Micro prism reflective film

A microprism and reflective film technology, applied in the optical field, can solve the problems of high reflective brightness, inability to achieve high reflectivity, low reflective film reflective brightness, etc., and achieve the effect of high reflective brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The preparation method of microprism reflective film provided by the invention comprises the steps:

[0082] (1) preparing an anti-fouling and anti-scratch coating on the first optical surface of the substrate layer;

[0083] (2) preparing a microprism structure layer on the second optical surface of the substrate layer;

[0084] (3) prepare a metal reflective layer on the first optical surface of the sealing layer, and press the microprism structure layer in step (2) tightly on the metal reflective layer;

[0085] (4) The second optical surface of the sealing layer is bonded to the upper surface of the adhesive layer, and the release layer is bonded to the lower surface of the adhesive layer.

[0086] Further, the antifouling and anti-scratch coating in step (1) is prepared by solvent coating method or gravure coating method.

[0087] Further, in step (1), the anti-fouling and anti-scratch coating is prepared by the following method: coating the first optical surface...

Embodiment 1

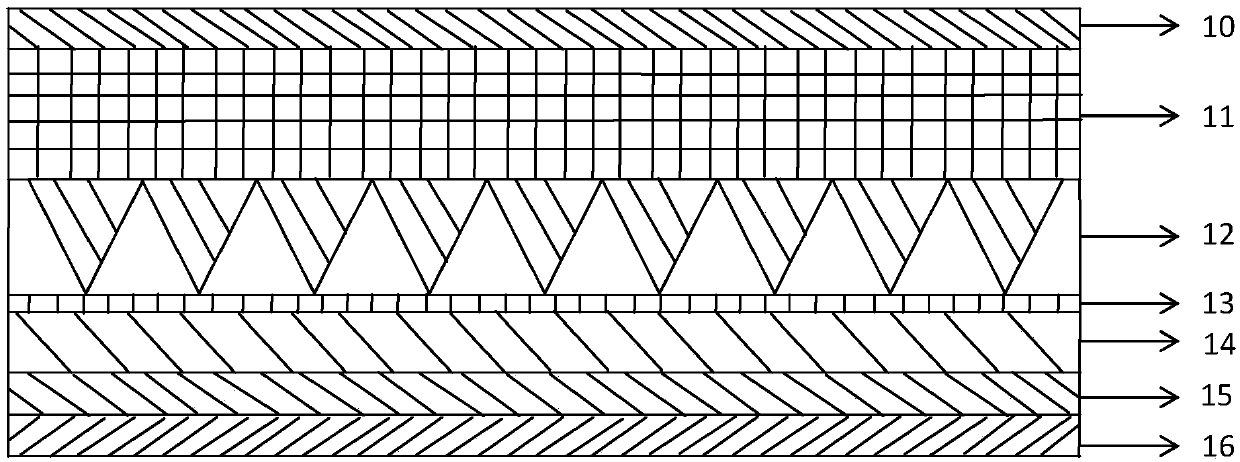

[0095] The present invention provides a kind of microprism reflective film, and described microprism reflective film comprises antifouling and anti-scratch coating 10, base material layer 11, microprism structure layer 12, metal reflective layer 13, sealing layer 14, adhesive layer 15 and peeling layer 16.

[0096] The antifouling and anti-scratch coating 10 is made of fluorinated polyurethane acrylate with a thickness of 4 μm; the material of the substrate layer 11 is polycarbonate with a thickness of 150 μm; the cube-corner prism structures in the microprism structure layer 12 are closely arranged, The material of the microprism structure layer 12 is polyester acrylate with a thickness of 80 μm; the material of the metal reflective layer 13 is a silver coating with a thickness of 70 nm; the material of the sealing layer 14 is PET with a thickness of 25 μm; the material of the bonding layer 15 It is an acrylate pressure-sensitive adhesive with a thickness of 20 μm; the materi...

Embodiment 2

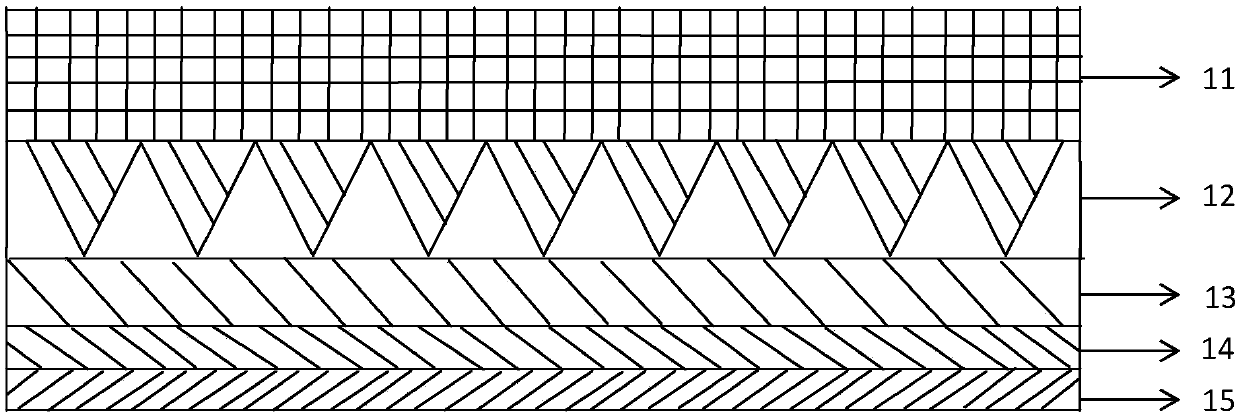

[0098] As the microprism reflective film provided in Example 1, wherein the material of the anti-fouling and scratch-resistant coating 10 is fluorinated polyurethane acrylate, and the thickness is 3 μm; the material of the substrate layer 11 is polyethylene terephthalate , a thickness of 250 μm; the cube-corner prism structures in the microprism structure layer 12 are closely arranged, the material of the microprism structure layer 12 is polyurethane acrylate, and the thickness is 70 μm; the material of the metal reflection layer 13 is aluminum coating and silver coating, The thicknesses are respectively 30nm and 40nm, which are sequentially arranged on the surface of the first optical surface of the sealing layer 14; the material of the sealing layer 14 is a PET layer with a thickness of 50 μm; the material of the bonding layer 15 is an acrylate pressure-sensitive adhesive with a thickness of 25 μm; the material of the release layer 16 is polypropylene with a thickness of 25 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com