Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Scratch will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

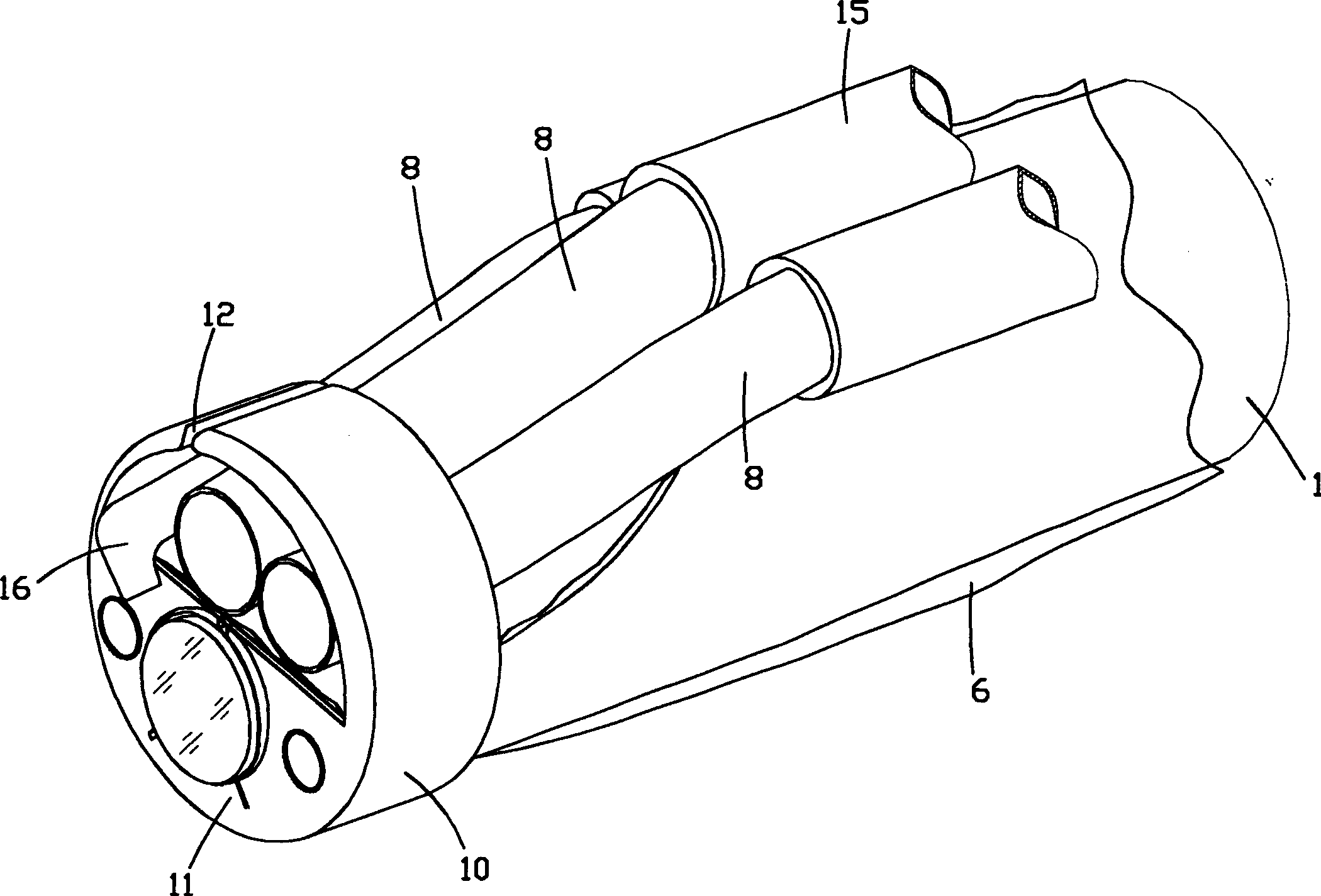

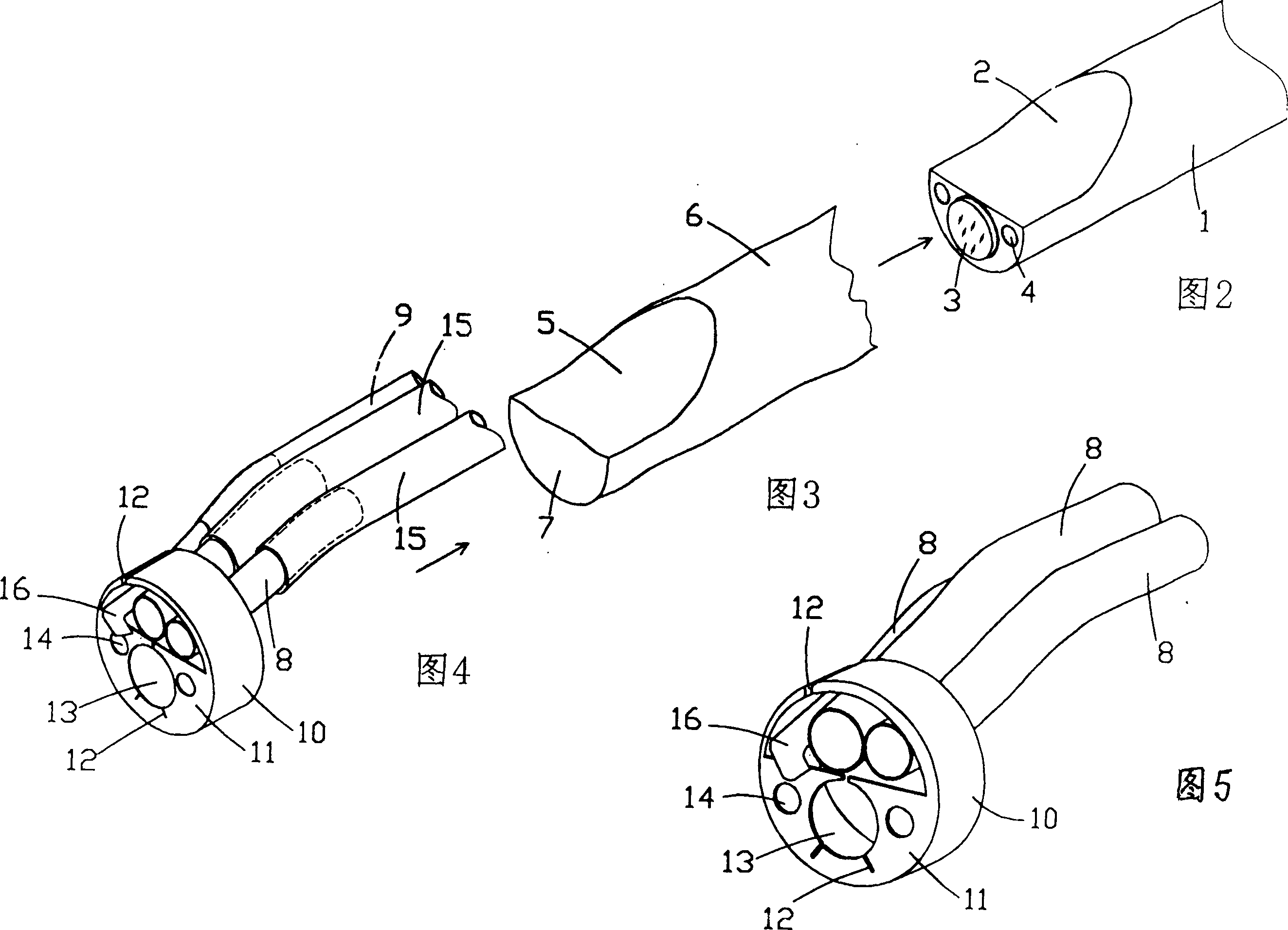

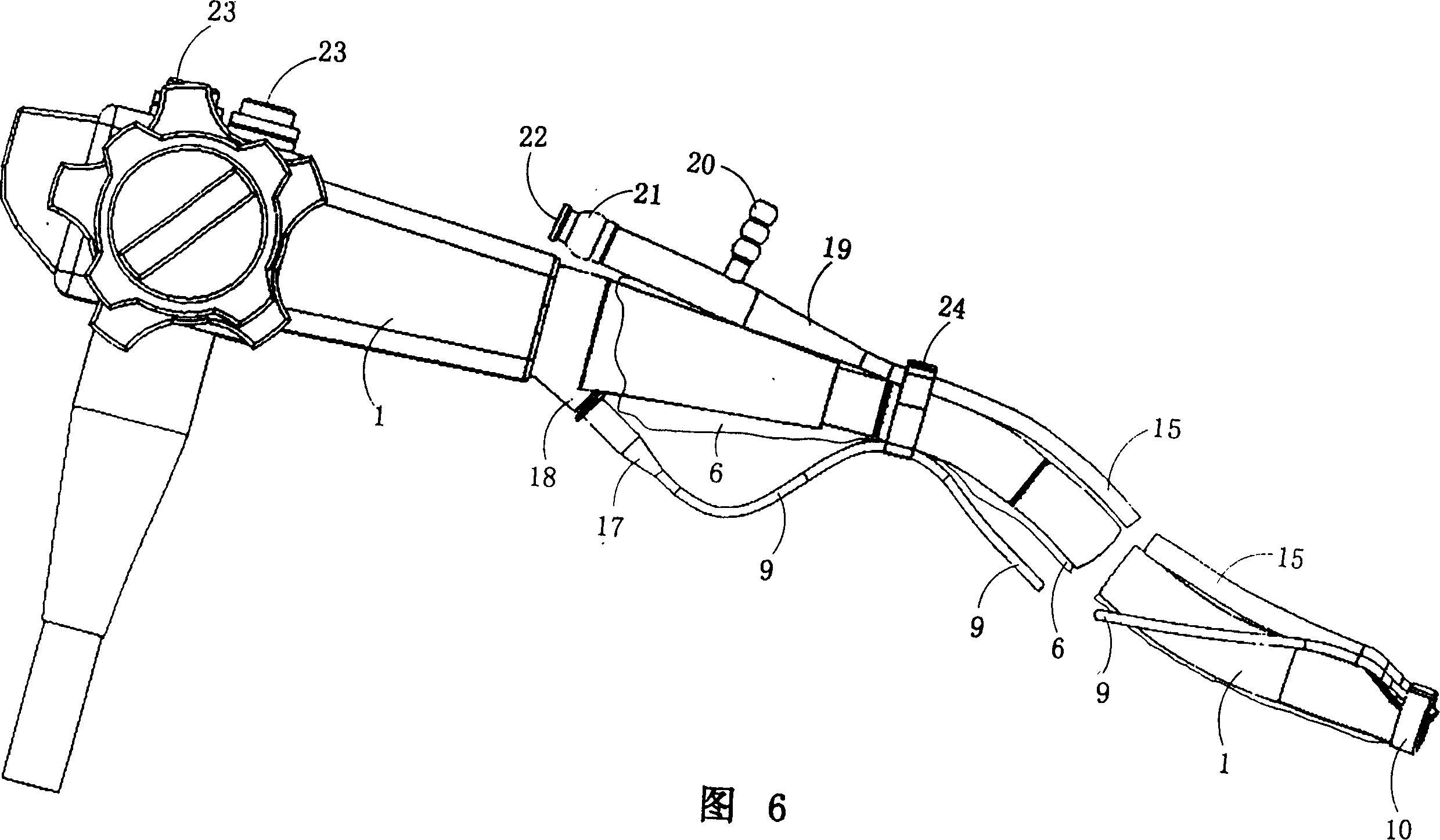

Endoscope system with disposable sheath

InactiveCN1486667AImprove turnover rateExtended service lifeSurgeryEndoscopesMedical equipmentEndoscope

The present invention belongs to the field of medical equipment, and the endoscope system with disposable sheath includes endoscope body and open-ended pipe. The endoscope system features that it has one isolating sleeve bag of transparent and tough material to cover the endoscope body and connected pipes set outside the isolating sleeve bag. After being used, the isolating sleeve bag together with the outside pipes is disposed while the expensive endoscope body is sterilized for reuse. The present invention can raise the utilization of the endoscope and prolong its service life.

Owner:姜克让 +1

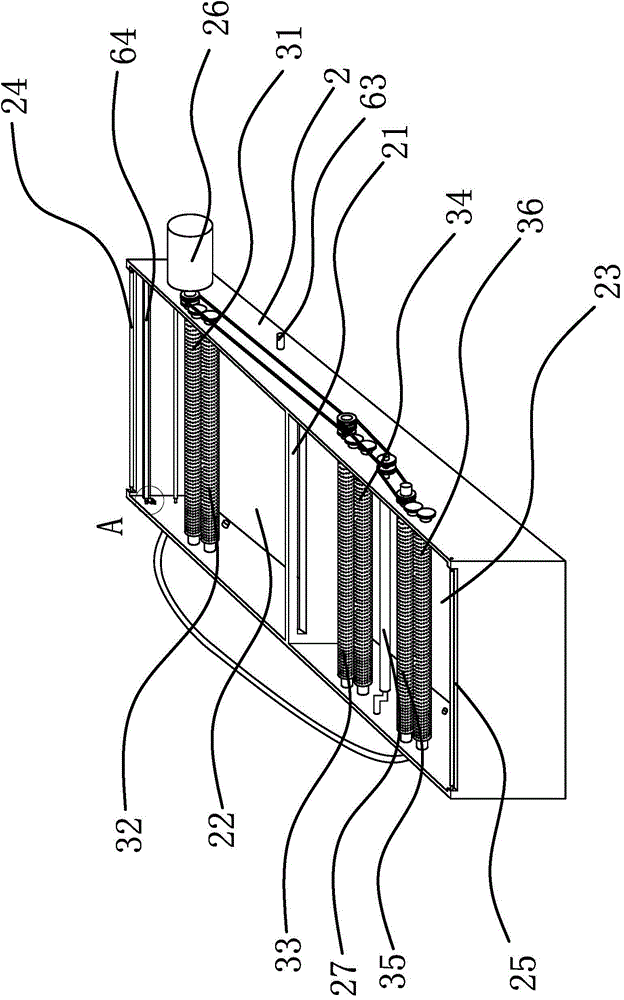

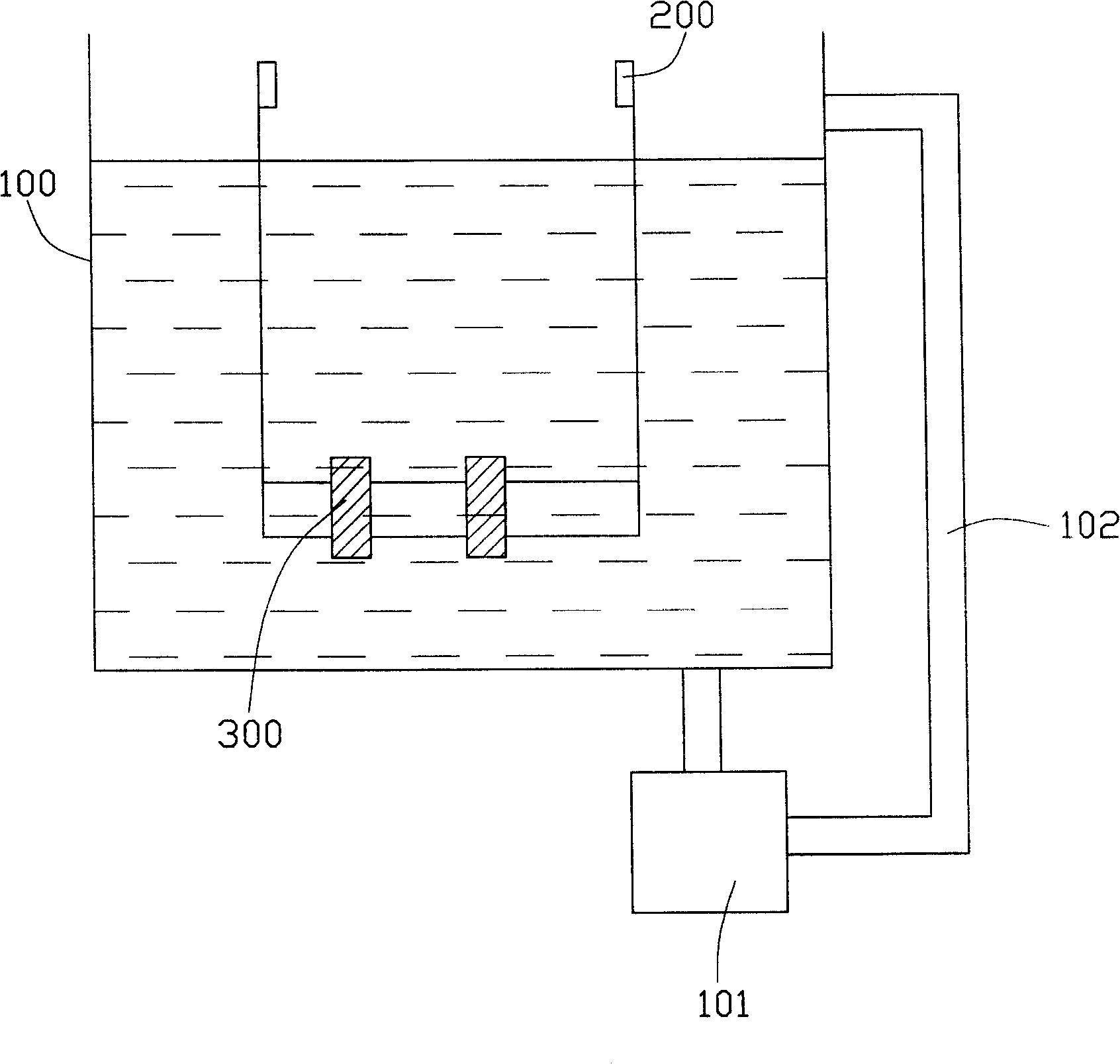

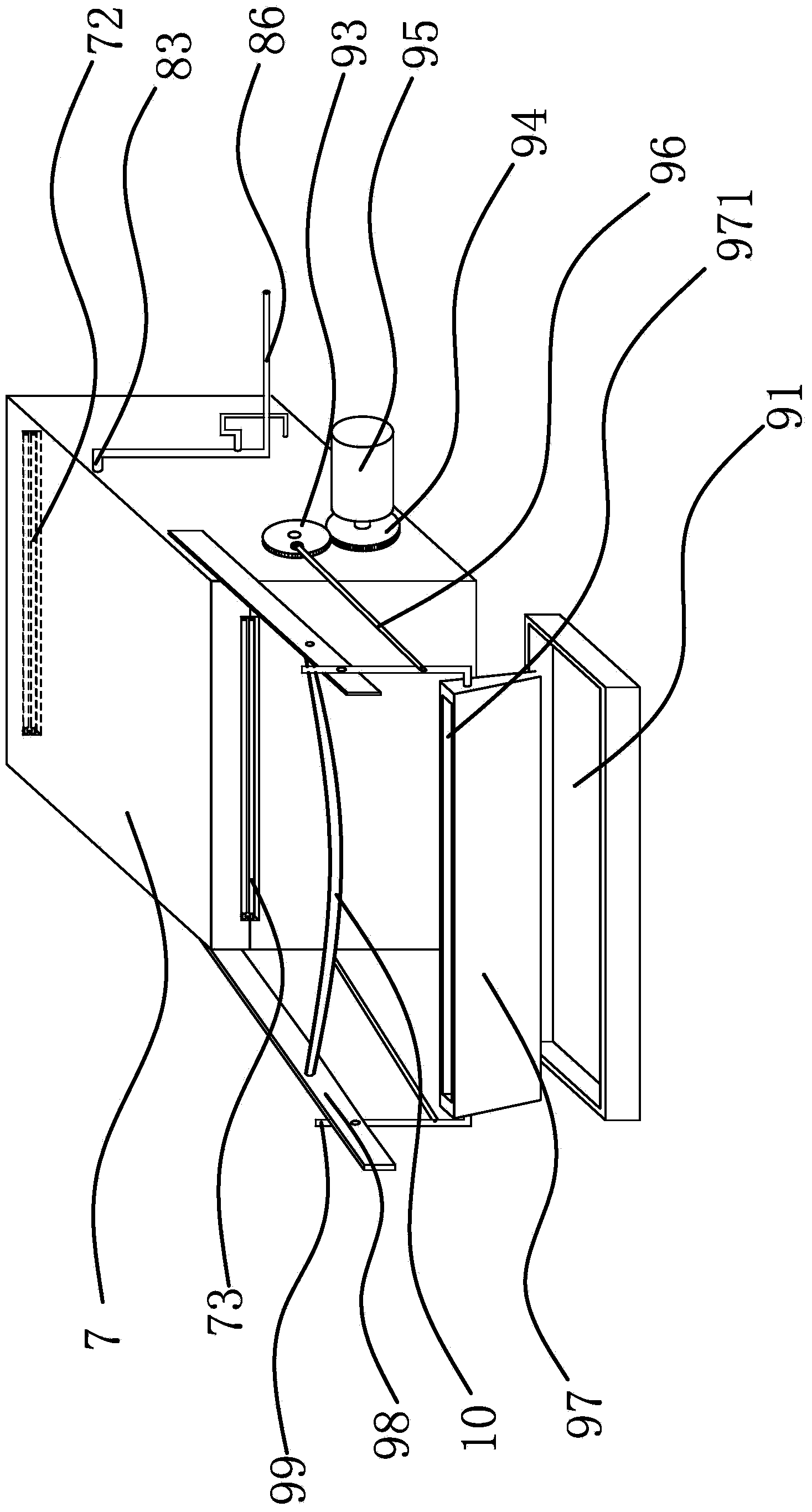

All-in-one machine for shell fabric washing and drying

ActiveCN103409960ASimple structureWash and rinse thoroughlyTextile treatment machine partsDrive motorWater washing

The invention provides an all-in-one machine for shell fabric washing and drying, and belongs to the technical field of machines. The all-in-one machine solves the technical problems that shell fabric is incapable of being washed, dried and collected at one time after being woven. The all-in-one machine for shell fabric washing and drying comprises a base, wherein the base is provided with a washing box; the box body of the washing box is partitioned into a washing tank and a bleaching tank through a partition board in the middle part of the washing box; two ends of the washing box are respectively provided with a shell fabric inlet I and a shell fabric outlet II; the inner wall of the washing box is provided with a washing roller I and a washing roller II which are parallel to each other; the washing roller I and the washing roller II are both positioned in the washing tank; the washing roller I is driven by a driving motor I; the base is further provided with a drying box; a shell fabric collecting device is arranged between the drying box and the base; the base is further provided with a shell fabric collecting box. The all-in-one machine has the advantages that the shell fabric can be washed, dried, collected and the like at one time.

