Pressing force adjustment device for flow distribution pairs

A technology of adjusting device and pressing force, which is applied in the field of hydraulic pressure, can solve problems such as too large matching gap between the valve plate and the plunger cylinder, increased friction between the valve plate and the plunger cylinder, and reduced mechanical efficiency, so as to ensure volumetric efficiency, The structure of the oil circuit is simple and the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

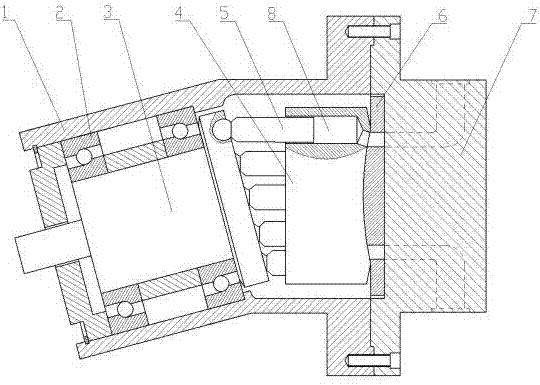

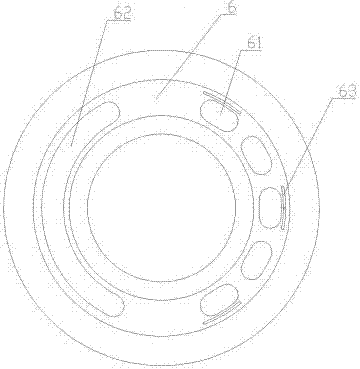

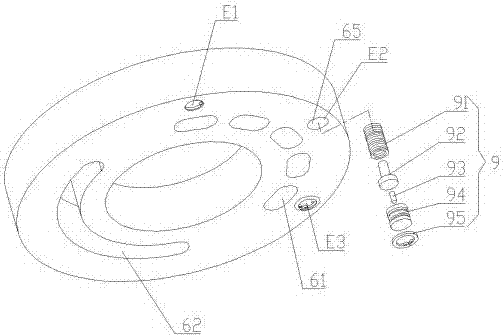

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples. The principles and features of the present invention will be described below in conjunction with the accompanying drawings. It should be noted that the embodiments in the present application and the features in the embodiments can be combined without conflict. The examples given are only for explaining the present invention, not for limiting the scope of the present invention.

[0035] Since the pressing force regulating device of the distribution pair provided by the present invention can be used for hydraulic components such as axial piston pumps (motors), floating cup hydraulic pumps (motors) and hydraulic transformers based on the former two, the The common feature is that they all have a flow distribution pair. The present invention will be described in detail below mainly taking an axial piston pump as an example.

[0036] A device for adjusting the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com