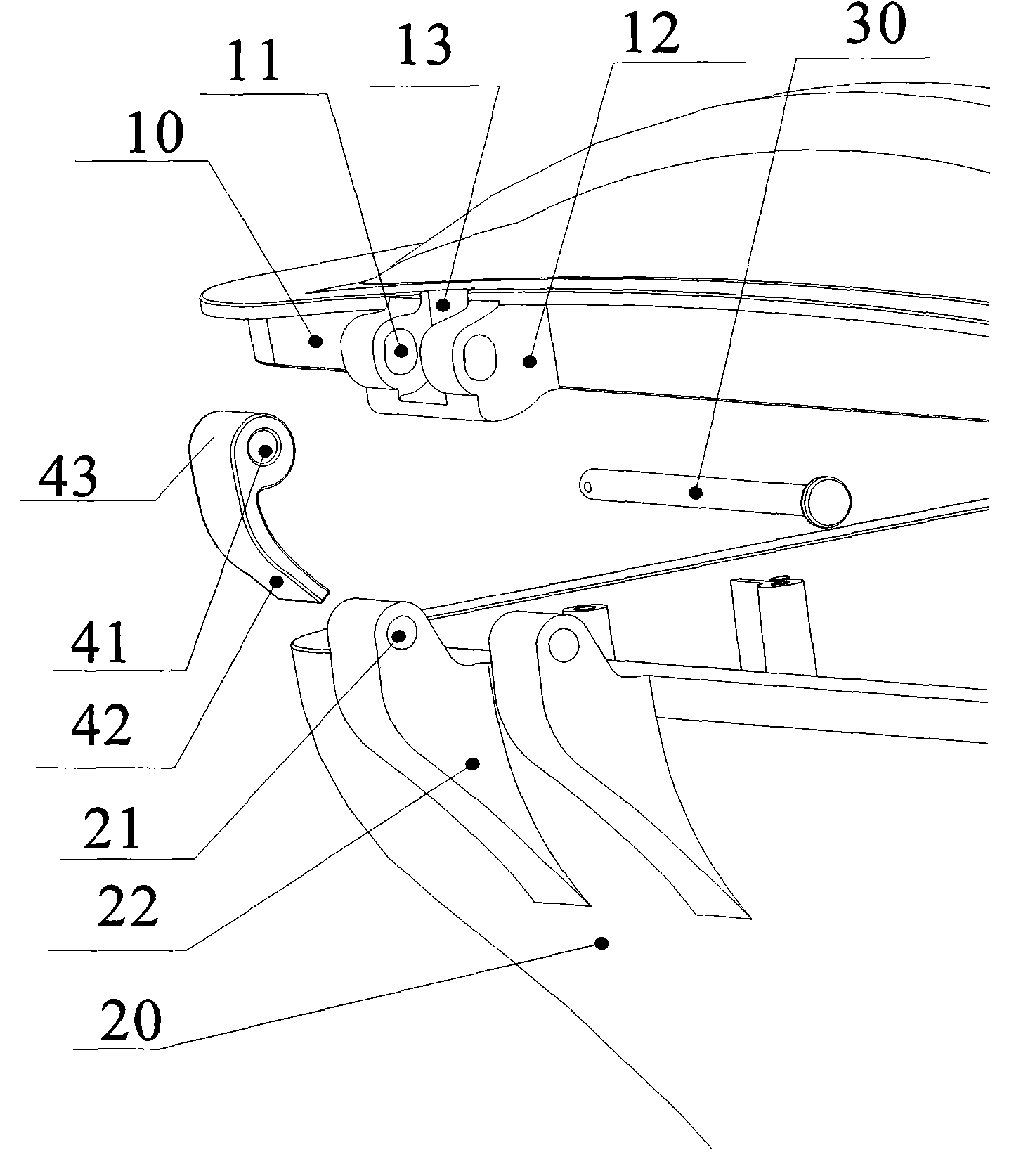

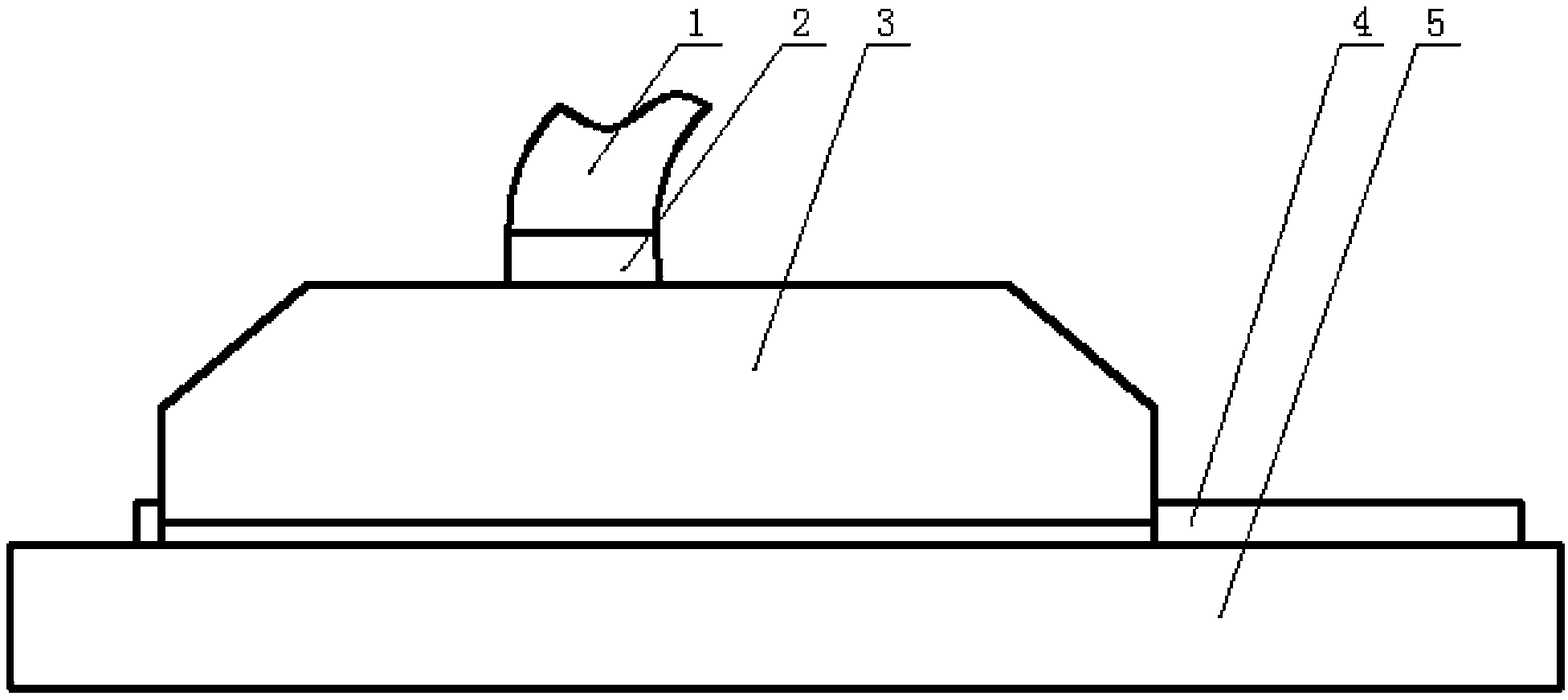

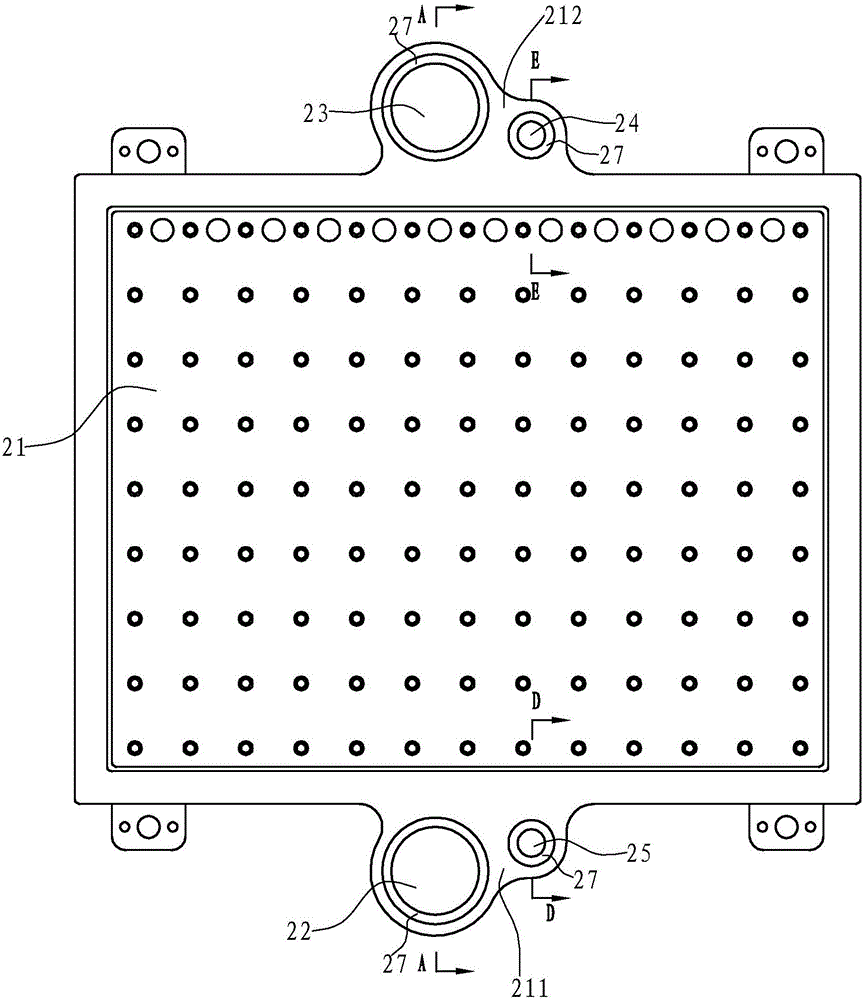

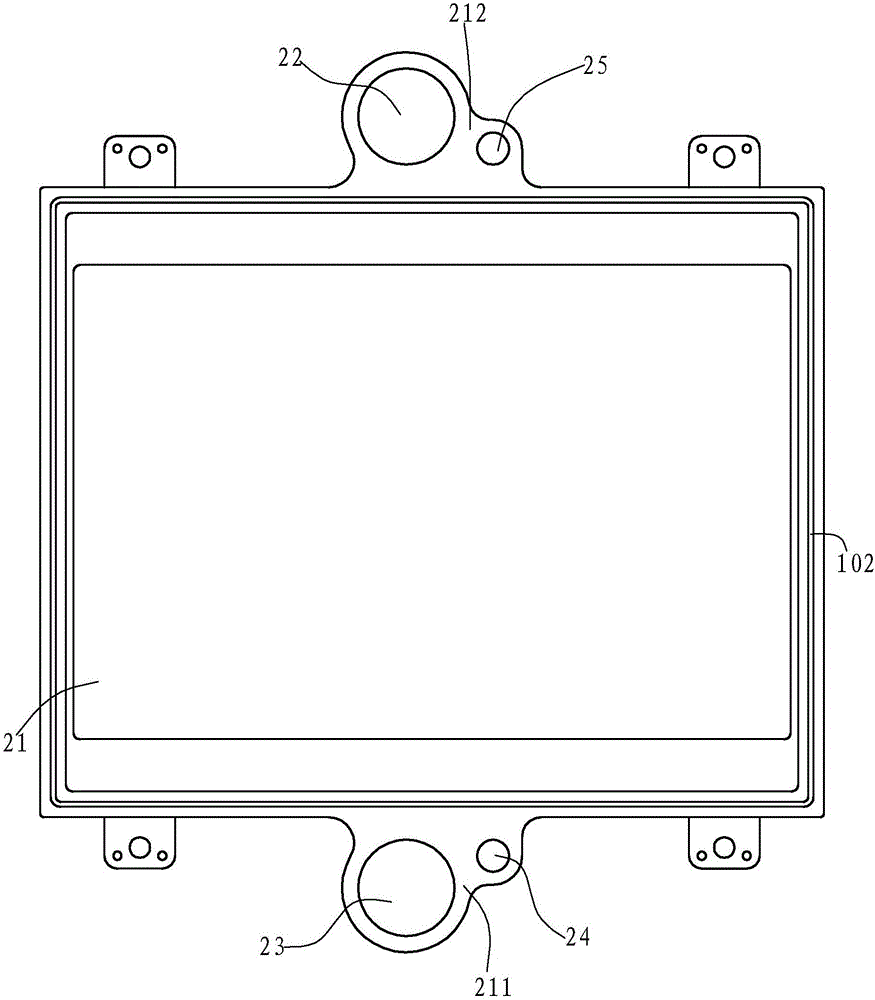

Lamp locked and sealed by cam

The invention relates to a lamp locked and sealed by a cam. The lamp locked and sealed by the cam comprises a lamp body (20), a lamp cover (10), a sealing ring (50), a pin shaft (30) and a cam handle (40), wherein the sealing ring (50) is arranged between a contact surface of the lamp body (20) and the lamp cover (10); the pin shaft (30) is arranged on the outer side of the lamp body (20); the axis of the pin shaft (30) is parallel with the contact surface; a through hole (41) is formed at one end of the cam handle (40), so that the cam handle (40) is sleeved on the pin shaft (30) to rotate around the pin shaft (30); one end, where the through hole (41) is formed, of the cam handle (40) has a cam structure (43); the center of the through hole (41) serves as a rotating pivot; a sliding groove (13) is formed on the outer side, opposite to the cam handle (40), of the lamp cover (10); and the bottom of the sliding groove (13) extends below the through hole (41) of the cam handle (40) and contacts with the outer curved surface of the cam structure (43). The gap between the lamp cover and the lamp body is regulated by changing the distance between the outer curved surface of the cam structure (43) and the rotating pivot, so that the lamp realizes the switchover of lock sealing or cover-opening maintenance, is simple in operation, guarantees the sealing pressing force between a front cover and the lamp body, and effectively reduces the external force required by the operation.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