Owner:ZHEJIANG HUAYUAN TEXTILE

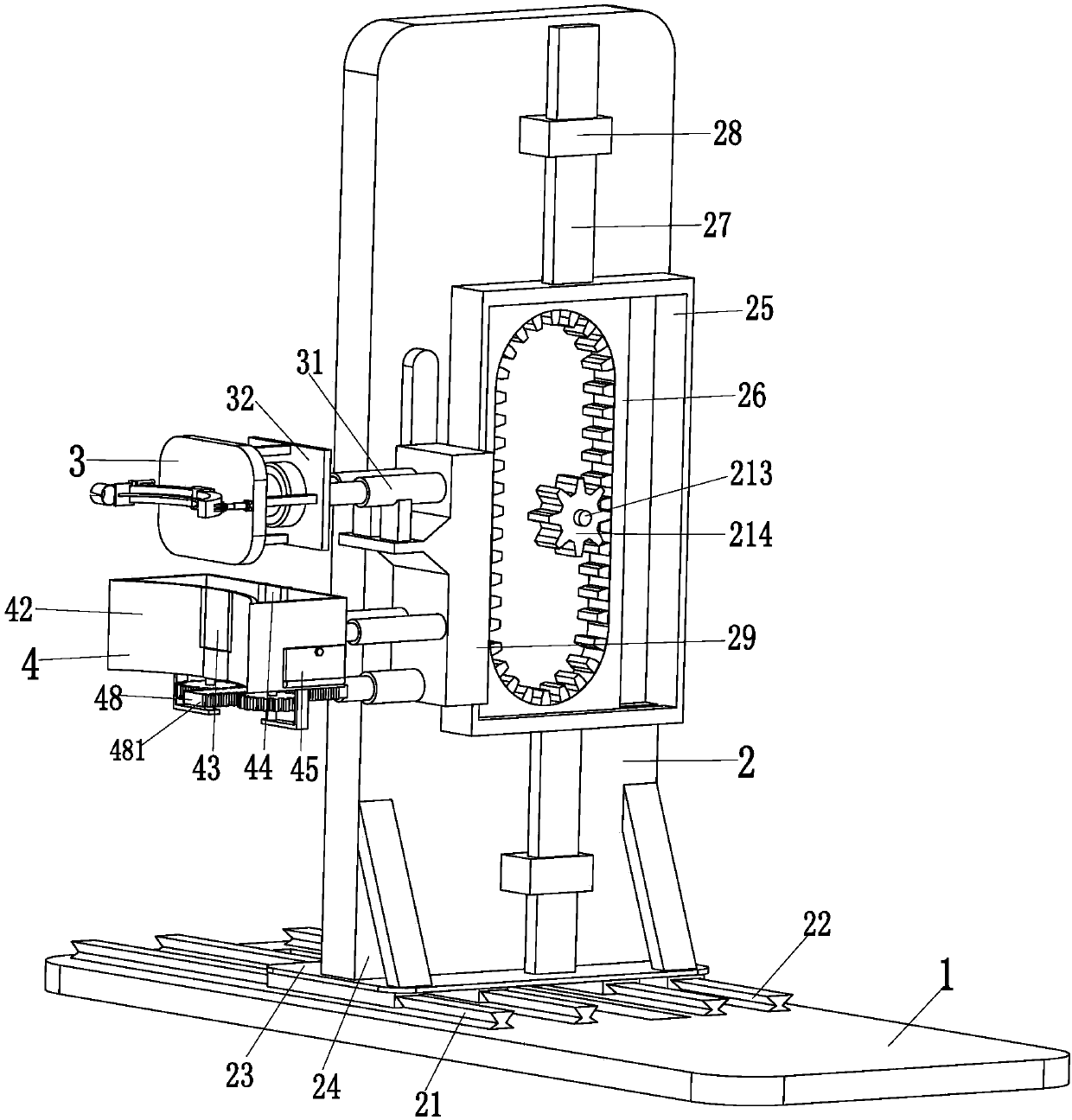

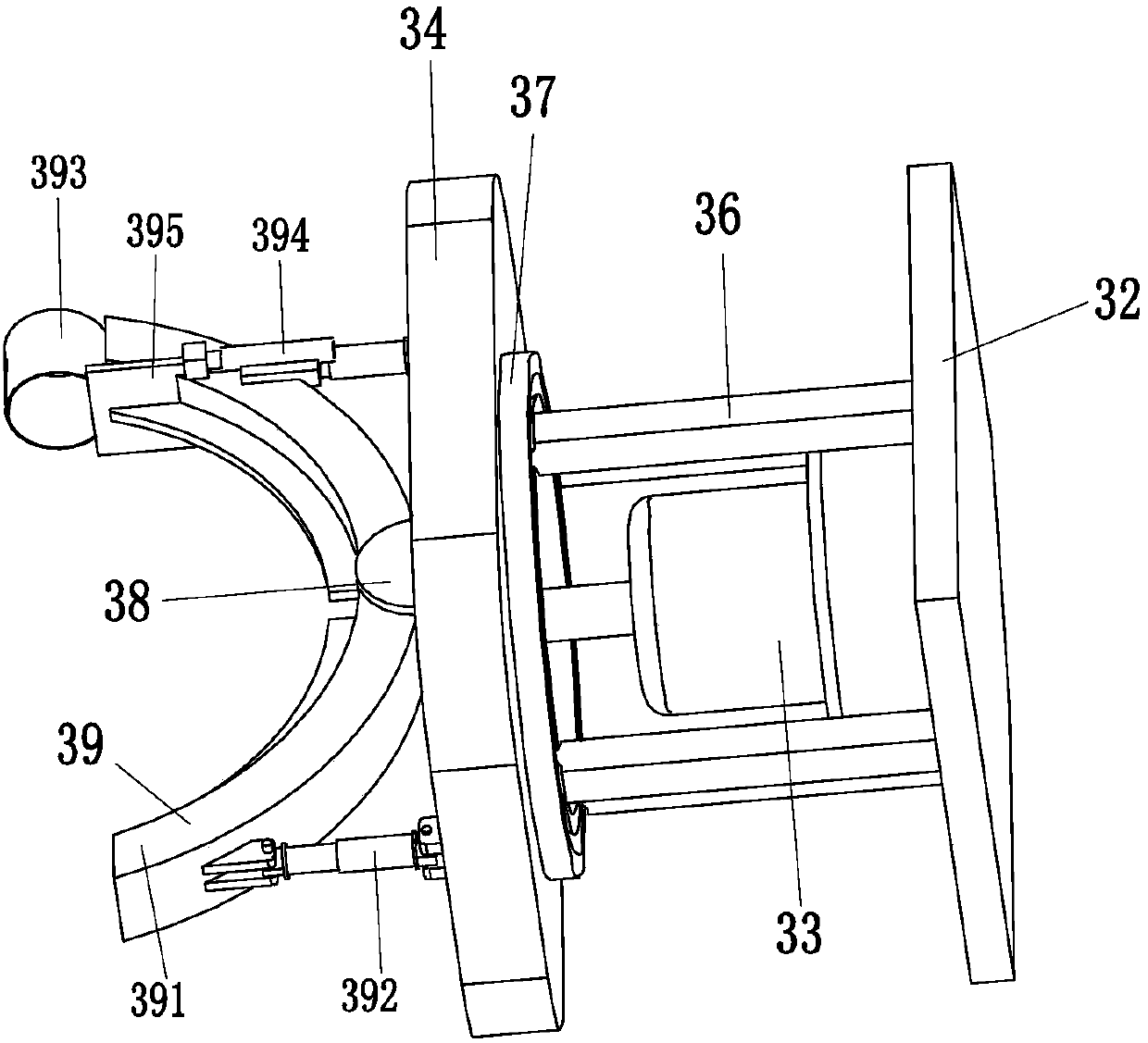

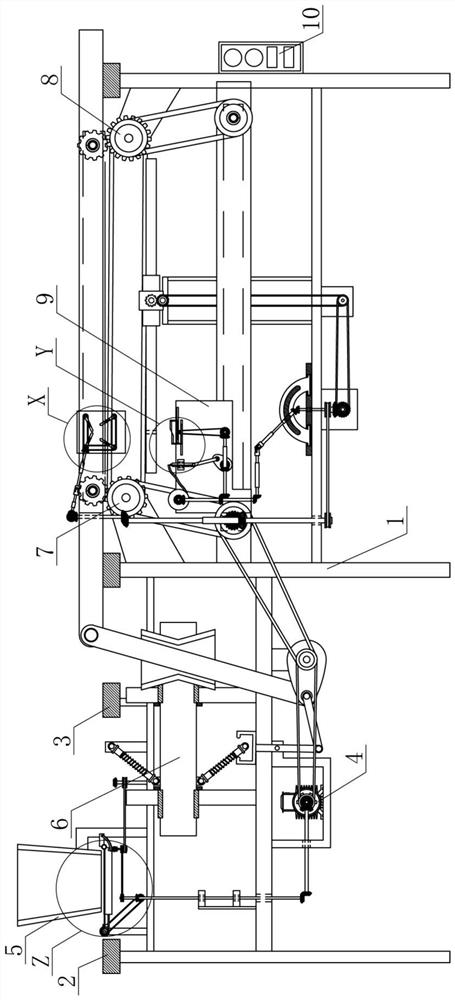

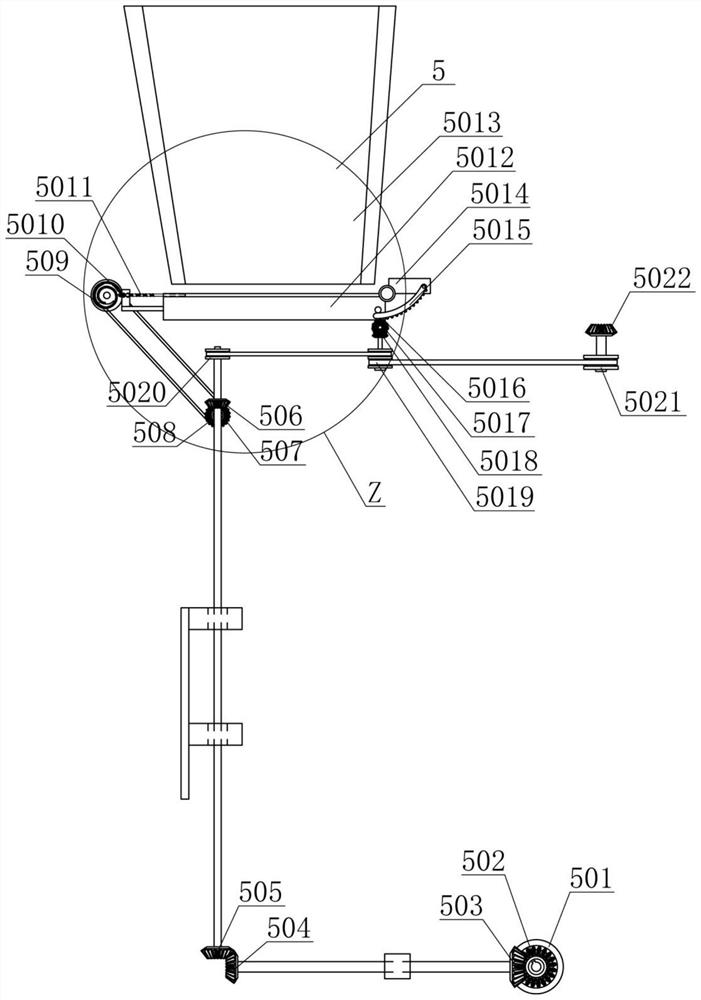

Pine bark treatment machine for acquiring rosin which mainly comprises natural resin and is raw material for preparing latex paint

The invention relates to a pine tree skin treatment machine for the collection of natural resin rosin, which is a raw material for latex paint preparation There are a rotating device and a lifting support device, the scraping device and the recovery device are installed on the rotating device, and the two slotting devices are symmetrically installed on the lifting support device. The invention can solve the problem that the existing manual scraping and grooving of pine trees have poor skin scraping effect and easily scratch the tree, the scraped pine bark cannot be recycled, two kinds of tools are required for scraping and straight grooving, and the inclined It is impossible to control the groove depth and other problems when grooving; it can automatically scrape the bark of pine trees, and automatically open straight grooves and oblique grooves for pine trees. Recycling, skin scraping and straight grooving require advantages such as a tool.

Owner:宋当建

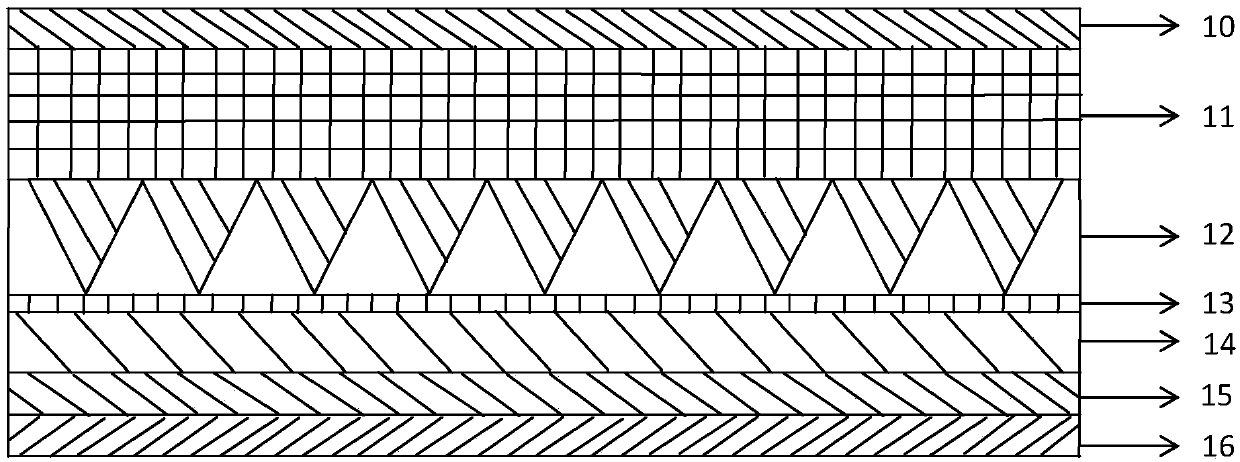

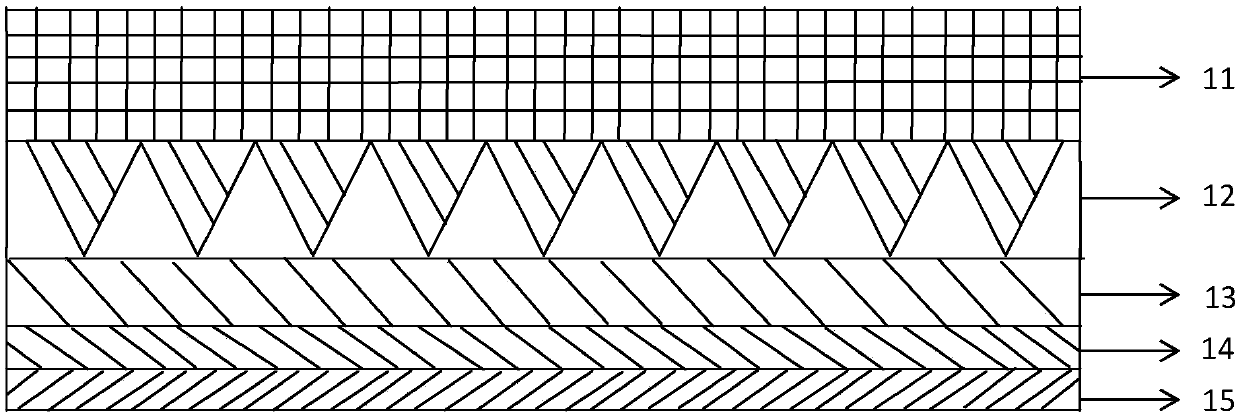

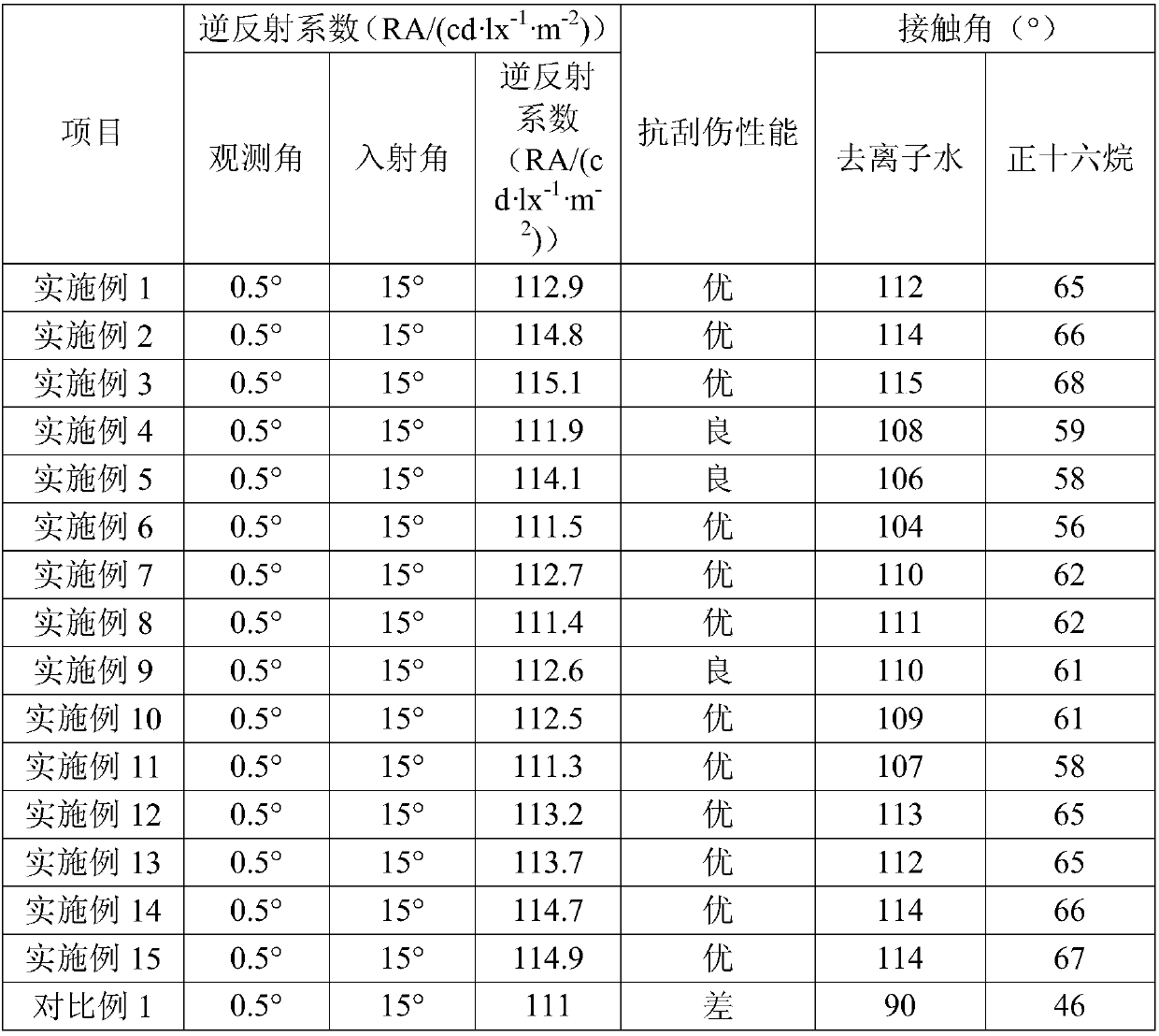

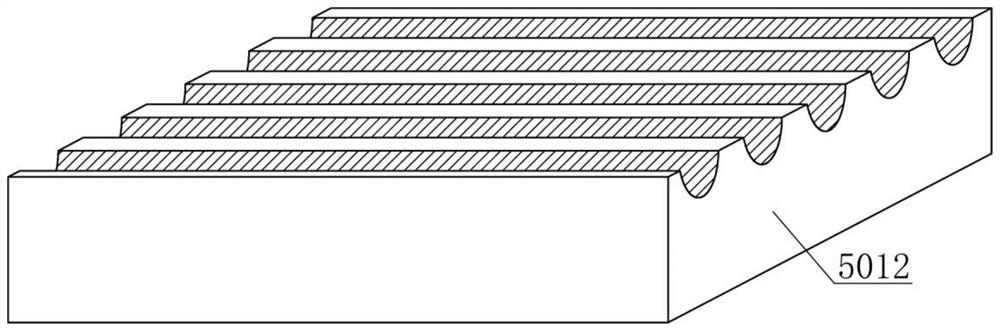

Micro prism reflective film

ActiveCN107817543AHigh reflective brightnessSolve the problem of not being able to achieve high reflectivityPrismsPrismOptoelectronics

The invention relates to the field of optical technologies, and in particular relates to a micro prism reflective film. In order to solve the problems of low reflection brightness and scratch of the existing reflective film in an external environment, the invention provides the micro prism reflective film. The micro prism reflective film comprises an anti-fouling anti-scratch coating, a substratelayer, a micro prism structure layer, a metal reflective layer and a sealing layer in order. The micro prism reflective film provided by the invention has the advantages of high reflection brightnessand scratch prevention in practical application in the external environment, and solves the problem that a micro prism reflective film provided with a traditional sealing layer cannot realize high reflectance.

Owner:NINGBO EXCITON TECH

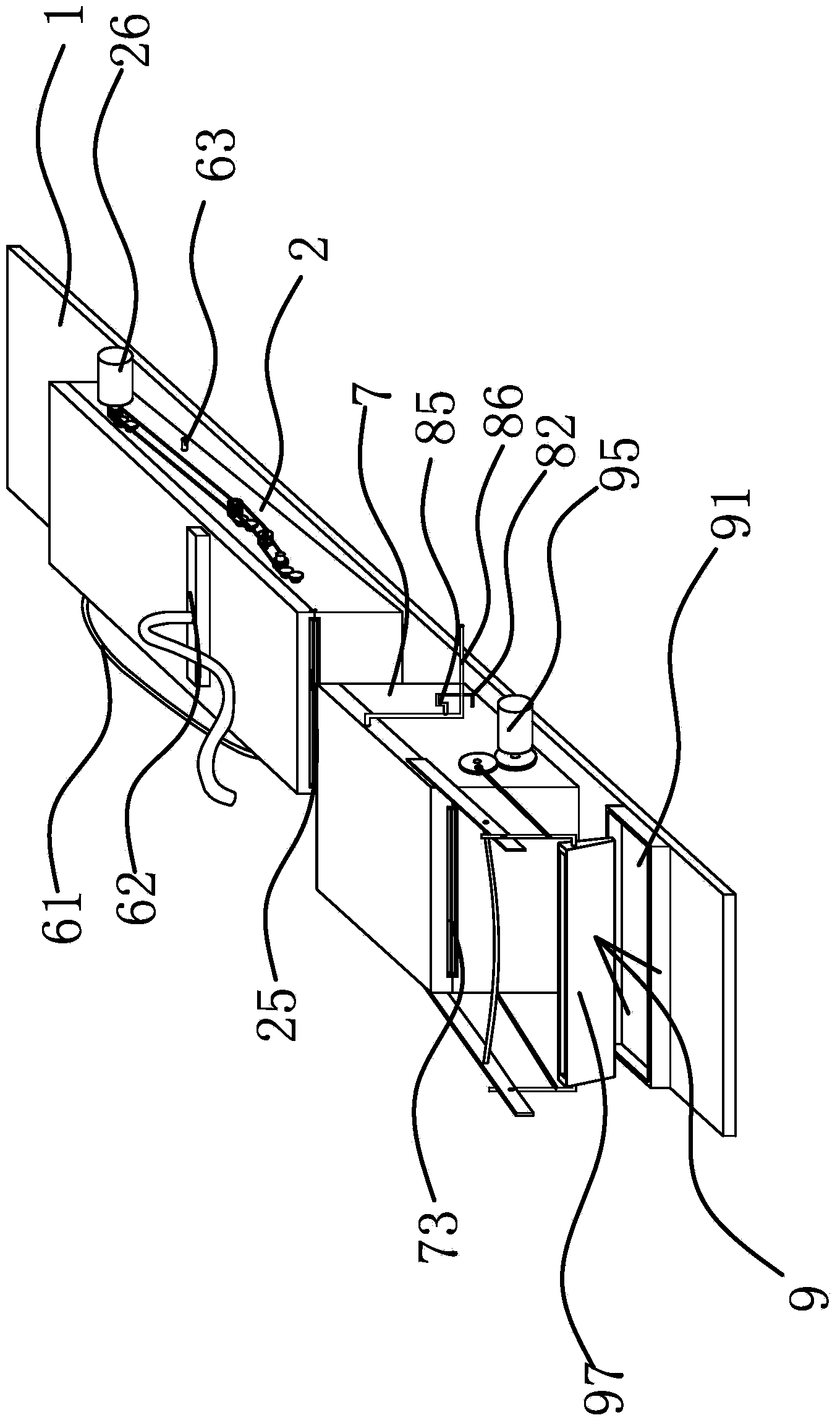

Fabric washing and drying integrated machine with fabric collection device

ActiveCN104480656ASolve cleaning difficultiesSimple structureLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringDrive motor

The invention provides a fabric washing and drying integrated machine with a fabric collection device and belongs to the technical field of machinery. By means of the machine, the technical problems that fabrics cannot be washed, dried, collected and the like through one step after being woven are solved. The machine comprises a base, a washing case is arranged on the base, and a case body of the washing case is partitioned into a washing tank and a rinsing tank through a partition plate. A first fabric inlet and a second fabric inlet are formed in the two ends of the washing case respectively. A first washing roller and a second washing roller which are parallel are arranged on the inner wall of the washing case and are both disposed in the washing tank. The first washing roller is driven by a first drive motor, a drying case is further arranged on the base, a fabric collecting unit is arranged between the drying case and the base, and a fabric collecting box is further arranged on the base. The machine has the advantage of being capable of completing washing, drying, collecting and the like of fabrics.

