Lamp locked and sealed by cam

A technology of cam locking and lamps, which is applied to the components of lighting devices, lighting and heating equipment, lighting devices, etc., can solve the problems of inconvenient disassembly and assembly, large sealing pre-tightening force, etc., to reduce external force and facilitate opening , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

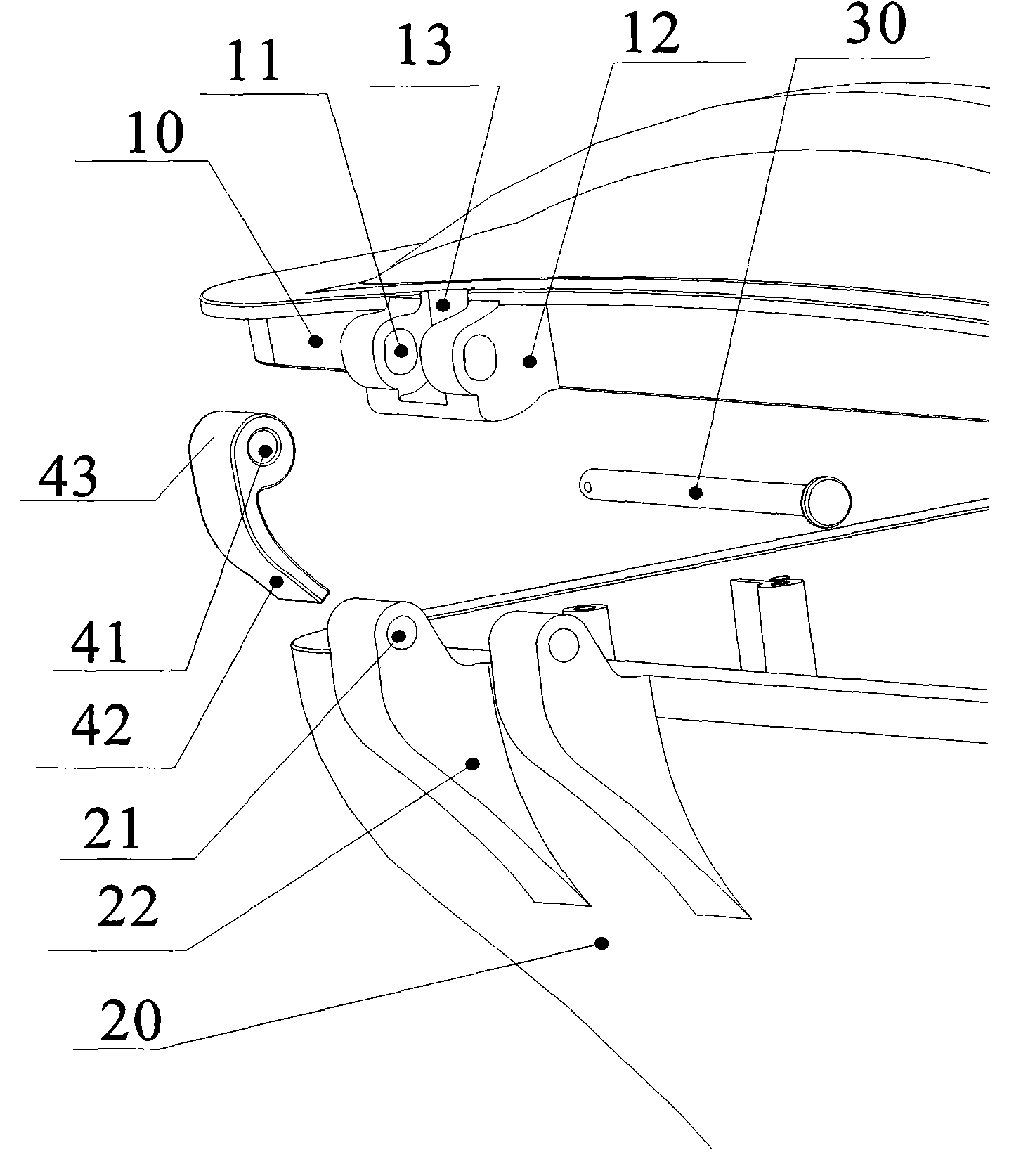

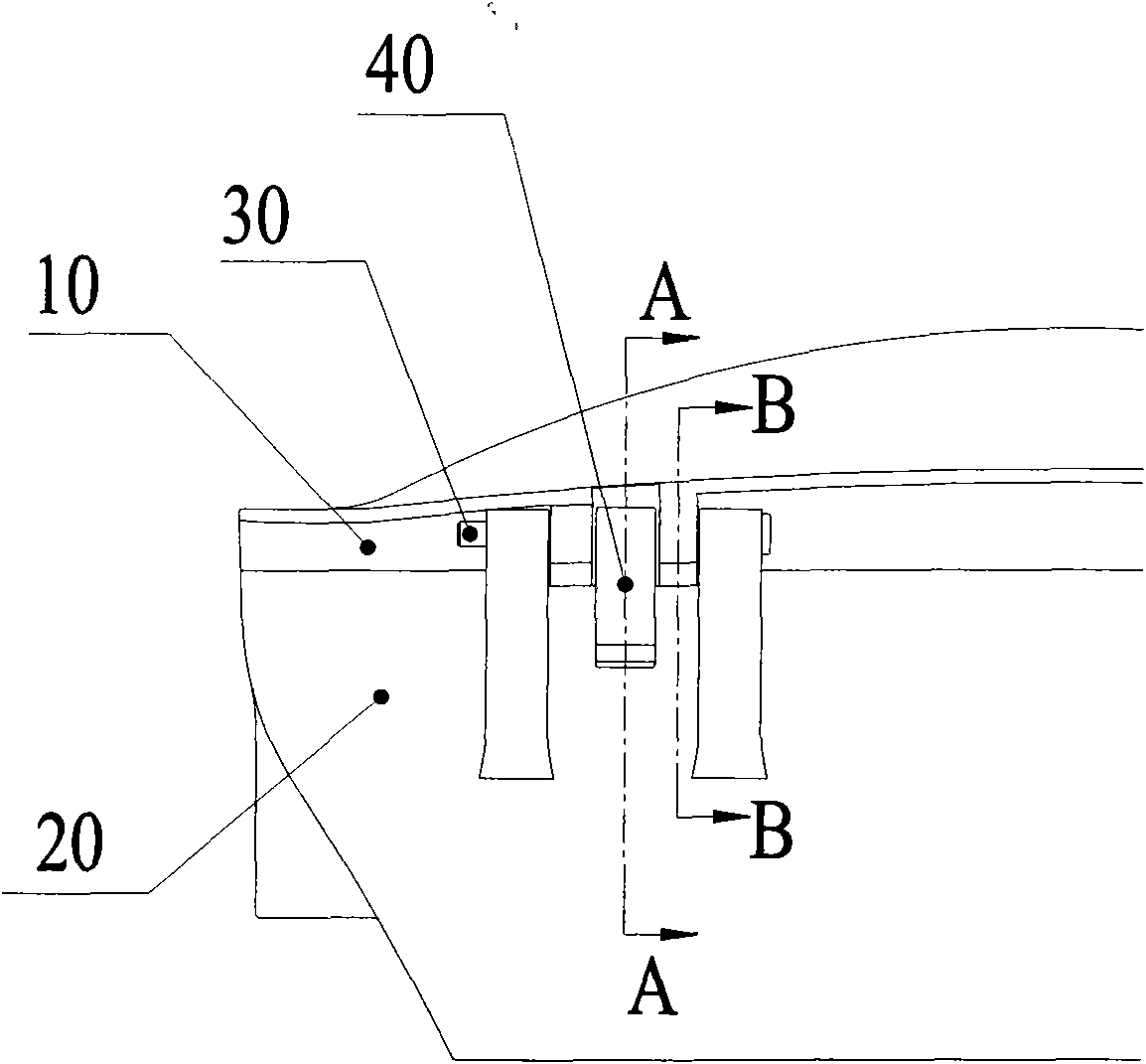

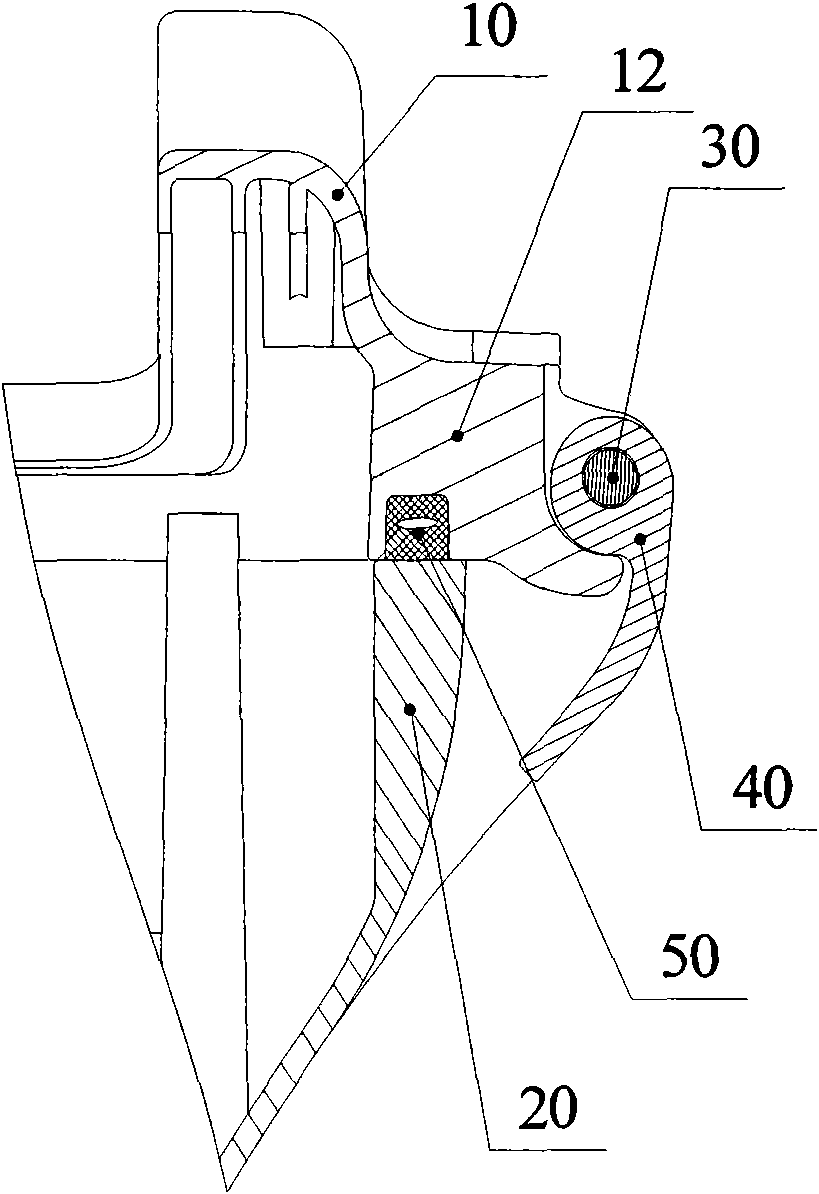

[0021] figure 1 The illustrated locking and sealing structure of the lamp of the present invention is applied to a preferred embodiment of a tunnel lamp, which includes a lamp body 20 , a lamp cover 10 , a pin shaft 30 , a cam handle 40 and a sealing ring 50 .

[0022] Wherein, the lamp cover 10 is located above the lamp body 20. In this embodiment, the lamp cover 10 has a sealing groove on the contact surface with the lamp body 20, and the sealing ring 50 is put into the sealing groove to seal the lamp cover 10 and the lamp body 20. role.

[0023] One end of the outer side of the lamp body 20 and the lamp cover 10 is provided with protruding protrusions, which are respectively two lugs 22 and two convex plates 12 shown in the figure, wherein the two lugs 22 are located on the two sides. Outside the convex plates 12, the cam handle 40 is located in the middle of the two convex plates 12.

[0024] As shown in the figure, both the lug 22 and the cam handle 40 are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com