Sealing plugging cover for aeroengine test lead

An aero-engine and test lead technology, which is applied in the field of aero-engines, can solve the problems of increased engine development cycle and cost, different sealing plug specifications, long development cycle, etc., and achieves flexible changes in caliber size, wide application range, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

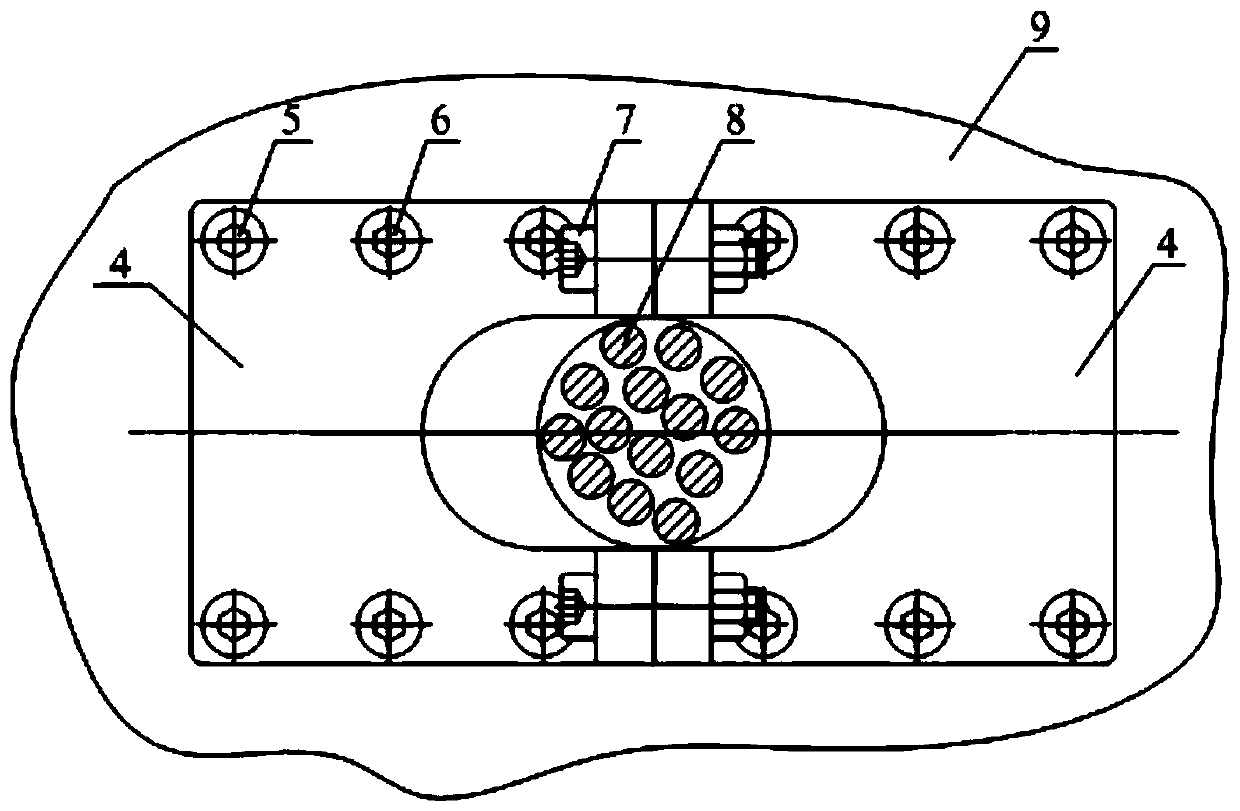

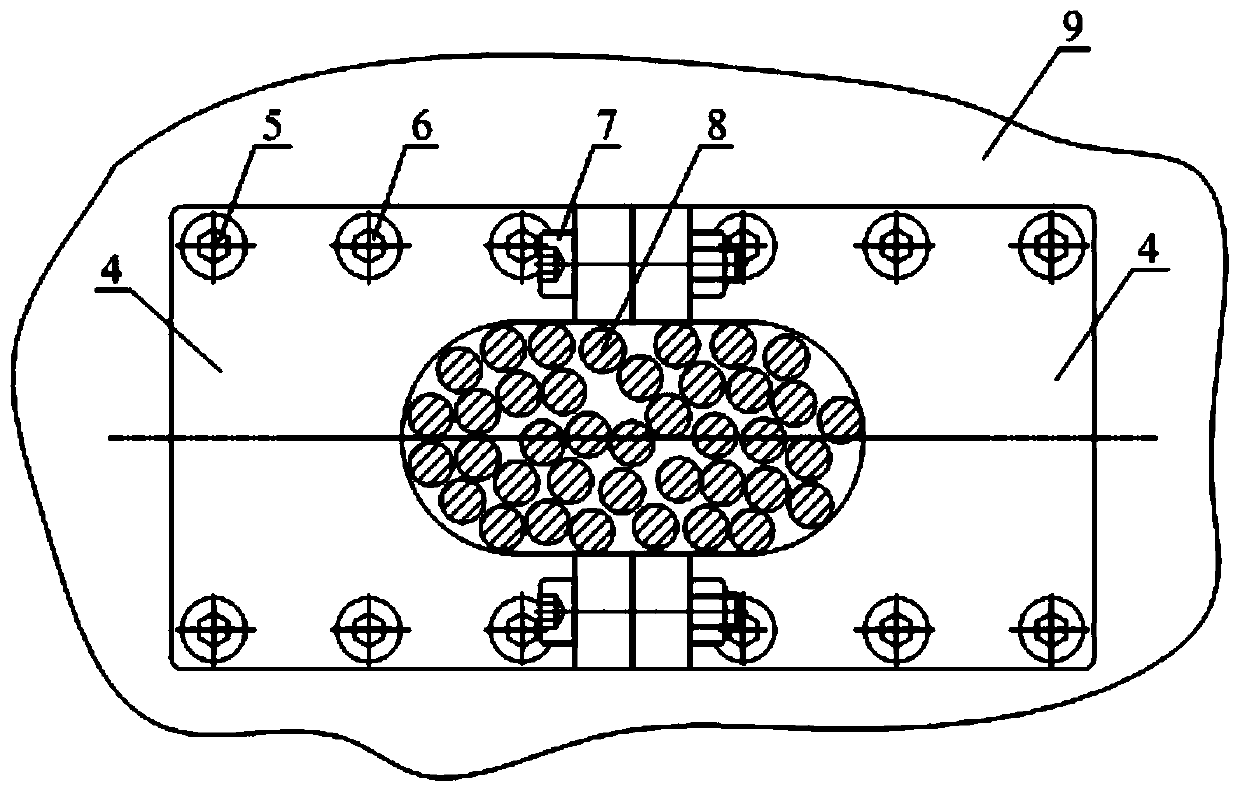

[0035] Such as Figure 1-10 As shown, a sealing plug for aero-engine test lead wires includes an adjusting piece 1, a base 2, a spring 3 and a cover plate 4;

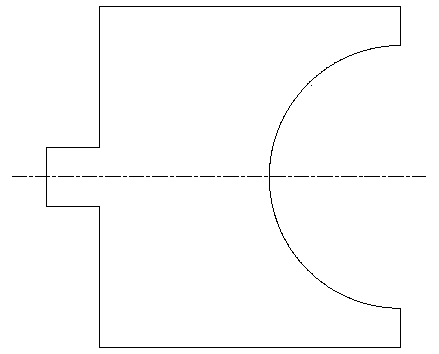

[0036] The side of the base 2 is provided with a threaded hole a2-1 and a light hole a2-2;

[0037] The center of the base 2 is provided with a sliding groove 2-3, and the bottom is provided with an installation groove 2-4;

[0038] The outline shape of the main body of the cover plate 4 is the same as that of the base 2, and there are threaded holes b4-1 and light holes b4-2 at the same opening positions as the base 2;

[0039] Both the threaded hole a2-1, the threaded hole b4-1 and the light hole a2-2, the light hole b4-2 are through holes;

[0040] One end of the cover plate 4 is provided with an installation edge 4-4, and an unthreaded through hole a4-3 is provided on the installation edge 4-4;

[0041] The outline shape of the main body of the sealing gasket 10 is the same as that of the base 2, and a non-thread...

Embodiment approach 2

[0053] combined with Figure 1 ~ Figure 2 The specific implementation of the present invention is described. The sealing plug of the embodiment adopts the design concept of split body and modularization. The central diameter of the cover is not affected by the test lead connector, which not only has high convenience in installation and disassembly, but also can complete the connection between the connector and the test lead before the lead, which improves the accuracy of the test.

Embodiment approach 3

[0055] combined with Figure 8 ~ Figure 10 Describe the specific embodiment of the present invention, the spring 3 of the embodiment is a key structure in the design of the sealing plug, the natural length of the spring 3 should be connected with the adjustment piece 1 according to the spring 3 and after being installed on the base 2, the adjustment piece and the base 2 The length of the front end surface is flat or slightly protruding. The purpose of this design is to ensure that the spring 3 always has a part of the elastic potential energy so that the adjustment piece 1 can press the test lead 8, reduce the leakage of the airflow along the radial direction of the engine, and ensure The sealing plug has a better sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com