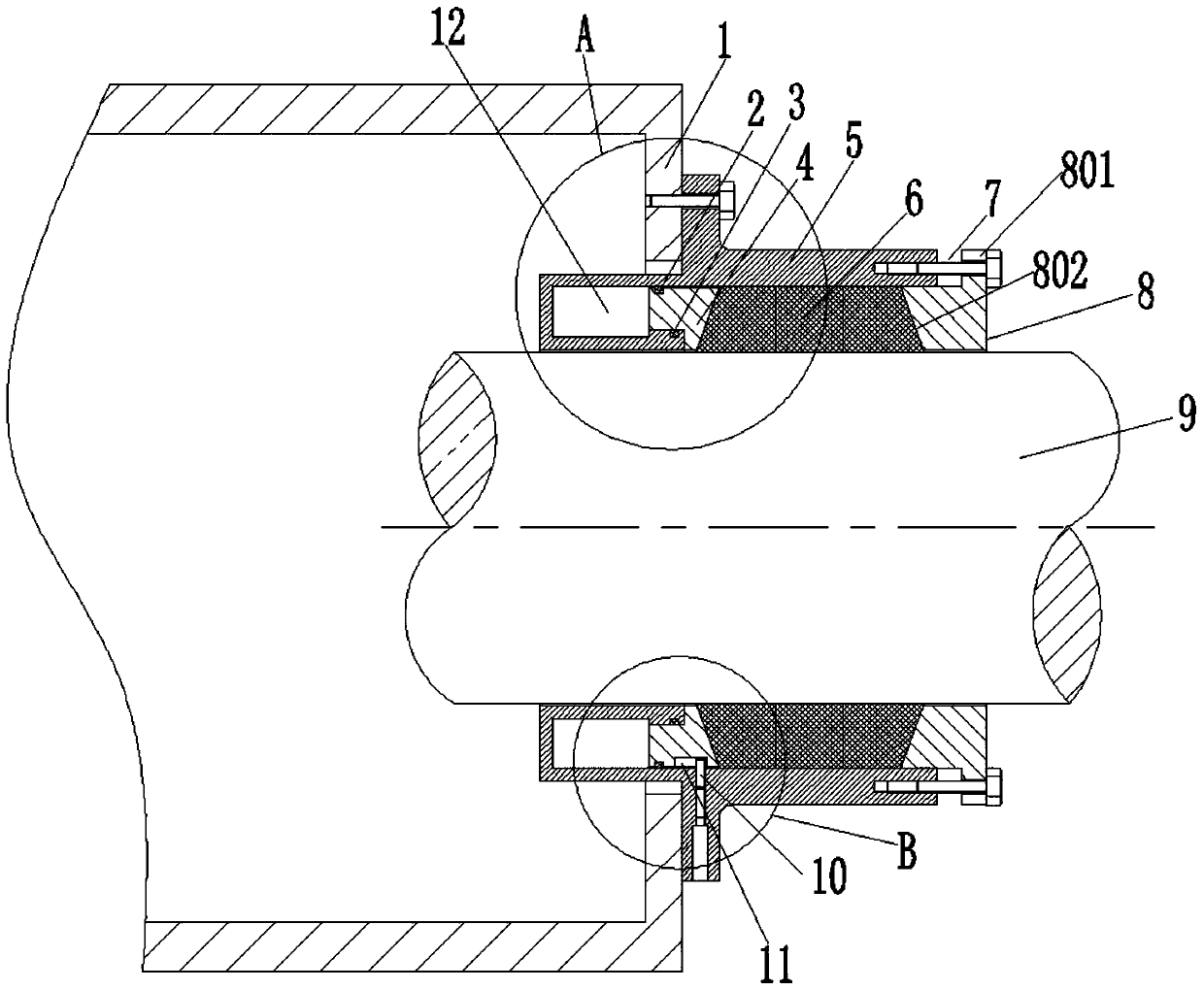

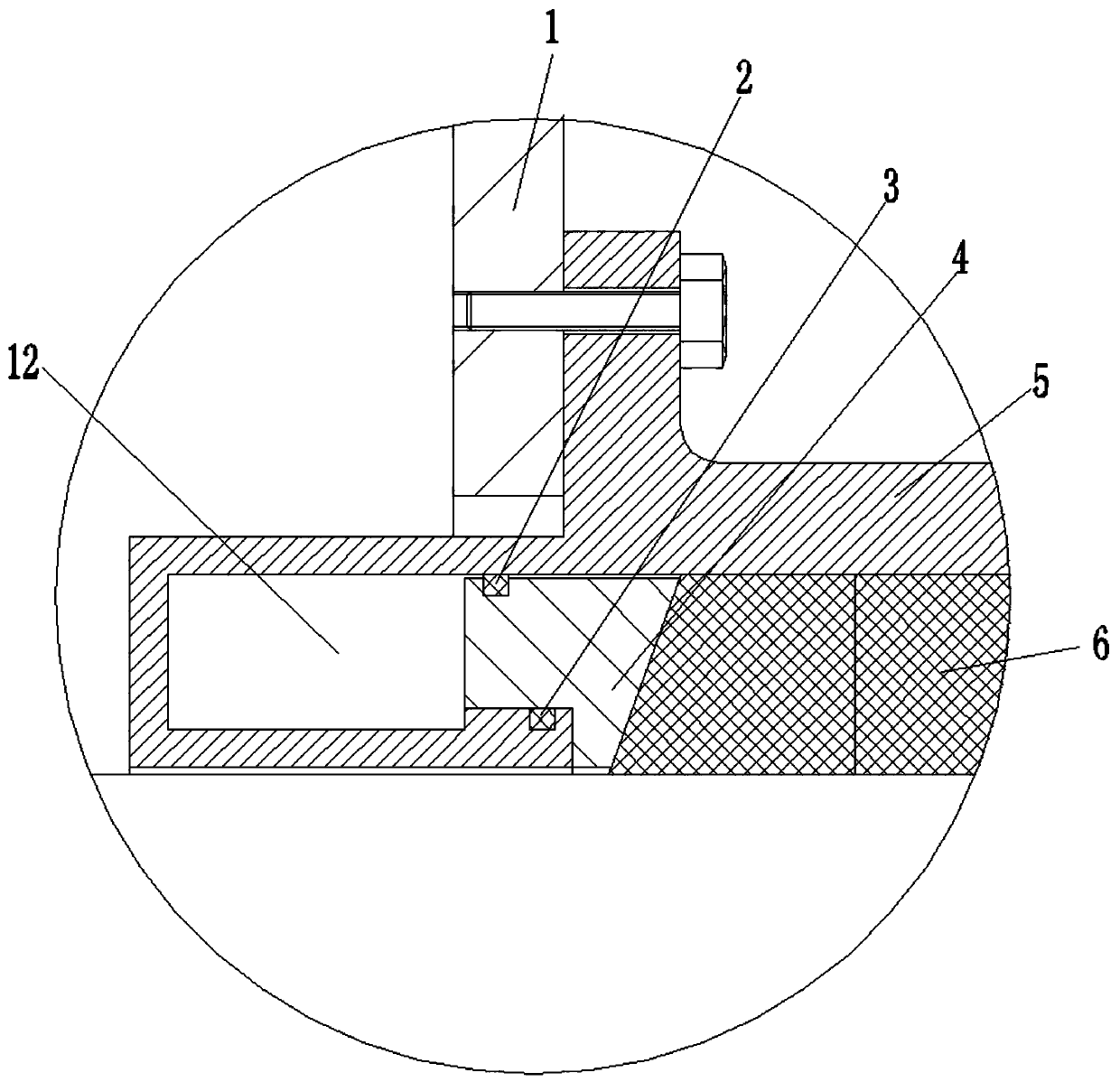

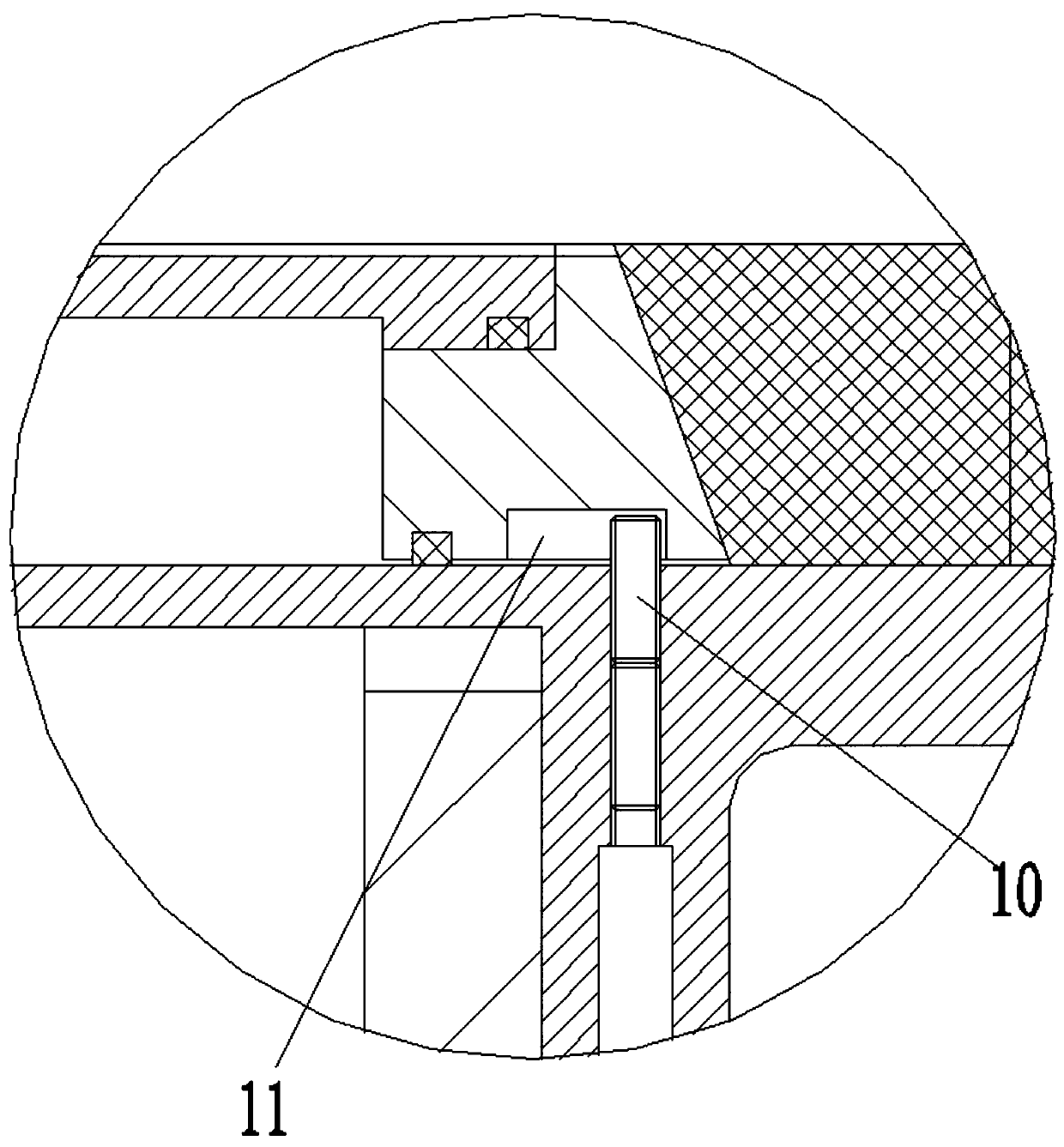

Submarine cable fixing device with sealing and temporary clamping functions and fixing method

InactiveCN105610113ARealize temporary clamping effectImprove sealingCable installations on groundCable junctionsElastomerFlange

The invention discloses a submarine cable fixing device with sealing and temporary clamping functions and a fixing method. The submarine cable fixing device comprises a protective tube, a connecting flange plate, a temporary clamp, a base plate, a pressing plate and an outer cover, wherein the connecting flange plate consists of two symmetrical half parts, the protective tube is arranged on the outer side of the protective tube, and the connecting flange plate is connected with the protective tube through bolts and nuts; the temporary clamp consists of two symmetrical half parts, and is mounted inside the connecting flange plate; the base plate consists of two symmetrical half parts, and is connected with the connecting flange plate through base plate bolts; the pressing plate consists of two symmetrical half parts, and is connected with the base plate through pressing plate bolts; and the outer cover consists of two symmetrical half parts, and is mounted at the position of a groove of the connecting flange plate. The fixing device disclosed by the invention integrally adopts a hover type symmetrical structure, and is convenient to mount; the temporary clamp adopts a special elastomer material, and can hold submarine cables tightly through extrusion with the submarine cables, so that the temporary clamping function for the submarine cables is realized, the device such as an independent temporary clamp or traction network cover does not need to be used, the cost is reduced, and the efficiency is improved.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

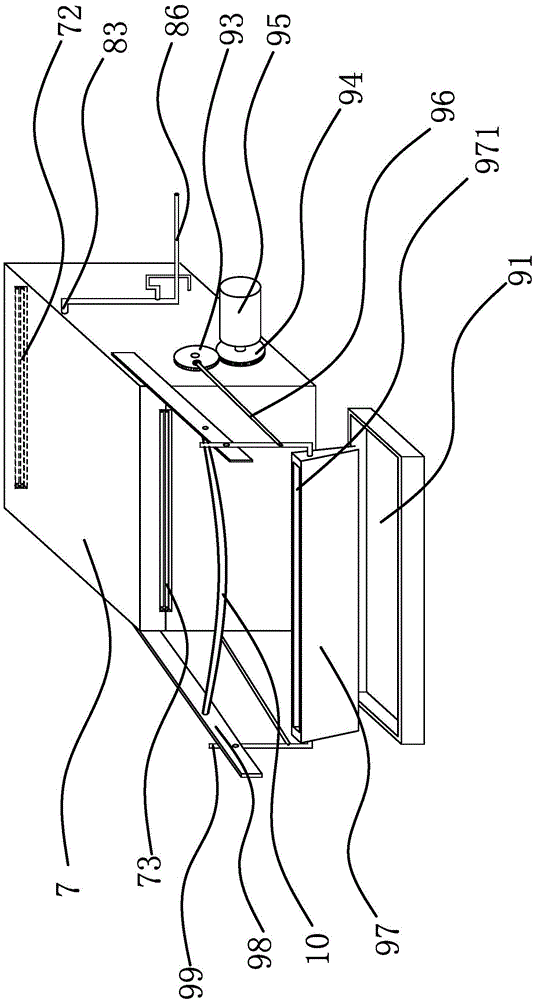

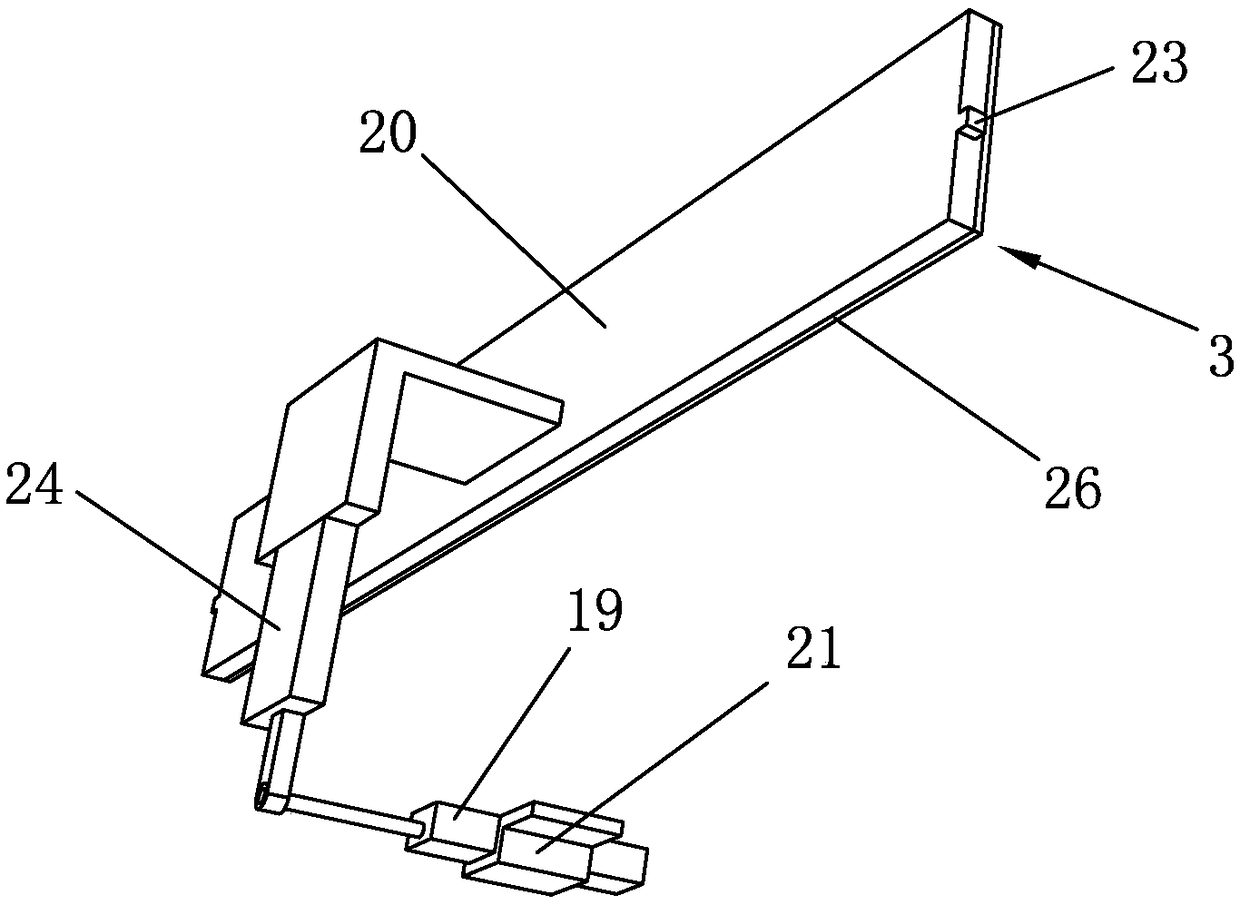

Fabric washing and drying integrated machine with fabric collection device

ActiveCN104480656ASolve cleaning difficultiesSimple structureLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringDrive motor