Owner:四川九五一七实业有限公司

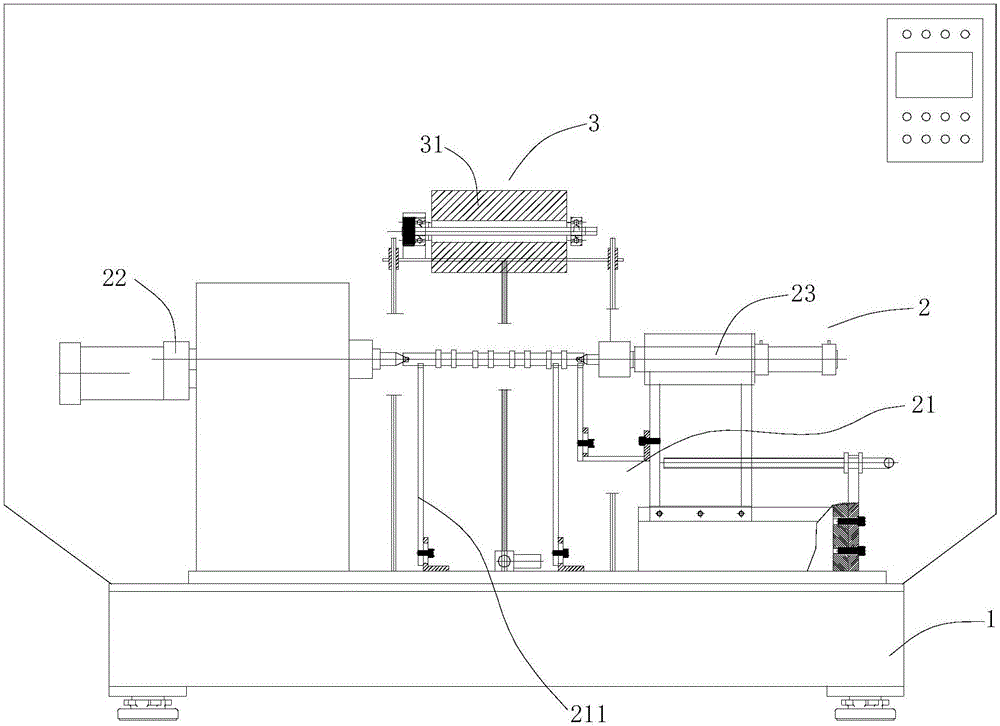

Automatic deburring machine for engine camshaft

InactiveCN106736963AGood removal effectHigh densityEdge grinding machinesGrinding drivesDrive motorEngineering

The invention discloses an automatic deburring machine for an engine camshaft. The automatic deburring machine comprises a base, wherein a camshaft clamping mechanism and a deburring mechanism are arranged on the base; the camshaft clamping mechanism comprises a frame body, as well as rotary driving devices and tailstock jacking devices, which are arranged on the frame body; jack rods of the tailstock jacking devices and rotary output shafts of the rotary driving devices are oppositely and coaxially arranged; the deburring mechanism comprises an abrasive wire brush roller and a driving motor used for driving the abrasive wire brush roller to rotate; and the abrasive wire brush roller is parallel to the jack rods of the tailstock jacking devices and the rotary output shafts of the rotary driving devices. The automatic deburring machine for the engine camshaft has the advantages that the occupation is small, the deburring effect is good, the production efficiency is high, and batch production can be easily realized.

Owner:魏显懿

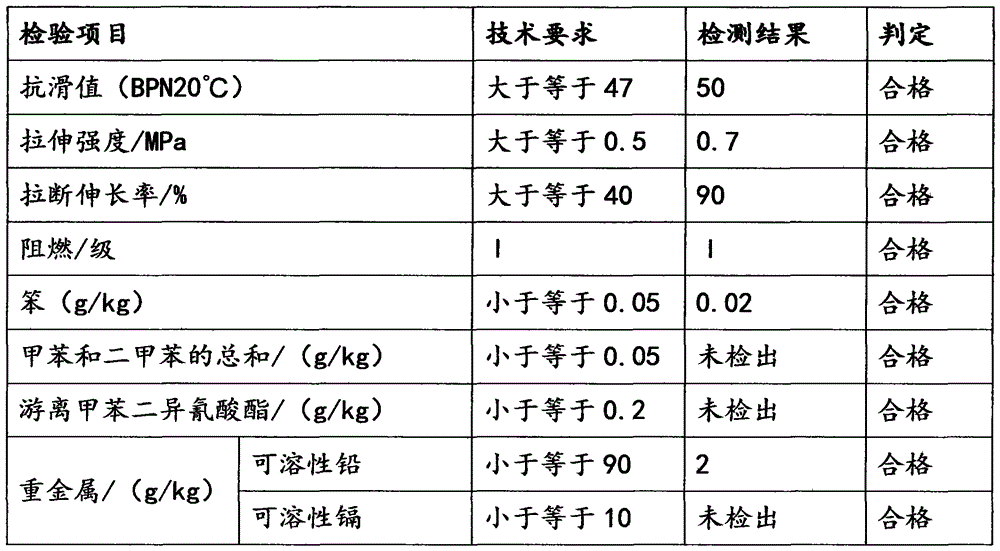

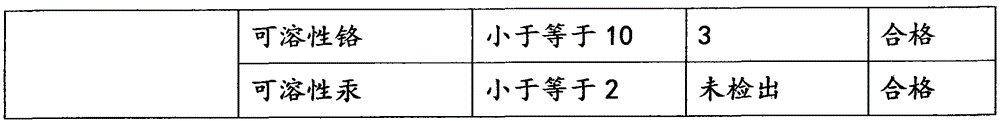

Silicon pu type plastic court

ActiveCN104846717BProtect the jointsReduce the risk of injuryGround pavingsPolyurea/polyurethane coatingsEngineeringBall tennis

The invention relates to a synthetic court, and in particular relates to a silicon PU type synthetic court which is suitable for various competition places, is high in elasticity, has anti-abrasion and anti-skid and anti-aging effects, is integrally molded, is uniform in surface layer thickness and is colorful and is used for solving the technical problems in the prior art. The silicon PU type synthetic court comprises a basic layer, a waterproof layer, a silicon PU elastic layer and a cover finishing coat protection layer, wherein the silicon PU elastic layer consists of a leveling layer and a reinforcement layer. The silicon PU type synthetic court can be widely applied to basketball, tennis ball and badminton ball places with various fundamental planes, various indoor and outdoor leisure areas, gymnasiums, gymnasium activity places and the like.

Owner:GUANGZHOU SHENGBANG SPORTS GROUND MATERIAL CO LTD

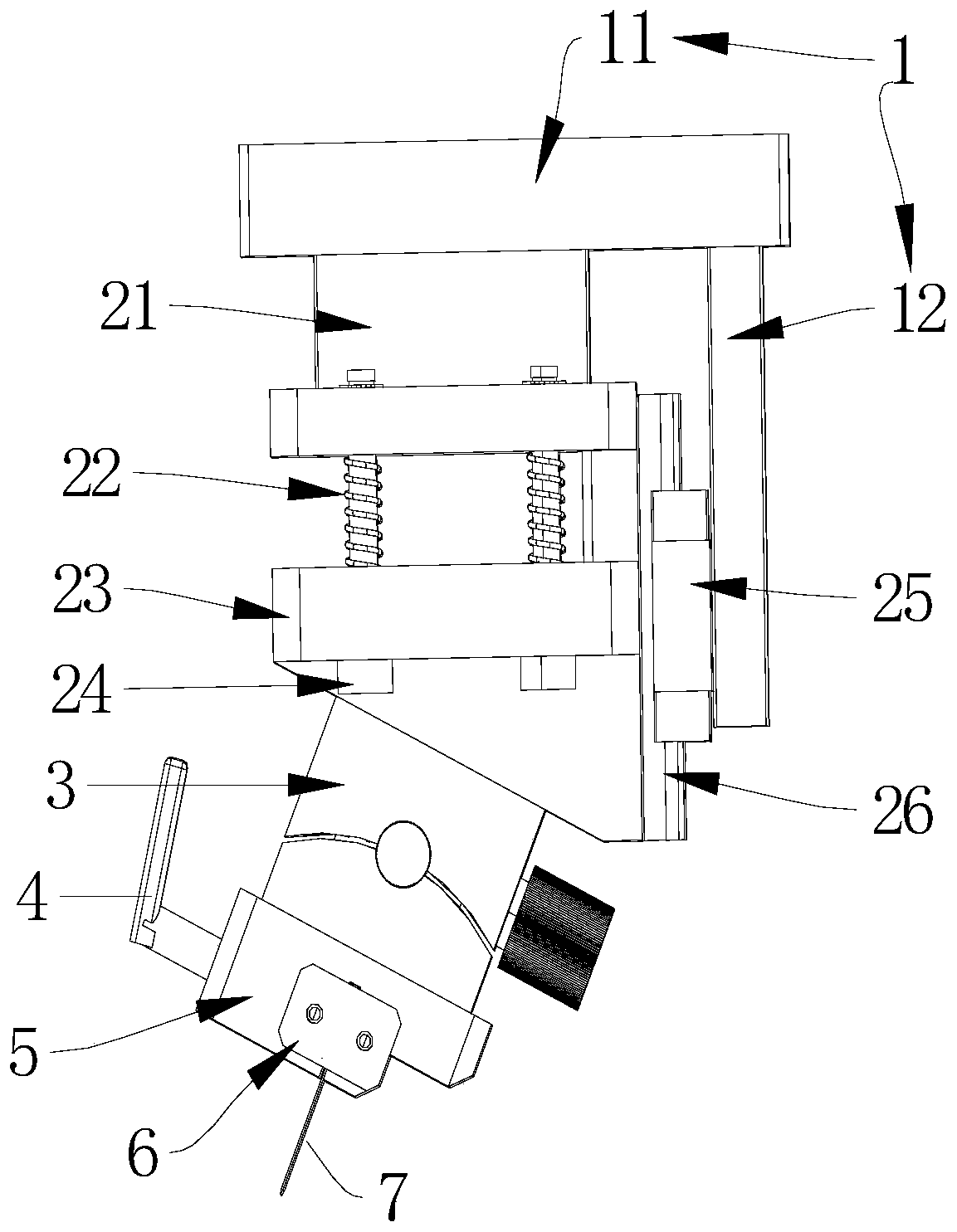

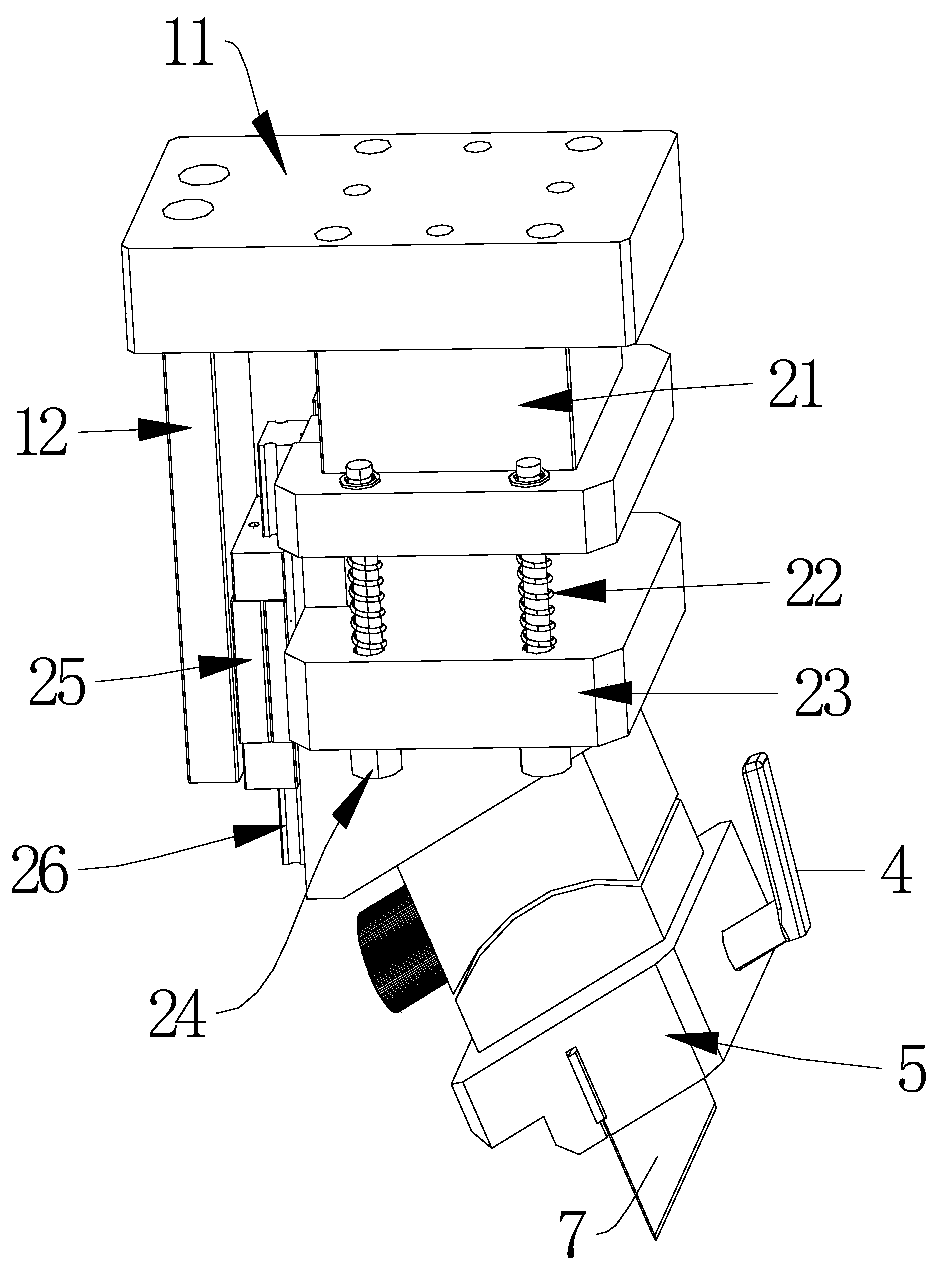

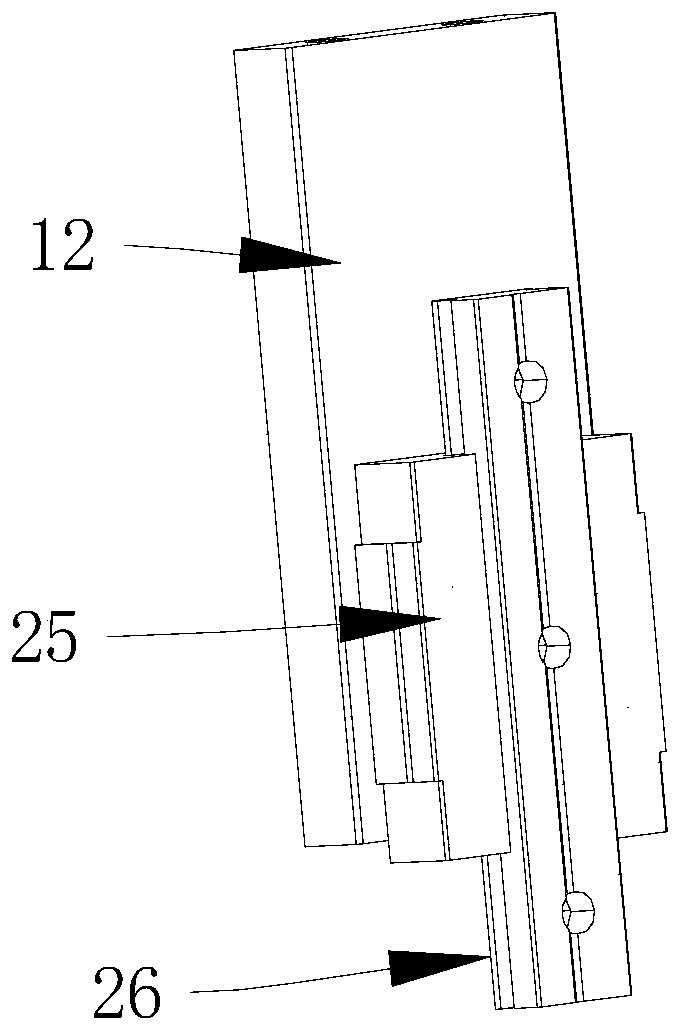

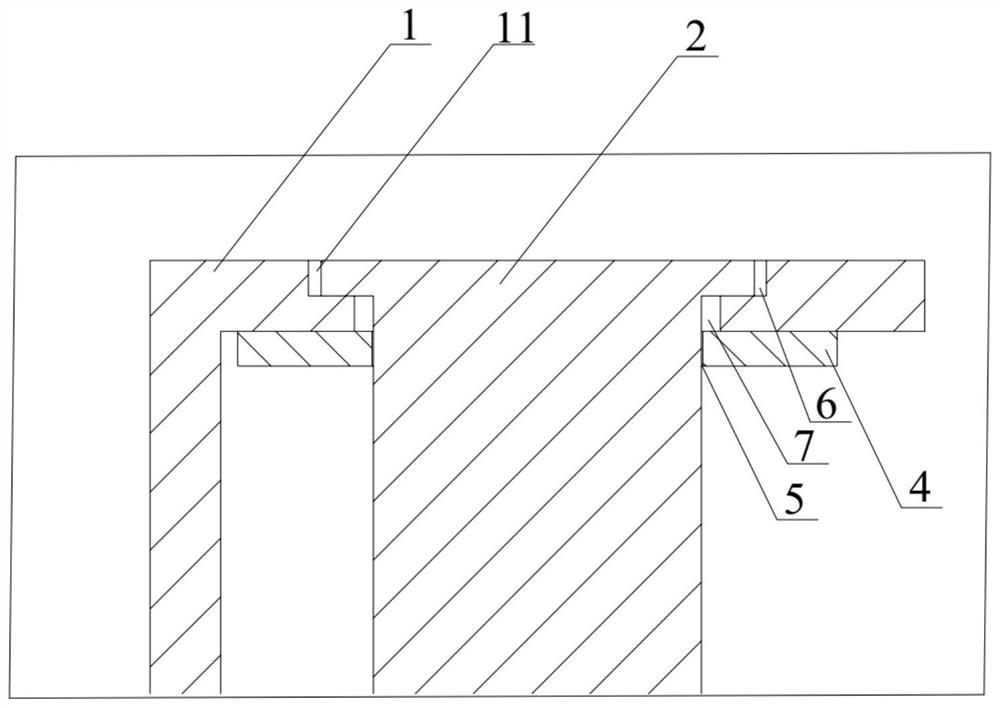

Mold pressing and edge sealing device and edge sealing method thereof

ActiveCN109955575AReduce usageAvoid scratchesLamination ancillary operationsLaminationAdhesiveSpecial design

The invention discloses a mold pressing and edge sealing device and an edge sealing method thereof. Through a special design of a three-layer mold, a front face fabric is bonded with a main body of abase plate through polypropylene (PP), and adhesives such as glue and the like are not needed. The use of adhesives such as glue and the like is reduced as much as possible, so that an excellent volatile organic compound (VOC) level of smell is guaranteed; meanwhile, edges of a product is not exposed, the edges of the product is well protected by the front face fabric, and a user and a target piece are prevented from being scratched. The mold pressing and edge sealing device is particularly suitable for mould pressing and edge sealing of a fiber reinforced honeycomb trunk board. The device hasa good appearance, is simple in process, is simple and convenient, and has a high automation degree. The edges covered by the soft fabric do not have sharp parts or residual fibers, so that safety isensured when the user holds the end part, and the user is prevented from being scratched during assembly. Odor is prevented, glue is not needed, edge sealing is convenient, the effect is good, the edges are safe and smooth, objects cannot be scratched, operation is simple, and production efficiency can be improved.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

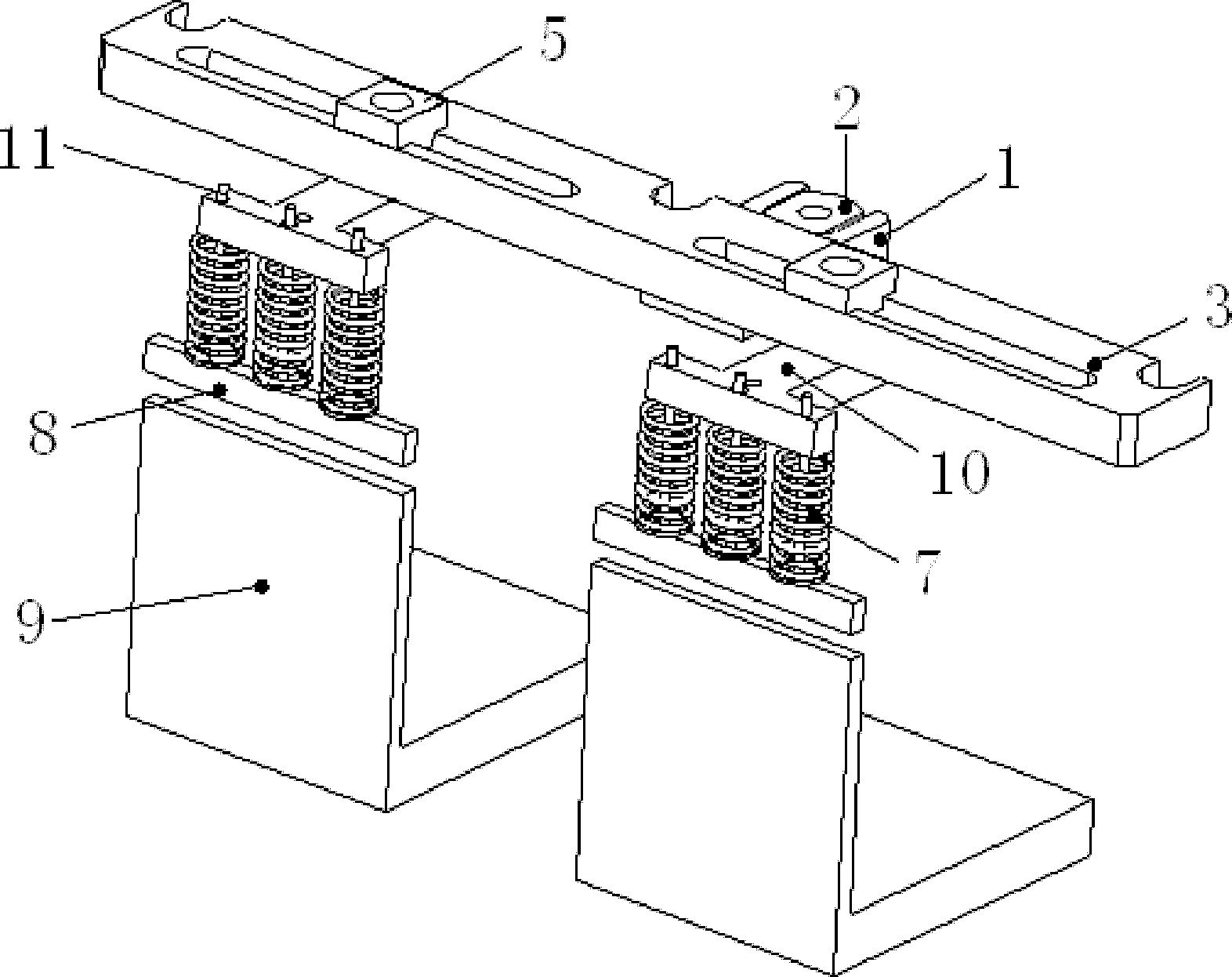

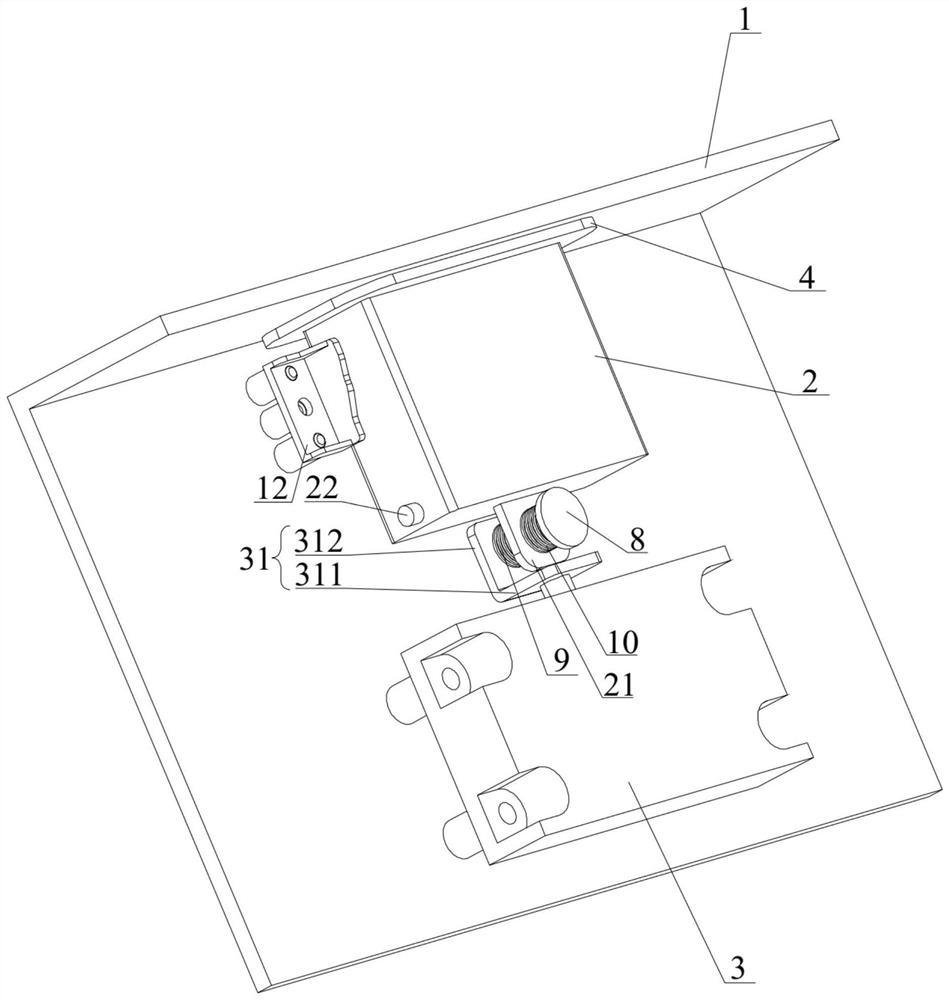

Positioning system for laser printer

ActiveCN102514403AAvoid partial printing, frequent alarms, affecting production efficiency and other issuesImprove general performanceOther printing apparatusEngineeringBlock match

The invention relates to a printer, in particular to a positioning system for a laser printer, which comprises a positioning plate, a cylinder clamp and a positioning device, wherein the cylinder clamp is arranged on the positioning plate and connected with the printer through a cylinder clamp connector, and the positioning device is arranged below the positioning plate. The positioning device comprises an upper pressing block component and a lower pressing block, the upper pressing block component is slidably connected with the positioning plate, and the lower pressing block matched with the upper pressing block component is fixed below the upper pressing block component. The positioning system for the laser printer has the advantages of accuracy in positioning, difficulty in damaging positioned products, high universality, high compatibility and low cost.

