Flange connection leakage early warning device

An early warning device and flange technology, which is applied in the direction of measuring the rate of increase and deceleration of the fluid, using liquid/vacuum degree for liquid tightness measurement, etc., can solve leakage, difficult monitoring and early warning of flange connection structure, loosening or pre-tightening Insufficient power and other problems, to achieve the effect of improving service life, reducing maintenance and shutdown times, and responding quickly and accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

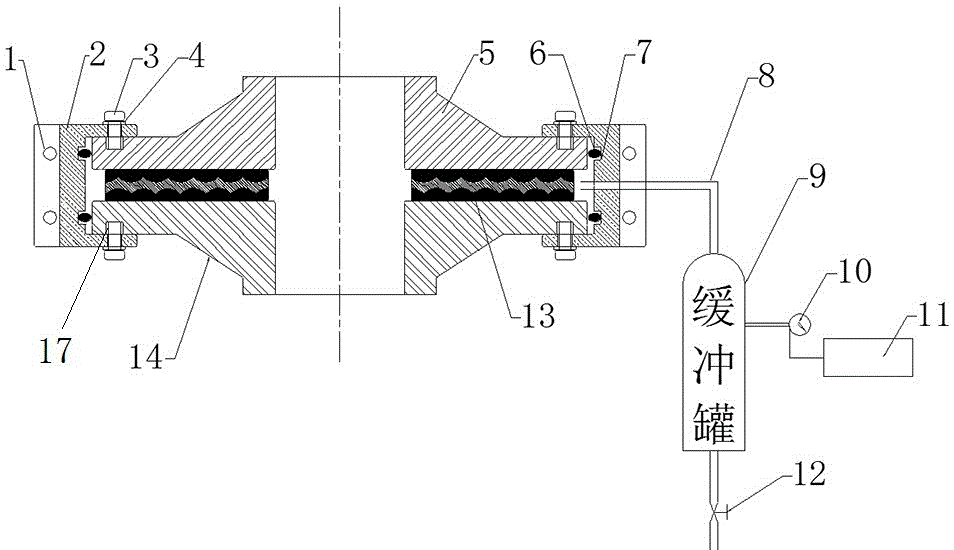

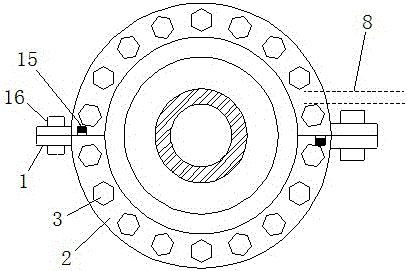

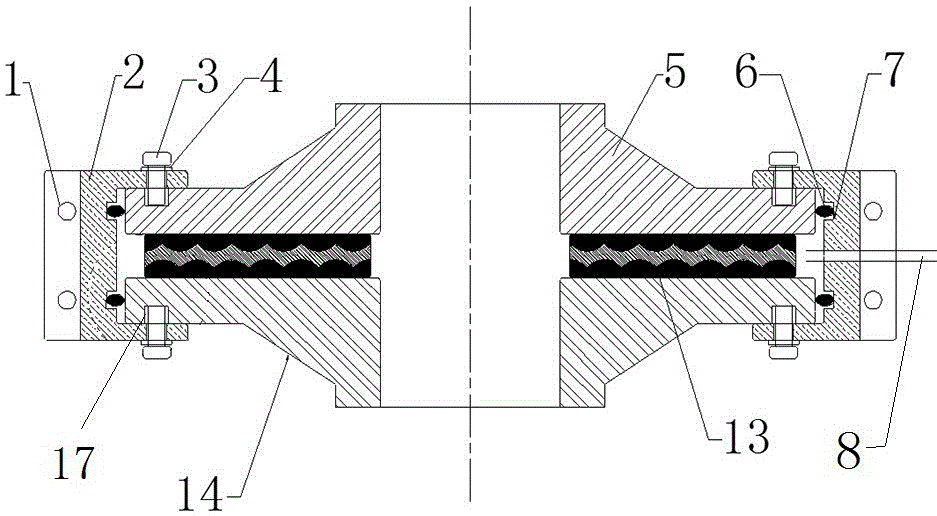

[0014] In order to better understand the present invention, below in conjunction with embodiment and accompanying drawing, technical scheme of the present invention is described further (as Figure 1-3 shown).

[0015] A flange connection leakage early warning device, which includes a flange sealing system and a leakage protection early warning system;

[0016] The flange sealing system is mainly composed of a pair of metal clamps 2, the metal clamps 2 are semi-circular, and a groove with a rectangular cross section is opened on the inner side (that is, the cross section of the metal clamp 2 is "[" type), The pair of metal clamps 2 cooperate with each other to seal and hold the edge of the flange (the flange is composed of the upper flange 5, the lower flange 14 and the gasket 13) (that is, the edge of the flange is completely sealed. wrapped); the surface of the upper flange 5 and the lower flange 14 of the flange (that is, the upper surface of the upper flange 5 and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com