High-toughness cold-mixing modified resin material for paving roads and bridges and preparation method of high-toughness cold-mixing modified resin material

A modified resin, high toughness technology, used in building insulation materials, building components, climate change adaptation and other directions, can solve the problems of incomplete solution, inconvenient operation and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh bisphenol A type E51, 10 parts; butyl glycidyl ether (BGE), 2 parts; carboxyl-terminated liquid nitrile rubber, 3 parts, mix the above materials and stir at a stirring speed of 30r / min for 1h, put into 1~2MPa pressure, 60~80°C reaction for 1~2h to prepare A component.

[0030] Weigh spirocyclic diamine normal temperature flexible curing agent, 8 parts; 90# petroleum asphalt, 2 parts; isopropyl triisostearyl titanate, 3 parts; nano calcium carbonate filler, 1 part, mix the above materials And stir at a stirring speed of 20r / min for 1h, put into a pressure of 1-2MPa, and react at 80-100°C for 1-2h to obtain component B.

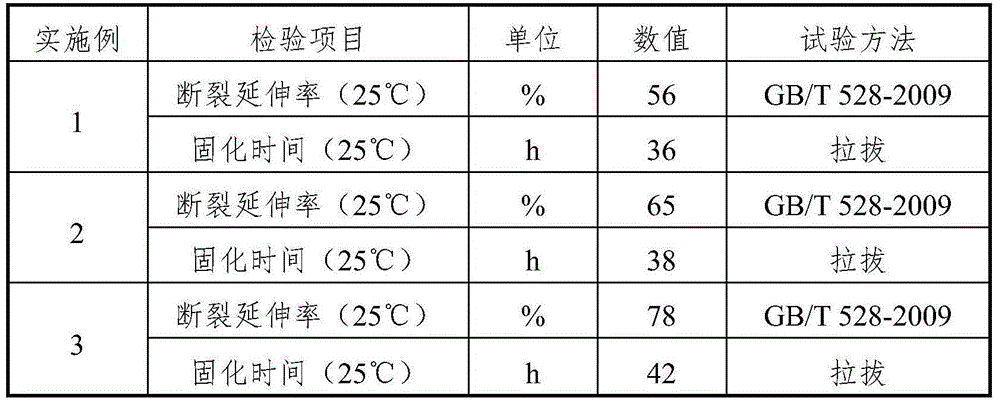

[0031] Mix component A and component B according to the ratio of 10:8 at room temperature and stir for 3 minutes at a stirring speed of 20r / min to prepare a high-toughness cold-mix modified resin material for road and bridge pavement, which should be prepared within 60 minutes before use , the material performance test data are shown in Table 1. ...

Embodiment 2

[0033] Weigh bisphenol A type E42, 15 parts; butyl glycidyl ether (BGE), 3 parts; epoxy-terminated liquid nitrile rubber, 5 parts, mix the above materials and stir at a stirring speed of 30r / min for 1.5h , put into 1~2MPa pressure, react at 60~80℃ for 1~2h, and make A component.

[0034] Weigh spirocyclic diamine normal temperature flexible curing agent, 12 parts; 110# petroleum asphalt, 3 parts; isopropyl triisostearyl titanate, 4 parts; nano calcium carbonate filler, 1 part, mix the above materials And stir at a stirring speed of 30r / min for 1.5h, put into a pressure of 1-2MPa, and react at 80-100°C for 1-2h to obtain component B.

[0035] Mix component A and component B according to the ratio of 10:10 at room temperature and stir for 5 minutes at room temperature with a stirring speed of 30r / min to prepare a high-toughness cold-mix modified resin material for road and bridge pavement, which should be prepared within 60 minutes before use , the material performance test dat...

Embodiment 3

[0037] Weigh bisphenol A type E44, 20 parts; propylene glycidyl ether AGE, 5 parts; carboxyl-terminated liquid nitrile rubber, 4 parts, mix the above materials and stir at a stirring speed of 30r / min for 2h, and put in 1~2MPa React under pressure at 60-80°C for 1-2 hours to obtain component A.

[0038] Weigh aryl ether ester diarylamine normal temperature flexible curing agent, 15 parts; 90# petroleum asphalt, 3 parts; chloropropyltrimethoxysilane, 4 parts; nano-silica filler, 1 part, mix the above materials and Stir at a stirring speed of 30r / min for 2h, put in a pressure of 1-2MPa, and react at 80-100°C for 1-2h to obtain component B.

[0039] Mix component A and component B according to the ratio of 10:12 at room temperature and stir for 5 minutes at a stirring speed of 30r / min to prepare a high-toughness cold-mix modified resin material for road and bridge pavement, which is prepared within 60 minutes before the use of the material. The material performance test data are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com