Owner:NANTONG FUJITSU MICROELECTRONICS

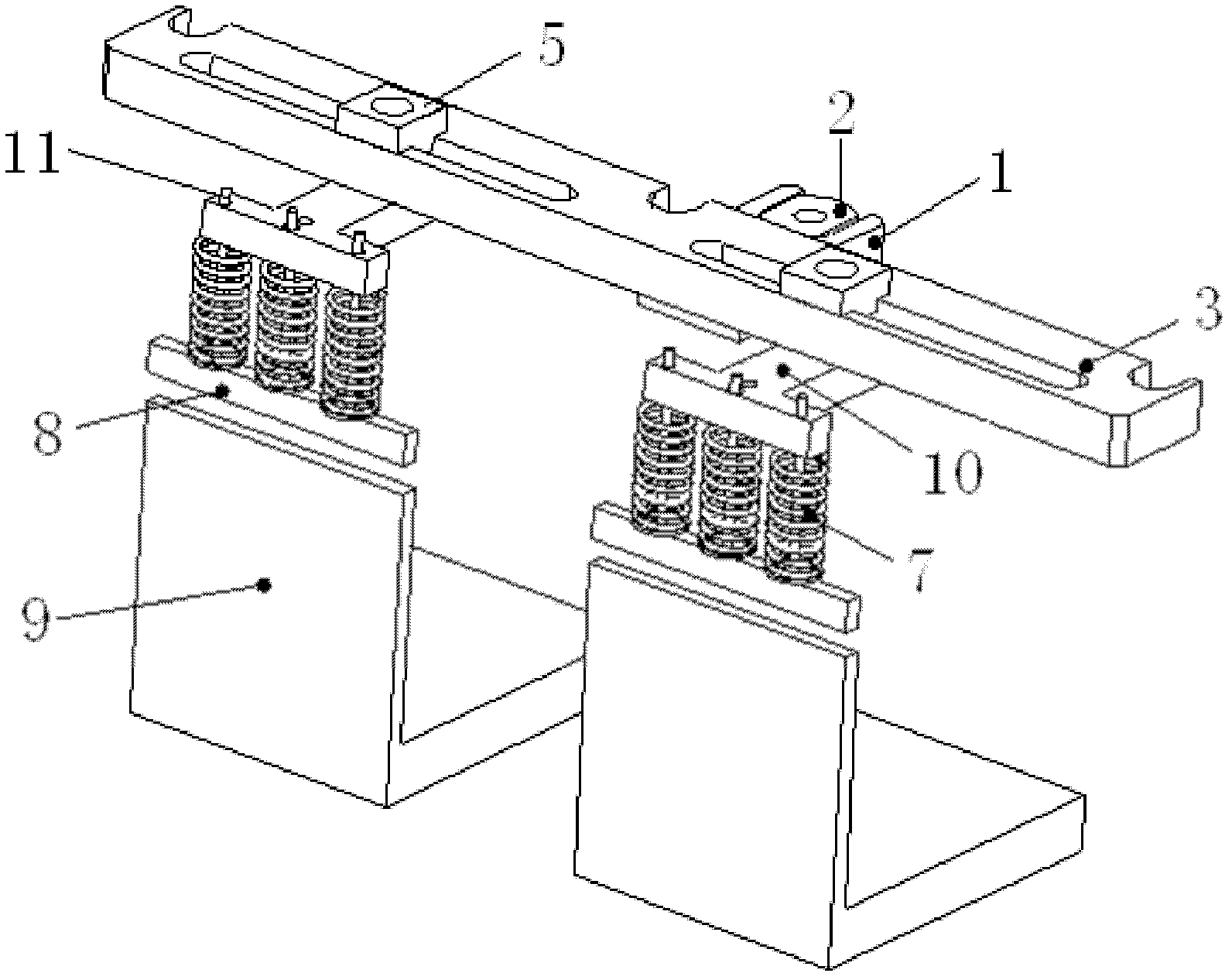

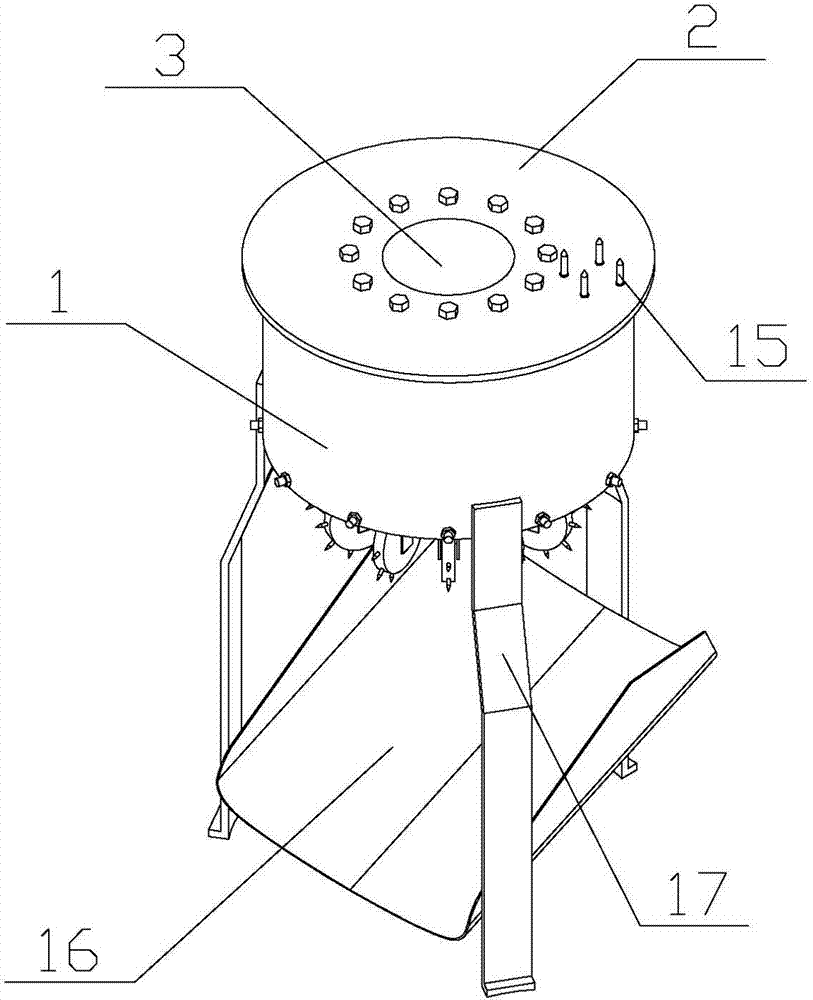

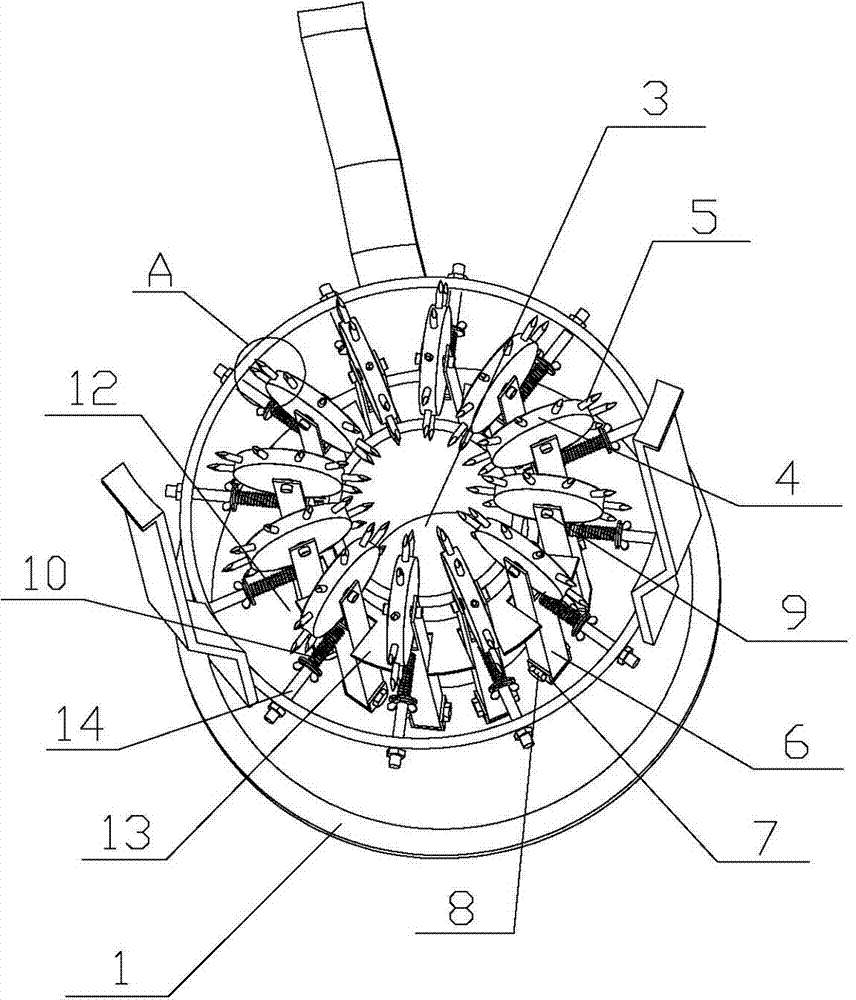

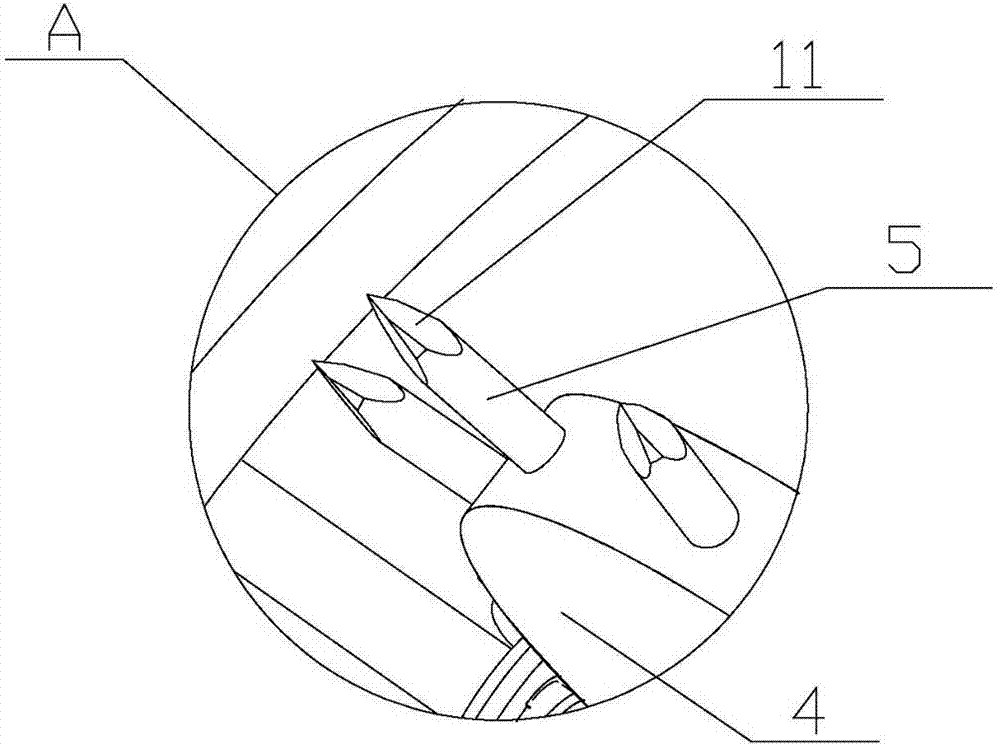

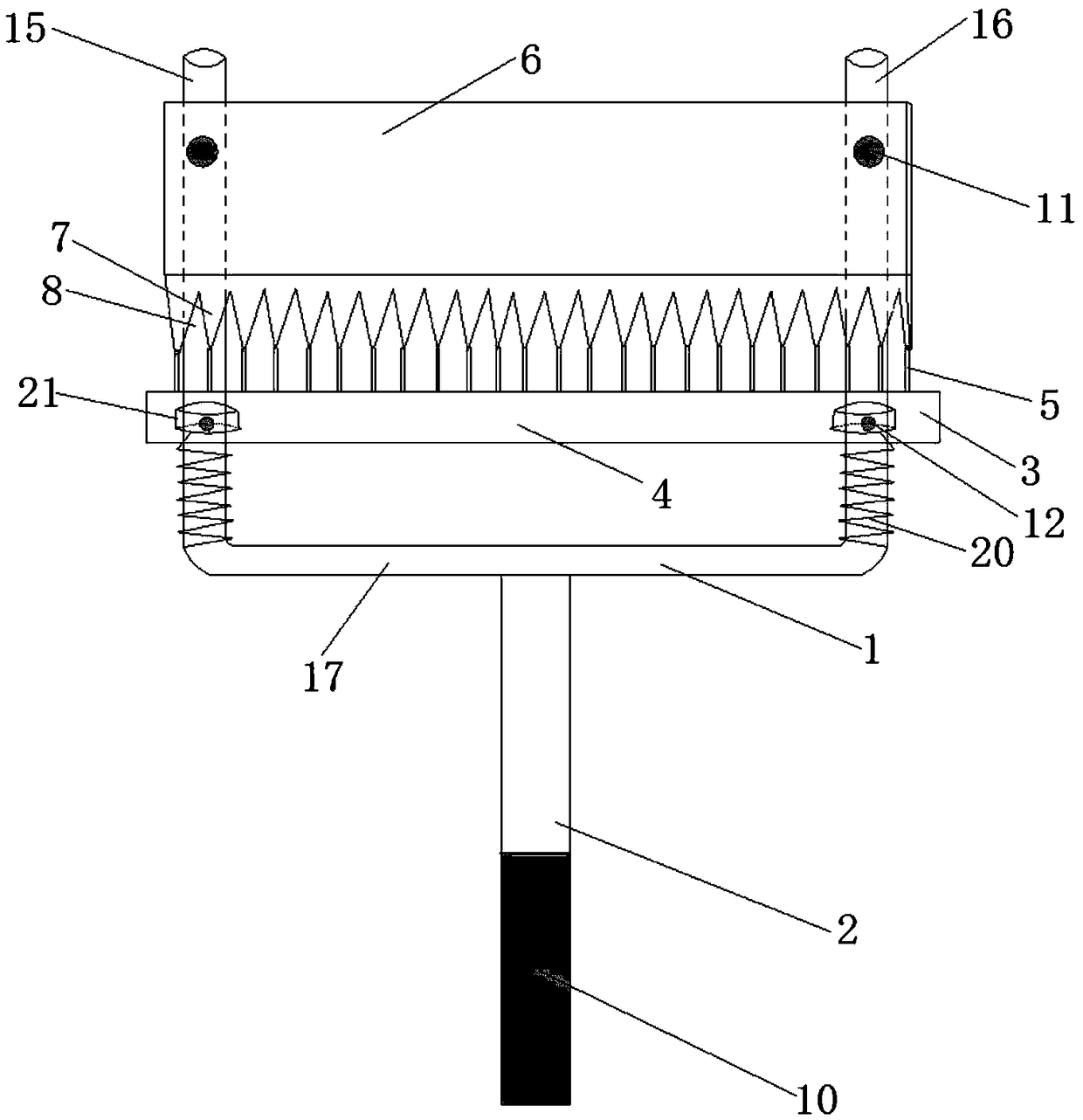

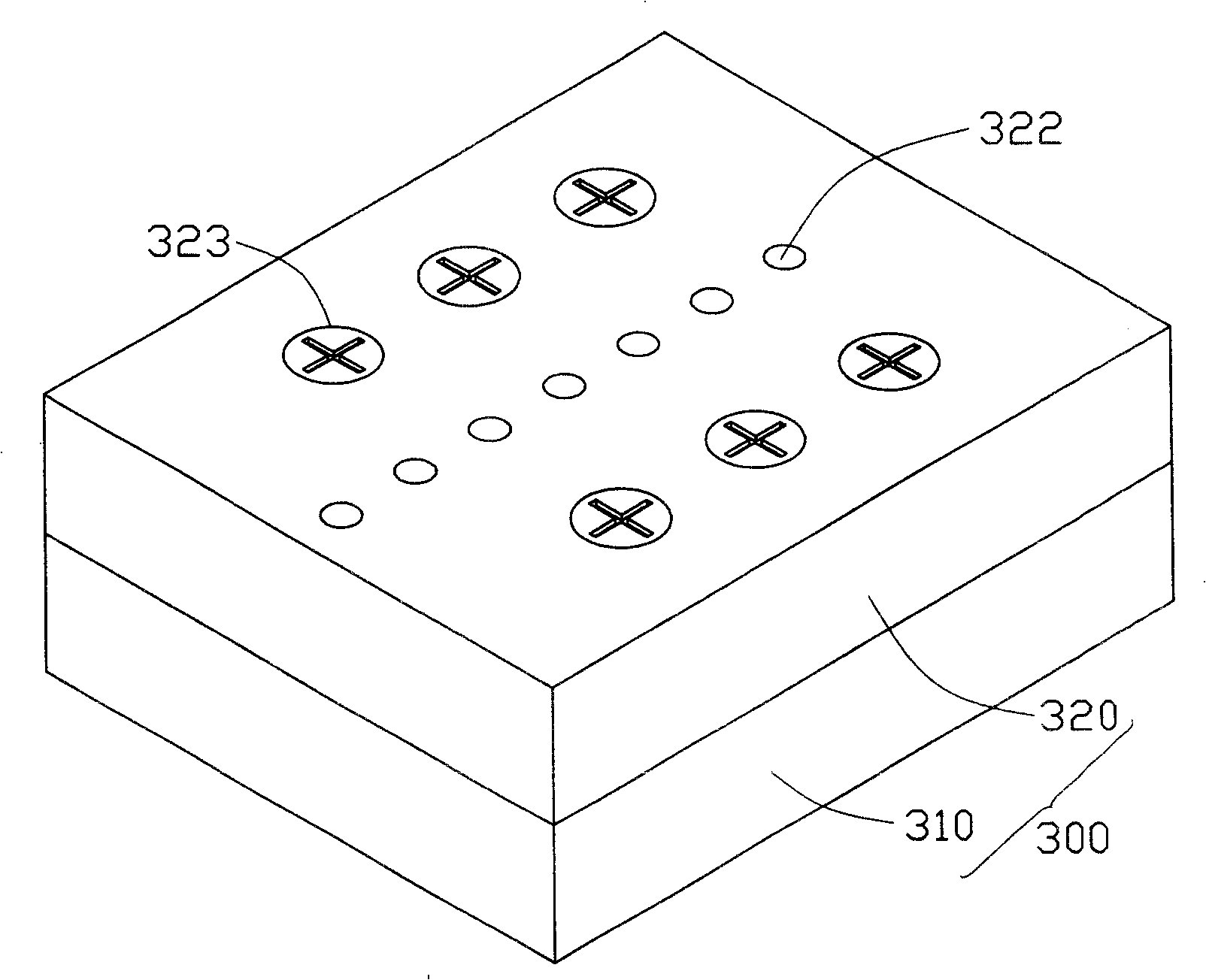

Bacteria stick quick perforating machine

A bacteria stick quick perforating machine comprises a machine frame, wherein a circular table is arranged on the machine frame, a bacteria stick channel is formed in the circular table, piercing blocks are arranged at an outlet of the bacteria stick channel, stings are arranged on the piercing blocks, a support is arranged on the bottom face of the circular table, and the support is connected with the circular table through springs. The bacteria stick quick perforating machine has the advantages that the structure is reasonable, using is convenient, installing and maintaining are convenient, automation of bacteria stick perforating is achieved, work efficiency is improved, labor intensity of workers for perforating operation is lowered, production cost is lowered, perforated bacteria stick holes can be evenly distributed, mycelia in bacteria sticks can normally grow, yield of mushrooms can be improved, income of bacteria growers can be improved, accidental injuries of workers can not occur in the automatic bacteria stick perforating process, personal safety of the workers is protected, the using effect is good, and popularization is facilitated.

