Automatic deburring machine for engine camshaft

A technology for deburring machines and camshafts, which is applied to grinding drive devices, parts of grinding machine tools, and machine tools suitable for grinding the edge of workpieces, etc. It can solve the problem of difficult removal of burrs on both sides of the cam and switching of chip wheel brushes Long time, not suitable for mass production, etc., to achieve good deburring effect, save installation time, and small machine tool footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

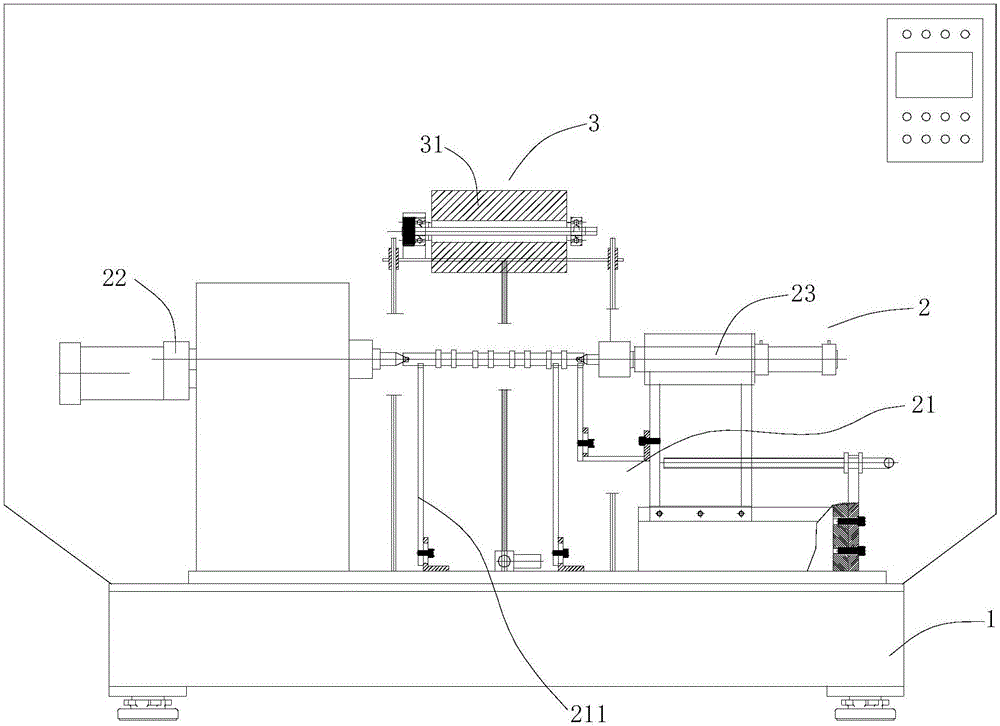

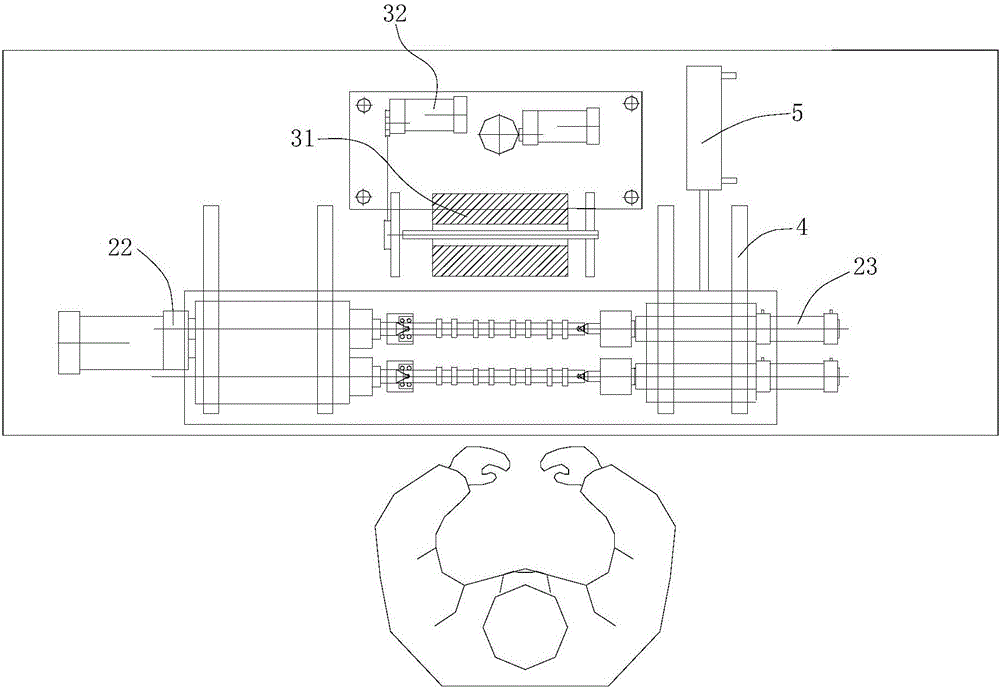

[0022] During specific implementation: if figure 1 and figure 2 As shown, an engine camshaft automatic deburring machine includes a base 1, a cam clamping mechanism 2 and a burr removal mechanism 3 are arranged on the base 1, the cam clamping mechanism 2 includes a frame body 21, and a set The rotary driving device 22 and the tailstock tightening device 23 on the frame body 21, the tailstock tightening device 23 includes a push rod capable of extending and contracting in the axial direction, and the push rod of the tailstock tightening device 23 is connected to the The rotary output shafts of the rotary driving device 22 are relatively and coaxially arranged, and the maximum distance between the two is greater than the length of the camshaft to be deburred, and the minimum distance is less than the length of the camshaft to be deburred; the deburring mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com