Hub main nut screwing and bearing pre-tightening force measuring machine and using method thereof

A bearing preload and main nut technology, applied in the field of auto parts assembly, can solve the problems of wasting labor costs, unable to realize automatic mechanical operation, time-consuming and labor-intensive, etc., and achieve the effects of simple operation, labor cost saving, and accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

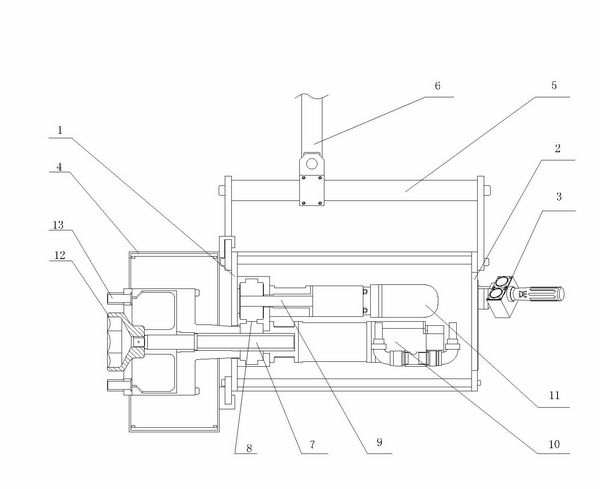

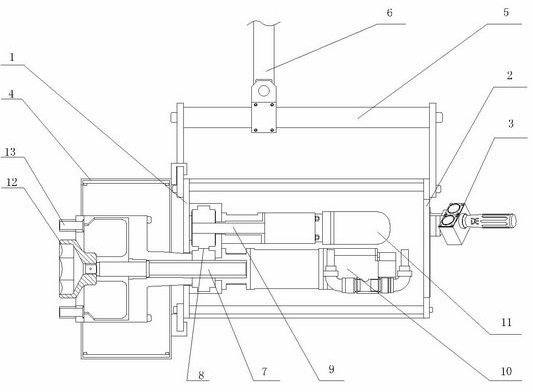

[0013] figure 1 The reference signs shown are as follows: front cover plate 1, rear cover plate 2, operating handle 3, protective cover 4, guide post 5, suspension device 6, nut tightening shaft 7, gear 8, rotary measuring shaft 9, first servo Motor 10, second servo motor 11, special sleeve 12, rotary measuring wrench 13.

[0014] figure 1 In the schematic diagram of a hub main nut tightening and bearing pretightening force measuring machine shown, it includes: front sealing plate 1, rear sealing plate 2, operating handle 3, protective cover 4, guide column 5, suspension device 6, nut Tightening shaft 7, gear 8, rotary measuring shaft 9, first servo motor 10, second servo motor 11, special sleeve 12, rotary measuring wrench 13; it is characterized in that: rear sealing plate 2 is provided with operating handle 3, front The cover plate 1 is connected with the protective cover 4 and the guide post 5, the guide post 5 is connected with the suspension device 6, the nut tightenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com