Owner:李明

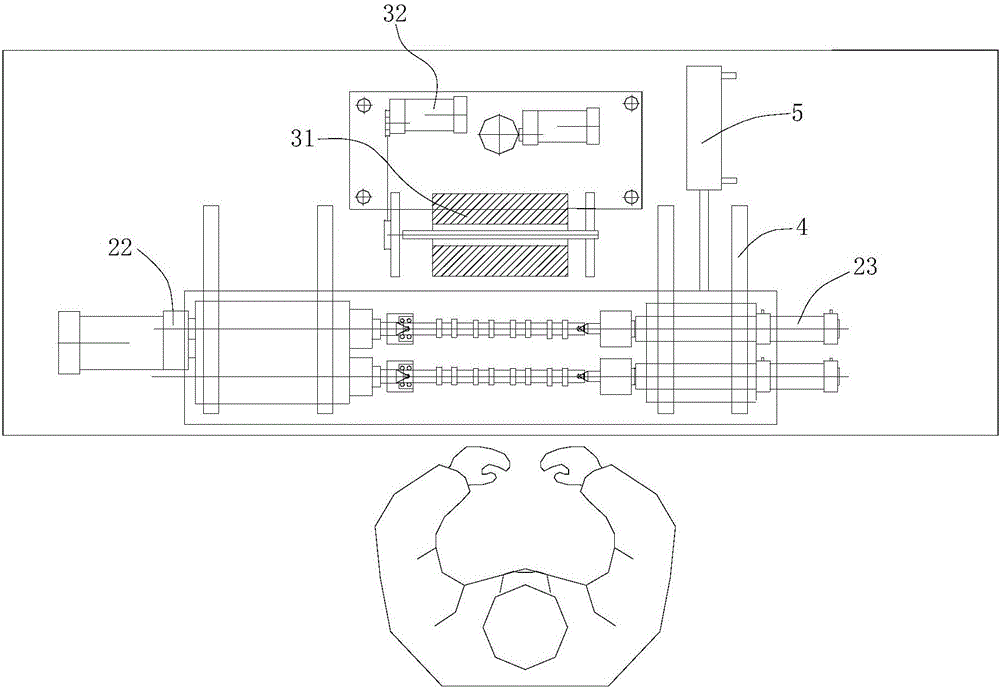

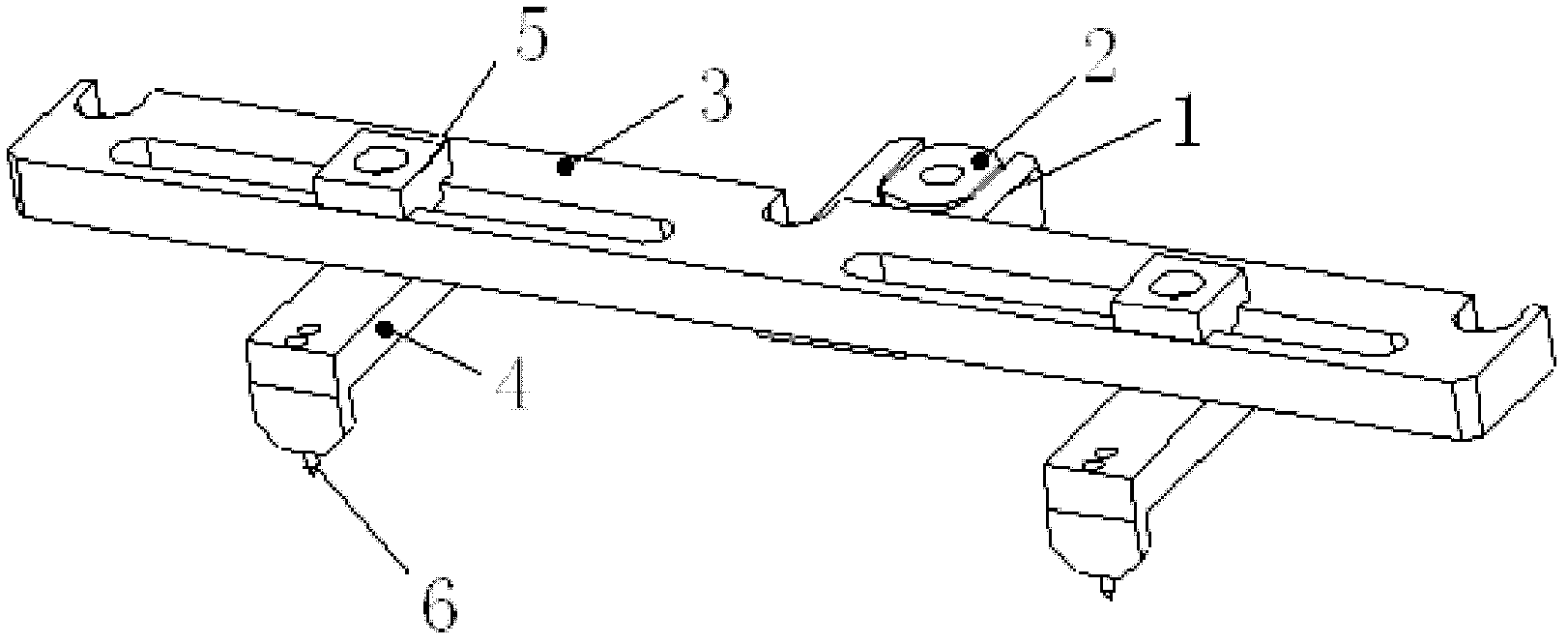

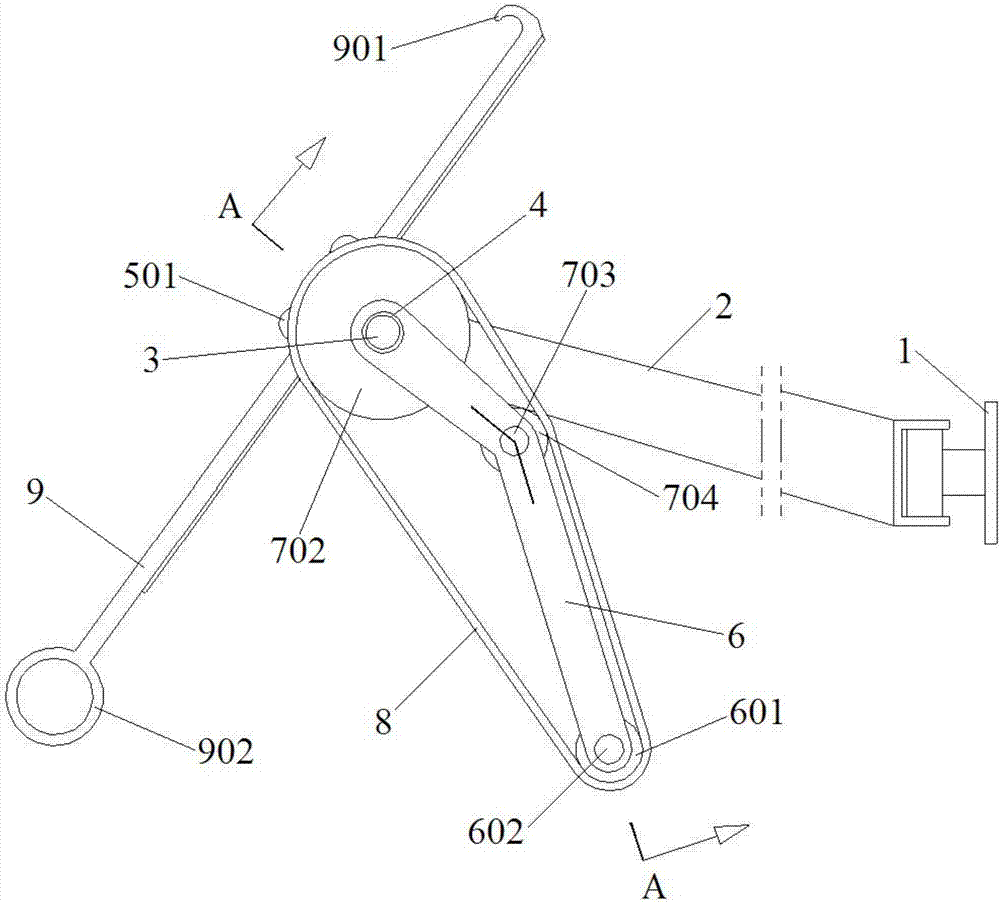

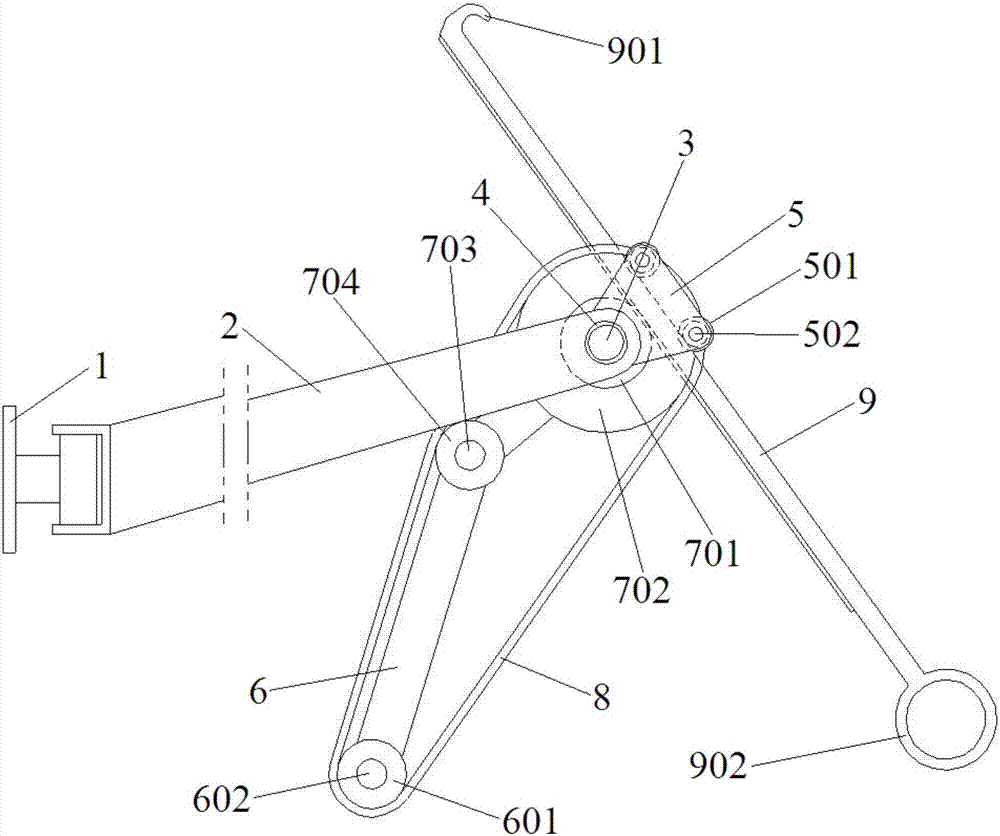

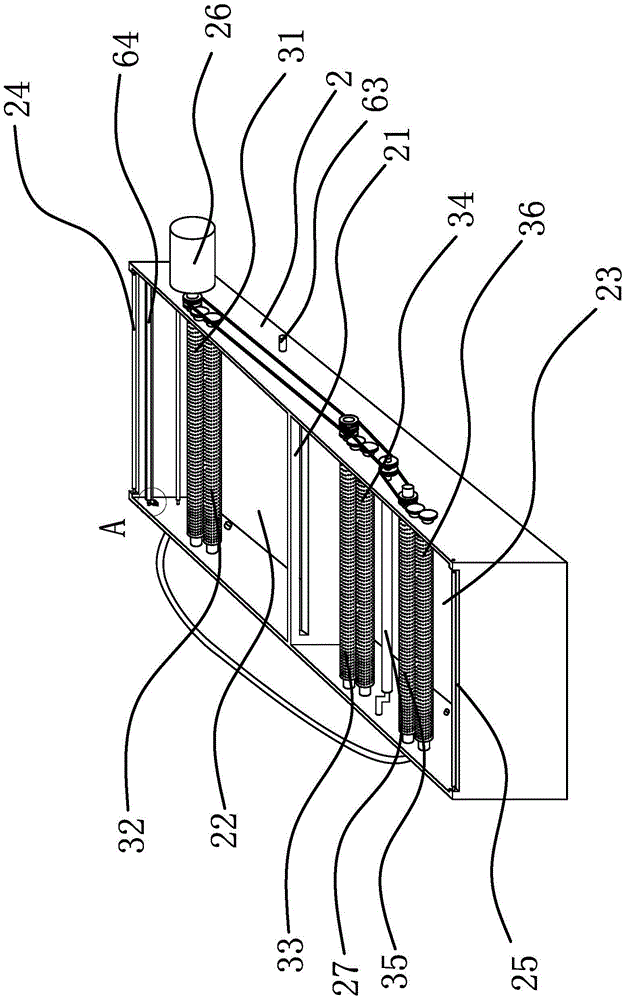

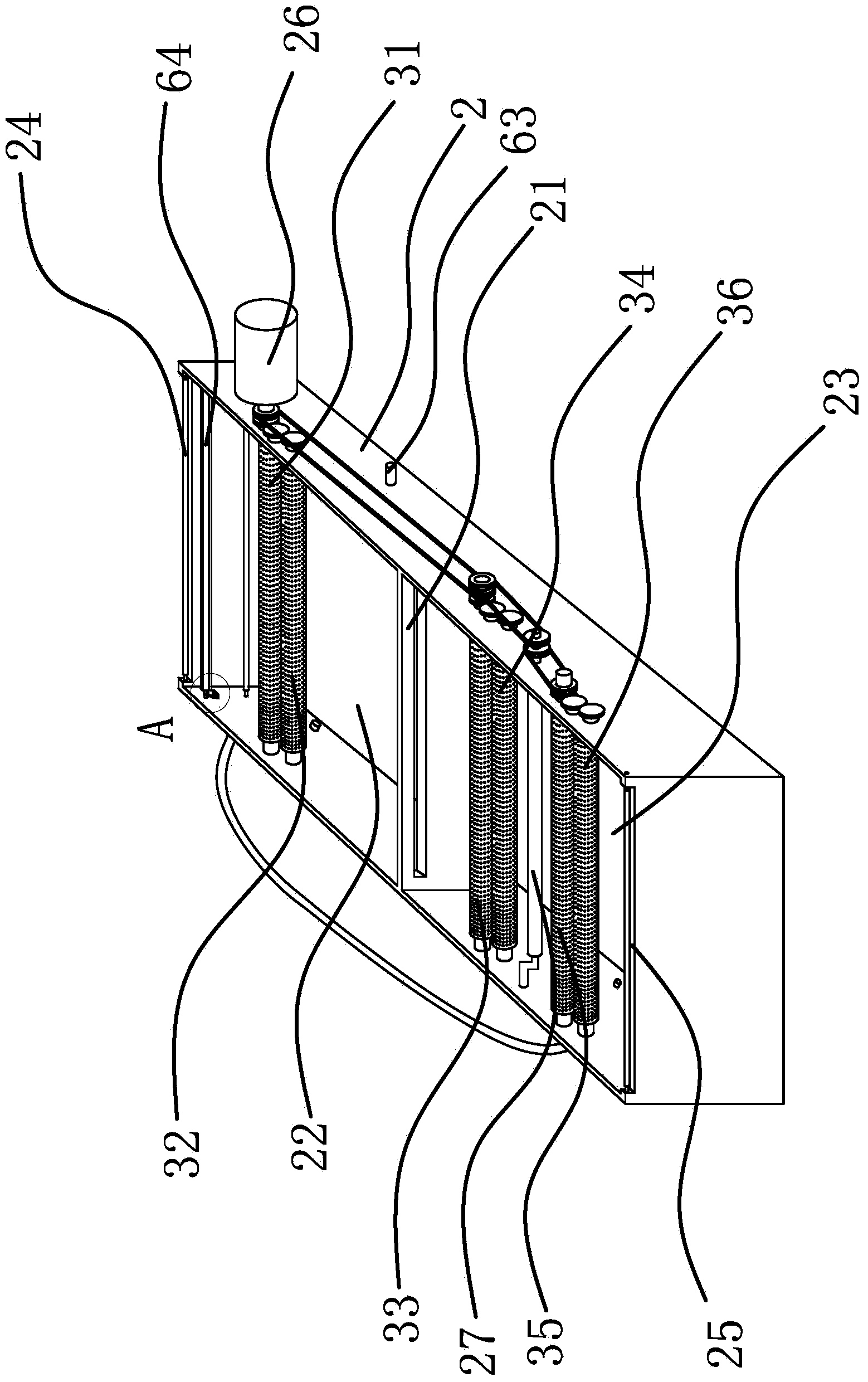

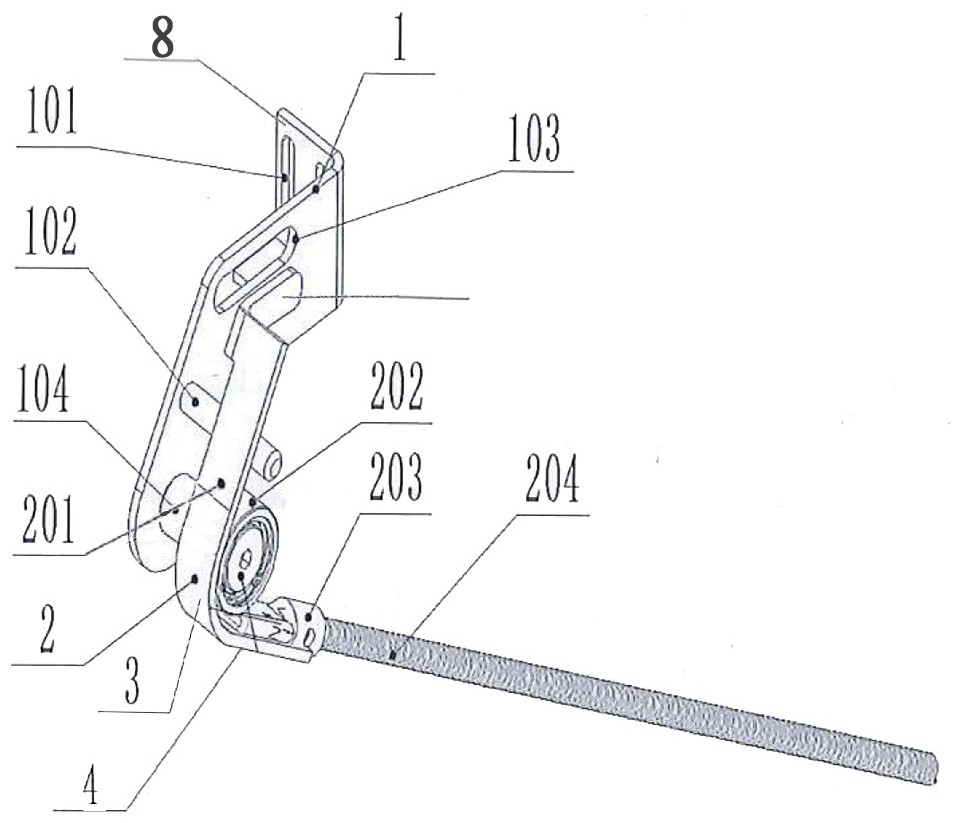

Shaving injury preventing shaving device for automobile tire and method thereof

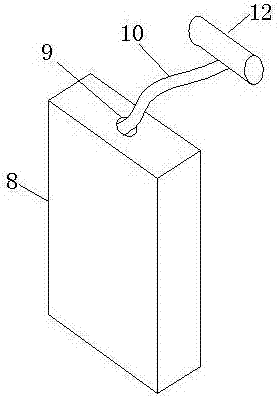

PendingCN109500839AAvoid scratchesScratch will notTyresMetal working apparatusEngineeringScrew thread

The invention discloses a shaving injury preventing shaving device for an automobile tire and a method thereof. The shaving injury preventing shaving device comprises a U-shaped tool rest, a shaving blade and ashaving injury preventing component; the U-shaped tool rest comprises a left vertical rod, a right vertical rod and a cross rod, springs and fixing sleeving rings successively sleeve the left vertical rod and the right vertical rod from bottom to top correspondingly, and second thread holes are formed in the fixing sleeving rings; V-shaped grooves are formed in the upper surface of the cutting edge end of the shaving blade, an inclined face is arranged on the lower surface of the cutting edge end of the shaving blade, triangular cutter teeth are formed at the intersections of the inclined face and the V-shaped grooves, and first fixing holes matched with first thread holes are formed in the shaving blade; the shaving injury preventing component comprises a rectangular body and aplurality of rectangular top strips, second fixing holes matched with the second thread holes are formed in the two ends of the rectangular body, the bottom ends of the rectangular top strips are connected with the side face of the rectangular body, and V-shaped grooves are formed in the top ends of the rectangular top strips; the shaving injury preventing component is fixedly installed on the fixing sleeving rings; and the top ends of the triangular cutter teeth are arranged opposite to the top ends of the rectangular top strips, and inserted into the V-shaped grooves in the top ends of the rectangular top strips.

