System for preventing bags from being stuck on soft tissue production line

A production line and soft pumping technology, applied in CCTV systems, TV system components, cardboard items, etc., can solve the problems of card packs, low friction of conveyor belts, production line shutdowns, etc. , the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

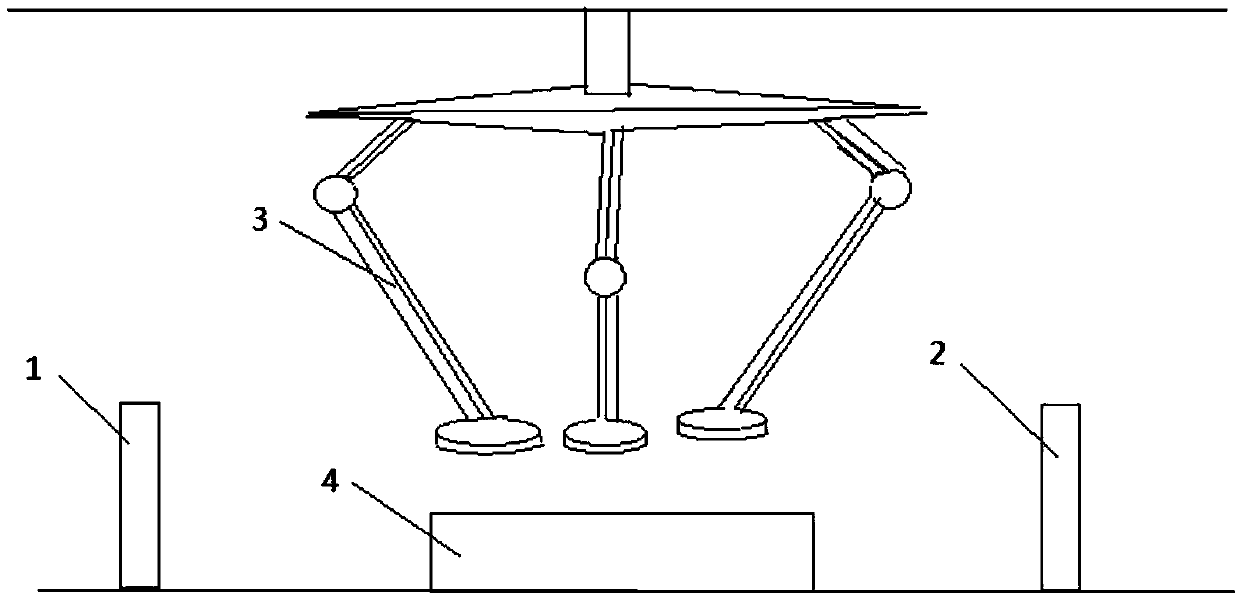

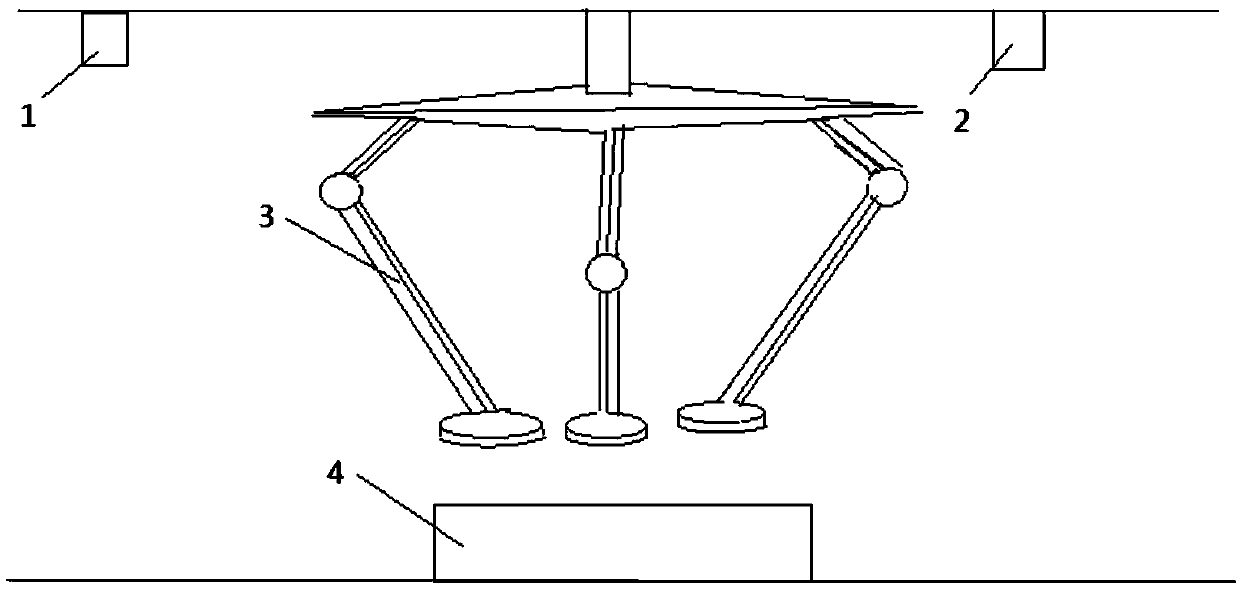

[0024] An anti-jamming package system for a soft paper pumping production line, including a first camera 1, a second camera 2, a spider robot 3 and a controller. Draw bag 4 to shoot, the spider robot 3 is located between the two cameras and above the track, and the controller is connected to the two cameras and the spider robot 3 respectively;

[0025] During the transportation of the soft bag 4, it passes through the first camera 1 first, and the first camera 1 transmits the captured video to the controller. The controller performs image recognition and judges whether the pose 4 of the soft bag is correct. If not, the spider The robot 3 descends and adjusts the pose of the soft bag 4. After the adjustment, the spider robot 3 resets, and the second camera 2 continues to shoot and transmits the image to the controller. If the pose of the soft bag 4 is incorrect, the spider robot 3. Transfer the soft drawer 4 to the outside of the track.

[0026] The bottom of Spider Robot 3 is...

Embodiment 2

[0031] The difference from Embodiment 1 is that the first camera 1 and the second camera 2 are installed on both sides of the track respectively, and take pictures of the two sides of the soft drawer 4 respectively, so that the rectangular soft drawer can be identified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com