The invention provides a fabric washing and drying integrated machine with a fabric collection device and belongs to the technical field of machinery. By means of the machine, the technical problems that fabrics cannot be washed, dried, collected and the like through one step after being woven are solved. The machine comprises a base, a washing case is arranged on the base, and a case body of the washing case is partitioned into a washing tank and a rinsing tank through a partition plate. A first fabric inlet and a second fabric inlet are formed in the two ends of the washing case respectively. A first washing roller and a second washing roller which are parallel are arranged on the inner wall of the washing case and are both disposed in the washing tank. The first washing roller is driven by a first drive motor, a drying case is further arranged on the base, a fabric collecting unit is arranged between the drying case and the base, and a fabric collecting box is further arranged on the base. The machine has the advantage of being capable of completing washing, drying, collecting and the like of fabrics.

Owner:四川九五一七实业有限公司

Solid wood cutting saw

InactiveCN104249390ALarge transmission forceStable transmission speedFeeding devicesCircular sawsSolid woodDrive motor

The invention relates to a solid wood cutting saw. The solid wood cutting saw comprises a machine base, a machine cover, conveying devices, a cutting saw body, a plurality of pressing rollers and a dust-sucking device, wherein the machine cover is fixedly arranged at the upper end of the middle part of the machine base; a workpiece inlet / outlet is formed between the lower part of each of the two transverse sides of the machine cover and the machine base; the conveying devices are transversely and coaxially arranged on the upper part in the machine base; the cutting saw body connected with a driving motor is arranged on the machine cover and the machine cover between the conveying devices; the pressing rollers are arranged in the machine cover on the two transverse sides of the cutting saw body at intervals; the dust-sucking device is arranged at the top of the machine cover above a cutting device. The solid wood cutting saw is simple in structure, scientific in design, uniform in pressure, high in processing efficiency and high in processing precision, the flatness of a product is improved, the labor intensity of workers is effectively reduced, and the production efficiency is improved.