Owner:徐小丽

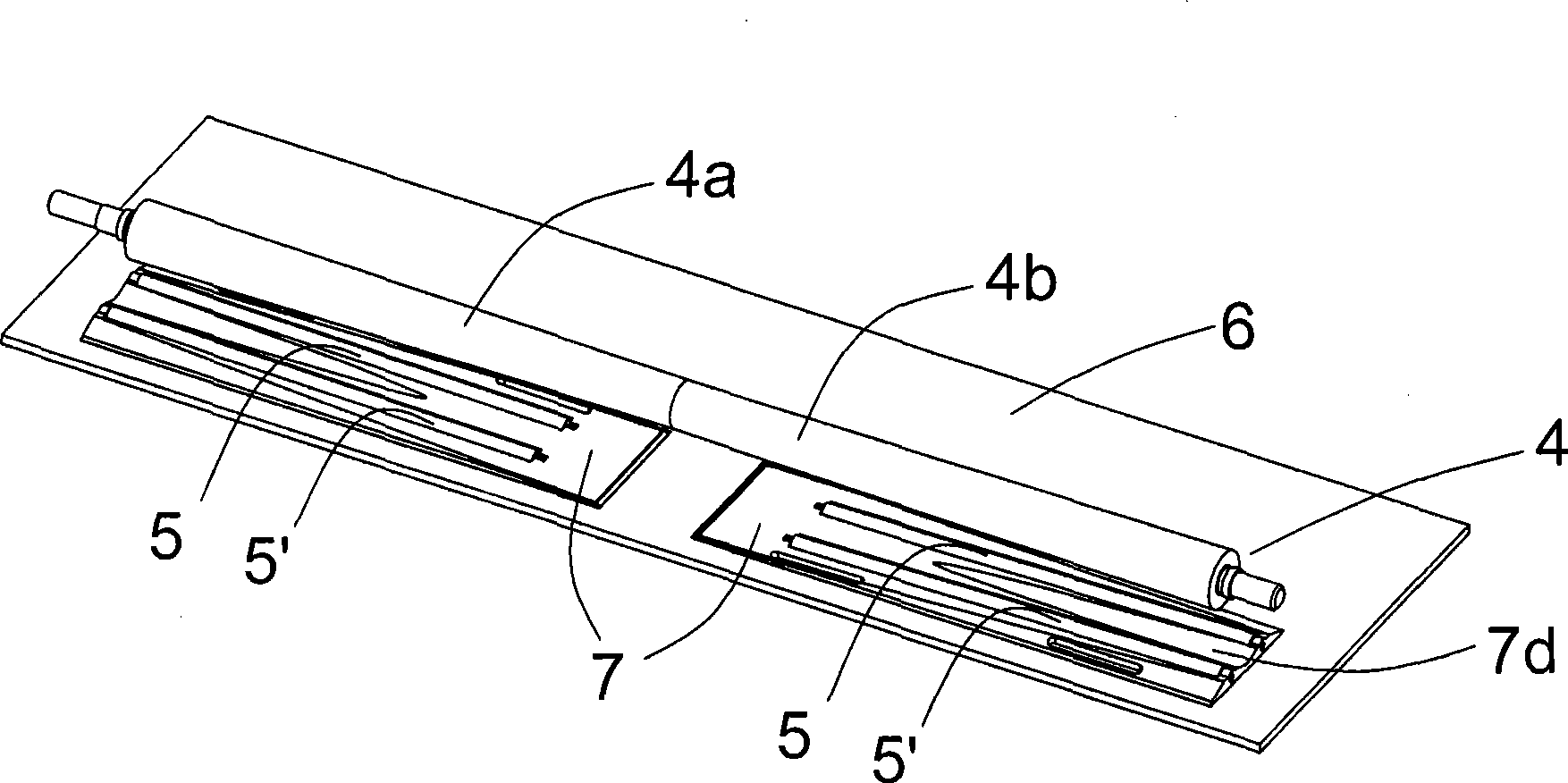

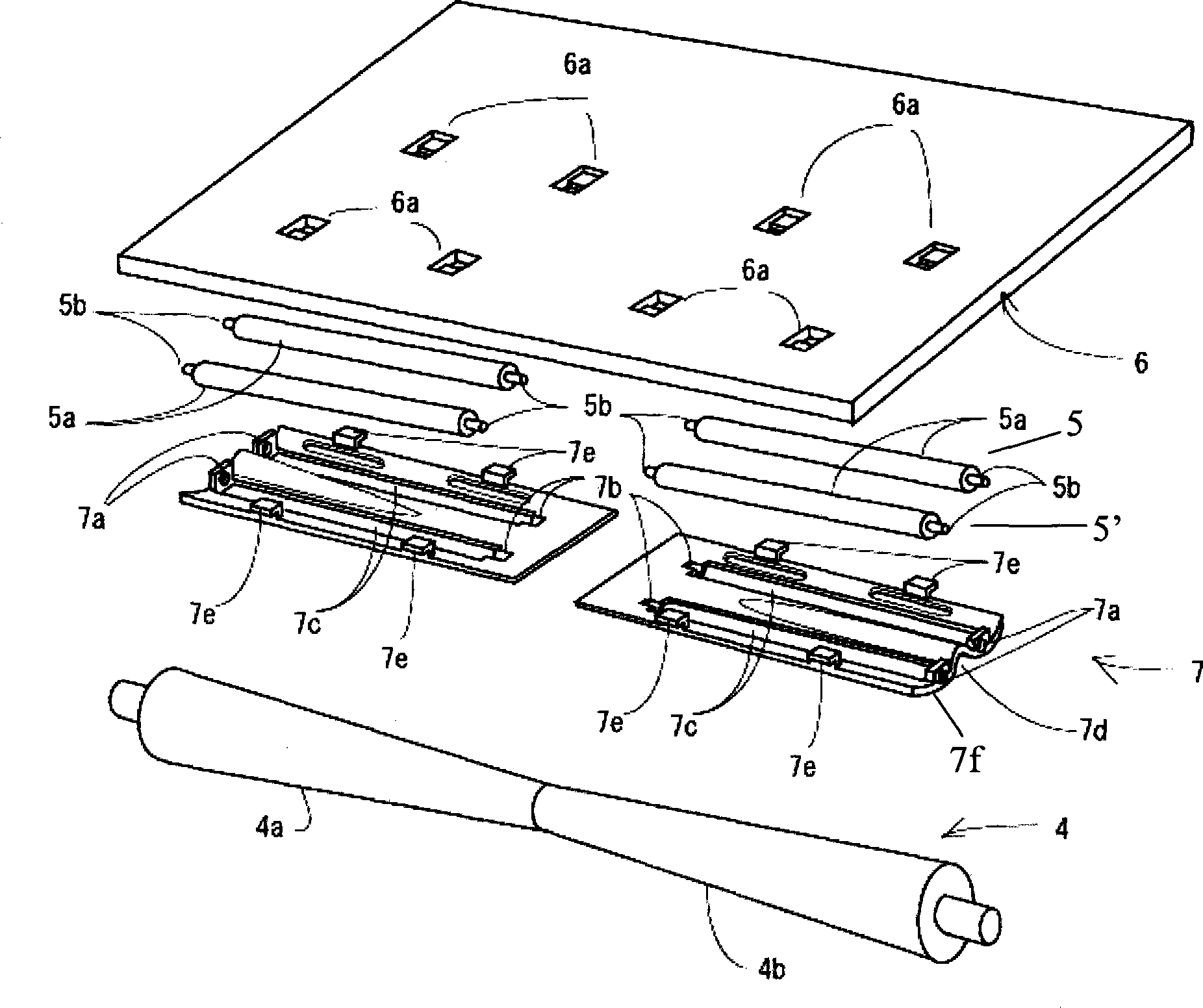

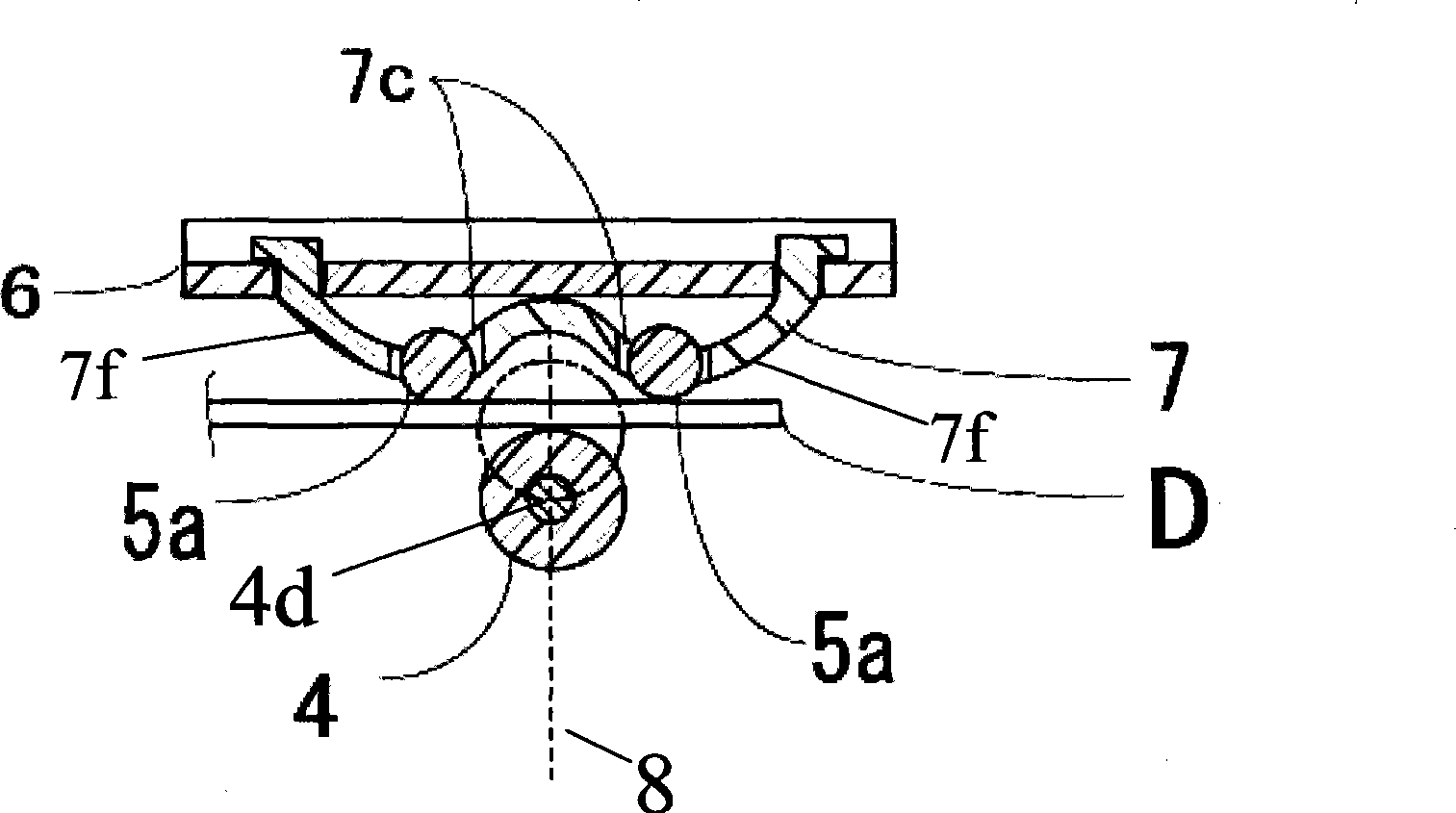

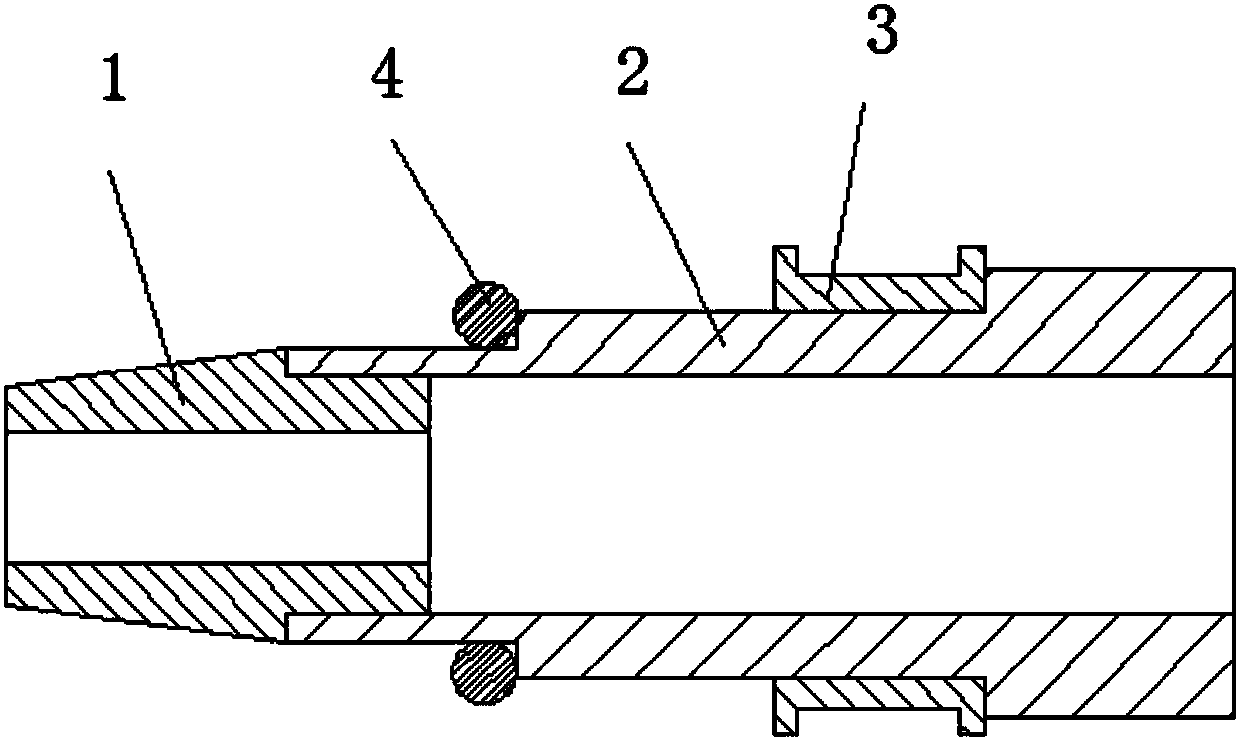

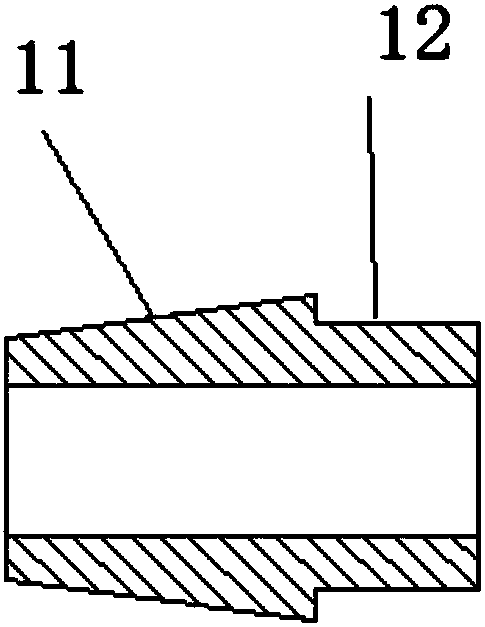

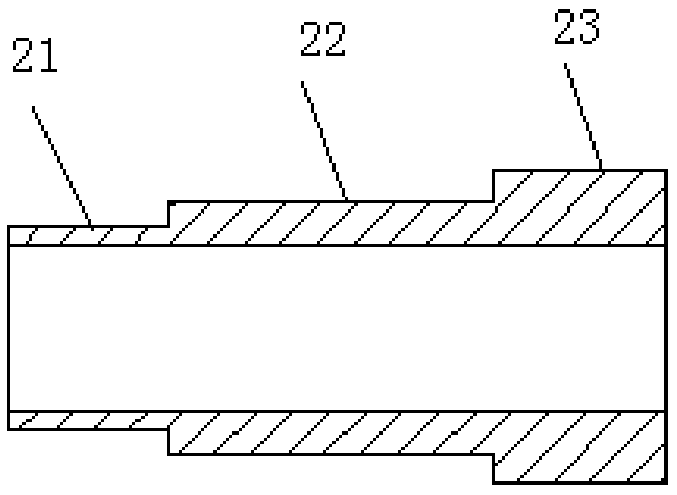

Optical disk conveying device

InactiveCN101477815AMiniaturizationAvoid scratchesRecord information storageMiniaturizationEngineering

The invention discloses a device for conveying an optical disk, which comprises a carrying roller, a guide part positioned above the carrying roller, an elastic part used for pressing the carrying roller towards the guide part, and a motor used for driving the carrying roller to rotate, wherein, the roller body of the carrying roller is a bipyramidal structure with the diameter which is shrunken from the two ends to the middle gradually; at least a turnable driven roller is mounted on the position which is opposite to each pyramidal of the carrying roller on the guide part, the rotating shafts of the driven rollers are positioned in a plane or are parallel to the plane, and the rotating shaft of the carrying roller is positioned in the plane and the plane is perpendicular to the roof of an optical playing device, and the driven rollers which are close to one end of the middle part of the carrying roller tilts upwards to enable the driven roller to contact with only the outer edge of the optical disk when the optical disk is inserted. The device can enable the front side and the back side of the optical disk to be not scratched, is suitable for the optical playing device with two surfaces of the used optical disk as the recording surfaces, and can realize the miniaturization of the optical disk playing device.

Owner:GULIN ELECTRICAL EQUIP CO LTD SHENZHEN

Ceramic chip scraper

The invention provides a ceramic chip scraper and belongs to the technical field of ceramic product production. The ceramic chip scraper comprises a fixing frame, an elastic sliding mechanism, an angle table, a knife rest and a scraping knife, wherein the elastic sliding mechanism is installed on the fixing frame and has the up-and-down movement freedom degree; the angle table is fixedly connectedwith the elastic sliding mechanism; the knife rest is fixedly connected with the angle table; and the scraping knife is mounted on the knife rest, and the angle of the scraping knife is adjusted through the angle table, and the scraping knife and a ceramic chip are elastically and tightly pressed through the elastic sliding mechanism. By means of the ceramic chip scraper provided by the invention, the effect that the operation force of the scraping knife is consistent is guaranteed through the elastic sliding mechanism and the angle table, molten slag removing is complete, the ceramic chip isnot damaged by scraping, the chip scraping mode adopts a chip scraping table device to drive chip scraping operation, and time and efforts are saved.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Manual type bathing and back rubbing device

The invention discloses a manual type bathing and back rubbing device. The manual type bathing and back rubbing device comprises a base, a first sleeve, a second sleeve, a bathing strip and a rack, wherein a horizontal swinging frame is hinged on the base, and a first horizontal shaft is horizontally fixed at the end part of the horizontal swinging frame; the first sleeve rotatably sheathes on the first horizontal shaft, the two ends of the first sleeve are respectively fixedly connected with a swinging control frame and a back rubbing frame, two pressing wheels are rotatably arranged on the swinging control frame in parallel, and driven belt pulleys are rotatably arranged on the back rubbing frame in parallel; the second sleeve rotatably sheathes on the first sleeve, the two ends of the second sleeve are respectively fixedly connected with a driving gear and a driving belt pulley; the bathing strip sheathes on the wheel surfaces of the driving belt pulley and the driven belt pulleys; and the rack is inserted into a space between the two pressing wheels and the driving gear. The manual type bathing and back rubbing device has the advantages that a user can rub the back by virtue of one-hand operation, and one hand can be vacated for guaranteeing self security, so that the user can hold the body steady in time when the sole of a foot slips, and the probability that a fall damage accident happens during bathing is reduced.

Owner:曹一璠

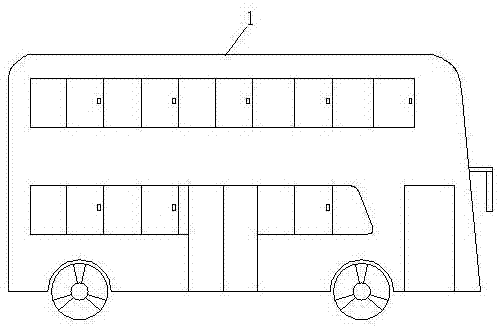

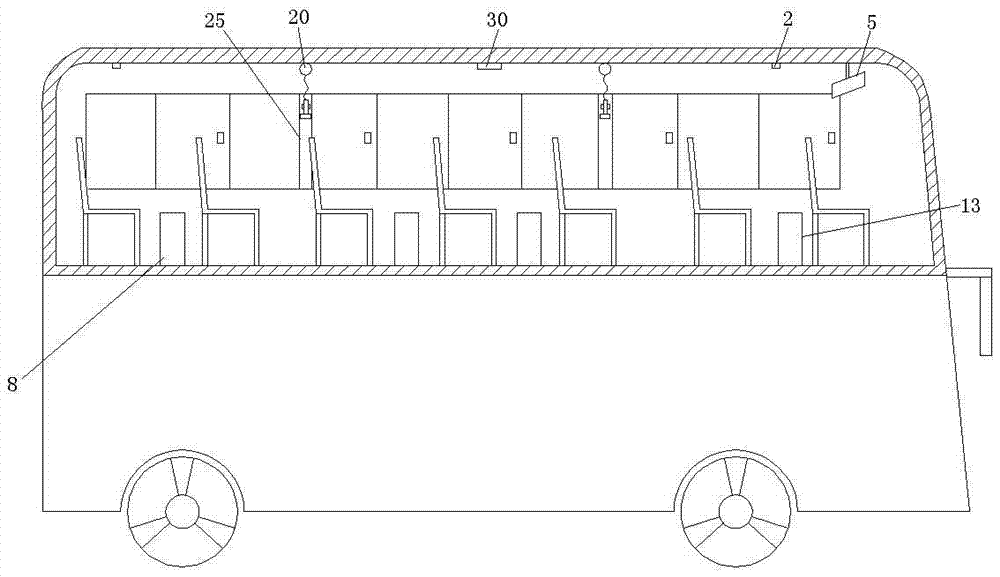

Safe escape device and temperature control device applied to high-rise bus

PendingCN106965765AMonitor temperature in timeControl temperatureAir-treating devicesPedestrian/occupant safety arrangementTemperature controlDriver/operator

The invention provides safe escape device and temperature control device applied to a high-rise bus. A bus body with an upper layer and a lower layer is arranged; an escape protection device is mounted in an upper layer compartment; the escape protection device comprises an accommodating part and a telescopic part; the telescopic part is arranged in the accommodating part; one end of the telescopic part is fixed together with the accommodating part; the other end of the telescopic part can be pulled out from the accommodating part and extend out of a window; passengers in the upper layer escape through the telescopic part; a temperature control device is also mounted in the upper layer compartment; the temperature control device comprises a plurality of sensors; the plurality of temperature sensors are connected with a control part and a display part in sequence; and the temperature sensors display the detected upper layer temperatures on the display part positioned on a cab instrument panel. The safe escape device and temperature control device applied to the high-rise bus have the advantages that the structure is simple, the design is novel, the device is easy to operate, a driver can monitor and master the temperature of the upper layer compartment in time and can monitor and master the safe escape device of the passengers in time.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

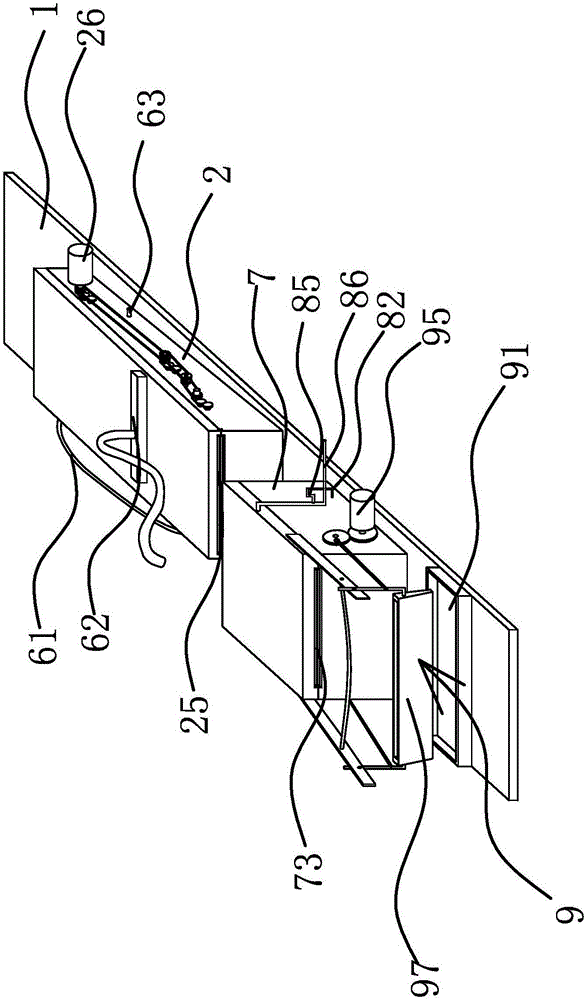

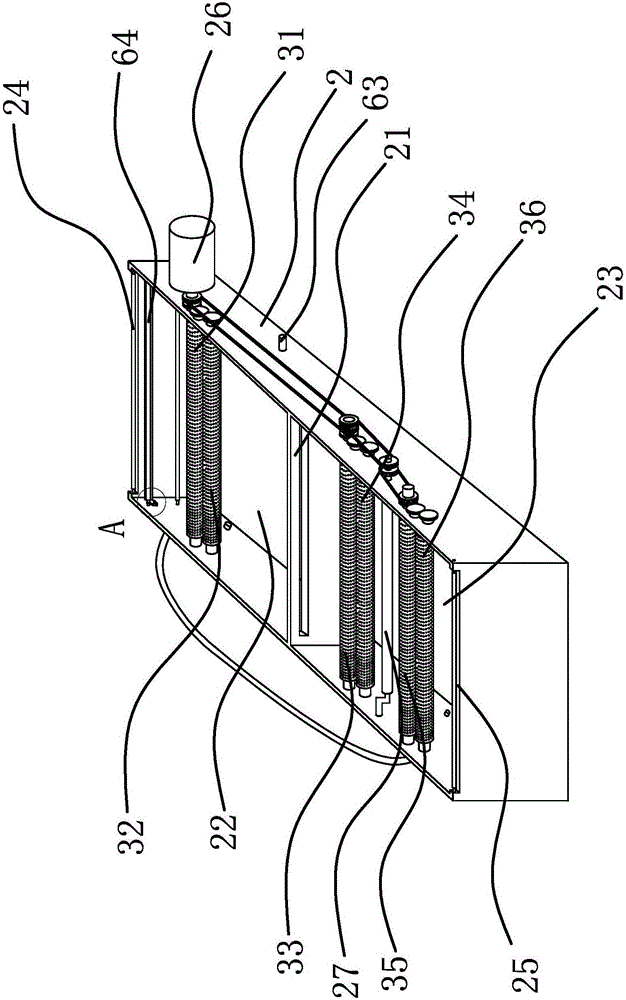

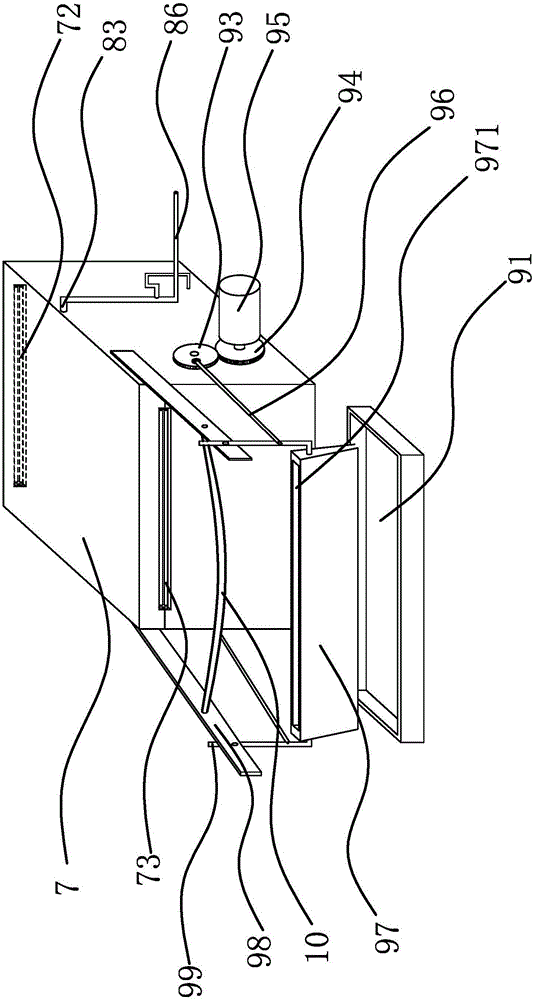

A fabric washing and drying machine with a fabric collecting device

ActiveCN104480656BSolve cleaning difficultiesSimple structureLiquid/gas/vapor removalTextile treatment machine arrangementsDrive motorEngineering

The invention provides a fabric washing and drying integrated machine with a fabric collection device and belongs to the technical field of machinery. By means of the machine, the technical problems that fabrics cannot be washed, dried, collected and the like through one step after being woven are solved. The machine comprises a base, a washing case is arranged on the base, and a case body of the washing case is partitioned into a washing tank and a rinsing tank through a partition plate. A first fabric inlet and a second fabric inlet are formed in the two ends of the washing case respectively. A first washing roller and a second washing roller which are parallel are arranged on the inner wall of the washing case and are both disposed in the washing tank. The first washing roller is driven by a first drive motor, a drying case is further arranged on the base, a fabric collecting unit is arranged between the drying case and the base, and a fabric collecting box is further arranged on the base. The machine has the advantage of being capable of completing washing, drying, collecting and the like of fabrics.

Owner:四川九五一七实业有限公司

Cloth for automobile garment

InactiveCN102320167APrevent infiltrationNot scratchedRemovable external protective coveringsMetal layered productsPolyesterSurface layer

The invention discloses cloth for an automobile garment. A surface layer of the cloth is made of polyester taffeta; a bottom layer of the cloth is made of acupuncture cotton, hot air cotton, PP (Polypropylene) cotton or spunlaced cotton; the surface layer is seamlessly compounded and bonded with the bottom layer through glue; silver is uniformly coated on the surface of the polyester taffeta on the surface layer of the cloth; and after the silver is coated, a water-resistant layer and a coating are sequentially and uniformly coated on the surface of the polyester taffeta. The automobile garment made of the material can achieve functions of a general automobile garment, has high firmness and cannot be torn off at the same time; and in addition, the automobile garment can be used for preventing automobile paint from being scratched and playing roles of preserving heat, insulating and resisting water and coldness.

