A pin automatic plug-in device for pcb board

A PCB board and pin technology, which is applied in the field of pin automatic plug-in device, can solve problems such as inability to perform batch pin welding, damage to the printed circuit of the PCB board, and pin deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

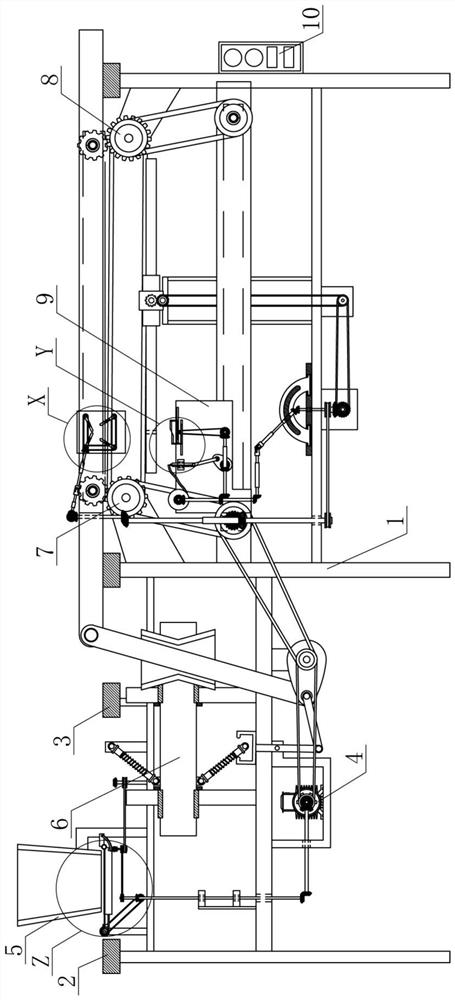

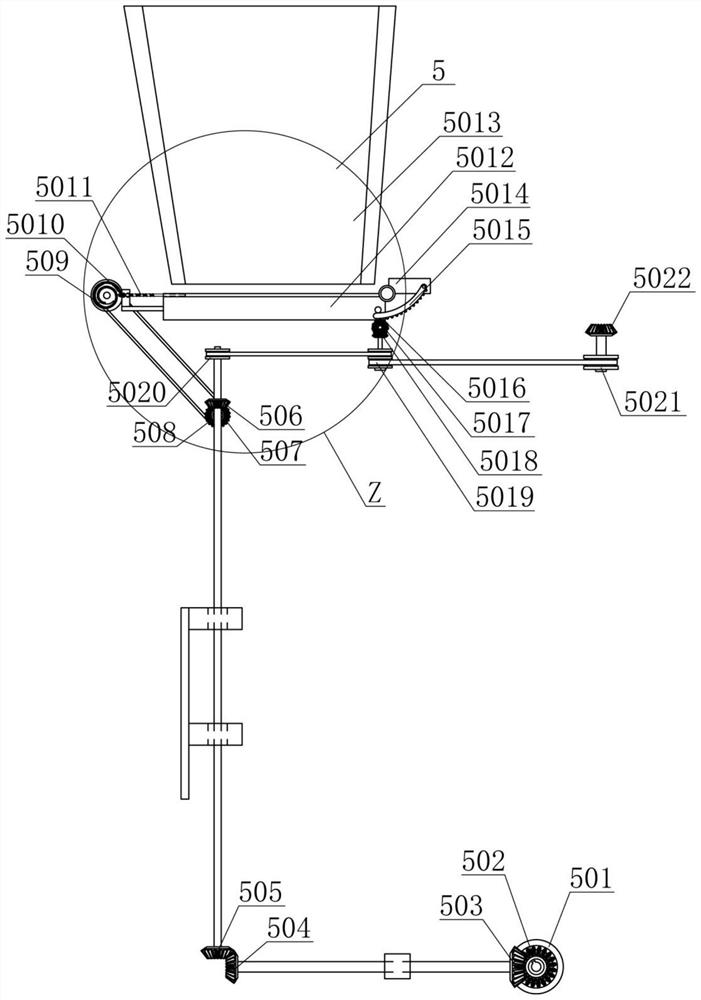

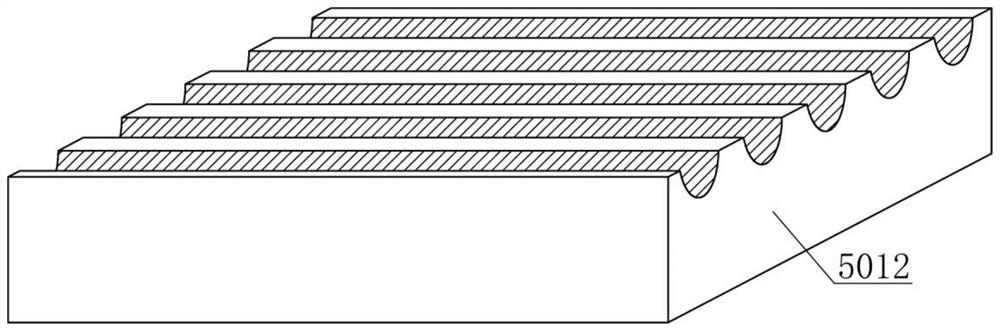

[0030] A pin automatic plug-in device of a PCB board, such as Figure 1-8As shown, it includes a fixed frame 1, a first limit block 2, a second limit block 3, a stepper motor 4, a pin standing mechanism 5, a reverse pin insertion mechanism 6, a first transmission wheel 7, and a second Transmission wheel 8, cutting and welding review mechanism 9 and controller; the top left end of fixed frame 1 is welded with first limit block 2; the left middle part of fixed frame 1 top is welded with second limit block 3; the left middle part of fixed frame 1 is welded with The stepper motor 4 is bolted; the left end of the fixed frame 1 is provided with a pin stand mechanism 5, and the bottom right of the rear end of the pin stand mechanism 5 is connected with the stepper motor 4; the left middle top of the fixed frame 1 is provided with a reverse Pin insertion mechanism 6, and the left end of reverse pin insertion mechanism 6 is connected with pin standing mechanism 5 by belt; The middle to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com