Owner:天津福通木业有限公司

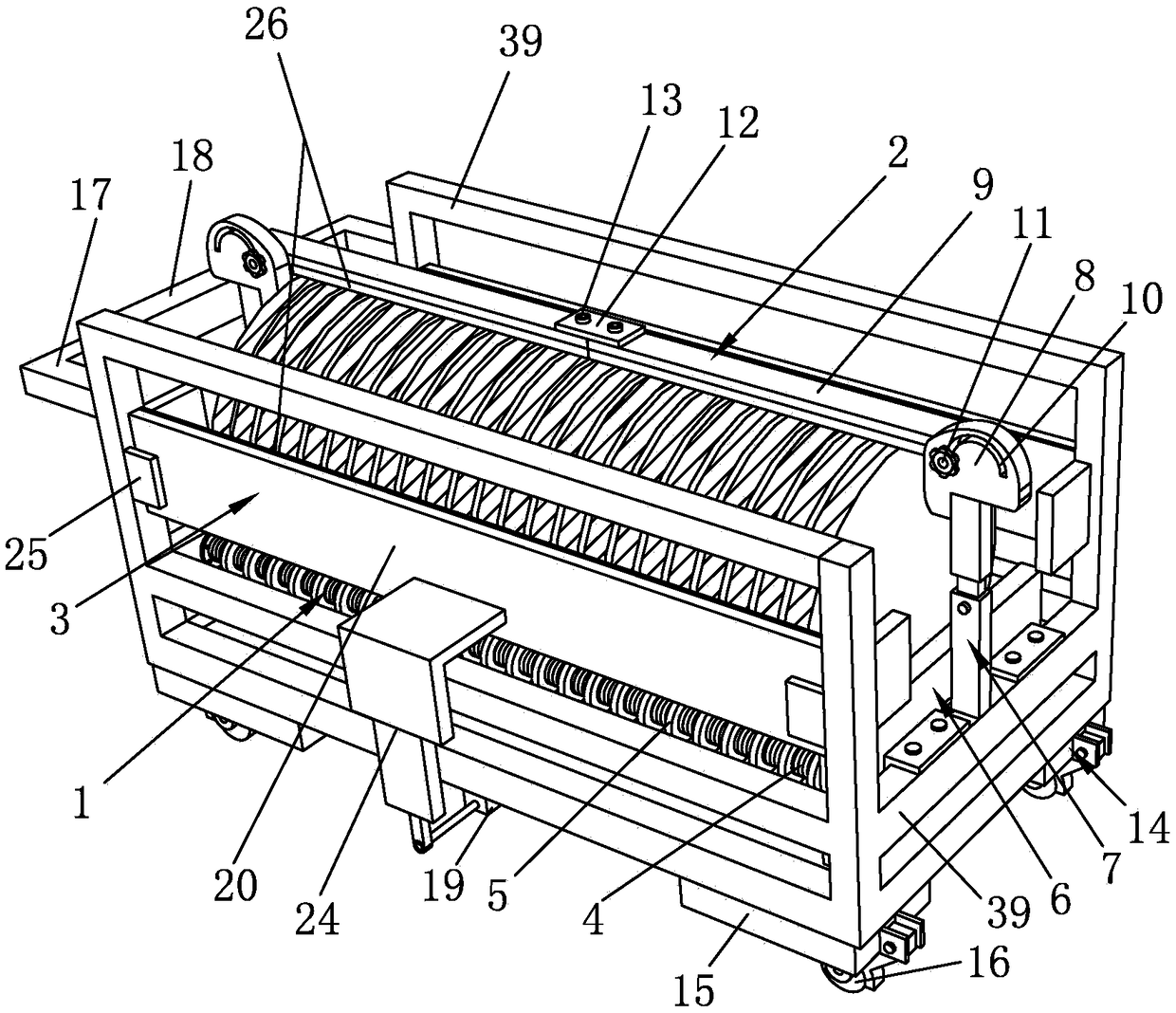

Rubber tube-free precise plate-type filtering machine

ActiveCN105854368AImprove sealingGuaranteed tightnessMembrane filtersFiltration separationPulp and paper industryFilter paper

The invention relates to a rubber tube-free precise plate-type filtering machine. The rubber tube-free precise plate-type filtering machine comprises a rack and a filter box, a paper feeding mechanism, a paper discharging mechanism, a hydraulic device and an electric control device which are installed on the rack; the paper feeding mechanism and the paper discharging mechanism are located on the two sides of the filter box so as to drive filter paper to complete filtering work in the filter box, the hydraulic device cooperates with the filter box to conduct the filtering work, and the paper feeding mechanism, the paper discharging mechanism and the hydraulic device are connected with the electric control device and controlled by the electric control device. The filter box in the rubber tube-free precise plate-type filtering machine is good in sealing property and reliable in sealing, the hydraulic device is low in energy consumption and long in service life, a support assembly is reliable in installation and good in rigid strength, and the electric control device is high in operating flexibility.

Owner:NINGBO CHUANGLI HYDRAULIC MACHINERY MFG CO LTD

Edge locking clamp for rolling of film rolls

InactiveCN104016171AReach steady edgeTo achieve the locking effectWebs handlingEngineeringMechanical engineering

Owner:永新股份(黄山)包装有限公司

Horizontal solid wood board slicing sawing machine

InactiveCN104249393ALarge transmission forceStable transmission speedSawing apparatusVeneer manufactureSolid woodEngineering

The invention relates to a horizontal solid wood board slicing sawing machine, which comprises a stand, a hood, a dust collection device, a pipeline, conveying devices and a cutting device, wherein the hood is fixedly arranged at the upper end of the middle part of the stand; the conveying devices are transversely and coaxially arranged on the inner upper part of the stand; the cutting device is arranged on the hood and the stand between the conveying devices, is connected with a driving device, and is structured in a way that a plurality of blades are fixedly arranged in a cutter frame at an equal interval; a plurality of pressure rollers are arranged at intervals in the hood on the two sides of the cutting device; a dust hood is arranged at the top of the hood above the cutting device; the dust collection device is connected to and arranged at the upper end of the dust hood; the pipeline is connected to the dust collection device. The horizontal solid wood board slicing sawing machine is simple in structure, scientific in design, uniform in pressure and high in machining efficiency and machining accuracy, the smoothness of a product is improved, the labor intensity of a worker is effectively reduced, and the production efficiency is improved.

Owner:TIANJIN KAIXIN WOOD IND

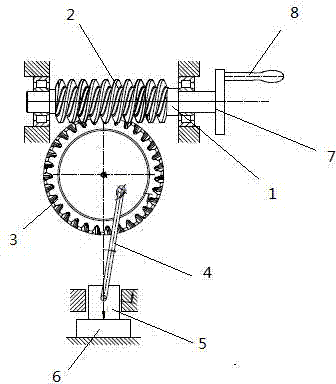

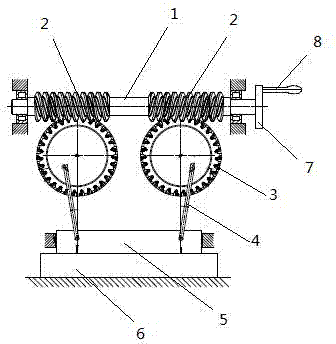

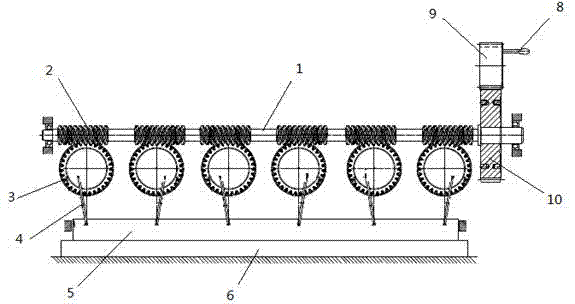

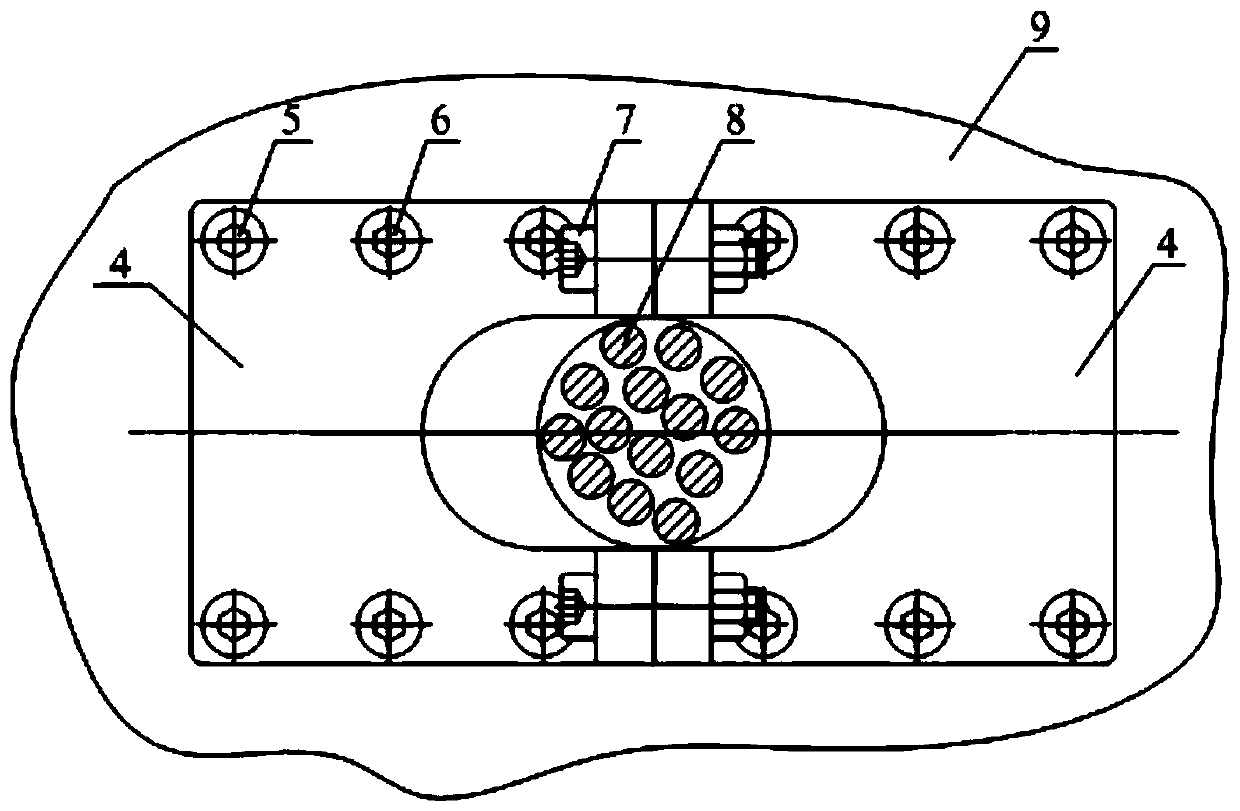

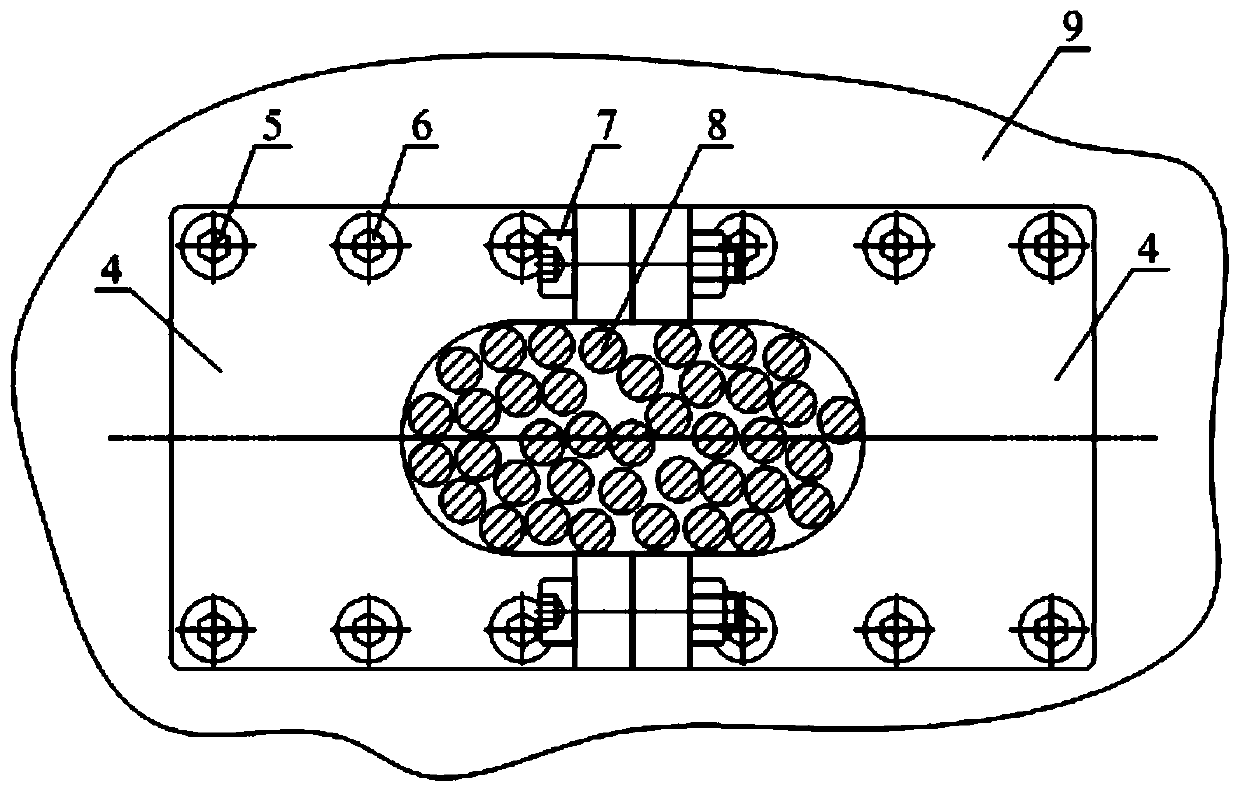

Manual pressing device based on worms, worm wheels and crank connecting rod transmissions