Owner:陈统奎

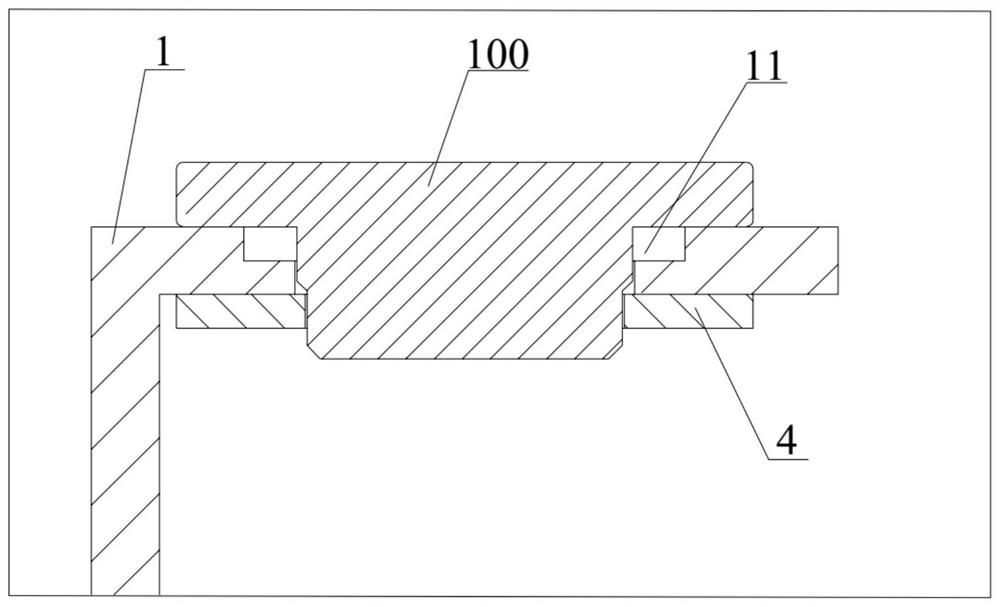

Shaft steel wire baffle ring mounting tool

Owner:天津市百成油田采油设备制造有限公司

Fixture

InactiveCN100411820CEasy to operateReduce hardnessWork holdersCleaning processes and apparatusEngineeringBiomedical engineering

The fixture has a holding part and a buckling part. The holding part is provided with notch structure for the element to be set, and the buckling part is provided with through hole communicated with the notch structure. The holding part and the buckling part cooperate to fix element, especially element with small size or irregular shape.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Anhydrous automobile detergent

InactiveCN106190602AEliminate damageAvoid scratchesInorganic/elemental detergent compounding agentsAnionic surface-active compoundsWaxEmulsion

The invention discloses an anhydrous automobile detergent, which comprises the following ingredients (by weight): 0.1-10% of activated silica microparticles of 2,000-4,000 meshes, 0.1-20% of a palm wax emulsion, 0.1-5% of an anionic surfactant, 0.1-5% of hydroxypropyl-cellulose and 100% of a solution. The anhydrous automobile detergent provided by the invention can thoroughly remove oily dirt, spot, silt and surface oxide on parts such as car body and slit, etc. The detergent contains activated silica microparticles, the anionic surfactant and the palm wax emulsion. During each time of car washing, automobile finish surface care is carried out. Washing, waxing and glazing are finished at a time without scratches. After car washing, automobile finish surface is bright.

Owner:嘉兴国弘物业管理有限公司

Machining method for precious metal article

The invention discloses a machining method for a precious metal article. The method comprises the process of making a precious metal blank into a lath and is characterized by comprising the step of titanium plating, wherein the titanium plating step comprises the steps of plating a titanium film on the surface of the precious metal lath through a magnetron sputtering method and then carrying out subsequent machining. According to the machining method for the precious metal article, a rolling technology is optimized, a precious metal commemorative coin is produced by combining a titanium plating technology and a stamping technology, so that the wear resistance, the corrosion resistance and the hardness of the precious metal commemorative coin can be improved under the conditions that the forming quality and the machining precision are ensured, and therefore the quality of the precious metal commemorative coin can be guaranteed for a long time.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

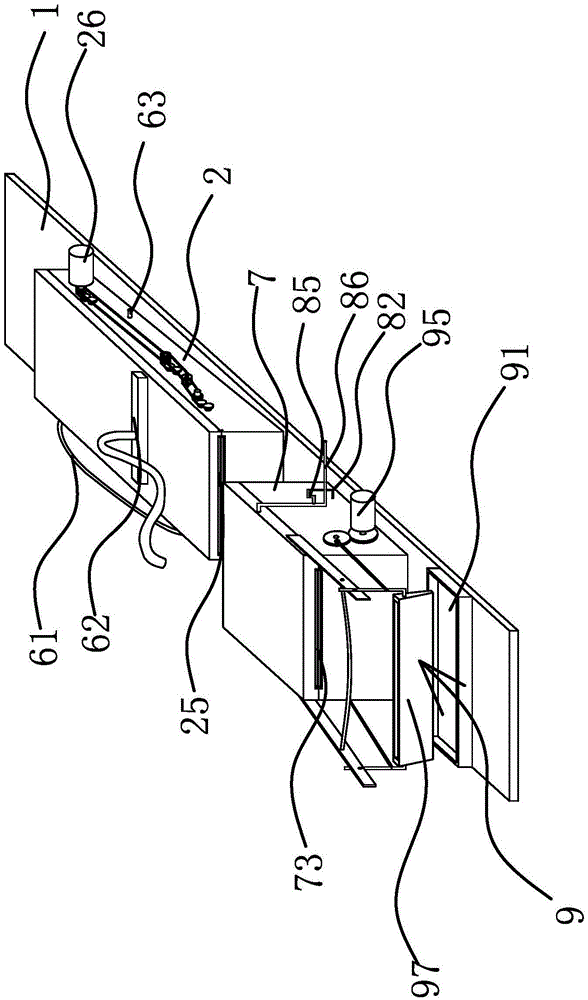

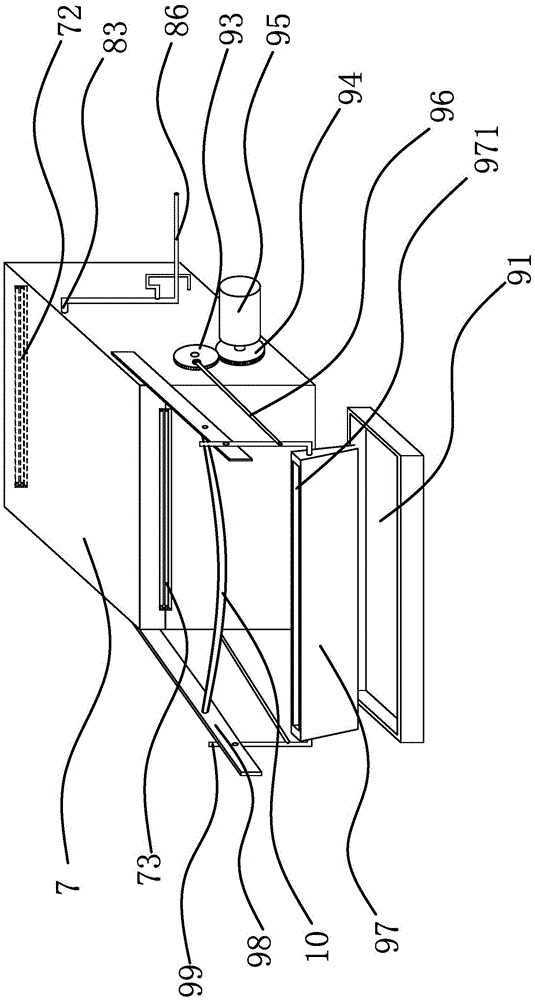

A pin automatic plug-in device for pcb board

ActiveCN110785076BEasy to holdThe clamping pin state facilitatesElectrical componentsFixed frameElectric machinery

The invention relates to circuit board production, in particular to an automatic PCB pin insertion device. The technical problem to be solved by the present invention is to provide an automatic PCB pin insertion device. The automatic PCB pin insertion device includes a fixed frame, a first stopping block, a second stopping block, a stepping motor, a pin erecting mechanism, a reverse pin insertionmechanism, a first driving wheel, a second driving wheel, a cutting and soldering review mechanism and a controller. The top of the left end of the fixed frame is welded to the first stopping block. The left middle of the top of the fixed frame is welded to the second stopping block. The left middle of the fixed frame is in bolted connection with the stepping motor. The pin erecting mechanism is disposed on the left end in the fixed frame. The automatic PCB pin insertion device achieves effects of facilitating pin clamping, positioning PCB holes, shortening the pins to avoid scratching users and damaging other boards in transit, and avoiding damaging the use states of components during cutting.

Owner:江西众达泰科技有限公司

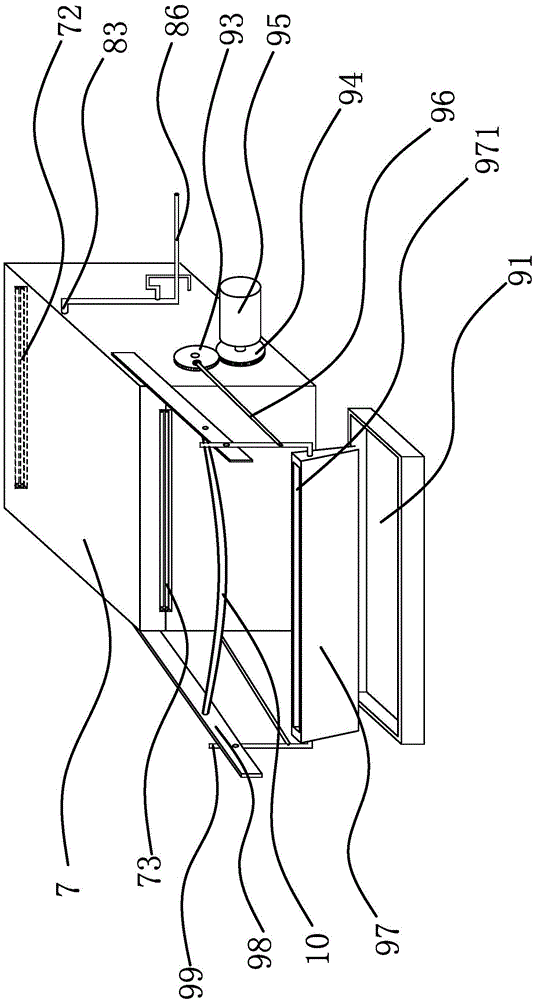

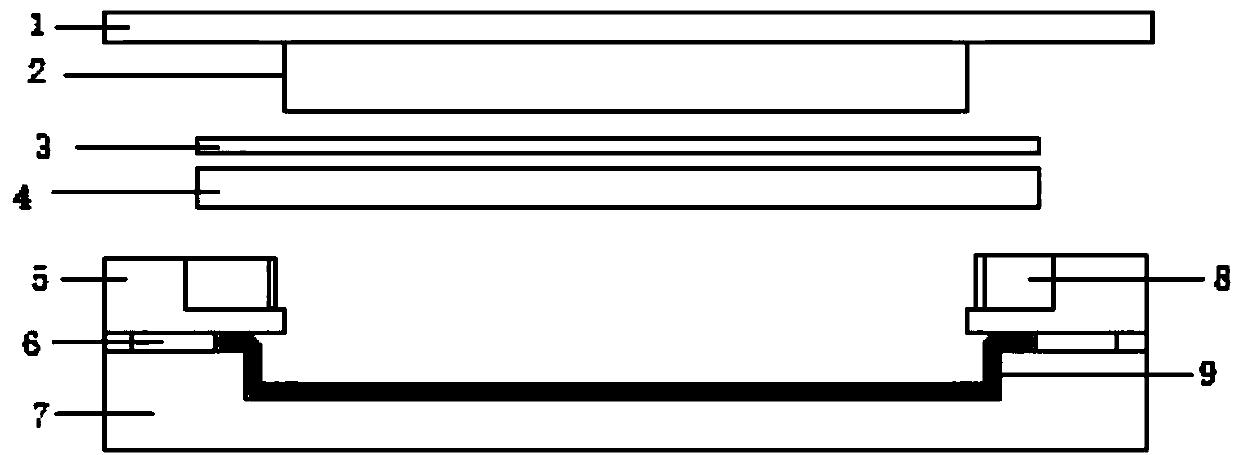

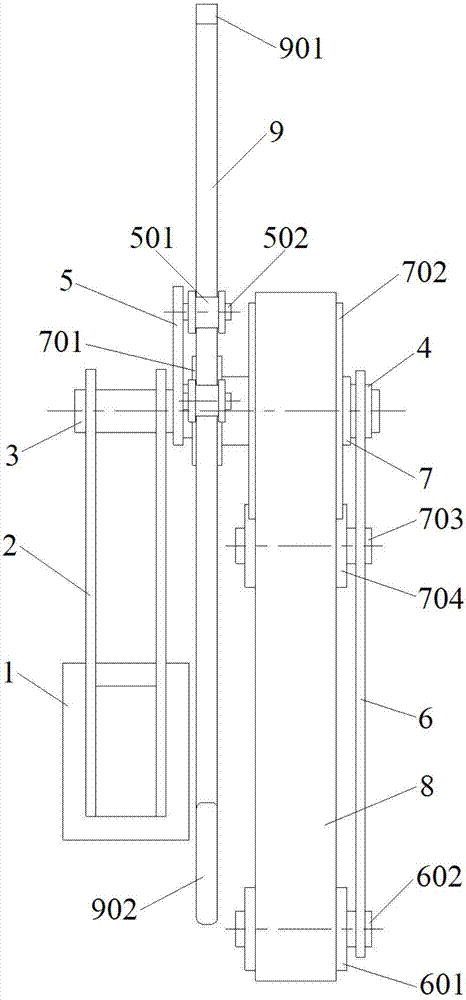

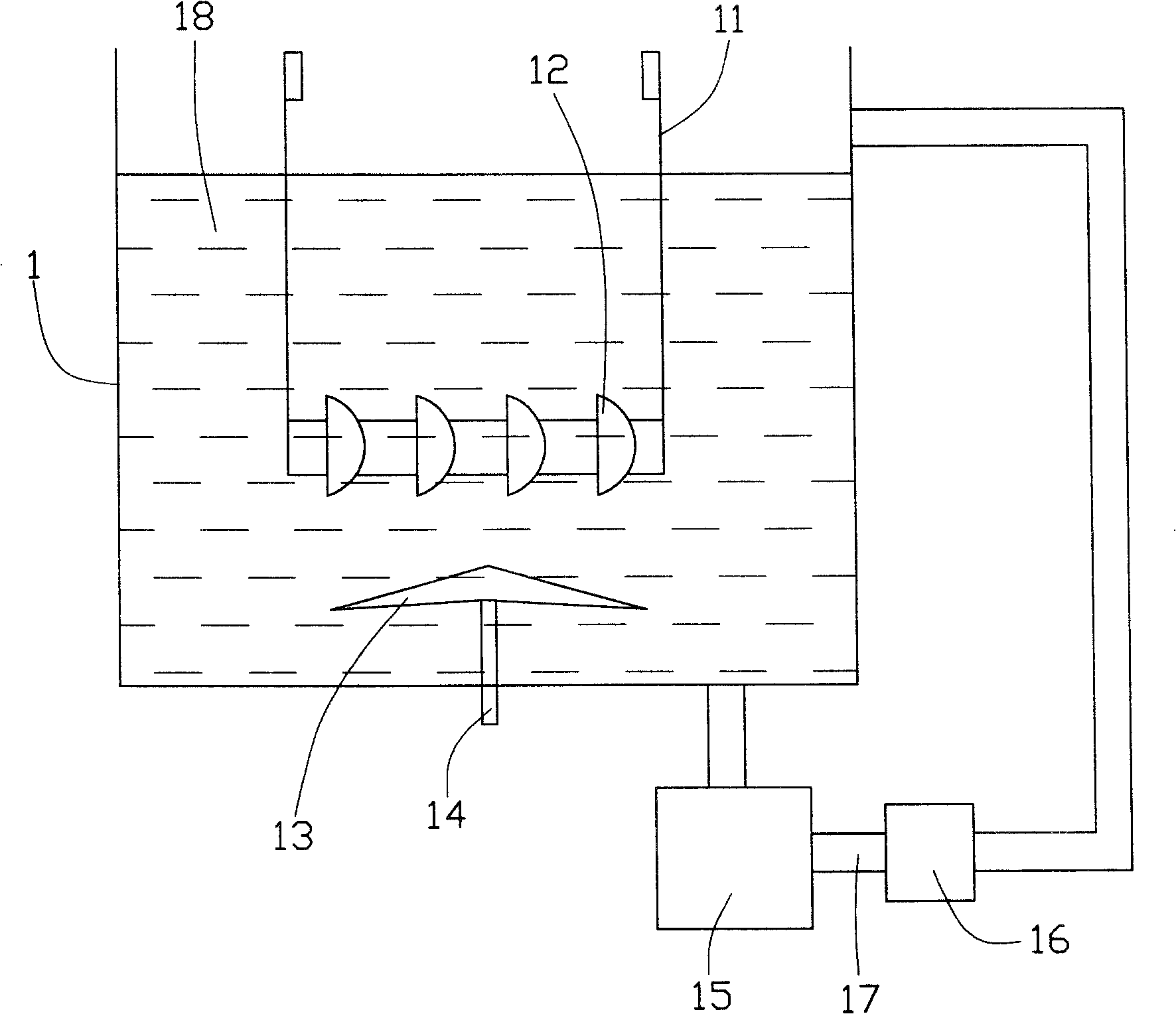

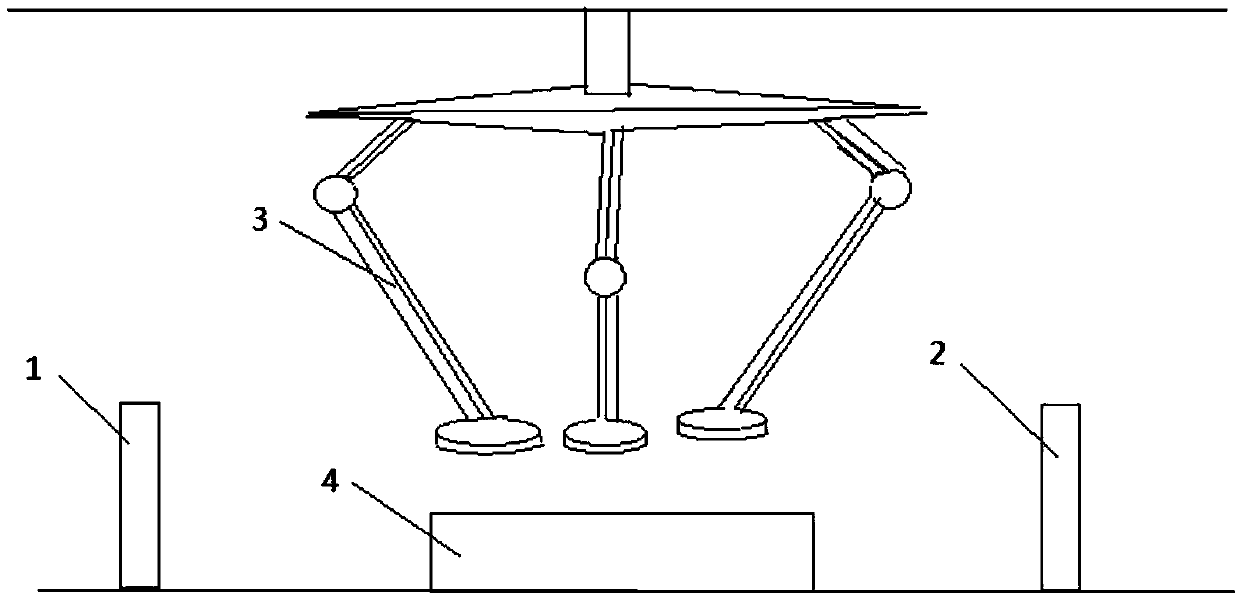

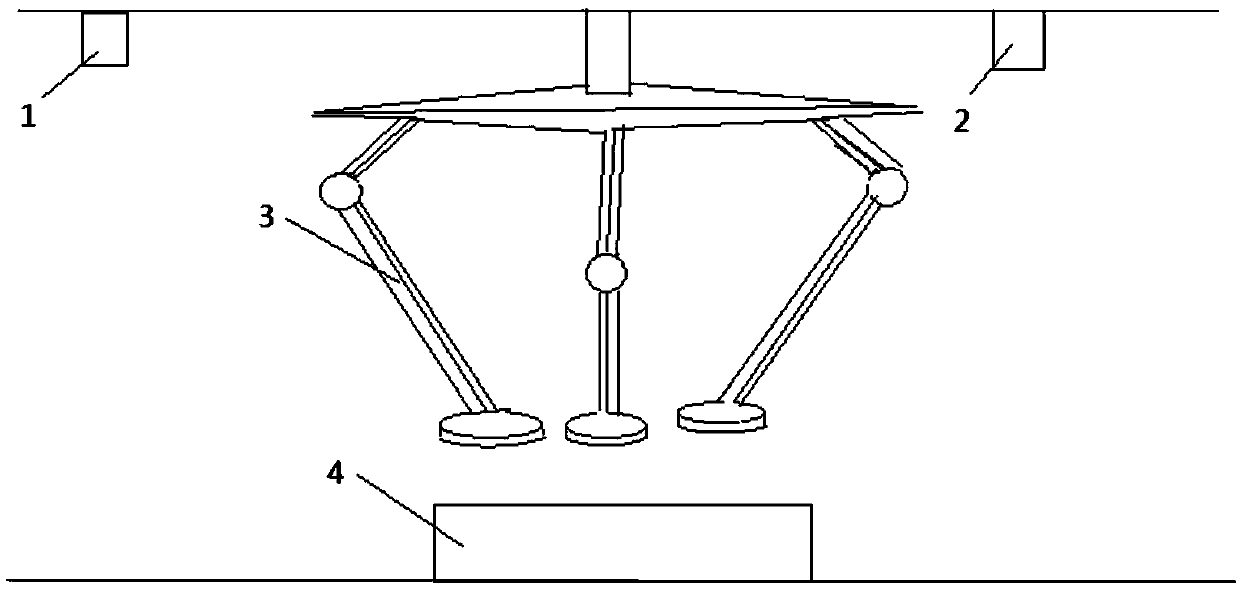

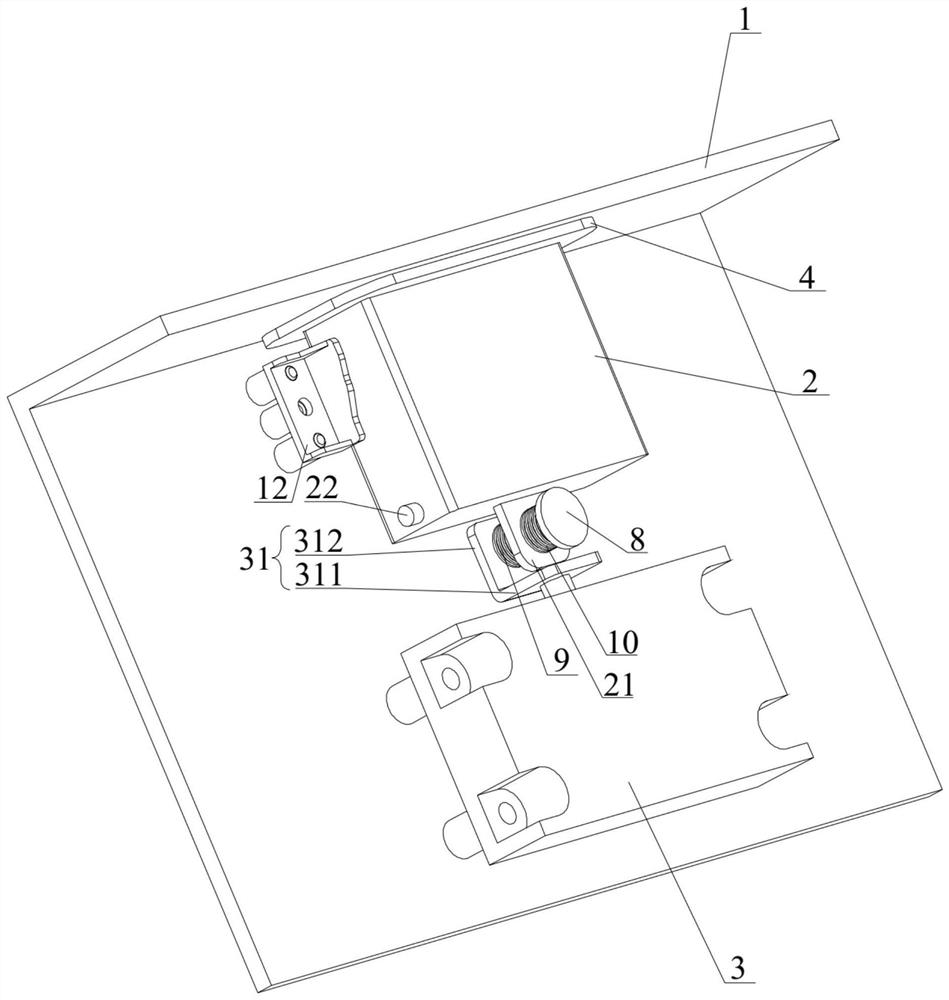

System for preventing bags from being stuck on soft tissue production line

ActiveCN110962396AScratch will notImage recognition method is simpleTelevision system detailsPaper/cardboard articlesProduction lineComputer science

The invention relates to a system for preventing bags from being stuck on a soft tissue production line. The system is characterized by comprising a first camera (1), a second camera (2), a spider robot (3) and a controller, wherein the first camera (1) and the second camera (2) are arranged front and back in the conveying direction of a track and shoot soft tissue bags (4); the spider robot (3) is located between the two cameras and above the track; and the controller is connected with the two cameras and the spider robot (3). Compared with the prior art, the soft tissue bags are shot throughthe cameras, the soft tissue bags which are inaccurate in pose are recognized and are rapidly rotated by the spider robot, and thus the bags are prevented from being stuck.

