Bamboo-charcoal slow rebounding pillow

A slow-rebound and slow-rebound sponge technology, applied in pillows, other chemical processes, chemical instruments and methods, etc., can solve the problems of accumulated lactic acid, muscle fatigue, cervical vertebra compression, etc., and achieve stable soft and hard properties, breathable and moisture-permeable Good, little effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

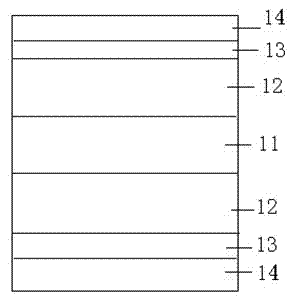

[0044] like figure 1 As shown, the pillow includes a pillow body and a pillowcase 14. The pillow body includes a high-elastic sponge pillow core 11, an air bag 12 and a bamboo charcoal slow-rebound sponge pillow core 13. Set in the bamboo charcoal slow rebound sponge pillow core 13, the air bag 12 is provided with one end of a trachea (not shown in the figure), the other end of the trachea is connected with an air valve 15 and is arranged on the bamboo charcoal slow rebound sponge pillow core 13 outside. One corner of the pillowcase 14 is provided with a triangular elastic protective cover 16 ( figure 2 ), one side of the protective cover 16 is open for storing and hiding the air valve 15, and is convenient for storing or taking out the air valve 9, so as to prevent the air valve 9 from touching the skin during sleep.

[0045] Bamboo charcoal powder preparation: Pilot test is carried out in a vertical moving bed dry distillation carbonization furnace, with bamboo chips (abo...

Embodiment 2

[0055] The structure of the pillow is the same as that of the first embodiment, except that the shape of the elastic protective cover 16 is S-shaped.

[0056] The preparation raw material and preparation method of bamboo charcoal slow-rebound sponge are the same as in Example 1, except that the preparation of bamboo charcoal powder is carried out in a pilot test in a 16-tube conjoined column and tube moving bed dry distillation carbonization furnace, with Mengzong bamboo with an average moisture content of 30% piece (about 40cm in length), the temperature of each temperature measuring point, the drying area A is 200°C, the pre-carbonization area B is 270°C, and the carbonization area C is 500°C. When the temperature is raised, part of the combustion gas and bamboo vinegar liquid are introduced from the external combustion type. Part of the non-condensable gas in the condenser is burned at the same time, so that the temperature of the combustion zone is raised to 750°C at a rate...

Embodiment 3

[0061] Pillow structure is with embodiment one.

[0062] The preparation of bamboo charcoal powder is with embodiment one, and difference is the preparation raw material of bamboo charcoal slow rebound sponge and preparation method.

[0063] Preparation raw materials of bamboo charcoal slow rebound sponge:

[0064] 1-3 parts of bamboo charcoal powder with a particle size of 1500-2800 mesh; the first polyol: a polymer of 85 parts by weight of ethylene glycol and propylene glycol, with a functionality of 3 and a hydroxyl value of 99 mgKOH / g; the second polyol: three 10 parts by weight of copolyol of methylolpropane and butylene oxide, EO content 80%, hydroxyl value 22mgKOH / g; MDI isocyanate 30 parts by weight; cyclopentane, n-butane, 5-15% sodium bicarbonate 6 parts by weight of foaming agent formed from the solution; 6 parts by weight of triethylenediamine; 0.5 parts by weight of sulfonate flame retardant; 0.8 parts by weight of room temperature vulcanized silicone rubber toug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com