The invention discloses a manual pressing device based on worms, worm wheels and crank connecting rod transmissions. The manual pressing device comprises a rotary shaft, wherein at least two worms are fixedly arranged on the rotary shaft, the worm wheels meshed with the worms are arranged under the corresponding worms, the crank connecting rod transmissions are arranged on the worm wheels, and the tail ends of the crank connecting rod transmissions are connected to the same press block. The symmetrical synchronous multi-point driving is achieved, the manual pressing device is compact in structure, simple and convenient to use and rapid in positioning and pressing, the synchronous multi-point or multi-station pressing can be achieved according to the demands of workpieces, and accordingly labor productivity and product quality are improved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Sealing plugging cover for aeroengine test lead

The invention discloses a sealing plugging cover for an aeroengine test lead. The side surface of a base is provided with a threaded hole and a light hole; the center of the base is provided with a sliding groove, and the bottom is provided with a mounting groove; the main body contour shapes of a cover plate and a sealing pad are the same as that of the base; the cover plate is provided with thesame threaded hole and the same light hole as the base; the sealing pad is a through hole without thread; one end of the cover plate is provided with a mounting edge, and the mounting edge is providedwith a through hole without thread; one end of a spring is clamped on an adjusting piece and one end ejects in the base mounting groove; the cover plate and the base are fixed together through a screw a to form a sealing plugging cover; one sealing pad and the sealing plugging cover are mounted on the engine through a screw b, test leads are combed, the other sealing pad and the sealing pluggingcover are mounted on the engine through a screw b, and the two sealing plugging covers are fixedly connected through a screw c; and a cavity is formed after the two sealing plugging covers are connected, and the spring drives the adjusting piece to adjust the cavity to a minimum bundling state, an intermediate bundling state and a maximum bundling state.

Owner:SHENYANG JIANZHU UNIVERSITY

Placing frame of circular plates for building construction and placing method thereof

ActiveCN109398868ARealize the initial limitAvoid wear and tearContainers to prevent mechanical damageRigid containersEngineeringMechanical engineering

The invention discloses a placing frame of circular plates for building construction. The placing frame comprises a support body, and further comprises a clamping assembly, a top pressing assembly anda side pressing assembly, wherein the top pressing assembly is symmetrically arranged on the support body in a front-back symmetry mode, the side pressing assembly is symmetrically arranged on the support body in a left-right symmetry mode. The placing method comprises the following steps of a, preparing working; b, hoisting and placing of circular plates; c, pressing the side surface of the circular plates; d, pressing the top surface of the circular plates. According to the placing frame and the placing method, the circular plates are vertically placed through the placing frame, and mutualextrusion cannot be caused between every two adjacent round plates; the clamping and positioning in various directions of the side surface and the top surface of the circular plates are realized through the design of the top pressing assembly and the side pressing assembly, so that the placing firmness of the circular plates can be effectively ensured, and meanwhile, the bottom of the circular plates can be clamped through the design of the clamping assembly, and the clamping assembly can be adjusted according to the thickness of the circular plates, so that the use range of the placing framecan be enlarged effectively.