Owner:上海东冠纸业有限公司

Brush wheel resin grinding sheet for grinding printed circuit board and manufacturing method thereof

InactiveCN107263342BExtended service lifeNot easy to cause scratchesAbrasion apparatusGrinding devicesEpoxyEngineering

The invention discloses a brush wheel resin grinding disc for grinding a printed circuit board and a manufacturing method thereof. The brush wheel resin grinding disc is prepared from the following raw materials in parts by weight: 10 to 25 parts of phenolic resin, 10 to 20 parts of epoxy resin, 10 to 15 parts of vinylite, 30 to 70 parts of green silicon carbide, 2 to 5 parts of AC foaming agent, 8 to 18 parts of polyamide resin, 13 to 17 parts of ethyl ester, 1 to 2 parts of silicone oil, 1 to 6 parts of silicon carbide whisker, 2 to 6 parts of aluminium borate whisker, 1 to 2 parts of starch, and 1 to 2 parts of dextrin. The brush wheel resin grinding disc for grinding the printed circuit board is long in service life, has favorable traceability for grinding materials during grinding, cannot scratch a grinding surface, is uniform in grinding force, can be used for getting a favorable and uniform grinding surface, and is cost-saving, high in production efficiency, and free of toxicity.

Owner:广州捷骏电子科技有限公司

An improved fabric washing and drying machine

ActiveCN104389130BSolve cleaning difficultiesSimple structureLiquid/gas/vapor removalTextile treatment machine arrangementsDrive motorWater washing

The invention provides a water-washing and drying all-in-one machine for a fabric with an improved structure, belongs to the technical field of machines, and aims to solve the technical problems of failure in performing water washing, drying and collection on the fabric after weaving, and the like. The water-washing and drying all-in-one machine for the fabric with the improved structure comprises a base, wherein a washing tank is arranged on the base; the middle part of the washing tank is partitioned into a washing groove and a rinsing groove through a clapboard; the two ends of the washing tank are provided with a fabric inlet I and a fabric outlet II respectively; the inner wall of the washing tank is provided with a washing drum I and a washing drum II which are parallel to each other; both the washing drum I and the washing drum II are positioned in the washing groove; the washing drum I is driven by a driving motor I; a drying box is further arranged on the base; a fabric collecting device is arranged between the drying box and the base; a fabric collecting box is further arranged on the base. The water-washing and drying all-in-one machine has the advantages that water washing, drying and collection of the fabric can be finished at one time, and the like.

Owner:苏州盛泽科技创业园发展有限公司

All-in-one machine for shell fabric washing and drying

ActiveCN103409960BSolve cleaning difficultiesSimple structureTextile treatment machine partsDrive motorEngineering

The invention provides an all-in-one machine for shell fabric washing and drying, and belongs to the technical field of machines. The all-in-one machine solves the technical problems that shell fabric is incapable of being washed, dried and collected at one time after being woven. The all-in-one machine for shell fabric washing and drying comprises a base, wherein the base is provided with a washing box; the box body of the washing box is partitioned into a washing tank and a bleaching tank through a partition board in the middle part of the washing box; two ends of the washing box are respectively provided with a shell fabric inlet I and a shell fabric outlet II; the inner wall of the washing box is provided with a washing roller I and a washing roller II which are parallel to each other; the washing roller I and the washing roller II are both positioned in the washing tank; the washing roller I is driven by a driving motor I; the base is further provided with a drying box; a shell fabric collecting device is arranged between the drying box and the base; the base is further provided with a shell fabric collecting box. The all-in-one machine has the advantages that the shell fabric can be washed, dried, collected and the like at one time.

Owner:ZHEJIANG HUAYUAN TEXTILE

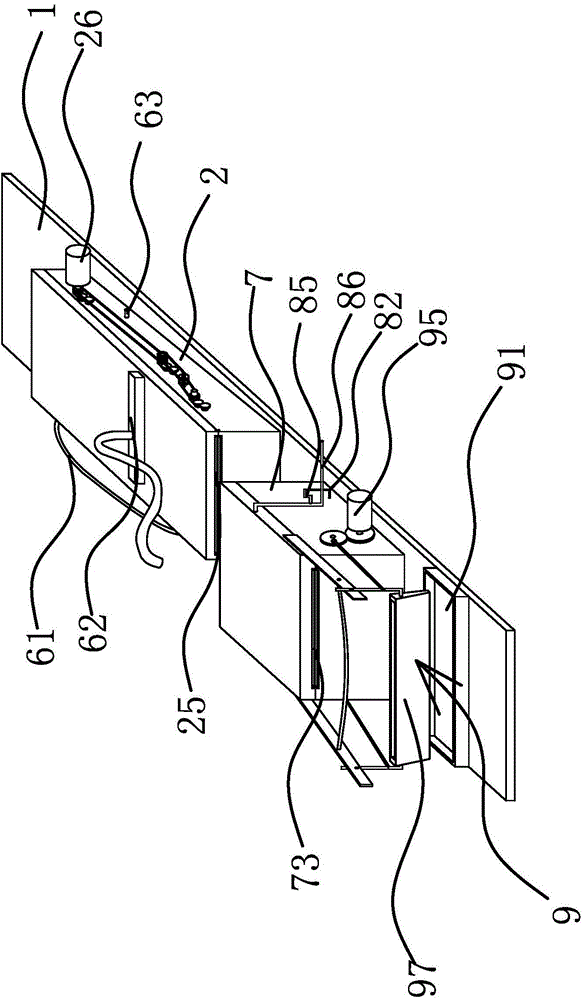

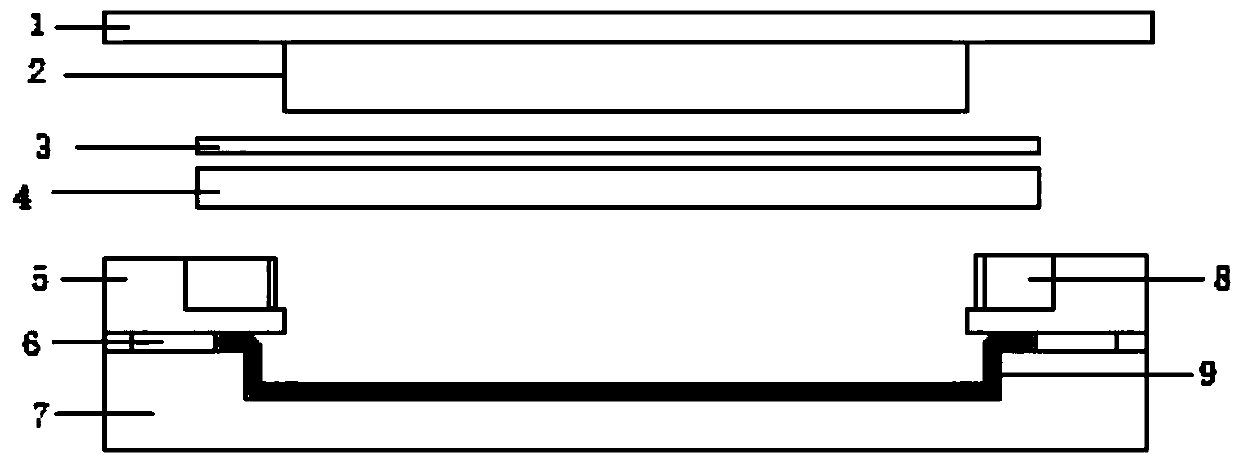

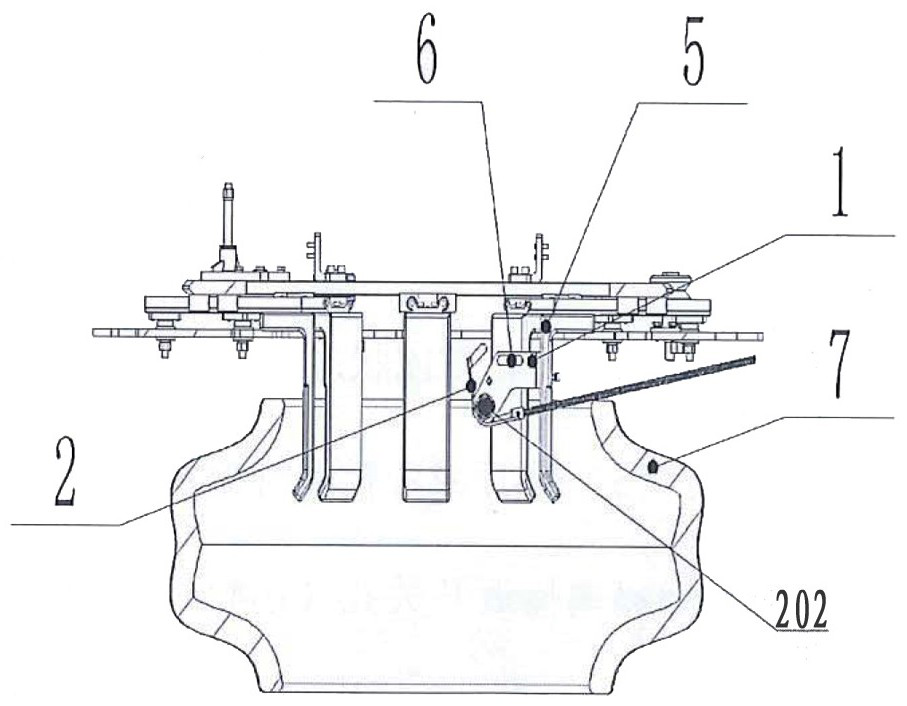

Automatic tire blank conveying manipulator tire contact device

PendingCN112405964AScratch will notIt will not cause the situation that cannot be effectively detectedTyresAutomotive engineeringMechanical engineering

The invention relates to the field of tire production and conveying, in particular to an automatic tire blank conveying manipulator tire contact device. The automatic tire blank conveying manipulatortire contact device comprises a support, a tension spring and a tension spring tire contact rod. The tension spring tire contact rod is an L-shaped rod formed by a long arm and a short arm, and the short arm of the tension spring tire contact rod is fixedly connected with the tension spring and colinear with the short arm. One end of the support is rotatably connected with the tension spring tirecontact rod, and a proximity switch hole is further formed in the support. The tire contact device has the advantages that the tire contact device is installed on the inner side of a mechanical gripper, so that a tire blank cannot be scratched, and the situation that the tire contact device is not concentric with a manipulator, and consequently effective detection cannot be achieved cannot be caused; and the tire contact device is installed on the inner side of the mechanical gripper, the tire blank cannot be damaged, and meanwhile the problem that a mechanism gets stuck and cannot perform detection due to dead corners when being in contact with tires of some specifications is solved; and the problem that a seam allowance and a tire side wall are scratched due to the sticky problem of thetire blank and the too large sliding resistance of the tire contact plate is also solved.

Owner:HEFEI WANLI TIRE CO LTD

A camera module and display device

ActiveCN112135030BAvoid problems such as scratching and grindingScratch will notTelevision system detailsColor television detailsDisplay deviceCamera module

The invention discloses a camera module and a display device, and relates to the technical field of display devices. The camera module includes a casing and a camera, the camera is arranged in the casing, and the camera can extend out of the casing or be hidden in the casing, the casing is provided with a lifting hole, and a first gap is arranged between the lifting hole and the camera; the inner side of the lifting hole A flexible hole is provided, and a second gap is arranged between the flexible hole and the camera, and the second gap is smaller than the first gap. The camera module provided by the present invention avoids problems such as scratching and grinding powder caused by hard contact between the casing and the camera during the lifting process, and the flexible material of the flexible hole is moderately soft and hard, which can adjust the gap between the cameras It will not scratch the camera.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

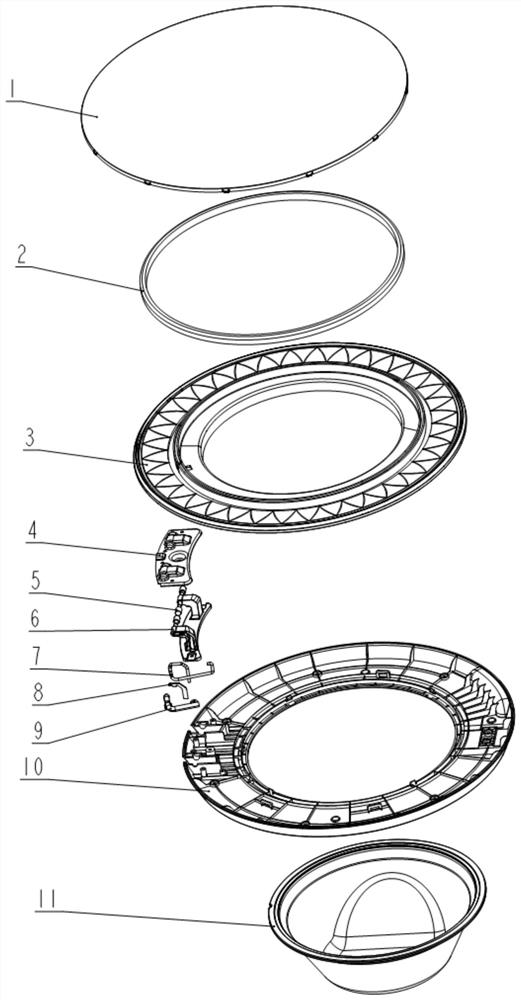

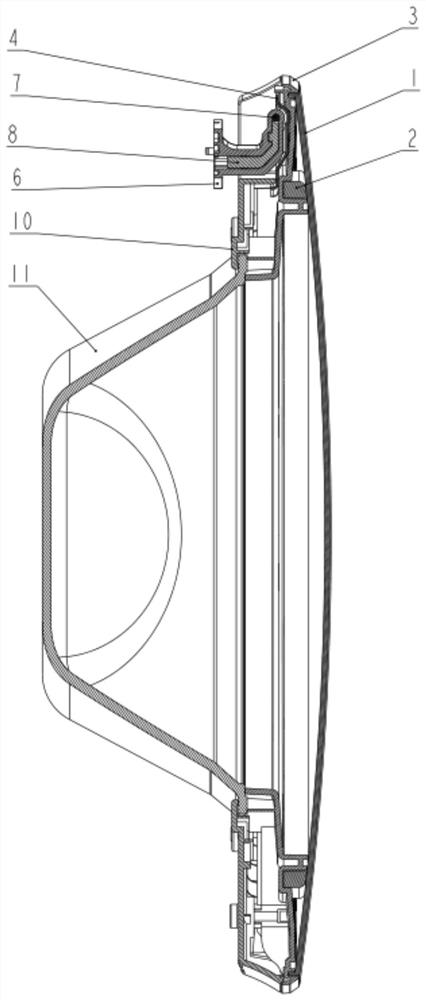

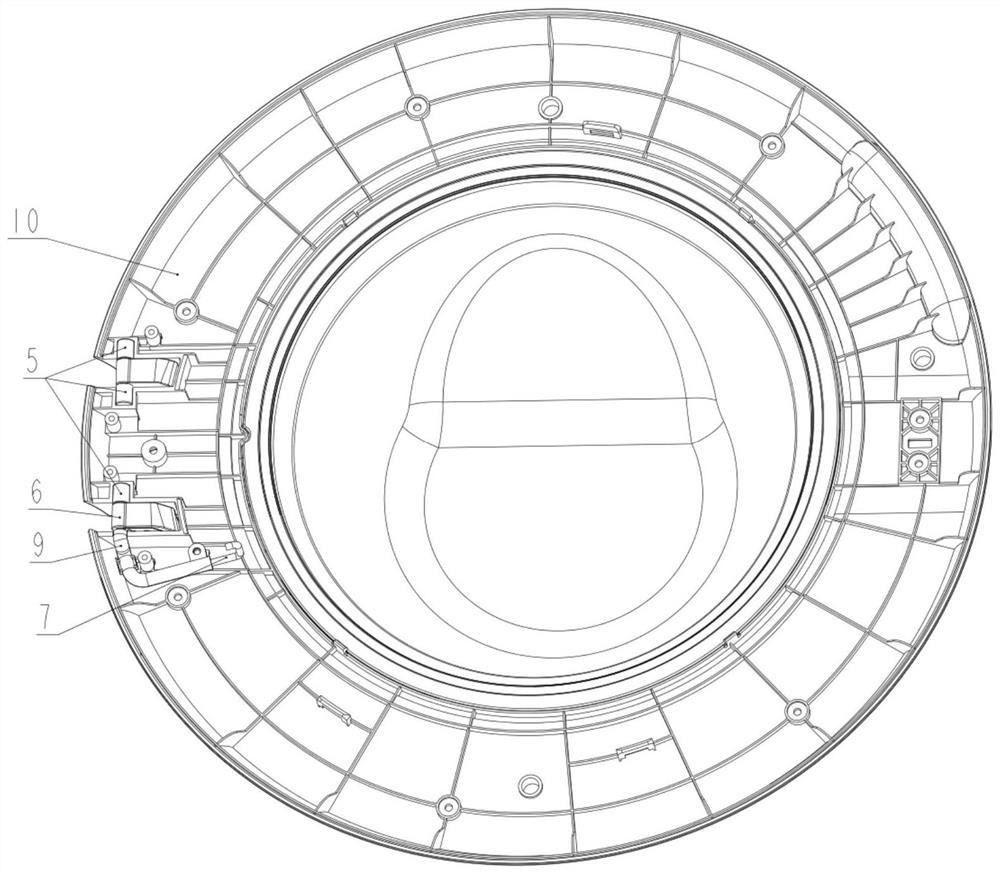

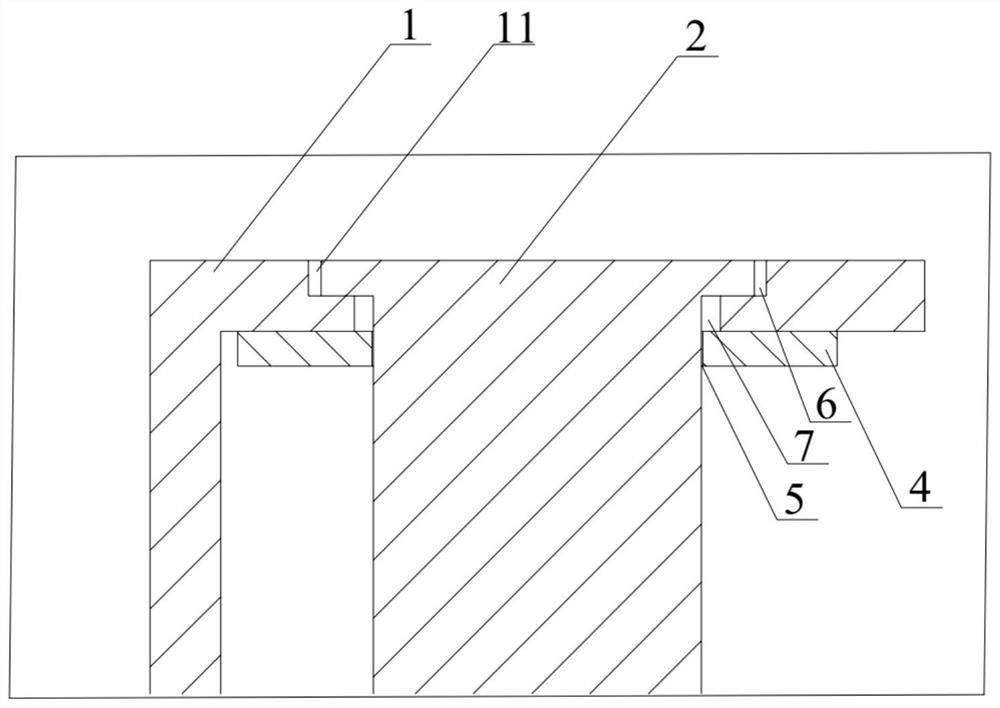

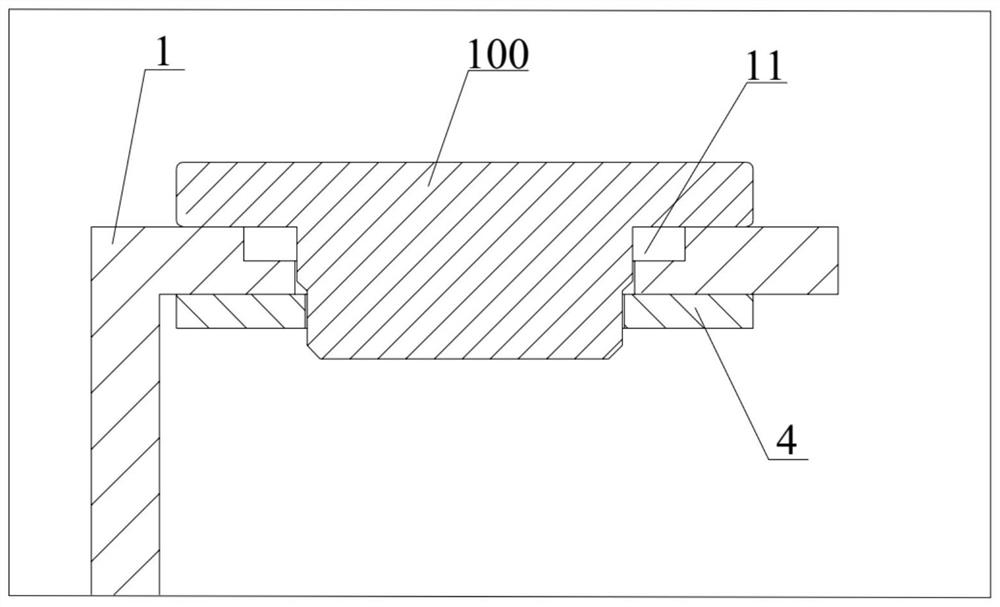

Hinge structure of washing machine and washing machine

PendingCN111705477AAvoid failureScratch reliableOther washing machinesTextiles and paperStructural engineeringWire breakage

The invention discloses a hinge structure of a washing machine and the washing machine. The hinge structure comprises a hinge, a hinge cover used for covering a wiring harness of a breathing light inthe hinge, a shaft sleeve mounted on a hinge shaft of the hinge, a hinge reinforcing plate used for fixing the shaft sleeve, and a wire guide frame used for preventing the wiring harness from being scratched. The wiring harness of the breathing light is mounted in the hinge and the wire guide frame, the breathing light is mounted on a washing machine door assembly, the designed hinge structure enables the wiring harness of the breathing light to be hidden in the hinge and be reliably fixed, the hinge cannot be leaked out, after a door of the washing machine is opened, the wiring harness cannotbe seen, the whole washing machine looks attractive, in addition, when the washing machine door assembly rotates and drives the wiring harness of the breathing light to rotate, the wiring harness cannot be scratched by a door inner ring, and the phenomenon that wire breaking appears in the breathing light, and failures happen can be avoided.

Owner:ANHUI KONKA TONGCHUANG HOUSEHOLD APPLIANCES

Camera module and display device

ActiveCN112135030AAvoid problems such as scratching and grindingScratch will notTelevision system detailsColor television detailsDisplay deviceEngineering

The invention discloses a camera module and a display device, which relate to the technical field of display devices. The camera module comprises a shell and a camera, the camera is arranged in the shell and can extend out of the shell or be hidden in the shell, a lifting hole is formed in the shell, and a first gap is formed between the lifting hole and the camera; a flexible hole is formed in the inner side of the lifting hole, a second gap is formed between the flexible hole and the camera, and the second gap is smaller than the first gap. According to the camera module provided by the invention, the problems of scratching, grinding and the like caused by hard-to-hard contact between the shell and the camera in the lifting process are avoided, and the flexible material of the flexible hole is moderate in hardness, so that the effect of adjusting the gap of the camera can be achieved, and meanwhile, the camera cannot be scratched.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com