Full-automatic antique wood floor making machine

A wood flooring and processing machine technology, applied in wood processing equipment, manufacturing tools, etc., can solve problems such as waste of resources, low production efficiency, and single visual effect, and achieve the effects of reducing movement resistance, high processing efficiency, and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

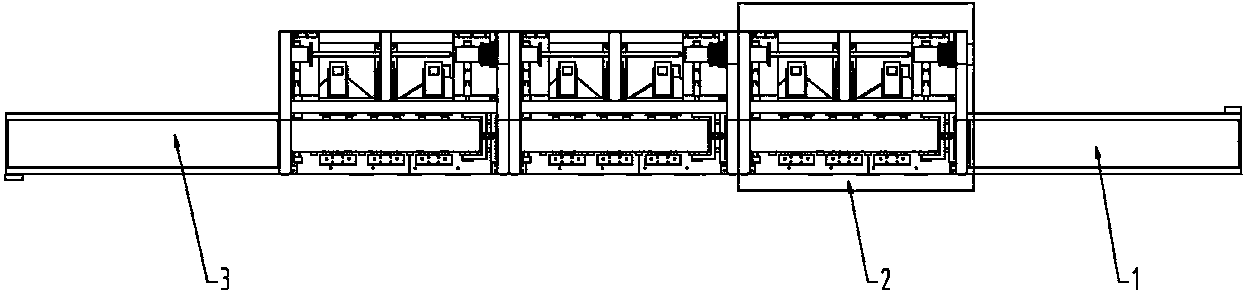

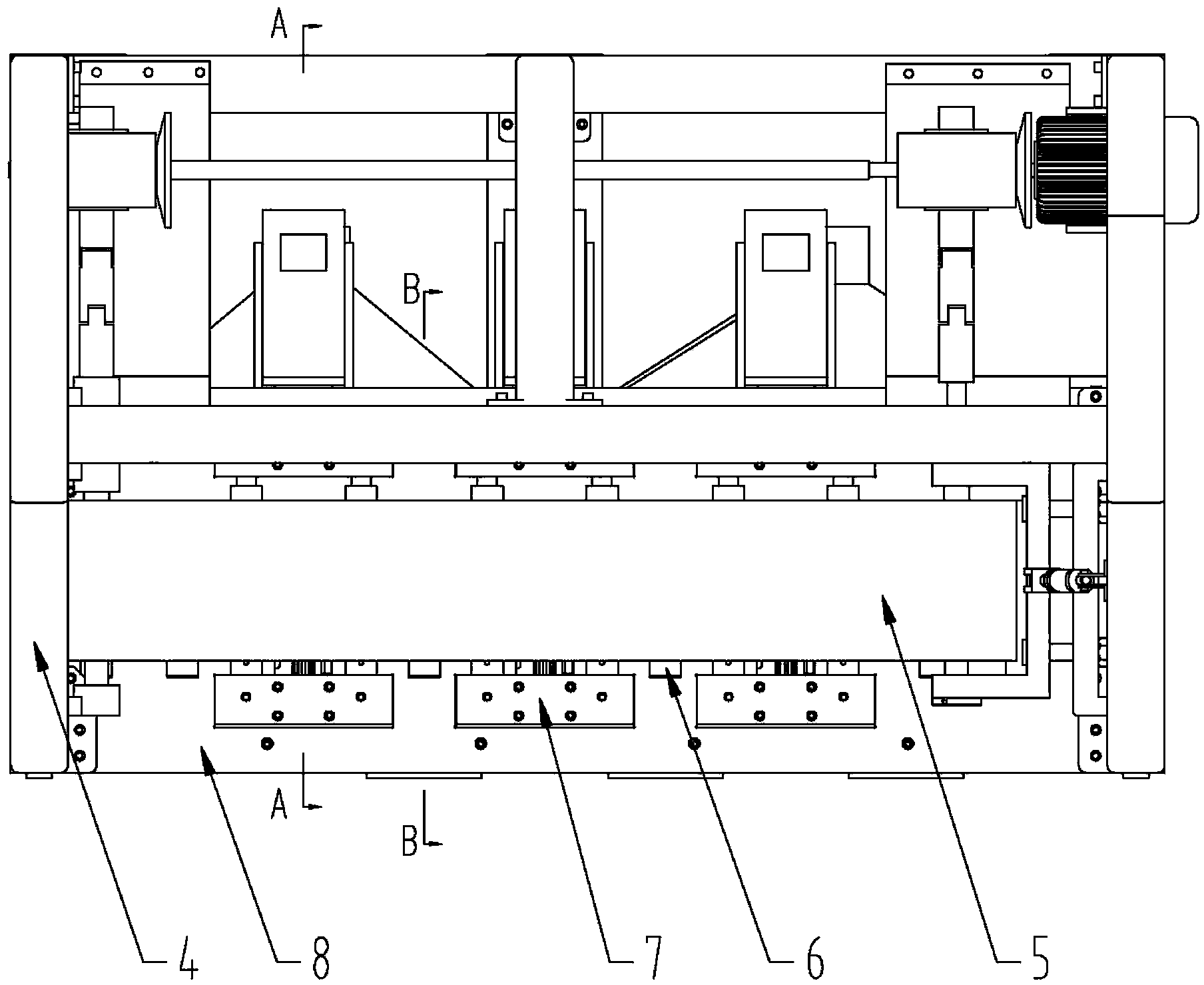

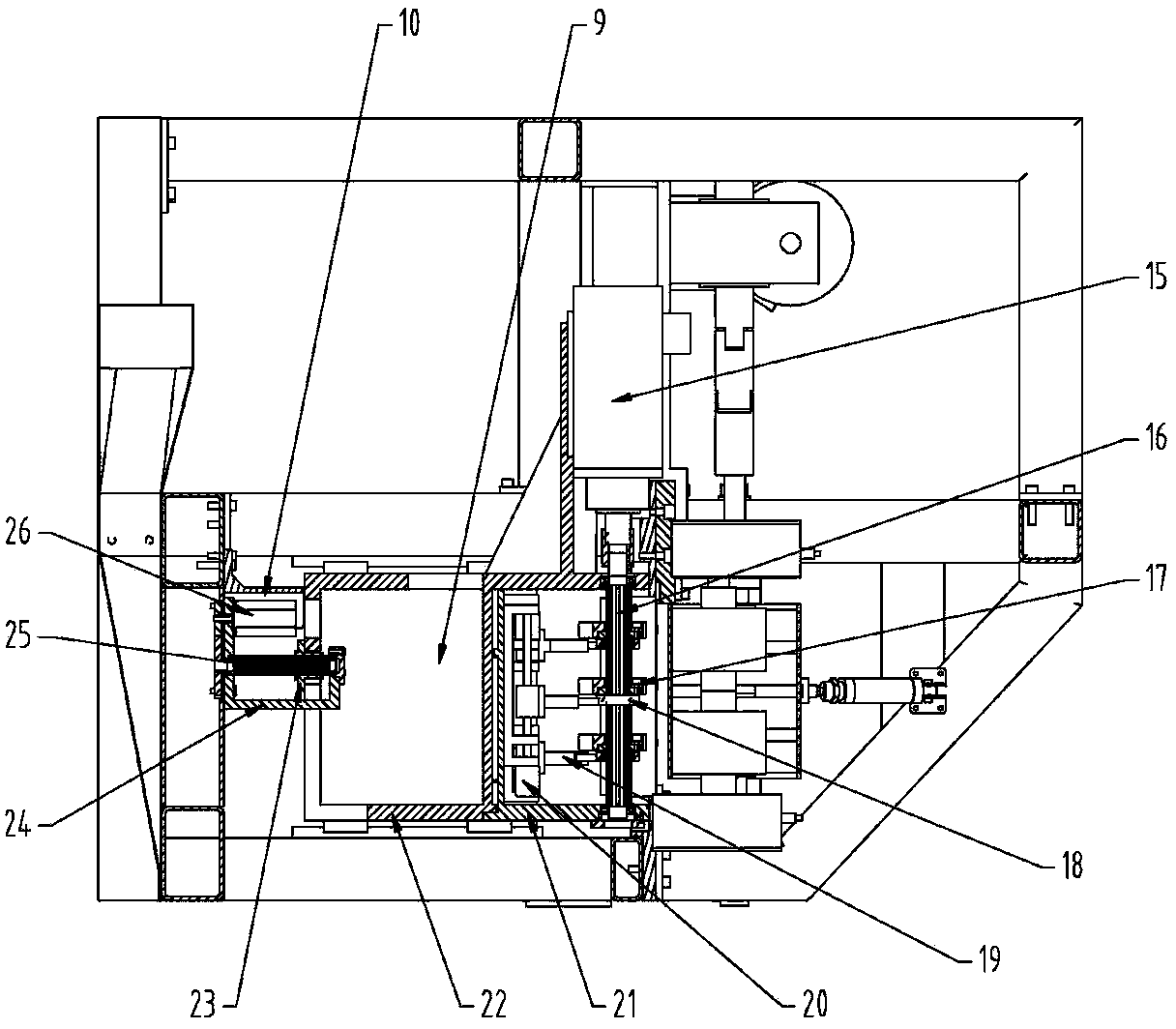

[0029] Such as Figure 1-7 Shown: a fully automatic antique wood floor processing machine, including a feeding device 1, a mutually independent processing unit 2 and a discharging device 3, the feeding device 1 and the discharging device 3 are respectively arranged on the feeding side of the processing unit 2 On the export side of the finished product, the processing units 2 can be used independently or in combination. When processing wood floors, the processing units 2 can be freely combined according to the length and output requirements of the wood floors. The number of processing units 2 is usually one to three. wait. The processing unit 2 includes a frame 4 that constitutes the overall frame of the processing machine. A transmission device 5, a pressing device 7, a platen device 8 and a cutting system 9 are installed on the frame 4. A chip removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com