Owner:衢州永辰建设有限公司

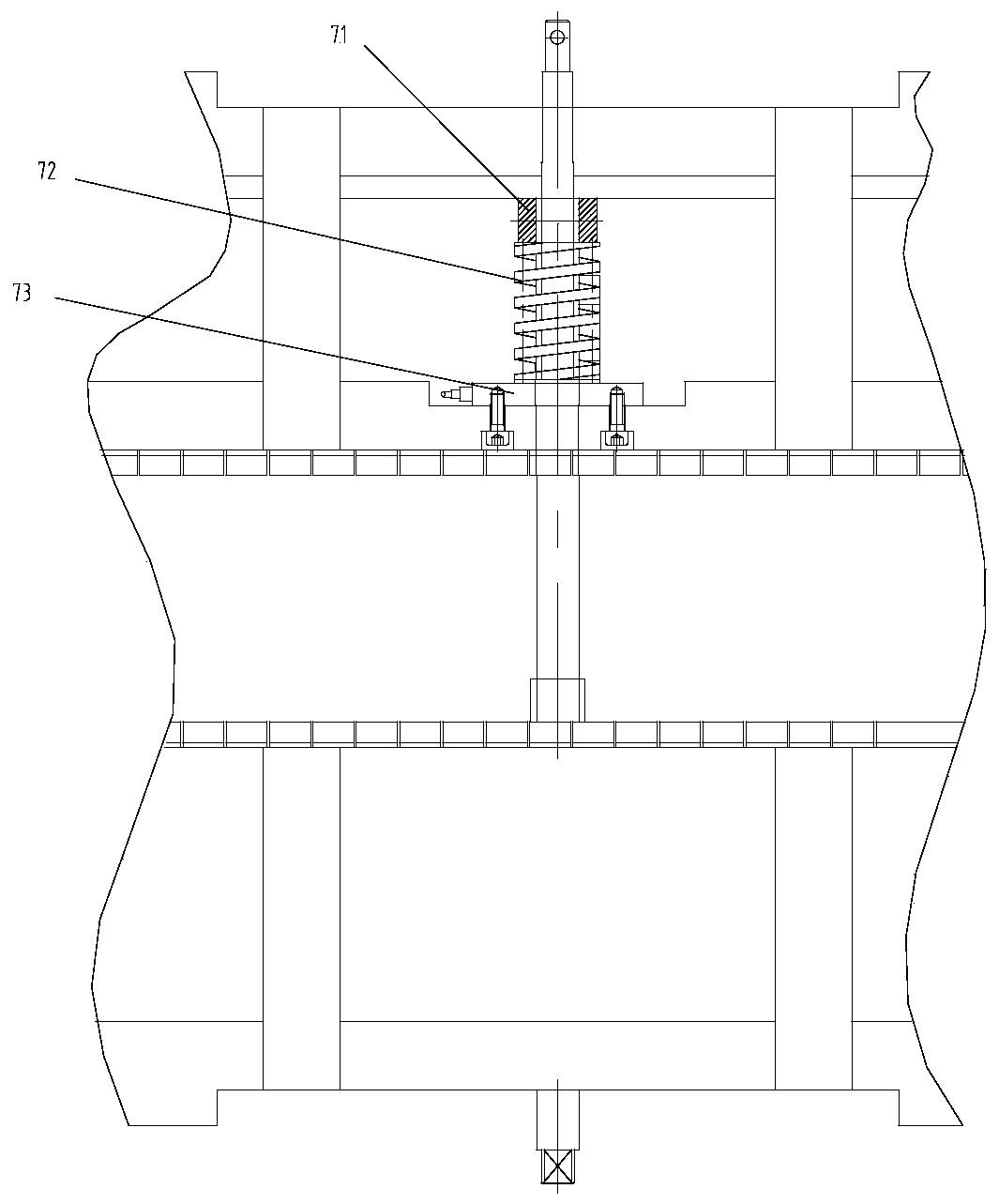

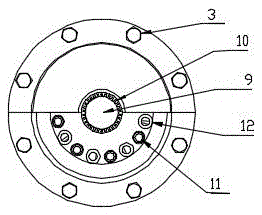

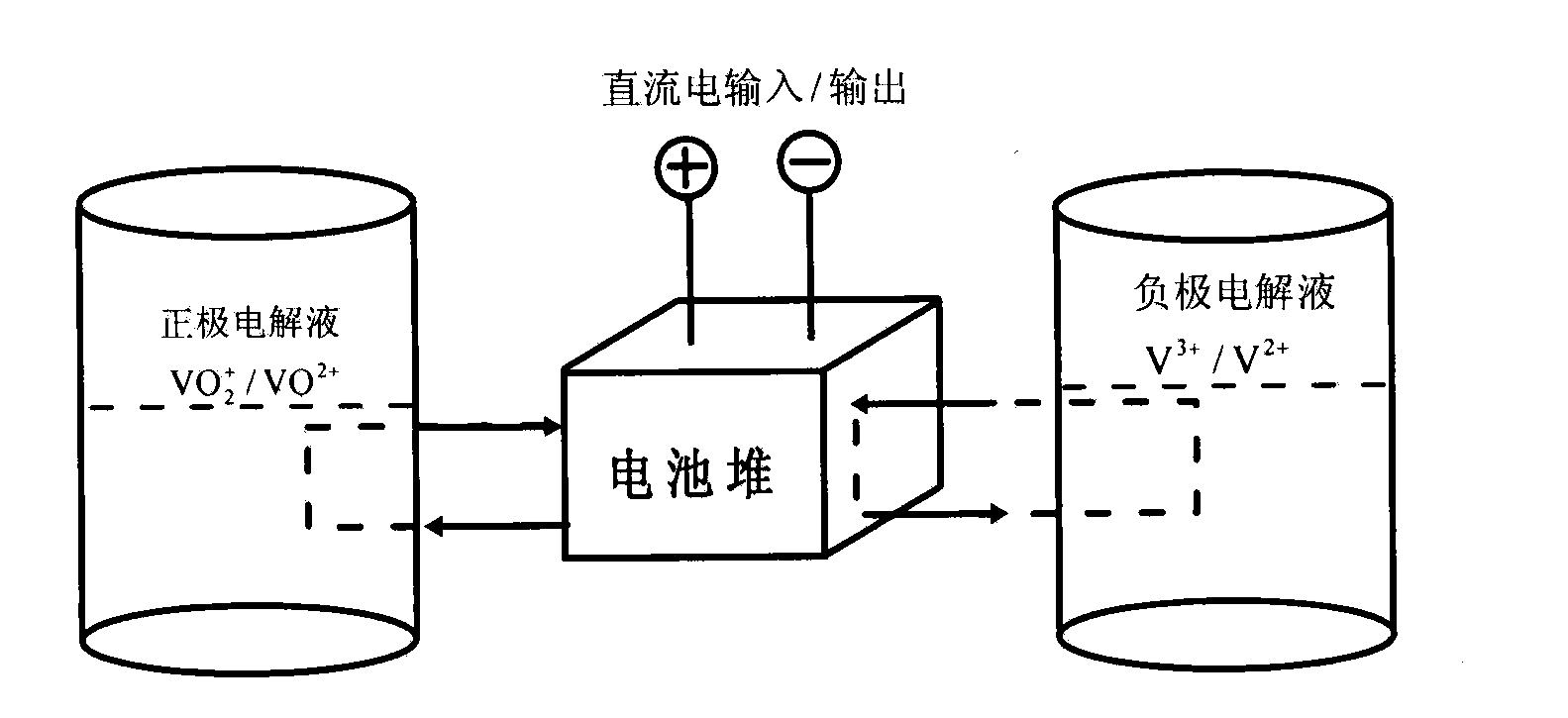

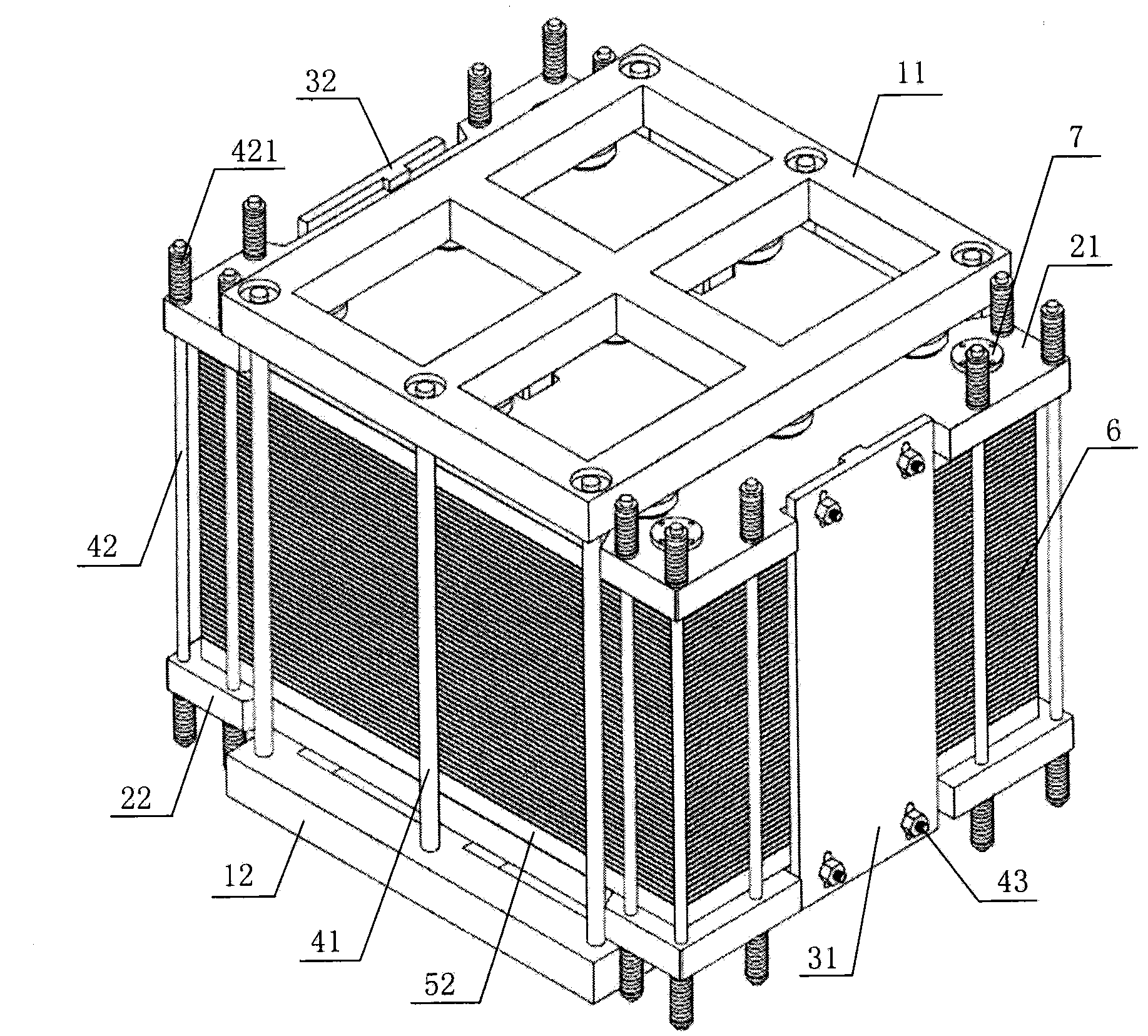

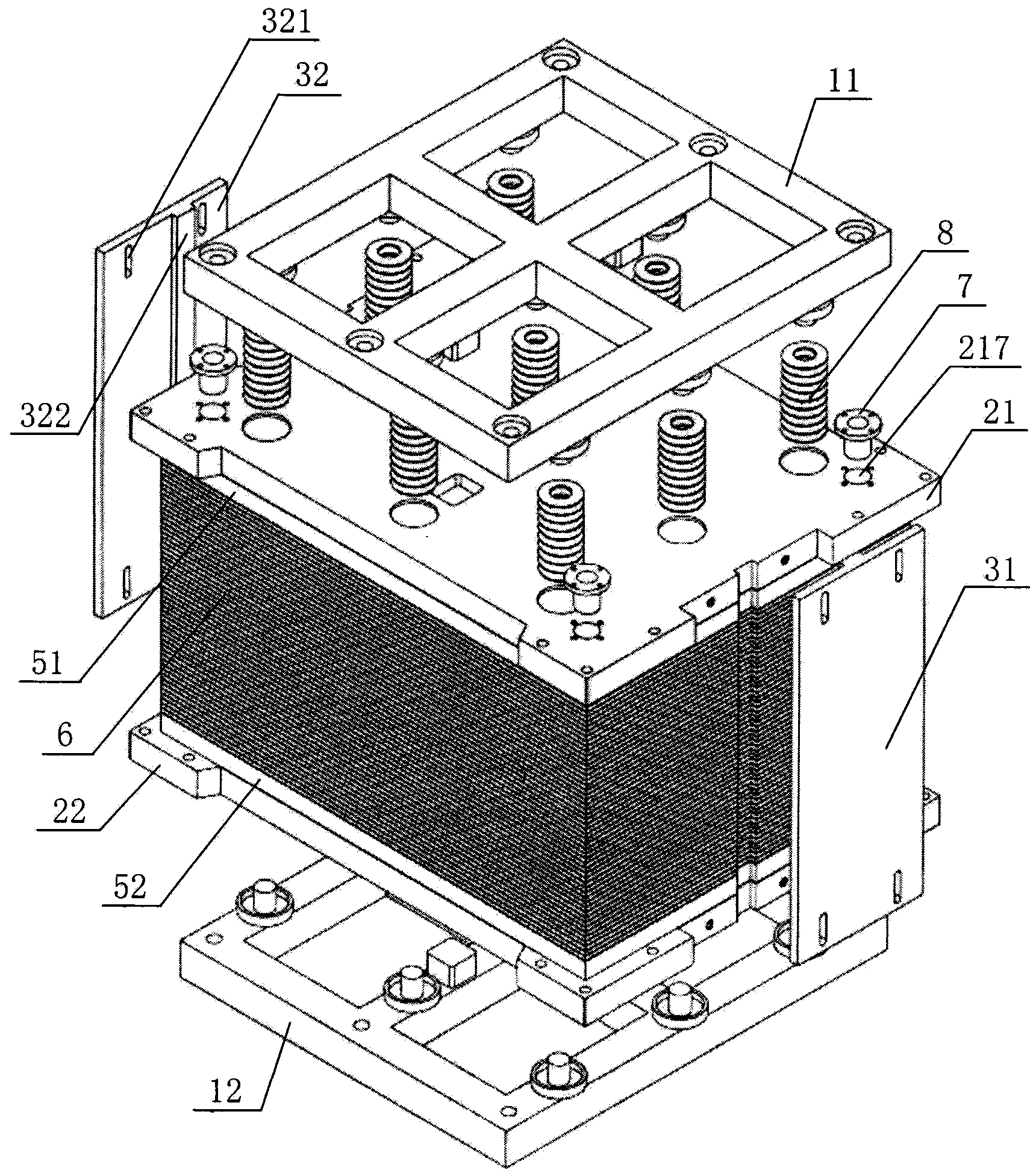

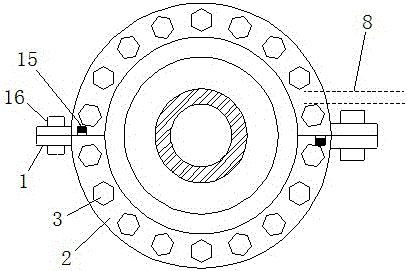

End plate pressing component of redox flow cell galvanic pile

ActiveCN102306821BEvenly distributed pressing forceGuaranteed pressing forceFuel cells groupingFinal product manufactureElectrolyte leakageManufacturing technology

The invention provides an end plate pressing component of a redox flow cell galvanic pile, belonging to the field of manufacturing technology of redox flow cell galvanic pile. The end plate compressing component is characterized by comprising end plates on two sides, pressing frames which are pressed on the end plates and pressing connecting pieces of the pressing frames, wherein the end plates are provided with blind holes for placing disc springs; and the pressing frames are provided with disc spring guide bars, guide posts for positioning the end plates and limit plates for positioning the end plates and each unit frame of the redox flow cell. The end plate pressing component provided by the invention can exactly position and press each part in the redox flow cell galvanic pile, ensures that pressing force on the plane of each plate frame of the redox flow cell is distributed evenly, and is convenient to assemble the galvanic pile. Through the matching between the strip bulges on the limit plates and the groove on each cell plate frame, the electrolyte leakage caused by local dislocation of each cell plate frame of the redox flow cell is avoided. Elastic parts are used for compensating the deformation caused by temperature change as well as the local deformation caused by vibration in the transport process, keeping the original pressing force on the galvanic pile and improving the sealing reliability of the galvanic pile.

