Double-layer coated essence microcapsule and preparation method thereof

A fragrance microcapsule and double-layer coating technology, which is applied in the direction of microcapsule preparation, microsphere preparation, essential oil/fragrance, etc., can solve the problem of insufficient mechanical strength and heat resistance of the wall material during the fragrance retention time, and cannot meet the requirements of polymer materials. Problems such as thermoforming processing requirements, to achieve excellent mechanical properties such as heat resistance and toughness, improved mechanical properties of capsule materials, and easy to uniformly disperse the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of double-layer coated essence microcapsules of the present invention comprises prepolymer synthesis, emulsification dispersion, microcapsules are coated twice continuously and post-processing steps:

[0032] 1. Prepolymer synthesis: The experimental equipment is a thermometer, a stirrer, a three-necked flask with a reflux condenser, and a beaker.

[0033] Add 0.36g of gelatin, 3.6g of melamine, 4.0g of 37% formaldehyde and 25g of water into a 250ml three-neck flask respectively, adjust the pH value to 8.0 with sodium hydroxide solution, then heat to 65°C, keep the reaction solution for 20- After 60 minutes, a gelatin-modified resin prepolymer solution was prepared and cooled to room temperature for later use.

[0034] 2. Emulsification and dispersion: Add 180g of water with 0.2g of gum arabic dissolved in a 500ml beaker, turn on the homogeneous emulsifier (model ESR, Shanghai Specimen Model Factory), add 12.0g of jasmine and strong flavor (...

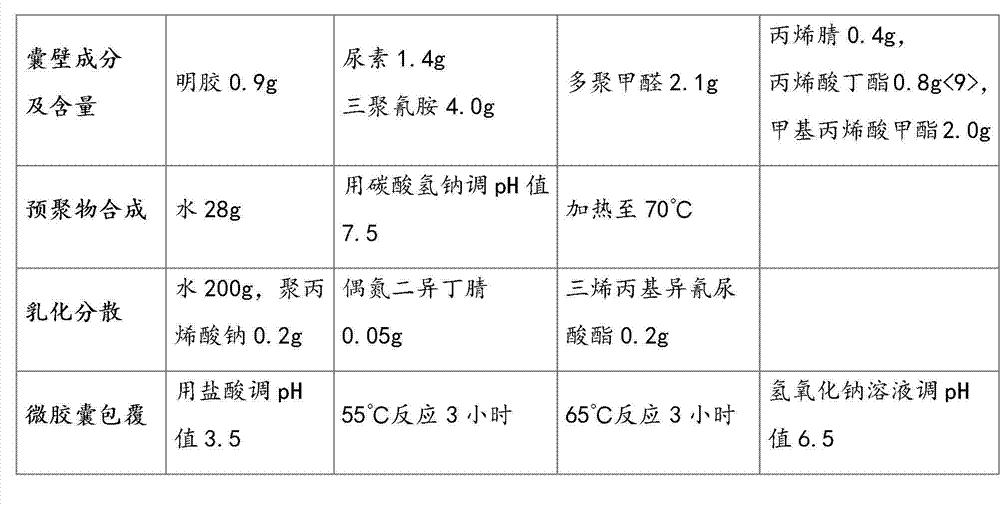

Embodiment 2

[0038]

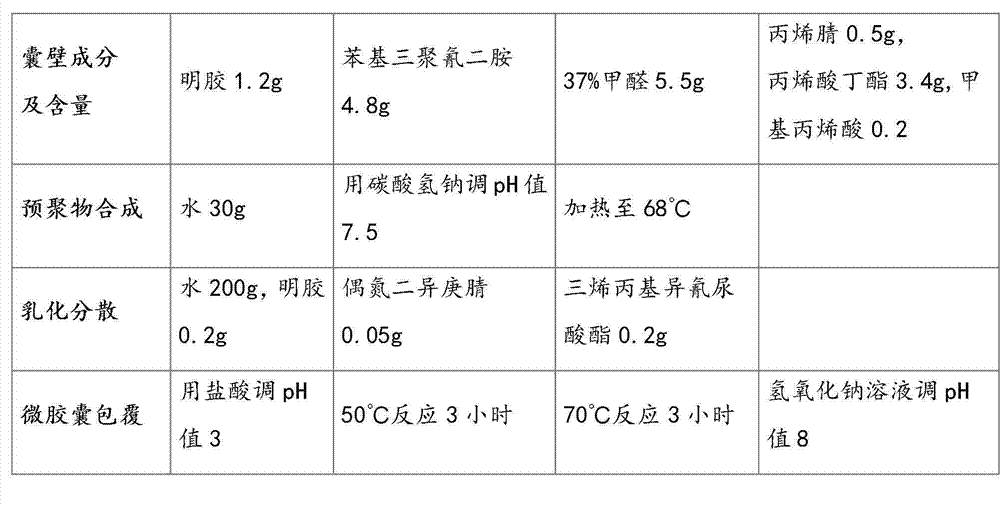

Embodiment 3

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com