Owner:TSINGHUA UNIV +1

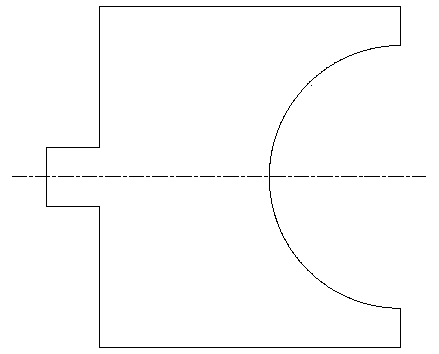

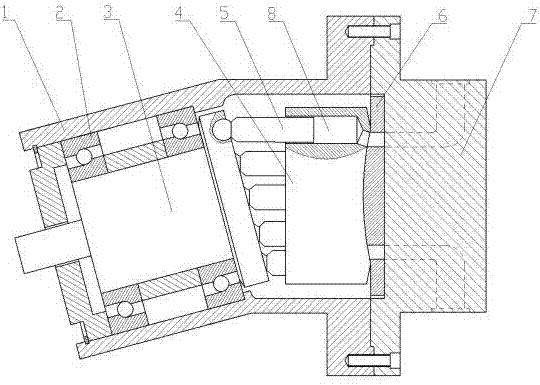

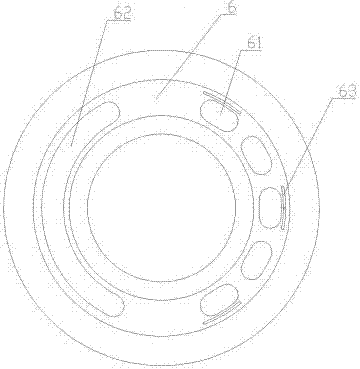

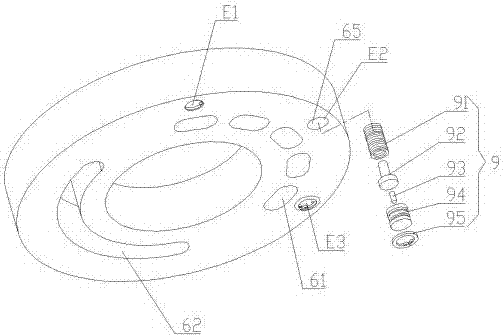

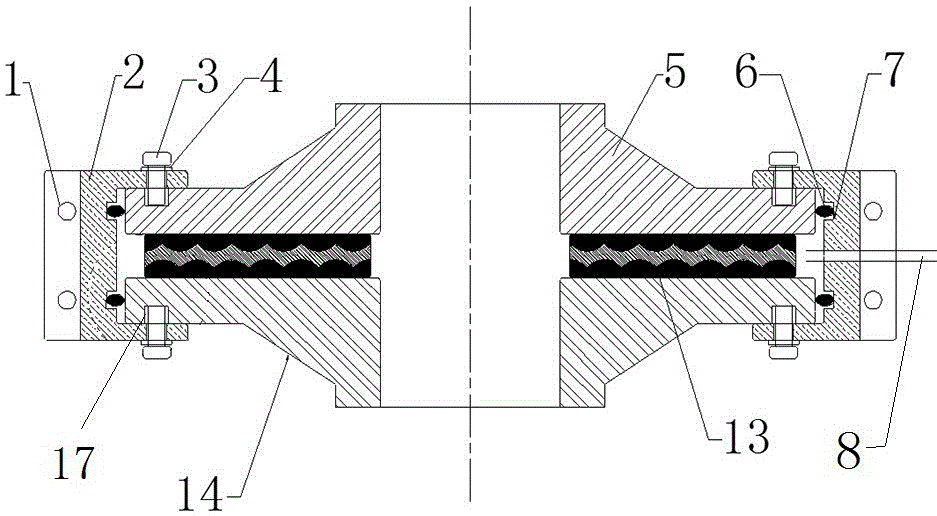

Pressing force adjustment device for flow distribution pairs

The invention relates to a pressing force adjustment device for flow distribution pairs. The pressing force adjustment device comprises a plunger tray, a flow distribution plate and a bearing device, and further comprises a pressing force adjustment assembly. The pressing force adjustment assembly is arranged on the flow distribution plate or the bearing device. Through the pressing force adjustment assembly installed in an installation hole, high-pressure oil can be led into the space between the plunger tray with relative rotation and the flow distribution plate or led into the space between the flow distribution plate and the bearing device; through leading-in of the high-pressure oil, a part of friction force of the flow distribution pairs can be counteracted, thus it can be guaranteed that on the premise of an appropriate redundant pressing force coefficient, friction force between the flow distribution plate and the plunger tray or friction force between the flow distribution plate and the bearing device is reduced, and occurrence of a plate burning phenomenon is avoided; meanwhile, leakage quantity increase caused by an excessive gap between the flow distribution pairs cannot happen, and volumetric efficiency is guaranteed.

Owner:BENGBU KUNPENG FOOD & BEVERAGE

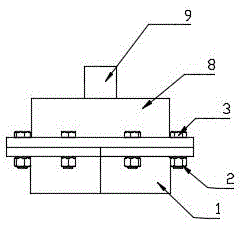

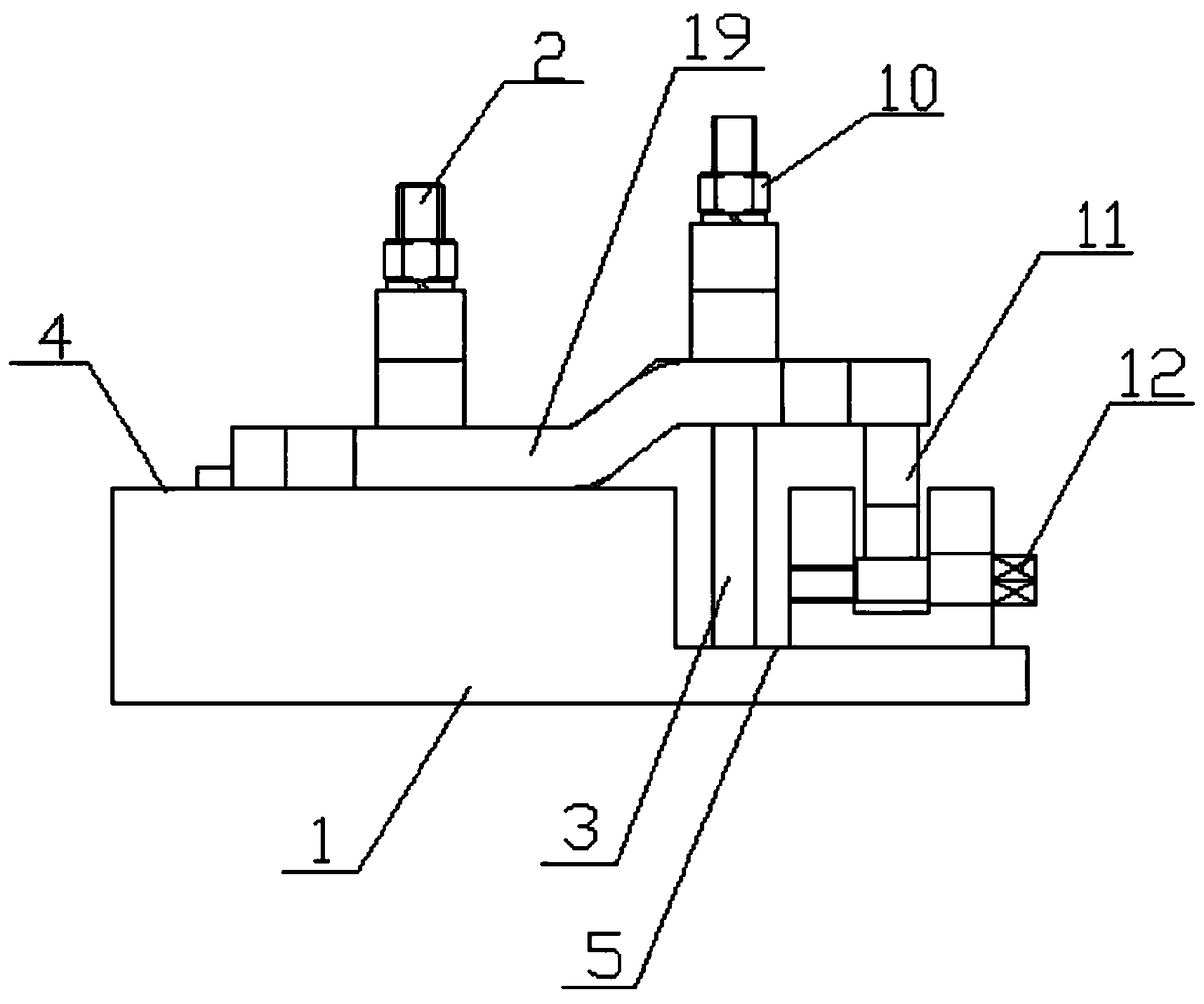

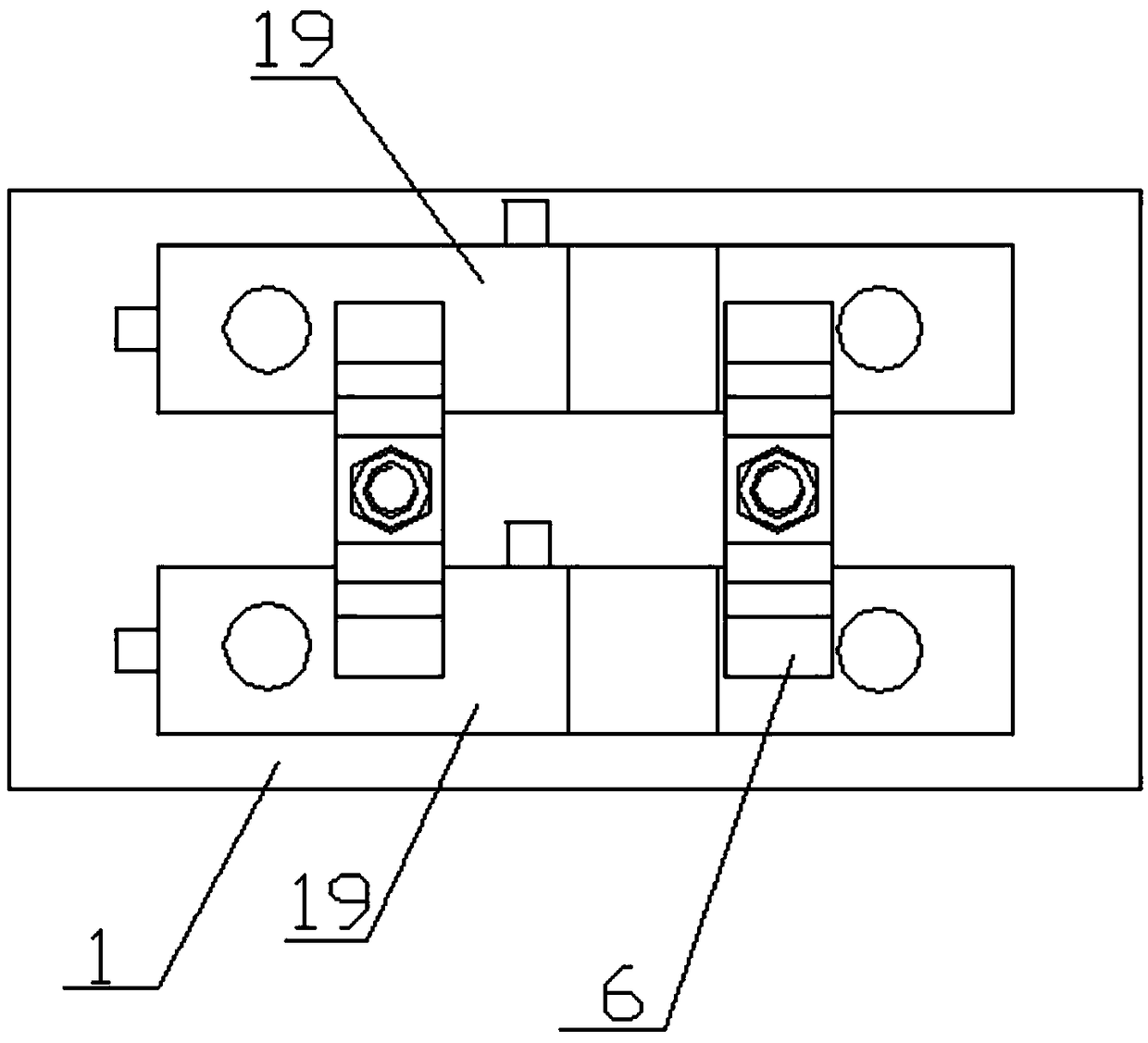

Cranked plate hole-boring clamp

ActiveCN108381235AGuaranteed pressing forceImprove vibrationWork clamping meansPositioning apparatusEngineeringSelf positioning

The invention discloses a cranked plate hole-boring clamp. The cranked plate hole-boring clamp comprises a base, a first threaded rod, a second threaded rod, a floating self-positioning device and twofloating pressing devices. The base is provided with a first workpiece supporting surface and a second workpiece supporting surface, and the height of the second workpiece supporting surface is lessthan that of the first workpiece supporting surface. Each floating pressing device comprises a floating pressing plate and a pressing cushion block. The two sides of the lower end surface of each floating pressing plate are provided with pressing plate supporting parts correspondingly. The upper end faces of the floating pressing plates are provided with arc surface protrusions. The lower end faces of the pressing cushion blocks are provided with positioning grooves matched with the arc surface protrusions. The lower end of the first threaded rod sequentially penetrates through a locking nut,the corresponding pressing cushion block and the corresponding floating pressing plate and then is connected to the first workpiece supporting surface. The lower end of the second threaded rod sequentially penetrates through a locking nut, the corresponding pressing cushion block and the corresponding floating pressing plate and then is connected to the second workpiece supporting surface. The cranked plate hole-boring clam can clamp two to-be-machined workpieces at a time, and the machining precision of the workpieces can be improved.

Owner:ANHUI HUANGSHAN HENGJIU CHAIN TRANSMISSION CO LTD

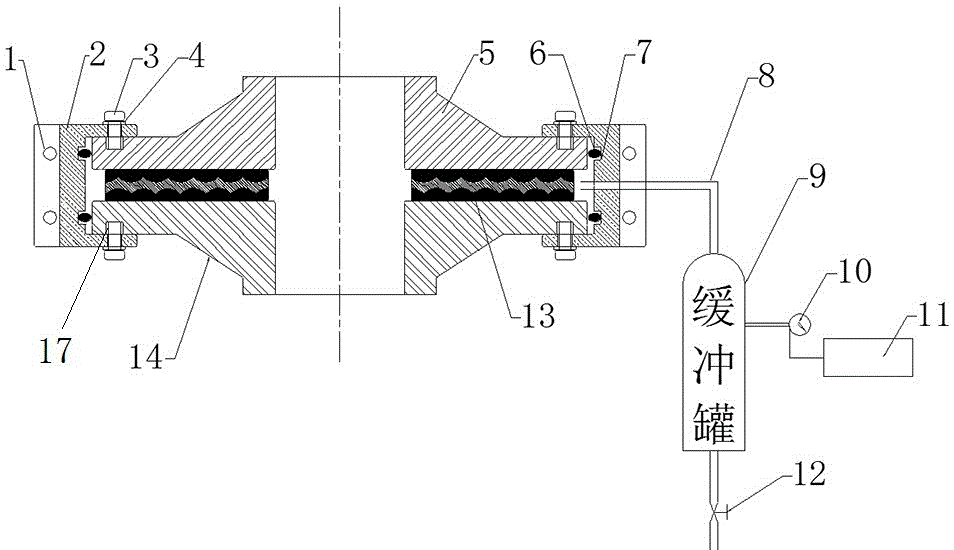

Flange connection leakage early warning device

InactiveCN105928669AGood sealingPrevent leakageMeasurement of fluid loss/gain rateEngineeringHigh pressure

The invention relates to a flange connection leakage early warning device which is characterized by comprising a flange sealing system and a leakage protection early warning system. The flange sealing system is mainly composed of a pair of metal hoops which are semicircular-ring-shaped, and the internal sides of the metal hoops are provided with grooves of which the cross sections are rectangular. The pair of metal hoops are mutually matched so as to clamp the edge of a flange in a sealing way. The leakage protection early warning system comprises a buffer tank which is provided with a pressure gauge, and a spherical valve is arranged at the bottom part of the buffer tank. An alarm device is also connected on the pressure gauge. The buffer tank is connected with one metal hoop in a communicating way through a leakage medium discharge channel. The device can be applied to the complex conditions of high temperature, high pressure and vibration and can maintain great sealing performance for a long time so that leakage of the flange can be effectively prevented, the leakage situation of the flange can be monitored in real time, the early warning device performs early warning to prompt personnel evacuation when leakage occurs, and the buffer tank is arranged to buffer leakage for time of personnel evacuation.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

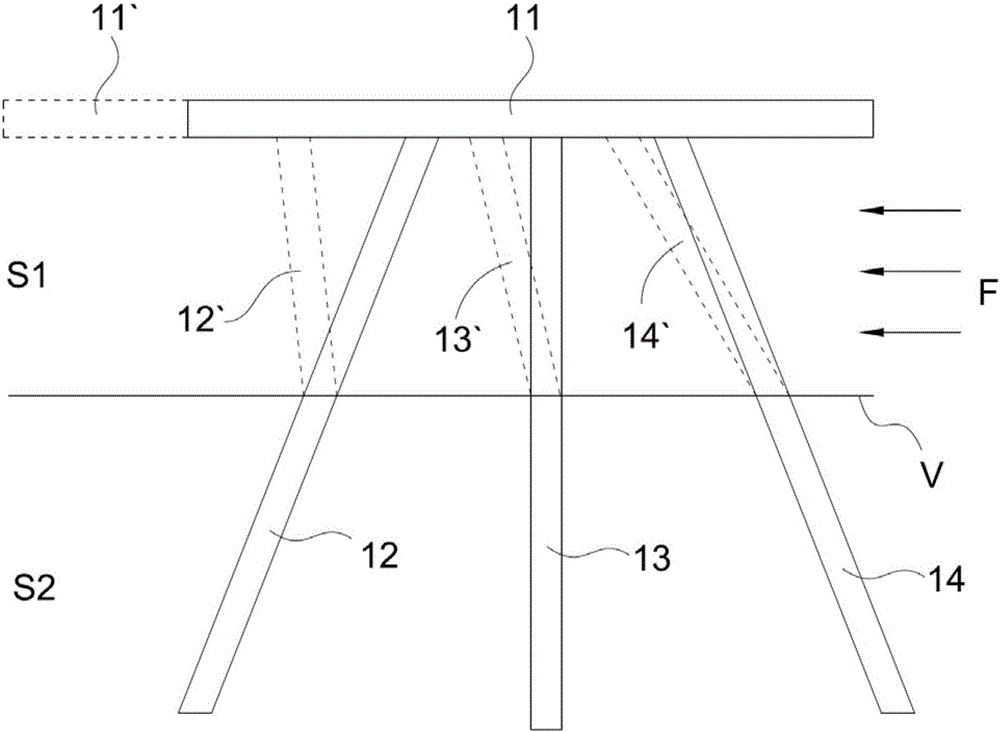

Pressing arm type feeding mechanism for bending center

ActiveCN111545660AGuaranteed pressing forceImprove accuracyMetal-working feeding devicesPositioning devicesStructural engineeringSlider crank

The invention relates to the technical field of bending equipment, and in particular relates to a pressing arm type feeding mechanism for a bending center. The mechanism comprises a C-shaped pressingarm, a swing arm mechanism and a lifting mechanism as well as a pressure bearing mechanism and a rotating mechanism are respectively arranged at two free ends of the C-shaped pressing arm correspondingly, and a sliding mechanism is arranged below the C-shaped pressing arm; the swing arm mechanism is a slider-crank mechanism driven by a swing arm servo motor, the lifting mechanism is connected below the slider-crank mechanism and can realize lifting movement along a lifting sliding rail fixed to the C-shaped pressing arm, and a vertically-arranged pressing shaft is connected to a pressing shaftcarrier through a pressing shaft bearing; and the rotating mechanism is arranged below the pressure bearing mechanism and drives a pressure bearing disc in the pressure bearing mechanism to rotate. Acrank connecting rod structure is adopted for pressing a plate, so that the pressing force for the plate is guaranteed, and the accuracy of the pressing position and the moving position is improved;and by adopting the structure that a support seat of the pressure bearing disc, a first support post and a second support post are matched with each other, the bearing pressure of a rotary speed reducer is reduced, and further, the service life of the rotary speed reducer is prolonged.

Owner:青岛艾特智能装备有限公司

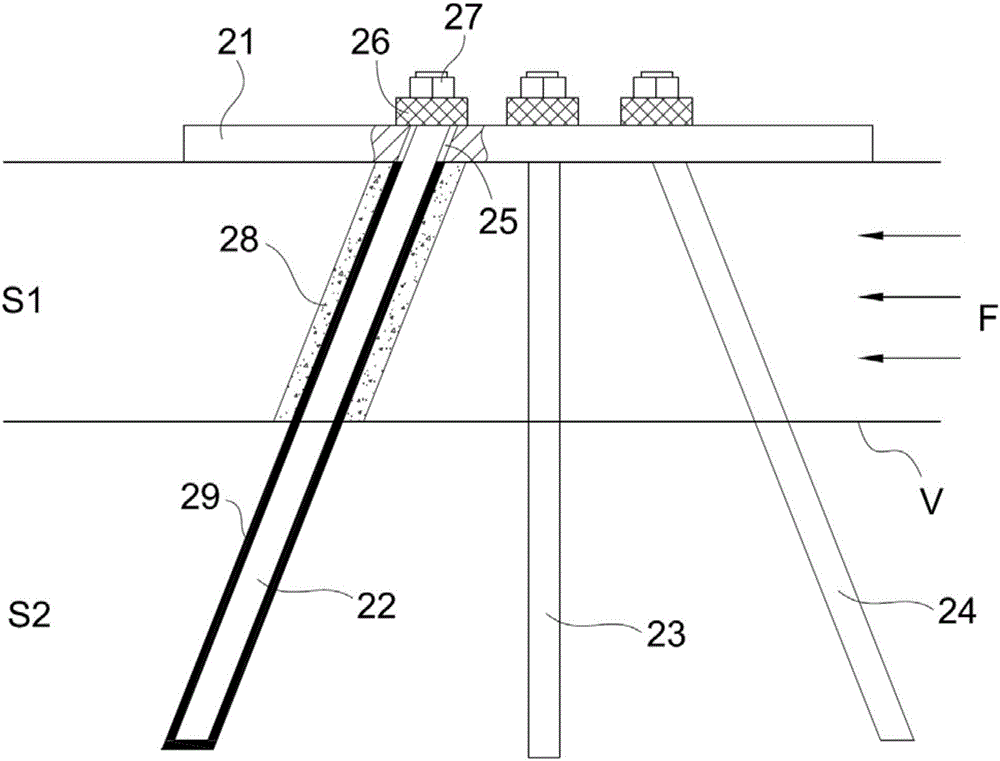

Inclined arrangement mini pile structure

ActiveCN105804100AReduce frictionImprove the lubrication effectProtective foundationExcavationsLandslideEngineering

The invention discloses an inclined arrangement mini pile structure. The inclined arrangement mini pile structure is used for fixing a landslide mass on a base rock. The inclined arrangement mini pile structure comprises at least one group of mini pile assembly which penetrates through the landslide mass to be fixedly connected with the base rock. Each group of mini pile assembly comprises at least three mini piles and a top plate which is arranged on the surface of the landslide mass and used for connecting the mini piles into a whole. The mini piles include the first mini piles, the second mini piles and the third mini piles. The second mini piles are perpendicular to the surface of the landslide mass. The first mini piles are arranged in an inclined mode in a direction facing the exerting direction of thrust of the landslide mass. The third mini piles are arranged in an inclined mode in the exerting direction of the thrust of the landslide mass. Lubricating interlayers are disposed between parts, located in the landslide mass, of the first mini piles and the landslide mass. By means of the inclined arrangement mini pile structure, the effect that the inclined piles towards the thrust of the landslide mass always have pre-tightening force can be ensured, and the whole mini pile structure is better in slope fixing effect.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Thermal force compression sealing device

The invention discloses a thermal force compression sealing device in the technical field of shaft end sealing structures. The device comprises a sealing seat arranged on a conditioning device shell and a rotating shaft movably arranged at the center of the sealing seat in a sleeving mode, a sealing filler is pressed between the outer wall of the rotating shaft and the inner wall of the sealing seat, the outer side end of the sealing seat is provided with a gland for pressing the outer side face of the sealing filler, the inner side end of the sealing seat extends into the conditioning deviceshell and is provided with a sealing groove, a groove opening of the sealing groove is provided with a movable gland for compressing the inner side face of the sealing filler, the movable gland is circumferentially positioned on the sealing seat and can move axially along the sealing seat, and an internal hollow sealing cavity structure is formed between the movable gland and the sealing groove. The thermal force compression sealing device has the advantages that it is ensured that the rotating shaft are tightly pressed through the inner side and the outer side of the sealing filler at the same time, and therefore, the device is suitable for sealing of the rotating shaft end of a feed conditioning device, and the sealing effect is improved.

Owner:FAMSUN CO LTD

Temperature-compensated deep-cold laser impact experimental fixture

ActiveCN110153563AGuaranteed pressing forceImprove efficiencyLaser beam welding apparatusEngineeringMechanical engineering

The invention provides a temperature-compensated deep-cold laser impact experimental fixture. The temperature-compensated deep-cold laser impact experimental fixture comprises a spring and sliding block compression piece and a camping piece, wherein the spring and sliding block compression piece comprises two identical spring and sliding block units, each spring and sliding block unit comprises anouter sliding block, a spring and an inner sliding block, each spring is connected with the corresponding outer sliding block and the corresponding inner sliding block, and each outer sliding block and each inner sliding block can slide along the straight line; and the clamping piece is used for clamping the two outer sliding blocks from the outer side surfaces of the two outer sliding blocks, the two spring and sliding block compression pieces are located on the same straight line and symmetrically distributed, and under the action of the clamping piece, the two inner sliding blocks can clamp a sample workpiece from the two ends of the sample workpiece. The temperature-compensated deep-cold laser impact experimental fixture can actively compensate for the plastic shrinkage of the samplein the deep-cold environment in real time, and the clamping force of the fixture to the sample in the reinforcement process is ensured all the time.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com